Self-expanding plugging agent

A technology of self-expanding and plugging agent, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as plugging of drilling fluid permeability and leakage, and achieve the effect of safe construction and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 10 parts by weight of self-expanding plugging polymer particles, 10 parts by weight of coke particles, 5 parts by weight of corn stalk debris, 10 parts by weight of asbestos fibers, 20 parts by weight of calcium carbonate powder, 5 parts by weight of clam shells Chips and 10 parts by weight of sawdust; wherein,

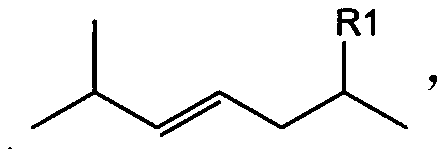

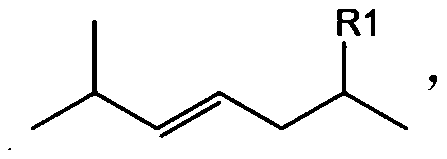

[0032] The particle size of self-expanding polymer particles is 20-40 mesh, which is obtained by copolymerization of 30 parts by weight of acrylamide, 15 parts by weight of methyl acrylate, 10 parts by weight of potassium acrylate and 10 parts by weight of the fourth monomer Object (number average molecular weight is 8,000,000); The structural formula of the 4th monomer is: R1 is

[0033] Sawdust is made by mixing 10 parts by weight of sawdust with a particle size of 20-40 mesh, 20 parts by weight of sawdust with a particle size of 60-80 mesh, and 10 parts by weight of sawdust with a particle size of 100-120 mesh. The dried alkalized pine sawdust obtained ...

Embodiment 2

[0035] 15 parts by weight of self-expanding plugging polymer particles, 15 parts by weight of coke particles, 10 parts by weight of corn stalk debris, 5 parts by weight of asbestos fibers, 20 parts by weight of calcium carbonate powder, 10 parts by weight of clam shells Chips and 10 parts by weight of sawdust; wherein,

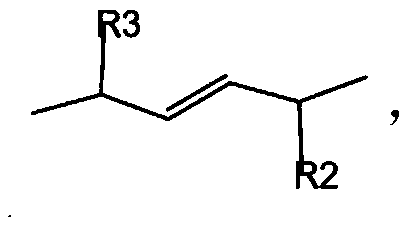

[0036] The particle size of the self-expanding polymer particles is 20-40 mesh, which consists of 35 parts by weight of acrylamide, 20 parts by weight of a mixture of methyl acrylate and butyl acrylate (the molar ratio of the two is 1:3), 5 parts by weight The mixture of potassium acrylate and acrylic acid (the molar ratio of the two is 1:5) and the copolymer obtained by copolymerization of the fourth monomer of 15 parts by weight (the number average molecular weight is 12 million); the structural formula of the fourth monomer is: Among them, R 2 for R 3 for

[0037] Sawdust is mixed by 5 parts by weight of sawdust with a particle size of 20-40 mesh, 1...

Embodiment 3

[0039] 15 parts by weight of self-expanding plugging polymer particles, 15 parts by weight of coke particles, 10 parts by weight of corn stalk debris, 10 parts by weight of asbestos fibers, 15 parts by weight of calcium carbonate powder, 10 parts by weight of clam shells Chips and 15 parts by weight of sawdust; wherein,

[0040] The particle size of the self-expanding polymer particles is 20-40 mesh, which consists of 35 parts by weight of acrylamide, 20 parts by weight of a mixture of methyl acrylate and butyl acrylate (the molar ratio of the two is 2:3), 5 parts by weight The mixture of potassium acrylate and acrylic acid (the molar ratio of the two is 1:1) and the copolymer obtained by copolymerization of the fourth monomer of 15 parts by weight (the number average molecular weight is 14 million); the structural formula of the fourth monomer is: Among them, R 2 for R 3 for

[0041] Sawdust is made by mixing 10 parts by weight of sawdust with a particle size of 20-40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com