Patents

Literature

545 results about "Asbestos fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Although asbestos fibers are microscopic in nature, they are extremely durable and resistant to fire and most chemical reactions and breakdowns. These properties of asbestos supported its use for many years in a number of different commercial and industrial settings, as well as in a wide range of consumer products.

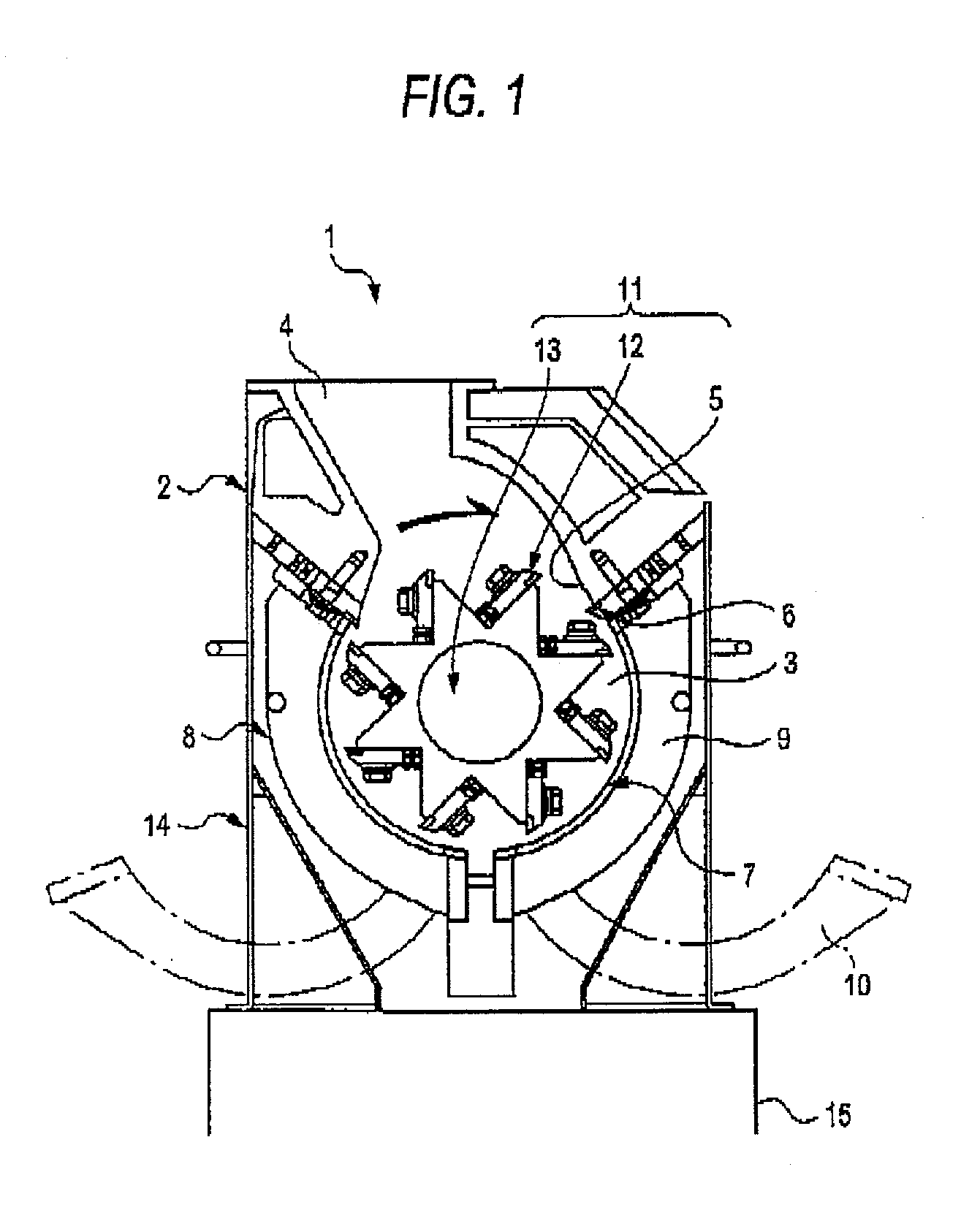

Friction material and method of mix-fibrillating fibers

A friction material comprising a fibrous reinforcement, a friction modifier and a binder, characterized by being free from asbestos fiber and containing, as the organic fibrous reinforcement, a mixture of a dry aramid pulp with at least one member selected from the group consisting of a wet aramid pulp, a woodpulp and an acrylic pulp.

Owner:AKEBONO BRAKE IND CO LTD +1

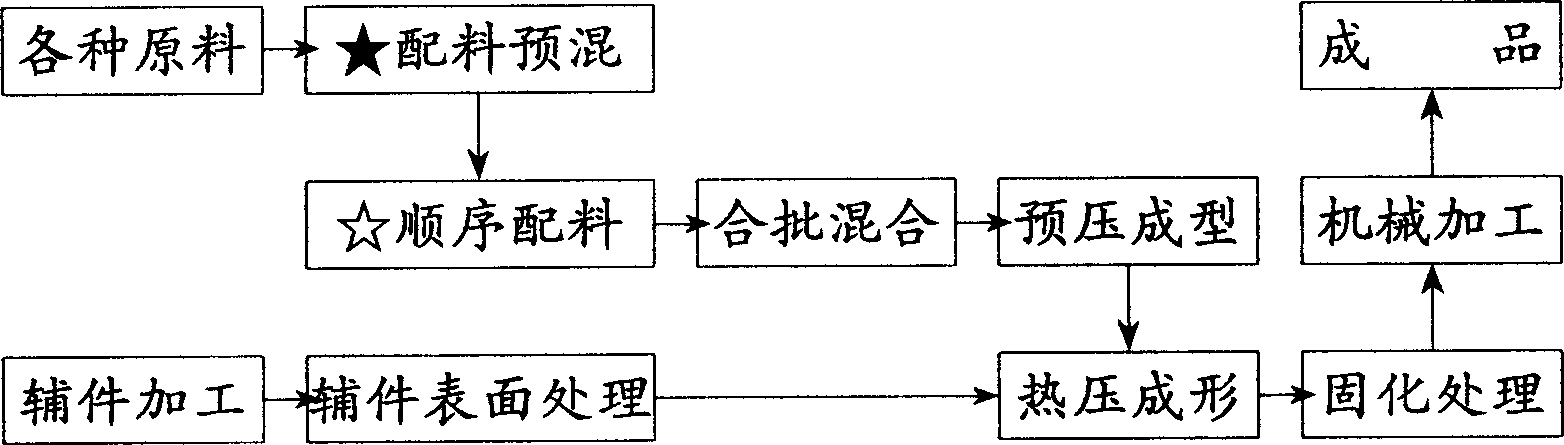

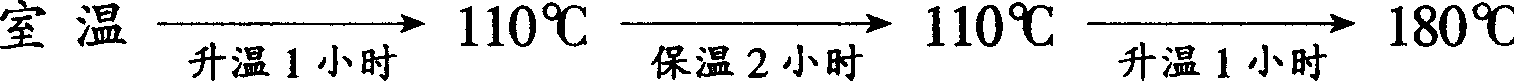

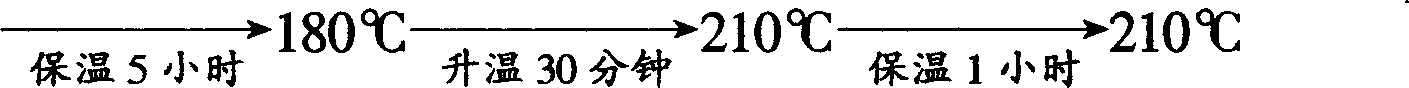

Environment-protection type high-performance automobile braking piece and making method

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

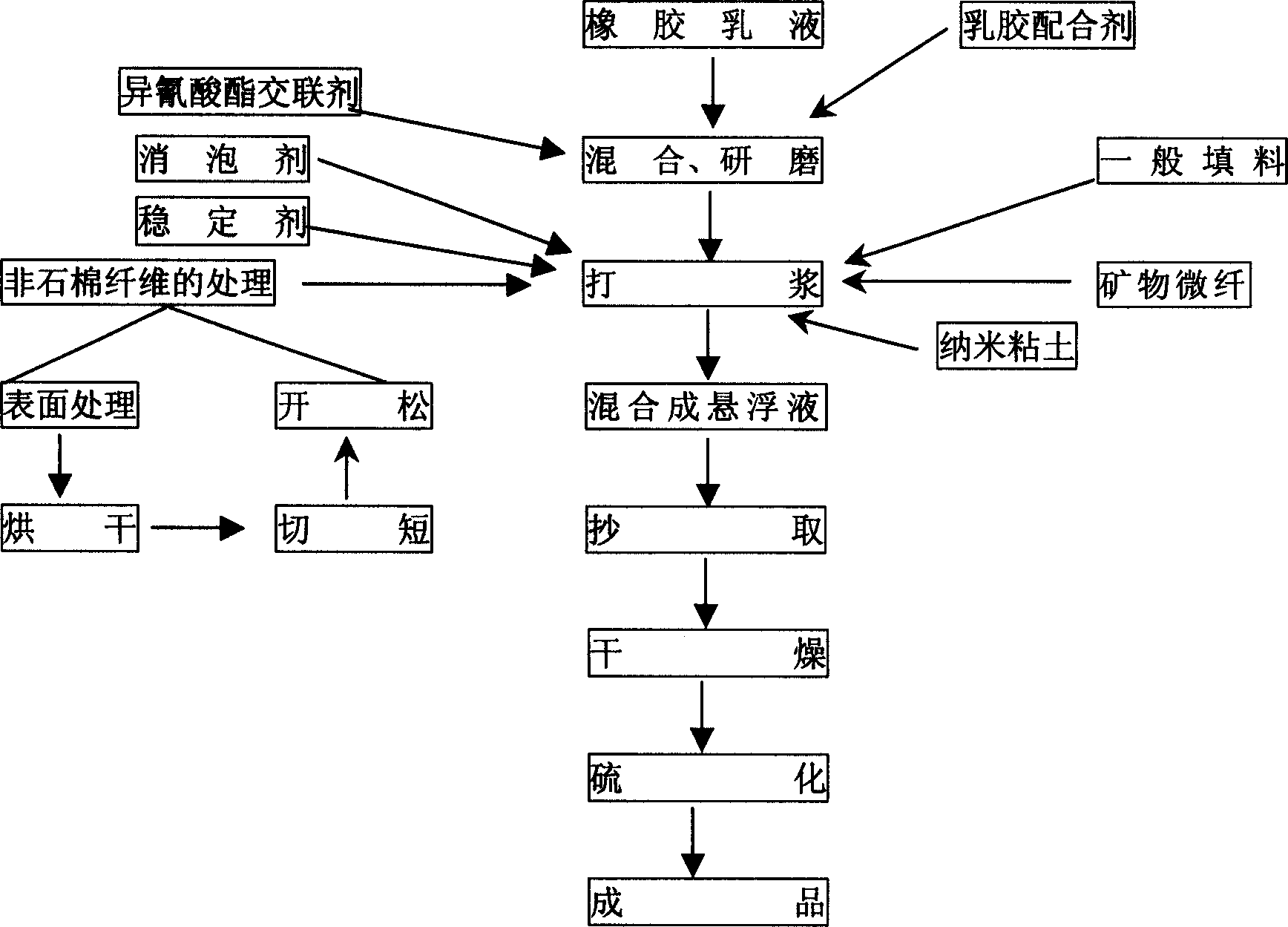

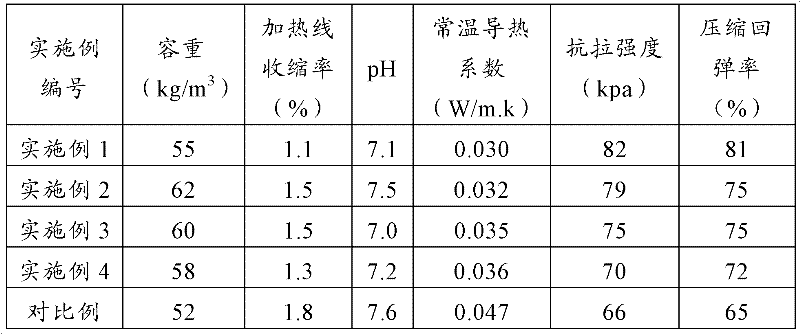

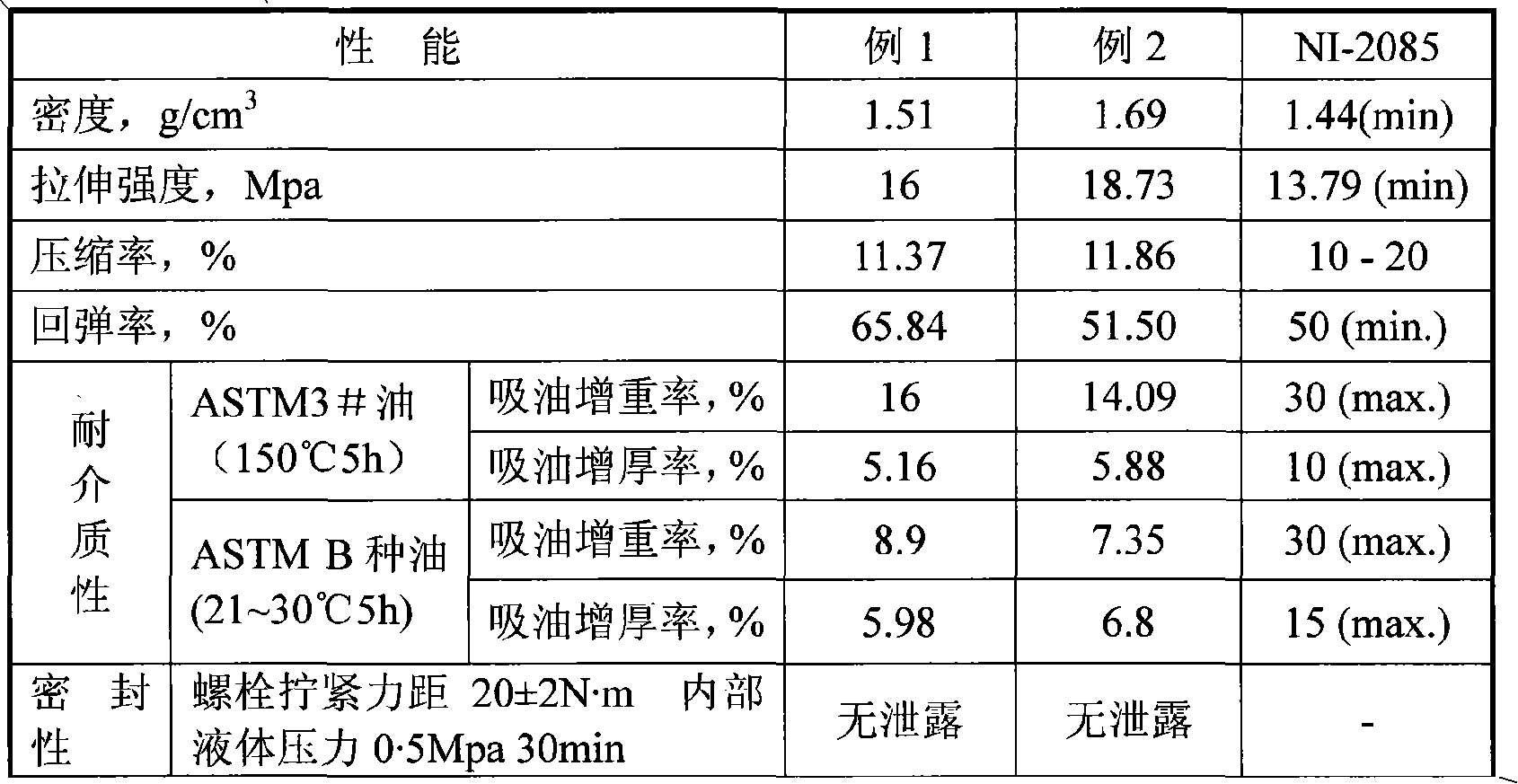

Process for preparation formation of nonasbestos fibre enhanced latex sealing plate

InactiveCN1557865AImprove mechanical propertiesMechanical properties such as good transverse tensile strengthEmulsionPolymer science

The present invention belongs to the field of fiber reinforced composite rubber elastomer material producing technology. The technological process includes preparing materials including non-asbestos fiber, rubber emulsion, cross-linking agent, stuffing, auxiliary additive, etc.; treating non-asbestos fiber; compounding emulsion; preparing suspension; forming; drying and rolling sulfurization. The present invention features the specific material proportion, traditional process and wet formation. The technological process is environment friendly and has no environmental pollution, and the sealing gasket plate of the non-asbestos fiber reinforced composite rubber elastomer material has relatively high mechanical performance and chemical corrosion resistance.

Owner:SHANGHAI UNIV

Curable leak-stopping agent

The invention relates to a curable leak-stopping agent. The curable leak-stopping agent comprises the following components which are mixed by weight percentage: 30 to 50 percent of curable material blast furnace, 5 to 15 percent of high filtration material diatomite or fly ash, 15 to 25 percent of fibrous material asbestos fiber, cotton fiber or cob, 2 to 5 percent of soft elasticity expansion material elastic tyre rubber and 20 to 30 percent of acid-soluble material calcium carbonate. The leak-stopping agent provided in the invention can be used independently. The curing time is controllable; the leak-stopping efficiency is high and the leak-stopping agent does not discriminate leakage layer apertures or crack dimensions. The leak-stopping agent is an efficient and curable leak-stopping agent which can be used to stop crack leakage and cave nonreservoir and reservoir leakage.

Owner:DAQING PETROLEUM ADMINISTRATION +1

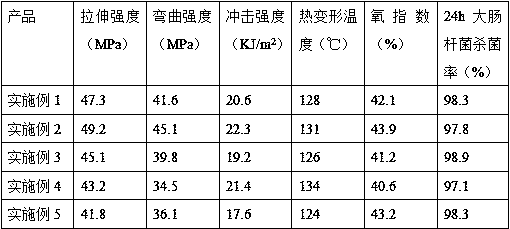

Asbestos fiber reinforced thermoplastic base wood and plastic composite material and preparing method thereof

The invention belongs to the field of building material, in particular to a wood and plastic composite material, a preparing method and application thereof. The asbestos fiber reinforced thermoplastic base wood and plastic composite material is prepared from the following raw materials by weight percentage: 20%-45% of plastic, 30%-60% of wood powder, 5%-30% of asbestos fiber, 0.5%-3% of coupling agent, 0-2% of plastizer, 0-2% of stabilizer, and 0-4% of lubricant. The processed wood and plastic composite material has mechanical property higher than that of the wood and plastic material singly using the coupling agent, various mechanical property indexes being equal or exceeding that of the wood and plastic material simultaneously reinforced by using the coupling agent and the glass fiber, and cost greatly lower than that of the coupling agent and the glass fiber used at present, and can be widely applied to the fields of buildings, automobiles, transportation, aerospace and military; after discard, the product processed by the asbestos fiber reinforced thermoplastic base wood and plastic composite material can be used as a raw material to be reprocessed profiles through removing surface contaminants and crushing, therefore, the invention has the advantages of repetitive reutilization and wide popularization and application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Graphene-modified wear-resistant rubber

The invention relates to a graphene-modified wear-resistant rubber. The graphene-modified wear-resistant rubber comprises, by weight, 48.9 to 56.5% of synthetic rubber, 1.5 to 2.5% of a sulfuration promoter, 8 to 18% of graphene, 25 to 30% of a filling material, 1.5 to 5% of a plasticizer and 0.1 to 3% of an auxiliary agent. According to the invention, graphene is added into the rubber so as to improve strength of the rubber, and since graphene has good lubrication effect, wear resistance of the rubber can be improved; and addition of asbestos fiber and polyimide fiber enables heat resistance of the rubber to be substantially improved.

Owner:余姚市振大塑胶有限公司

Screened sealing material without asbestos fiber and its prepn process

InactiveCN1847355ASo as not to damageHigh tensile strengthOther chemical processesHigh resistanceSodium Bentonite

The present invention is screened sealing material without asbestos fiber and its preparation process. The sealing material is prepared with fiber 10-70 wt%, stuffing 30-80 wt%, adhesive 1-10 wt%, latex 5-20 wt% and compounding agent 4-10 wt%, where the latex is synthetic latex or natural latex, the adhesive is polymer adhesive or polymer adhesive composition, the stuffing is graphite powder, bentonite, etc. of granularity over 120 meshes, and the fiber is 1000 deg.c over high temperature treated mineral wool fiber, short glass fiber, ceramic fiber, etc. The sealing material has high tensile strength, high oil tolerance, high heat resistance, long service life and no harmful asbestos.

Owner:舟山海山机械密封材料股份有限公司

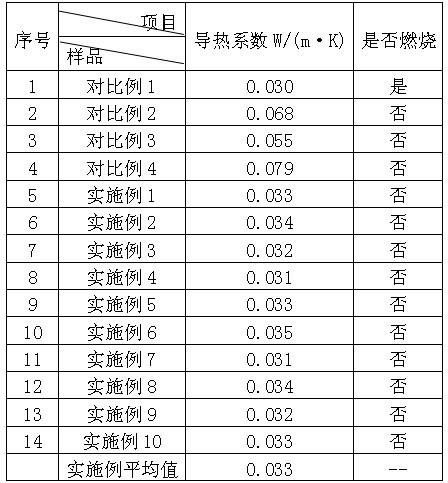

Heat preservation and insulation felt material and preparation method thereof

InactiveCN102174973AImprove insulation effectGuaranteed insulation effectThermal insulationLaminationFiberAsbestos fibers

The invention discloses a heat preservation and insulation felt material which is composed of heat preservation sheets and reflection material which are pasted together alternately. Each heat preservation sheet mainly comprises asbestos-free manmade inorganic fiber, inorganic heat preservation particles, a reflection sheet, a dispersing agent, an adhesive agent and the like. The heat preservationand insulation felt material has the advantages of low heat conduction coefficient, good heat preservation property, high use temperature and wide application range; more important, the heat preservation and insulation felt material does not contain asbestos fiber while keeping the advantages of soft texture, no burning, low heat conduction coefficient, easiness of construction and the like. The heat preservation and insulation felt material meets the requirements of professional health protection and environment protection, and can be widely used for device and pipeline heat preservation.

Owner:成都亚恩科技实业有限公司

Composite heat-insulating material and preparation method thereof

The invention relates to a composite heat-insulating material, comprising the following ingredients: 0.4-10 wt% of sepiolite, 0-5 wt% of brucite, 0-15 wt% of alumina silicate fiber, 5-10 wt% of asbestos fiber, 0.5-8 wt% of aerogel, 0-12 wt% of diatomite, 0-3 wt% of bentonite, 1-5 wt% of perlite, 0.5-5 wt% of dispersant, 0.1-1 wt% of polyvinyl alcohol, 0-1 wt% of soluble glass, 0-0.015 wt% of sodium cetanesulfonate, and the balance consisting of clear water. The invention also discloses a preparation method of the composite heat-insulating material. The composite heat-insulating material disclosed herein has low heat-insulating coefficient, good flexibility, and high tensile strength, and is difficult to pulverization. In addition, the method has the advantages of simple process, high production efficiency, and low energy consumption.

Owner:张永武

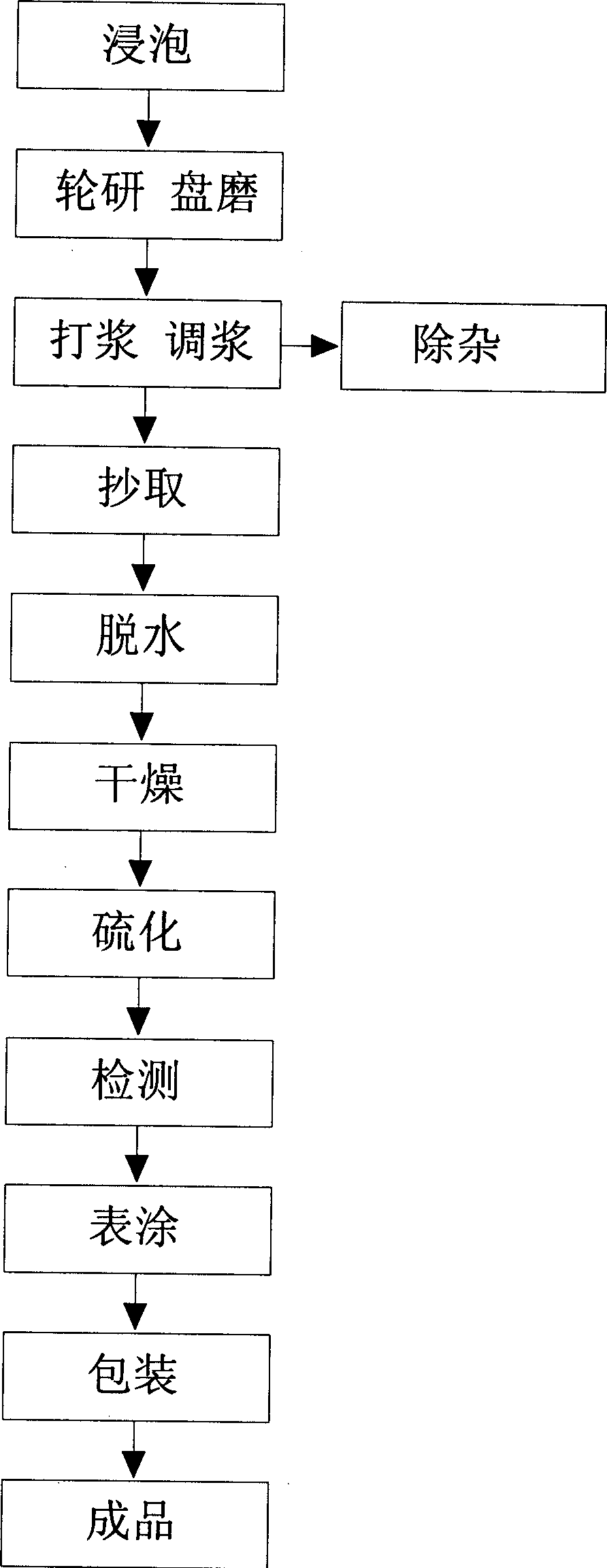

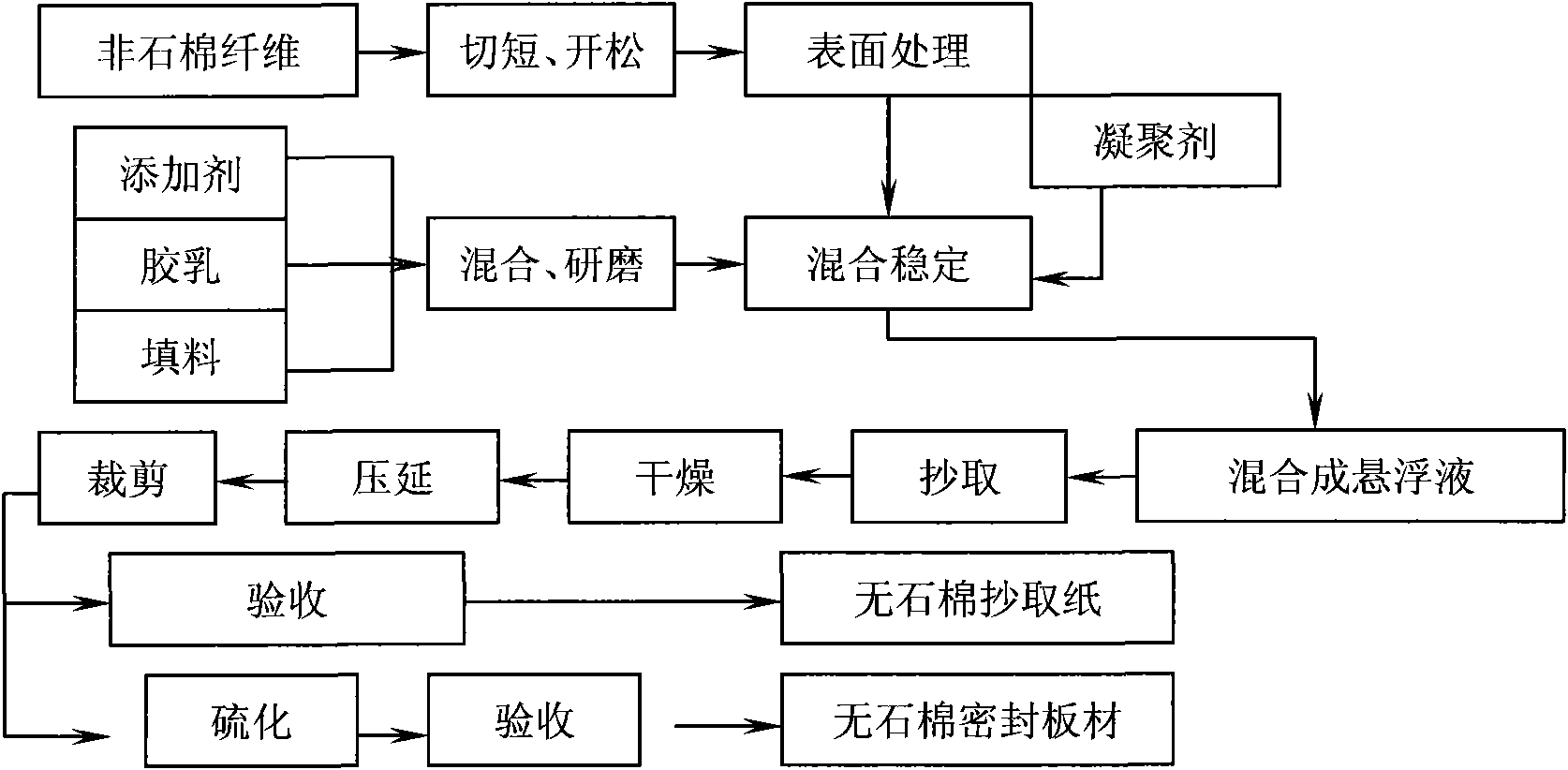

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

Diaphragm of supercapacitor

InactiveCN1553462AHigh tensile strengthElectrolytic capacitorsCell component detailsFiberInternal resistance

Membrane of capacitor is made from asbestos fiber and reinforcing material. Reinforcing material is added into asbestos fiber. Composite membrane dedicated to super capacitor with properties of ultrathin, densification, low resistance and high intensity is produced through paper making method of wet process. The invented product is wide applicable to insulation material in super capacitor possessing lowered internal resistance and raised characteristic of high power.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

Method and material for manufacturing fiber cement board

The various embodiments herein provide a method and materials to produce non-asbestos Fiber Cement Board (FCB). According to one embodiment herein, a new material including Cement (60%-75% by weight), Acrylic fiber (1%-4% by weight), Nano silicate (1%-4% by weight), slake lime stone powder (5%-20% by weight), waste cardboard pulp paper (3%-12% by weight) and some polymeric additives are used to make FCB in the Hatcheck process. In another embodiment, a method to make FCB using this method in the Hatcheck process, only some small changes are needed. According to another embodiment, the FCB produced in this method can be used for cladding, internal wall and external walls.

Owner:AVANT GARDE PATENTS

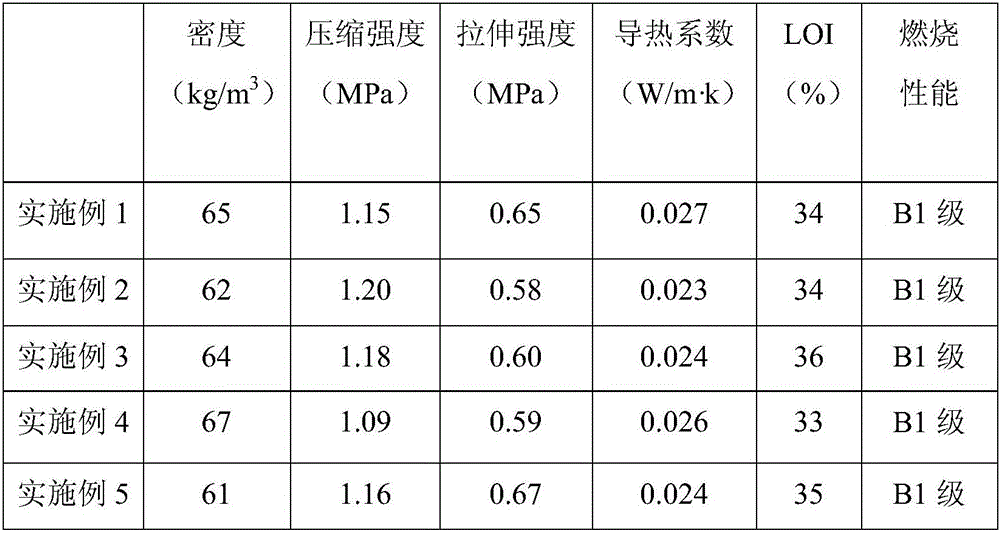

High-strength and flame-retardant hard polyurethane thermal insulation material for building and preparation method of thermal insulation material

The invention discloses a high-strength and flame-retardant hard polyurethane composite. The composite is prepared as follows: flame-retardant hard polyurethane foam plastic and modified asbestos fibers are mixed and injected into a mold for foaming forming, wherein the flame-retardant hard polyurethane foam plastic contains a component A and a component B, the component A comprises polyalcohol, a catalyst, a foaming agent, a stabilizer, a crosslinking agent and a compound flame retardant, and the component B is polyaryl polymethylene isocyanate. The specific flame retardant is selected for compounding, obtained hard polyurethane foam doesn't contain halogen, and the limit oxygen index is high. After the asbestos fibers are modified with a physical-chemical method, the prepared flame-retardant hard polyurethane composite has higher compression strength, tensile strength and shock resistance while compared with ordinary polyurethane / inorganic filler. The technological procedure is easy to operate, the cost is low, and the prepared high-strength and flame-retardant hard polyurethane thermal insulation material has good application prospect. The invention discloses a preparation method of the thermal insulation material.

Owner:NANJING UNIV

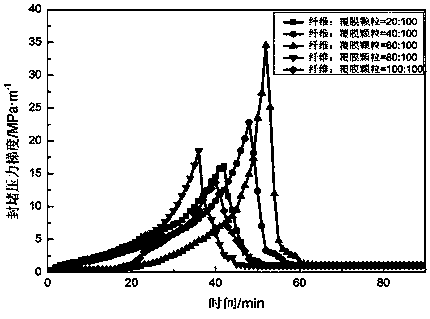

Composite water-soluble temporary plugging agent for oilfield steering fracturing construction

InactiveCN110776888AMeet the temporary plugging requirements of diversion fracturing constructionMeet the temporary blocking requirementsDrilling compositionPolyesterPolyvinyl alcohol

The invention discloses a composite water-soluble temporary plugging agent for oilfield steering fracturing construction, wherein the composite water-soluble temporary plugging agent comprises the following raw materials by weight: 32.1-53.6 parts of a coating material, 17.9-29.8 parts of temporary plugging particles and 16.7-50.0 parts of temporary plugging fibers, wherein the coating material isselected from sodium polyacrylate, sodium carboxymethyl cellulose, bone glue and gelatin, the temporary plugging particles are selected from sea salt particles, potassium chloride particles, calciumcarbonate particles and calcium chloride particles, and the temporary plugging fibers are selected from polyvinyl alcohol fibers, polyester fibers, asbestos fibers and cotton fibers. According to theinvention, the composite water-soluble temporary plugging agent is suitable for plugging cracks with millimeter-scale crack widths, can resist a temperature of 120-140 DEG C, has a plugging pressure gradient peak value of more than 30 MPa / m, and can be completely dissolved into a clear liquid with a viscosity close to the viscosity of water within 2 h at 140 DEG C; and the composite water-solubletemporary plugging agent has characteristics of large plugging pressure gradient, short plugging removal time, no damage to stratum and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-insulativity concrete

The invention discloses high-insulativity concrete which is prepared by mixing the following components in percentage by weight: 100 parts of cement, 10 to 70 parts of mineral admixture, 180 to 300 parts of fine aggregate, 200 to 360 parts of coarse aggregate, 5 to 20 parts of redisperable polymer emulsion or emulsion powder, 5 to 15 parts of paraffin, 1 to 5 parts of asbestos fibers, 1 to 5 partsof admixture, 1 to 3 parts of rubber powder and 60 to 80 parts of water. The high-insulativity concrete has high resistivity, good anti-permeability, good freezing resistance, good water resistance and high durability, and meanwhile, has better peaceability, liquidity and consistency; the high-insulativity concrete can be applied to production of a track bed slab and a sleeper in the subway engineering, and can also be used for concrete engineering which needs high insulativity, such as a track plate of a high speed railway ballastless track, a high-voltage wire pole and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Environmental-protection high-performance wood-plastic composite

The invention discloses an environmental-protection high-performance wood-plastic composite, which comprises the following components in mass percent: 35-65 percent of surface-modified wood fiber, 5-30 percent of asbestos fiber, 25-50 percent of polyethylene plastic, 2-10 percent of unsaturated polyester resin adhesive solution, 2-10 percent of red phosphorus, 0.5-3 percent of mildew-proof additive, 0.5-3 percent of anti-wear additive, 1-10 percent of char-forming agent, 2-8 percent of foaming agent, 2-7 percent of assistant agent and 1-3 percent of dye. The proper fire resistance, the proper waterproofness, the proper abrasive resistance and the proper antibacterial property of the wood-plastic composite are improved through adding the assistant agent and the like, and therefore, the application field of the wood-plastic composite is also broadened while the performance of a traditional wood-plastic composite is improved.

Owner:广东国景家具集团有限公司

Boron mud/loess ceramsite concrete hollow insulation block and preparation method thereof

The invention discloses a boron mud / loess ceramsite concrete hollow insulation block and a preparation method thereof. The block is prepared from the following raw materials by weight: 125 to 145 parts of ordinary Portland cement grade 42.5, 540 to 580 parts of stone chippings, 28 to 32 parts of boron mud, 12 to 16 parts of loess, 8 to 12 parts of paper pulp waste liquid, 3 to 5 parts of straw ash, 4 to 6 parts of light calcium carbonate, 20 to 30 parts of soluble glass, 8 to 12 parts of straw powder, 3 to 4 parts of a foaming agent, 1 to 1.5 parts of foots, 2 to 3 parts of an asbestos fiber, 0.6 to 1.2 parts of a redispersible latex powder and 160 to 210 parts of water. The boron mud / loess ceramsite concrete hollow insulation block produced in the invention has the advantages of high strength, low density, good heat insulation performance, good impact resistance, small possibility of water absorption, fire resistance, flame retardation, good weatherability, environment-friendliness, energy conservation and the like and has great market space and development prospects in the application field of building energy conservation in China.

Owner:池州市新蕾绿色建材有限公司

Composite nylon material and preparation thereof

The invention relates to a compound nylon material. The compound nylon material contains nylon, glass fiber and coupling agents, wherein the compound nylon material also contains asbestos fiber. The invention also relates to a method for preparing the compound nylon material. The compound nylon material provided by the invention is good in both mechanical properties and high temperature resistance.

Owner:BYD CO LTD

Degradable environment-friendly plastic

The invention discloses degradable environment-friendly plastic which comprises polylactic acid, polycaprolactone, a stabilizer, an antioxidant, short asbestos fibers, a bulking agent and a coupler. The formula of the degradable environment-friendly plastic comprises the following components in percentage by weight: 34-37% of polylactic acid, 15-17% of polycaprolactone, 2-4% of the stabilizer, 1.5-2.5% of the antioxidant, 23-28% of the short asbestos fibers, 4-6% of the bulking agent, 2-5% of the coupler and 0.5-3.5% of the balance of impurities. According to the plastic disclosed by the invention, polylactic acid and polycaprolactone with high environmental protection degree are polymerized and used, so that the plastic has higher stability, good heat resistance, strong toughness and good degradability, and the production cost is lowered by the formula and the plastic is applicable to wide popularization and use.

Owner:卢洁

Preparation technology of plant ash-containing light partition board

The invention discloses a preparation technology of a plant ash-containing light partition board, which is prepared from the following raw materials by weight part: 15-20 of portland cement, 38-40 of plant ash, 10-15 of night tide soil, 8-12 of phosphogypsum powder, 4-6 of diatomite, 8-10 of mineral mixture burned powder, 1-1.5 of sodium hexametaphosphate, 1-2 of asbestos fiber, 6-9 of a hydrogen peroxide solution with a concentration of 25-35%, and a proper amount of water. The partition board prepared by the invention has the advantages of high strength, good shock resistance, and low volume weight. And the asbestos fiber has certain strength improving effect.

Owner:ANHUI BUYETIAN INTERLLIGENT DISPLAY TECH

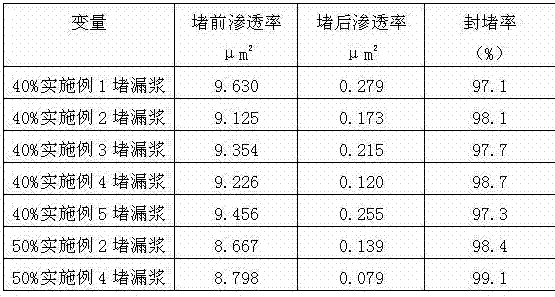

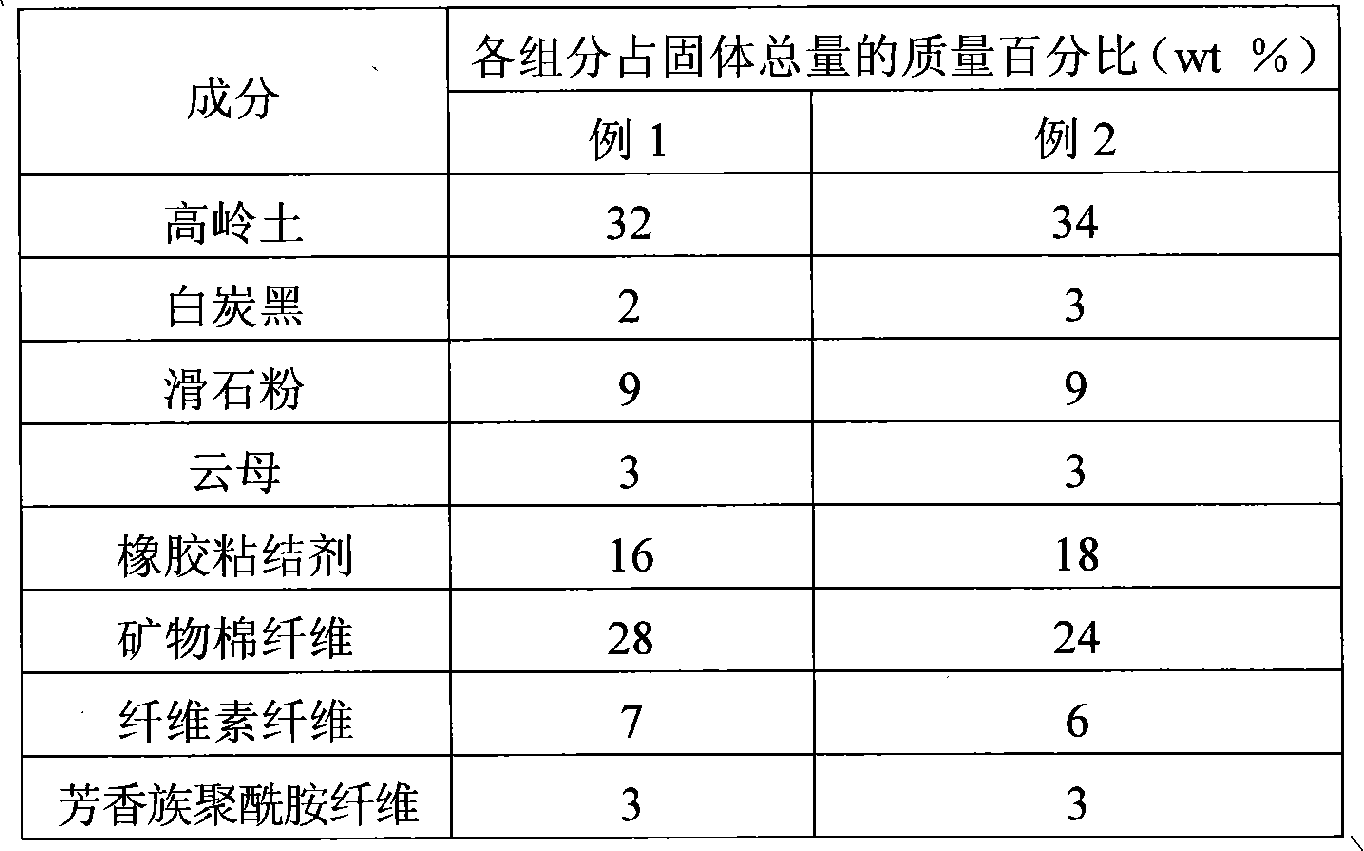

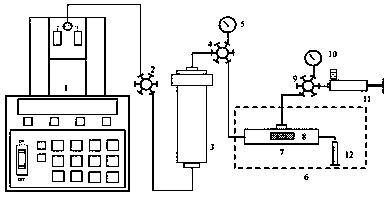

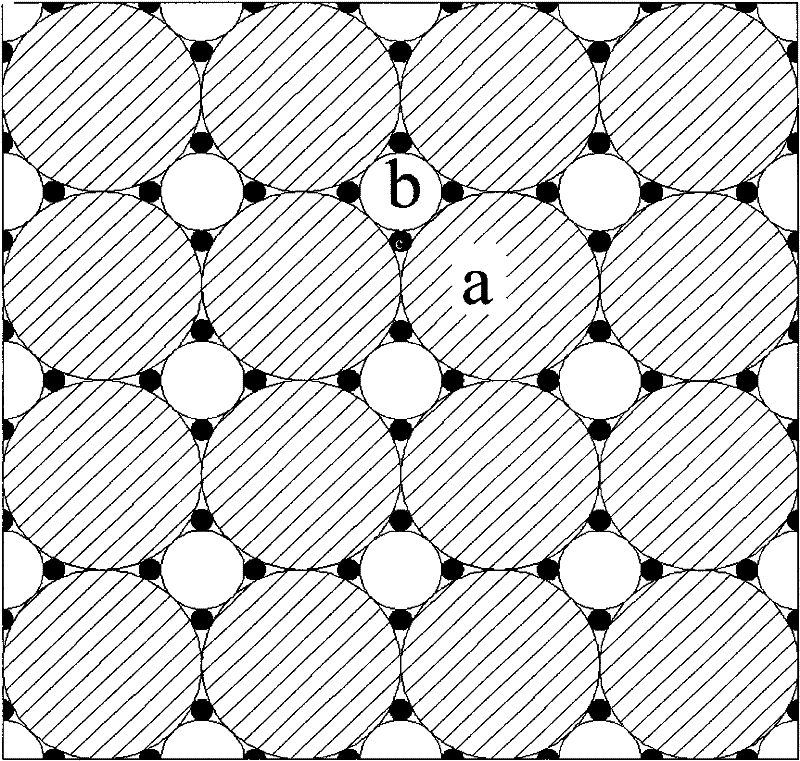

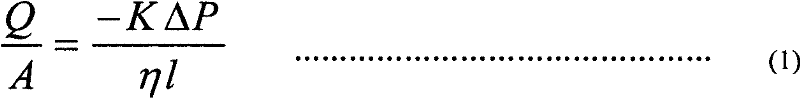

Non-asbestos fiber compound sealing material

InactiveCN102212332AImprove other performanceReduce porosityOther chemical processesFiberHeat resistance

The invention relates to a non-asbestos fiber compound sealing material, in particular to a high-performance paper-making method material, and belongs to the cross field of material science and paper-making technology. The non-asbestos fiber compound sealing material consists of non-asbestos fiber, rubber latex, mixed inorganic fillers and an auxiliary agent, wherein the mixed inorganic fillers are formed by the gradation of minimum two types, at most six types of fillers of different average grain sizes, and the average grain size of the bigger fillers is more than 2.5 times that of the adjacent smaller fillers. Because the closest packing theory is adopted in the invention and the fillers are formed by the gradation of the fillers of different average grain sizes, the close packing microporous material structure can be obtained while less rubber latex is consumed, various important indexes, such as the sealing property, mechanical strength and heat resistance, of the product are greatly improved, and the high-performance non-asbestos fiber compound sealing material is obtained. By the gradation of the fillers, the paper machine paper-making property of the pulp is improved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

High-temperature-resistant thermal-insulation fireproof material

A high-temperature-resistant thermal-insulation fireproof material is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of black mud powder or black mud particles, 7-10 parts of hollow glass beads, 7-10 parts of industrial magnesium chloride, 7-10 parts of meerschaum, 7-10 parts of aluminous cement, 1-4 parts of carbon fiber, 3-5 parts of asbestos cellulose, 1-3 parts of a foaming agent and 1-3 parts of an AES activator. The material is good in fireproof and thermal-insulation performances, low in cost and small in density, and is applicable to prepare firewalls and the like.

Owner:上海汇友精密化学品有限公司

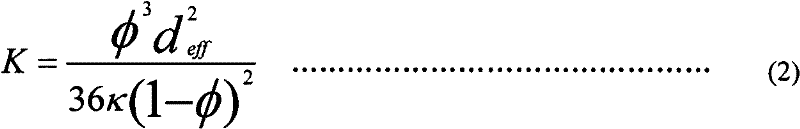

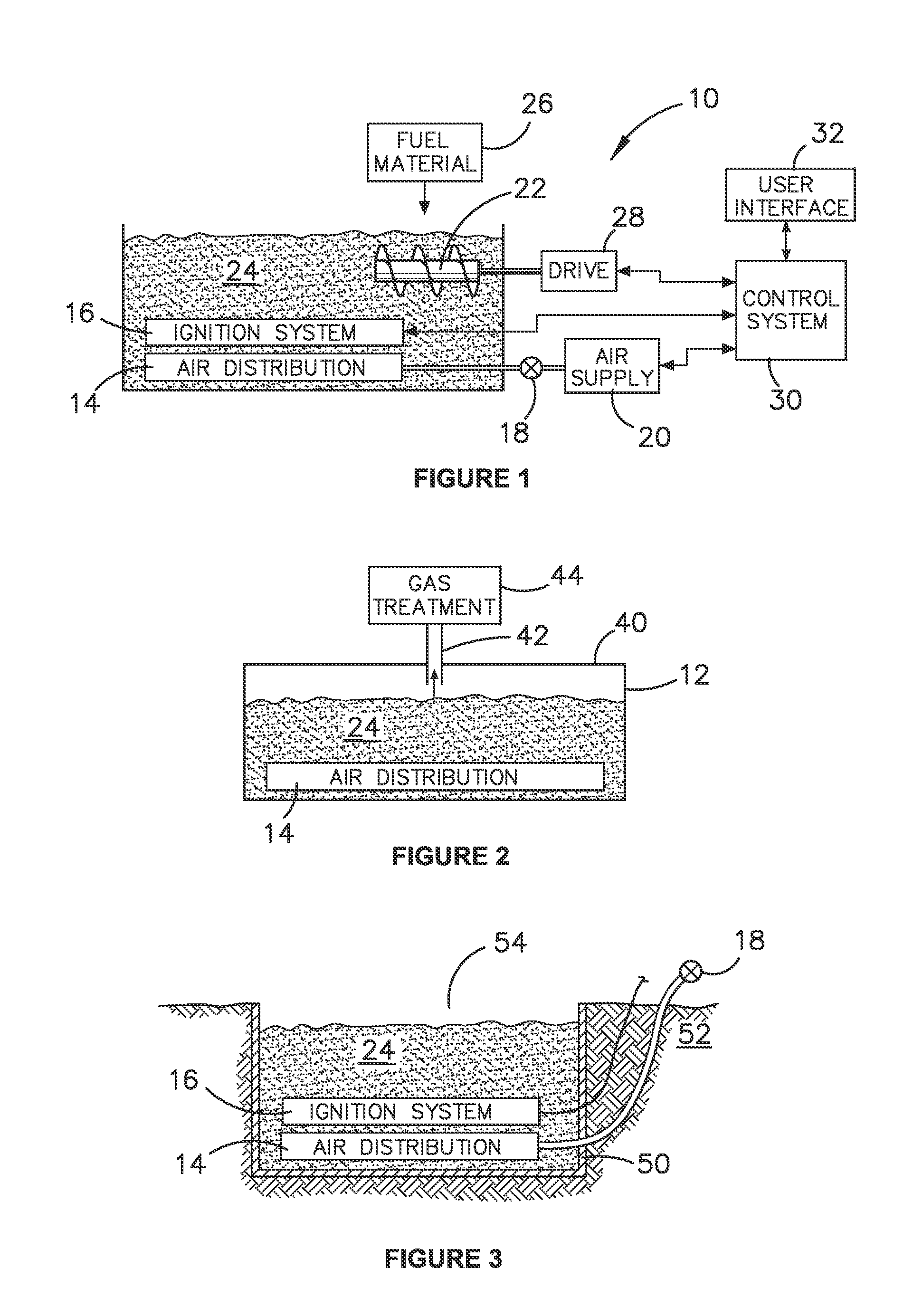

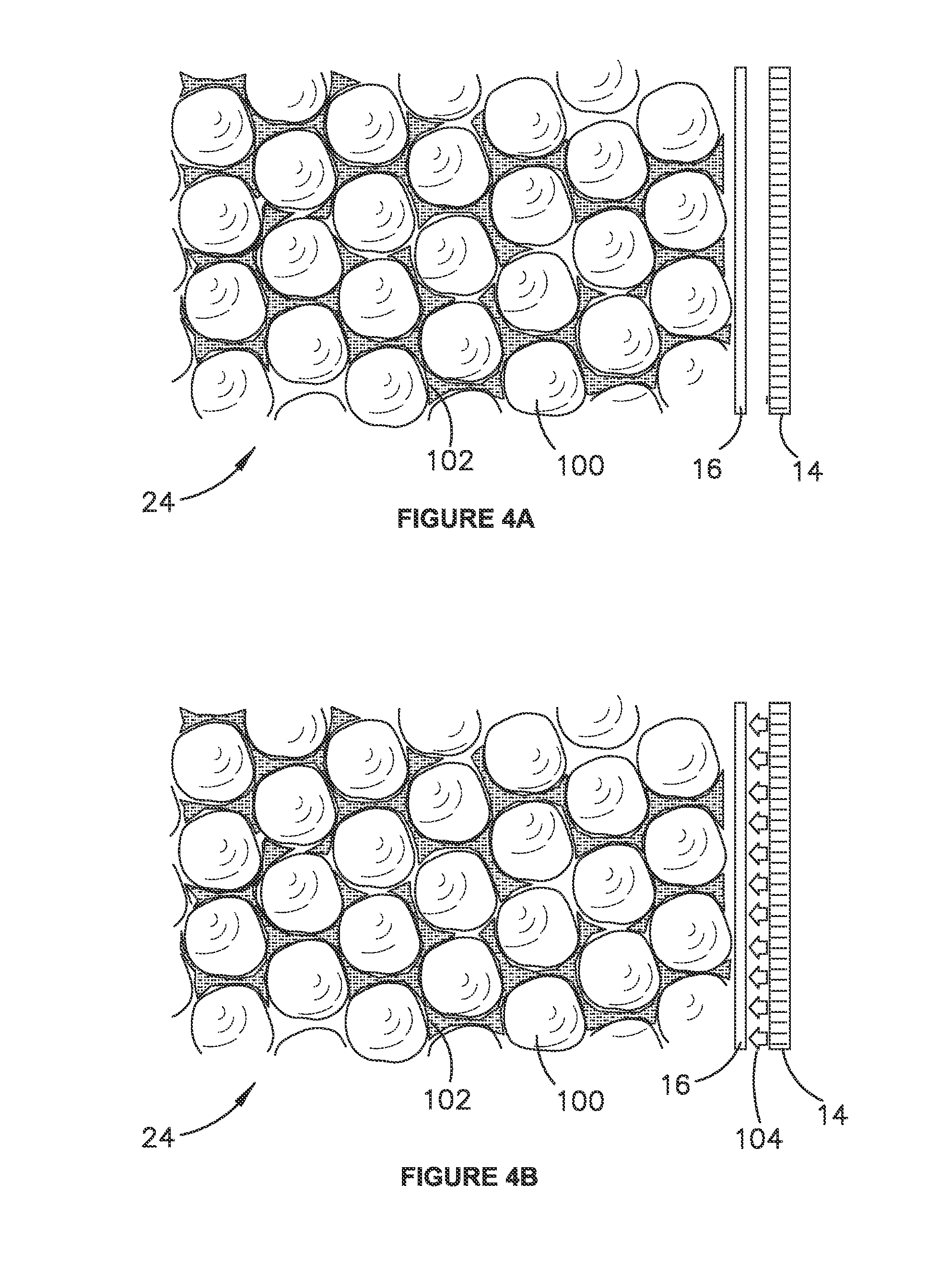

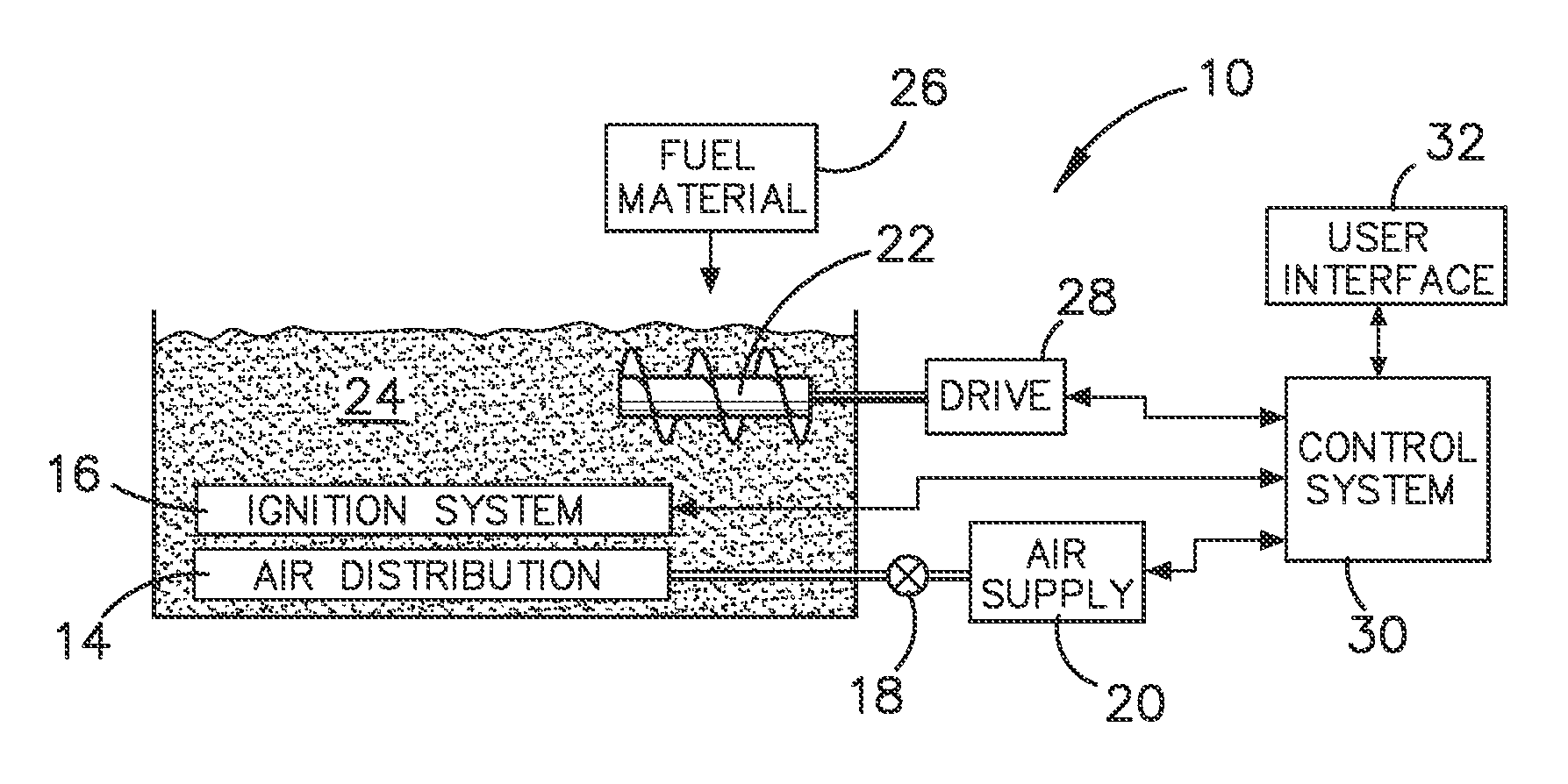

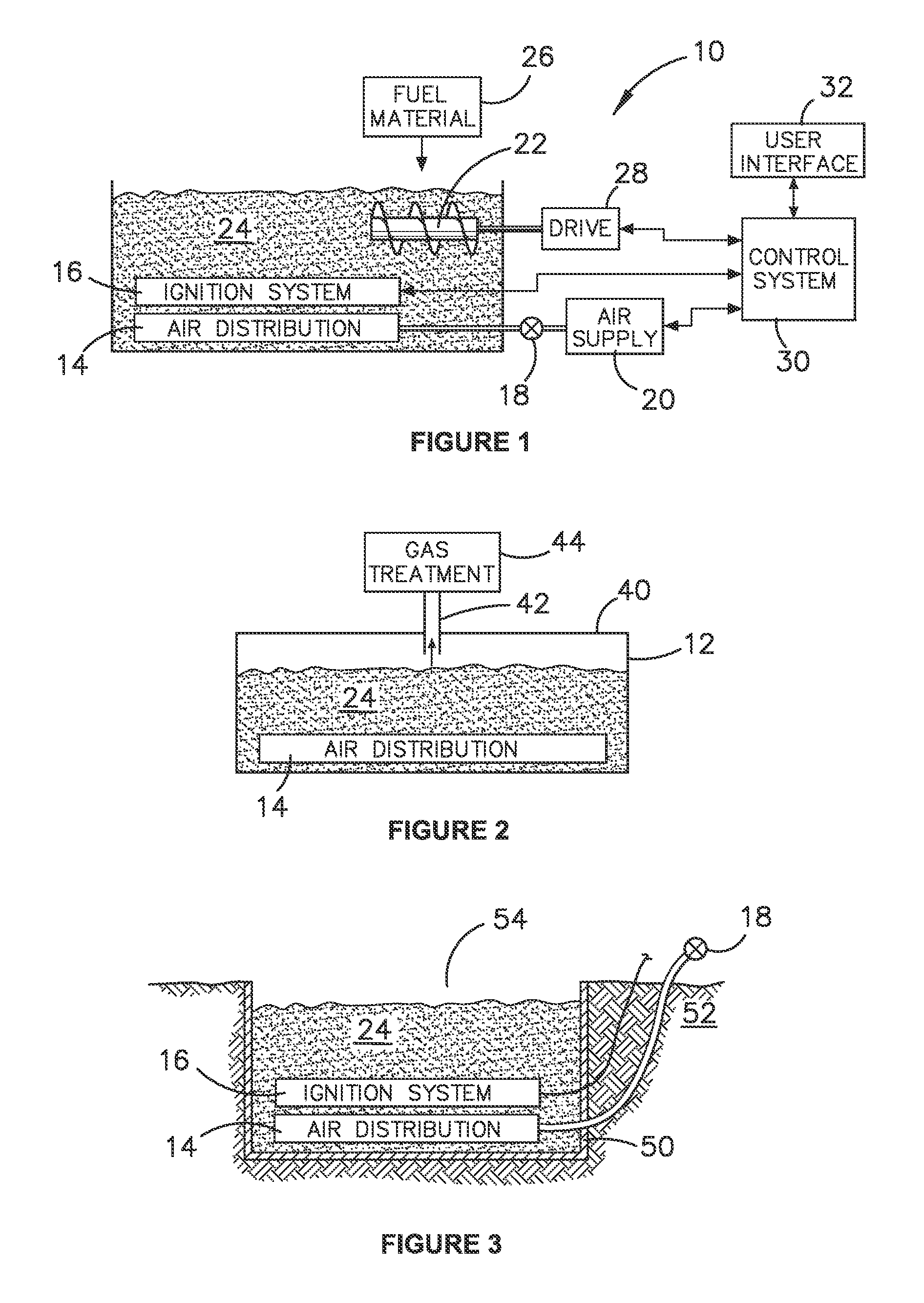

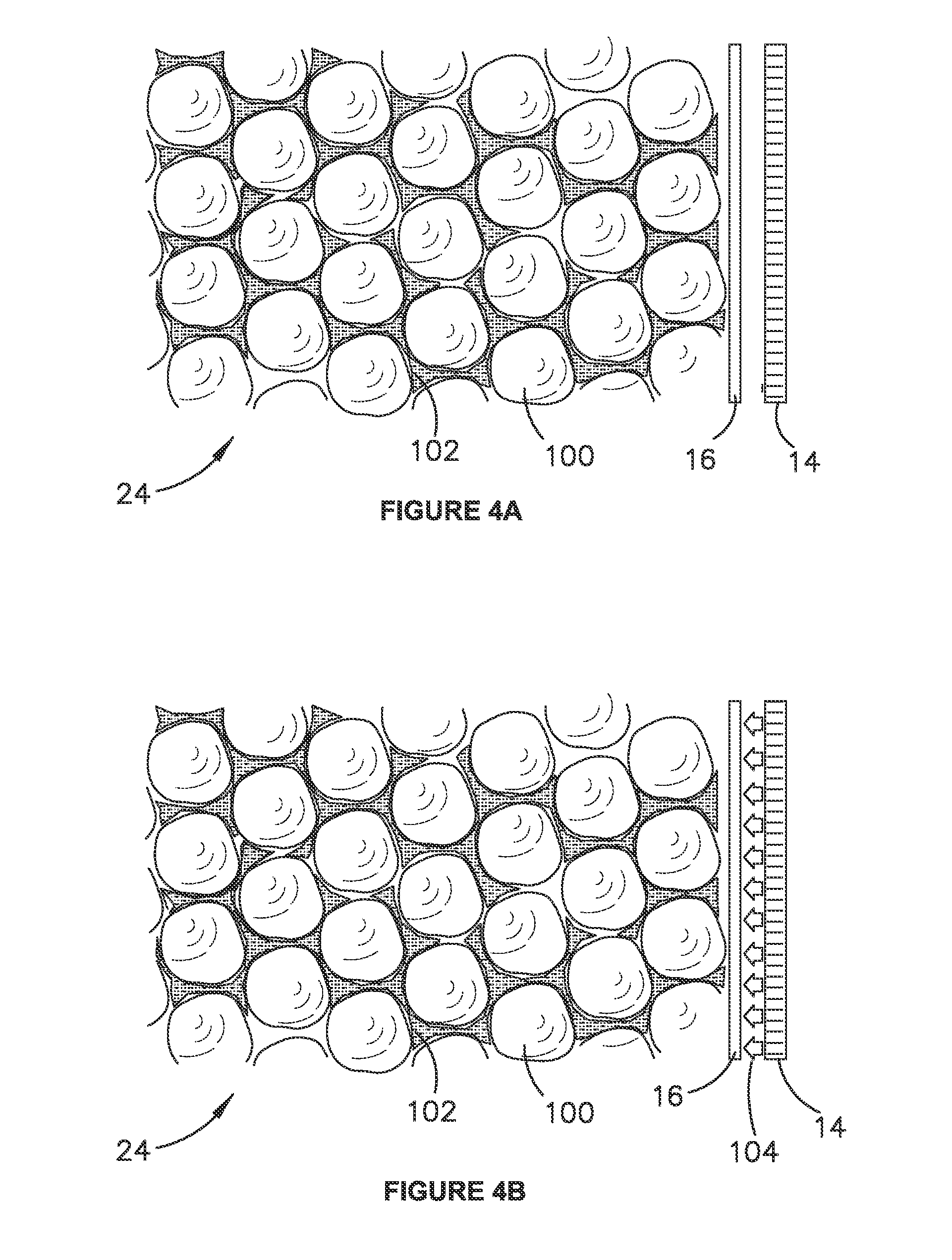

Thermal Treatment of a Contaminated Volume of Material.

ActiveUS20120288332A1Transportation and packagingContaminated soil reclamationFuranPolychlorinated biphenyl

A method is provided for remediating porous contaminated material. In the method, fuel material is combined with the contaminated material and a smoldering combustion process is initiated in the contaminated material to remediate the contaminated material. Control systems are provided to control the smoldering combustion process. The contaminated material may include oily waste, asbestos fibers, and / or at least one of a chlorinated solvent, a polychlorinated biphenyl (PCB), a dioxin, a furan and a polynuclear aromatic hydrocarbon (PAH).

Owner:CHEVROU USA INC

Nano-calcium carbonate modification method and application of nano-calcium carbonate to PVC (polyvinyl chloride) wood-plastic plate

The invention discloses a nano-calcium carbonate modification method and an application of nano-calcium carbonate to a PVC (polyvinyl chloride) wood-plastic plate. The nano-calcium carbonate modification method includes the steps: adding dispersing agents and crystal form control agents in a carbonation process; performing modification through diglycolamide oleate borate and dodecafluoro heptyl propyl polyhedral oligomeric silsesquioxane. The obtained modified nano-calcium carbonate has high dispersity, high toughness, weather resistance, flame resistance and excellent mechanical properties. The PVC wood-plastic plate comprises, by weight, 100 parts of PVC resin, 10-20 parts of EVA (ethylene-vinyl acetate) resin, 40-60 parts of bamboo powder, 30-50 parts of modified nano-calcium carbonate,3-5 parts of asbestos fibers, 4-6 parts of shell powder, 3-5 parts of polyacrylamide, 1-3 parts of polyether modified polydimethylsiloxane, 3-5 parts of composite foaming agents, 1-3 parts of coupling agents, 2-4 parts of stabilizing parts, 1-3 parts of lubricants, 0.5-1.5 parts of antibacterial agents and 3-5 parts of processing aids. The PVC wood-plastic plate has the advantages of high strength, high toughness, strong impact resistance, good flame resistance, strong antibacterial property, heat resistance, difficulty in deformation, good stability and the like.

Owner:钦州市宝业坭兴陶厂

Deterioration resistant non-asbestos wrap type clutch face sheet and process for making same

The present invention discloses one kind of anti-degradation non-asbestos wound clutch block and its making process. The anti-degradation non-asbestos wound clutch block contained non-asbestos fiber thread, rubber, compounding agent, adhesive, friction stuffing and lubricant and is formed through soaking in resin, stoving, soaking in adhesive slurry, stoving, winding, hot pressing and other steps. It has stable friction performance, better high temperature anti-degradation performance, less wear, long service life, great cracking strength and bending strength, no toxic asbestos fiber and no environmental pollution, and may be used to replace wound asbestos clutch.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

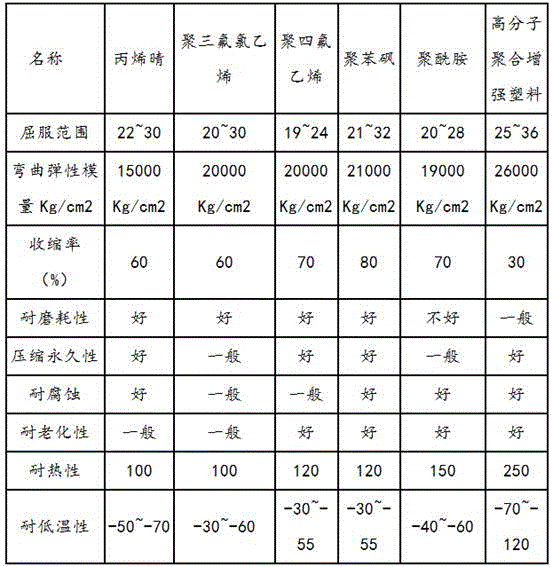

High-molecular polymerization reinforced plastic and preparation method thereof

The invention discloses high-molecular polymerization reinforced plastic. The high-molecular polymerization reinforced plastic is prepared from the following materials in parts by weight: 90 to 120 parts of polyvinyl chloride resin, 80 to 800 parts of phenolic resin, 80 to 100 parts of epoxy resin, 60 to 80 parts of wood flour, 20 to 36 parts of glass fiber, 16 to 28 parts of diatomaceous earth, 15 to 25 parts of asbestos fiber, 10 to 20 parts of tar stone powder, 11 to 19 parts of fiber cloth waste, 8 to 14 parts of antimonous oxide, 16 to 20 parts of graphite, 30 to 40 parts of dioctyl phthalate, 7 to 9 parts of stearate and 7 to 9 parts of organic tin. The high-molecular polymerization reinforced plastic has the advantages of high strength, corrosion resistance and wear resistance.

Owner:惠州市瑞诺科技有限公司

Environmental protection plastic

The invention discloses an environmental protection plastic, which comprises, by mass percentage, 20-30% of polylactic acids, 25-40% of polycaprolactone, 25-40% of short asbestos fibers, 5-12% of compatibilizers and 2-8% of coupling agents. According to the environmental protection plastic, the polylactic acids and the polycaprolactone which are environment-friendly and degradable are used to be polymerized, a plurality of auxiliaries are added, intensity, toughness and heat-resistant performance are improved, the production cost is lowered, general-purpose plastics can be replaced, and the environmental protection plastic can be applied to the field of engineering plastics.

Owner:常熟市海虹苗木花卉有限公司

Thermal treatment of a contaminated volume of material

A method and apparatus for remediating porous contaminated material. In the method, fuel material is combined with the contaminated material and a smoldering combustion process is initiated in the contaminated material to remediate the contaminated material. Control systems are provided to control the smoldering combustion process. The contaminated material may include oily waste, asbestos fibers, and / or at least one of a chlorinated solvent, a polychlorinated biphenyl (PCB), a dioxin, a furan and a polynuclear aromatic hydrocarbon (PAH).

Owner:CHEVROU USA INC

Heat-proof magnetic conveyor belt cover rubber and preparation method thereof

The invention provides heat-proof magnetic conveyor belt cover rubber. The cover rubber comprises the following components in parts by weight: 100 parts of ethylene propylene diene monomer rubber, 2-5 parts of anti-aging agent, 5-10 parts of zinc oxide, 2-8 parts of magnesium oxide, 1-3 parts of stearic acid, 25-50 parts of carbon black, 4-6 parts of dicumyl peroxide, 30-50 parts of asbestos fiber, 150-300 parts of magnetic powder, and 5-20 parts of paraffin oil. In addition, the invention further provides a preparation method of the heat-proof magnetic conveyor belt cover rubber. The heat-proof magnetic conveyor belt cover rubber meets the heat-proof property of high-temperature parts conveyed on an iron making and steel making production line, the heated aging damage rate of the conveyor belt can be reduced, and the service life of the conveyor belt can be prolonged; furthermore, metal parts falling on the conveyor belt can be effectively adsorbed, the slippage of the metal parts can be prevented, unnecessary damage can be reduced, the production of next procedure can be favorably carried out, and the working efficiency can be improved.

Owner:江苏凯嘉橡胶科技股份有限公司

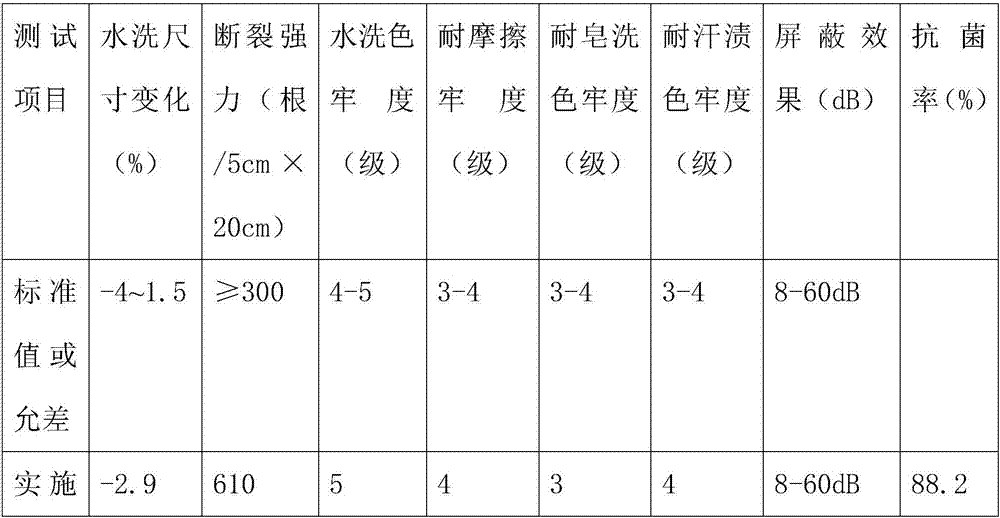

Antibacterial and radiation-proof spun fiber for medical fabric and preparation method thereof

InactiveCN107190356AExcellent antibacterial and radiation protection performanceImprove absorbing performanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer sciencePolypyrrole

The invention discloses an antibacterial and radiation-proof spun fiber for medical fabric and a preparation method thereof. The antibacterial and radiation-proof spun fiber for medical fabric is prepared from the raw materials of polylactic acid, modified ricinus silk, polypropylene filament yarn, polyester fiber, wool fiber, zein fiber, nylon fiber, jute fiber, asbestos fiber, cotton stalk bark fiber, pentaerythritol, acetic ester, propylene glycol, nano zinc oxide, nano titanium oxide, barium alginate, magnesium oxide, carbon black, polypyrrole, sliver nitrate, silane coupling agent KH-550 and antibacterial modification additives. The antibacterial and radiation-proof spun fiber for medical fabric is excellent in antibacterial and radiation-proof properties.

Owner:安徽新生纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com