Composite heat-insulating material and preparation method thereof

A heat insulation material and raw material technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of unsatisfactory heat insulation performance and long drying time, and achieve low heat insulation coefficient, high production efficiency, and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

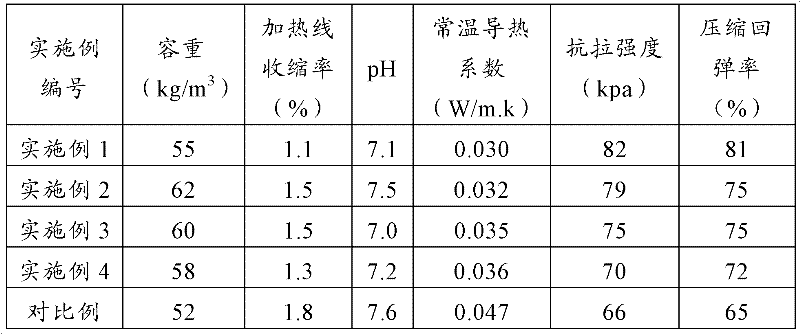

Examples

Embodiment 1

[0032] Raw material weighing: SiO 2 Airgel (average particle size 5nm, 80% (volume) pore size less than 25nm, Shanxi Tianyi Nano Material Co., Ltd.) 85kg, diatomaceous earth 15kg, aluminum silicate fiber 120kg, sepiolite 110kg, brucite 50kg, asbestos 80kg of fiber, 50kg of perlite, 10kg of diethyloctyl sodium sulfosuccinate, 8kg of polyvinyl alcohol, and 800kg of clear water.

[0033] Preparation method: first add 10kg of diethyloctyl sodium succinate to 800kg of clear water to dilute, then put 120kg of aluminum silicate fiber and 80kg of asbestos fiber into it and soak for 10 minutes; then, mix the obtained mixture with Add other raw materials together into the hexagonal mixing container at one time and stir slightly (control the speed at 120 rpm to prevent the fibers from being chopped at too high a speed), stop stirring after 3-5 minutes; let stand for 10 minutes to get a coarse slurry material; start stirring again, control the speed of 300 rpm, and stop stirring after 25...

Embodiment 2

[0035] Raw material weighing: SiO 2 Airgel (average particle diameter 7.6nm, 80% (volume) pore diameter is less than 25nm, Shanxi Tianyi Nano Material Co., Ltd.) 50kg, diatomaceous earth 30kg, bentonite 2kg, aluminum silicate fiber 180kg, sepiolite 70kg, water magnesium Stone 25kg, asbestos fiber 100kg, perlite 30kg, sodium tripolyphosphate 30kg, polyvinyl alcohol 4kg, clear water 900kg.

[0036]Preparation method: First add 30kg of sodium tripolyphosphate to 900kg of clear water to dilute, then put 180kg of aluminum silicate fiber and 100kg of asbestos fiber into it and soak for 10 minutes; add the resulting mixture together with other materials for six Stir slightly in the angular stirring container (control the speed at 100 rpm, in case the fiber is chopped at too high speed), stop stirring after 3-5 minutes, and start stirring again after standing for 10 minutes, control the speed at 200 rpm, and stop stirring after 30 minutes to make the slurry fine and the air bubbles f...

Embodiment 3

[0038] Raw material weighing: SiO 2 Airgel (average particle size 10nm, 80% (volume) pore size less than 25nm, Shanxi Tianyi Nano Material Co., Ltd.) 15kg, diatomaceous earth 140kg, bentonite 30kg, aluminum silicate fiber 140kg, sepiolite 20kg, asbestos fiber 95kg , perlite 40kg, sodium lauryl sulfate 20kg, water glass 8kg, polyvinyl alcohol 2kg, sodium cetylsulfonate 0.2kg, clear water 800kg.

[0039] Preparation method: first add 20kg of sodium lauryl sulfate to 800kg of clear water to dilute, then put 140kg of aluminum silicate fiber and 95kg of asbestos fiber into it and soak for 10 minutes; mix the resulting mixture with other materials once Add it into a hexagonal mixing container and stir slightly (control the speed at 80 rpm to prevent the fibers from being chopped up if the speed is too high), stop stirring after 3-5 minutes, and start stirring again after standing for 10 minutes to control the speed At 100 rpm, stop stirring after 35 minutes to make the slurry fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com