Steel door capable of fire prevention, theft prevention and noise prevention

An anti-noise, steel technology, applied in the field of fire doors, can solve the problems of perlite board and panel disconnection, failure to meet fire protection requirements, easy deformation of fire door frames, etc., to increase overall strength and impact resistance, prevent open flames, etc. It has obvious effects on smoke diffusion and three defenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

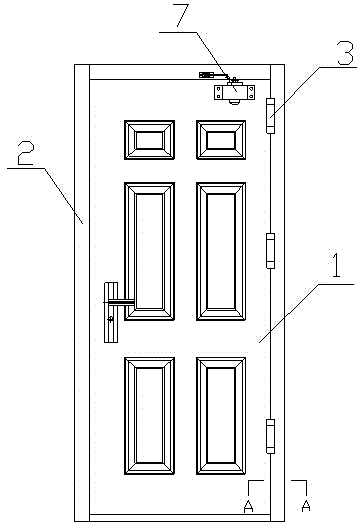

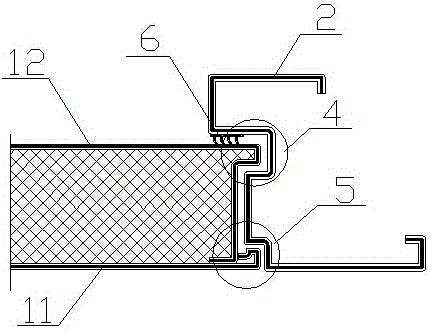

[0022] Example: see figure 1 , figure 2 , a fireproof, anti-theft and noise-proof steel door, comprising a door leaf 1, a door frame 2 and a hinge 3, the frame body 11 and the door frame 2 are stamped and formed by a composite steel plate, the composite steel plate includes a first steel plate, a second steel plate and The adhesive between the first steel plate and the second steel plate, the first steel plate and the second steel plate are fastened together by the adhesive; the overall structural strength of the door leaf 1 and the door frame 2 is higher, the stability is better, and the Effectively prevent the door leaf 1 and the door frame 2 from being deformed by heat. One side of the door leaf 1 is hinged with the door frame 2 through a hinge 3; the hinge 3 adopts a fireproof hinge 3, so that the fireproof performance is better. A fireproof door closer 7 is also provided between the upper end of the door leaf 1 and the upper end of the door frame 2. When a fire occurs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com