Process for preparation formation of nonasbestos fibre enhanced latex sealing plate

A non-asbestos fiber and sealing gasket technology, which is applied in the field of fiber-reinforced rubber elastomer composite material manufacturing process, can solve pollution and other problems, and achieve the effect of good chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] Specific embodiments of the present invention are now described in the following:

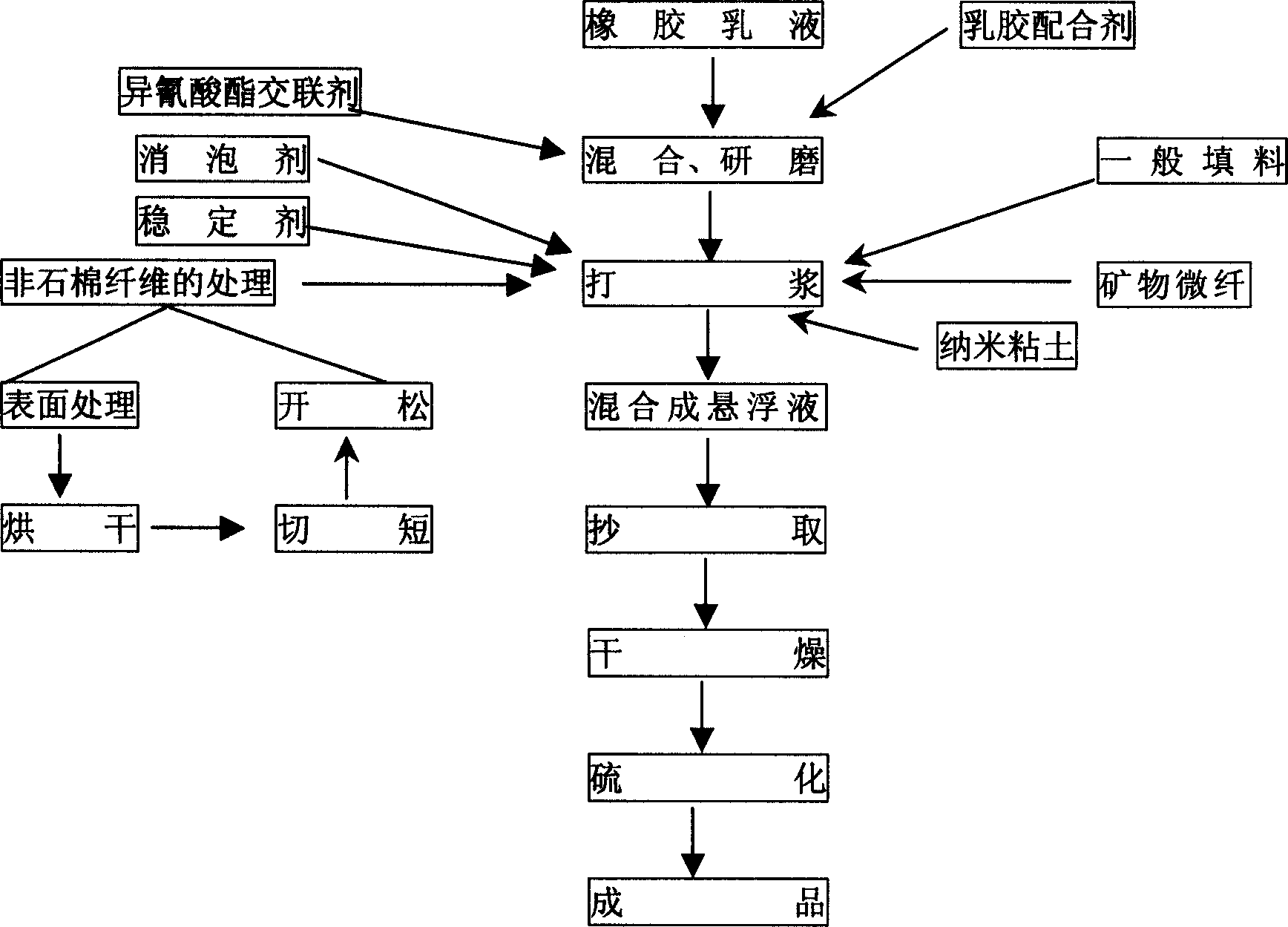

[0030] The molding process flow chart of the non-asbestos reinforced latex gasket plate of the present invention can be found in figure 1 , each step in the technological process of the inventive method is described as follows:

[0031] a. Treatment of non-asbestos fibers:

[0032] ①Shortening of fibers

[0033] The shortening of non-asbestos fibers should be controlled and the initial aspect ratio L / D should be 100-200. Different types of fibers have large differences in strength and toughness. For inorganic non-asbestos fibers with poor toughness, such as glass fiber, slag wool, titanate fiber, etc., the initial length-to-diameter ratio is preferably 200; and for organic fibers with excellent toughness, such as polysulfone fiber, aramid fiber, and Apmoc, etc. For fiber, it is better to choose 100-120, otherwise it will cause difficulty in uniform dispersion with rubber and filler d...

Embodiment 1

[0048] Embodiment one: in the present embodiment, the components of the non-asbestos fiber-reinforced latex gasket sheet and their proportioning ratio (percentage by dry mass) are as follows:

[0049] Formula A

[0050] Aramid pulp 13.00%

[0051] Glass fiber (L / D=200) 12.00%

[0052] Fibrous sepiolite 25.00%

[0053] Natural Rubber Emulsion 20.00%

[0055] Antiager D 0.20%

[0056] Casein 0.13%

[0057] Potassium hydroxide 0.03%

[0058] Lanolin 0.04%

[0059] Accelerator TMTD 0.18%

[0060] Sulfur 0.20%

[0061] Water-dispersible blocked isocyanate emulsion 2.02%

[0062] Nanoclay 5.00%

[0064] Calcium Carbonate 7.00%

[0065] Talc 5.00%

[0066] Diatomaceous earth 5.00%

[0067] A total of 50Kg (dry mass) of the above-mentioned components is taken according to the above wet molding process to obtain the non-asbestos fiber reinforced latex gasket plate of the present invent...

Embodiment 2

[0072] Embodiment two: in the present embodiment, each component of non-asbestos fiber reinforced latex gasket plate and its proportioning (dry mass percentage) are as follows:

[0073] Formula B

[0074] Kevlar pulp 10.00%

[0075] Glass fiber (L / D=200) 12.00%

[0076] Carbon fiber (L / D=160) 5.00%

[0077] Fibrous sepiolite 25.00%

[0078] Nitrile Rubber Emulsion 15.00%

[0079] Carboxylated styrene-butadiene emulsion 5.00%

[0081] Antiager D 0.20%

[0082] Casein 0.02%

[0083] Lanolin 0.10%

[0084] Accelerator ZDC 0.20%

[0085] Sulfur 0.30%

[0086] Water-dispersible blocked isocyanate emulsion 2.52%

[0087] Nanoclay 5.00%

[0089] Calcium Carbonate 7.00%

[0090] Talc 4.00%

[0091] Diatomaceous earth 4.00%

[0092] 50Kg (dry mass) of the above-mentioned components is obtained according to the above wet-process molding process to obtain the non-asbestos fiber rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com