Patents

Literature

51results about How to "Good rebound rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

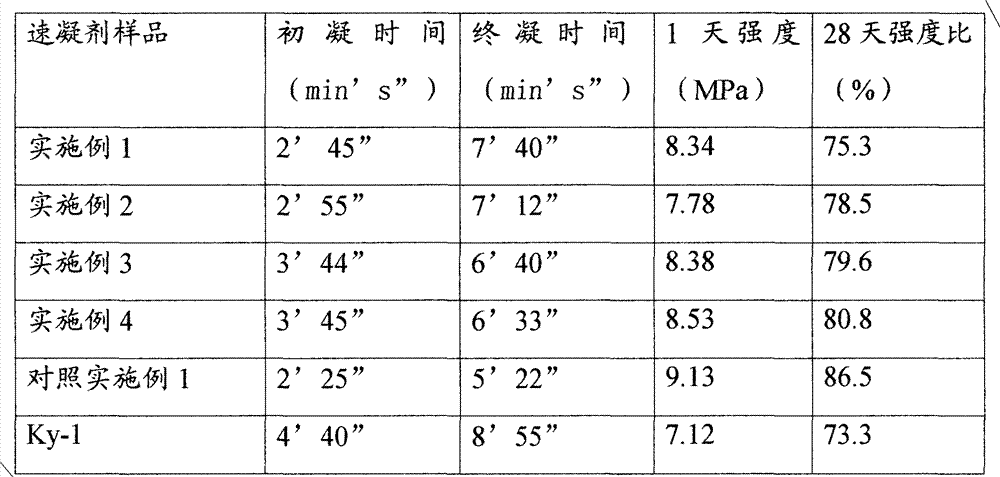

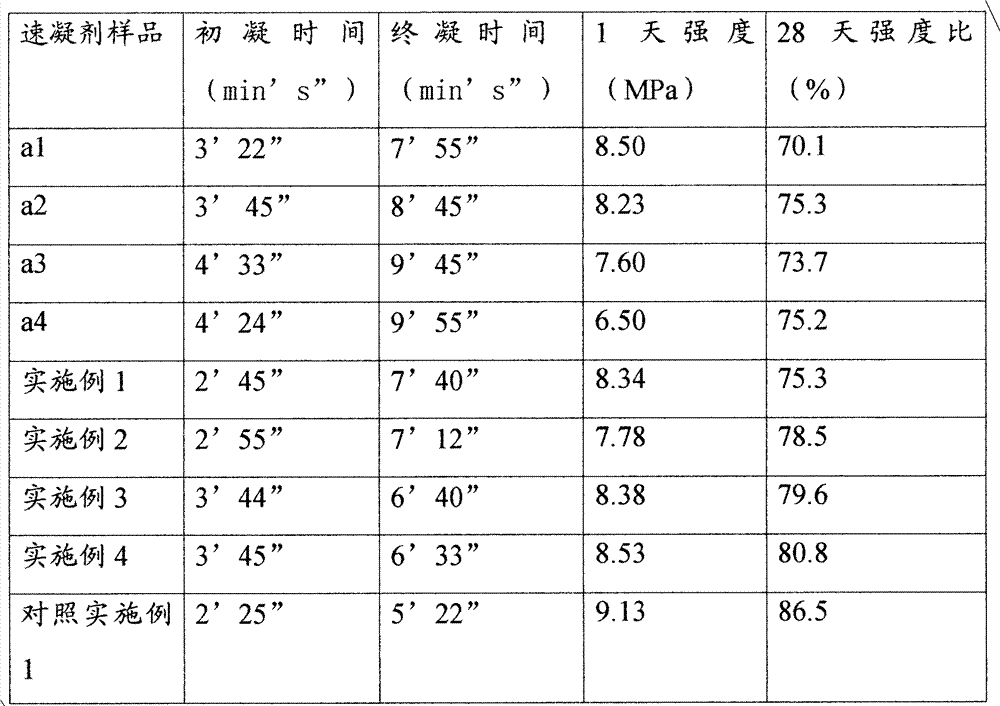

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

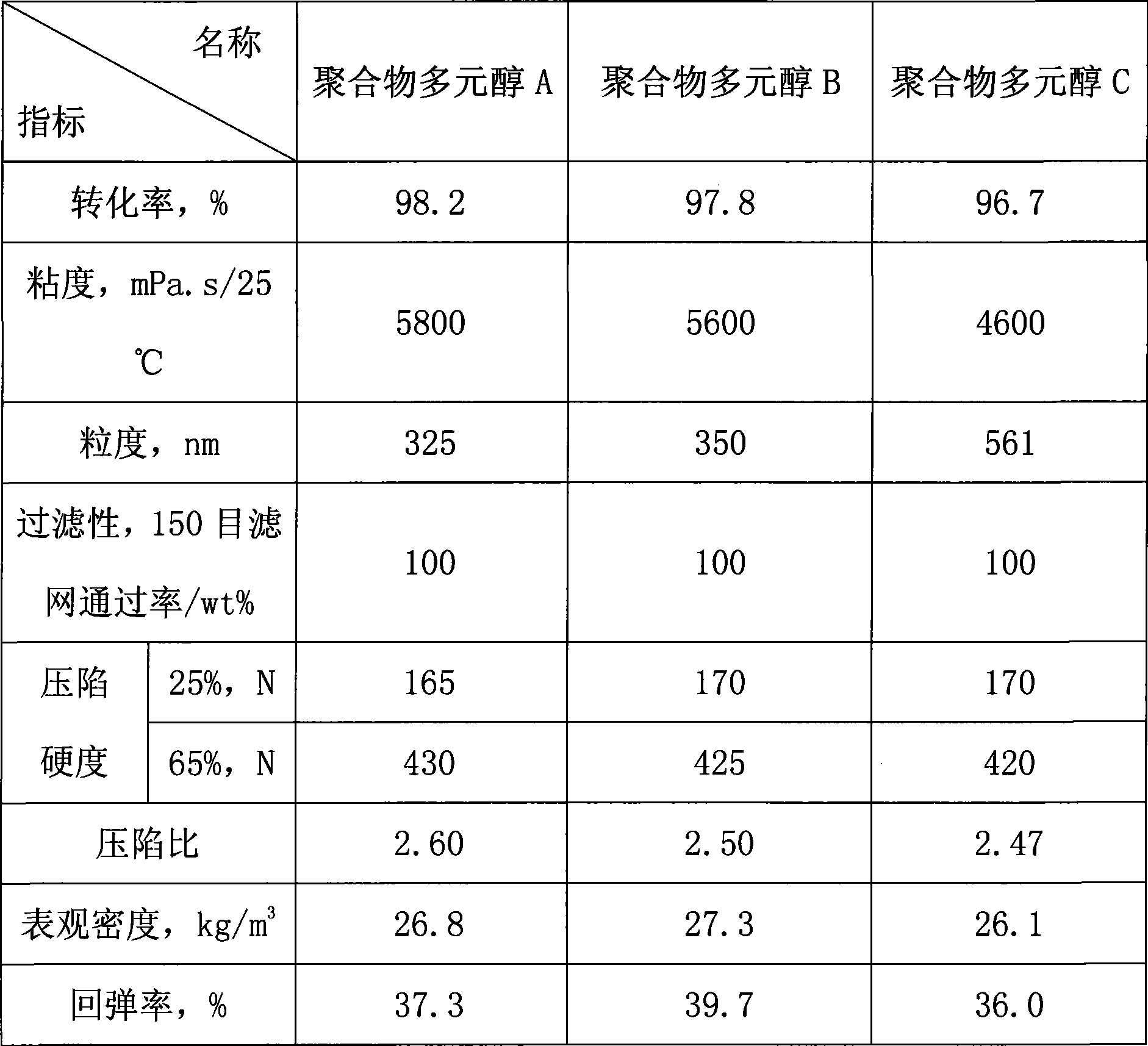

Method for producing high-solid content low-viscosity polymer polylol

The invention relates to a method for preparing polymer polyol with high solid content and low viscosity. The method adopts an intermittent method or a continuous method, and uses a basic polyether polyol as a continuous phase to perform in situ polymerization on a vinyl monomer, polyether polyol, a dispersing agent, and a chain transfer agent under the action of a free radical initiator to produce the polymer polyol with high solid content and low viscosity; or the method uses a certain amount of the polymer polyol with target solid content as a substrate material, mixes the raw materials such as the basic polyether polyol, the free radical initiator, the vinyl monomer, the dispersing agent, and the chain transfer agent evenly according to certain mixture ratio, and adds the mixture to the substrate material continuously to be polymerized so as to obtain the polymer polyol with high solid content and low viscosity. The polymer polyol produced by the method has the advantages of low viscosity, stable dispersion of solid particles, small average particle size of the solid particles, and even particle size. The polymer polyol improves the physical mechanical properties of products applying the polymer polyol, and has wide application range.

Owner:TIANJIN DAGU CHEM CO LTD

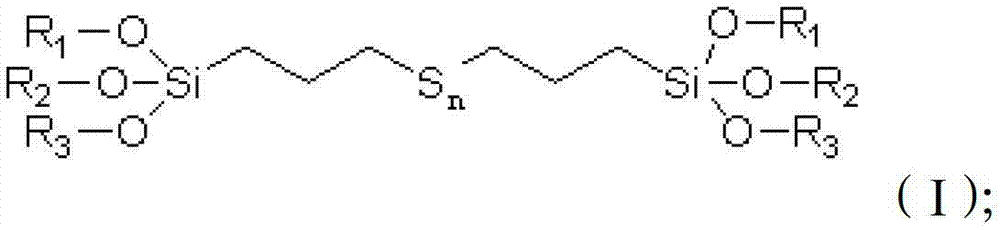

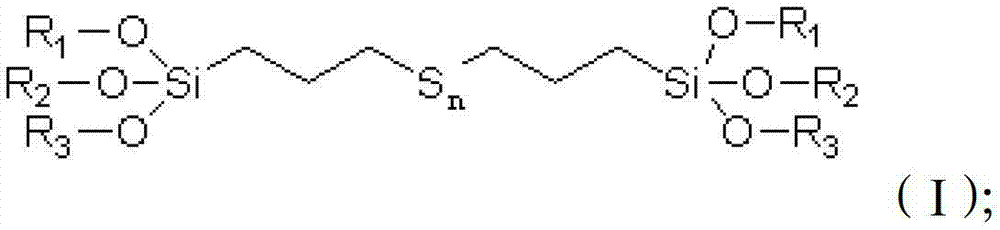

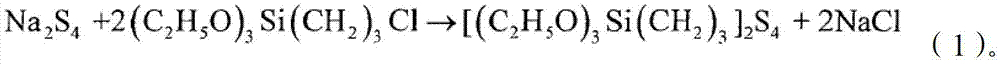

Surface modified aramid fiber, surface modification method thereof and static sealing material

ActiveCN103194898AIncrease surface polarityImprove mechanical propertiesFibre typesMechanical propertyAramid

The invention provides a surface modified aramid fiber and a surface modification method of the surface modified aramid fiber. The surface modification method comprises the steps of coating silane coupling agent solution or a dispersion liquid on the surface of the aramid fiber and then drying the aramid fiber under the condition of being contacted with air, thus obtaining the surface modified aramid fiber, wherein a silane coupling agent has a structure in the formula (I) in the specification; n is 2 or 4; and R1, R2 and R3 are independently selected from alkyl with number of carbon atoms being 1-5. When being adopted to produce composite materials, the aramid fiber prepared by the surface modification method provided by the invention can prevent precipitation and deposition of base materials while improving the mechanical properties of the composite materials and is simple, easy and safe in production operation. The invention also provides a static sealing material. The static sealing material adopts the surface modified aramid fiber and has relatively good mechanical property, sealing property and other properties.

Owner:廊坊佰昂密封材料有限公司

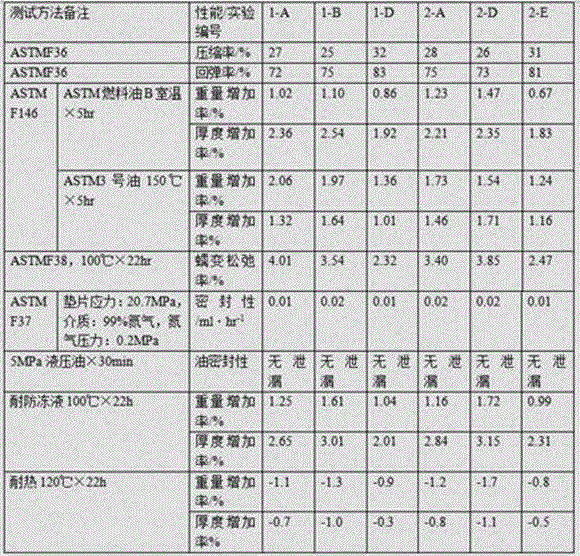

Foaming nitrile rubber metal composite plate and preparation method thereof

ActiveCN106752403AImprove performanceImprove sealingOther chemical processesConjugated diene hydrocarbon coatingsFoam rubberComposite plate

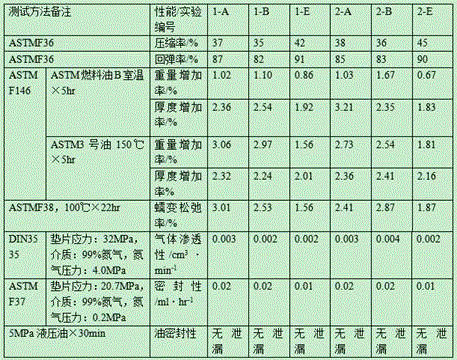

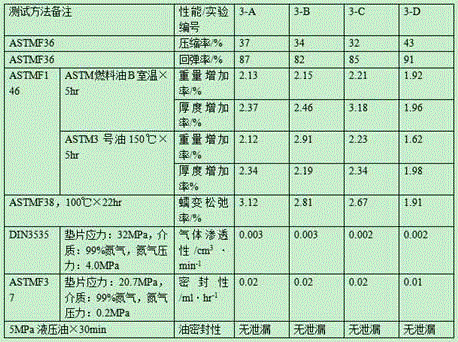

The invention provides a foaming nitrile rubber metal composite plate and a preparation method thereof, and relates to a sealing material. The foaming nitrile rubber metal composite plate comprises a metal base plate, wherein a foaming rubber layer is arranged at the surface of the metal base plate; the foaming rubber layer is prepared from the following raw materials in parts by mass: 100 parts of nitrile rubber, 1 to 10 parts of zinc oxide, 2 to 10 parts of accelerant, 0.5 to 5 parts of sulfur, 20 to 40 parts of carbon black, 1 to 5 parts of foaming agent, and 1 to 10 parts of additive. The foaming nitrile rubber metal composite plate has the advantages that the compression rate is 32 to 47%, the resilience rate is more than 80%, the creepage relaxation rate is less than 4%, the sealing property ml / hr is equal to or less than 0.02, and the oil sealing and non-leakage properties are realized; for resistant fuel B at room temperature after 5h, the weight increase is less than 2%, and the thickness increase is less than 4%; for resistant ASTM No.3 fuel at the temperature of 150 DEG C after 5h, the weight increase is less than 4%, and the thickness increase is less than 3%; the excellent compression rate, resilience rate, anti-creepage property, temperature and oil-resistant property and the like are realized.

Owner:南阳天一密封股份有限公司

Low-cost magnesium gunning material and its preparation method

The invention discloses a low-cost magnesium gunning material and its preparation method. The low-cost magnesium gunning material is prepared from the following components of: by weight, 25-38 parts of recycled magnesia of 1-3mm, 32-42 parts of recycled magnesia of 0.088-1mm, 6-12 parts of a recycled magnesium powder of 200 meshes, 8-12 parts of a sintered magnesium powder, 1-5 parts of sodium silicate, 1-5 parts of calcium hydroxide and 3-10 parts of ultrafine slurry. When in use, the above magnesium gunning material is sprayed onto ladle damaged positions by the use of a spray gun so as to complete the repairing work. The magnesium gunning material has characteristics of low cost, good fluidity, high adhesive rate, rapid reaction, fast hardening, low spring rate, erosion resistance, anti-stripping capacity and the like, is applicable to hot repairing of ladle, especially to hot repairing of slag line portions, and can be used to effectively prolong service life of ladle.

Owner:山西高科耐火材料股份有限公司

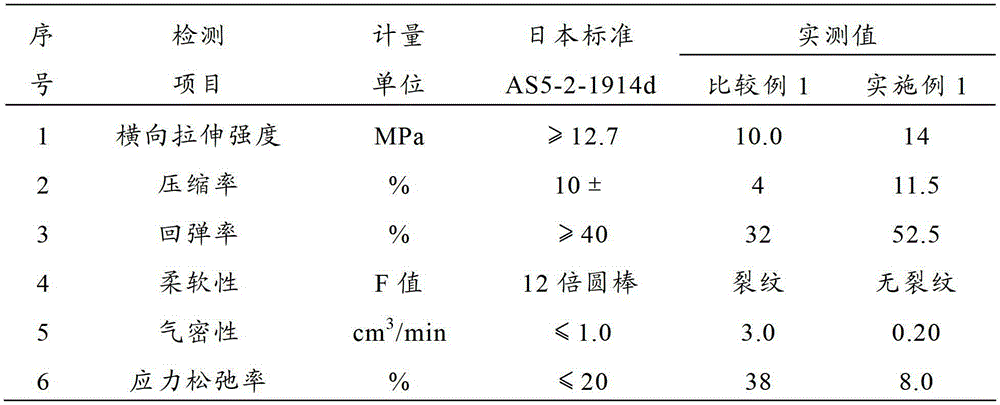

Aramid fiber dispersion liquid and dispersion method and static sealing material of aramid fiber

ActiveCN103146193AImprove mechanical propertiesGood transverse tensile strengthOther chemical processesMechanical propertyAramid

The invention provides an aramid fiber dispersion method and aramid fiber dispersion liquid. The dispersion method comprises the step of dispersing the aramid fiber in a dispersion medium to obtain the aramid fiber dispersion liquid; the dispersion medium is a mixed solution or dispersion liquid of organosilicon surfactant and polyoxyethylene, the organosilicon surfactant has a structure expressed by formula (I), wherein n is 1, 2 or 3; R and R1 are independently selected from alkyl with carbon atom number of 1-5; and X refers to a halide ion. According to the invention, the organosilicon surfactant is compounded with the polyoxyethylene to disperse the aramid fiber to obtain a better dispersion effect, so that the application in the field of composite materials is more extensive. The invention further provides a static sealing material, and the aramid fiber dispersion liquid is adopted to improve such performances of the static sealing material as mechanical property and sealing property, etc. [(R3N)nSiR14-n]X (I).

Owner:廊坊佰昂密封材料有限公司

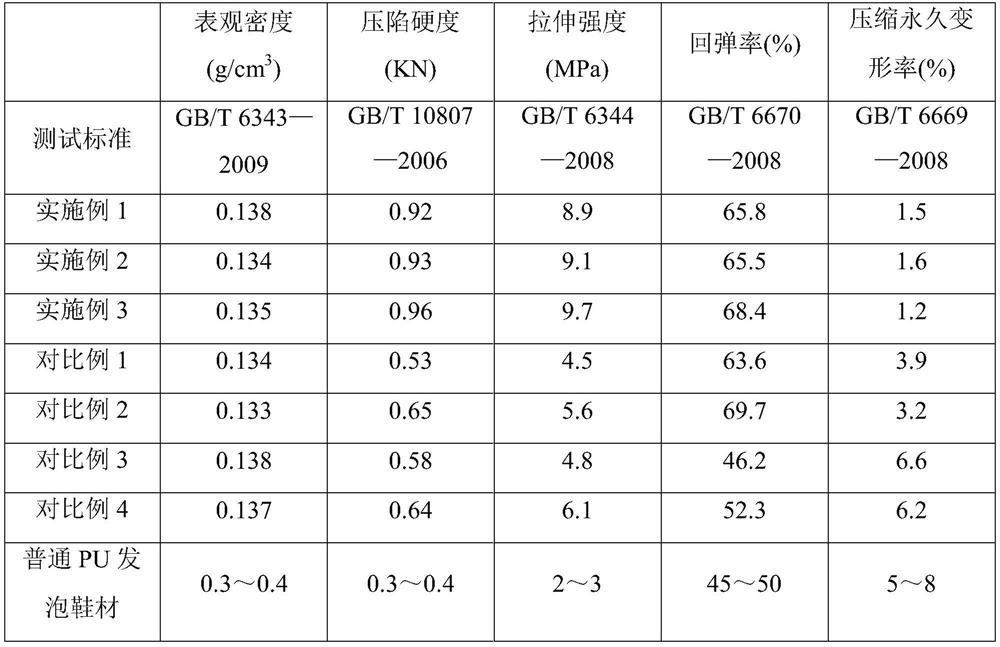

PU foaming shoe material capable of releasing negative ions and preparation method thereof

The invention discloses a PU foaming shoe material capable of releasing negative ions and a preparation method thereof. The PU foaming shoe material is prepared from the following raw materials in parts by weight: 70-80 parts of polyester polyurethane, 12-16 parts of ethylene-vinyl acetate copolymer, 5-7 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of a negative ion additive, 1.2-1.7 parts of 4-methylbenzenesulfonyl hydrazine, 0.45-0.55 parts of triethylene diamine, 0.08-0.12 parts of triallyl isocyanurate, 2-3 parts of talcum powder, 2-4 parts of titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate, wherein the negative ion additive is a mixture of opal powder and medical stone powder, and the mass ratio of opalpowder to medical stone powder is 1: (0.6-0.8). The PU foaming shoe material capable of releasing negative ions is small in density and light in weight; the indentation hardness is high, the tensile strength is high, and the mechanical property is good; the rebound rate is high, the compression set rate is low, the elasticity is good, and permanent deformation is not likely to happen in the usingprocess; and the overall performance is excellent.

Owner:ZHEJIANG SEMIR GARMENT CO LTD +1

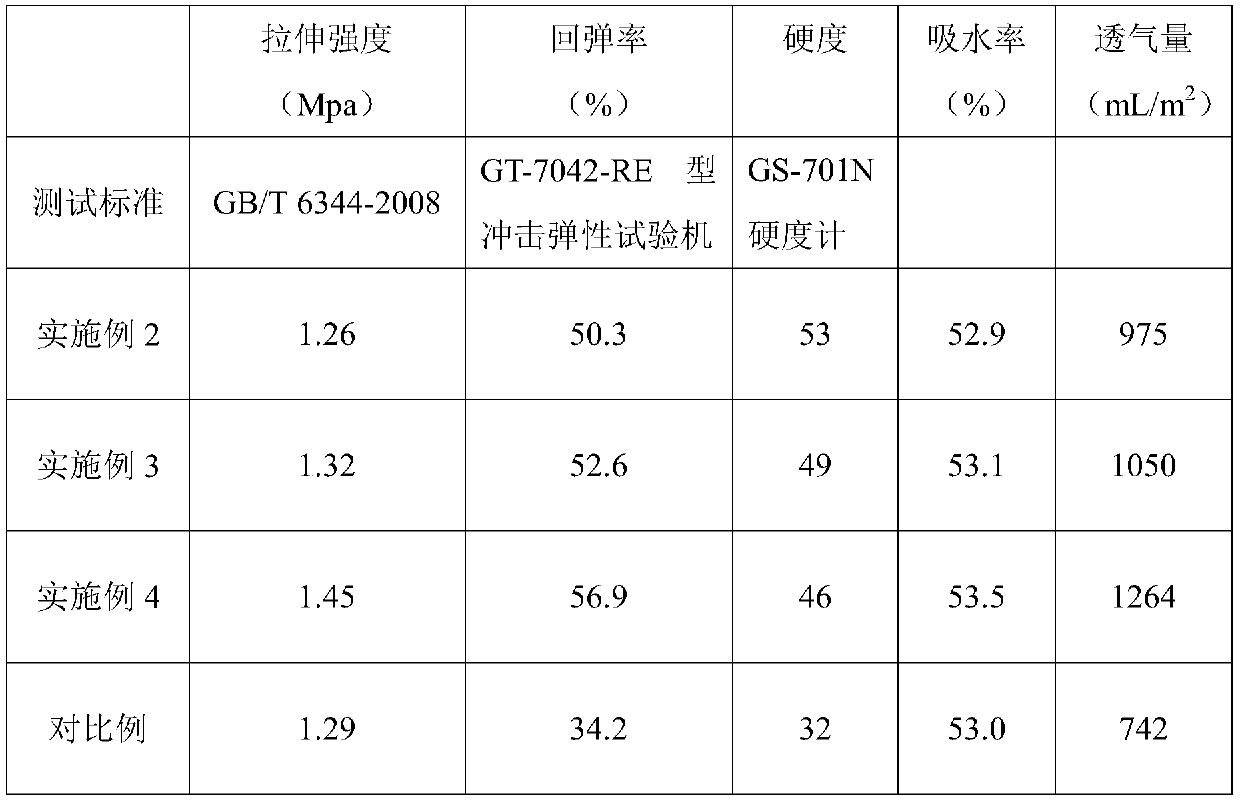

Graphene regenerated rubber-plastic foamed insole and preparation method thereof

The invention discloses a graphene regenerated rubber-plastic foamed insole and a preparation method thereof. The foamed insole is prepared by the following raw materials in parts by weight: 17-22 parts of an ethylene-vinyl acetate copolymer, 35-42 parts of an ethylene-vinyl acetate copolymer offcut grinding powder, 5-7 parts of ethylene propylene diene monomer rubber, 3-6 parts of oxidized polyethylene, 3.5-5.5 parts of graphene, 1-1.5 parts of carboxylated graphene, 30-37 parts of a thermoplastic polyester elastomer, 10-14 parts of a polyester-polyether block copolymer, 2-4 parts of fluorinated polyethylene, 1.2-2.3 parts of a foaming agent, 0.7-1.1 parts of a bridging agent, 2.5-4.5 parts of aluminum silicate fiber tubes, 2.5-4 parts of an antioxidant, and 3-4.5 parts of zinc stearate.The graphene regenerated rubber-plastic foamed insole has good mechanical properties such as high tensile strength and the like, the hardness is moderate, the air permeability is good, the service life as an insole material is long, the foamed insole is not easy to have excessive deformation, and the comfort degree is high. The recycling of EVA is realized, the utilization rate of EVA is improved,the raw material cost is reduced, and thus the foamed insole is more environment-friendly.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Fluororubber metal composite plate and preparation method thereof

InactiveCN106752442AImprove performanceImprove sealingOther chemical processesCoatingsCalcium hydroxideSodium Bentonite

The invention provides a fluororubber metal composite plate and a preparation method thereof, and relates to a sealing material. The fluororubber metal composite plate comprises a metal base plate, wherein fluororubber coating layers are arranged at both sides of the metal base plate; each fluororubber coating is prepared from the following raw materials in parts by mass: 100 parts of fluororubber, 1 to 10 parts of magnesium oxide, 2 to 10 parts of calcium hydroxide, 2 to 10 parts of vulcanizing agent, 0.5 to 5 parts of accelerant, 20 to 40 parts of carbon black, 1 to 5 parts of modified bentonite, and 1 to 10 parts of additive. The fluororubber metal composite plate has the advantages that the compression rate is 21 to 32%, the resilience rate is more than 65%, the creepage relaxation rate is less than 5%, the sealing property ml / hr is equal to or less than 0.02, and the oil sealing and non-leakage properties are realized; the oil-resistant, cold-resistant and heat-resistant properties are good, the excellent resilience rate, anti-creepage property, temperature and oil-resistant property and the like are realized, and the comprehensive effect is obvious.

Owner:南阳天一密封股份有限公司

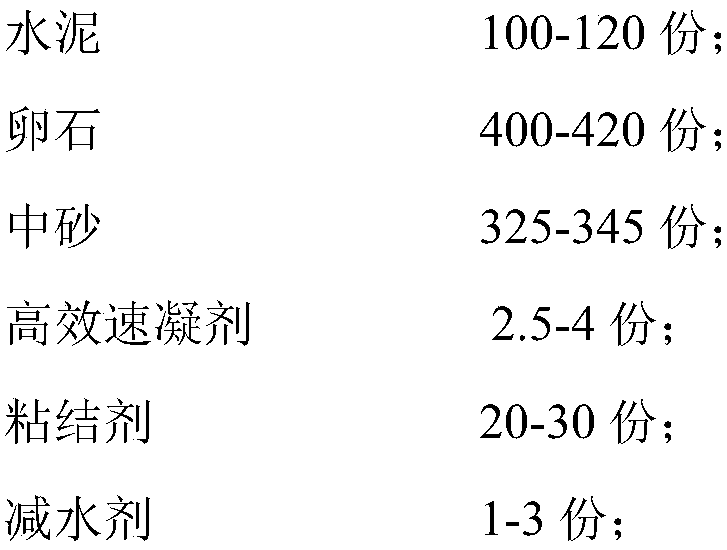

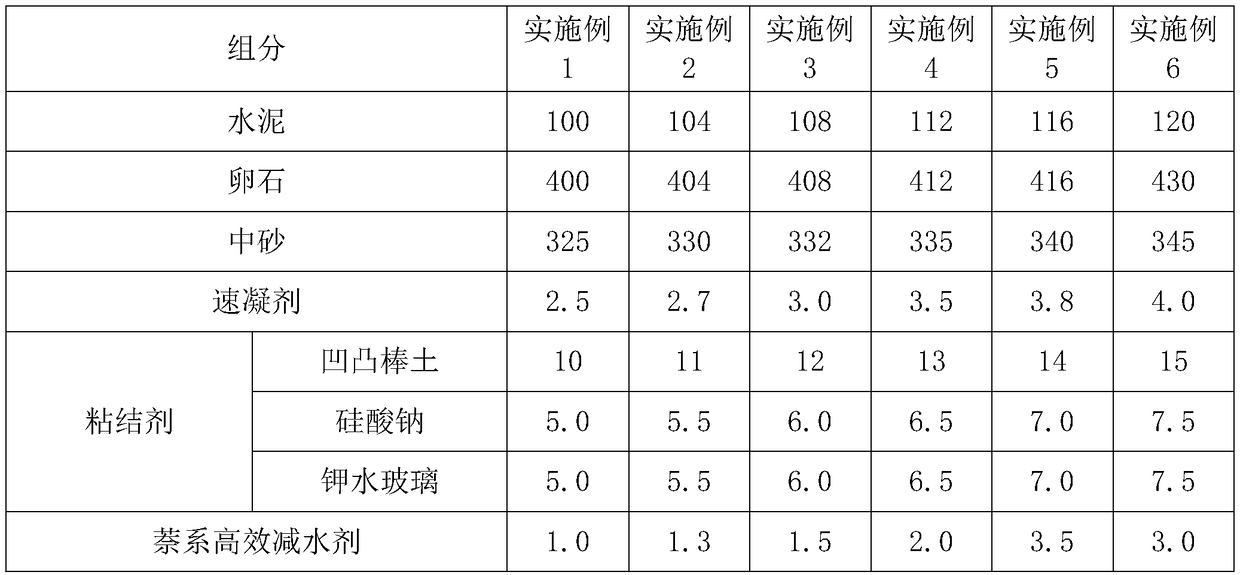

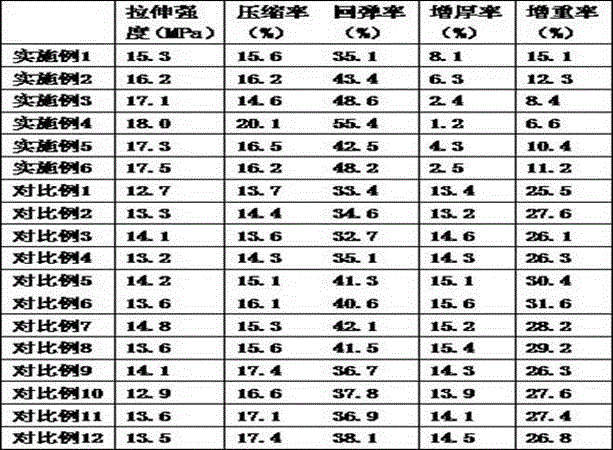

Precast dry-mix sprayed concrete

The invention discloses a precast dry-mix sprayed concrete which belongs to the technical field of building materials. The key point of the technical scheme is that the precast dry-mix sprayed concrete includes the following components in parts by weight: cement, pebbles, medium sand, a high-efficiency accelerator, a binder and a water reducer, wherein the cement is P.042.5 grade ordinary Portlandcement, the binder includes attapulgite, sodium silicate and potash water glass with the weight ratio of 2:1:1. According to the invention, cement-aggregate ratio and sand ratio are reasonably controlled, strength and compactness of concrete are improved, and on the other hand, dust pollution and disability are reduced; dryness of the dry mixture is improved through the attapulgite, sodium silicate and potash water glass, the adhesive force and viscosity after jetting are improved, the disability is reduced; besides, both sodium silicate and potash water glass have excellent heat resistance,thereby improving the heat resistance of the concrete.

Owner:北京建工新型建材有限责任公司

Graphene regenerated EVA (ethylene-vinyl acetate) forming sole colloidal particle and preparation method thereof

The invention discloses a graphene regenerated EVA (ethylene-vinyl acetate) forming sole colloidal particle and a preparation method thereof. The colloidal particle is prepared from, by weight, 22-28parts of ethylene-vinyl acetate copolymers, 45-50 parts of ethylene-vinyl acetate copolymer scrap grinding powder, 13-17 parts of oxidic polyethylene, 4-7 parts of graphene, 1-2 parts of carboxylatedgraphene, 2-4 parts of antioxidants, 1.5-3 parts of light stabilizers and 3-5 parts of zinc stearate. According to the graphene regenerated EVA forming sole colloidal particle, raw materials are carefully selected, a formula is reasonable, the graphene regenerated EVA forming sole colloidal particle serves as an EVA forming sole material, the colloidal particle has the advantages of high tensile strength, tearing strength and rebound rate, good bending resistance and rebound resilience, low size shrinkage rate and the like, the performances of the forming sole colloidal particle is close to even superior to those of marketing EVA sole materials, the EVA is recycled, the utilization rate of the EVA is increased, costs of raw materials are reduced, and the colloidal particle is more environmentally friendly.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

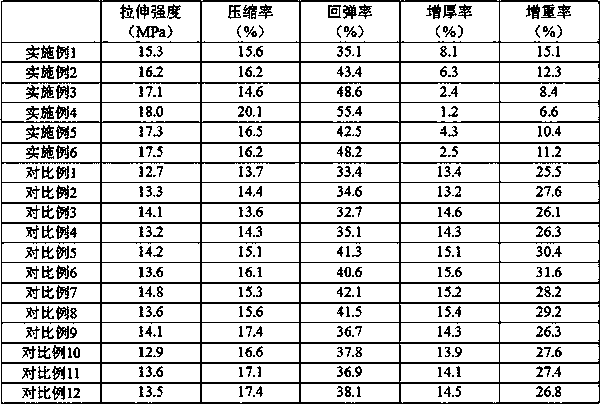

Antifreeze liquid resisting water pump gasket and preparation method of antifreeze liquid resisting water pump gasket

ActiveCN106750669AAchieve strengthImprove mechanical propertiesEngine sealsCoatingsFiberUltimate tensile strength

The invention relates to an antifreeze liquid resisting water pump gasket and a preparation method of the antifreeze liquid resisting water pump gasket. The antifreeze liquid resisting water pump gasket is prepared from a main material and an auxiliary material in parts by weight and is prepared from the following components in parts by weight: 100 parts of the main material, 3 to 15 parts of mica powder, 20 to 30 parts of kaolin, 10 to 20 parts of talcum powder and 5 to 10 parts of a coloring agent; the main material is prepared from an antifreeze liquid resisting hydroxyl silicone oil substance, butadiene styrene rubber and fibers at the mass ratio of (3 to 5) to 40 to (55 to 57); the antifreeze liquid resisting hydroxyl silicone oil substance is prepared from the following components in parts by weight: 30 to 40 parts of hydroxyl silicone oil, 2.5 to 3 parts of a vulcanizing agent, 2 to 3 parts of a vulcanizing accelerant and 1 to 3 parts of an anti-ageing agent. By researching antifreeze liquid, antifreeze liquid resisting materials are pertinently selected; all the raw materials have mutual effect through a special process, so that a prepared sealing gasket has good resilience rate, tensile strength and compression ratio, and also has an excellent antifreeze liquid resisting performance; the weight gain of the sealing gasket is less than 20 percent and the thickening rate of the sealing gasket is less than 10 percent within 22h at the temperature of 100 DEG C.

Owner:南阳天一密封股份有限公司

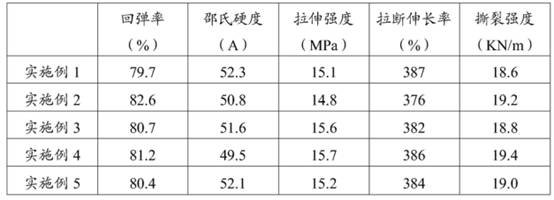

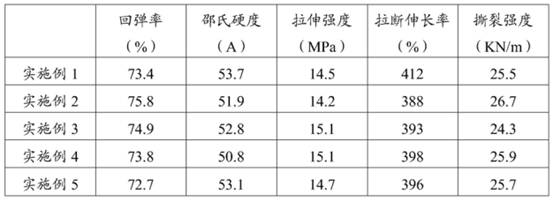

Composite plastic material for runway and preparation method of composite plastic material

The invention belongs to the field of plastic materials, and discloses a composite plastic material for a runway and a preparation method of the composite plastic material. The composite plastic material is composed of polypropylene, poly(decamethylene-decanedioic acid), poly(4-methyl-1-amylene), PTMEG, phenyltrissilane, bisphenol A diglycidyl ether, polyethylene wax, barium sulfate, zirconia and antioxidant BHT. The preparation method includes the steps of grinding, high-speed mixing, double-screw extruding, granulating, drying and product obtaining. The composite plastic material for the prepared runway has the advantages of being high in rebound rate, tensile strength and elongation at break, and the performance of the plastic runway is effectively improved.

Owner:JIN BAOLI TECH SUZHOU

Protection block of motor vehicle and manufacturing process thereof

ActiveCN102225688AHigh hardnessLow elastic modulusBumpersRubber layered productsEngineeringStearic acid

The invention relates to the technical field of safe collision prevention of motor vehicles, in particular to a protection block of a motor vehicle and a manufacturing process thereof. The protection block is provided with an external rubber block and a bottom rubber block, wherein the elastic modulus of the bottom rubber block is more than that of the external rubber block; the two rubber blocks are superposed; the external rubber block mainly comprises the following raw materials: butadiene rubbers, natural rubbers, zinc oxide, stearic acid, vaseline, pine tar oil, sulfur and the like; and the bottom rubber block comprises the following raw material: polyurethaneWHT-1570IO. The manufacturing process comprises the steps of external rubber block processing, bottom rubber block processing and integral forming. The protection block and the manufacturing process have the following beneficial effects: the external rubber block and the bottom rubber block are respectively manufactured from two materials with different hardness; and the protection block can absorb the impact energy and buffer and resist strong impact and can inhibit resonance surge through interaction of the two rubber blocks, thus having good comprehensive collision defence effect.

Owner:山东驼风汽车科技股份有限公司

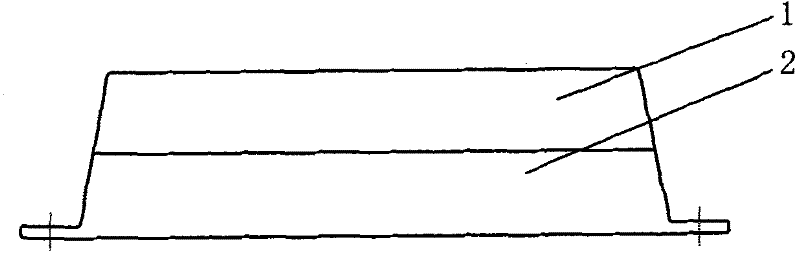

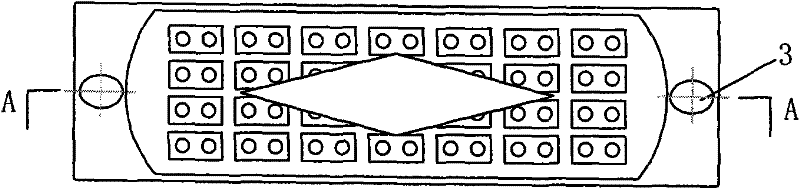

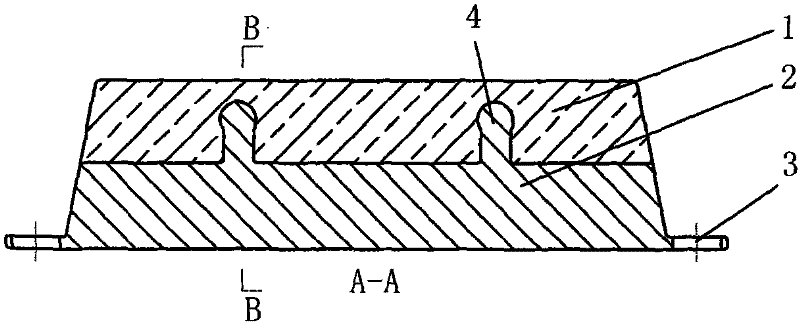

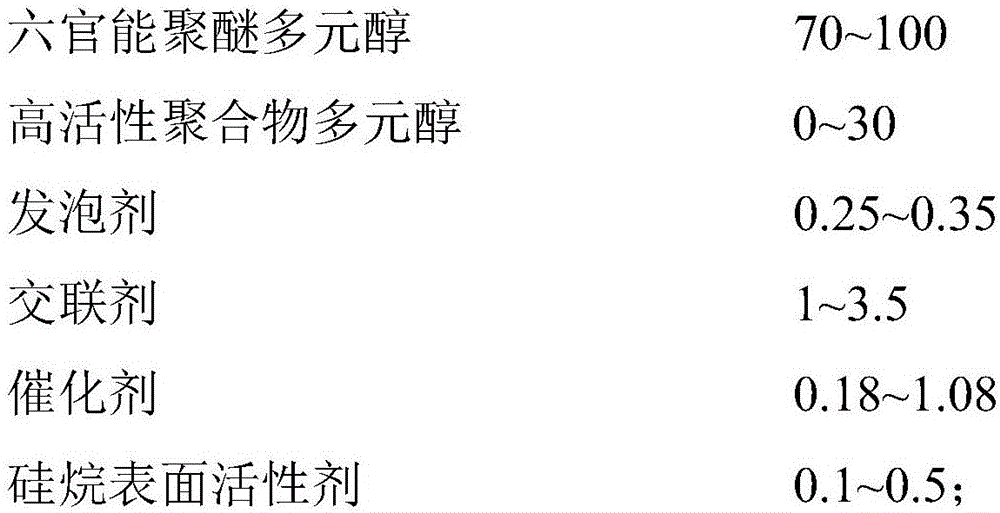

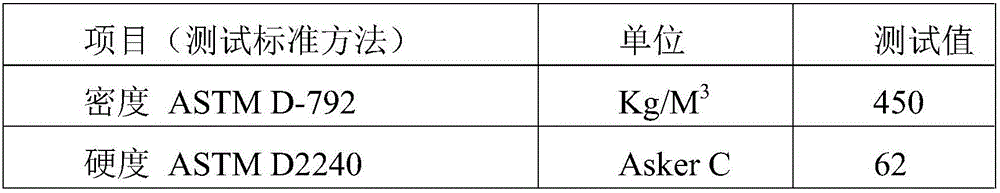

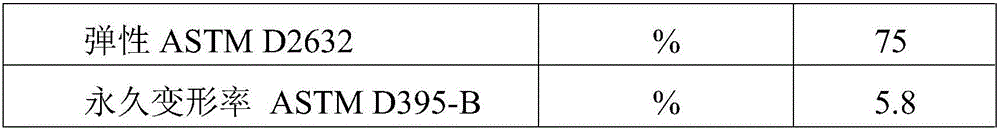

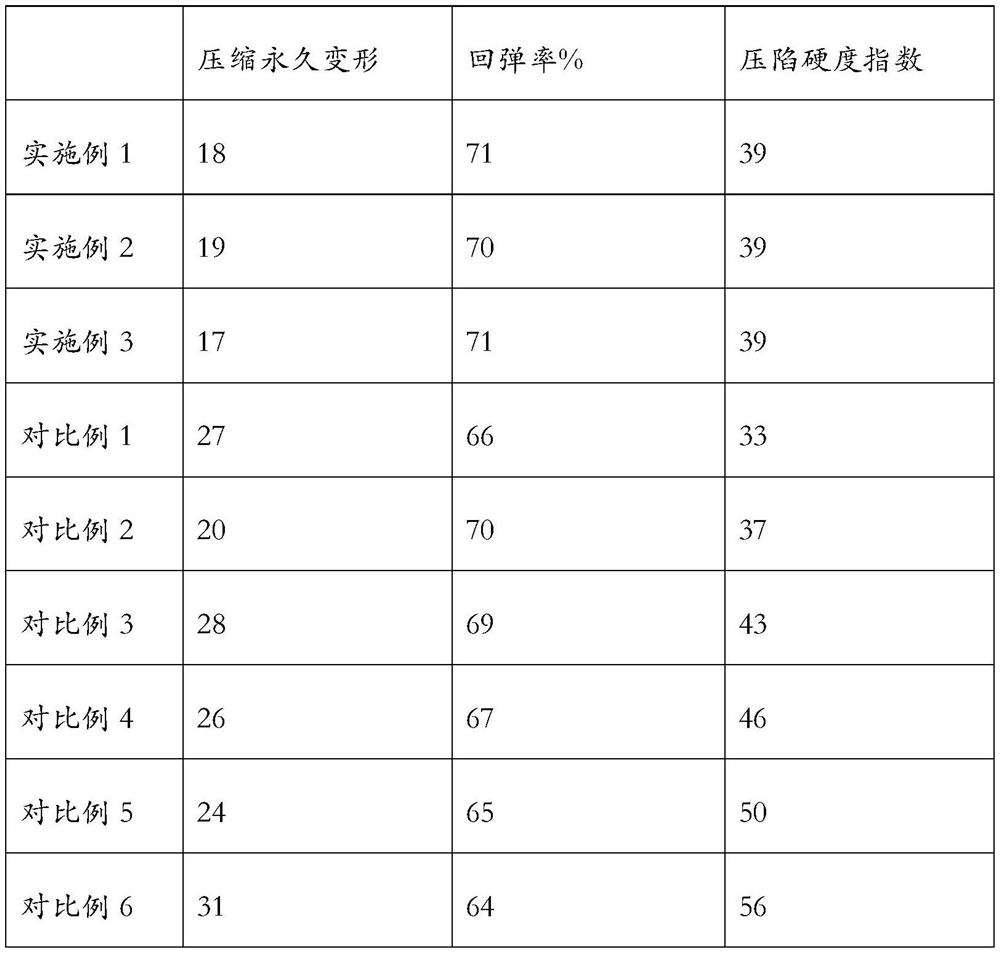

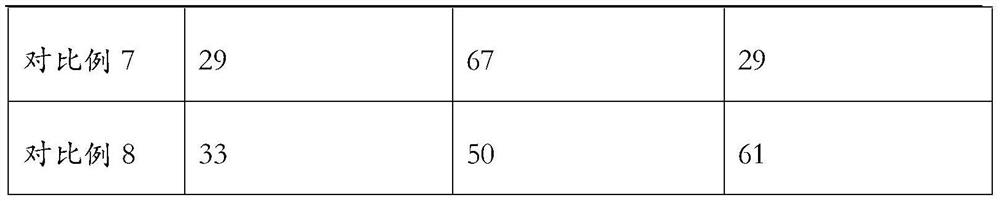

Ultrahigh-elasticity material and preparation method and application thereof

The invention belongs to the technical field of elastic materials and discloses an ultrahigh-elasticity material and a preparation method and application thereof. The ultrahigh-elasticity material is characterized by being prepared from a material A and a material B, the material A is composed of, by weight, 70-100 parts of hexa-functional polyether polyol, 0-30 parts of high-activity polymer polyol, 0.25-0.35 part of foamer, 1-3.5 parts of crosslinking agent, 0.18-1.08 parts of catalyst and 0.1-0.5 part of silane surfactant, and the material B is polyether polyol modified diphenylmethane diisocyanate prepolymer and accounts for 30-35% of total weight of the material A. the ultrahigh-elasticity material is high in elasticity (vertical resilience rate reaches 70-85%), large in supporting force (hardness reaches 25-75Asker C) and good in enduring comfort (thermocompression permanent deformation rate is less than or equal to 6%).

Owner:FOSHAN LINZHI POLYMER MATERIALS SCI & TECH CO LTD

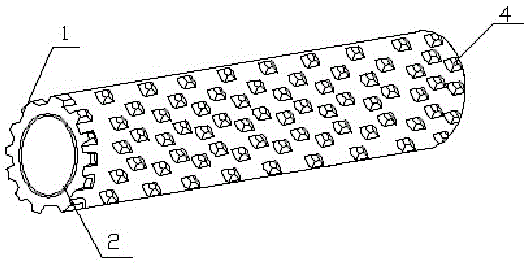

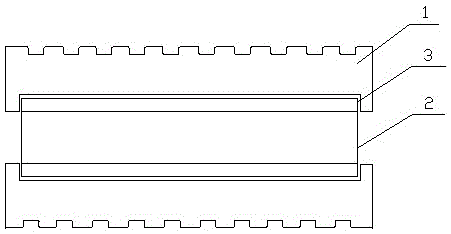

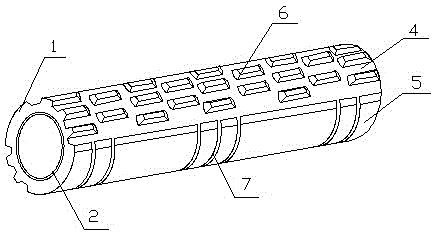

Hollow foam roller and machining technology thereof

The invention discloses a hollow foam roller. The hollow foam roller comprises an outer wrapping layer and an inside lining layer. The outer wrapping layer is a hollow cylinder. The inside of the outer wrapping layer is provided with a groove, in which the inside lining layer is arranged. Massage protrusions are arranged on the surface of the outer wrapping layer in a staggered mode. The shape of the inside lining layer is a hollow cylinder with two ends opened. The wall thickness of the inside lining layer is the same as the depth of the groove. The hollow foam roller has following beneficial effects: the hollow foam roller is low in cost, few in procedures, short in manufacture period, and reasonable in machining method; without utilization of glue, the purpose of saving energy and protecting environment is fulfilled; and the produced foam roller has advantages of non-splicing surface material, uniform hardness, high strength of a pattern surface, no crack, bright and colorful external appearance of a product, high rate of resilience, durability and no deformation.

Owner:ZHANGJIAGANG HONGLI RUBBER & PLASTIC PROD

Method for preparing polyurethane foamed plastic from economic forest processing residues

The invention discloses a method for preparing degradable biomass polyurethane foamed plastic from economic forest processing residues, belonging to the technical field of chemical industry of forest products. The method mainly comprises the following steps: uniformly mixing a liquefier and a catalyst in a 1-ton reaction kettle, adding economic forest processing residues, closing the reaction kettle feed port, starting a stirrer and a condensing unit, heating to 140-150 DEG C, liquefying for 60-90 minutes, naturally cooling to 40 DEG C, and adding oxide for neutralization until the pH value is 7-8; heating to 120-130 DEG C, adding a modifier, keeping the temperature for 30-60 minutes, heating to 150-160 DEG C, stirring under reflux for 1-2 hours, and terminating the reaction; cooling to room temperature to obtain the modified liquefying product; and mixing the liquefying product, polyether glycol, water, liquid CO2, silicon oil, an amine catalyst, a tin catalyst and a flame retardant under high pressure, sending into a V-shaped expansion chamber for expansion, and curing by heating to obtain the degradable biomass polyurethane foamed plastic. The method can obviously lower the production cost of the polyurethane foamed plastic and endow the polyurethane foamed plastic with biodegradability; and the detection shows that the polyurethane foamed plastic conforms to the national standard GB / T10802-2006.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Foaming material prepared from eucommia ulmoides latex and natural latex, method and application

The invention belongs to the technical field of latex material preparation, and particularly relates to a foaming material prepared from eucommia ulmoides latex and natural latex, a preparation methodof the foaming material and application of the foaming material to preparation of a latex pillow. The foaming material prepared by using the eucommia ulmoides latex and the natural latex is preparedby stirring and mixing the eucommia ulmoides latex and the natural latex, extruding, vacuumizing, injecting into a mold, charging supercritical CO2, vulcanizing, freezing and opening the mold. The foaming material has the beneficial effects that the foaming material, particularly the foaming pillow interior is prepared by combining the eucommia ulmoides latex and the natural rubber in a reasonableproportion range, and the foaming material, particularly the foaming pillow interior overcomes the defect that the pillow interior prepared by only taking the natural latex as a raw material is too soft due to the fact that the natural latex is too soft; and the foaming material or the foaming pillow interior is good in rebound resilience, not prone to deformation and good in supporting performance, has a shape memory function and is pleasant in user experience. And the process provided by the invention solves the problem of environmental pollution caused by adopting a chemical foaming agentin a common method.

Owner:山东贝隆新材料科技有限公司

Low-cost magnesium gunning material and its preparation method

Owner:山西高科耐火材料股份有限公司

Foam roller and processing method thereof

ActiveCN105107133ASimple materialLow costStiltsShock absorber matsHollow cylinderEnvironmentally friendly

The invention discloses a foam roller. The foam roller comprises an outer cladding and a lining column, wherein the outer cladding is a hollow cylinder; a groove is formed at the inner side of the outer cladding; the lining column is arranged in the groove; the surface of the outer cladding is provided with at least one group of buffer regions and massage regions; the surfaces of the buffer regions are in the shapes of circular arcs; spacing slots are formed among buffer regions at intervals; the massage regions are provided with massage convex points which are alternatively distributed; and the lining column is in the shape of a cylinder which is sealed at two ends. The foam roller is low in cost, less in working procedures, short in manufacturing period, scientific in processing method, and energy-saving and environmentally-friendly; the produced foam roller surface material is free of splicing, uniform in thickness, and high in pattern surface-skin strength; a product is bright in appearance, bright in color, durable in use, and is not deformed due to the fact that the EVA lining column is adopted.

Owner:ZHANGJIAGANG HONGLI RUBBER & PLASTIC PROD

Sole material, preparation method thereof and shoe product

The invention relates to the technical field of clothing production, and particularly discloses a sole material, a preparation method thereof and a shoe product, the sole material comprises a component A and a component B, the component A comprises the following raw materials: polyether polyol, polytetrahydrofuran ether glycol, an amine catalyst, a foaming agent, silicone oil and water; part of the component A and part of the component B are mixed to obtain an isocyanate prepolymer, and then the isocyanate prepolymer is mixed with the remaining component A to prepare the sole material. The rebound rate of the shoe sole material can be obviously improved, the weight of the shoe sole material is effectively reduced, and the problem that the weight of an existing shoe sole material cannot bereduced while the rebound rate is guaranteed is solved. The preparation method provided by the embodiment of the invention is simple, the rebound rate of the PU material can be effectively improved, the weight of the material can be reduced, and the prepared sole has lighter weight and higher rebound rate.

Owner:泉州市华登新材料科技有限公司

Sealing ring used for acid-resistant and alkali-resistant pump

A sealing ring used for an acid-resistant and alkali-resistant pump is characterized by comprising an engineering plastic ring and a weave fiber gland packing compression molding forming ring.

Owner:TIANJIN NENGXIN TECH

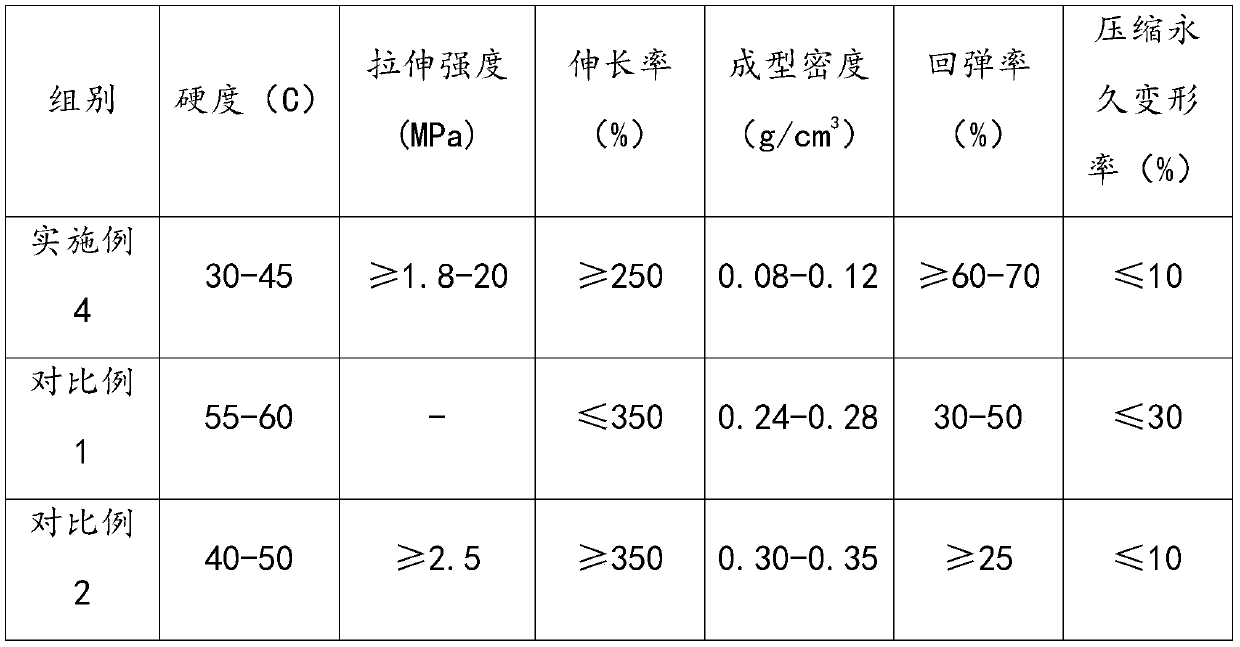

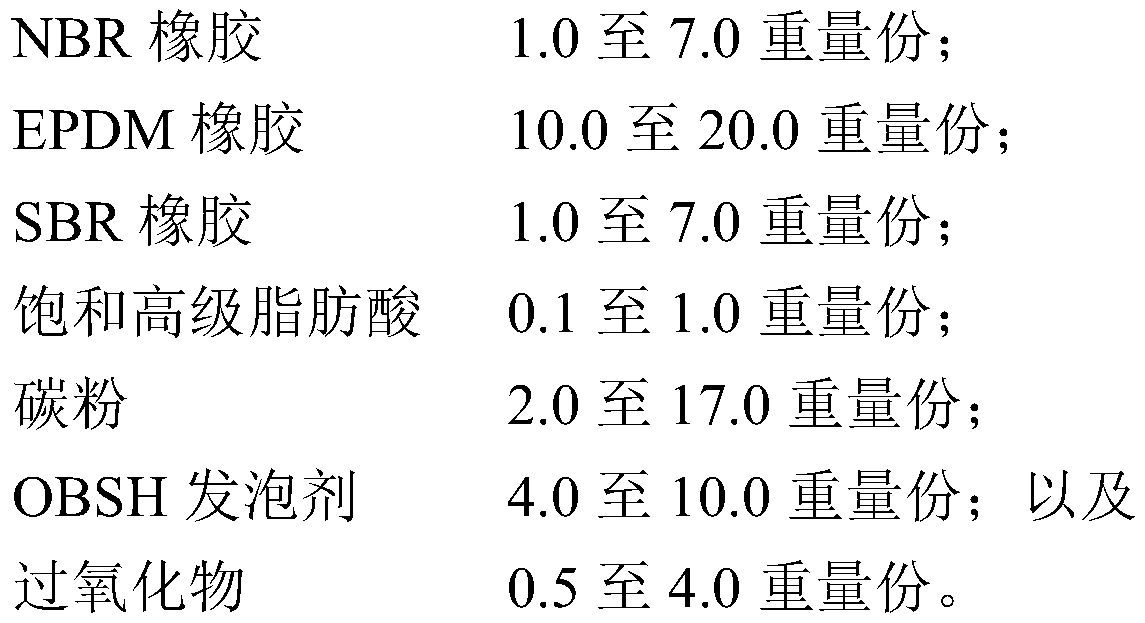

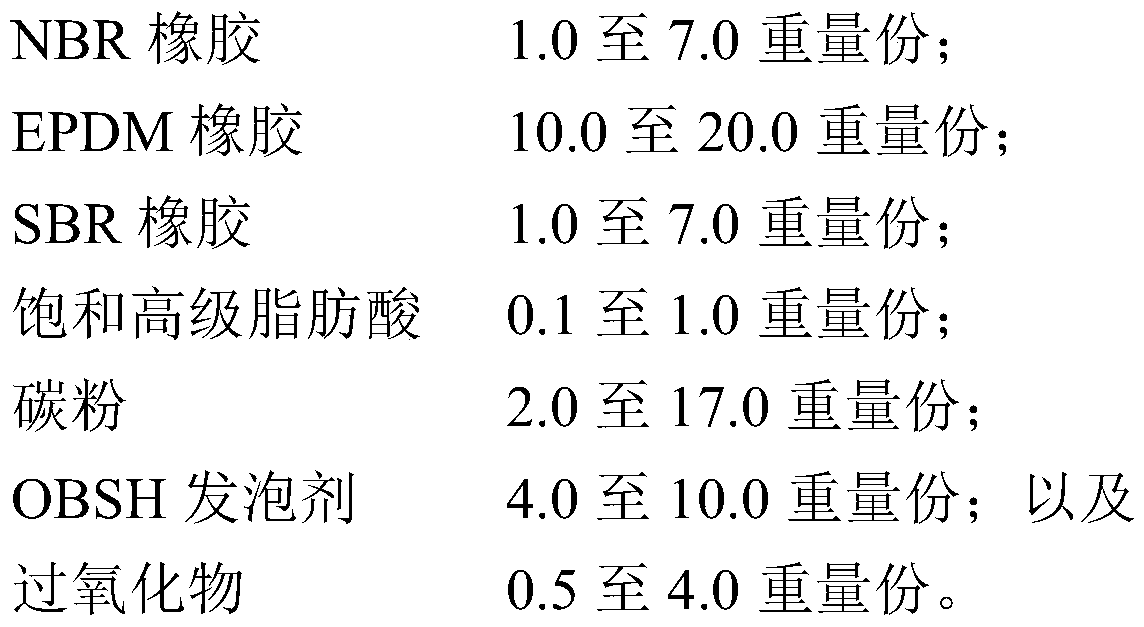

Foamed rubber and preparation method thereof

InactiveCN110684286AExcellent ozone resistanceSimple processElectrographic process apparatusPolymer scienceFoaming agent

The invention relates to a foamed rubber and a preparation method thereof. The foamed rubber comprises the following components in parts by weight: 1.0-7.0 parts of NBR rubber; 10.0 to 20.0 parts of EPDM rubber; 1.0 to 7.0 parts of SBR rubber; 0.1 to 1.0 part of a saturated higher fatty acid; 2.0 to 17.0 parts of carbon powder; 4.0 to 10.0 parts of OBSH foaming agent; and 0.5 to 4.0 parts of a peroxide. The foamed rubber disclosed by the invention has the advantages of appropriate resistivity, excellent ozone resistance, high recovery rate and good resilience. In addition, the preparation method of the foamed rubber is simple in process and easy to implement, and large-scale production can be achieved.

Owner:明治橡胶化成(深圳)有限公司

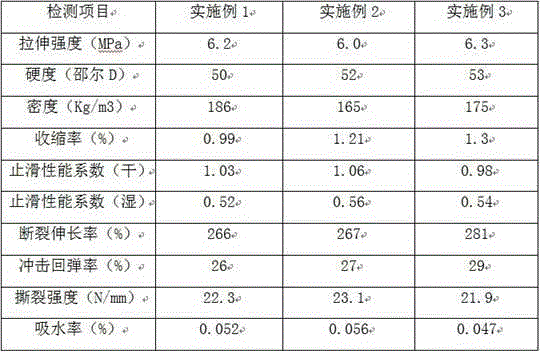

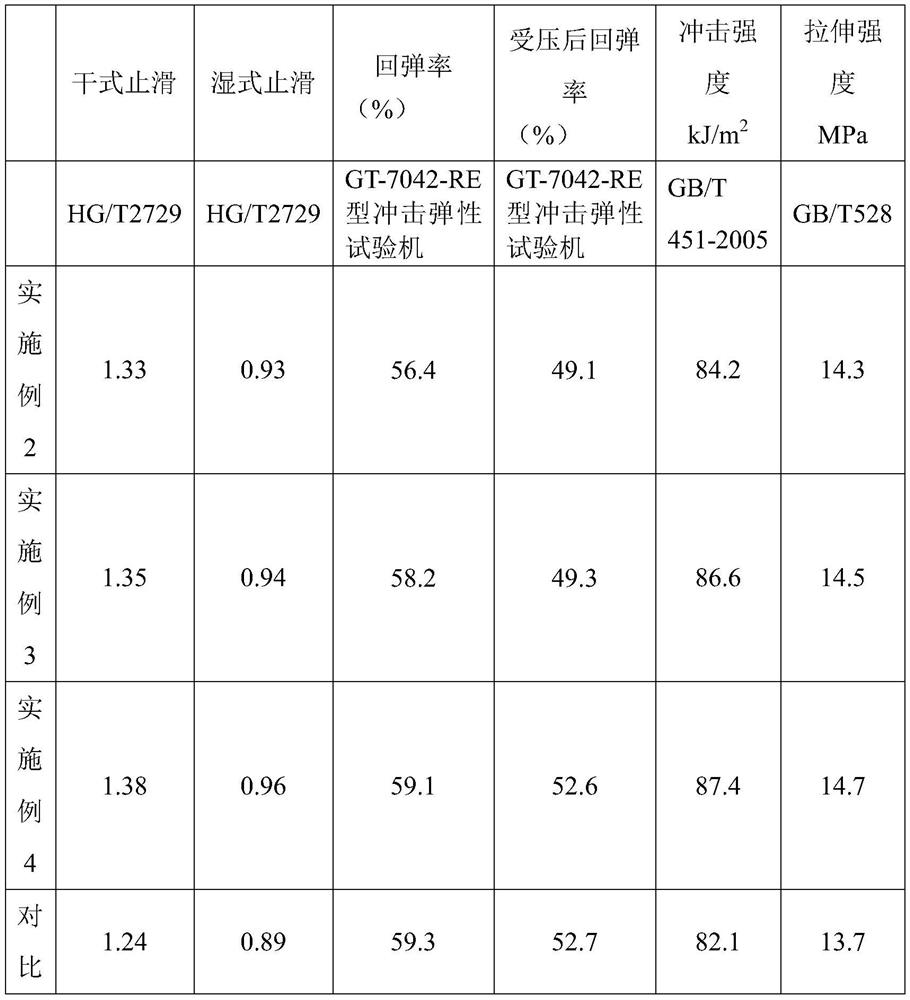

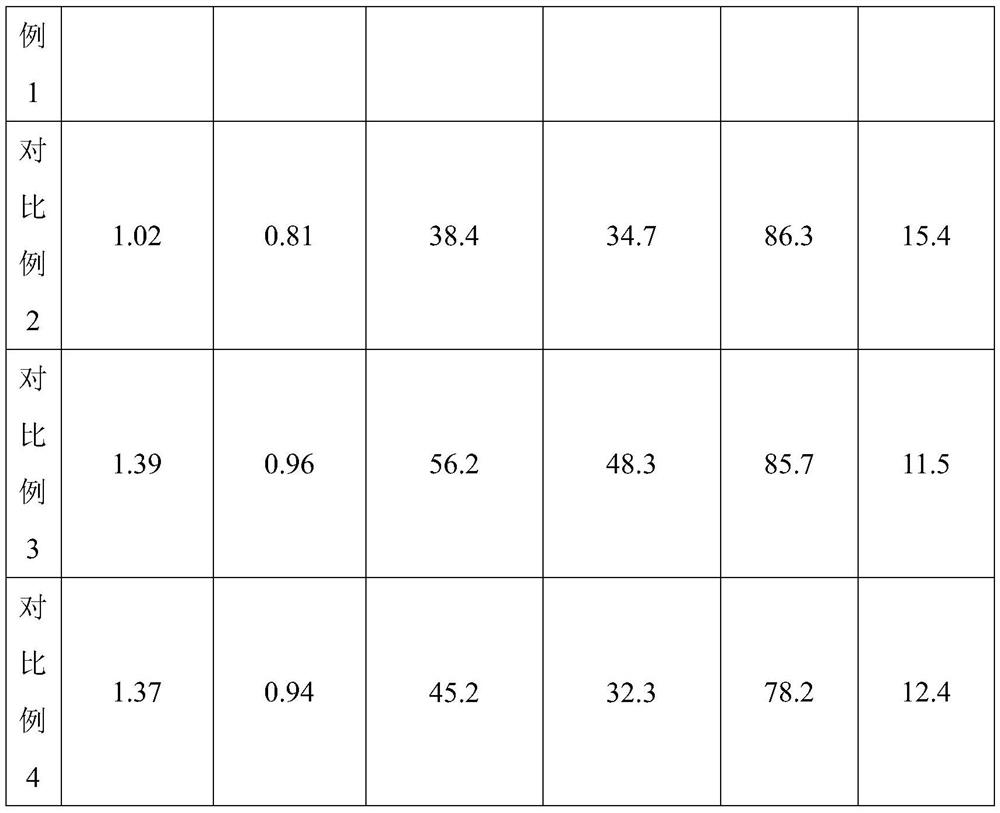

Sneaker sole with good anti-skid effect and preparation method thereof

PendingCN112812383AImprove skid resistanceGood slip coefficientSolesPolyurethane elastomerGlass fiber

The invention discloses a sneaker sole with a good anti-skid effect and a preparation method thereof. The sneaker sole with the good anti-skid effect is prepared from the following raw materials in parts by weight: 35 to 45 parts of natural rubber, 18 to 26 parts of butadiene rubber, 25 to 35 parts of a polyurethane elastomer, 6 to 9 parts of glass fiber, 1 to 1.5 parts of nano zinc oxide, 3 to 5 parts of a heat stabilizer, 1.3 to 1.7 parts of a cross-linking agent and 1.8 to 2.5 parts of a foaming agent. According to the sports shoe sole with the good anti-skid effect, the raw materials are selected, the content of the raw materials is optimized, the advantages of the raw materials are brought into full play, and the raw materials supplement and promote each other, so that the prepared sports shoe sole with the good anti-skid effect (dry-type anti-skid and wet-type anti-skid) is high in anti-skid coefficient and good in anti-skid effect. The sports shoe sole is high in resilience rate, still high in resilience rate after being pressed, good in resilience performance, high in impact strength and tensile strength, good in comprehensive mechanical property, good in shock absorption performance, low in density (the density tested is 0.21-0.22 g / cm < 3 >) and good in portability.

Owner:FUJIAN MEIMINGDA SHOES DEVING

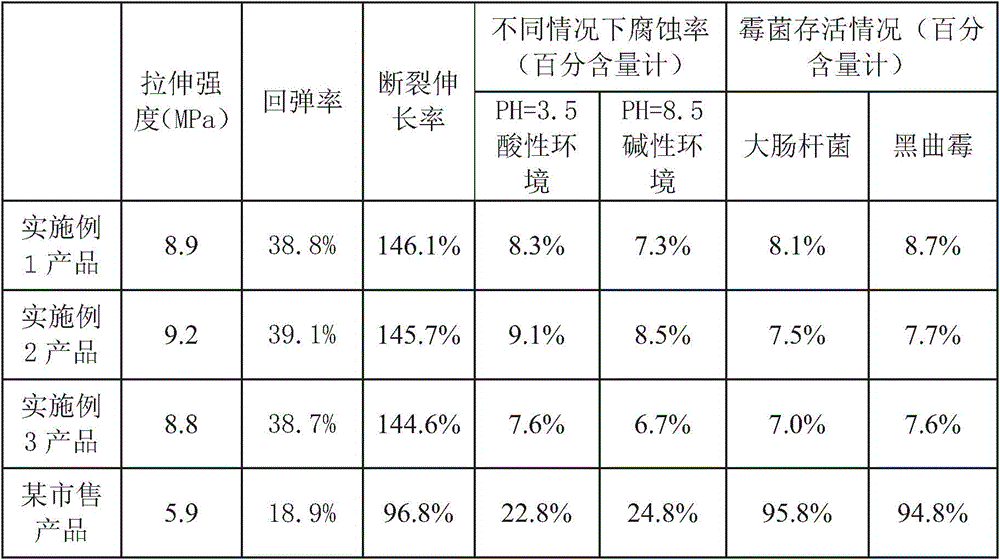

Playground track material

The invention relates to a playground track material. The playground track material is prepared from octadecyl imidazoline, alkyl sodium sulfonate, methyl vinyl silicone rubber powder, acrylate, molybdenum trioxide, tribasic lead sulfate, butadiene rubber powder, bisphenol-A diglycidyl ether, metallocene polyethylene, isoprene rubber powder, dioctyl sebacate, fluoroether rubber powder, dioctyl terephthalate, an ethylene-vinyl acetate copolymer, furan resin, graphite powder, MBS resin powder, hexamethylenetetramine, barium sulfate, wollastonite powder, 2-mercaptobenzimidazole, benzothiazole and ABS resin powder. The preparation process method of the track material is simple. The product has high resilience, tensile strength and elongation at break and also has high corrosion resistance and antibacterial performance.

Owner:孟根森

Sponge mattress production method

The invention discloses a sponge mattress production method, and relates to the technical field of mattress processing. The sponge mattress is made by dividing composite sponge, which is made from, byweight, natural latex, modified bamboo fiber, sulphur, citric acid, triethanolamine, sodium silicate, nanometer sericite, modified starch and ammonium sulfate. According to the sponge mattress production method, the prepared sponge mattress is high in tensile strength and rebound rate. Sponge used for the sponge mattress is a low-density porous open-type composite material. The porous open-type structure provides the prepared composite sponge material with excellent pressure-reduction, buffering, and compression fatigue resistance performance. The composite sponge material can be well appliedto prepare the sponge mattress. The prepared sponge mattress has certain formaldehyde adsorption performance, and can efficiently improve the indoor environment.

Owner:阜阳皖春家俬有限公司

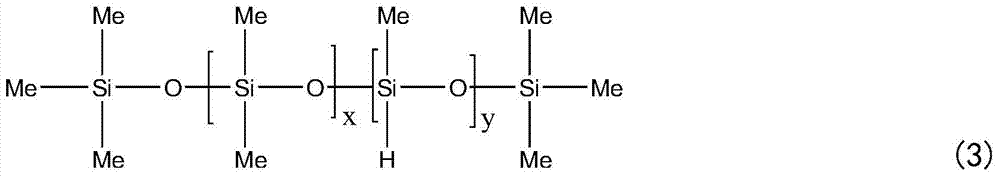

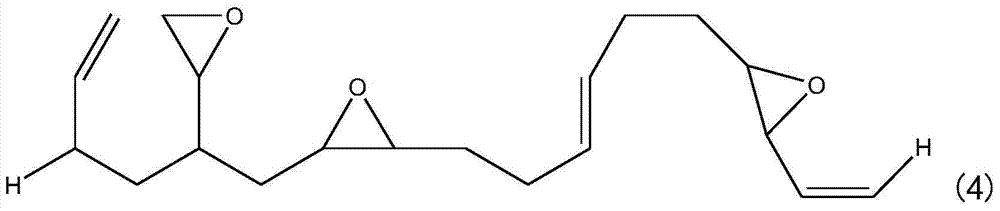

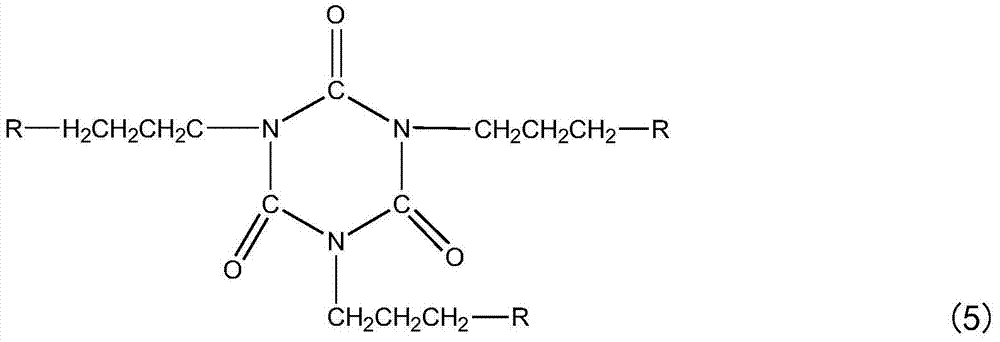

A special silicone adhesive for emi interface with high adhesion and high resilience

ActiveCN104877623BHigh viscosityExtended service lifeNon-macromolecular adhesive additivesMacromolecular adhesive additivesBond interfaceHeat resistance

A special silicone adhesive for EMI interface with high adhesion and high resilience, which is a one-component heat-curing adhesive, including: 64-91.8 parts of base paste, 5-20 parts of cross-linking agent, rebound rate 1-5 parts of control agent, 1-5 parts of adhesion promoter, 1-5 parts of heat stabilizer, 0.1-0.5 parts of catalyst, and 0.1-0.5 parts of inhibitor. The organosilicon adhesive prepared by the present invention has a high rate of resilience retention, and can maintain a relatively good rate of resilience after double 85, 1000h, high strength, and strong adhesion. It is suitable for aluminum substrates, ceramic substrates, galvanized The substrate has good bonding strength, high temperature bonding and bonding after aging maintain a relatively good bonding effect, and the heat resistance is very excellent.

Owner:YANTAI DARBOND TECH

A kind of high wear-resistant and high-temperature resistant rubber and its preparation method

ActiveCN110272594BImprove wear resistanceIncrease elasticityBuilding insulationsFiberPolymer science

The invention provides a high wear-resistant and high-temperature-resistant rubber and a preparation method thereof. Serpentine, microcrystalline cellulose, alcohol ether glycoside, dilauryl thiodipropionate, pitch fiber, diisopropyl xanthate disulfide, dilauryl thiodipropionate, palm wax, carbon black , dipentene and anti-aging agent as raw materials, the rubber has high wear resistance, rebound rate and high temperature and aging resistance, and has excellent tensile strength, elongation at break, tear strength and high stability. wide range. The preparation method of the invention has the advantages of simple process, convenient operation and control, stable quality, high production efficiency and low production cost, can make the prepared silicone rubber have better resilience, mechanical strength and stability, and can be produced in a large scale.

Owner:河北新尔特橡塑密封有限公司

Antifreeze-resistant water pump gasket and preparation method thereof

The invention relates to an antifreeze liquid resisting water pump gasket and a preparation method of the antifreeze liquid resisting water pump gasket. The antifreeze liquid resisting water pump gasket is prepared from a main material and an auxiliary material in parts by weight and is prepared from the following components in parts by weight: 100 parts of the main material, 3 to 15 parts of mica powder, 20 to 30 parts of kaolin, 10 to 20 parts of talcum powder and 5 to 10 parts of a coloring agent; the main material is prepared from an antifreeze liquid resisting hydroxyl silicone oil substance, butadiene styrene rubber and fibers at the mass ratio of (3 to 5) to 40 to (55 to 57); the antifreeze liquid resisting hydroxyl silicone oil substance is prepared from the following components in parts by weight: 30 to 40 parts of hydroxyl silicone oil, 2.5 to 3 parts of a vulcanizing agent, 2 to 3 parts of a vulcanizing accelerant and 1 to 3 parts of an anti-ageing agent. By researching antifreeze liquid, antifreeze liquid resisting materials are pertinently selected; all the raw materials have mutual effect through a special process, so that a prepared sealing gasket has good resilience rate, tensile strength and compression ratio, and also has an excellent antifreeze liquid resisting performance; the weight gain of the sealing gasket is less than 20 percent and the thickening rate of the sealing gasket is less than 10 percent within 22h at the temperature of 100 DEG C.

Owner:南阳天一密封股份有限公司

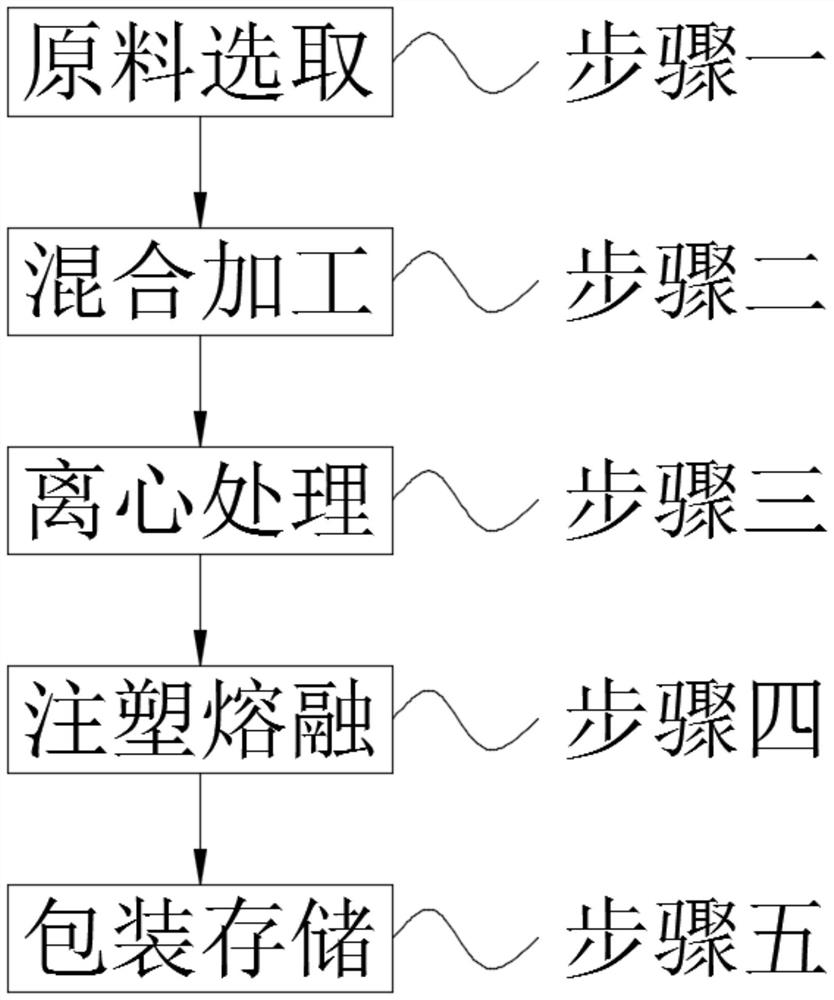

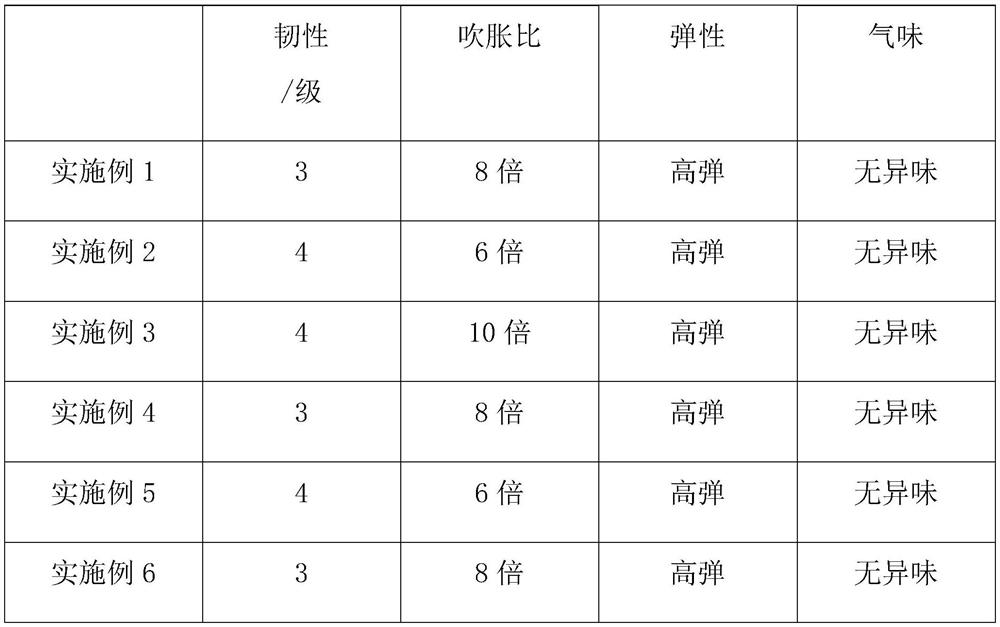

High-toughness inflatable TPE material and preparation method thereof

The invention discloses a high-toughness inflatable TPE material and a preparation method thereof. The high-toughness inflatable TPE material is prepared from, by mass, 20-40% of SEBS, 60-75% of filling oil, 5-10% of flexibilizer, 0.1-0.5% of antioxidant and 0.1-0.5% of anti-UV agent. The preparation method includes the following steps that 1, raw materials selecting; step 2, mixing and processing; step 3, centrifugal treatment; step 4, injection molding melting; and step 5, packaging and storing. According to the invention, SEBS is used as a base material, and a toughening agent is added, sothat the material has excellent toughness, does not influence hand feeling and mechanical properties, and has good resilience, and the product is easy to process and use; the material is good in flexibility, the blow-up ratio can reach 6-10 times, air leakage is avoided after the material is blown up by 8 times for more than three days, and the material is very suitable for balloons; the materialhas the characteristics of high elasticity, good temperature resistance and good cold resistance, and can be widely applied to high-ductility toy materials such as catharsis dolls and water polo balls.

Owner:中广核高新核材集团(东莞)祈富新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com