Protection block of motor vehicle and manufacturing process thereof

A technology for protective blocks and motor vehicles, applied in layered products, bumpers, rubber layered products, etc., can solve the problems of high rigidity of metal bumpers, heavy weight of metal bumpers, expansion of accident losses, etc., and achieve energy absorption effect Good, good comprehensive anti-collision, suppressing the effect of resonance surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

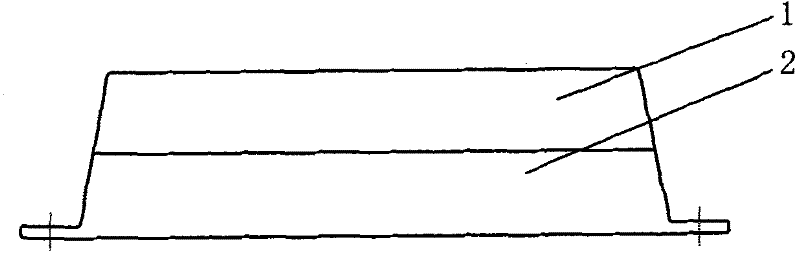

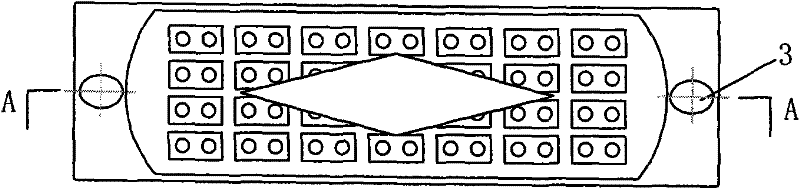

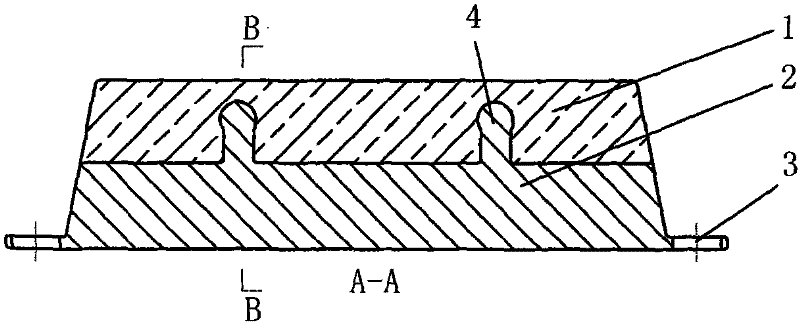

[0024] Such as figure 1 , figure 2 As shown, the motor vehicle protective block disclosed by the present invention is composed of an outer rubber block 1 and a bottom rubber block 2, and the two are stacked together. The two ends of the bottom rubber block 2 have holes 3 for easy installation, which can be directly connected with the automobile beam, longitudinal beam, chassis, body and other parts, which can effectively reduce the impact force from different directions, thereby improving the safety performance of the automobile.

[0025] Such as image 3 , Figure 4 As shown, the superposition of the outer rubber block 1 and the primer block 2 is achieved through the cooperation of the connecting pins 4 respectively located on the primer block and the outer rubber block and the corresponding connecting holes. That is, the connecting pin on the primer block cooperates with the connecting hole on the outer rubber block, or the connecting pin on the outer rubber block cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com