Fluororubber metal composite plate and preparation method thereof

A metal composite plate, fluororubber technology, applied in chemical instruments and methods, other chemical processes, coatings, etc., can solve the problem of the ability to resist creep and relaxation needs to be further improved, and achieve outstanding comprehensive effects, excellent sealing performance, excellent The effect of rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

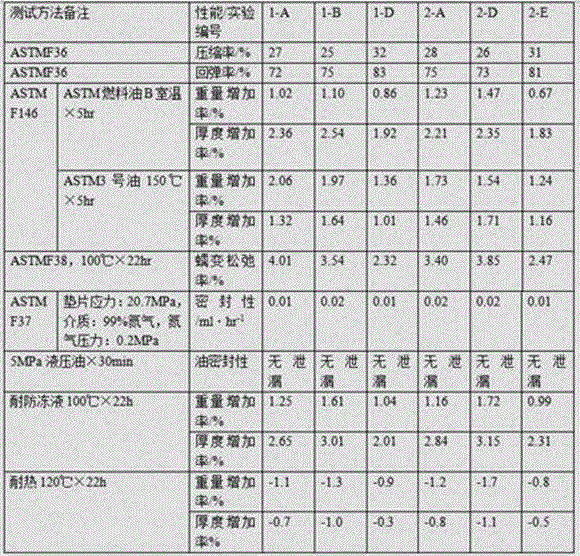

Examples

Embodiment 1

[0027] A fluororubber metal composite plate, comprising a metal substrate, the two sides of the metal substrate are provided with a fluororubber coating, and the fluororubber coating is made of the following raw materials in parts by mass: 100 parts of fluororubber, 4 parts of magnesium oxide, hydrogen 6 parts of calcium oxide, 4 parts of vulcanizing agent, 2 parts of accelerator, 25 parts of carbon black, 2 parts of modified bentonite, 5 parts of auxiliary agent.

[0028] Wherein, the carbon black is N990 carbon black; the modified bentonite is sodium-based bentonite.

[0029] The accelerator is a composition of benzyltriphenylphosphine chloride and tetramethylthiuram disulfide, and the weight ratio of the two is 5:1.

[0030] The additives are 2 parts by weight of paraffin oil and 3 parts by weight of carboxymethyl chitosan.

[0031] The raw materials and dosage of vulcanizing agent are shown in the following table:

[0032] .

[0033] The embodiment of this group is a ...

Embodiment 2

[0039] A fluororubber metal composite plate, comprising a metal substrate, the two sides of the metal substrate are provided with a fluororubber coating, and the fluororubber coating is made of the following raw materials in parts by mass: 100 parts of fluororubber, 1 part of magnesium oxide, hydrogen 2 parts of calcium oxide, 2 parts of vulcanizing agent, 0.5 parts of accelerator, 20 parts of carbon black, 1 part of modified bentonite, and 1 part of auxiliary agent.

[0040] Wherein, the carbon black is N990 carbon black; the modified bentonite is sodium-based bentonite.

[0041] The vulcanizing agent is bisphenol AF.

[0042] The auxiliary agent is paraffin oil.

[0043] The raw materials used for the accelerator and their dosage are shown in the table below:

[0044] .

[0045] The embodiment of this group is a preparation method of a fluororubber metal composite board, the fluororubber metal composite board includes a metal substrate, and the two sides of the metal su...

Embodiment 3

[0050] A fluororubber metal composite plate, comprising a metal substrate, the two sides of the metal substrate are provided with a fluororubber coating, and the fluororubber coating is made of the following raw materials in parts by mass: 100 parts of fluororubber, 10 parts of magnesium oxide, hydrogen 10 parts of calcium oxide, 10 parts of vulcanizing agent, 5 parts of accelerator, 40 parts of carbon black, 5 parts of modified bentonite, 10 parts of auxiliary agent.

[0051] Wherein, the carbon black is N990 carbon black; the modified bentonite is sodium-based bentonite.

[0052] The vulcanizing agent is a composition of bisphenol AF and urethane, and the weight ratio of the two is 7:1.

[0053] The accelerator is a composition of benzyltriphenylphosphine chloride and tetramethylthiuram disulfide, and the weight ratio of the two is 5:1.

[0054] The raw materials used in the additives and their dosage are shown in the table below:

[0055] .

[0056] A preparation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com