Patents

Literature

821 results about "Magnesium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium fluoride is an inorganic compound with the formula MgF₂. The compound is a white crystalline salt and is transparent over a wide range of wavelengths, with commercial uses in optics that are also used in space telescopes. It occurs naturally as the rare mineral sellaite.

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

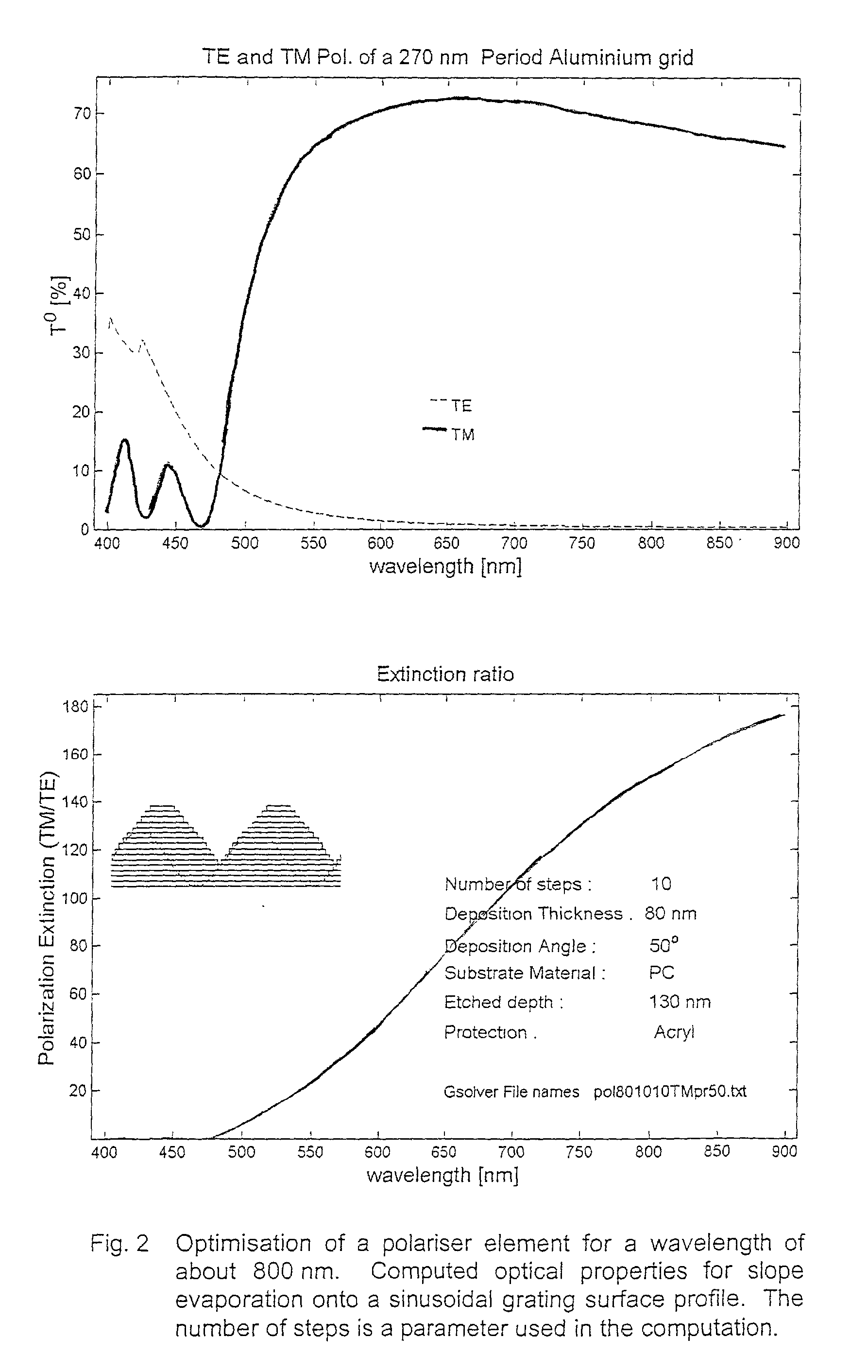

Polarisers and mass-production method and apparatus for polarisers

InactiveUS20020191286A1Low cost productionHigh hardnessPolarising elementsOptical articlesGratingLacquer

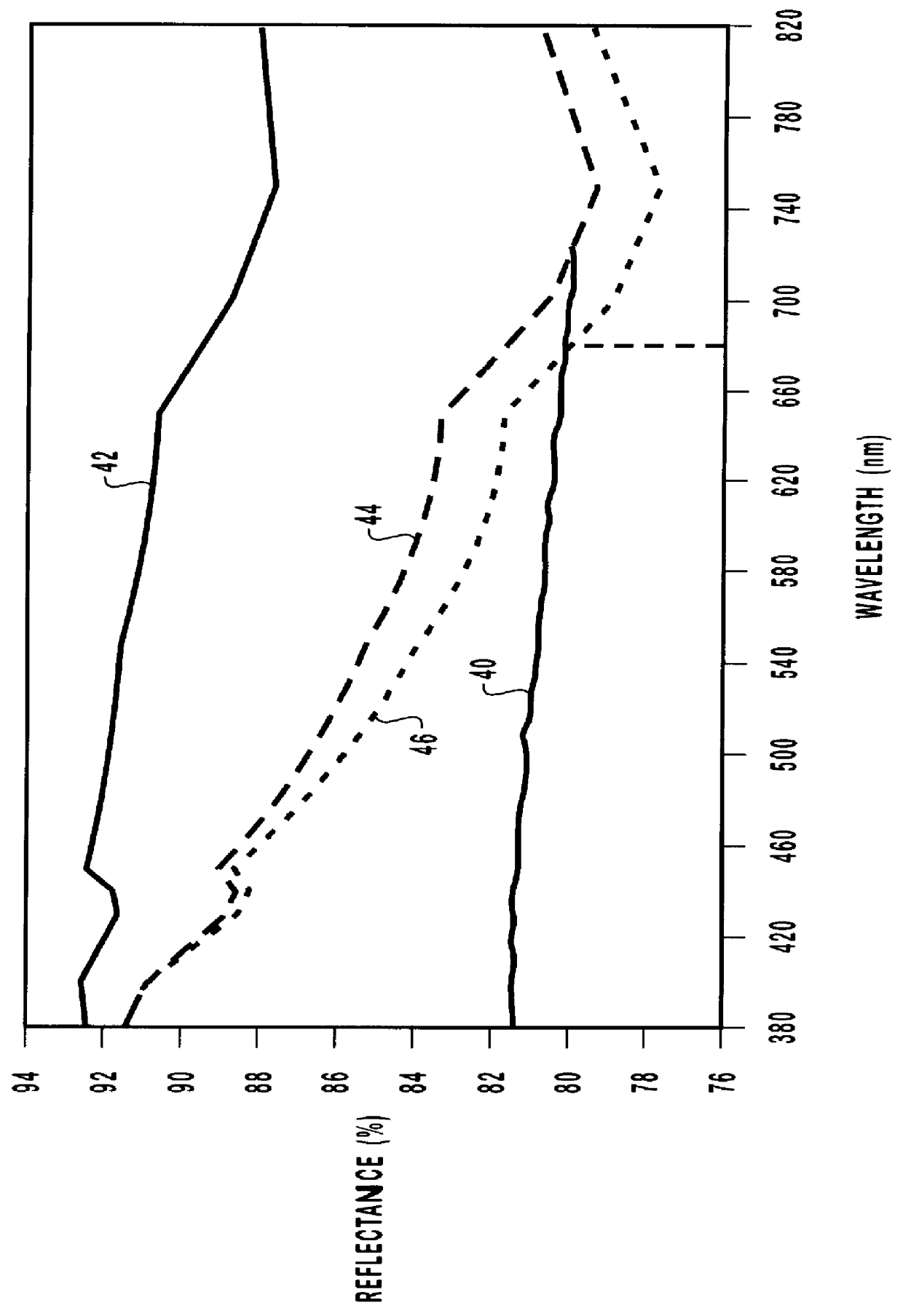

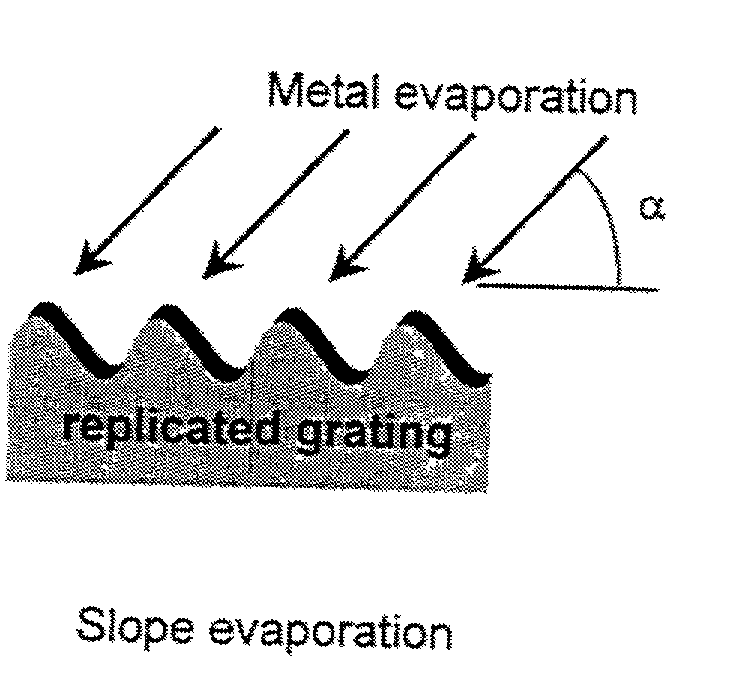

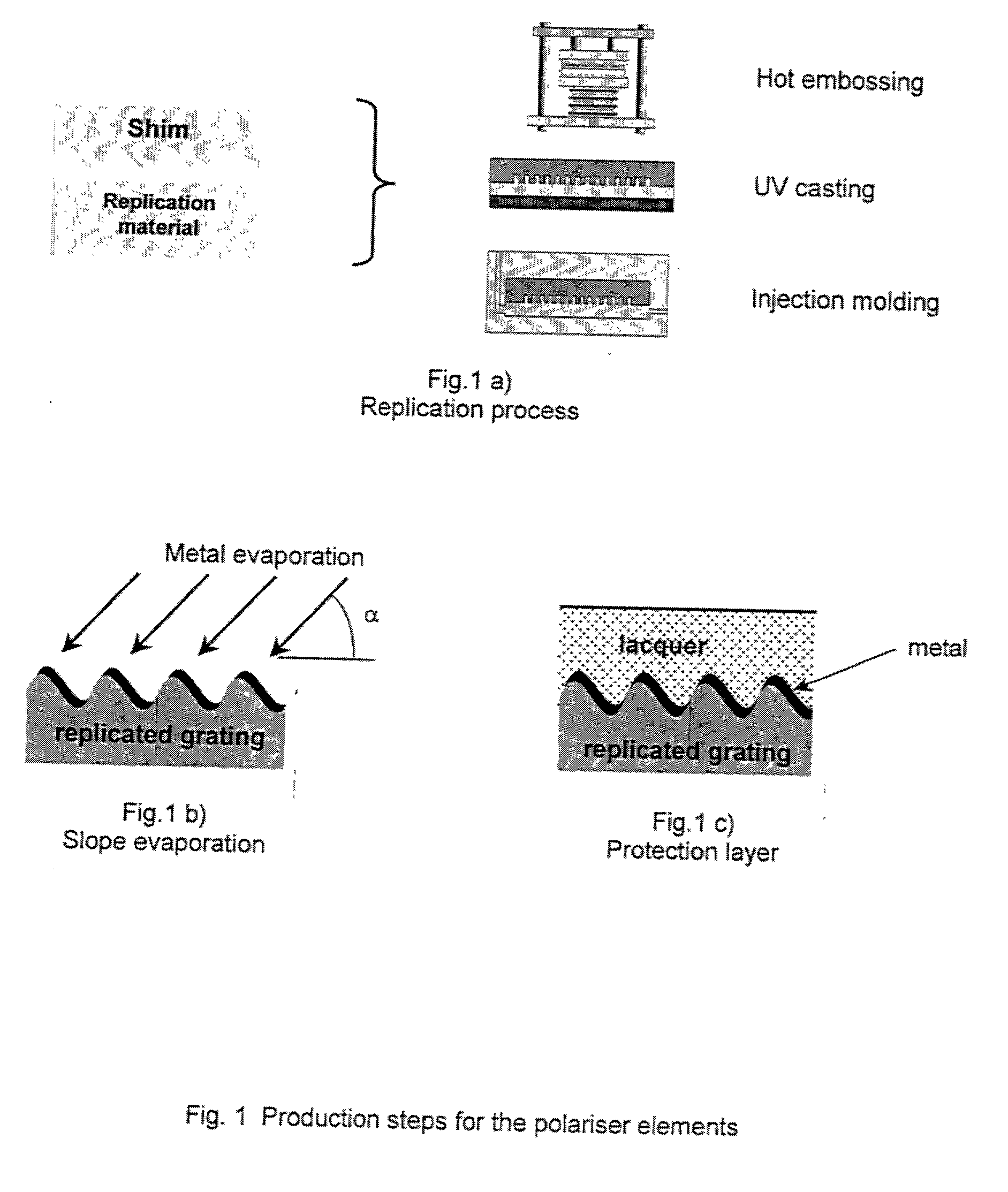

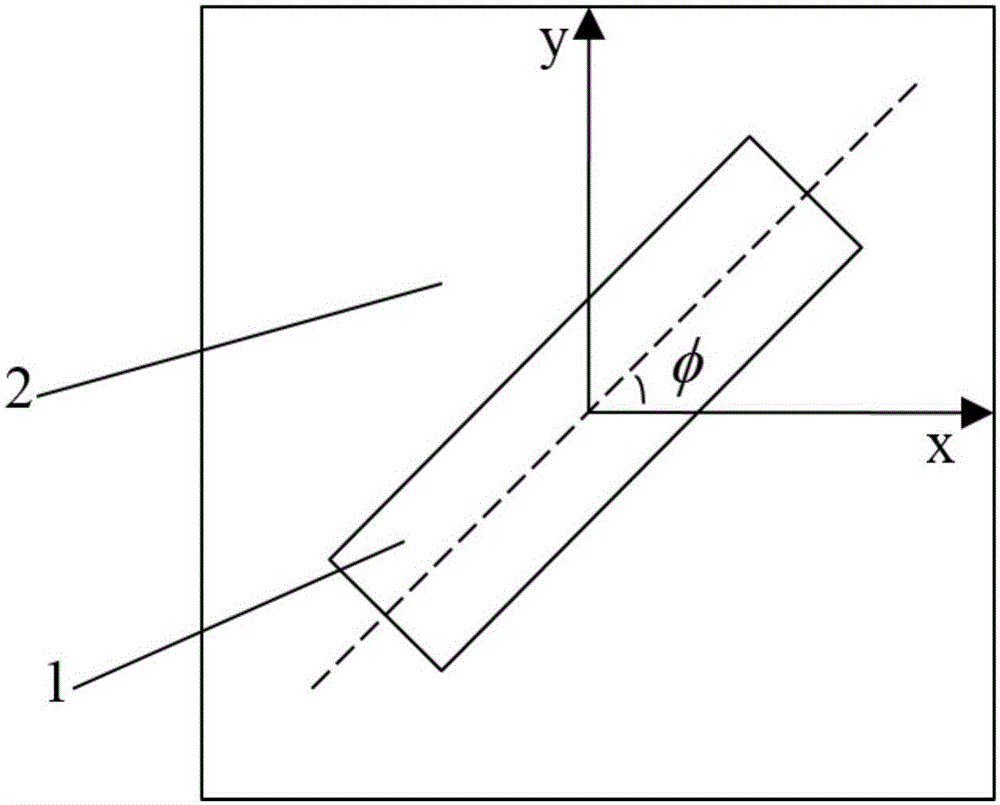

A method of mass producing polarizes comprises designing by rigorous diffraction theory an optimized grating profile, replicating the profile in a polymer or other substrate, and slope evaporating a metal onto the substrate. The angle of slope evaporation, the metal, and the thickness of the metal are optimized for a given wavelength using rigorous diffraction theory. The polarizer may be coated with a protective coating, such as an acrylic based lacquer or Magnesium Fluoride (MgF2). The optical effect of the coating is also taken into account in the design using rigorous diffraction theory.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

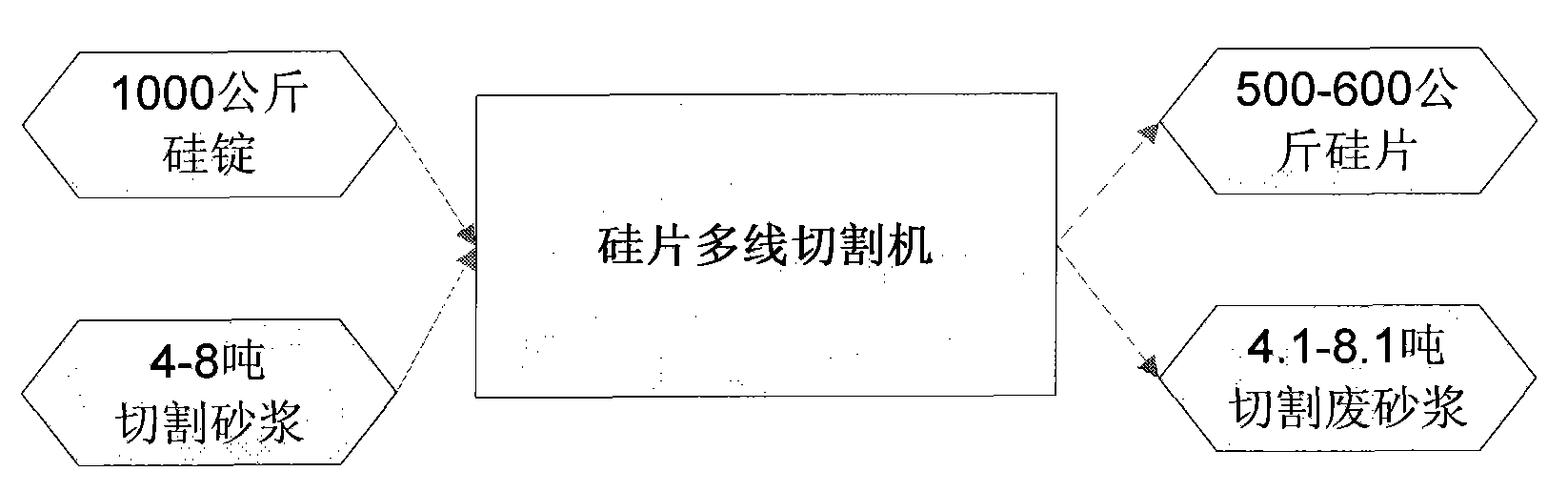

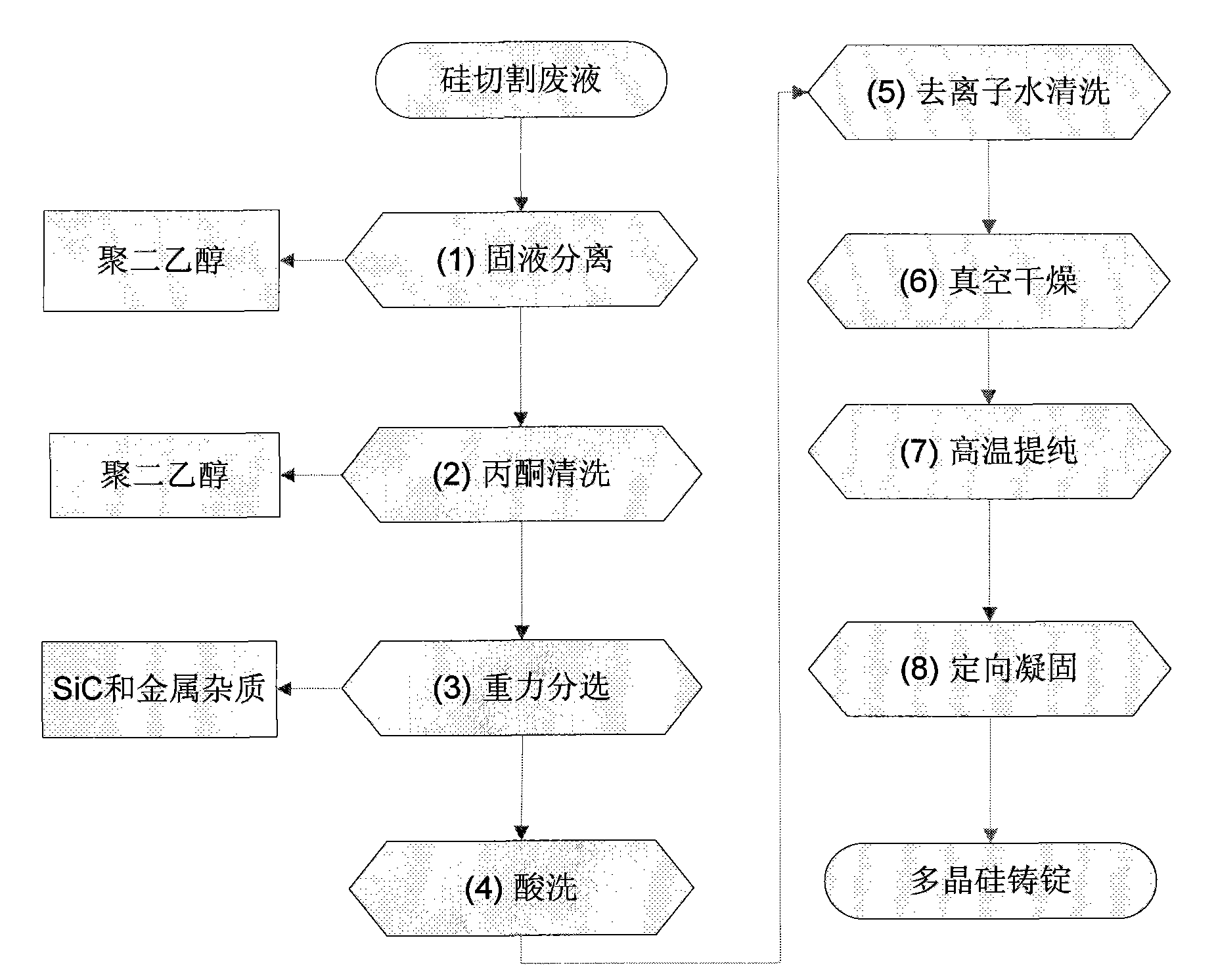

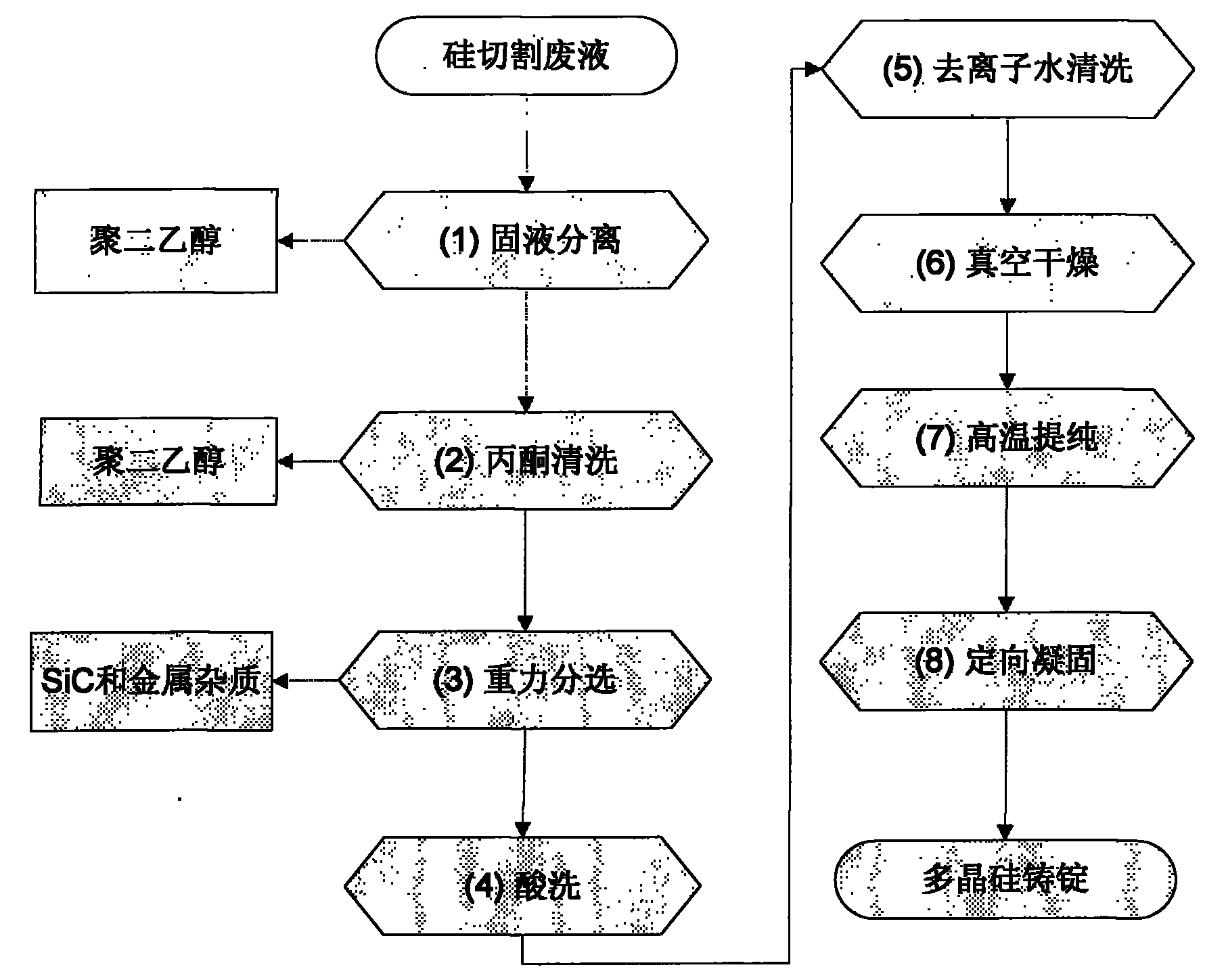

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

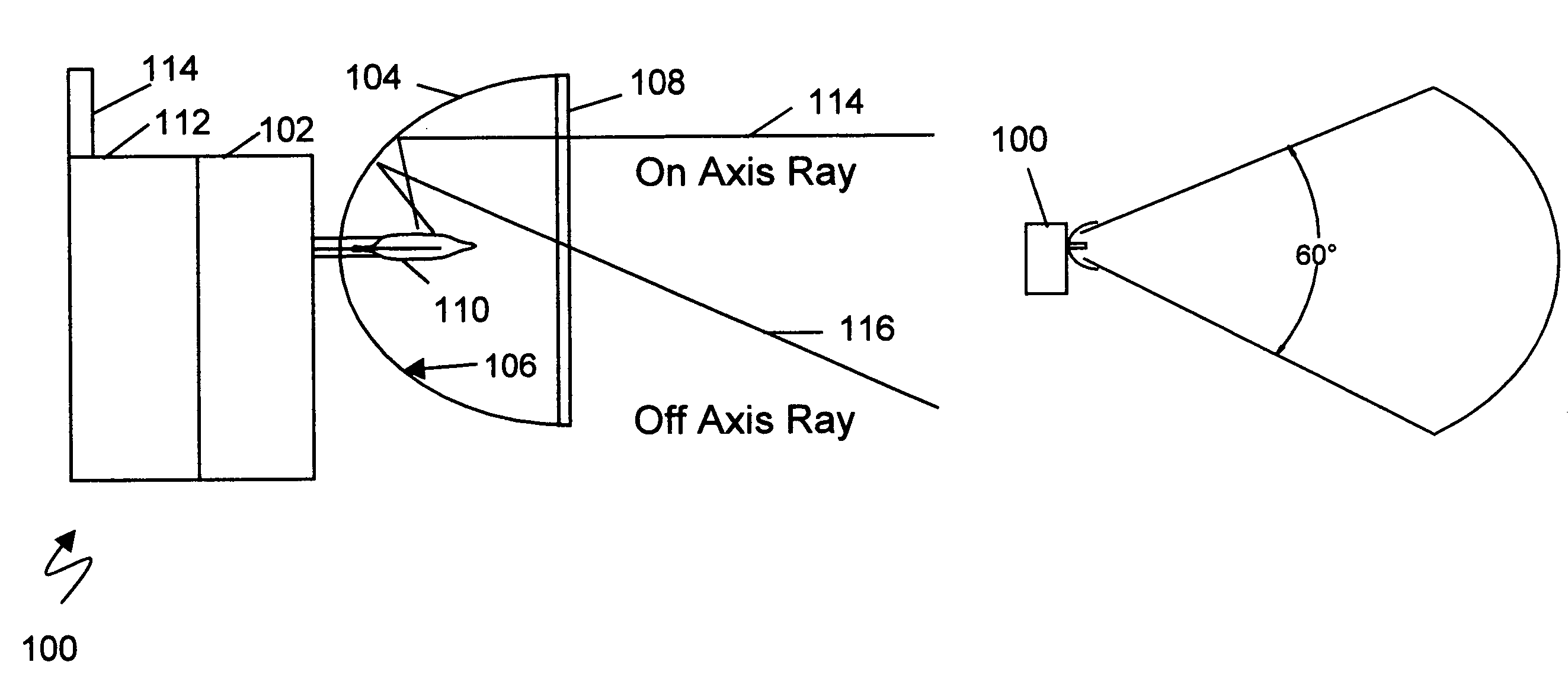

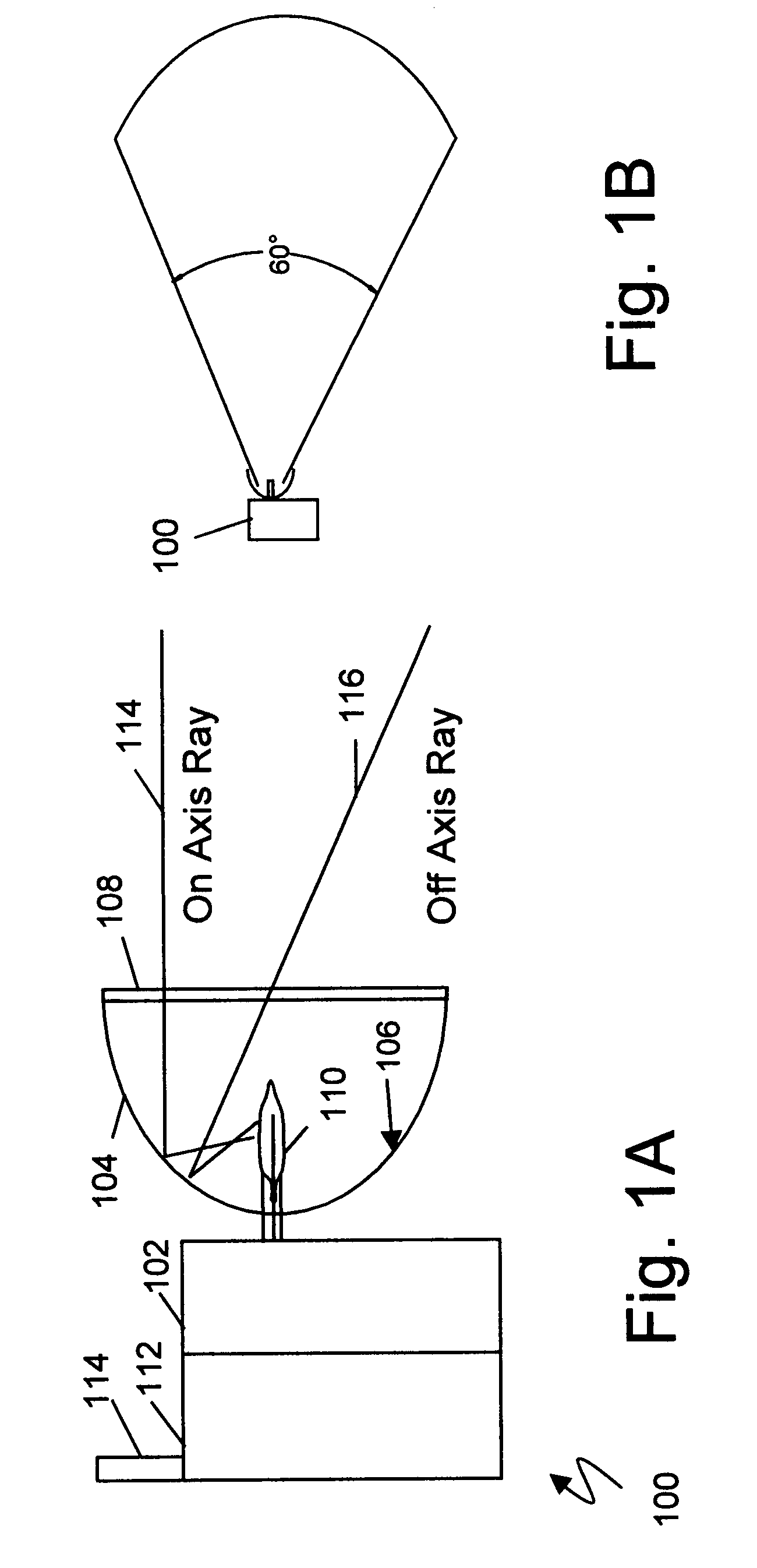

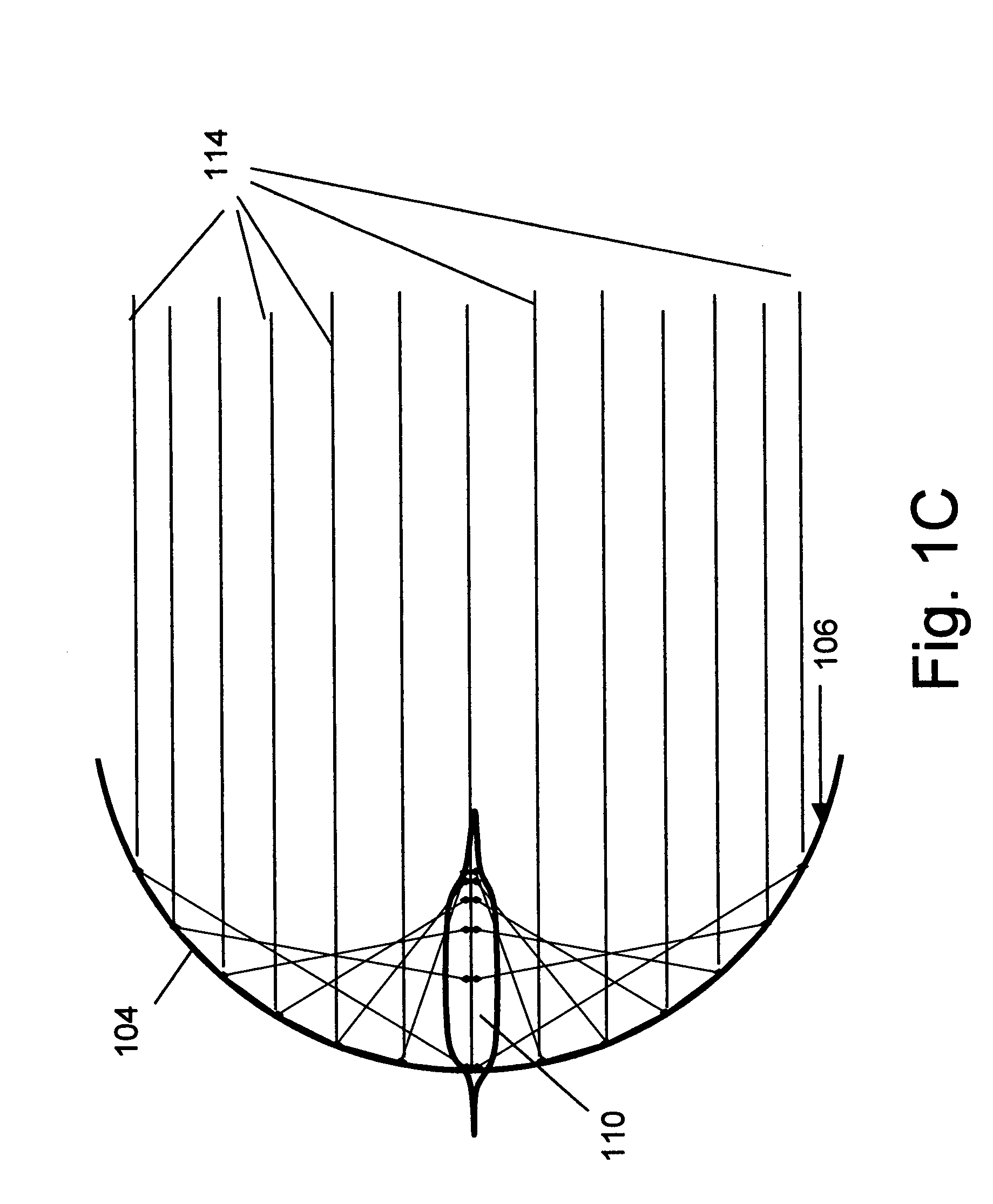

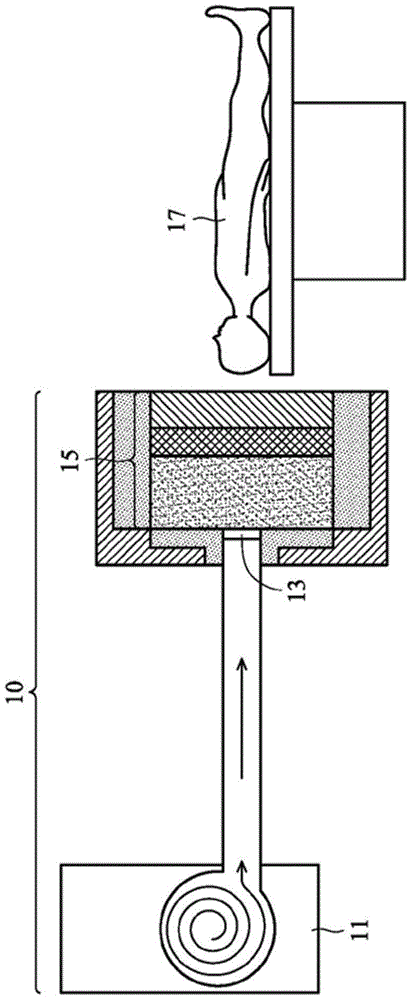

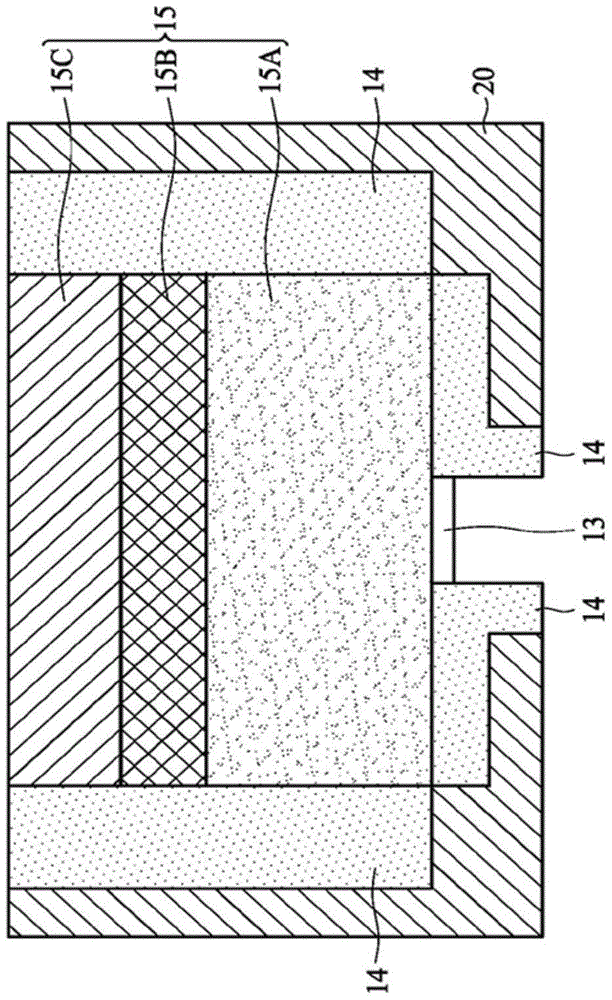

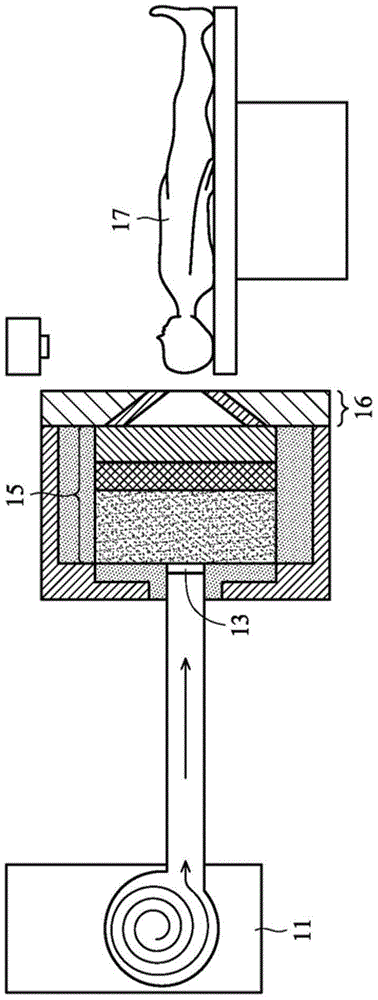

Optical flame detection system and method

ActiveUS7541938B1Improve reflectivityShort response timeRadiation pyrometryMaterial analysis by optical meansSilicon monoxideOptoelectronics

A long range optical sensor and system for detecting the flame of forest fires or other fires while rejecting false alarms due to solar radiation is described. The sensor utilizes a collector optic that collects energy from a wide field of view and concentrates the energy onto a detector. The collector may be a non-imaging collector and may match to a non-planar sensor. In one embodiment the sensor may be arrayed to achieve larger area coverage. In another, the sensor system may be scanned to increase the encompassed viewing area. Larger areas may be covered by RF radio links or networks interconnecting multiple arrayed sensor modules. UVC reflective coatings may include enhanced aluminum with silicon dioxide, silicon monoxide, or magnesium fluoride, or high phosphorous nickel phosphorous. In one embodiment a UVC sensitive Geiger Mueller tube may be coupled to a non-imaging spherical reflective collector. A catadioptric UVC / infra-red flame sensor is disclosed. Refractive or reflective designs are considered.

Owner:UNIVERSITY OF ALABAMA

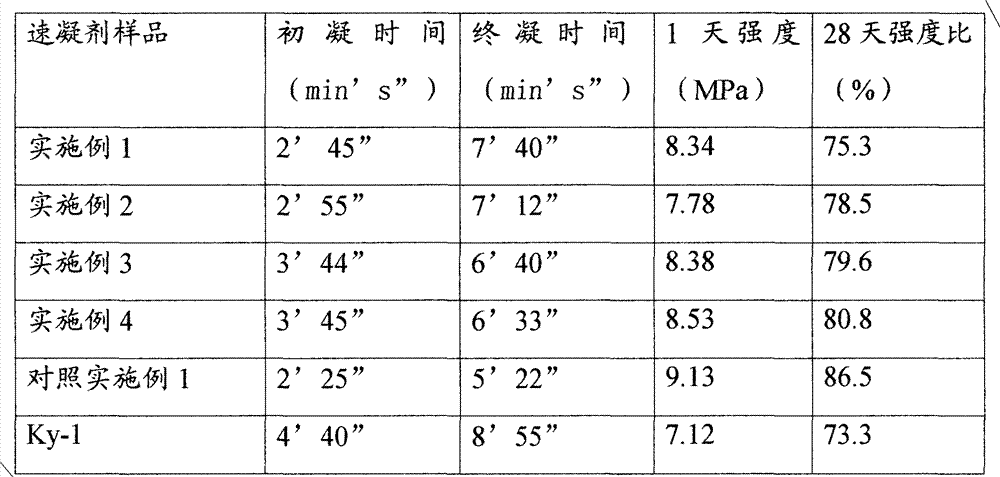

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

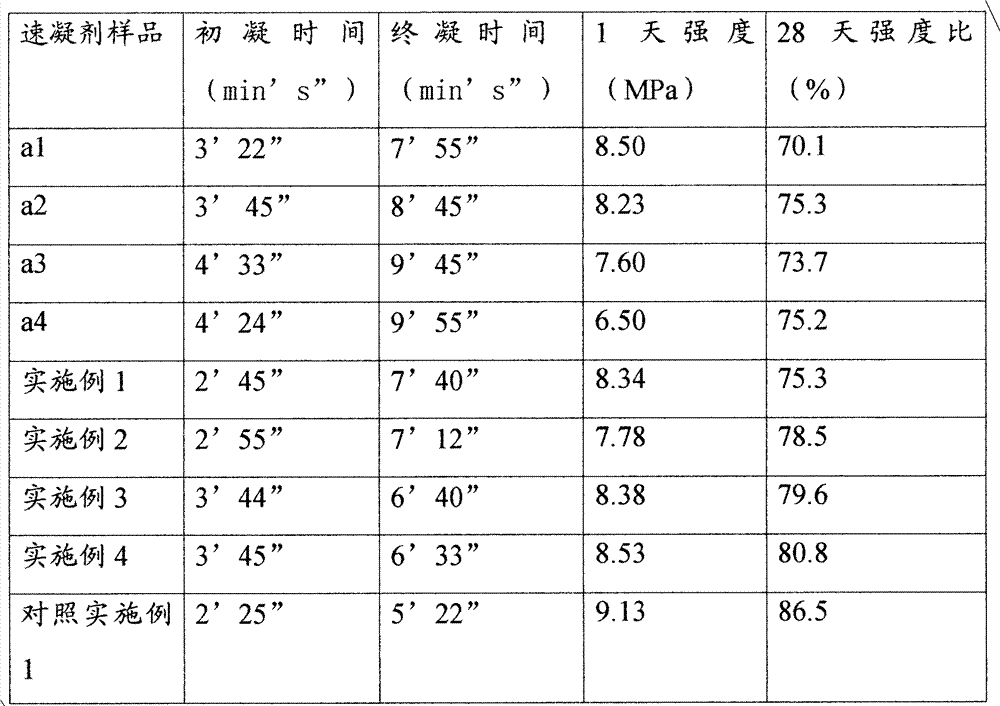

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

Silica-magnesium fluoride hydrate composite sols and process for their preparation

InactiveUS6291535B1Low refractive indexEasy to prepareMagnesium fluoridesMaterial nanotechnologyOrganic solventMagnesium salt

A sol comprising silica-magnesium fluoride hydrate composite colloidal particles used in an anti-reflection coating material for forming an anti-reflection coating and a process for its preparation are provided. A sol comprising silica-magnesium fluoride hydrate composite colloidal particles having a ratio of silica to magnesium fluoride hydrate MgF2.nH2O, n being in the range between 0.25 and 0.5, in terms of a SiO2 / MgF2 weight ratio of from 0.01 to 5 and a primary particle size of 5 to 50 nm. A process for the preparation of an aqueous sol comprising silica-magnesium fluoride hydrate composite colloidal particles which comprises the steps of adding an aqueous fluoride solution to a mixture liquid of a silica sol and an aqueous magnesium salt solution to produce a slurry of an agglomerate comprising silica-magnesium fluoride hydrate composite colloidal particles and removing the salts formed as by-products. A process for the preparation of an organosol further comprising the step of replacing water in the aqueous sol with an organic solvent.

Owner:NISSAN CHEM IND LTD

Thermal spray compositions for abradable seals

Owner:SULZER METCO CANADA INC

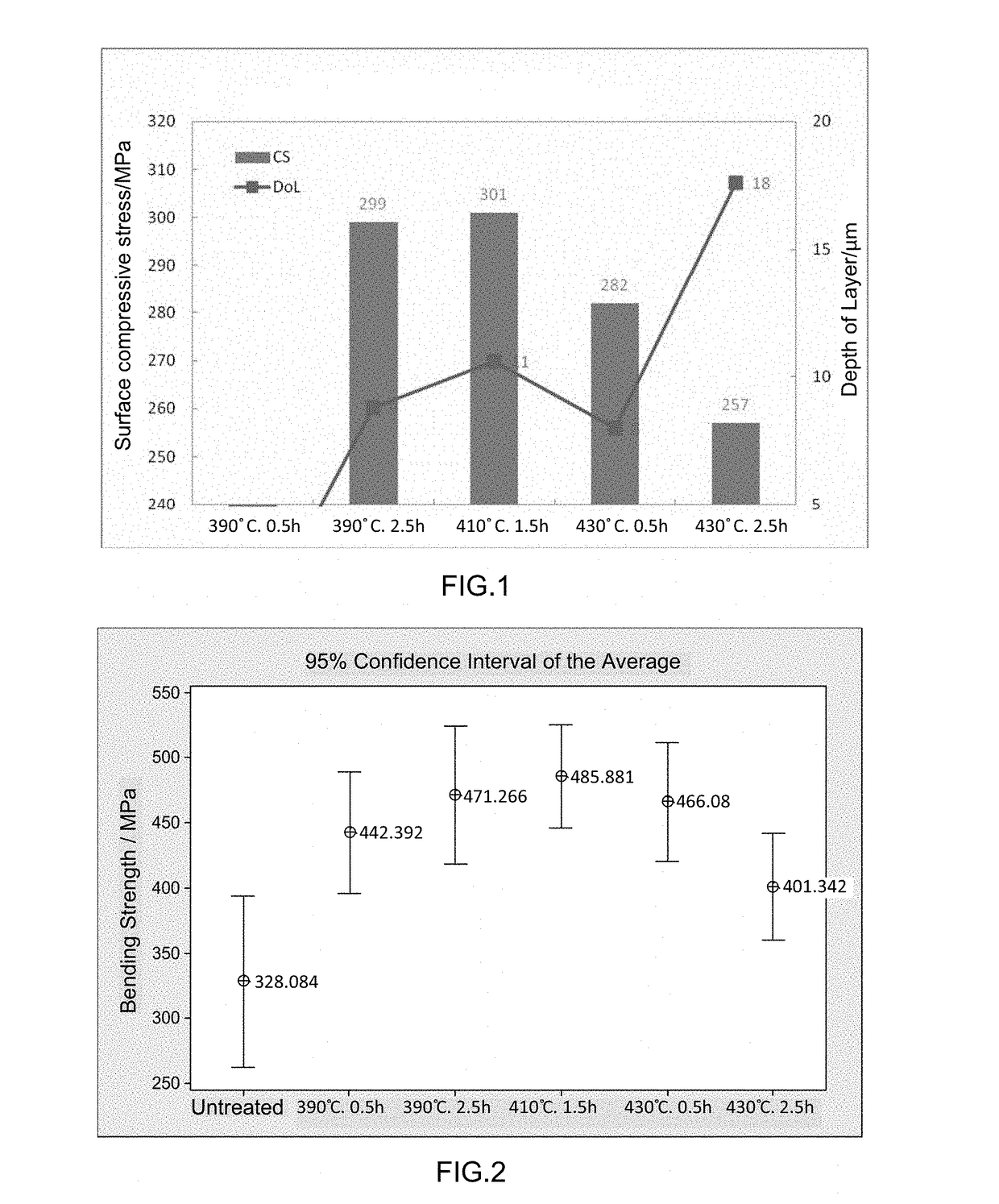

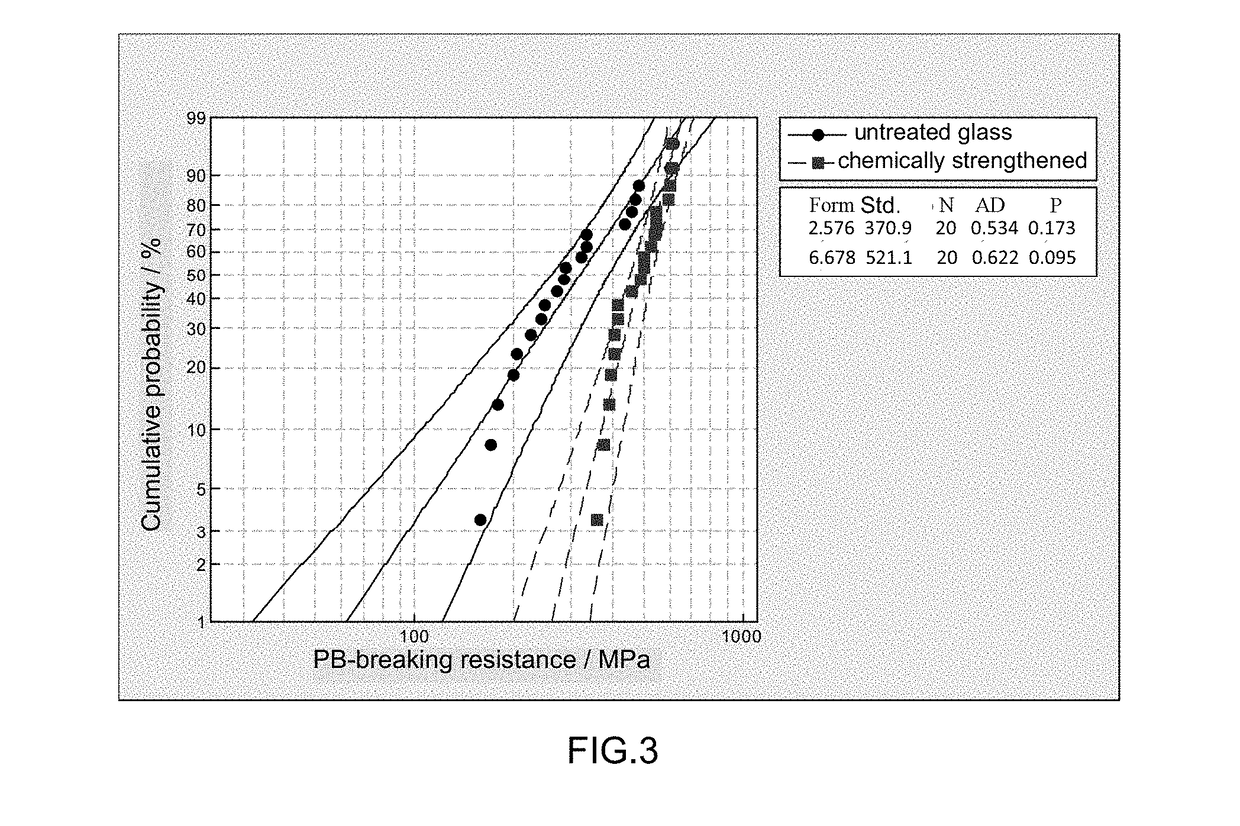

Coated chemically strengthened flexible thin glass

InactiveUS20170183255A1Improve antifouling performanceEasy to cleanGlass forming apparatusPriming paintsNiobiumCerium

A coated chemically strengthened flexible thin glass includes a coating of an adhesive layer in the form of a silicon mixed oxide layer, which contains or consists of a silicon oxide layer in combination with at least one oxide of aluminum, tin, magnesium, phosphorus, cerium, zirconium, titanium, cesium, barium, strontium, niobium, zinc, or boron, and magnesium fluoride, such as at least aluminum oxide.

Owner:SCHOTT AG

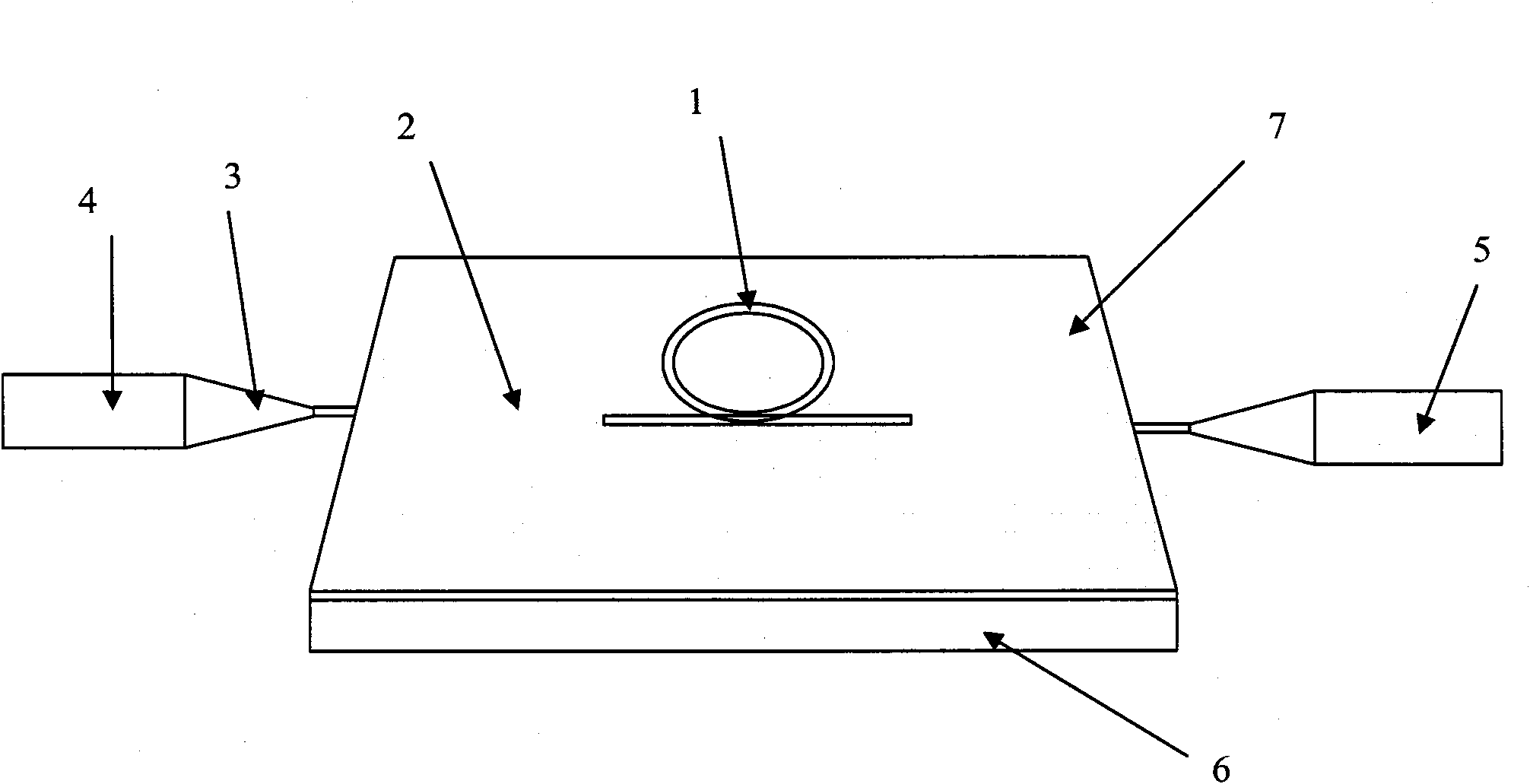

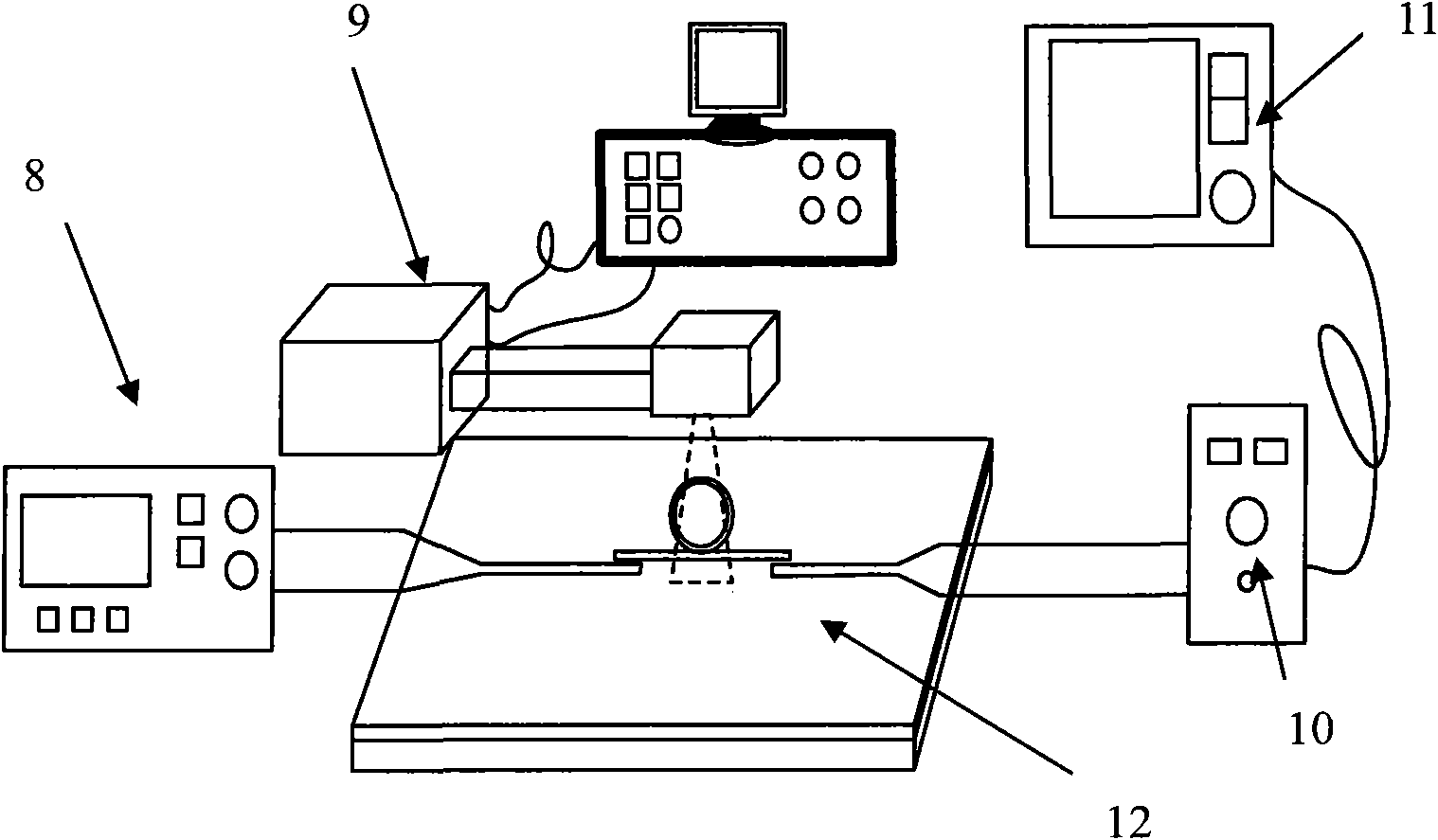

High sensitivity temperature sensor

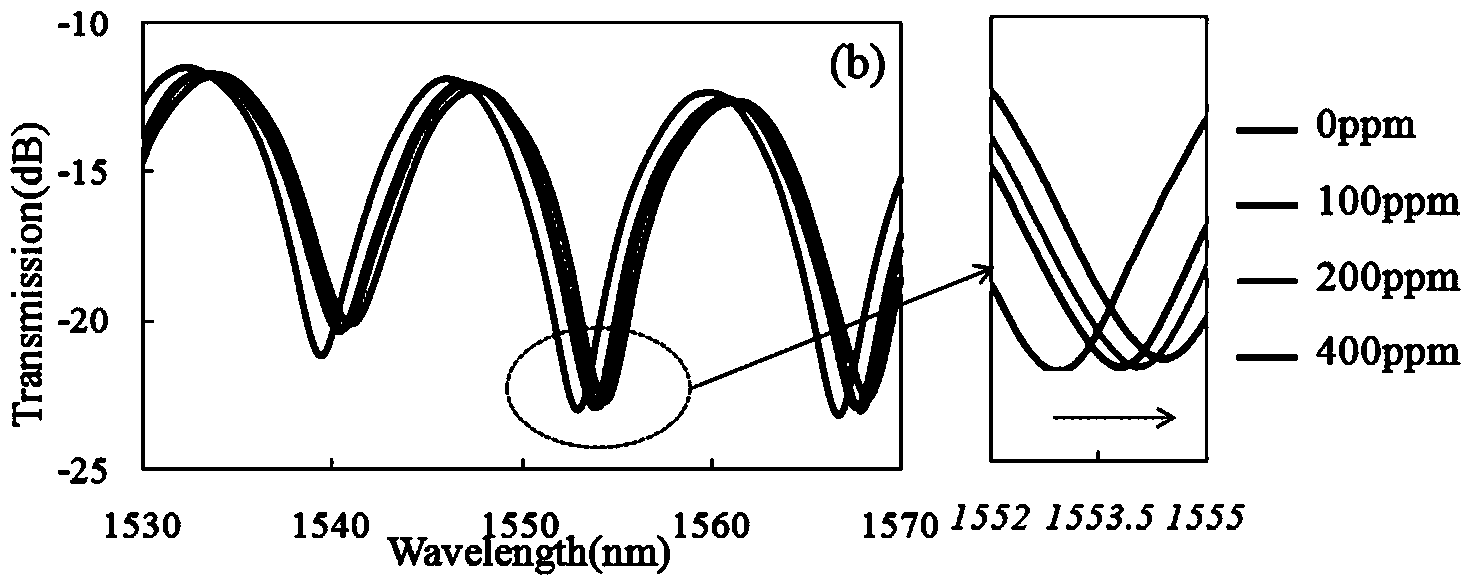

InactiveCN101598607AHigh measurement sensitivityImprove response speedCladded optical fibreThermometers using physical/chemical changesResonant cavityMicro nano

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Environment-friendly separation and recovery method of fluorine in fluorine-containing waste liquid

InactiveCN105948083AAchieve separationAchieve recyclingMagnesium fluoridesHydrogen fluorideRecovery methodEnvironmental resistance

The invention discloses an environment-friendly separation and recovery method of fluorine in a fluorine-containing waste liquid. According to the invention, a magnesium-containing compound is added into the fluorine-containing waste liquid as a precipitation agent, such that fluorine in the waste liquid is selectively precipitated; filtering is carried out, and fluorine-removed liquid and magnesium fluoride precipitate are obtained; the fluorine-removed liquid is used in waste water recycling; the magnesium fluoride precipitate is decomposed with sulfuric acid, such that a series of compounds of fluorine are obtained; decomposition residue is subjected to a dissolution-crystallization treatment, such that magnesium sulfate crystals are obtained; the obtained magnesium sulfate crystals are returned and recycled in the fluorine selective precipitation process; the crystallization mother liquor of magnesium sulfate is returned to the dissolution-crystallization process or the magnesium fluoride precipitation decomposition process. The method has the advantages of simple process, simple operation, low production cost, and good fluorine-removing effect. With the method, fluorine resource utilization is realized. The method also has the advantages of no fluorine-containing waste production and no three-waste emission.

Owner:CENT SOUTH UNIV

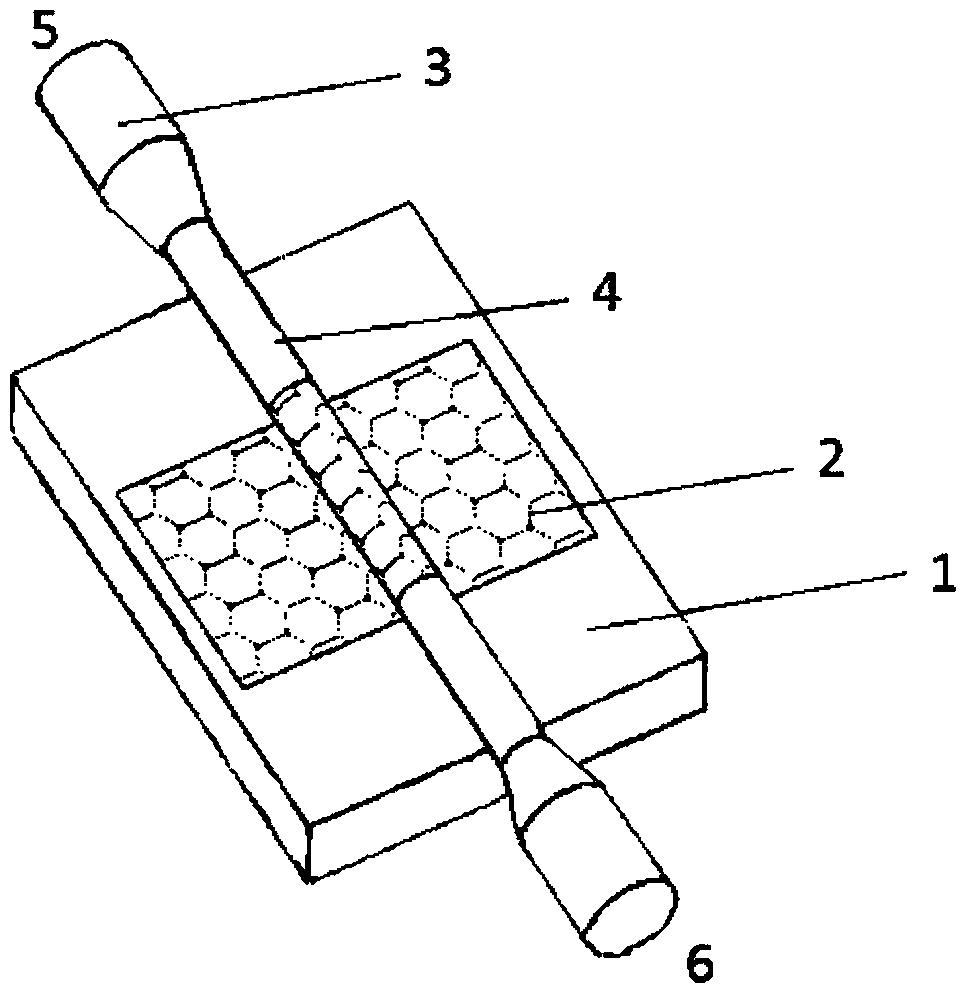

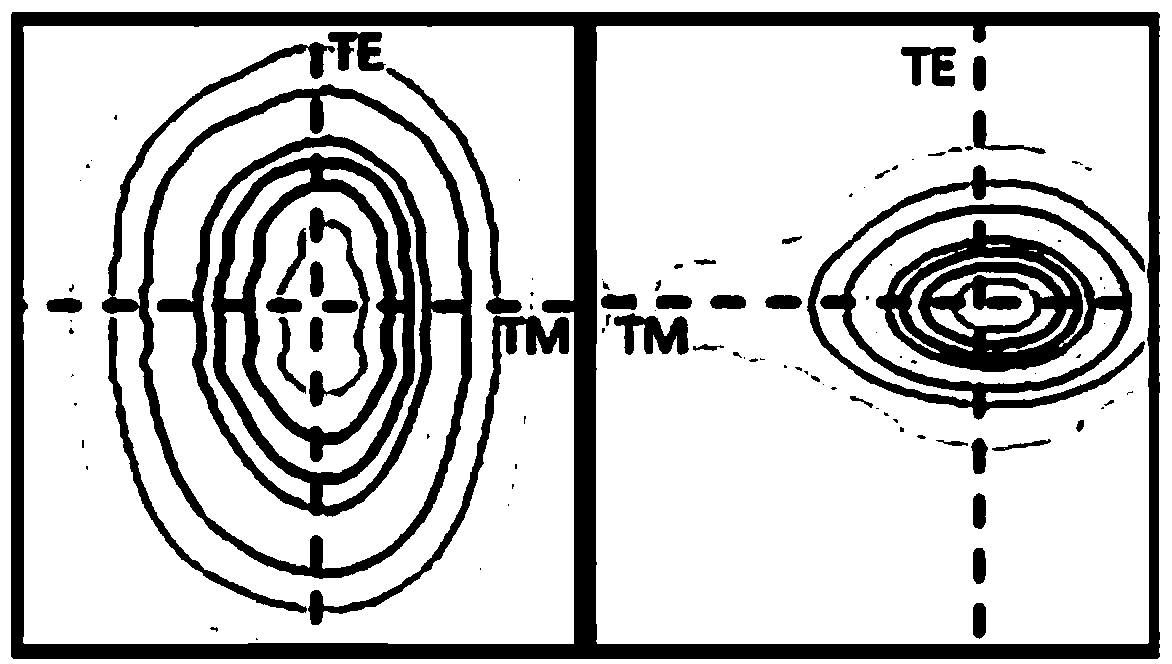

Active agent for laser welding and method for laser welding by utilizing same

InactiveCN102179645AStrong penetrating powerIncrease profitWelding/cutting media/materialsSoldering mediaAluminium chlorideLithium chloride

The invention discloses an active agent and a method for carrying out surface treatment on materials to be welded of aluminium and aluminium alloys so as to improve the energy utilization rate of the aluminium and the aluminium alloys, deepen the fusion depth of welding seams and further obtain higher welding quality. The active agent for laser welding consists of a chloride and a fluoride, wherein the mass ratio of the chloride to the fluoride is (1-2): (1-4); the chloride is at least one of lithium chloride, sodium chloride, potassium chloride, zinc chloride, magnesium chloride, aluminium chloride, calcium chloride or tin chloride; and the fluoride is at least one of lithium fluoride, sodium fluoride, magnesium fluoride or calcium fluoride. When the surface treatment is carried out, firstly the fluoride and the chloride are mixed fully and uniformly, water is added to form a supersaturated solution, then the supersaturated solution is coated on the surface of a welded test piece as a coating agent, then drying is carried out, and finally laser welding is carried out under the condition of gas protection.

Owner:TIANJIN UNIV

Silicon solar cell front face electrode silver paste and preparing method thereof

InactiveCN104157328AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesivePotassium

The invention discloses silicon solar cell front face electrode silver paste. The silicon solar cell front face electrode silver paste comprises, by mass, 75-80 percent of silver powder, 3-10 percent of lead-free glass powder, 10-15 percent of organic vehicle and 0.5-3 percent of additive. The silver powder is the spherical micro silver powder with nano bismuth serving as the core, the silver content is 99.1-99.7 percent, the bismuth content is 0.3-0.9 percent, the particle size is 1-2 microns, the tap density is 4.5-5.0 g / ml, the specific surface area is 0.4-1.0 m<2> / g, and the silver powder is prepared by conducting liquid-phase chemical reduction on bismuth nitrate and silver nitrate through glyoxal or acetaldehyde. Bismuth-silicon-antimony-molybdenum lead-free glass powder serves as an adhesive, and potassium fluotitanate, potassium fluoroaluminate, magnesium fluoride and the like are added to serve as the silicon nitride antireflective film eroding additive. According to the silicon solar cell front face electrode silver paste, the contact resistance between a silver electrode and a silicon wafer can be reduced, the stripping strength of the electrode is improved, the electrical property of a solar cell is improved, the production cost of the conductive silver paste is reduced, and the requirement for nonexistence of lead and environmental friendliness are met.

Owner:天津顺御科技有限公司

Micro optical fiber gas sensor covered by adopting graphene

InactiveCN103954590AReusableSmall sizePhase-affecting property measurementsRefractive indexMagnesium fluoride

The invention discloses a micro optical fiber gas sensor covered by adopting graphene and relates to the field of gas sensors, in particular relates to the field of an optical fiber intermodal interference sensor. A micro optical fiber which is drawn to have two thick ends and thin middle through a fused biconical taper method is arranged on a magnesium fluoride substrate, a single-layer graphene material covers the middle section of the micro optical fiber, and because the single-layer graphene material is extremely sensitive to chemical bonds between atoms and an extranuclear electron state is extremely sensitive to an ambient environment, distribution of a dielectric constant is changed due to contact between the material and trace gas molecule, so that the optical refractive index is changed, and finally the intermodal interference spectrum of light propagated in the optical fiber is changed, the gas types are identified by detecting the interference spectrum, and the aims of the gas sensor are achieved. Therefore, the micro optical fiber gas sensor has the advantages of small size, high precision, high sensitivity, stability in operation and repeated utilization effect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

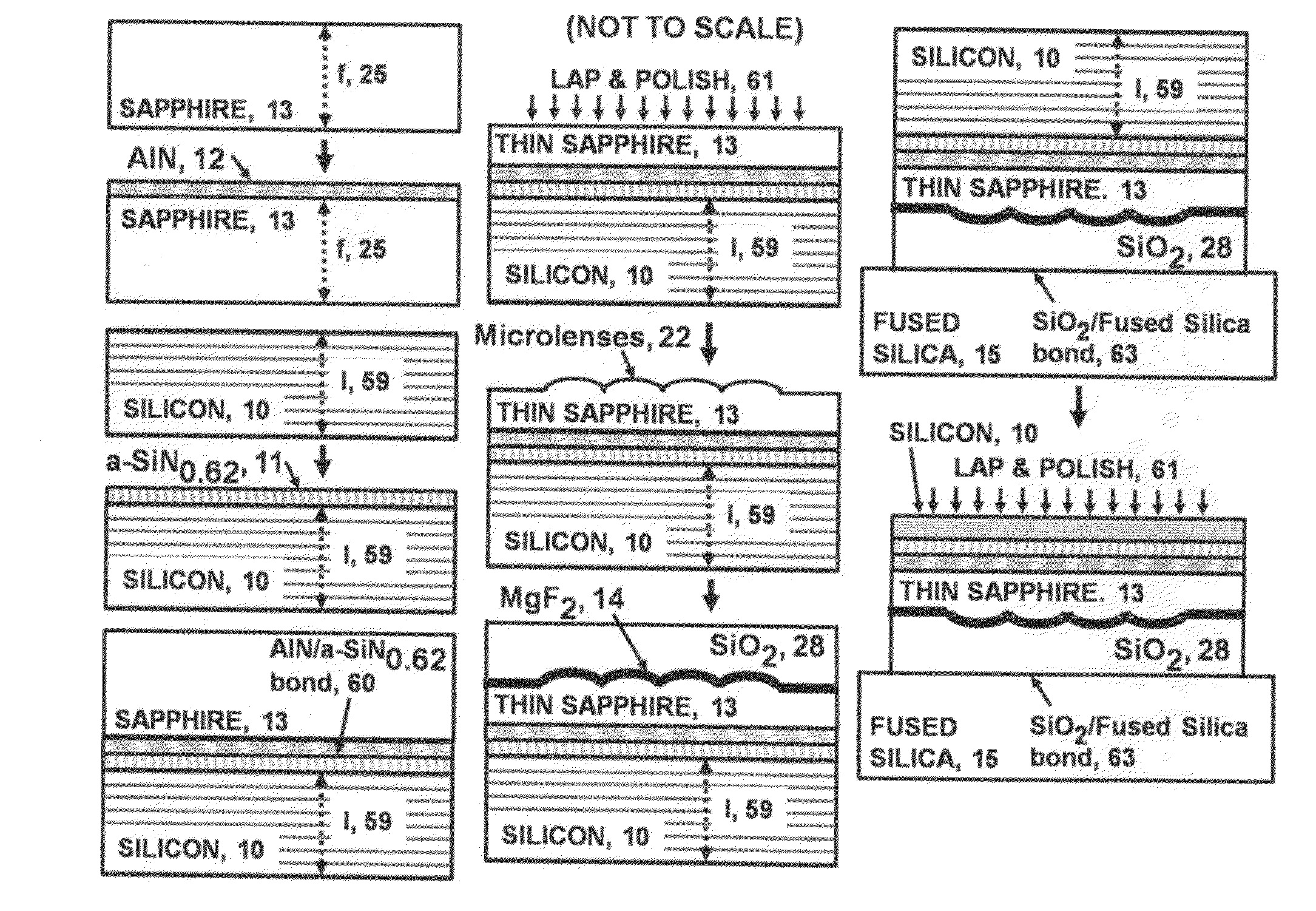

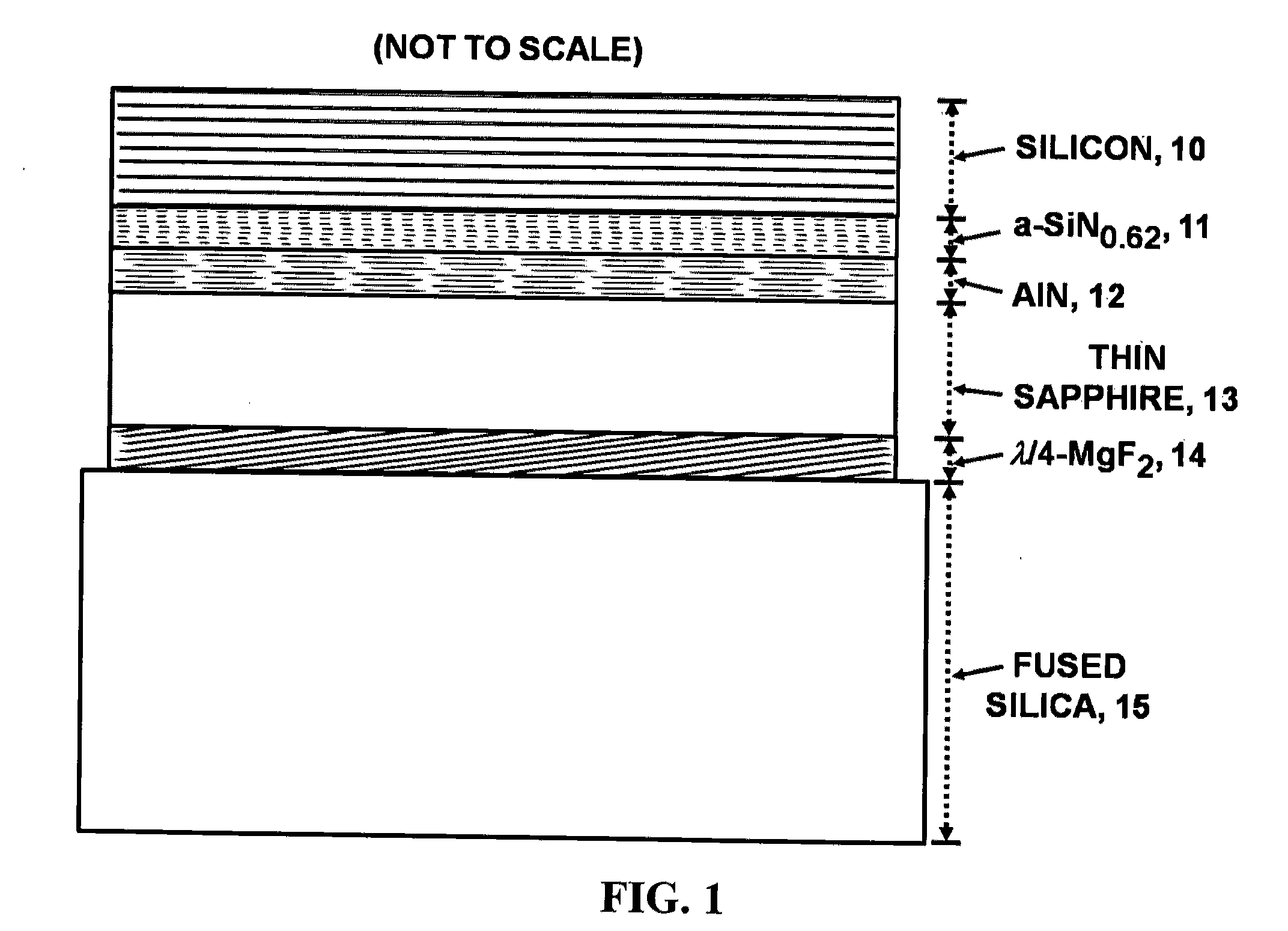

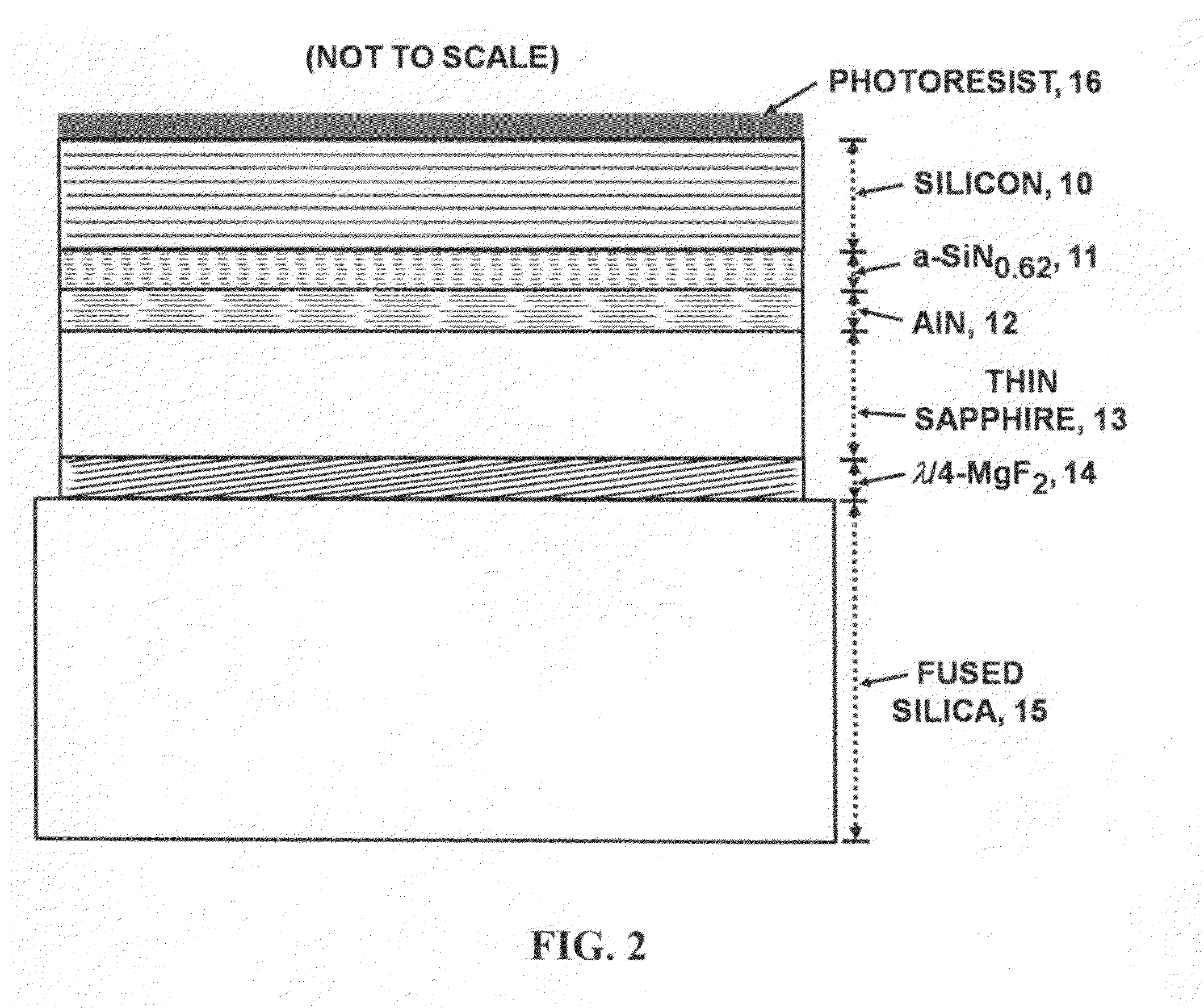

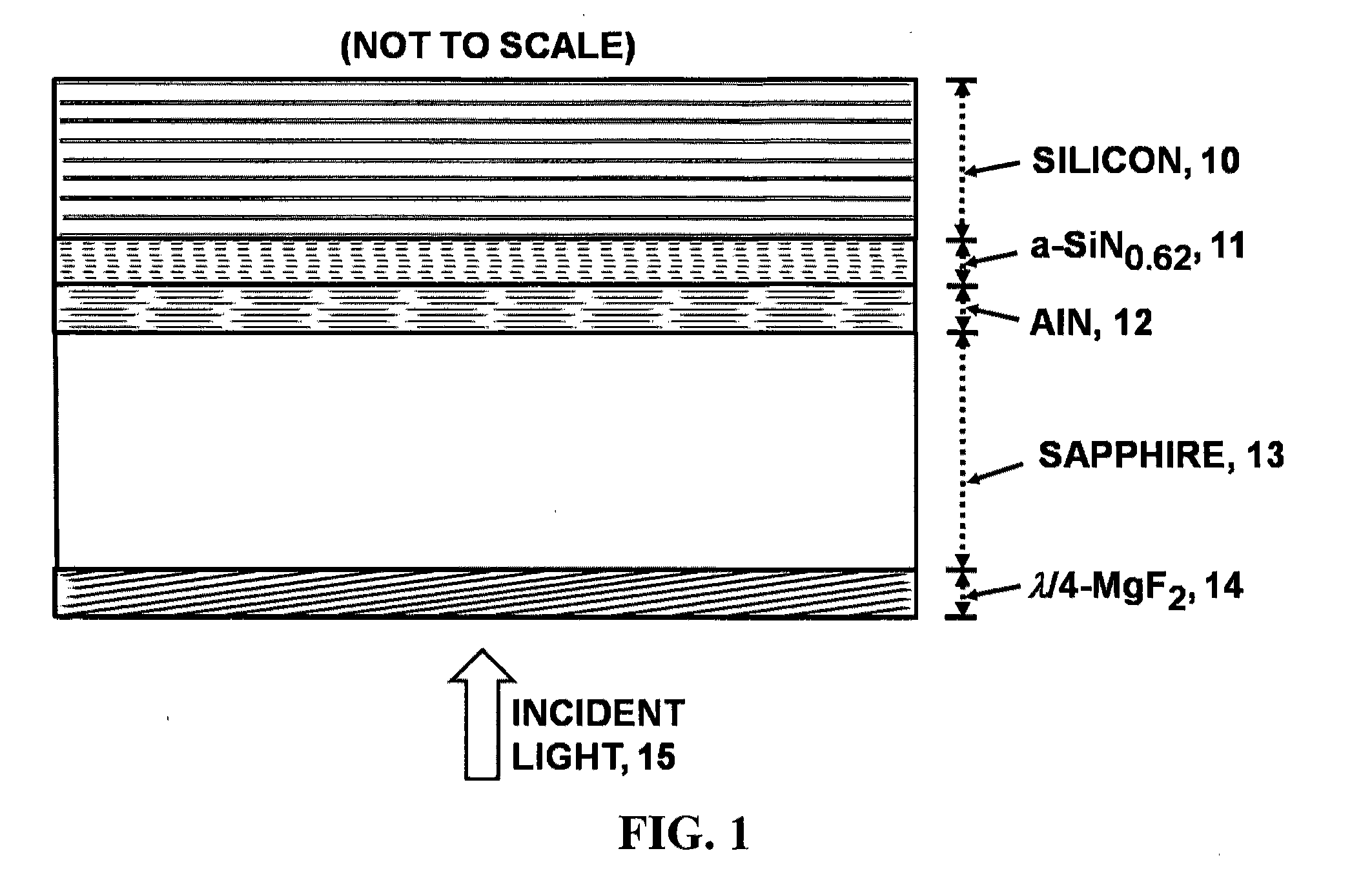

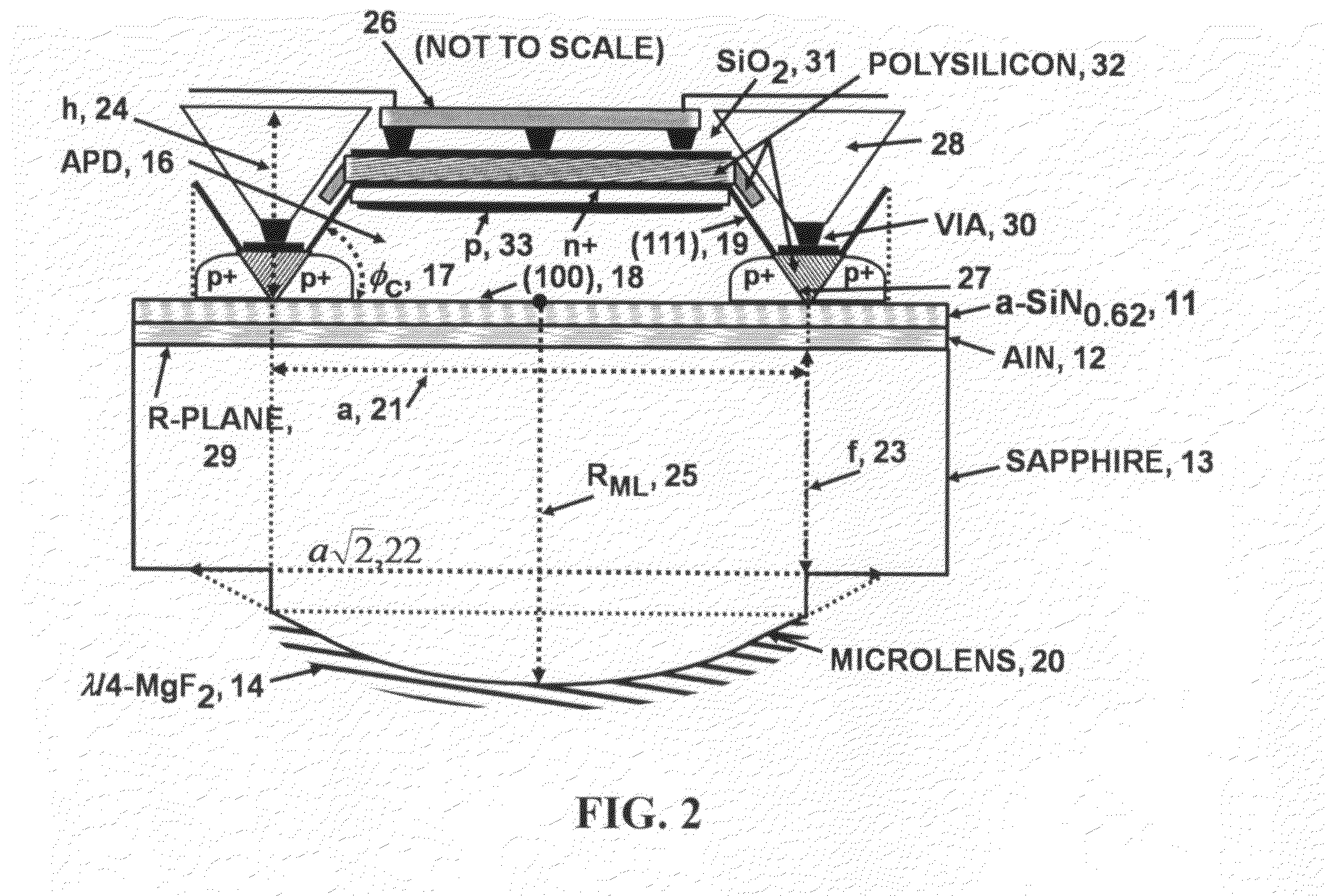

Thin, very high transmittance, back-illuminated, silicon-on-saphire semiconductor substrates bonded to fused silica

InactiveUS20120299143A1High light transmittanceSuppression problemSolid-state devicesSemiconductor/solid-state device manufacturingSingle crystalSilicon dioxide

A very high transmittance, back-illuminated, silicon-on-thin sapphire-on-fused silica wafer substrate design is presented for enabling high quantum efficiency and high resolution, silicon or silicon-germanium avalanche photodiode detector arrays with improved indirect optical crosstalk suppression. The wafer substrate incorporates a stacked antireflective bilayer between the sapphire and silicon, comprised of single crystal aluminum nitride (AlN) and non-stoichiometric, silicon rich, amorphous silicon nitride (a-SiNX<1.33), as well as a one quarter wavelength, magnesium fluoride (λ / 4-MgF2) back-side antireflective layer which is bonded to a fused silica wafer. The fused silica provides mechanical support, allowing the sapphire to be thinned to optimal thickness below 50 μm, for improved optical transmittance and in conjunction with monolithic sapphire microlenses, suppression of indirect optical crosstalk from multiple reflections of APD emitted light. After solid-state device fabrication, the silicon can be coated with photoresist and the fused silica dissolved in buffered hydrogen fluoride (HF) to recover the thin Si—(AlN / a-SiNX<1.33)-sapphire-(MgF2).

Owner:STERN ALVIN GABRIEL

Filter and neutron beam source

Disclosed is a filter including a second layer disposed between a first layer and a third layer. The first layer is composed of iron. The second layer is composed of 1 part by volume of lithium fluoride, 20 to 50 parts by volume of aluminum, and 50 to 80 parts by volume of aluminum fluoride. The third layer is composed of 1 part by weight of lithium fluoride and 99 to 100 parts by weight of magnesium fluoride.

Owner:HERON NEUTRON MEDICAL CORP

Anti-light reflection ultraviolet light curing coating for plastic surfaces

InactiveCN101775254AObvious anti-light reflection effect of ultraviolet lightImprove wear and scratch resistancePolyurea/polyurethane coatingsRainbowUltraviolet lights

Owner:WUJIANG YOUXIN NEW MATERIAL TECH

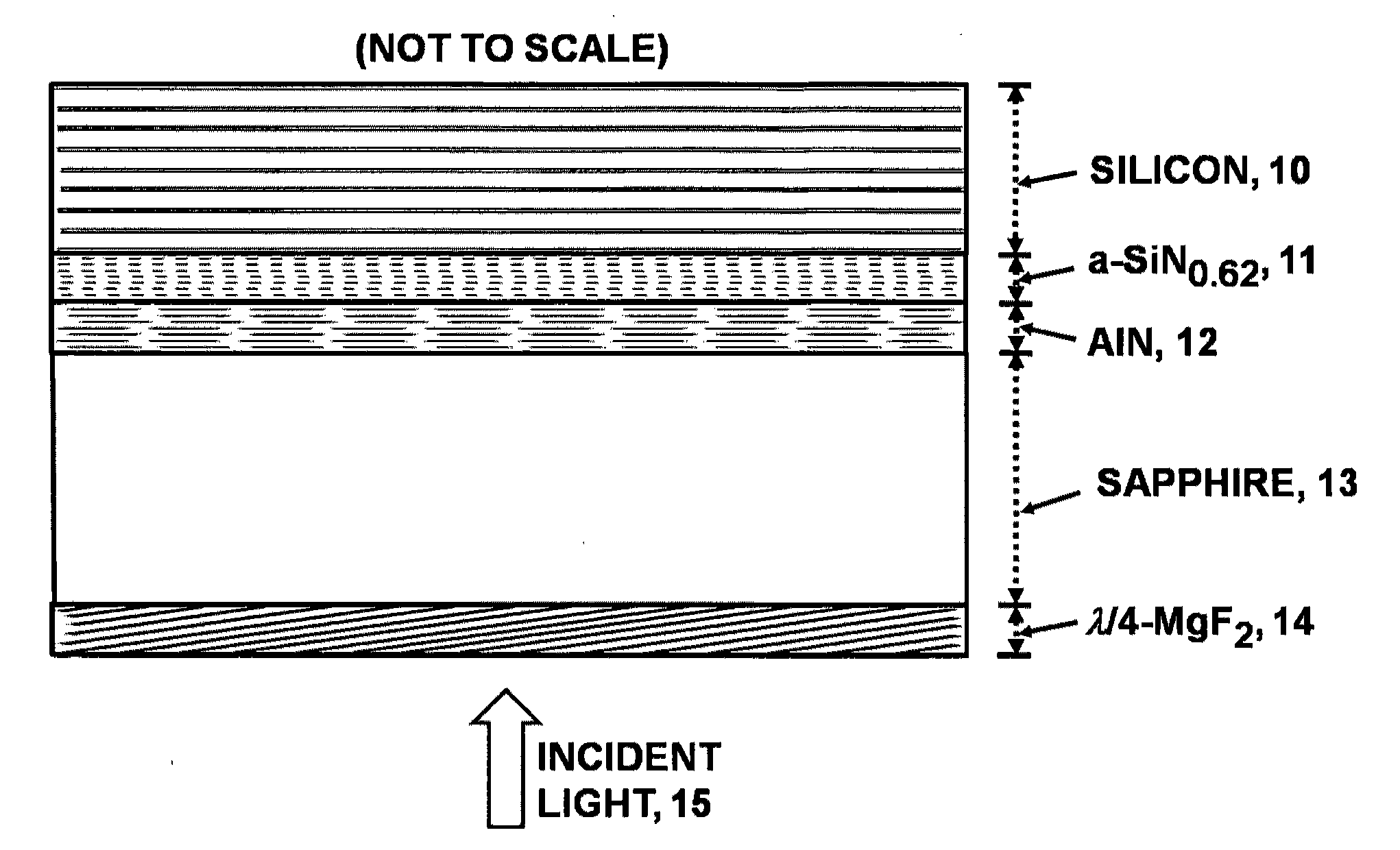

Very high transmittance, back-illuminated, silicon-on-sapphire semiconductor wafer substrate for high quantum efficiency and high resolution, solid-state, imaging focal plane arrays

InactiveUS20120193636A1High light transmittanceImprove quantum efficiencyLaser detailsSolid-state devicesSingle crystalRefractive index matching

An advanced, very high transmittance, back-illuminated, silicon-on-sapphire wafer substrate design is presented for enabling high quantum efficiency and high resolution, silicon or silicon-germanium avalanche photodiode detector arrays. The wafer substrate incorporates a stacked antireflective bilayer between the sapphire and silicon layers, comprised of single crystal aluminum nitride (AlN) and non-stoichiometric, silicon rich, amorphous silicon nitride (a-SiNX<1.33), that provides optimal refractive index matching between sapphire and silicon. A one quarter wavelength, magnesium fluoride (λ / 4-MgF2) antireflective layer deposited on the back surface of the thinned sapphire provides refractive index matching at the air-sapphire interface. Selecting a composition of x=0.62 for a-SiNX, tunes an optimal refractive index for the layer. Selecting design thicknesses of 52 nm for single crystal AlN, 30 nm for a-SiN0.62, and 120 nm for λ / 4-MgF2 yields a back-illuminated optical transmittance T>50% for 250-300 nm, T>70% for 300-400 nm and T>90% for 400-1100 nm.

Owner:STERN ALVIN GABRIEL

Preparation method of magnesium oxide foam ceramic filter for filtering magnesium and magnesium alloy melt

InactiveCN101785944BHigh strengthImprove adhesionFiltration separationProcess efficiency improvementOxide ceramicWater based

The invention provides a magnesium oxide ceramic foam filter for filtering a magnesium and magnesium alloy melt and a preparation method thereof, relating to the field of metallurgy. The process is as follows: a polyurethane foam template is soaked in sodium hydroxide solution (10%) for 30 minutes under the temperature of 50 DEG C and is then washed by water and dried; electric-melting magnesium oxide, magnesium fluoride and water are mixed in a ball-milling manner according to the mass ratio so as to obtain water-based dispersion slurry; the polyurethane foam template is soaked in the slurry, and bisque is obtained through repeated slurry dipping and centrifugal slurry throwing; the bisque is put into an oven; finally, the dried bisque is put into a high-temperature furnace, is heated to 1,200 to 1,300 DEG C at the speed of 1 to 3 DEG C / min, is heat-preserved for 2 hours, and is then naturally cooled in a furnace body. An obtained product of the invention has good chemical stability in the magnesium and the magnesium alloy melt, does not pollute the magnesium and the magnesium alloy melt, has good functions of absorbing and filtering nonmetallic inclusions in the magnesium and the magnesium alloy melt, and is suitable for filtering as well as purifying the magnesium and the magnesium alloy melt.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

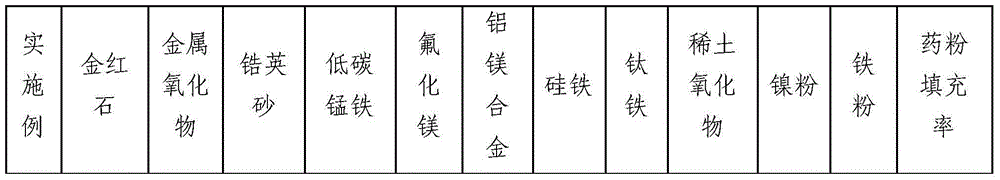

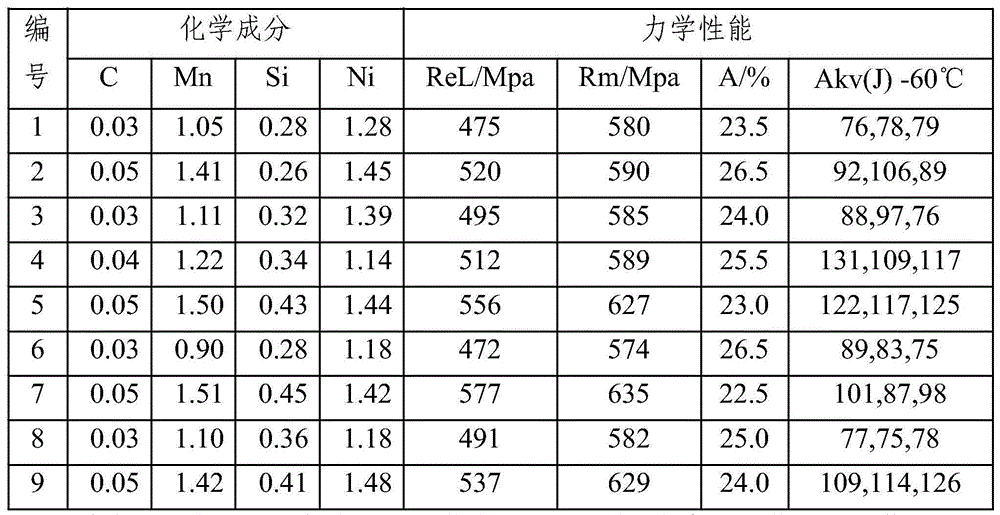

Flux-cored wire special for maritime work low-temperature high-strength steel

InactiveCN104959748ASimple welding processGood resistance to cold crackingWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention discloses a flux-cored wire special for maritime work low-temperature high-strength steel. The flux-cored wire is composed of carbon steel skin and a flux core. The flux-cored wire comprises, by mass, 35%-40% of rutile, 2%-5% of magnesium oxide and / or calcium oxide, 0.5%-2% of zircon sand, 15%-25% of low-carbon ferromanganese, 4%-6% of magnesium fluoride, 2%-4% of aluminum magnesium alloy, 7%-10% of ferrosilicon, 5%-8% of ferrotitanium, 0.5%-2% of rare earth oxide, 9%-11% of nickel powder and the balance iron powder and inevitable impurities. The flux-cored wire does not contain boron (B) and has excellent welding technological performance. The comprehensive performance of deposited metal and welded joints is that the yield strength is larger than or equal to 470 MPa, the tensile strength is larger than or equal to 550 MPa, the elongation is larger than or equal to 22%, and KV2 is larger than or equal to 50 J when the temperature is -60DEG C.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

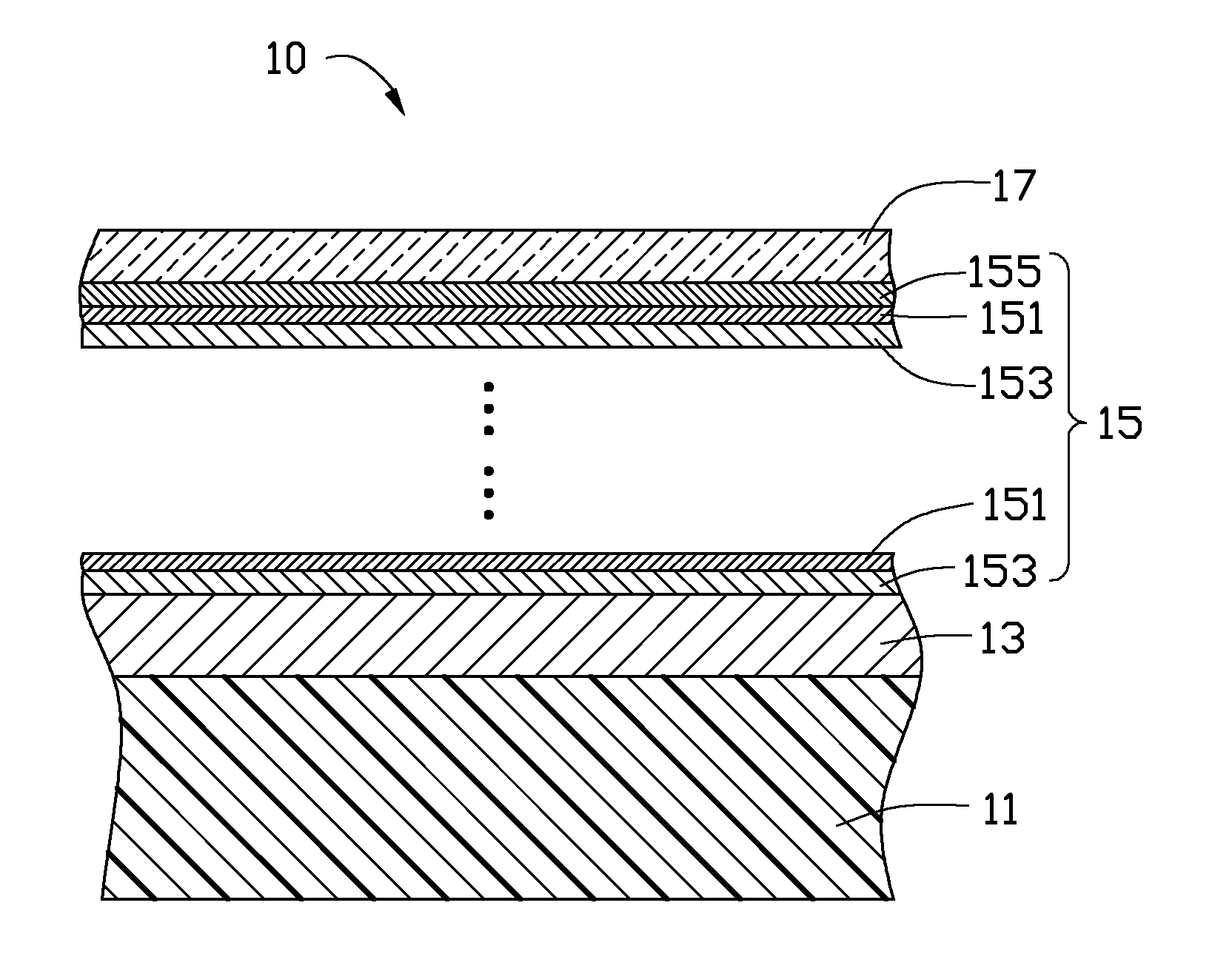

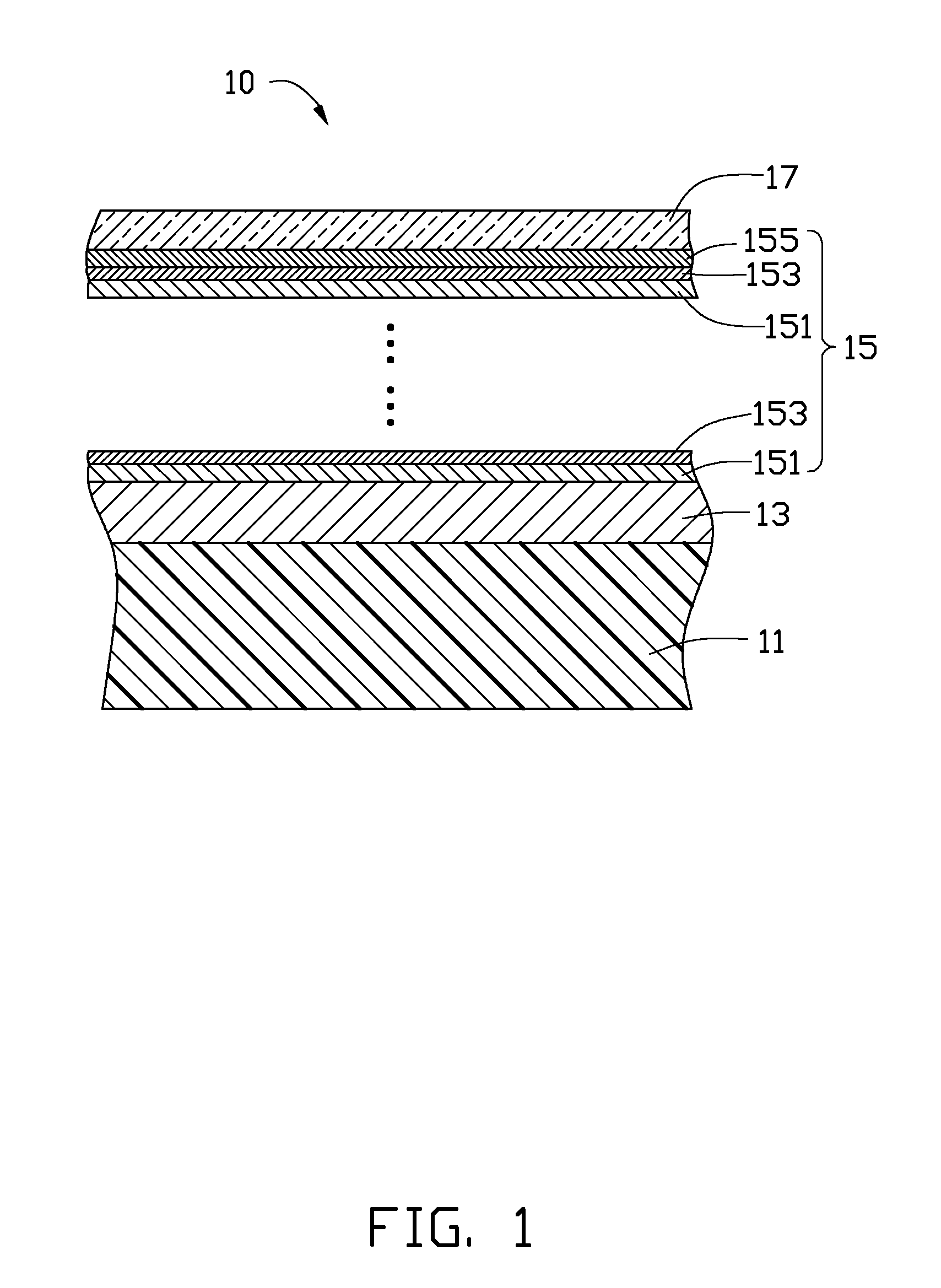

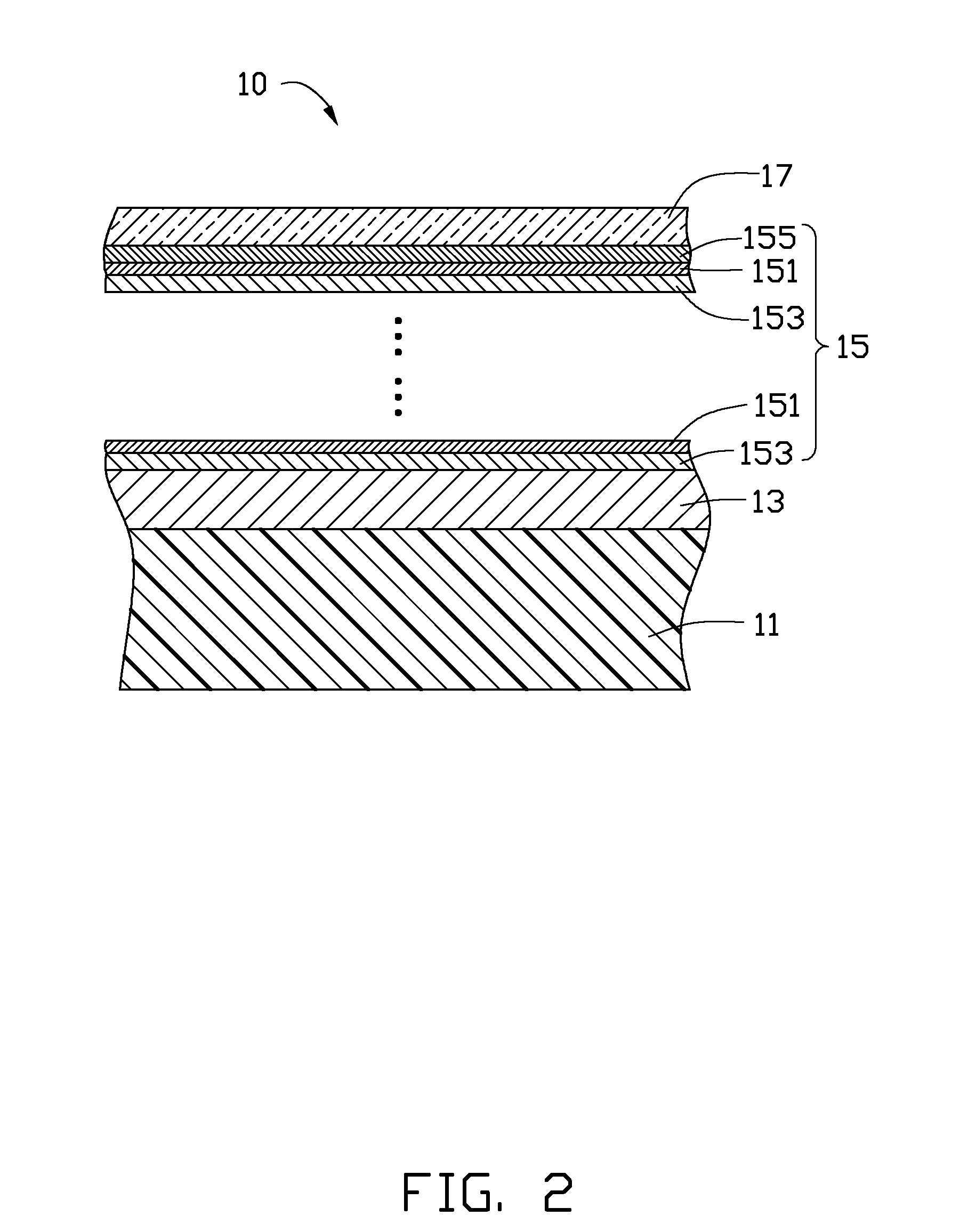

Electronic device housing

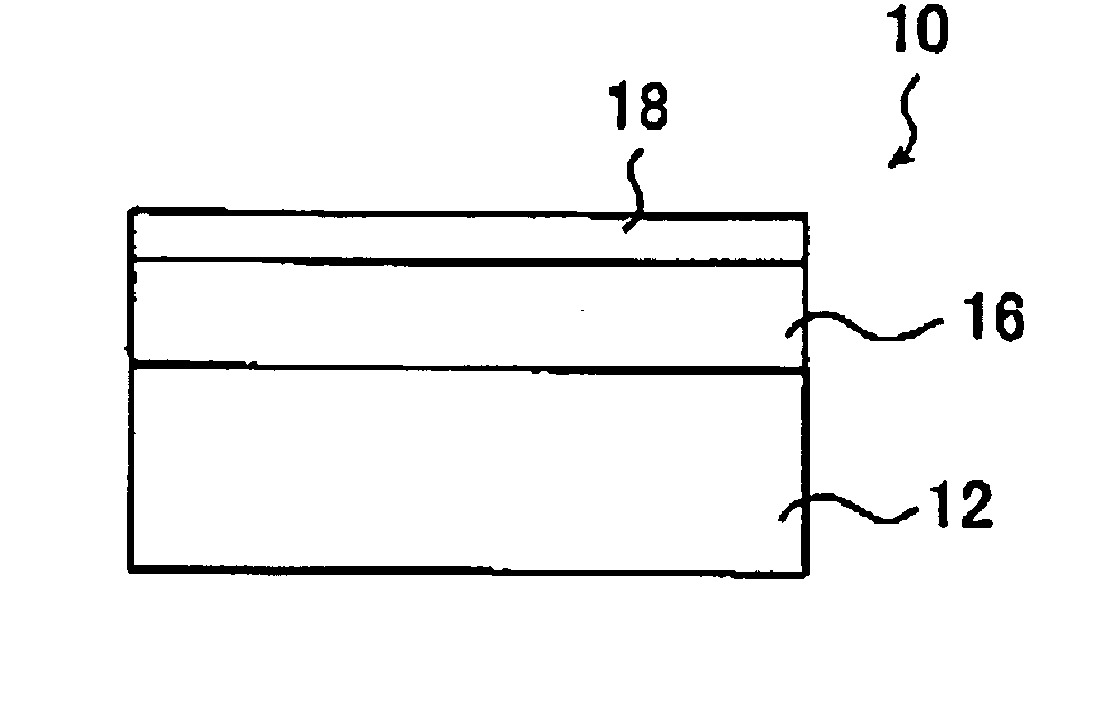

ActiveUS20110159277A1Ornamental structuresSynthetic resin layered productsMagnesium fluorideSilicon dioxide

An electronic device housing is provided. The electronic device housing comprises a substrate, a base paint coating formed on the substrate, and a metallic coating formed on the base paint coating. The metallic coating comprises a plurality of first layers interleaved with a plurality of second layers, and a third layer provided outermost. The first layer and the second layer are respectively a zirconium dioxide layer and an aluminum oxide layer, or are respectively composite component layer of niobium pentoxide and zirconium dioxide, and silicon dioxide layer. The third layer is a magnesium fluoride layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

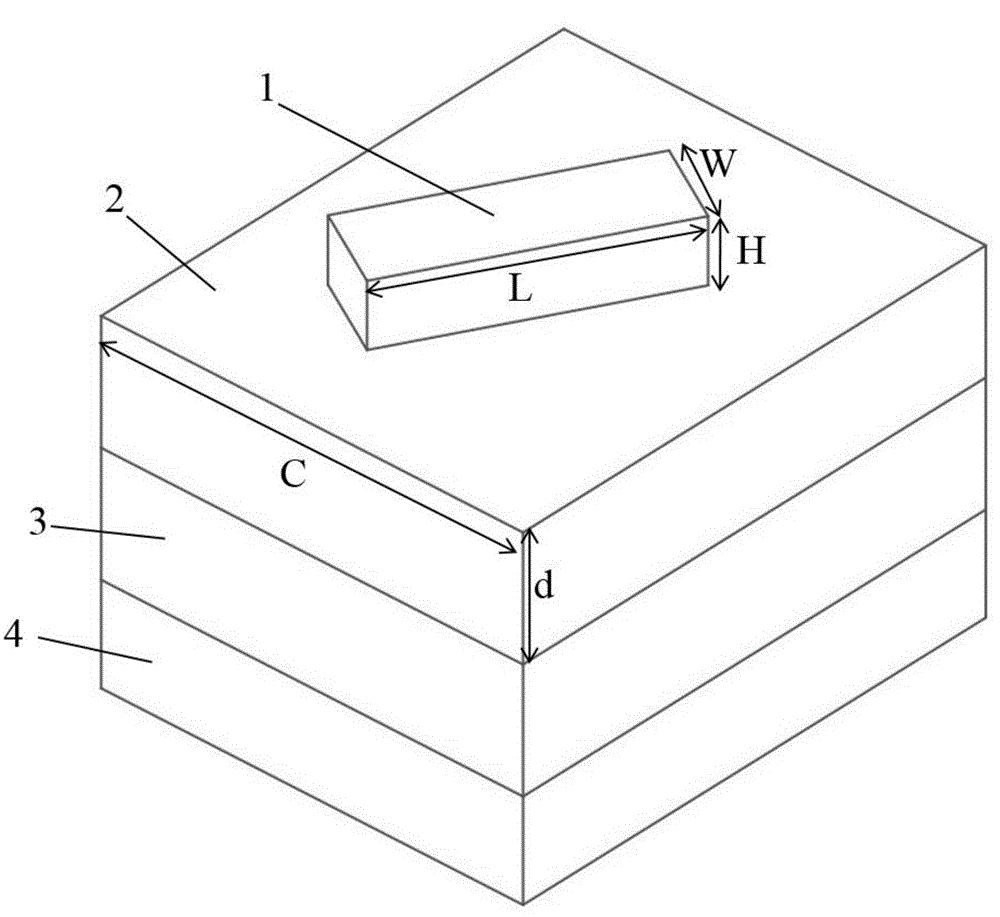

Broadband reflecting mirror

InactiveCN102112897AImprove reflectivityImprove heat resistanceSolar heating energyMirrorsRefractive indexSilicon oxide

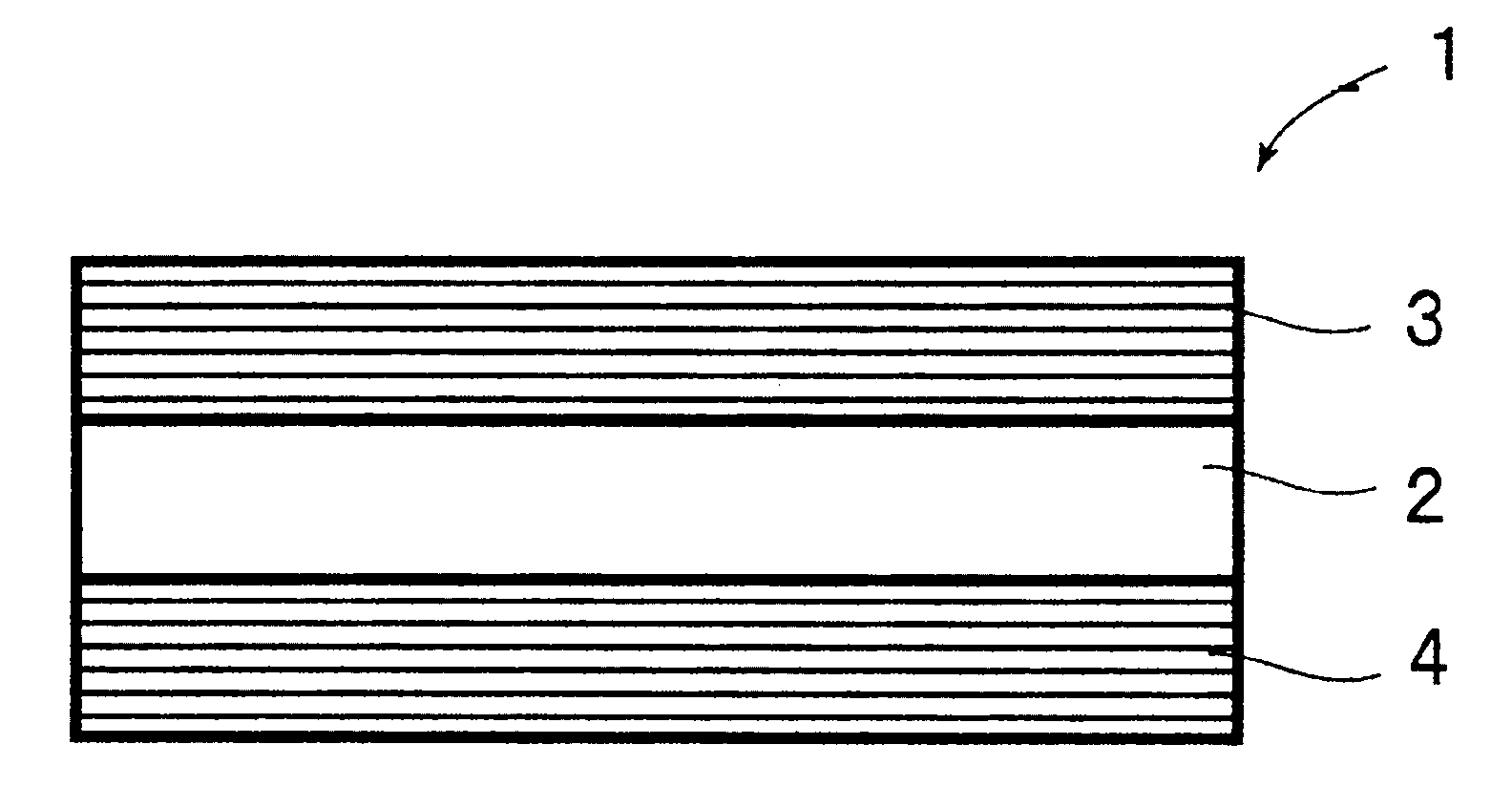

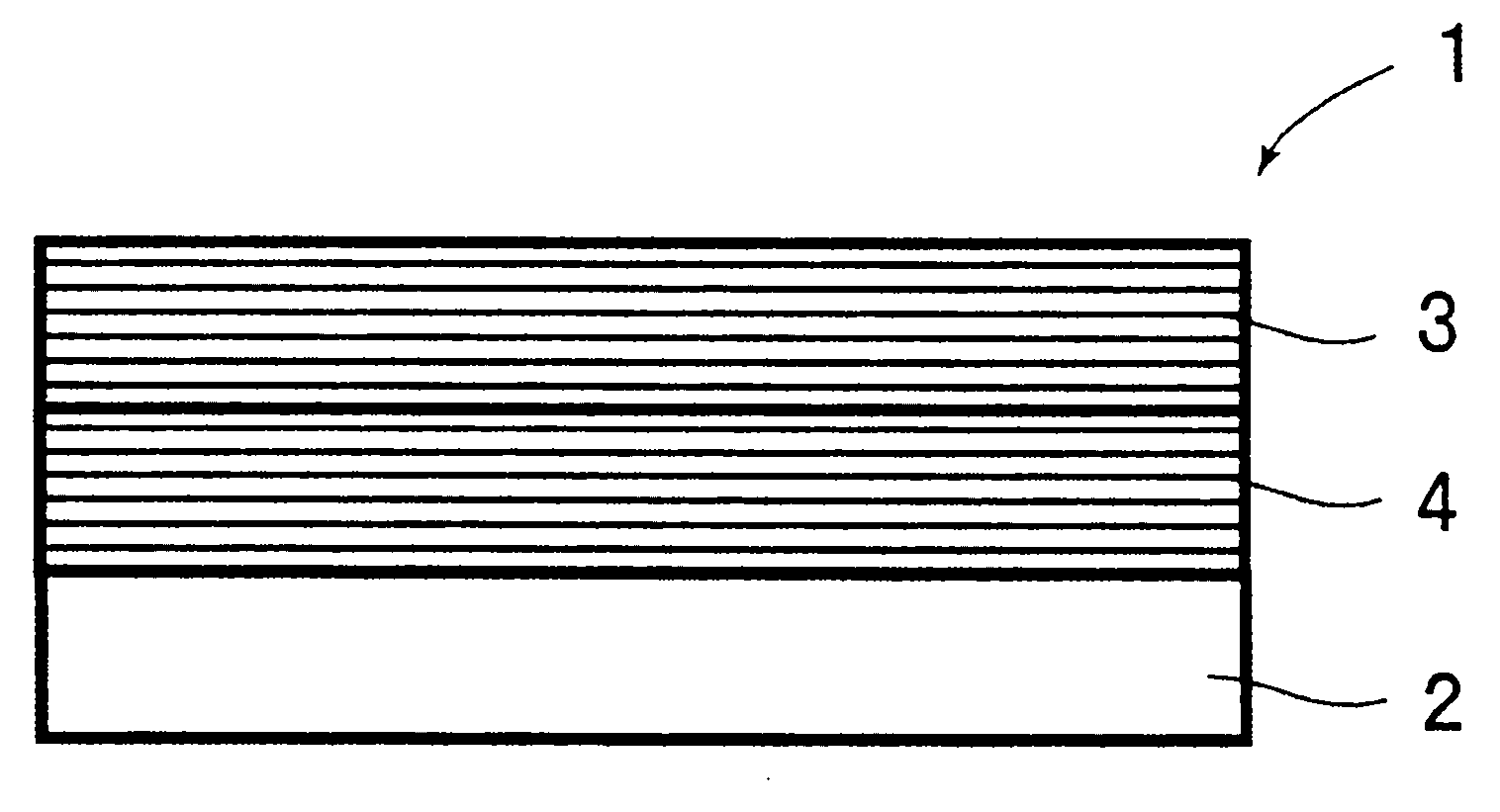

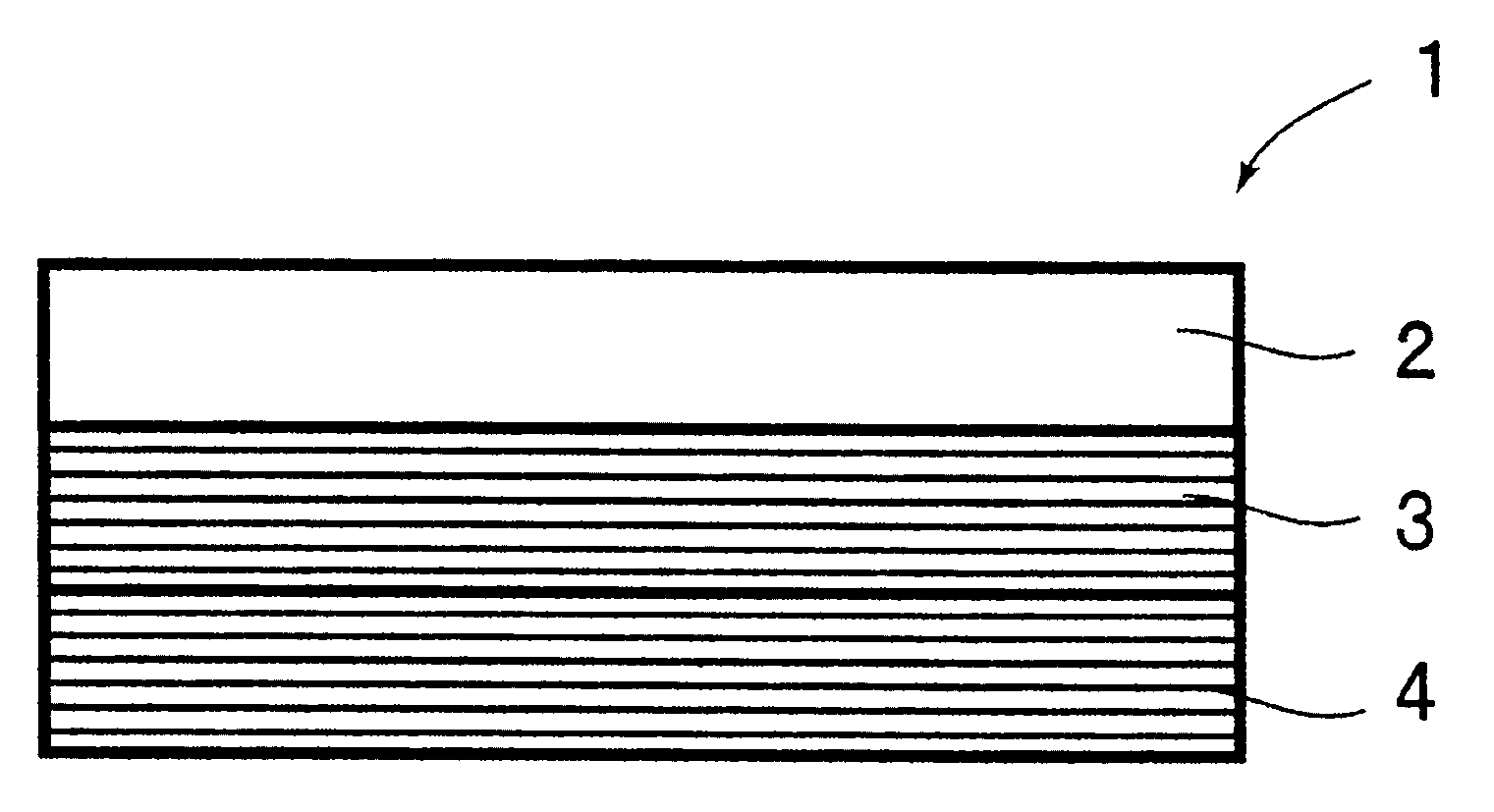

Provided is a broadband reflecting mirror that has a high reflectance in the band with wavelengths ranging from 400nm to 2,500nm, heat resistance, and flaw resistance. A broadband reflecting mirror (1) for reflecting light in a band with wavelengths ranging from 400nm to 2,500nm, is provided with a first reflecting stacked film (3) in which a first high refractive index material layer and a firstlow refractive index material layer are stacked alternately to reflect light with a band on a short wavelength side in the band with wavelengths ranging from 400nm to 2,500nm, a second reflecting stacked film (4) in which a second high refractive index material layer and a second low refractive index material layer are stacked alternately to reflect light with a band on a long wavelength side in the band with wavelengths ranging from 400nm to 2,500nm, wherein the broadband reflecting mirror is characterized in that the first reflecting stacked film (3) is arranged on the incident side of the light, while the second reflecting stacked film (4) is arranged at a position from which the light penetrating the first stacked film (3) can be reflected, and wherein the first high refractive index material layer is formed of at least one material selected from the group consisting of niobium oxide, titanium oxide, zirconium oxide, tantalum oxide, hafnium oxide, silicon nitride, yttrium oxide and indium tin oxide, the first low refractive index material layer is formed of at least one material selected from the group consisting of silicon oxide and magnesium fluoride, the second high refractive index material layer is formed of at least one material selected from the group consisting of silicon and germanium, and the second low refractive index material layer is formed of at least one material selected from the group consisting of silicon oxide and magnesium fluoride.

Owner:NIPPON ELECTRIC GLASS CO LTD

Optical component

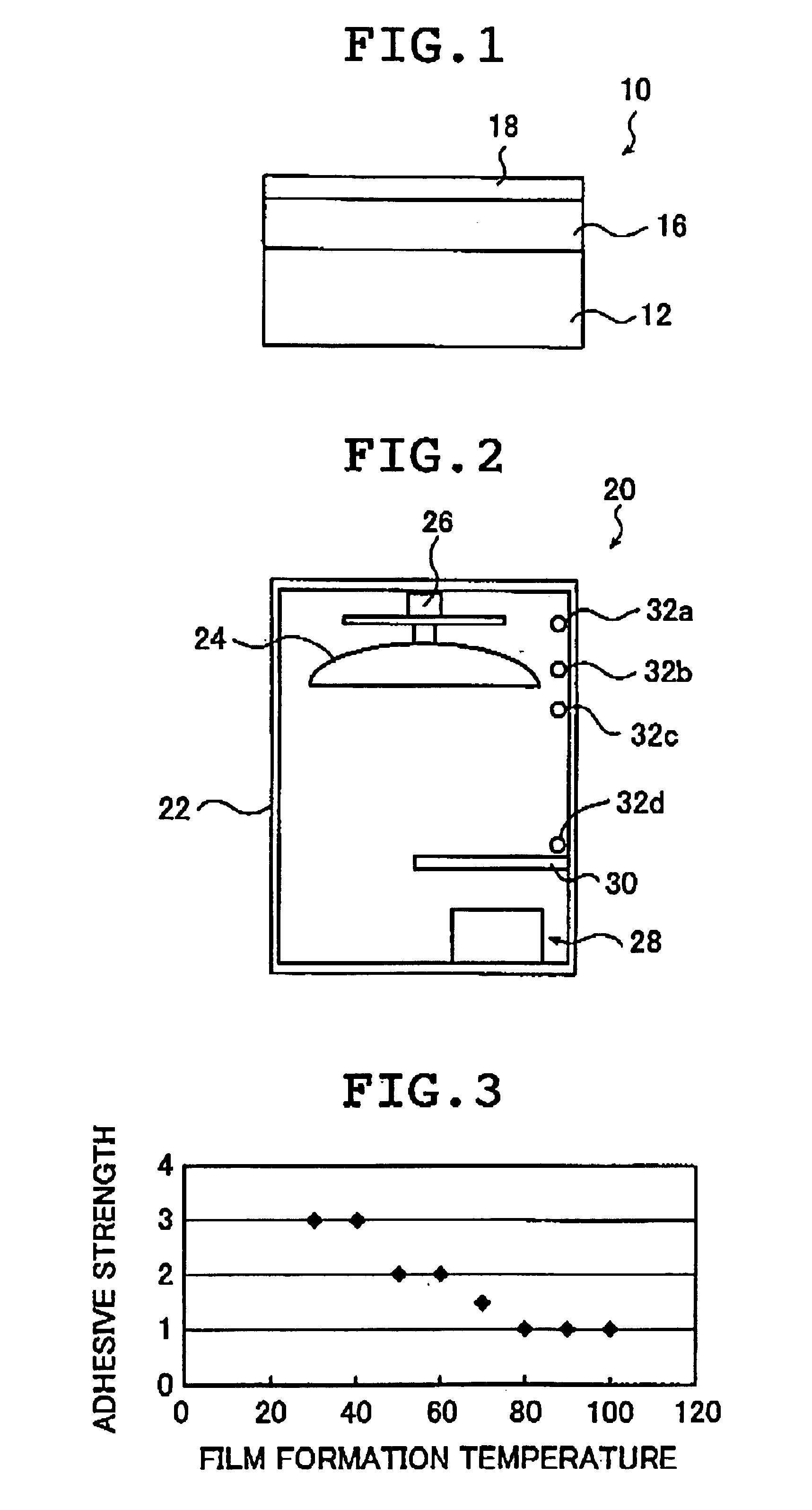

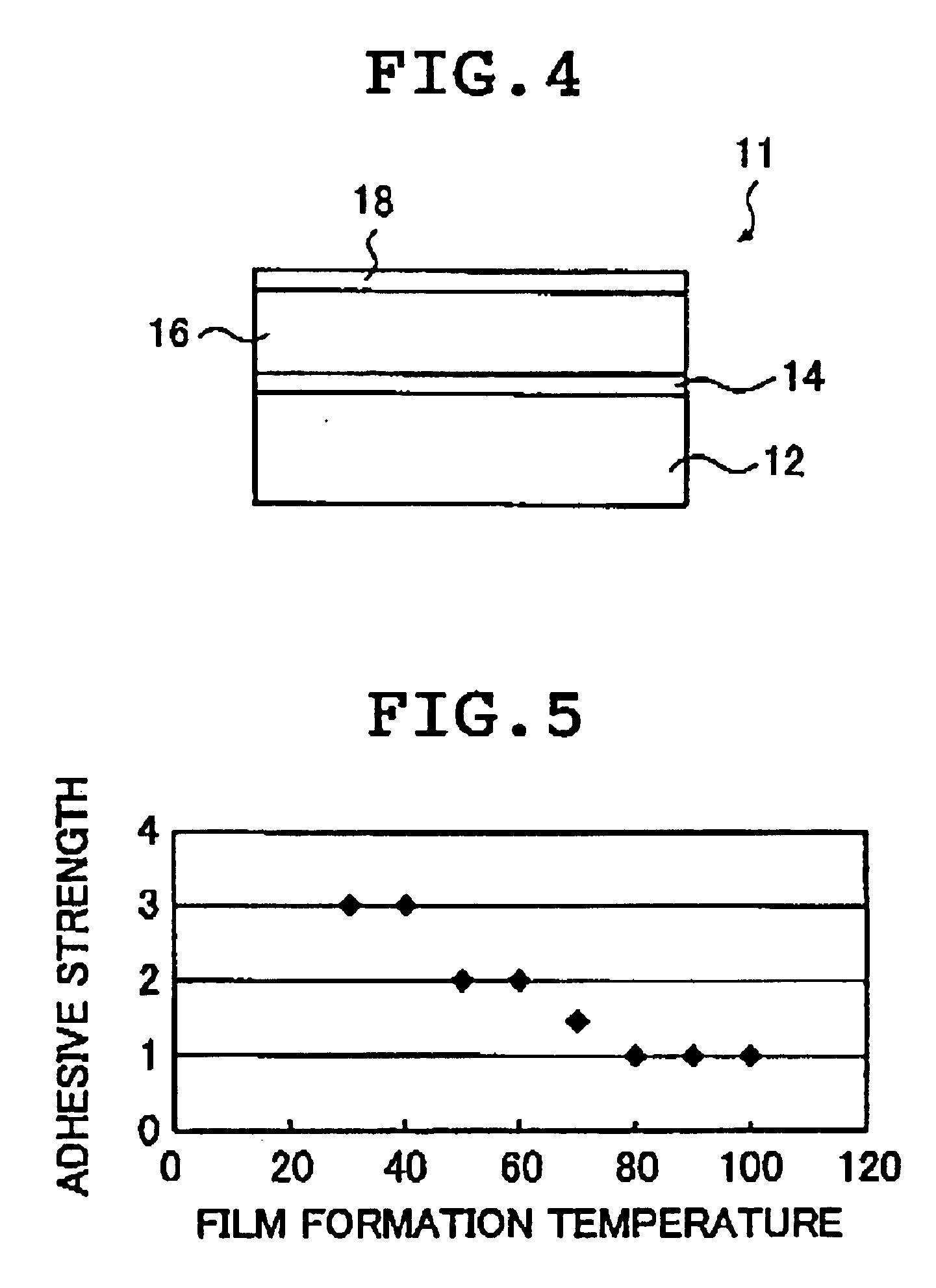

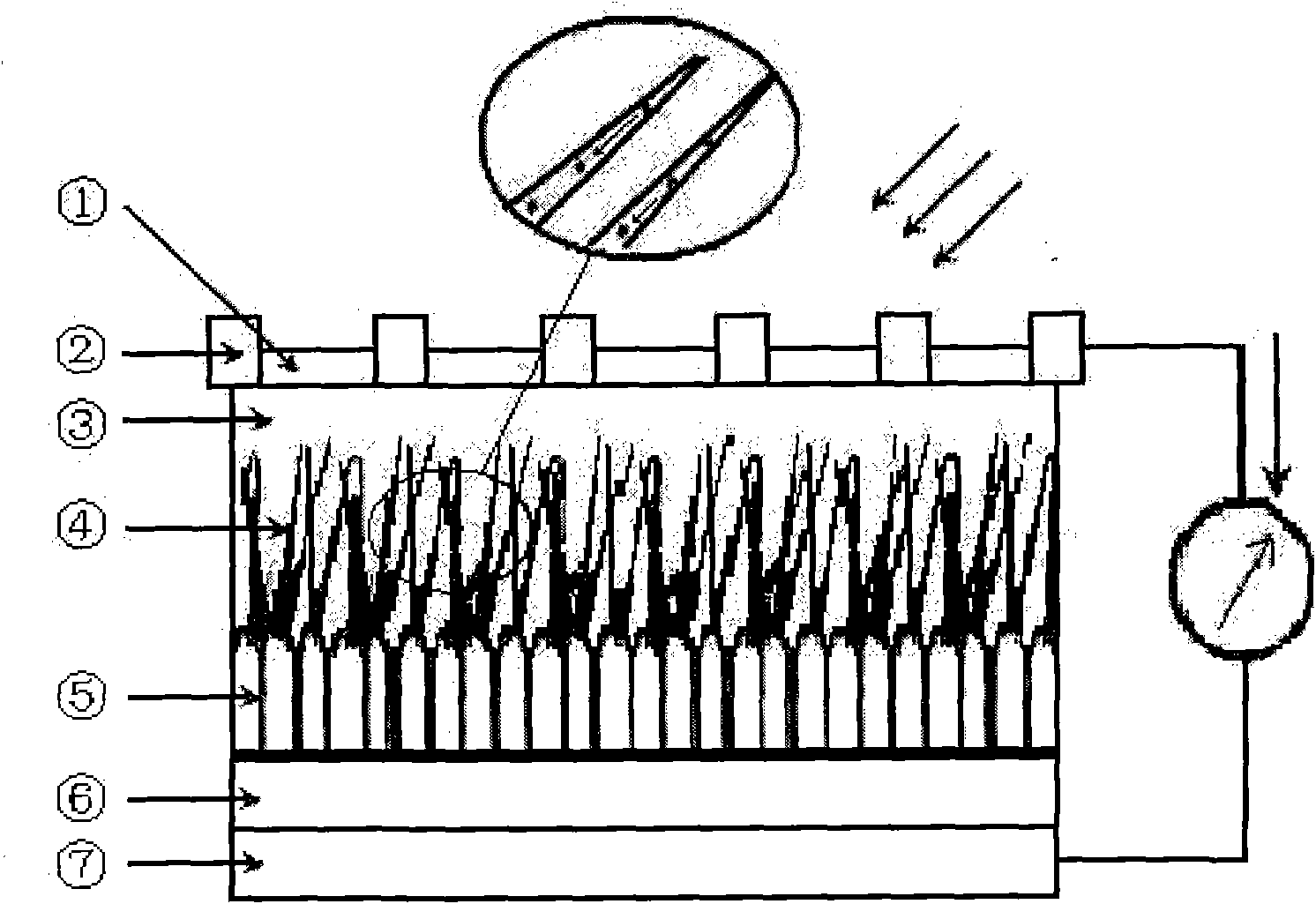

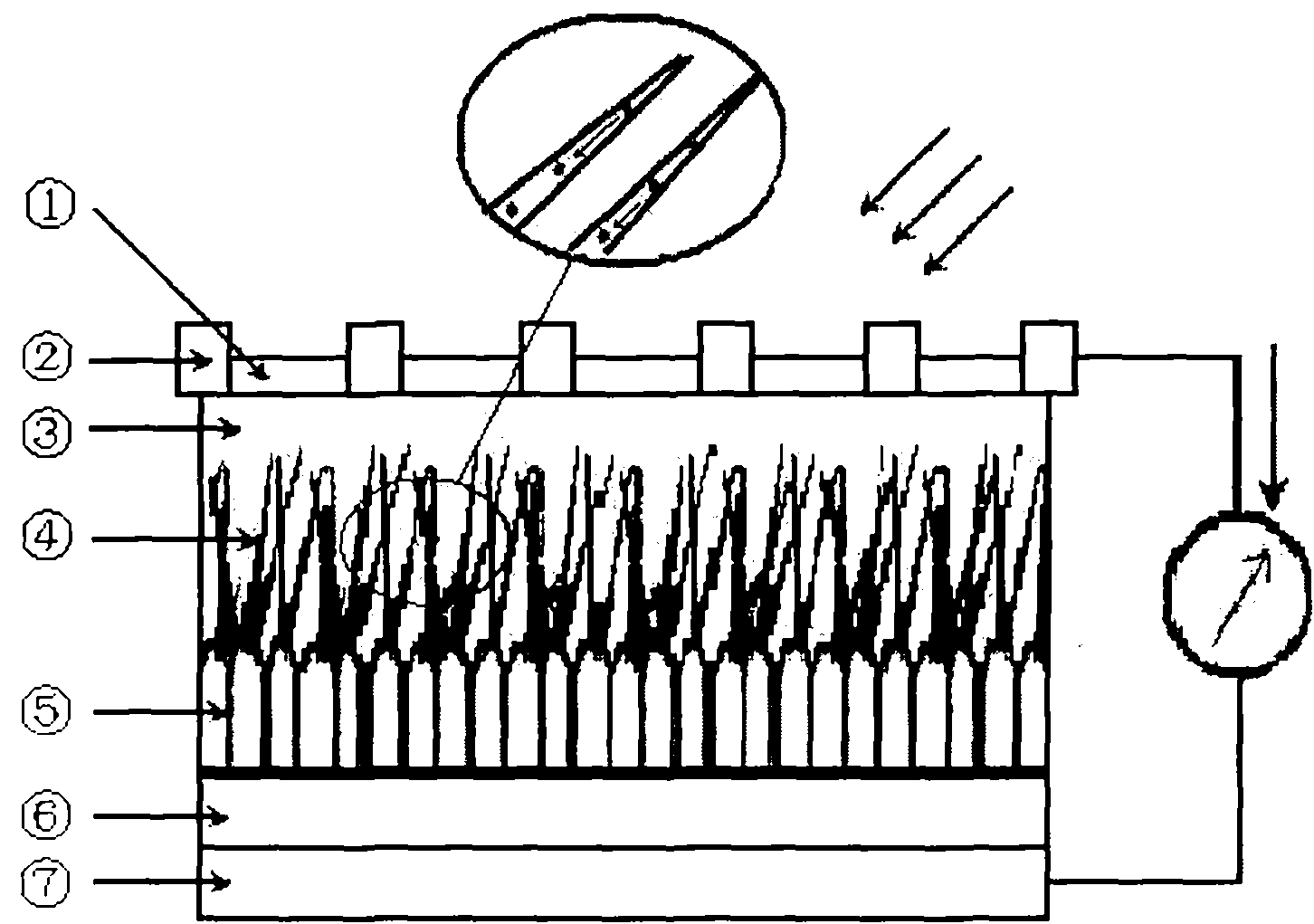

InactiveUS6863965B2Light weightLow costSynthetic resin layered productsVacuum evaporation coatingProduction rateOptoelectronics

This optical component includes a film formation substrate made of plastic, a magnesium fluoride film formed at an upper side of the film formation substrate and a first silicon oxide film formed on the magnesium fluoride film. The magnesium fluoride film may be formed on a surface of the film formation substrate. Alternatively, the optical component further may include a second silicon oxide film formed on a surface of the film formation substrate and between the film formation substrate and the magnesium fluoride film. The optical component can be realized, which is excellent in film adhesiveness, mechanical strength, drug resistance, environment resistance, and the like, as well as optical characteristics, and which is also excellent in productivity, film formation operability, cost, and the like.

Owner:FUJIFILM HLDG CORP +1

Preparation method of semiconductor nano-wire-based organic/inorganic composite solar cell

InactiveCN102148332ASmall lattice mismatchHigh degree of single crystalPolycrystalline material growthAfter-treatment detailsElectrochemical corrosionCorrosion

The invention discloses a preparation method of a semiconductor nano-wire-based organic / inorganic composite solar cell, belonging to the technical field of new energy resources. The method is characterized by comprising the following steps: preparing nano silicon with good light absorption performance in a visible light area by an electrochemical corrosion or hydrothermal corrosion technology; growing a zinc oxide or titanium dioxide or cadmium selenide nano-wire array on the nano silicon substrate by a high-temperature chemical vapor deposition method or low-temperature liquid phase chemical method; spinning poly-3-hexylthiophene (P3HT) or poly[2-methoxy-5-(2-ethyhexyloxy)-1,4-p-phenylene vinylene] (MEH-PPV) or poly(3-octylthiophene) (P3OT) on the nano-wire array to form a three-layer composite structure system; and finally preparing a magnesium fluoride or calcium fluoride surface anti-reflection film and metal film electrode to form a solar cell device. The process disclosed by the invention is simple, the operation is simply and easily implemented, the preparation conditions are mild, the repetition rate reaches 100%, and the prepared organic / inorganic composite material system is an important material for manufacturing a full-silicon-based solar cell device in the future.

Owner:BEIJING UNIV OF CHEM TECH

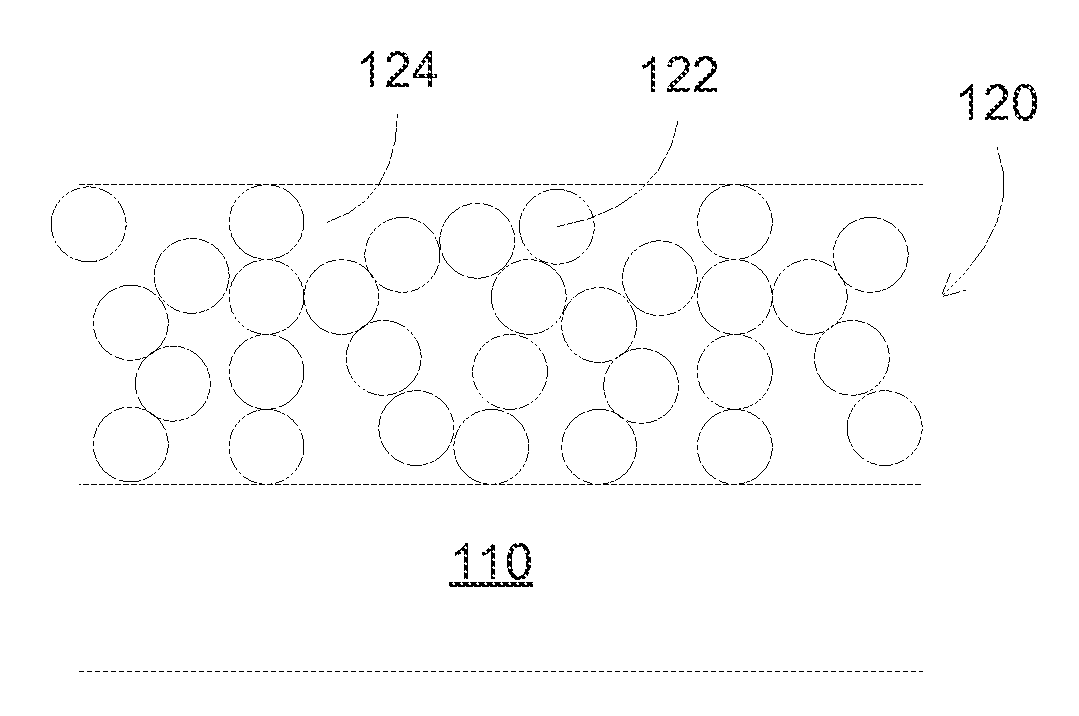

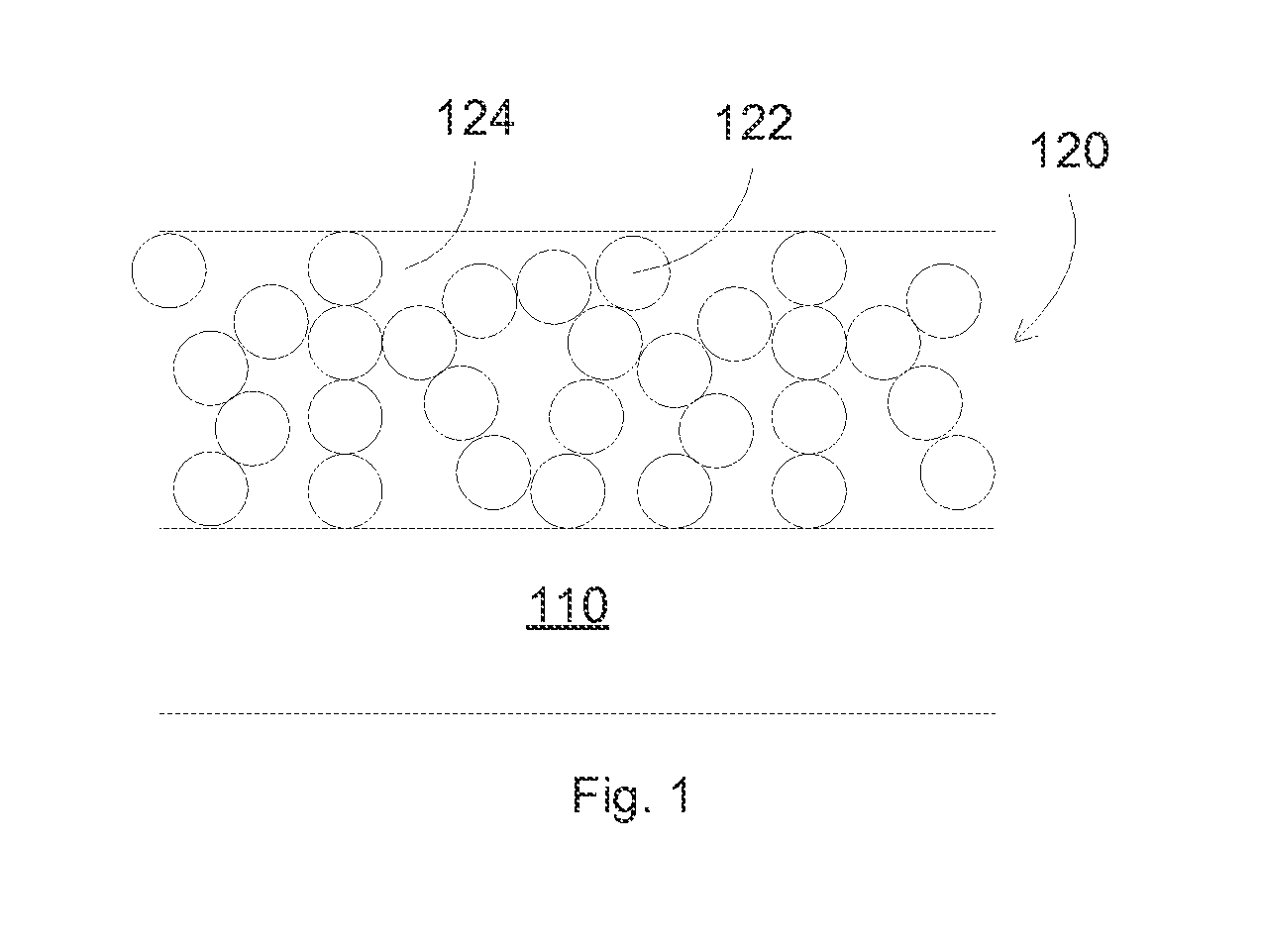

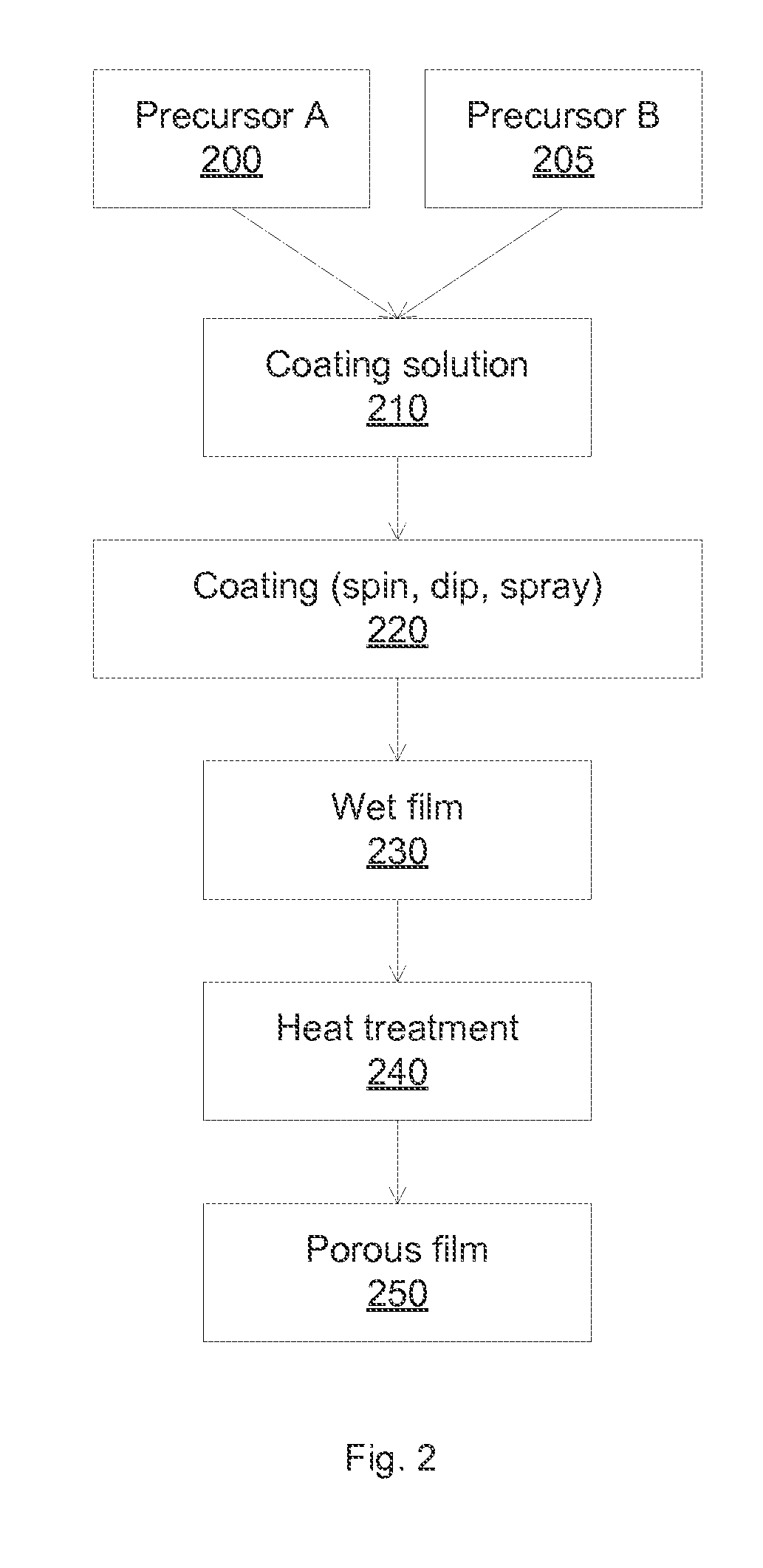

Magnesium Fluoride and Magnesium Oxyfluoride based Anti-Reflection Coatings via Chemical Solution Deposition Processes

InactiveUS20140147594A1Control levelPretreated surfacesLiquid/solution decomposition chemical coatingPorous coatingPhysical chemistry

Chemical solution deposition process can be used to deposit porous coatings containing magnesium fluoride and / or magnesium oxyfluoride. The chemical solution deposition process can utilize a solution containing a magnesium precursor, a fluorine precursor, together with a surfactant porogen. The surfactant porogen can improve the wettability of the coated layers, together with increase the control of the porosity level and morphology of the coated layers.

Owner:GUARDIAN GLASS LLC +1

Reflective aluminum nanorod array and method for realizing color hologram by using same

ActiveCN105068396ASimple processGood processing error toleranceNanoopticsInstrumentsDielectric substrateMagnesium fluoride

Owner:CHINA INFORMATION COMM TECH GRP CORP

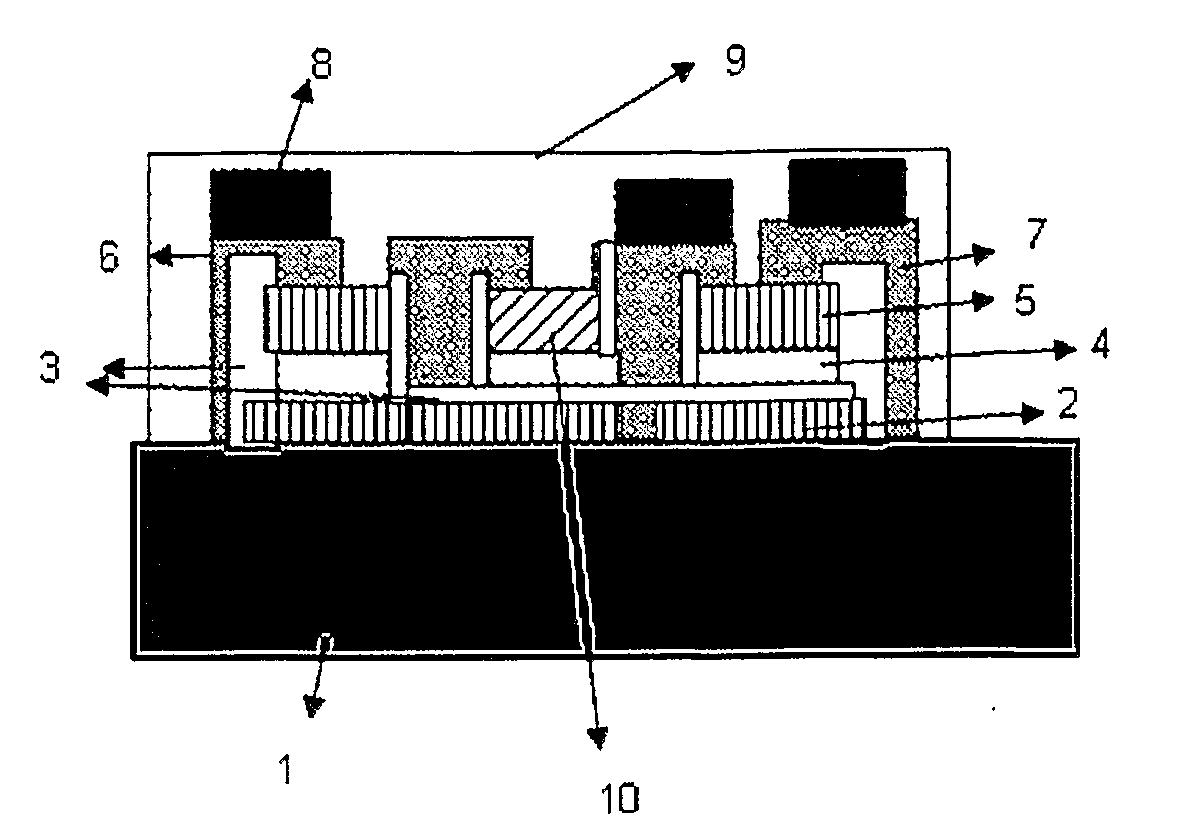

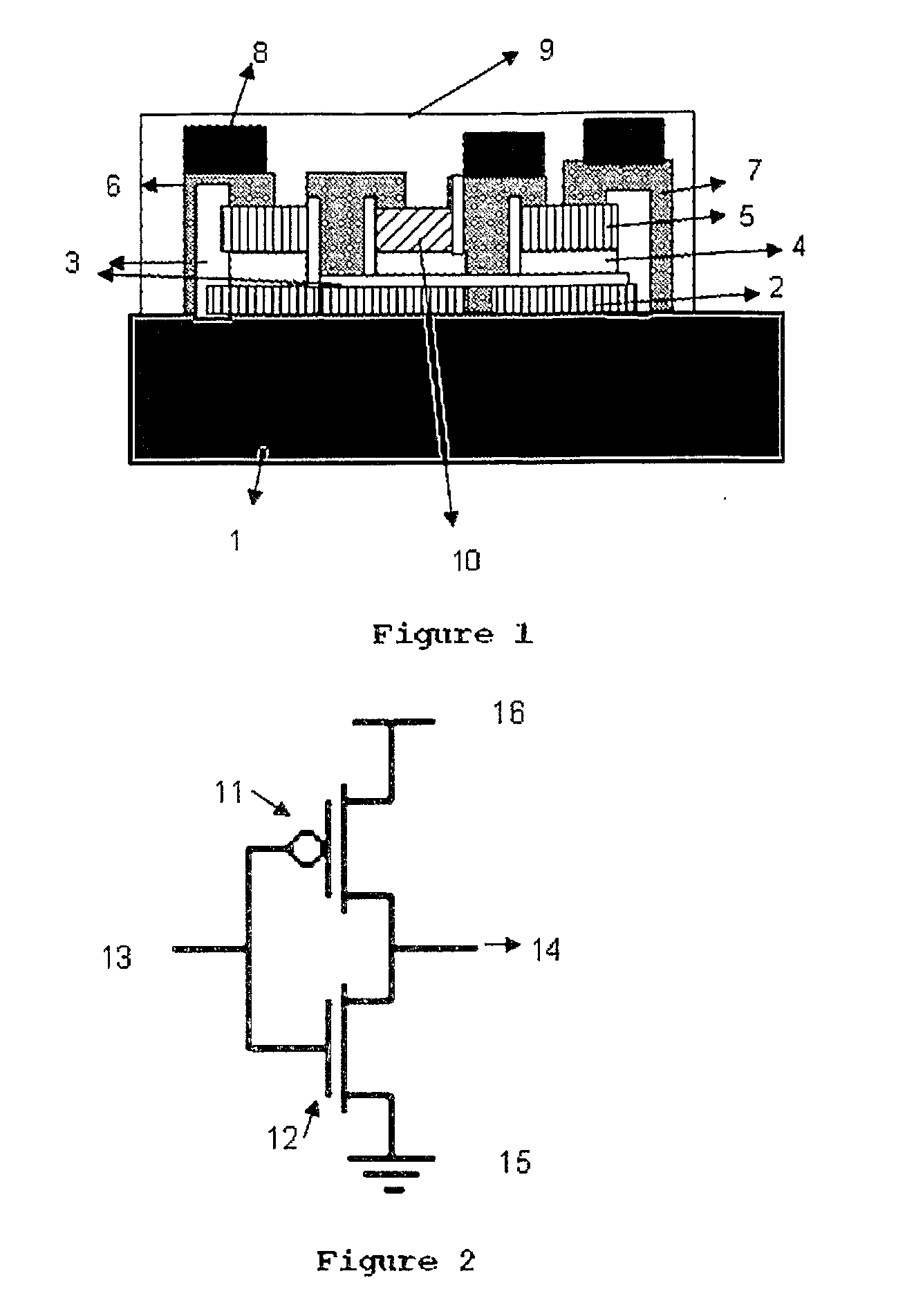

ELECTRONIC SEMICONDUCTOR DEVICE BASED ON COPPER NICKEL AND GALLIUM-TIN-ZINC-COPPER-TITANIUM p AND n-TYPE OXIDES, THEIR APPLICATIONS AND CORRESPONDING MANUFACTURE PROCESS

ActiveUS20100090216A1Easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionMetal foil

The present invention corresponds to the use of p and n-type oxide semiconductors based on copper nickel (OCux Niy, with 0<x<3; 0<y<3) or multicomponent Gallium-Tin-Zinc-Copper-Titanium oxide, designated here after as GSZTCO, in different molar compositions, having an amorphous or crystalline structure and with the electrical characteristics of a donor or electron acceptor semiconductor, doped or not doped with impurities, such as, Zirconium or nickel or nitrogen, as a way to control the semiconductor electronic behaviour (valence); including the manufacture process at room temperature or temperatures below 100° C. and their applications in optoelectronic and electronic fields is to manufacture devices, such as, Complementary-Metal-Oxide-Semi-conductors, thin film transistors, pn heterojunctions, logic gates, O-ring oscillators, using as substrate glass, metal foils, polymers or cellulose materials, in which a protection layer based on magnesium fluoride is used, together with a tantalum oxide matching layer of the active semiconductors to a dielectric, such as, silicon dioxide.

Owner:UNIV NOVA DE LISBOA

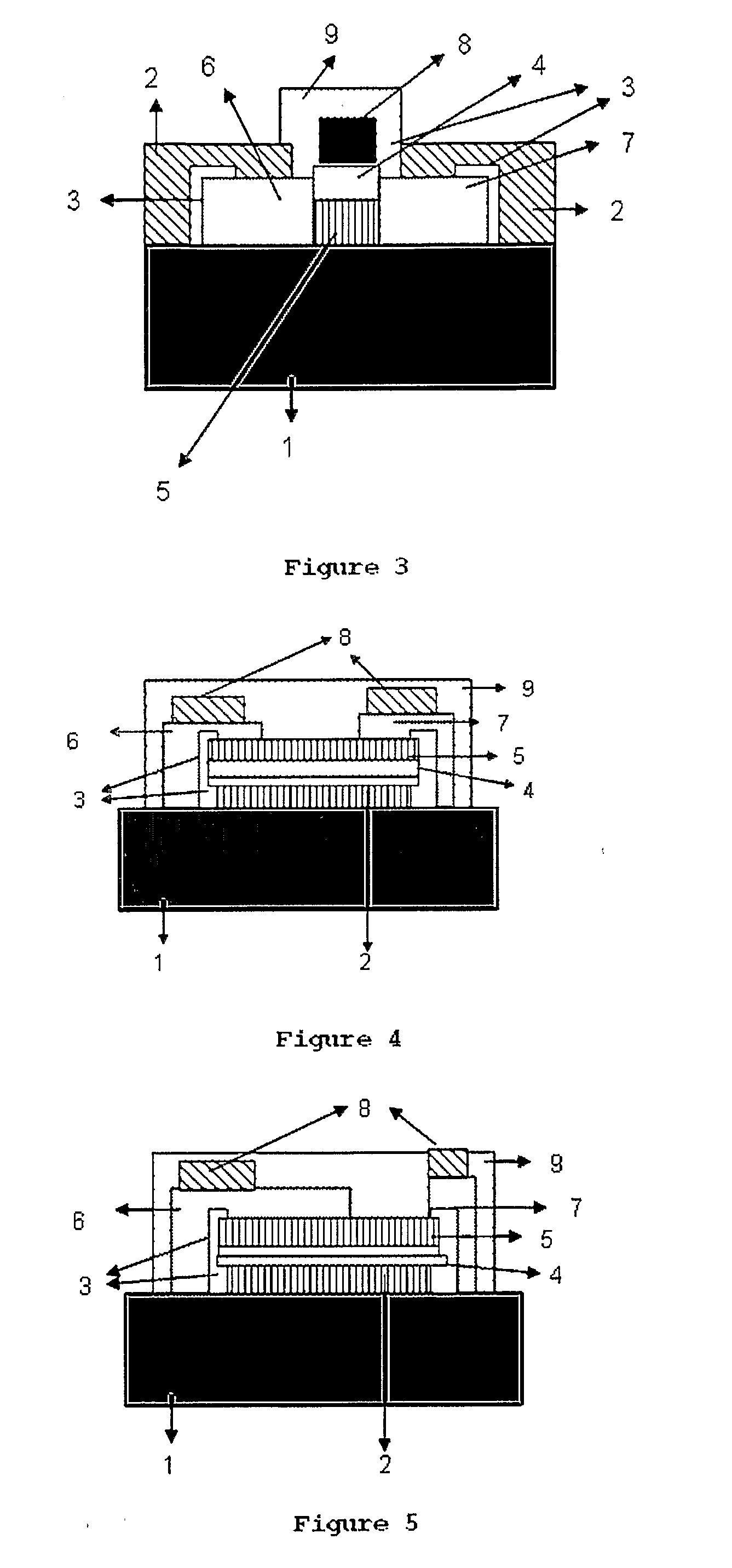

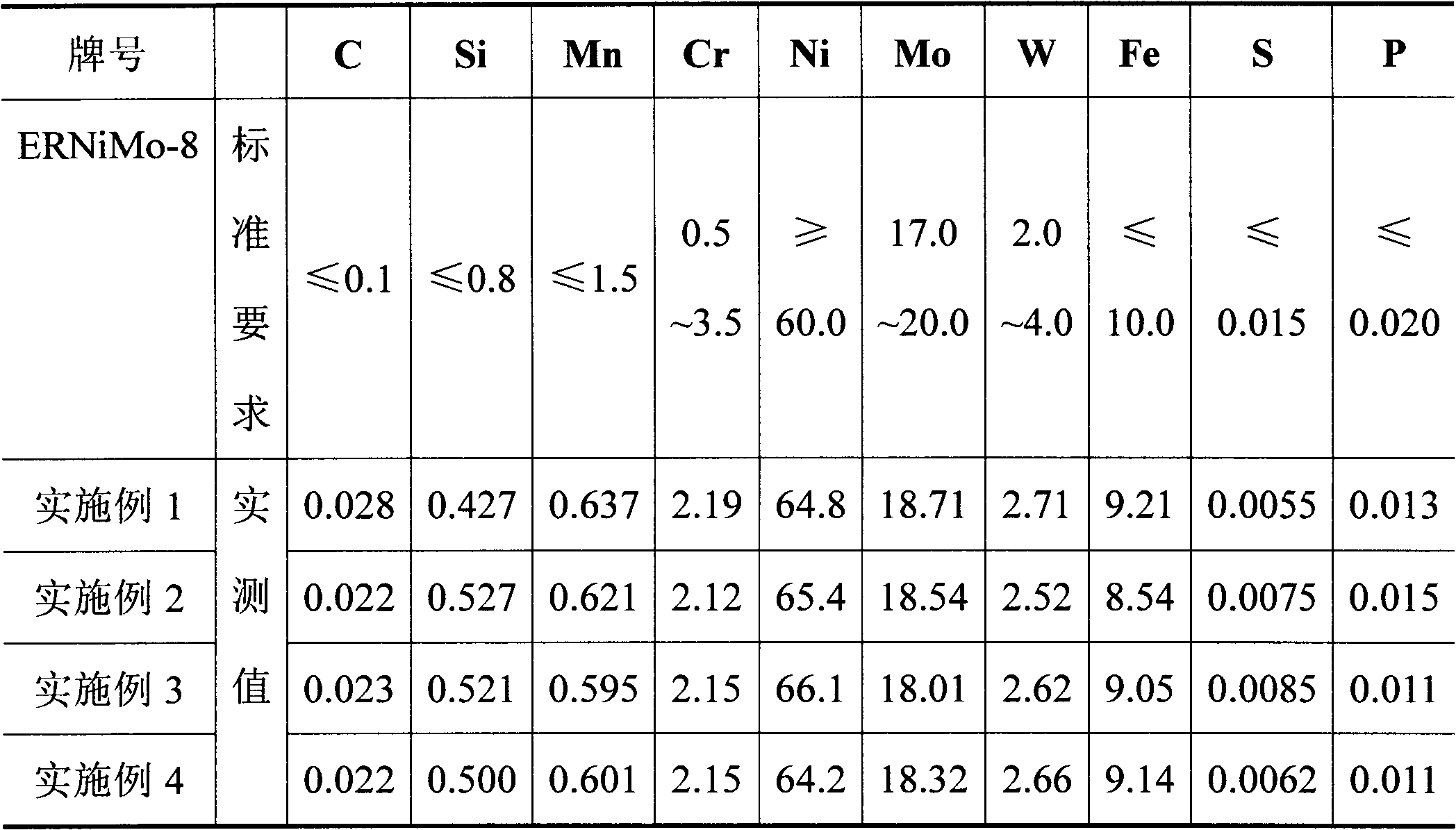

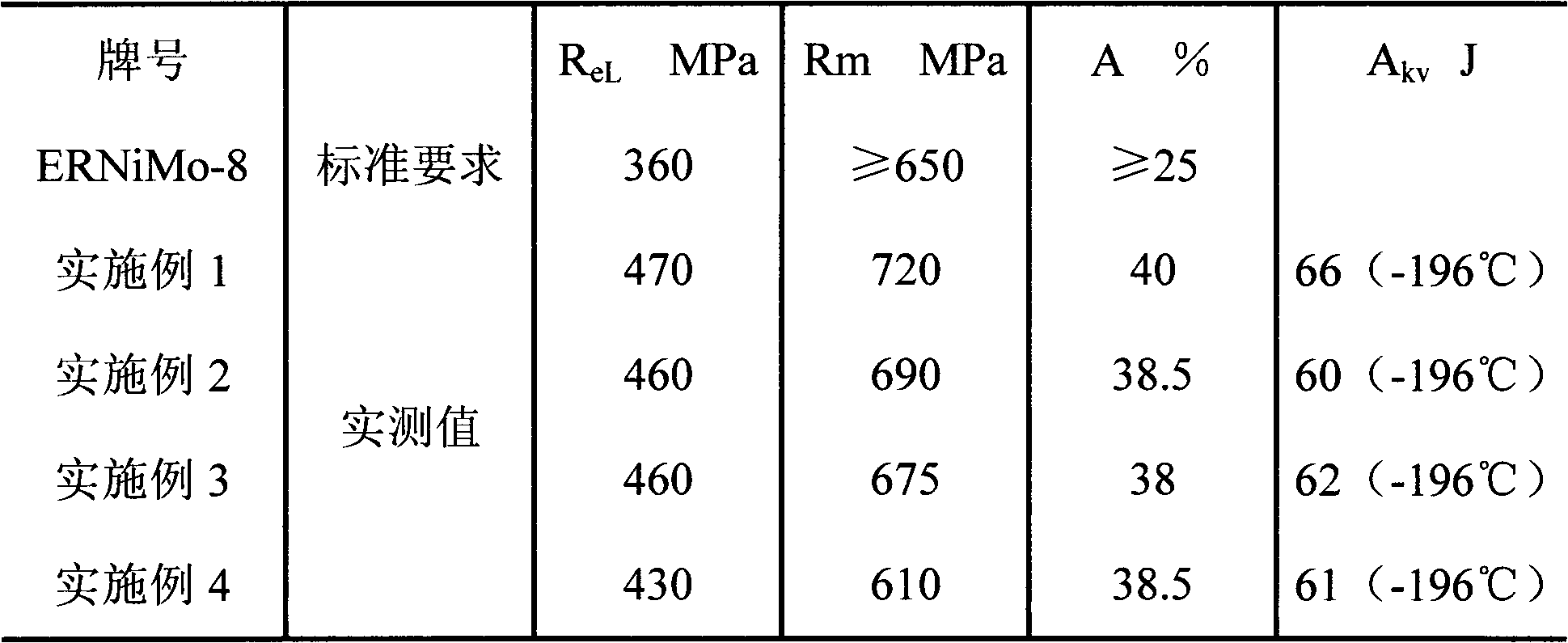

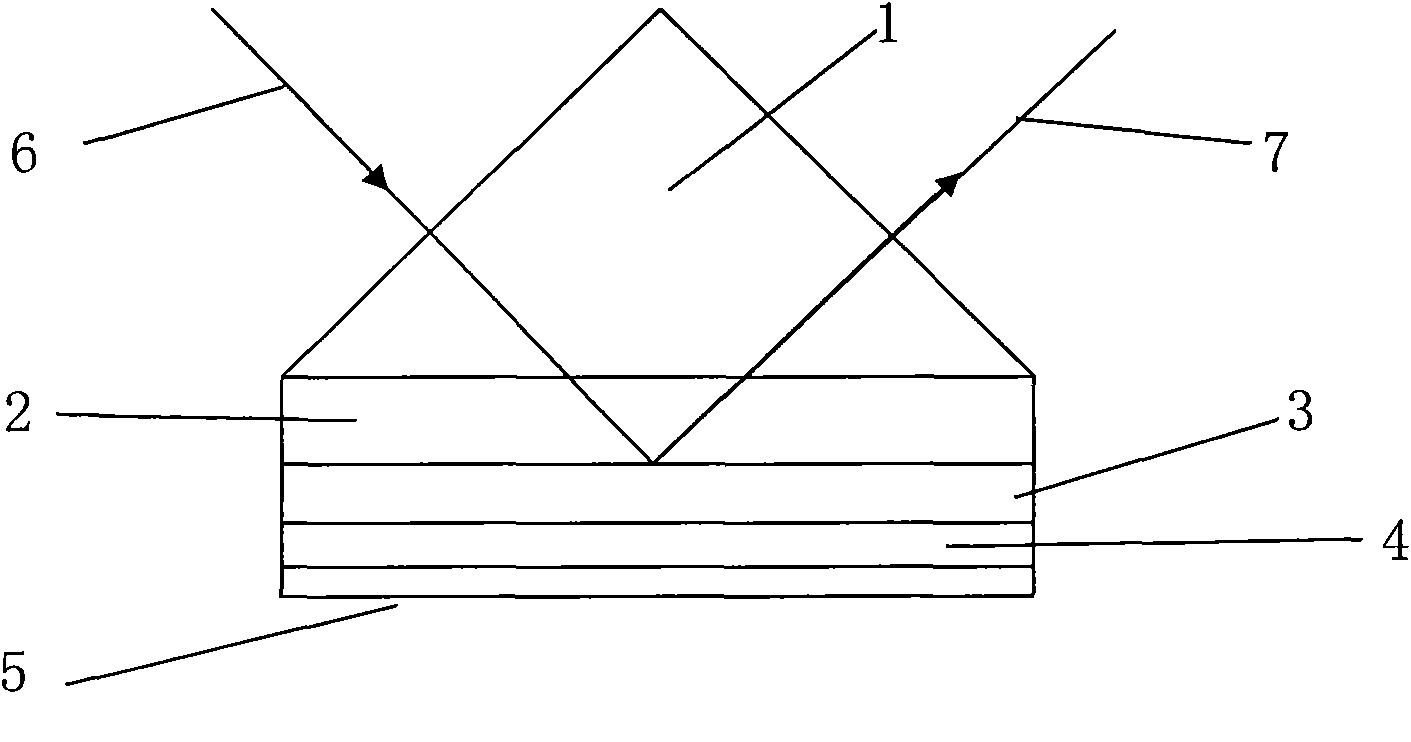

9Ni steel sintered flux and preparation method thereof

InactiveCN101954553AArc stabilizationBeautiful weld shapeWelding/cutting media/materialsSoldering mediaCooking & bakingWeld seam

The invention belongs to the field of welding material production, and discloses a 9Ni steel sintered flux and a preparation method thereof. The sintered flux comprises the following components in percentage by weight: 20 to 30 percent of dead-burned magnesite clinker, 8 to 18 percent of fluorite, 20 to 30 percent of corundum, 1 to 3 percent of elpasolite, 10 to 20 percent of grammite, 2 to 8 percent of strontium carbonate, 1 to 5 percent of rutile, 1 to 3 percent of silicon iron, 1 to 3 percent of ferrotitanium, 1 to 5 percent of manganese metal, 1 to 5 percent of magnesium fluoride and 1 to 3 percent of chromium oxide green. The preparation method comprises the following steps of: performing dry-mixing on mineral materials and iron alloy in a formula for 5 minutes; adding water glass to perform wet-mixing; then pelleting the mixture; drying pellets for 3 hours under the atmospheric environment; baking the pellets in a baking oven at a low temperature of 150 DEG C for 2 hours; then baking the pellets at a high temperature of 800 DEG C for 1 hour; performing furnace cooking, and crushing and screening the pellets to obtain a 12-60-mesh finished product of the flux. When the flux disclosed by the invention is matched with an ERNiMo-8 welding wire to perform welding, the flux has the following characteristics that: 1) a welding seam process has high performance, electric arcs during welding are stable, the surface of a welding seam is white and bright without an oxide color, molten slag is turned up automatically and can be taken off with a slight contact, the welded seam is formed to have a beautiful appearance, the welding bead height is moderate, and the welded same infiltration angle is moderate; 2) the flux can be matched with the ERNiMo-8 welding wire in use, and the comprehensive mechanical property is high; and 3) the flux can be matched with the ERNiMo-8 in use, and the chemical components of a deposited metal are easy to control.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Nickel-based welding rod for welding of ultralow-temperature container steel

InactiveCN106514049ASimple welding processImprove low temperature toughnessWelding/cutting media/materialsSoldering mediaAlternating currentRutile

The invention discloses a nickel-based welding rod for welding of ultralow-temperature container steel and belongs to the technical field of nickel-based welding rods. The nickel-based welding rod comprises a welding core and a coating covering the surface of the welding core. The welding core comprises the chemical components of, by weight percentage, 0-0.1% of C, 0-0.6% of Si, 1.5%-4.5% of Mn, 0-0.012% of S, 0-0.015% of P, 0-17.0% of Cr, 4.5%-9.5% of Mo, 0.5%-2.0% of Nb, 0.5%-2.0% of W, and the balance Ni. The coating comprises the powdery materials of, by weight percentage, 20%-38% of marble, 5%-8% of strontium carbonate, 1%-4% of potassium feldspar, 3%-13% of fluorite, 2%-10% of magnesium fluoride, 3%-15% of cryolite, 10%-20% of rutile, 2%-7% of ferrotitanium, 2%-6% of ferro-aluminium, 0.5%-2% of aluminum magnesium powder, 4%-7% of ferro-molybdenum, 2%-5% of ferroniobium and 1%-3% of ferrotungsten, and the sum of all the components is 100%. The nickel-based welding rod has excellent welding manufacturability in horizontal, transverse, vertical, overhead and other welding positions when an alternating current power source is adopted for welding, and the nickel-based welding rod also has excellent low temperature toughness.

Owner:CENT IRON & STEEL RES INST

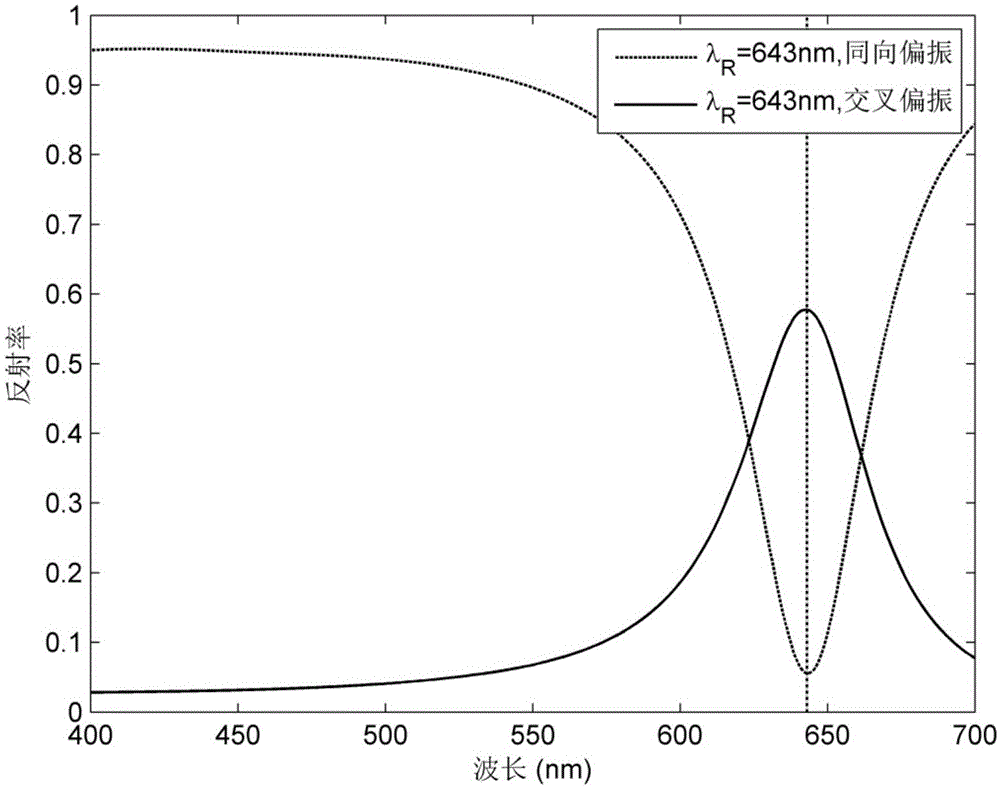

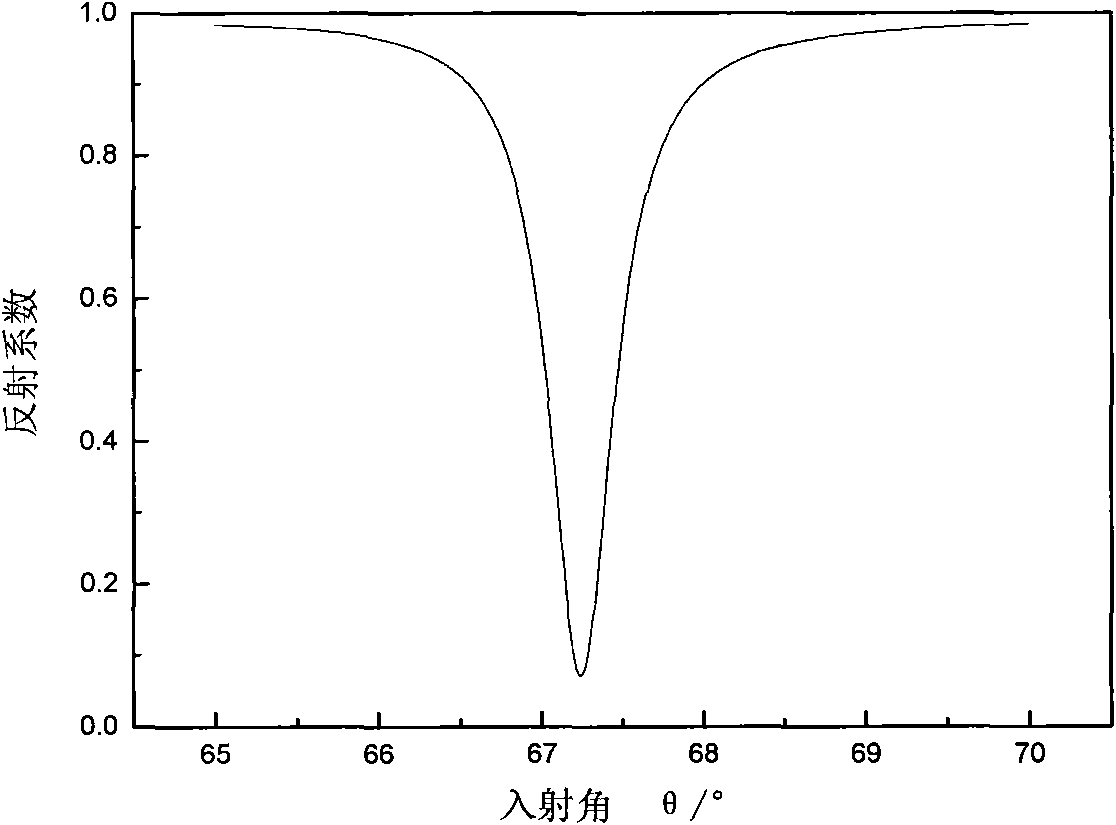

Long-range surface plasma resonance sensor and preparation method thereof

InactiveCN101936899AHigh sensitivityEasy to depositPhase-affecting property measurementsVacuum evaporation coatingResonance angleRefractive index

The invention discloses a long-range surface plasma resonance sensor and a preparation method thereof. The sensor is formed by bonding a BK7 prism and a glass slide through cedar oil, wherein the outer surface of the glass slide is plated with a magnesium fluoride thin film, a silver film and a gold film in turn; the gold film is directly contacted with biological solution to be detected and is used for detecting the biological solution in a mode of angle modulation; magnesium fluoride with the refractive index of about 1.38, which is close to that of the biological solution, can form approximatively symmetric structures on two sides of a metal conductive layer so as to ensure that surface plasmas on the two sides of the metal conductive layer are coupled to form the long-range surface plasma; compared with other metals, the metal silver used as the conductive layer has a narrower half band width of a resonance absorption peak, but has unsteady chemical properties; a conductive layer gold film can make a resonance angle generate a greater transition along with the change of the refractive index of the biological solution to be detected; simultaneously, the conductive layer gold film has stable chemical properties and high biological affinity. The specific multilayer film structure can integrate the advantages of each film and effectively improve the sensitivity of biological sensors.

Owner:EAST CHINA NORMAL UNIV

Method for extracting valuable metal from cobalt metallurgical waste

InactiveCN107058745AHigh recovery rateShort processCalcium/strontium/barium sulfatesProcess efficiency improvementSlagManganese

The invention provides a method for extracting valuable metal from cobalt metallurgical waste. The method comprises the following steps of S1, calcium removal, S2, copper separation, S3, calcium and magnesium removal, and S4 zinc separation. The method has the beneficial effects that 1, impurity removal liquid generated by the impurity removal procedure of cobalt wet metallurgy P204 or the valuable metal in manganese-rich slag after the impurity removal liquid is precipitated can be sufficiently utilized; 2, the metal recovery rate of the method is high, the recovery rate of calcium can reach 85% or over, and the recovery rates of copper, cobalt, manganese and zinc can reach 90% or over; 3, the technological process of the method is short and only has four steps, and applied raw and auxiliary materials are easy to obtain and low in cost; and 4, the technological process does not involve high temperature or high pressure, reaction conditions are mild, and the number of potential safety hazards is small. Calcium sulfate generated through the method can serve as a raw material for production of cement, a small amount of generated calcium fluoride slag and a small amount of generated magnesium fluoride slag can be sent to a fluorination plant to serve as raw materials, and environmental friendliness is achieved.

Owner:青海快驴高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com