Patents

Literature

84results about How to "Improve wear and scratch resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

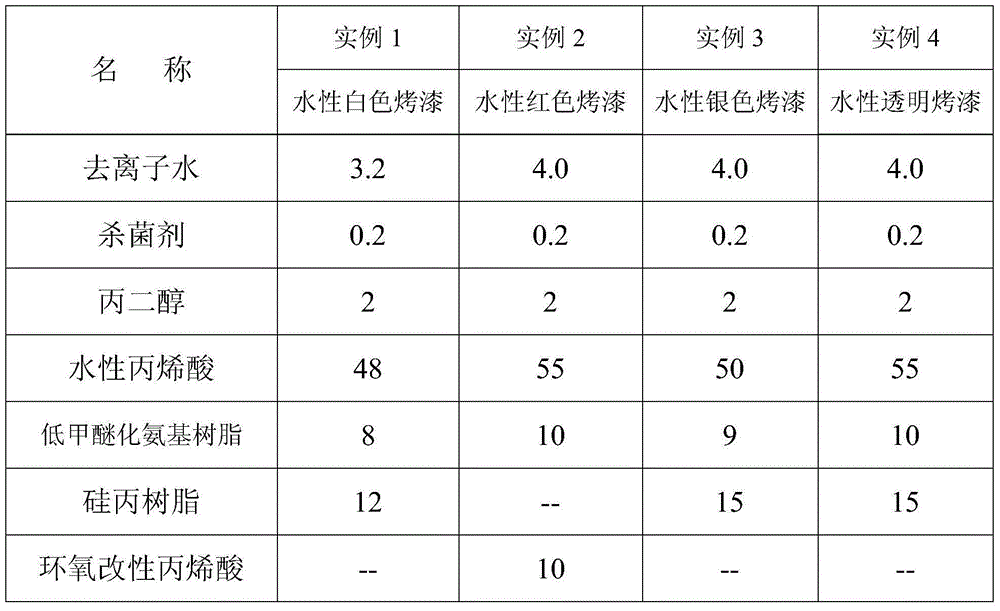

Preparation method of low-temperature curing water-based glass baking paint

ActiveCN103937360AIncrease the degree of cross-linkingLow curing temperatureCoatingsWater basedAcrylic resin

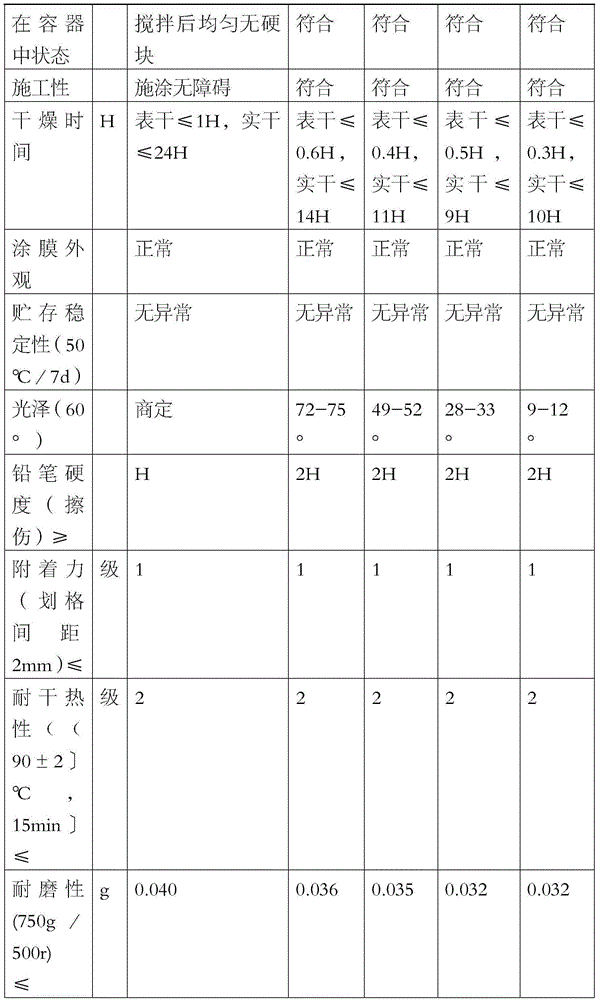

The invention relates to a preparation method of a low-temperature curing water-based glass baking paint composed of acrylic resin, amino resin, hydroxyl resin, a pigment or a colorant, a wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared low-temperature curing water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage; and a prepared paint film has the hardness reaching 2 H or more, has excellent anti-scratch wear-resisting properties, and is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

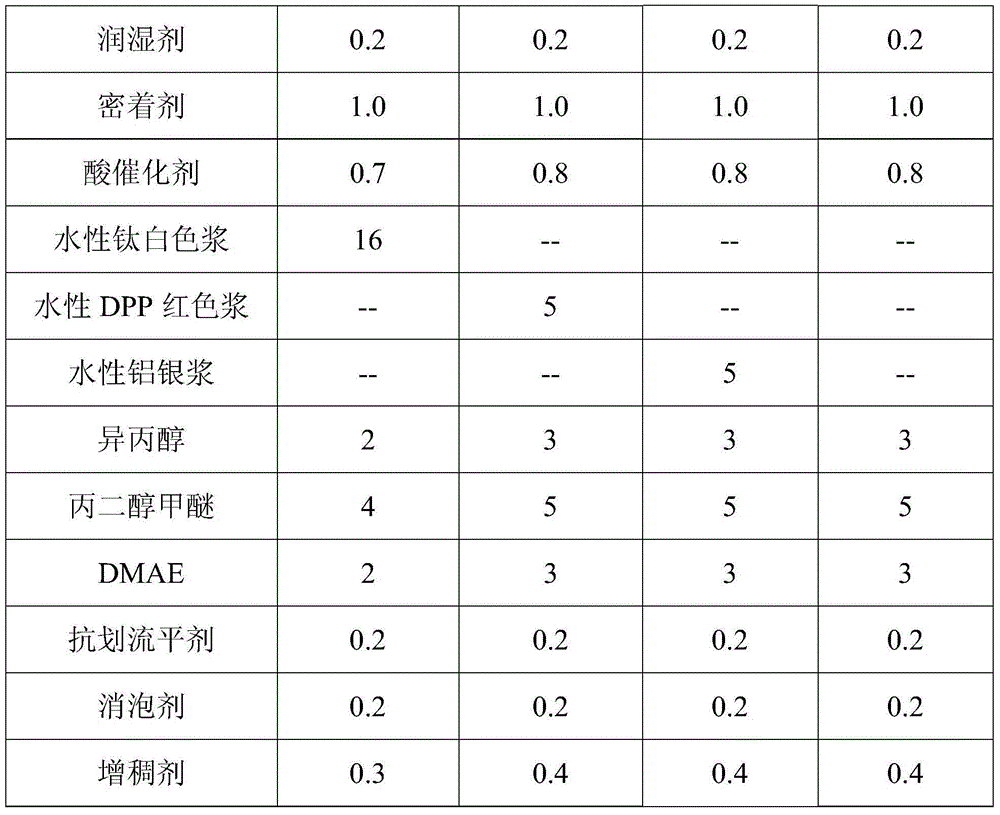

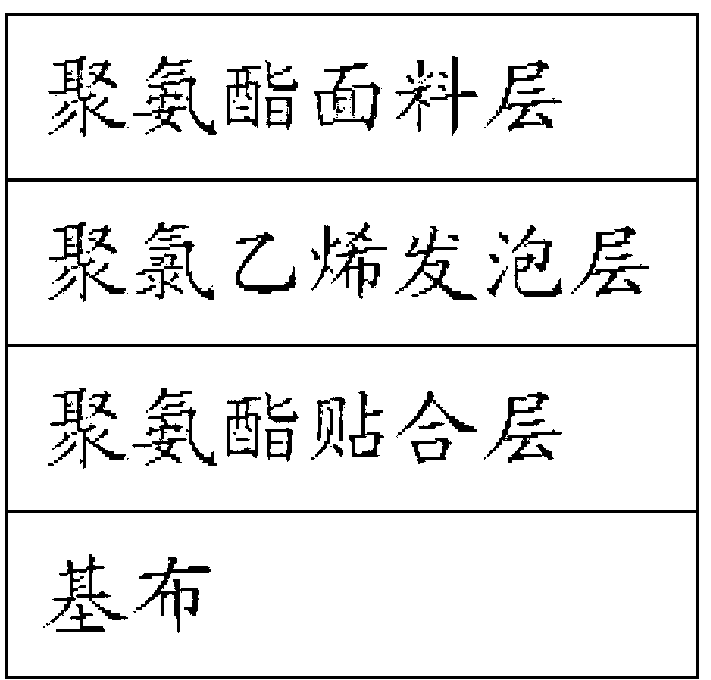

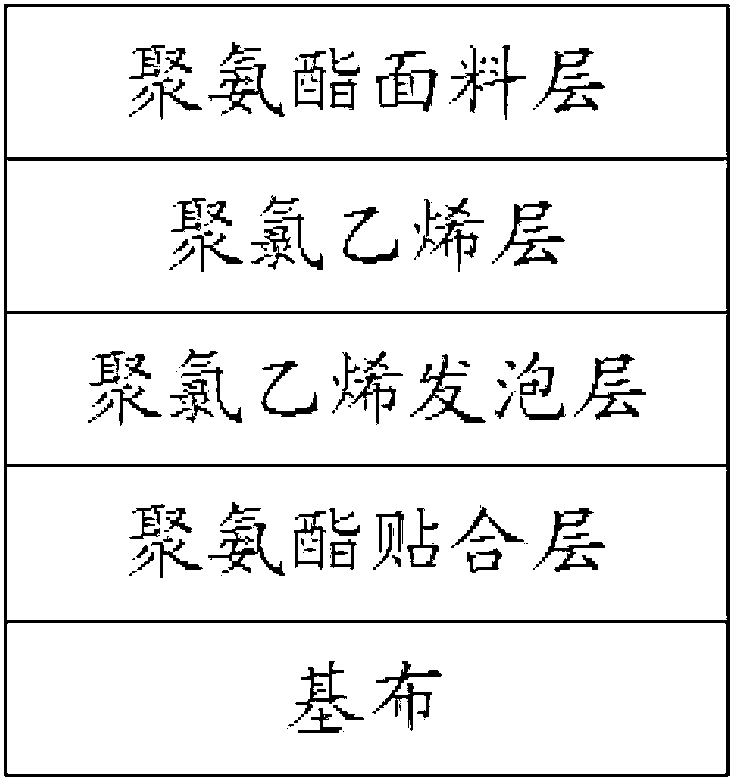

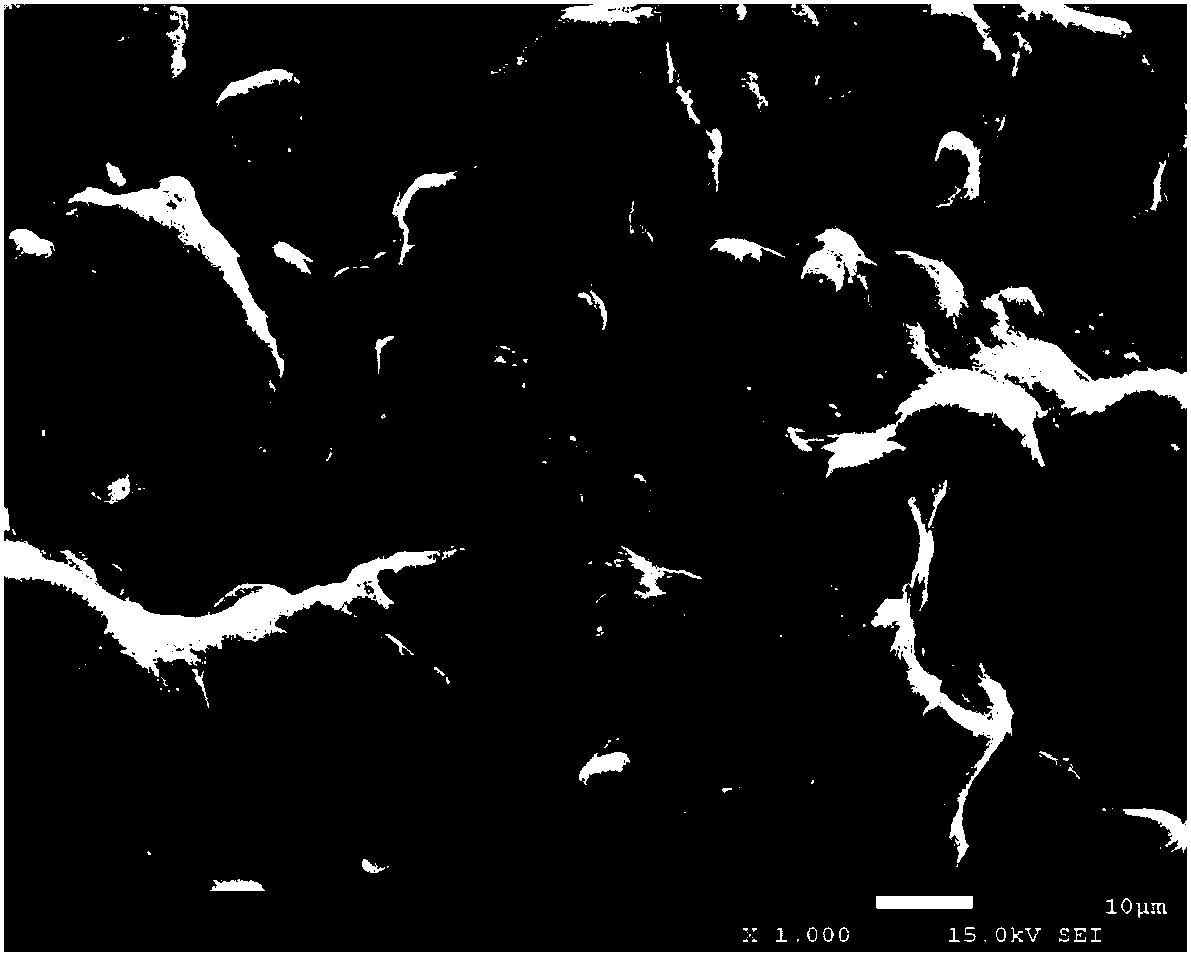

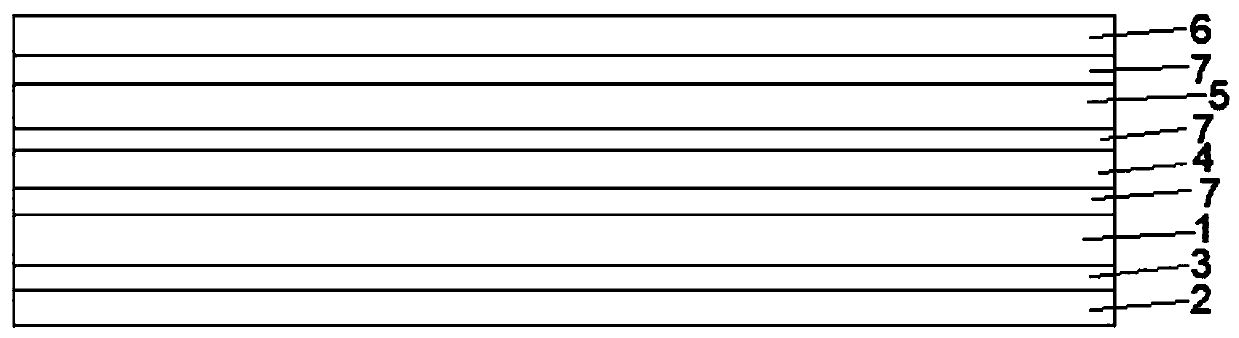

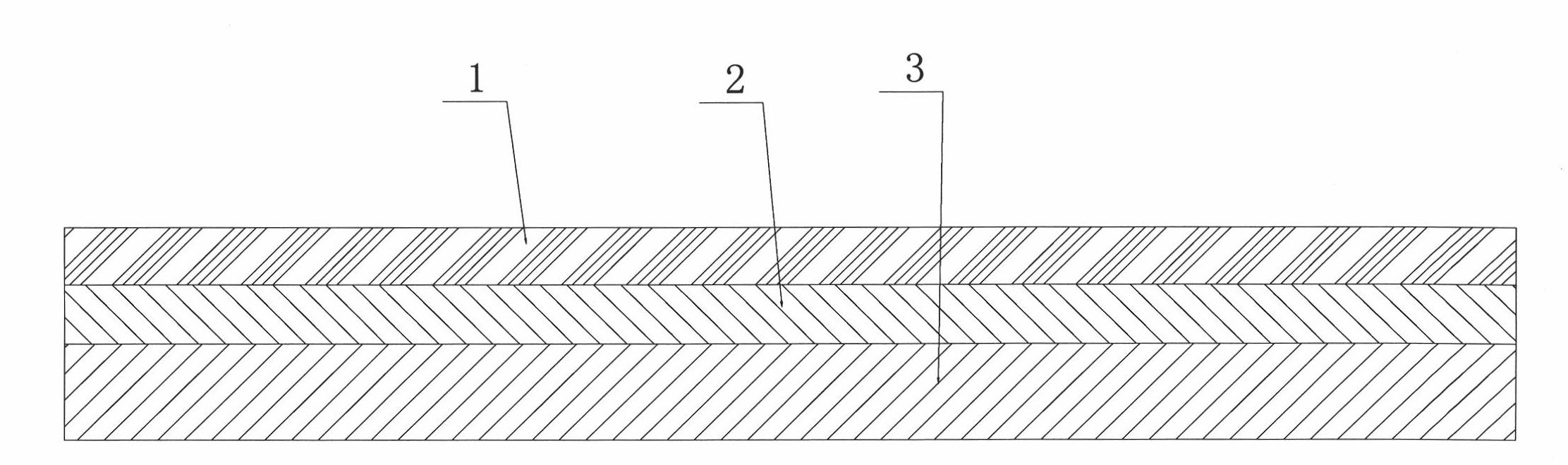

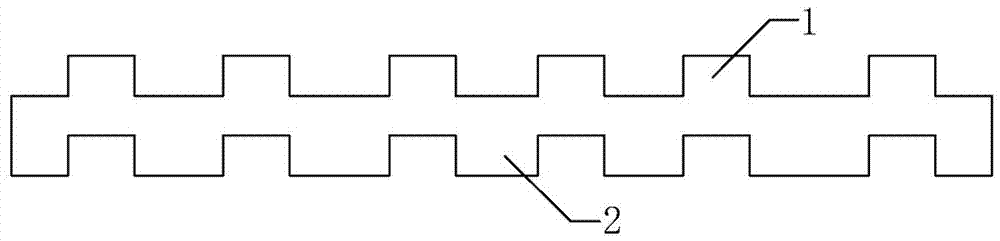

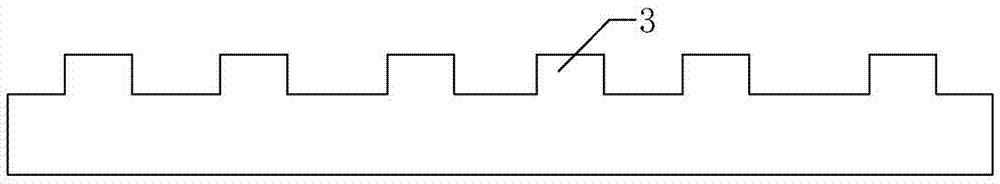

PU/PVC synthetic leather and its manufacturing method

ActiveCN102797164AImprove wear and scratch resistanceLamination ancillary operationsSynthetic resin layered productsWear resistantPolyvinyl chloride

The invention relates to the synthetic leather manufacturing field, especially to a wear-resistant and scratch-resistant PU / PVC (polyurethane / polyvinyl chloride) synthetic leather and its manufacturing method. The synthetic leather includes a base cloth layer, a polyurethane bonding layer, a polyvinyl chloride foaming layer, as well as a polyurethane fabric layer, and additionally includes a polyvinyl chloride layer, which is positioned between the polyvinyl chloride foaming layer and the polyurethane fabric layer. For the PU / PVC synthetic leather provided in the invention, under the circumstance of not changing the original physical circumstances of the PU / PVC synthetic leather, and by adding a polyvinyl chloride layer between the polyvinyl chloride foaming layer and the polyurethane fabric layer, the synthetic leather surface and the polyvinyl chloride foaming layer are separated. By making use of the scratch-resistant and wear-resistant characteristics of the polyvinyl chloride layer, the scratch resistance and wear resistance of the PU / PVC synthetic leather are greatly enhanced. Martindale wear resistant tests prove that the PU / PVC synthetic leather provided in the invention can resist wear up to over 100000 times.

Owner:FUJIAN POLYTECH TECH CO LTD

Wear-resistant Buna-N rubber thermoplastic elastomer composition and preparation method thereof

The invention discloses a wear-resistant Buna-N rubber thermoplastic elastomer composition and a preparation method thereof. The wear-resistant Buna-N rubber thermoplastic elastomer composition is prepared from Buna-N rubber, modified resin, a high-hardness silicate mineral substance and conventional auxiliary agents by blending. Raw materials of the wear-resistant Buna-N rubber thermoplastic elastomer composition comprise: by mass, 100 parts of Buna-N rubber (NBR), 0 to 60 parts of polyvinyl chloride (PVC) resin, 0 to 50 parts of styrene-butadiene-styrene block copolymer (SBS), 0 to 30 partsof a plasticizer dioctyl phthalate (DOP), 5.0 parts of a calcium-zinc composite stabilizing agent, 0 to 1.0 part of zine stearate, 0 to 0.6 parts of calcium stearate, 0.6 parts of eleaostearic acid, 0 to 0.5 parts of a composite antioxidant, 0 to 10 parts of potter's clay, and 15 to 60 parts of the high-hardness silicate mineral substance. The wear-resistant Buna-N rubber thermoplastic elastomer composition has excellent elasticity of a rubber elastomer, good scratch resistance and wear resistance and low raw material prices and can be recycled. The preparation method of the wear-resistant Buna-N rubber thermoplastic elastomer composition has simple preparation processes and a low production cost, and utilizes waste and old resources.

Owner:CHINA PETROLEUM & CHEM CORP

Material used for manufacturing handle of refrigerator door and preparation method thereof

ActiveCN103044862AIncrease the number of door openingsImprove mechanical propertiesRefrigerator carAcrylonitrile

The invention relates to a material used for manufacturing a handle of a refrigerator door and a preparation method thereof. The material composition comprises the following components in parts by weight: 40-83 parts of polybutylene terephthalate, 5-25 parts of acrylonitrile- styrene-acrylonitrile composition, 10-35 parts of glass fiber, 3-20 parts of crystal whisker, 2-10 parts of a compatilizer, 0.03-2 parts of an antibacterial agent, 0.01-2 parts of a lubricating agent and 0.01-2 parts of other auxiliaries; and the components are mixed in the formula, and then extrusion pelleting is carried out by virtue of an extruding machine, so that the material composition product is obtained. Compared with the prior art, the material composition provided by the invention is subjected to moulding and processing, the prepared handle of the refrigerator door is smooth and produces no warpage on the surface, no glass fiber is exposed, dimensional stability is good, and the prepared handle of the refrigerator door is resistant to scraping and has excellent antibacterial property.

Owner:HEFEI GENIUS NEW MATERIALS

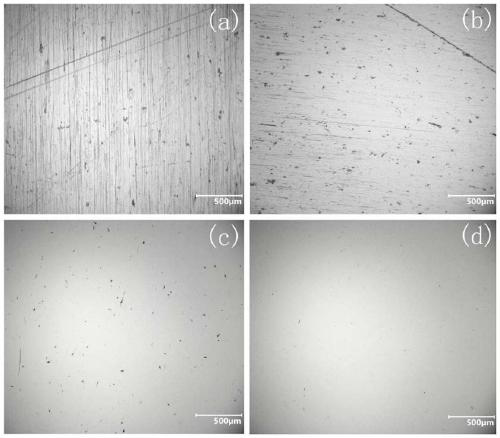

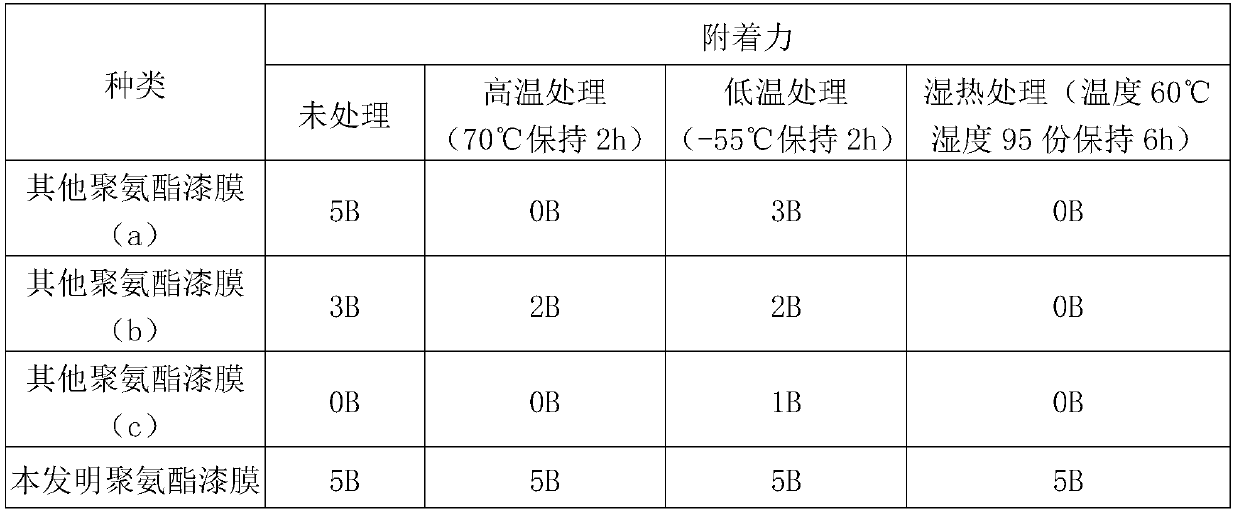

High-adhesion scratch-resistant wear-resistant polyurethane transparent coating material

ActiveCN111303754AImprove aging resistanceSmall particle sizeFireproof paintsPolyurea/polyurethane coatingsPolymer scienceSunscreen agents

The invention provides a high-adhesion scratch-resistant wear-resistant polyurethane transparent coating material, and relates to the technical field of coating materials. In the transparent coating material, the content of polyurethane soft segments ranges from 35% to 45%, and the polyurethane coating material is a two-component coating material and comprises a coating material agent A and a coating material agent B, wherein the coating material agent A comprises polyol, a chain extender, a catalyst, an adhesion promoter, a solvent, a leveling agent, a wetting agent and a sun-screening agent,and the coating material agent B is aliphatic diisocyanate. According to the invention, the polyurethane paint film has excellent mechanical properties and good resilience, and can significantly enhance the wear resistance and the scratch resistance of the polyurethane paint film, and after the paint film is scratched, scratches can be automatically repaired as before in a short time, so that theuse effect and protection effect of the product are improved, and good scratch resistance and wear resistance of the product are realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

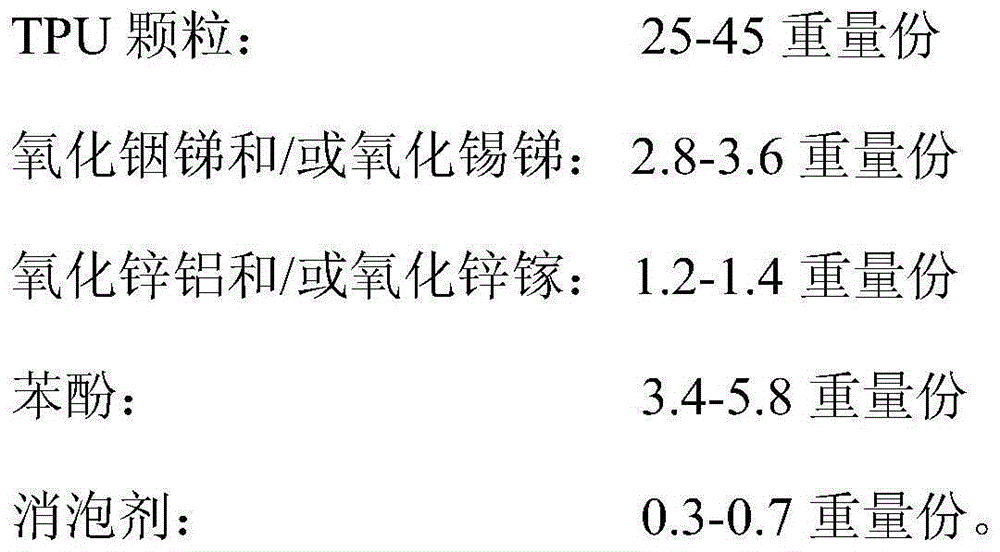

Thermal insulation TPU thin film for automobile film pasting and preparation method thereof

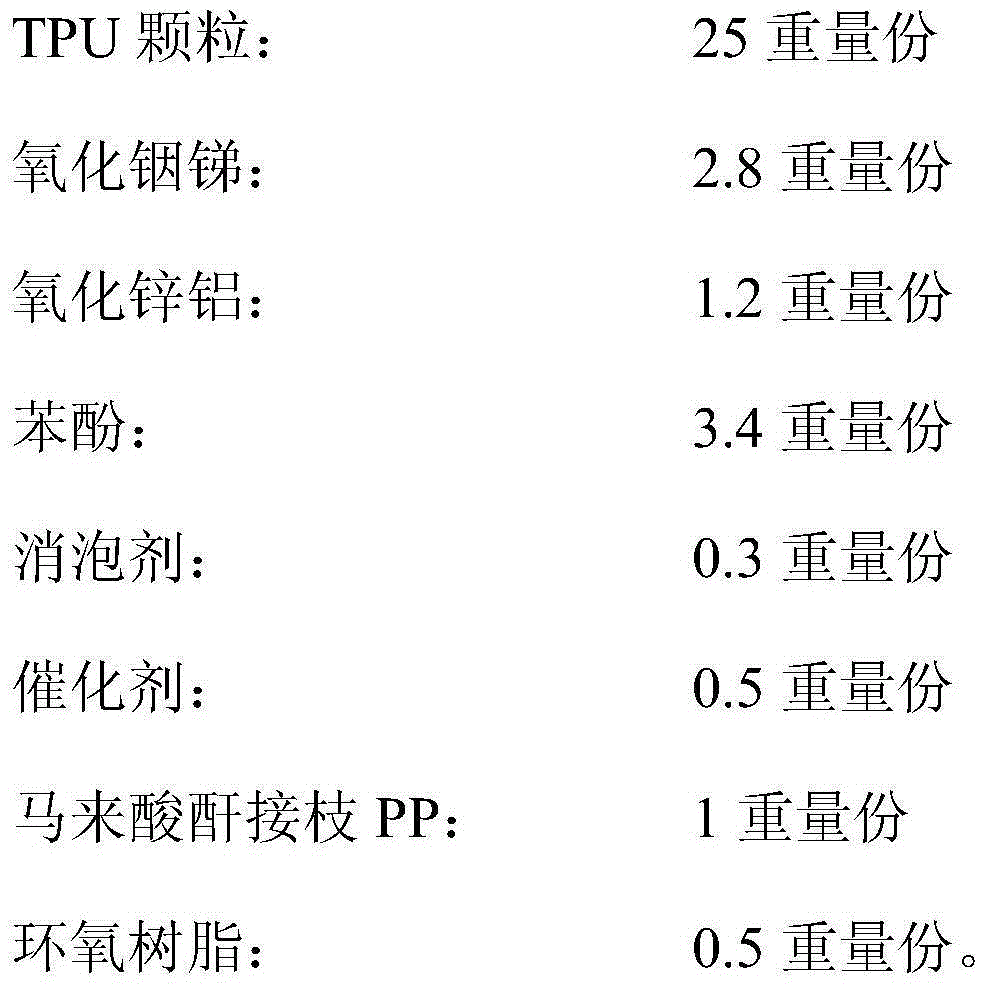

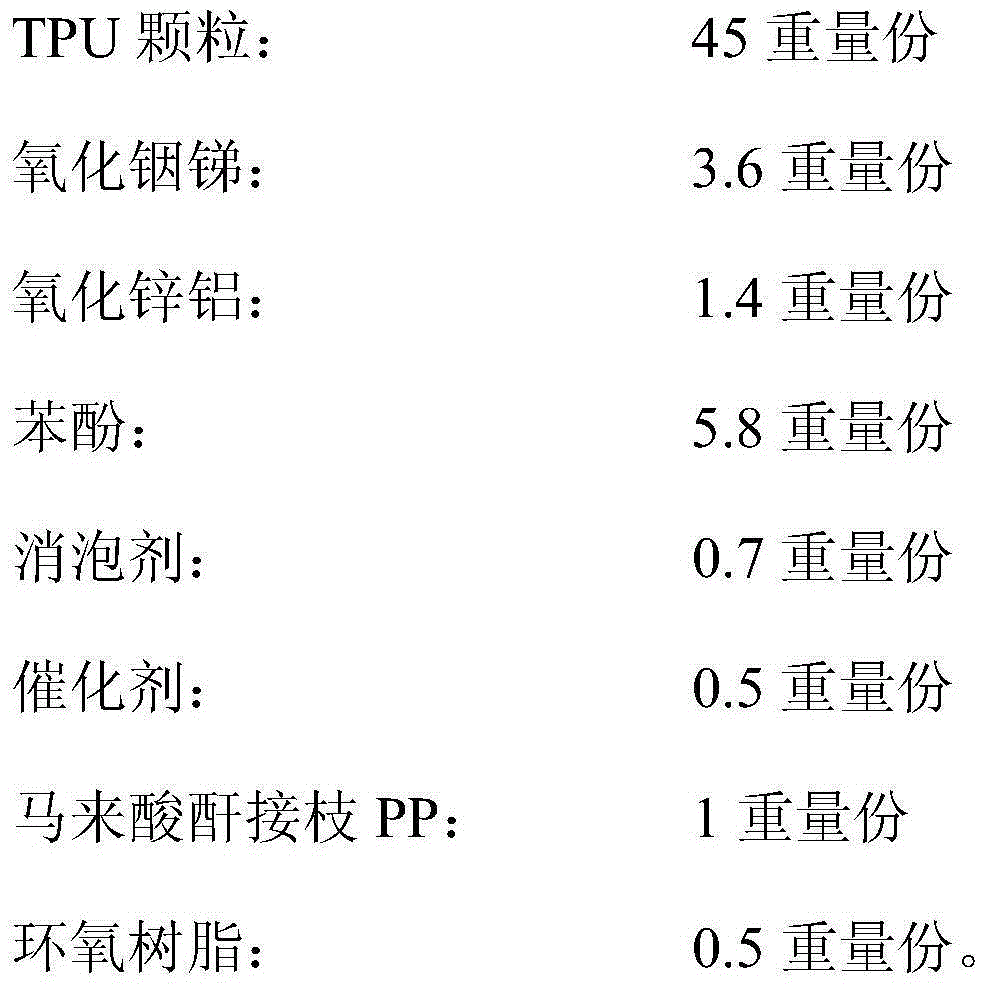

InactiveCN105038193AImprove scratch resistanceExtended service lifeFlat articlesAntimony oxideTransmittance

The invention relates to a thermal insulation TPU thin film for automobile film pasting and a preparation method thereof. The TPU thin film mainly comprises, by weight, 25-45 parts of TPU particles, 2.8-3.6 parts of indium and antimony oxide and / or tin and antimony oxide, 1.2-1.4 parts of zinc and aluminum oxide and / or zinc and gallium oxide, 3.4-5.8 parts of phenol and 0.3-0.7 part of defoaming agents. The preparation method includes the steps that firstly, the various raw materials are vacuumized and dehydrated; secondly, the raw materials where vacuum dehydration is performed are stirred and mixed and then extruded and formed through a tape-casting extruding machine, and the thermal insulation TPU thin film used for automobile film pasting is obtained. The light transmittance, the ultraviolet ray obstructing rate and the infrared ray obstructing rate of the TPU thin film are high, and the TPU thin film has lasting thermal insulation performance and an anti-dazzling effect. The thermal insulation TPU thin film is large in surface tension, resistant to scratch and abrasion, moderate in thickness, safe and capable of saving energy.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD

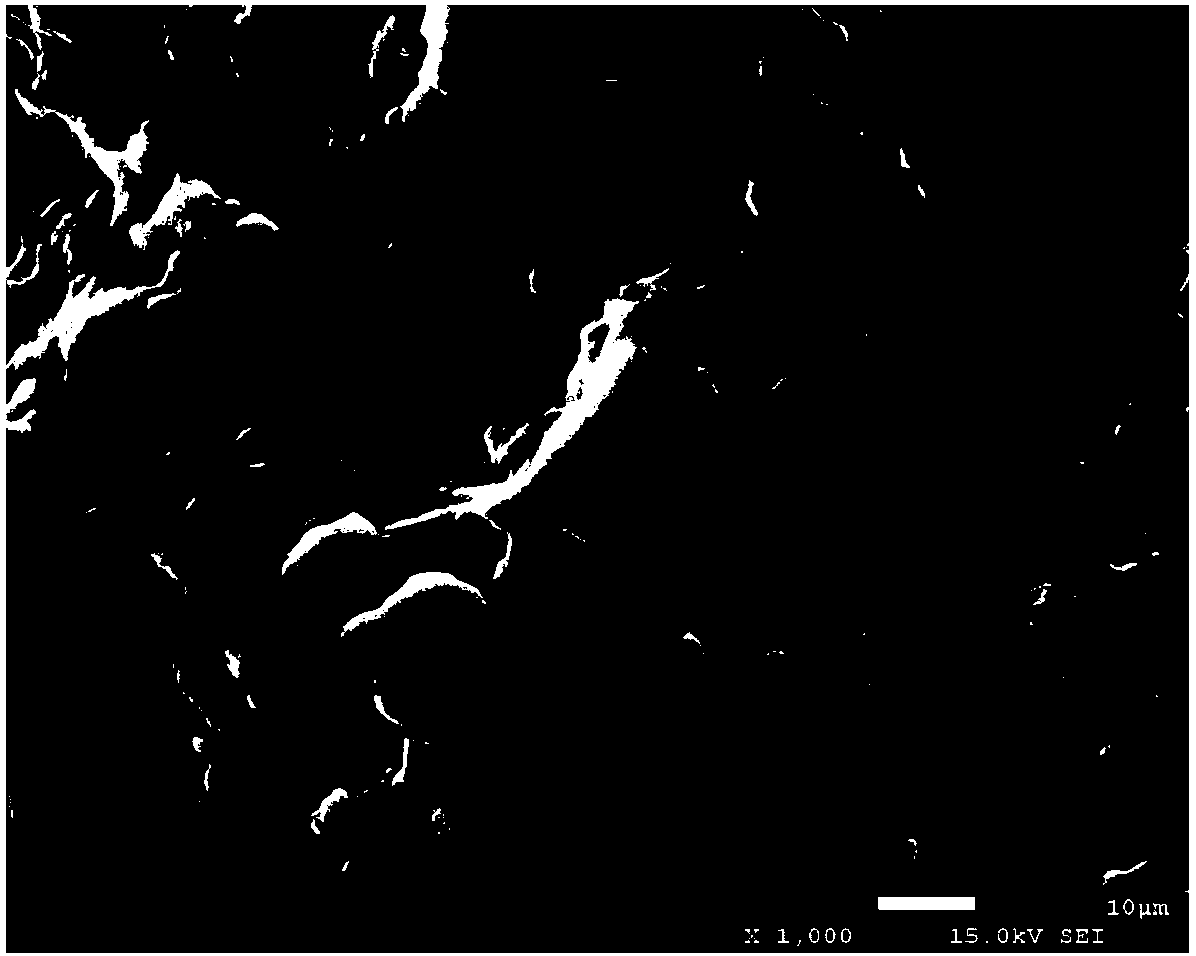

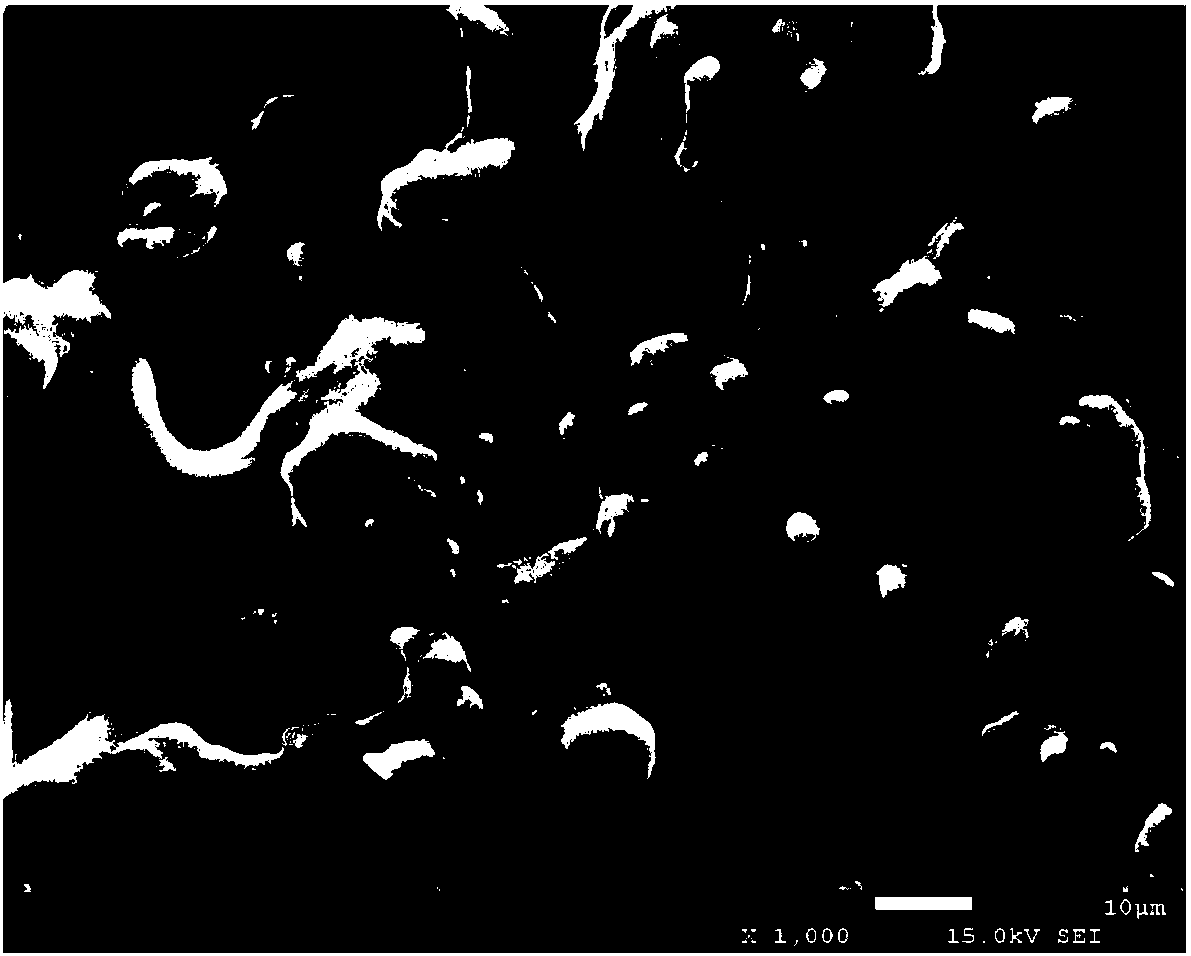

Dynamic vulcanization thermoplastic polyurethane/polysiloxane elastomer and preparation method thereof

ActiveCN108587123AGood dispersionAvoids problems associated with direct addition of high-viscosity polysiloxanesCross-linkPolymer science

The invention discloses a preparation method of a dynamic vulcanization thermoplastic polyurethane / polysiloxane elastomer. The preparation method comprises the following steps: firstly premixing thermoplastic polyurethane, methyl vinyl siloxane, a reinforcing filler and a chain extender, then carrying out melt extrusion pelletization inside an internal mixer or a double screw extrusion machine together with a catalyst to prepare a polyorganosiloxane master batch, then uniformly mixing thermoplastic polyurethane, the polyorganosiloxane master batch, a compatilizer and a polymerization inhibitor, and then adding a cross-linking agent and the catalyst for dynamic vulcanization. The methyl vinyl siloxane used for preparing the master batch is relatively low in viscosity and easy for good dispersion, and simultaneously chain growth can also be realized under the effect of the catalyst, and the viscosity and molecular weight of polyorganosiloxane are improved, so that the obtained elastomercan be of preferable mechanical property and sooth hand feeling, is easy for machining, and can be used in the application fields with high requirements such as buildings, automobile spare parts, electric wires and cables, medical apparatus and instruments and wearable equipment.

Owner:CHENGDU SILIKE TECH

Photocureable coating for pianos

The invention discloses a photocureable coating for pianos. A method for preparing the photocureable coating comprises the following steps: mixing 5 to 20 portions of active diluting agent, 55 to 70 portions of oligomer, 4 to 6 portions of powder, 3 to 4 portions of photoinitiator, and 0.4 to 0.6 portion of additive by weight, then stirring the mixture, grinding the mixture, and then adding a solvent which accounts for 10 to 12 percent of the total weight of the materials into the mixture to be stirred evenly to obtain photocureable coating for the pianos. The photocureable coating for the pianos has quick curing speed, can perform quick and continuous operation, and greatly improve production efficiency; the coating does not need to be heated and dried, so the coating can save 75 to 90 percent of energy sources than the prior heat dry coating during the construction; coating equipment for an UV coating is compact, does not need a drying tunnel, has simple and convenient operation, is easy to realize production automation, saves floor area, and reduces operation space; and the UV coating has no the volatilization of VOCs during the film formation, does not cause the pollution to the environment, and improves surface performances such as paint film hardness, flexibility, wear and scratch resistance, chemical resistance, high gloss, durability and the like.

Owner:浜二(宜昌)涂料有限公司

Resin composition for crazy horse leather resin composition

InactiveCN101284942ARubbing antique effect is goodStrong sense of leatherTextiles and paperEpoxyWear resistant

The invention relates to a resin compound used for crazy horse burnished leather, comprising polyurethane resin, dimethylformamide, floss powder, color-changing powder, acetone and epoxide resin, wherein, the color-changing powder is modified silicon dioxide and the melting point of the modified silicon dioxide is between 55 and 80 DEG C. Compared with the prior art, the crazy horse burnished leather prepared by the resin compound has good burnished archaizing effect, is close to corium, is smooth in the leather surface and has good scratch resistant and wear resistant performances.

Owner:JIANGSU BAOZE POLYMER MATERIAL

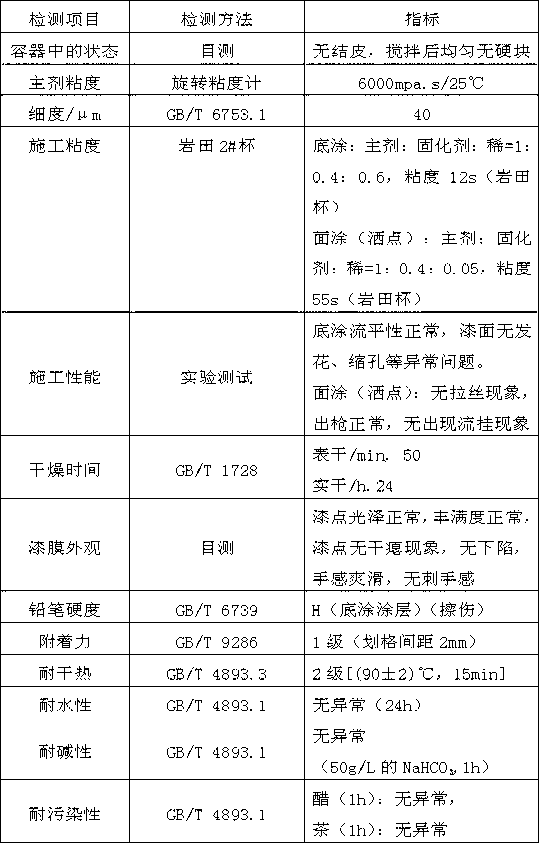

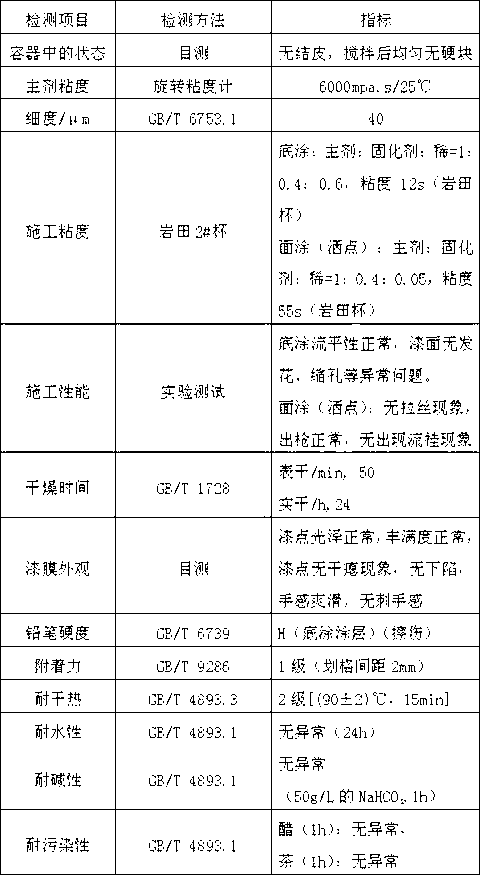

Double-component PU (Polyurethane) water drop effect decorative paint and preparation method thereof

The invention relates to the field of polymer materials, in particular to a coating technology, and especially relates to a double-component PU (Polyurethane) water drop effect decorative paint and a preparation method thereof. The double-component PU water drop effect decorative paint comprises three components of a main solvent, a curing agent and a diluent, wherein the main solvent comprises the following component by weight: synthetic fatty acid modified alkyd resin with a 70% solid content, epoxy resin, 10% organic bentonite anti-settling pulp, polyamide wax anti-settling pulp, color paste for PU, heavy calcium carbonate, glass powder, matte powder, an adhesive force accelerating agent, a wet dispersing agent, a functional assistant agent and a solvent. The double-component PU water drop effect decorative paint has the advantages of high solid content, high adhesion, excellent wear and scratching resistant performance, good temperature difference change resistant performance, water proofing, strong stereoscopic impression, obvious water-drop effect, protrusion without sinking and smooth hand feel.

Owner:HUIZHOU CHANGRUNFA PAINT

Hot-press-free antibacterial and anti-scraping optical explosion-proof film

InactiveCN109096940AEnhanced interfacial interaction forceGood dispersionFilm/foil adhesivesPolyureas/polyurethane adhesivesOptical transparencyTransmittance

The invention relates to hot-press-free antibacterial and anti-scraping optical explosion-proof film. Konjac glucomannan nanocrystalline is added into a protection layer and modified through chitosan,the interfacial interaction force among molecules in a formula system is greatly increased, the dispersing performance and the compatibility among components are improved, and thus the mechanical performance of the structure of the protection layer is improved; by adding inorganic and organic compound synergistic antibacterial agents, the antibacterial effect of the protection layer is greatly improved, and cross propagation of bacteria after surface contact of the human body is avoided; the antibacterial and anti-scraping optical explosion-proof film is subjected to hot-press-free curing molding, and the processing procedure and the processing cost are reduced; TPU is good in processability and flexibility and resistant to shock, an optical-grade PET base material is good in optical transparency, the requirement of the explosion-proof film for the optical performance is met, and the light transmittance of the explosion-proof film is increased. The explosion-proof film has good lighttransmittance, static resistance, wear resistance, scraping resistance and bacterial resistance; through the arrangement of the explosion-proof structure layer, the safety and stability during use areguaranteed, and meanwhile the requirement for optical-grade appearance is met.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Anti-scratching coating of electromechanical equipment

The invention relates to an anti-scratching coating of electromechanical equipment. The anti-scratching coating is prepared from the following components in parts by mass: 45 to 65 parts of epoxy-modified silicone resin, 12 to 22 parts of phenolic resin, 12 to 18 parts of filling material, 5 to 12 parts of titanium dioxide powder, 5 to 9 parts of white carbon black, 7 to 12 parts of amino siloxane, 5 to 10 parts of alumina silicate fiber and 10 to 25 parts of diluent. According to the technical scheme provided by the invention, the anti-scratching coating is good in abrasion-proof and anti-scratching performance, rapid in curing speed, stable in performance and strong in weatherability, thereby being capable of permanently protecting the electromechanical equipment.

Owner:NANTONG YAOHUA MECHANICAL & ELECTRICAL

Wear-resistant high-transmittance super-smooth PU open-type matte varnish and preparation method thereof

InactiveCN112646467AHigh hardnessGood yellowing resistancePolyurea/polyurethane coatingsRadiation-absorbing paintsCellulosePolymer science

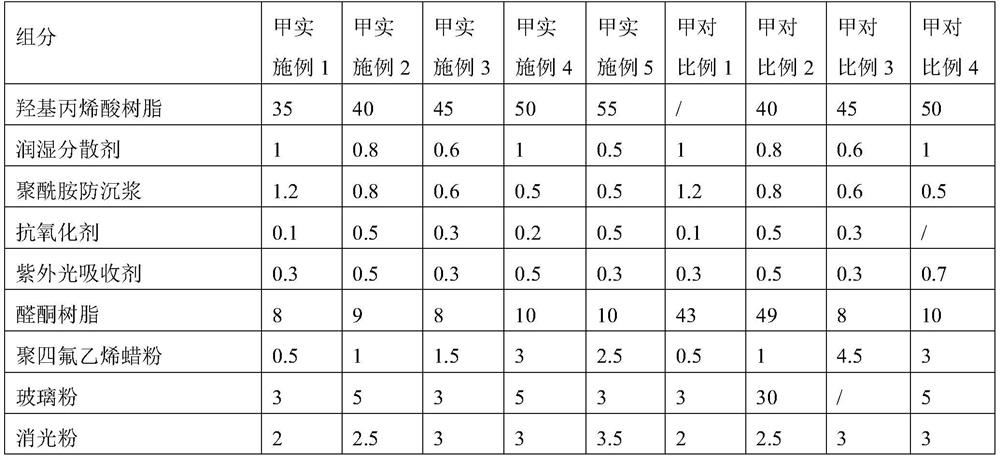

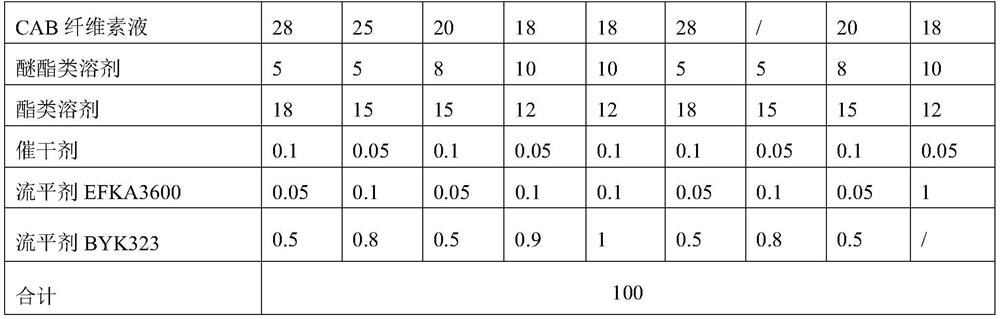

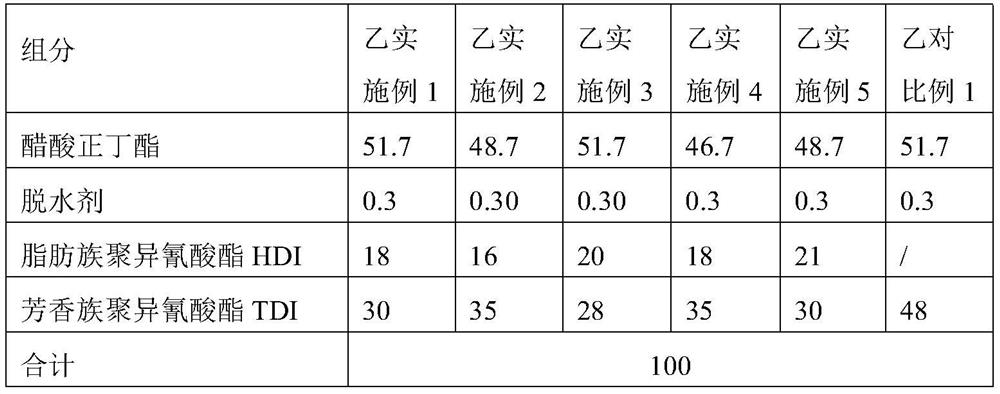

The invention belongs to the technical field of coatings. The wear-resistant high-transmittance super-smooth PU open type matte varnish comprises a component A, a component B and a diluent, and the mass ratio of the component A to the component B is 10:5-6; the component A comprises hydroxy acrylic resin, a wetting dispersant, polyamide anti-settling slurry, an antioxidant, an ultraviolet absorber, aldehyde ketone resin, wax powder, glass powder, extinction powder, CAB cellulose, an ether ester solvent, an ester solvent, an antifoaming agent, a leveling agent and a drier; and the component B comprises n-butyl acetate, a dehydrating agent, aromatic polyisocyanate and aliphatic polyisocyanate. The wear-resistant high-transmittance super-smooth PU open type matte varnish is high in paint film hardness, has good yellowing resistance, chemical resistance, scratch resistance and wear resistance, is applied to the surface of technical wood, and is good in solid wood texture, high in transparency, clear, not bloated and good in matte effect.

Owner:AODA KOALA PAINT HUIZHOU

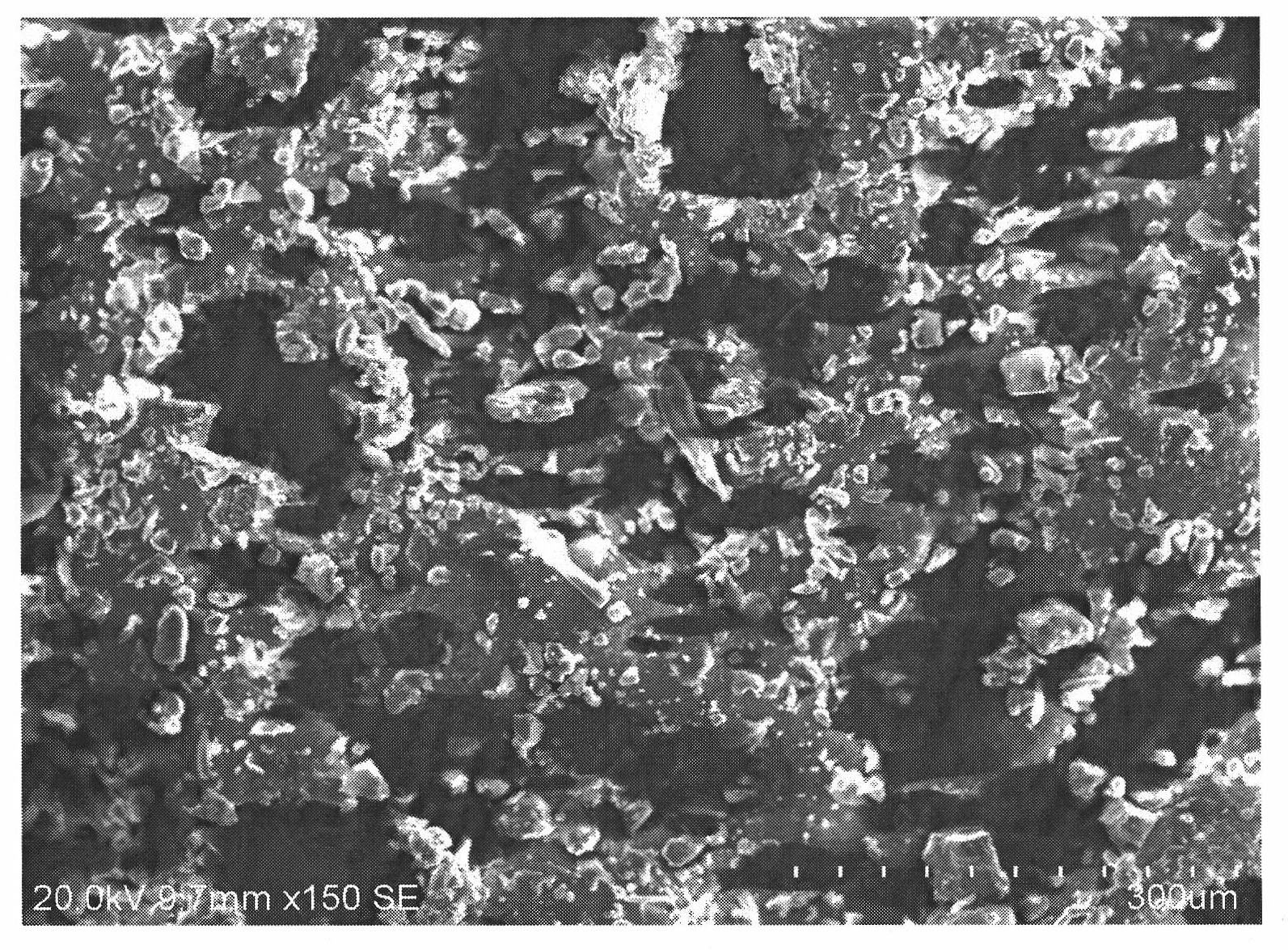

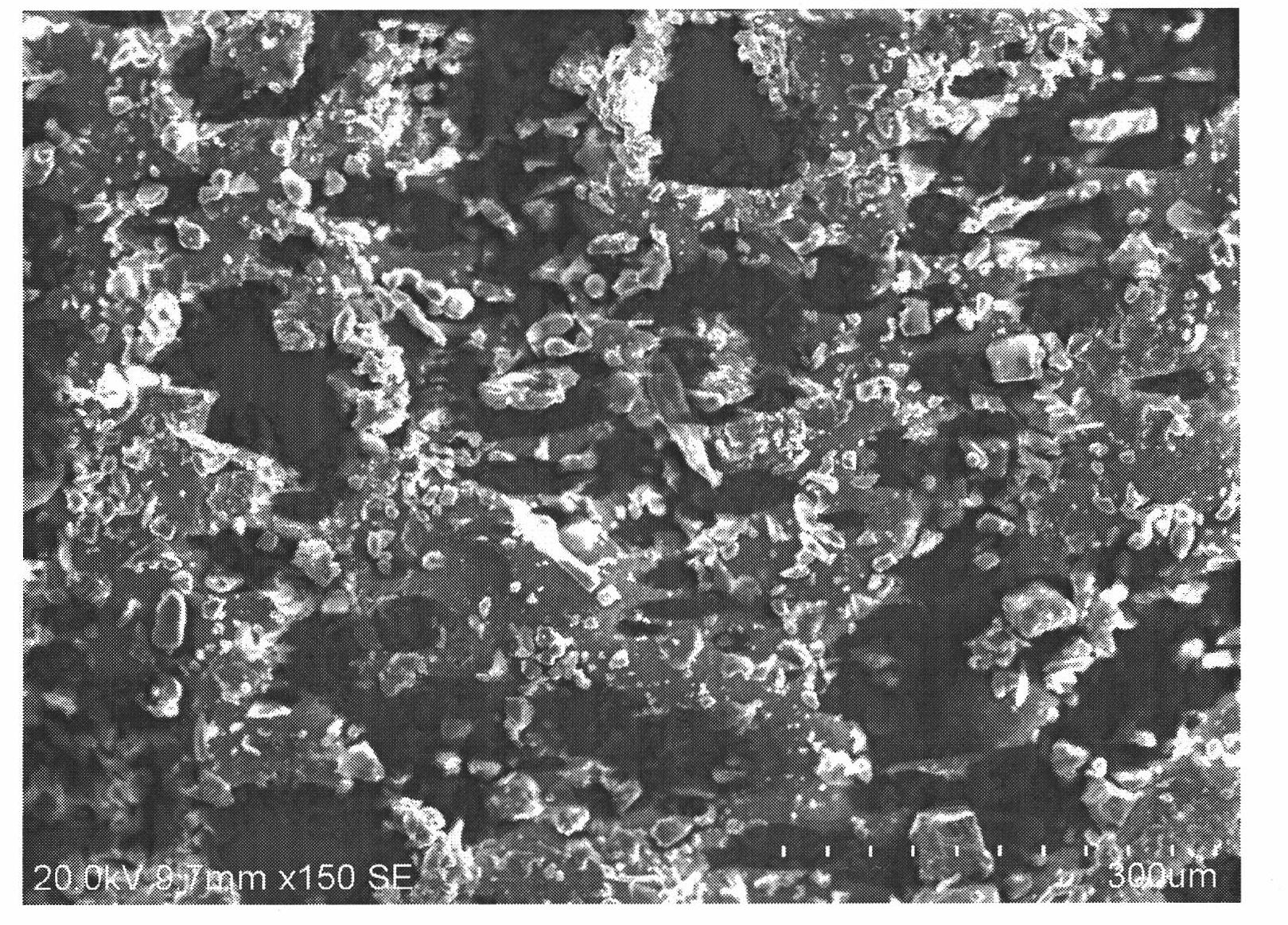

Metal substrate with thermally-sprayed anti-sticking wear-resistant coating and preparation method as well as application thereof

ActiveCN102166850AImprove surface strengthExcellent wear and scratch resistanceMetal layered productsThermal sprayingPolymer resin

The invention relates to anti-sticking wear-resistant treatment of a metal substrate, in particular to a metal substrate with a thermally-sprayed anti-sticking wear-resistant coating and a preparation method thereof as well as a driving roller adopting the substrate. A nickel-based alloy coating is arranged on the surface of the metal substrate with the thermally-sprayed anti-sticking wear-resistant coating, and a silicon polymer resin layer is arranged on the surface of the nickel-based alloy coating in a disperse combination mode. The invention also discloses a method for preparing the metal substrate with the thermally-sprayed anti-sticking wear-resistant coating as well as a driving roller adopting the metal substrate. The product disclosed by the invention has the advantages that the anti-sticking effect is improved, the service life is prolonged, the equipment maintenance and repair strength and period are reduced, the equipment service efficiency is increased, the product quality is improved, and the production cost is lowered.

Owner:德清创智科技股份有限公司

High-transparent anti-wear anti-scraping PC (Poly Carbonate) material and preparation method thereof

InactiveCN102585475AImprove scratch resistanceImprove wear and scratch resistanceEngineering plasticHardness

The invention relates to the field of modification of macromolecular thermoplastic materials, in particular to a modified formula of a high-transparent anti-wear anti-scraping PC (Poly Carbonate) material and a preparation method thereof. The modified formula comprises the following substances in parts by weight: 90-98 parts of PC (Poly Carbonate), 1-5 parts of anti-scraping agent, 0.5-3 parts of lubricating agent and 0.5-2 parts of antioxygen. According to the modified PC formula, the surface hardness of a PC resin is improved on the basis of not changing the mechanical property and the transparent property of the PC resin too much, and the application range in the anti-wear anti-scraping engineering plastic field is expanded. The anti-wear anti-scraping PC material disclosed by the invention has excellent flowability and a simple preparation process.

Owner:上海聚威新材料股份有限公司

Electroless engraving thermocompression bonding gold stamping process

ActiveCN107323115AImprove aestheticsImprove bronzing effectDuplicating/marking methodsInksEngravingStamping process

The invention relates to the technical field of gold stamping, and concretely relates to an electroless engraving thermocompression bonding gold stamping process, which comprises the following steps of A, printing: printing gold stamping oil on the surface of an object to be subjected to gold stamping, and obtaining a print with a preset pattern to be subjected to gold stamping; B, curing: carrying out photocuring treatment on the print obtained through the step A, and obtaining a solid print with a preset pattern to be subjected to gold stamping; and C thermocompression bonding: covering a gold stamping film on the surface of the solid print obtained through the step B, using a soft edition for carrying out thermocompression bonding treatment on the solid print covered with the gold stamping film, and obtaining a gold stamping product with the preset gold stamping pattern. The gold stamping process provided by the invention does not need electronic engraving for gold stamping, and is convenient and fast in process operation, high in production efficiency and low in production cost, so that the prepared gold stamping product has the characteristics of high glossiness, high attractiveness, good hand feeling, excellent three-dimensional effect and the like, and is stable in quality and suitable for large-scale production.

Owner:缪秉强

Method for manufacturing, transfer printing and testing of high temperature and corrosion resistant heat-transfer printing film

The invention provides a method for manufacturing, transfer printing and testing of a high temperature and corrosion resistant heat-transfer printing film. A manufactured heat-transfer printing film respectively comprises a basal layer, a release layer, a protective layer, a waterproof layer and a heatproof and isolation layer from the bottom up, and intaglio printing is adopted for forming of the heat-transfer printing film; after the intaglio printing, the heat-transfer printing film has excellent properties of high-temperature boiling, corrosion, scratching and abrasion resistance; heat preservation is performed for 1-2 hours at 63-67 DEG C, so that the heat-transfer printing film can be clear in character printing and strong in adhesive force, the high temperature resistant ultimate bearing capacity is improved by 3-4 times, and the corrosion resistant time is prolonged by 2-3 times. The method is simple, and has the advantages that the manufacturing is convenient, the product quality is high, the service life of a product is long, and the core competitiveness of an enterprise is remarkably improved.

Owner:HONORISE PACKING & PRINTING

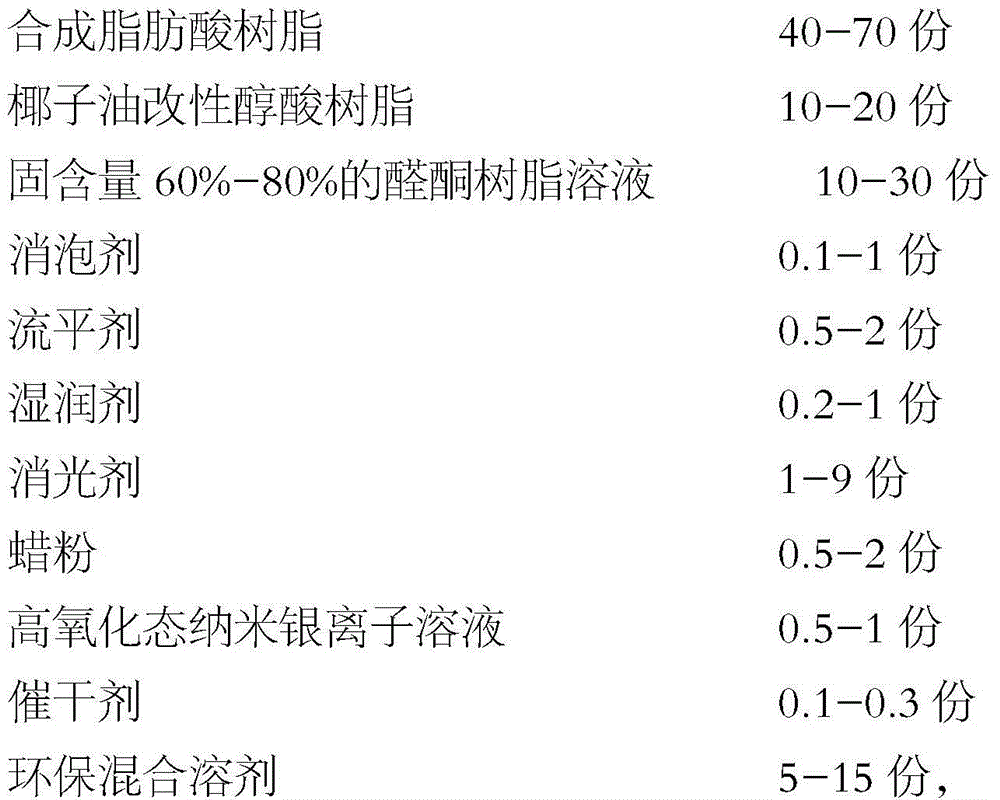

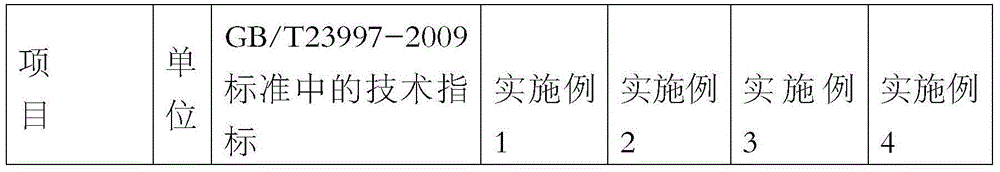

Special antimicrobial-function environment-friendly matte finish paint for children and preparation method thereof

ActiveCN104087140AImprove performanceGood quality coatingAntifouling/underwater paintsPaints with biocidesEnvironmental resistancePhysical well being

The invention particularly relates to a special antimicrobial-function environment-friendly matte finish paint for children and a preparation method thereof. A main paint of the finish paint is prepared from the following raw materials in parts by weight: 40-70 parts of synthetic fatty acid resin, 10-20 parts of coconut oil modified alkyd resin, 10-30 parts of aldehyde ketone resin solution with the solid content of 60-80%, 0.1-1 part of defoamer, 0.5-2 parts of leveling agent, 0.2-1 part of humectant, 1-9 parts of matting agent, 0.5-2 parts of wax powder, 0.5-1 part of high-oxidation-state nano silver ion solution, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The paint is environment-friendly and healthy, avoids the generation of substances which are harmful to good health of children, can form an antibacterial-function coating on the surface of the coated substance, and prevents secondary pollution. Besides, the paint can be directly used on a wood substrate, can not generate the phenomena of shrinkage and sinking of the paint film, and has the advantages of favorable hardness, favorable wear resistance and the like.

Owner:SKSHU PAINT

Aqueous PU self-curing paint and preparation method thereof

InactiveCN105295697AExcellent volume and high glossGood color development and levelingPolyurea/polyurethane coatingsChemistryDipropylene glycol

The invention discloses an aqueous PU self-curing paint and a preparation method thereof. The paint is prepared by blending the following components according to a certain ratio: aqueous hydroxyl acrylic acid emulsion, TeGo270 wetting agent, TeGo822 antifoaming agent, AMP95, TeGo4100 flatting agent, carbitol acetate, dipropylene glycol-butyl ether, anionic water, BYK425 polyurethane rheological aid, flash-rust inhibitor, aqueous hydroxyl acrylic acid emulsion, TeGo270 wetting agent, TeGo760 wetting dispersant, organic silicon wear-resistant powder (UNI CONE T-2050), and aqueous resin-free color paste. The paint has the characteristics that the properties of formed paint film are good, the drying speed is quick; solved are the problems that rust can easily grow on the metal substrate, which is covered by a conventional aqueous paint and the drying of conventional aqueous paint is slow; the content of VOC (volatile organic compound) is low, and the paint is safe and environment-friendly. The paint can be used to protect metal substrates, which have high environment protection requirements, such as automobile parts, machinery equipment, bridges, steel structure, net rack, and the like.

Owner:佛山市南海彤粤高分子材料有限公司

High gloss wax emulsion for waterborne varnish printing, and preparation method of high gloss wax emulsion

The invention relates to the field of petrochemical industry, in particular to high gloss wax emulsion for waterborne varnish printing, and a preparation method of the high gloss wax emulsion. The high gloss wax emulsion for waterborne varnish printing is prepared from high density polyethylene wax, Fischer-Tropsch wax, an emulsifying agent, alkali, a wetting dispersant and water; the high densitypolyethylene wax and the Fischer-Tropsch wax are mixed and emulsified; the molecular weight of the high density polyethylene wax is within a range of 500-5000, and the molecular weight of the Fischer-Tropsch wax is within a range of 500-1000; the emulsifying agent is an environment-friendly emulsifying agent which has a cyclic structure and has a carbon number of 10-35. According to the method, the wax emulsion is prepared by mixing and emulsifying the polar oxidized polyethylene wax and the non-polar Fischer-Tropsch wax, and is applied to the waterborne varnish printing, so that a high oilyfeeling and glossiness is provided for varnish, and the surface of the varnish has a high degree of fineness; furthermore, due to smoothness of the Fischer-Tropsch wax, the viscosity, caused by acrylate, of the varnish is greatly reduced, the surface friction coefficient is reduced, and the wear resistance and the scratch resistance are improved; the environmentally friendly emulsifying agent is used and water is used as a solvent, so that pollution caused by adopting NP / OP emulsifying agents in the past is avoided.

Owner:广州聚科环保科技有限公司

Ceramic material, digital glaze spraying ceramic rock plate as well as preparation method and application of digital glaze spraying ceramic rock plate

ActiveCN112500144AImprove high temperature resistanceGood chemical resistanceCeramic materials productionGlazeBasaltic rock

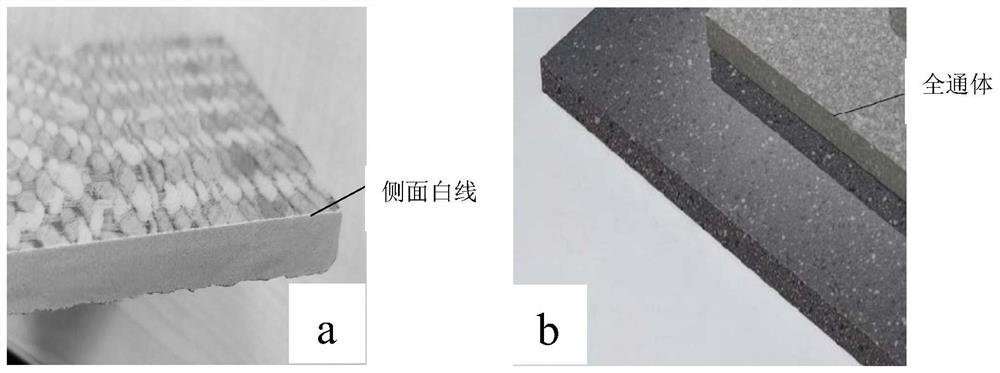

The invention belongs to the technical field of building ceramics, and discloses a ceramic material, a digital glaze spraying ceramic rock plate and a preparation method and application thereof, the ceramic material is mainly prepared from quartz, basalt and a flexural strength functional additive, the basalt is beneficial to improving the compactness and the like of the rock plate, sodium humatein the flexural strength functional additive can improve the drying flexural strength of a green body and shorten the drying time of the green body. The invention also provides a digital glaze spraying ceramic rock plate and a preparation method thereof, the main raw material of the rock plate is the ceramic material, and in the preparation method, digital glaze spraying is adopted for surface glaze application, so that the problems that the glaze surface of the ceramic rock plate produced by a traditional glaze spraying mode is too thick, and a relatively obvious white line isolation layer exists from the side view are avoided; and the full-body effect is achieved after the green body is subjected to polishing treatment. The obtained digital glaze spraying ceramic rock plate is more compact, more resistant to fire, high temperature, pollution and corrosion, free of permeation, high in hardness and extremely excellent in scratch resistance and wear resistance, and can be applied to thefields of buildings, decoration and the like.

Owner:FOSHAN OCEANO CERAMICS

Shrink-proof polyurethane sealant

InactiveCN104327786ASmall internal and external tensionStable qualityNon-macromolecular adhesive additivesOther chemical processesPOLYETHYLENE WAXSilane

The invention discloses a shrink-proof polyurethane sealant which comprises polyurethane resin, a flatting agent, a cross-linking agent, a lubricating agent, a surface control agent, a defoaming agent and a coupling agent, wherein the flatting agent is polyether modified silicone oil, the cross-linking agent is hydroxyethyl acrylate, the lubricating agent is butyl stearate, the surface control agent is polyethylene wax, the defoaming agent is phenethyl alcohol oleate, and the coupling agent is vinyl triethoxy silane. The shrink-proof polyurethane sealant is prepared from polyurethane resin and six additives including the flatting agent, the cross-linking agent, the lubricating agent, the surface control agent, the defoaming agent and the coupling agent, and the prepared product is small in internal and external tensile force, shrink-proof, stable in quality, fewer in bubbles, good in resistance to soiling and good in scratch resistance and wear resistance.

Owner:SUZHOU BAII ELECTRONICS TECH

High-hardness grit powder coating and preparation method thereof

InactiveCN107189628AIncrease thermal decomposition temperatureImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesOrganosiliconPolytetrafluoroethylene

The invention discloses a high-hardness grit powder coating. The raw material of the high-hardness grit powder coating is prepared from the following components in parts by weight: 25-35 parts of epoxy resin, 25-35 parts of terminal carboxyl polyester resin, 5-10 parts of organosilicon resin, 5-10 parts of fluorocarbon resin, 0.5-1 part of methylimidazole, 5-15 parts of nepheline powder, 5-10 parts of kaolin, 1-3 parts of pure polytetrafluoroethylene and 1-2 parts of pigments. The invention also provides a preparation method of the high-hardness grit powder coating. The preparation method of the high-hardness grit powder coating comprises the steps of weighing and preparing materials, premixing, melting and extruding, grinding, screening and packing finished product to obtain the high-hardness grit powder coating. According to the high-hardness grit powder coating and the preparation method thereof, the crosslinking density of the resin during reacting, the hardness of the fillers and the smoothness of additives are increased, so that the hardness of the coating surface is improved; the production cost is reduced; meanwhile, the uniformly distributed grit shape is formed in the surface of the film cured by the coating; the coating is high in decorativeness; the defects such as roughness and unevenness of the surface and the like can be remedied and covered.

Owner:浙江绿能塑粉科技股份有限公司

Composite purification packaging bag and preparation method thereof

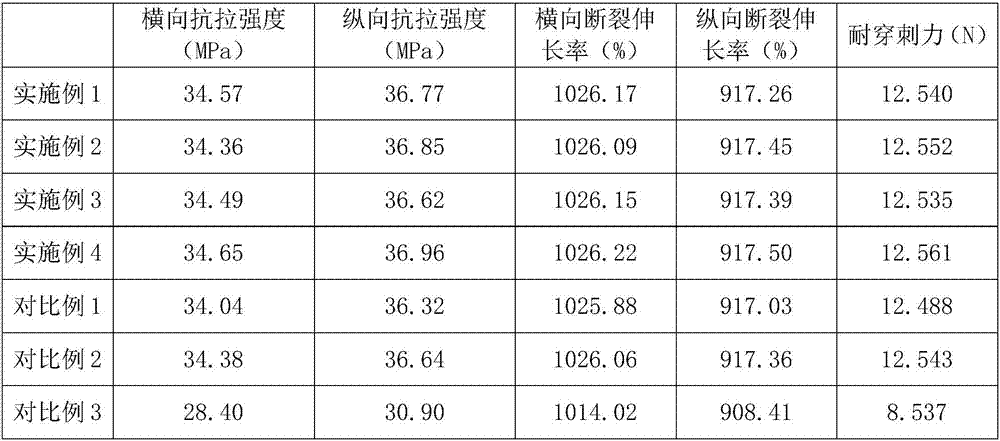

ActiveCN107540917AHigh tensile strengthHigh elongation at breakLinear low-density polyethyleneUltrasonic dispersion

The invention provides a composite purification packaging bag which is prepared from the following components in parts by weight: 50-60 parts of HDPE (High-Density Polyethylene), 35-45 parts of LLDPE(Linear low density polyethylene), 10 parts of a thermoplastic elastomer and 10 parts of composite calcium carbonate. Composite calcium carbonate is prepared by the following steps: putting calcium carbonate superfine powder into ultrapure water, performing ultrasonic dispersion for 30 minutes, adding isopropanol zirconium, tetraethoxysilane, water and ethanol, heating to 75 DEG C, performing magnetic stirring for 10 hours, performing centrifugation for 20 minutes to obtain a mixture, washing the mixture with deionized water twice, putting into a muffle furnace, performing pyrolysis for 1 hourat 450 DEG C, cooling to the room temperature, and grinding, thereby obtaining composite calcium carbonate. The invention further provides a preparation method of the composite purification packagingbag. The composite purification packaging bag provided by the invention is not only good in puncture resistance, but also very good in toughness, tearing resistance and scraping resistance.

Owner:GUANGDONG SUOREC TECH

Material for producing mobile phone shells, and preparation method of material

The invention discloses a material for producing mobile phone shells, and a preparation method of the material. The material is mainly prepared from the following components in parts by weight: 22-42parts of an acrylonitrile-ethylene propylene diene monomer (EPDM) rubber-styrene resin copolymer, 14-23 parts of polycarbonate, 13-26 parts of epoxy resin, 21-34 parts of nitrile rubber, 1.3-6.5 partsof glass fibers, 0.3-2.2 parts of silicon carbide whiskers, 0.5-3.8 parts of nano-titanium dioxide, 2-10 parts of a compatilizer, 0.05-2 parts of an antibacterial agent and 0.4-2 parts of a lubricating agent. The material is prepared by the steps of mixing at a high speed, extruding and granulating, and the like. The material for manufacturing the mobile phone shells is high in hardness, good inwear resistance and heat resistance, has a better antibacterial effect, and is simple in preparation technology and suitable for industrial production.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

High-temperature wear-resistant paint

InactiveCN104277504AImprove mechanical propertiesImprove high temperature resistanceCement coatingsWear resistantPhosphoric acid

The invention relates to high temperature wear-resistant paint. The technical scheme adopted by the invention is as follows: the high-temperature wear-resistant paint is characterized by comprising the following components: corundum fine powder, cement, fluorinated graphite, titanium dioxide, barium sulfate, talcum powder, aluminum triphosphate, sodium persulfate, N,N-dimethyl ethanolamine, aluminum oxide, calcium oxide, ammonium ferrous sulfate, silica micro powder and phosphoric acid. The high-temperature wear-resistant paint has the beneficial effects that the mechanical performances are excellent, the impact resistance is good, the high temperature resistance is excellent, the adhesive force is good, the scratch resistance and the wear resistance are excellent, the cost is low and the performances are stable.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Water-based anticorrosive coating and preparation method thereof

InactiveCN112795250AImprove the efficacy of absorbing UV raysImprove the quality of useAnti-corrosive paintsPolyurea/polyurethane coatingsPolyurethane dispersionWeather resistance

The invention relates to an anticorrosive coating and a preparation method thereof, and particularly discloses a water-based anticorrosive coating which comprises the components in parts by weight: 15-25 parts of a water-based acrylic emulsion, 10-20 parts of a water-based polyurethane dispersion body, 5-8 parts of a film-forming agent, 1-3 parts of an anti-rust agent, 0.1-0.5 part of an anti-rust pigment, 8-12 parts of a filler, 5-10 parts of a wear-resistant anti-aging agent, 4-7 parts of an auxiliary agent and the balance being deionized water. The anticorrosive coating disclosed by the invention has good weather resistance, yellowing resistance, high hardness, good gloss and excellent permeability, further improves the ultraviolet absorption effect of the coating, can prevent the photodegradation of the coating, reduces the photoinduced color development speed, improves the use quality of the coating, prolongs the service life of the coating, improves the smoothness and self-cleaning property of the surface of the coating, and further improves the coating scratch-resistant wear resistance and other properties; and the coating disclosed by the invention is low in odor, good in anti-corrosive effect, excellent in wear resistance and aging resistance, simple and convenient in preparation process and high in coating performance stability.

Owner:扬州郎康汽车水性涂料有限公司

Waterborne surface treating agent for PVC and PU artificial leather and preparation method and product thereof

InactiveCN107141989AHealth effectsMeet the protection requirementsFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPhenyl Ethers

The invention discloses a waterborne surface treating agent for PVC and PU artificial leather, and the surface treating agent is prepared from the following components: 25-60 parts of waterborne aliphatic polyurethane resin, 5-25 parts of waterborne acrylic resin, 10-35 parts of water, 5-15 parts of isopropanol, 0.1-3 parts of a poly-2-methyl-4-isothiazolin-3-one compound, 1-5 parts of a dispersant, 0.1-5 parts of a paracresol and dicyclopentadiene butyl compound, 0.1-5 parts of polyether modified polydimethyl siloxane, 0.1-5 parts of a silane coupling agent, 0.1-8 parts of propylene glycol phenyl ether, 0.1-8 parts of matting powder and 0.1-5 parts of an acrylate polymer. Correspondingly, the invention also provides a preparation method of the waterborne surface treating agent for PVC and PU artificial leather. The waterborne surface treating agent for PVC and PU artificial leather has multiple functions, integrates multiple properties of scratch resistance, wear resistance, high temperature resistance and yellow stain resistance, can achieve the operating requirements by only one-step treatment, and is simultaneously suitable for PVC and PU artificial leather.

Owner:MINGHAI CHEM ENTERPRISE

Scratch-resistant protective film and preparation method thereof

The invention discloses a scratch-resistant protective film and a preparation method thereof and belongs to the field of packaging industry. The scratch-resistant protective film comprises a substrate layer and a functional coating, wherein the substrate layer is PE which is 30-60 microns in thickness and the functional coating is 15-25 microns in thickness. The functional coating comprises the following components in parts by mass: 50-70 parts of organic silicon resin, 6-12 parts of polyisocyanate, 3-7 parts of nanotitanium oxide, 4-8 parts of a silane coupling agent, 0.5-2 parts of a graphite powder and 15-25 parts of deionized water. The scratch-resistant protective film disclosed by the invention is stable in viscous force and good in adhesiveness and re-peeling property, has a good wear-resistant and scratch-resistant performance, and can be effectively used for preventing household appliances from being physically scratched, so that the service lives of the household appliances are prolonged.

Owner:SUZHOU DINGLI PACKAGING

One-component thermoplastic acrylic paint coating technology

InactiveCN106362926AStrong adhesionGood flexibilityLiquid surface applicatorsCoatingsAcrylic paintWater content

The invention discloses a one-component thermoplastic acrylic paint coating technology. The one-component thermoplastic acrylic paint coating technology includes the following steps that it is ensured that the water content of wood is smaller than 10%, and construction is conducted on a plate which is polished and cleaned thoroughly; through spraying / brushing construction, seal primer is firstly used for completely sealing a white blank twice; after a paint film is dried and is polished and cleaned thoroughly, middle coating primer is directly used, and construction is conducted through spraying / brushing; after the paint film is dried, paint film fullness is obtained in a brushing manner through interlayer polishing and recoating; after the fullness of the paint film is obtained, a matt top coating is directly used, and construction is conducted through spraying / brushing; after the paint film is dried, the paint film fullness is obtained in a brushing manner through interlayer polishing and recoating; and after the top coating is brushed, it is ensured that the paint film is prevented from being touched by the outside before drying is completed. According to the coating technology, the requirement for use of outdoor woodware can be well met.

Owner:广东花王涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com