Electroless engraving thermocompression bonding gold stamping process

A technology of combining bronzing and electroengraving, applied in the field of bronzing, can solve the problems of reducing the beauty of bronzing products, difficult to meet mass production, expensive metal plates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

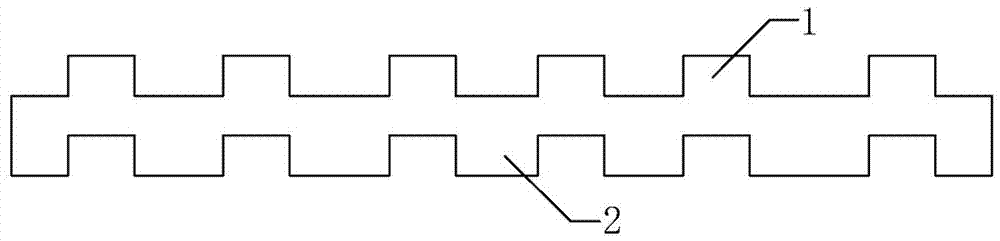

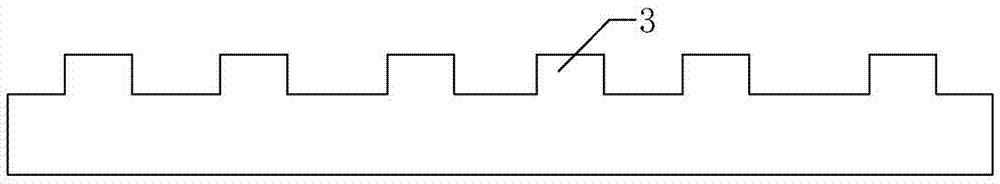

Image

Examples

Embodiment 1

[0064] An electroless engraving heat-pressing bronzing process, comprising the following steps:

[0065] A. Printing: Print bronzing oil on the surface of the object to be bronzed to obtain a printed object with a predetermined pattern to be bronzed;

[0066] B. Curing: The printed matter obtained in step A is subjected to photocuring treatment to obtain a cured printed matter with a predetermined bronzing pattern;

[0067] C. Hot pressing: cover the surface of the cured printed matter obtained in step B with the bronzing film, and use a soft plate to heat the cured printed matter covered with the hot stamping film, and then perform the hot pressing process to obtain a printed matter with a predetermined hot stamping pattern Bronzing products.

[0068] In the step A, the printing method of bronzing oil is screen printing.

[0069] In the step B, the photocuring method is UV photocuring; for the printed matter after screen printing in step A, the light intensity of the UV cur...

Embodiment 2

[0084] An electroless engraving heat-pressing bronzing process, comprising the following steps:

[0085] A. Printing: Print bronzing oil on the surface of the object to be bronzed to obtain a printed object with a predetermined pattern to be bronzed;

[0086]B. Curing: The printed matter obtained in step A is subjected to photocuring treatment to obtain a cured printed matter with a predetermined bronzing pattern;

[0087] C. Hot pressing: cover the surface of the cured printed matter obtained in step B with the bronzing film, and use a soft plate to heat the cured printed matter covered with the hot stamping film, and then perform the hot pressing process to obtain a printed matter with a predetermined hot stamping pattern Bronzing products.

[0088] In the step A, the printing method of bronzing oil is screen printing.

[0089] In the step B, the photocuring method is UV photocuring; for the printed matter after screen printing in step A, the light intensity of the UV curi...

Embodiment 3

[0104] An electroless engraving heat-pressing bronzing process, comprising the following steps:

[0105] A. Printing: Print bronzing oil on the surface of the object to be bronzed to obtain a printed object with a predetermined pattern to be bronzed;

[0106] B. Curing: The printed matter obtained in step A is subjected to photocuring treatment to obtain a cured printed matter with a predetermined bronzing pattern;

[0107] C. Hot pressing: cover the surface of the cured printed matter obtained in step B with the bronzing film, and use a soft plate to heat the cured printed matter covered with the hot stamping film, and then perform the hot pressing process to obtain a printed matter with a predetermined hot stamping pattern Bronzing products.

[0108] In the step A, the printing method of bronzing oil is gravure printing.

[0109] In the step B, the photocuring method is UV photocuring; for the printed matter after gravure printing in step A, the light intensity of the UV c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com