Patents

Literature

62results about How to "No dents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

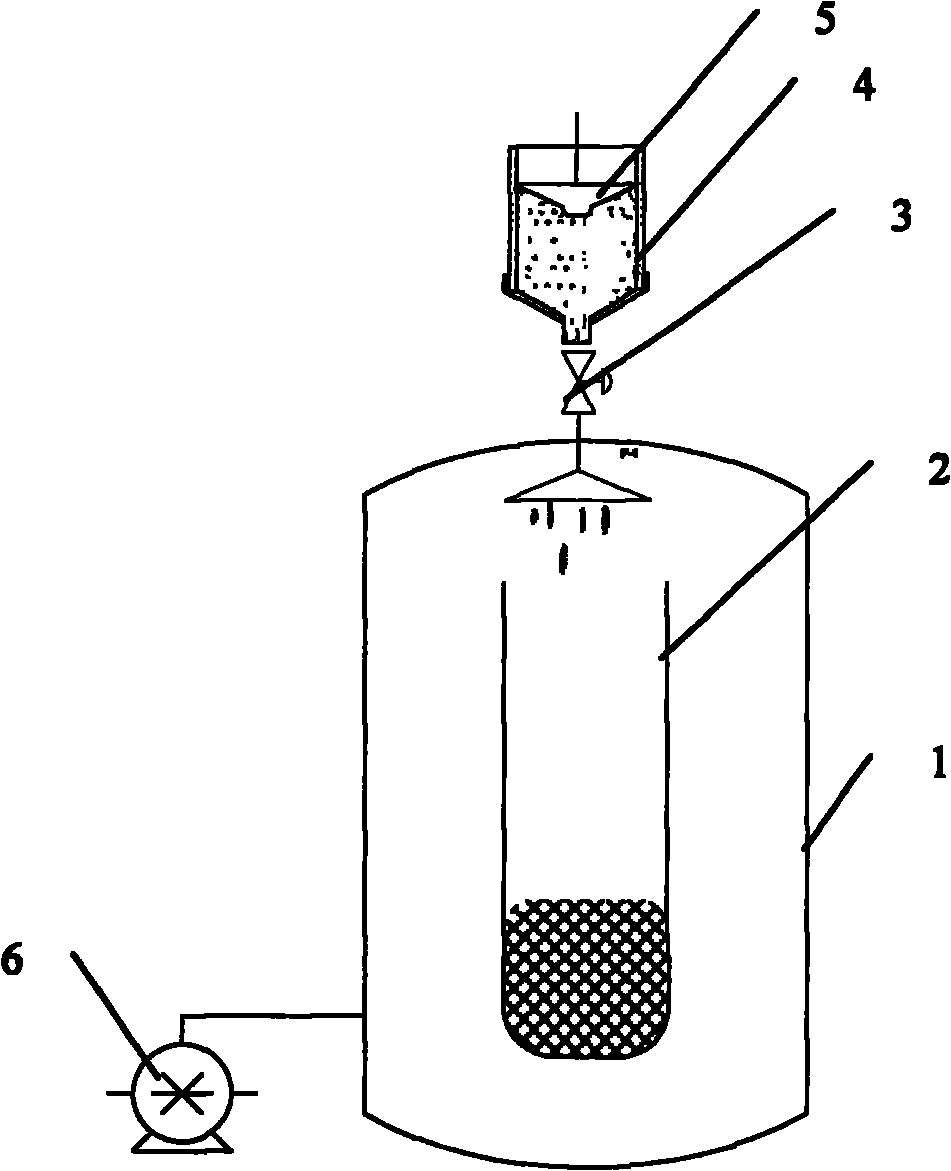

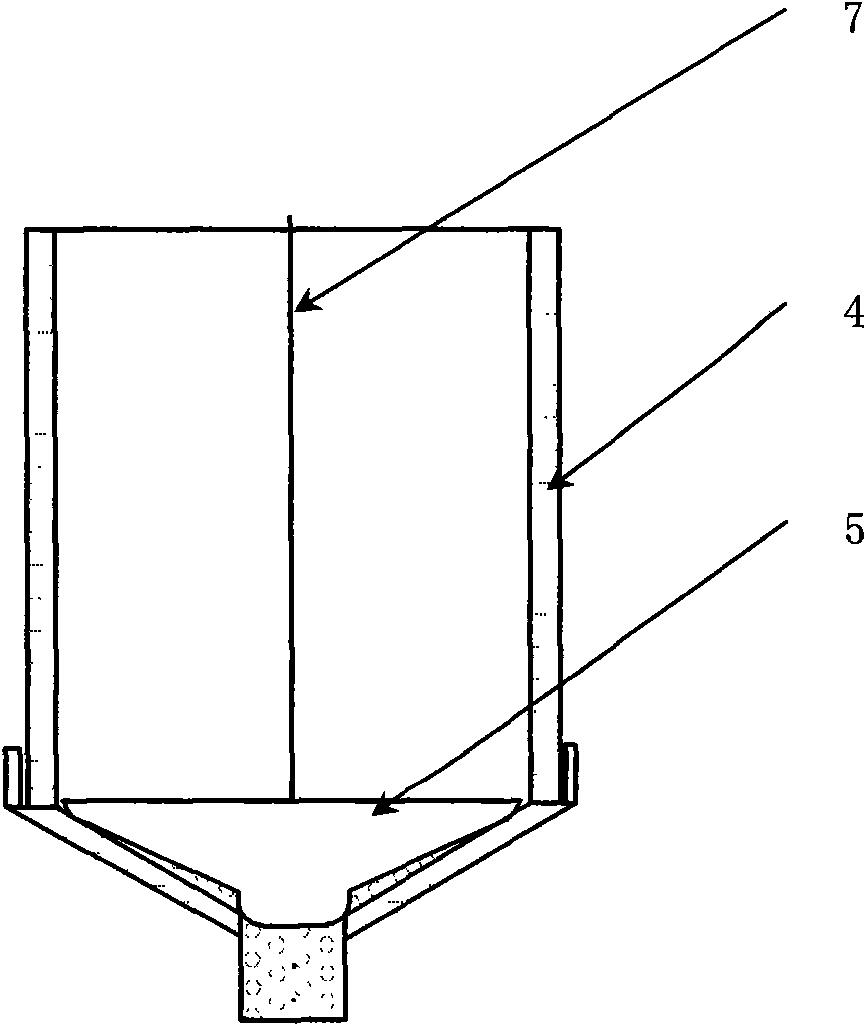

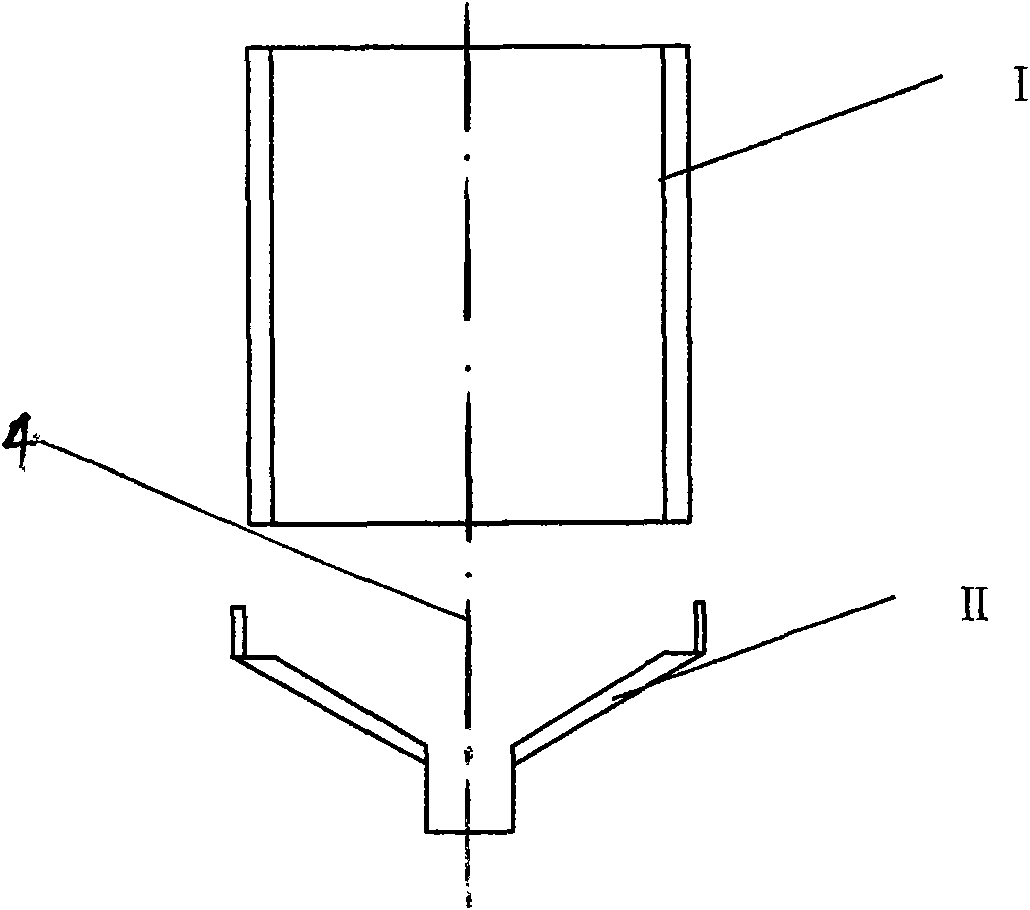

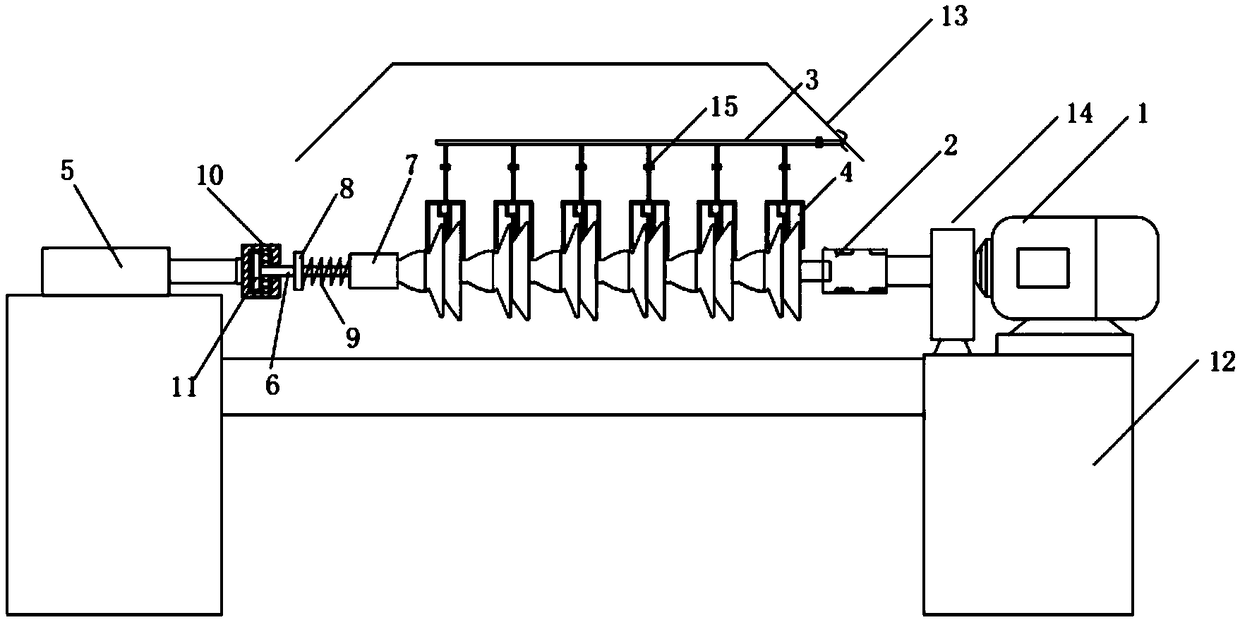

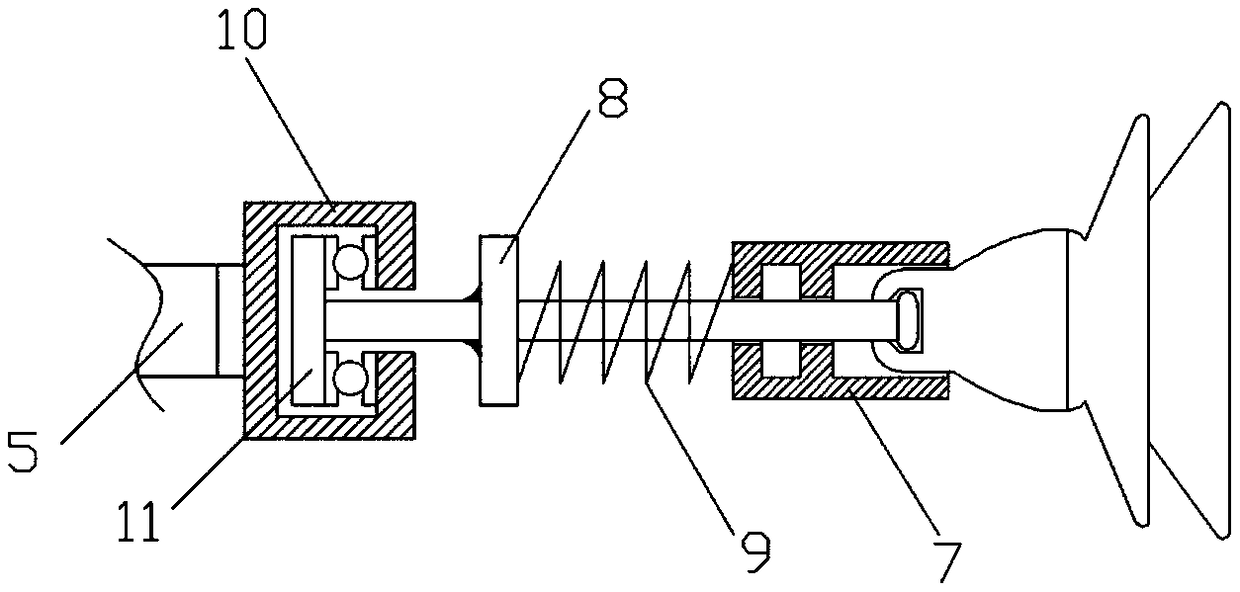

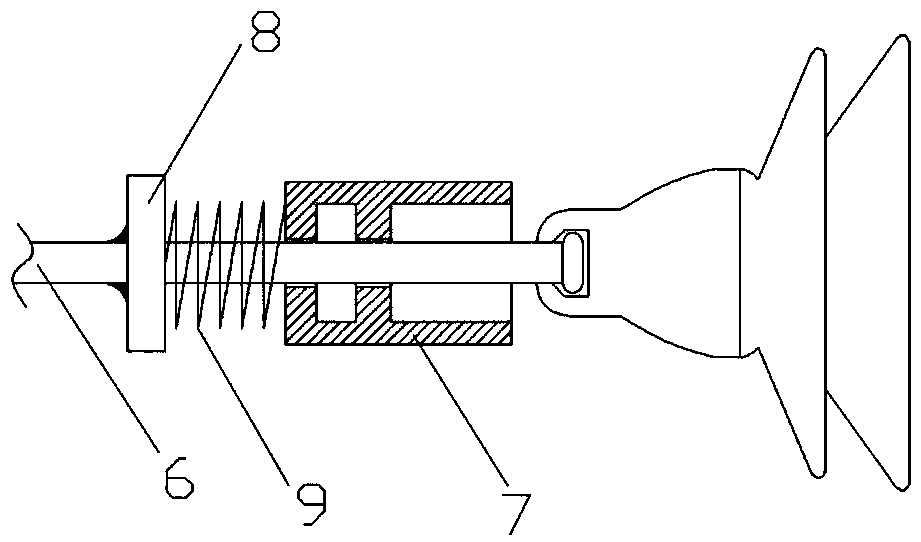

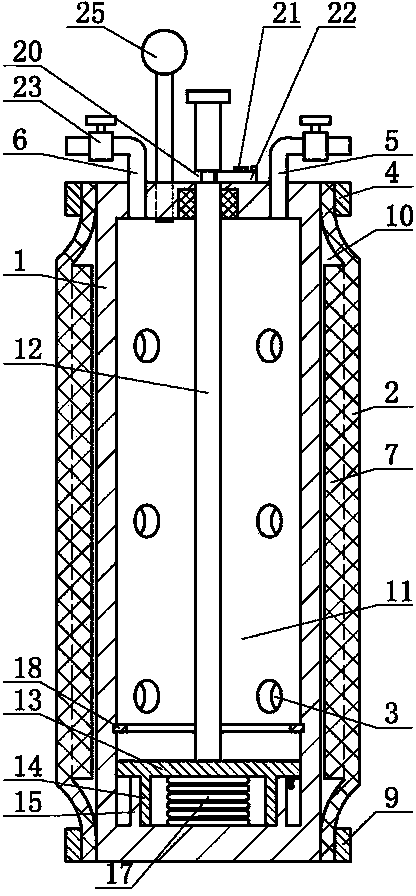

Automatically controllable explosive slurry casting system

ActiveCN101921158AReal-time cleaningNo dentsExplosive working-up apparatusAutomatic controlEngineering

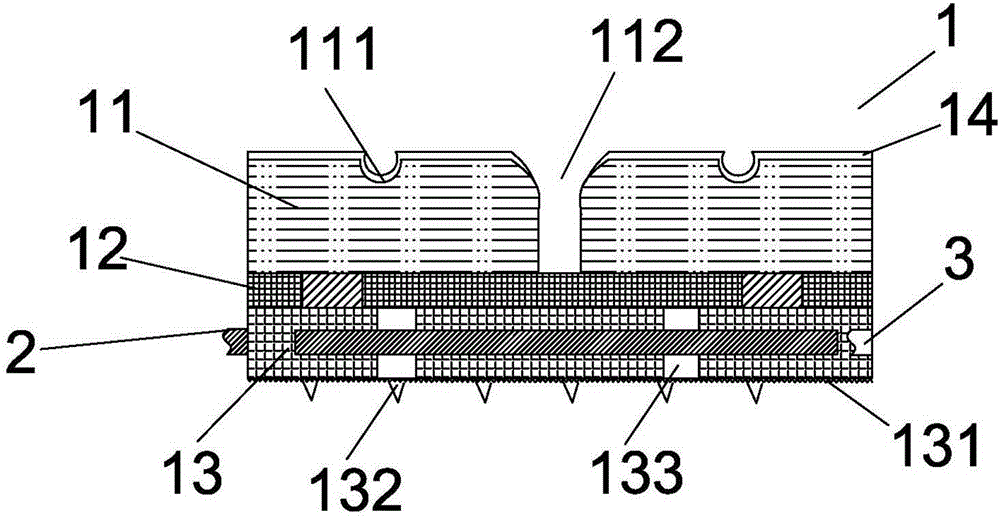

The invention discloses an automatically controllable explosive slurry casting system. A castable tank is communicated with a casting tank through a charging valve; a suspension valve is arranged in the castable tank and has a cone-like structure; the outer diameter of the suspension valve is matched with the inner diameter of the castable tank; and the lower structure of the suspension valve is matched with a charging hole of the castable tank. The suspension valve is used for controlling the liquid level of the explosive slurry in the casting process and cutting off the slurry charging whenthe casting is completed. Meanwhile, in order to facilitate controlling, detaching and cleaning the suspension valve, the slurry castable tank is modularly designed. The slurry in the castable tank can be automatically cleaned in real time, the system can be automatically closed when the slurry casting is completed, and safety accidents due to leakage of a vacuum system cannot be caused; meanwhile, the operation of personnel on dangerous goods is reduced.

Owner:中国航天科技集团公司第四研究院第四十二所

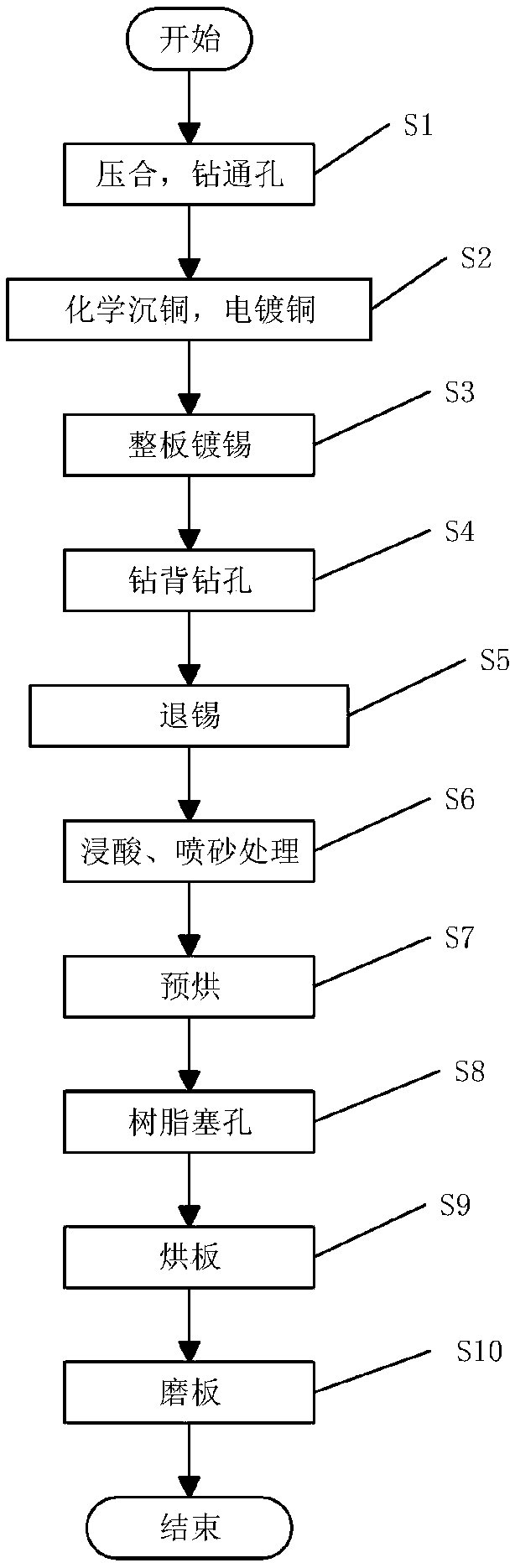

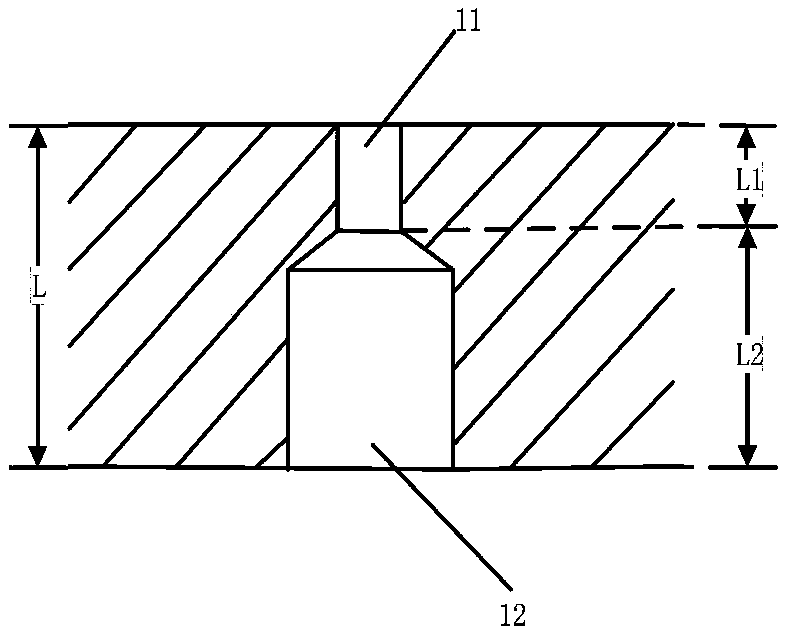

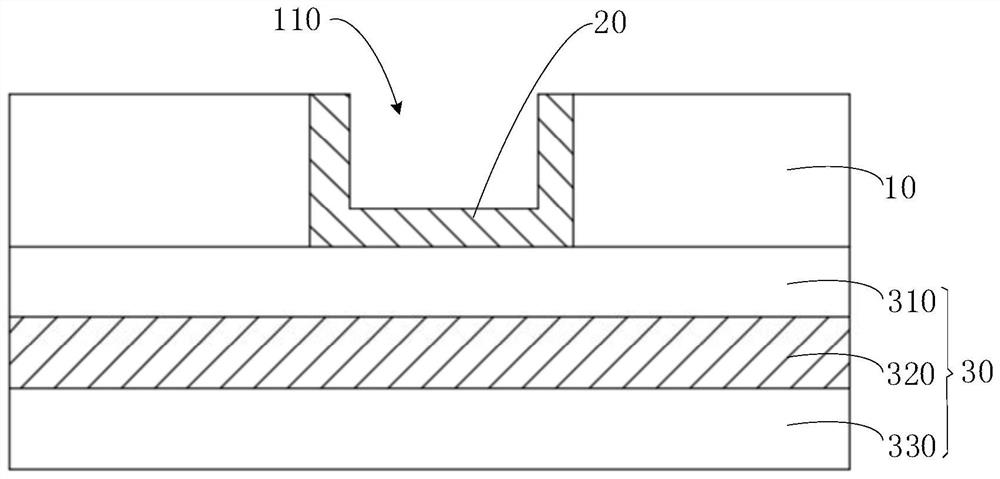

A manufacturing method of PCB back drill hole

ActiveCN108990279AQuality improvementReduce mutual interferencePrinted circuit manufactureTin platingEngineering

The invention discloses a manufacturing method of PCB back drill hole, which comprises the following steps: laminating, drilling through holes, chemical copper precipitation, electroplating copper, whole plate tin plating, drilling back drilling, tin removing, pre-drying plate, resin plug hole, drying plate and grinding plate; Wherein the back drill hole is a back drill hole having a special structure, wherein the depth ratio of the back drill hole depth to the through hole depth is greater than or equal to 1, and the depth of the back drill hole is greater than or equal to 0.5 mm; The pre-drying plate retains the residual temperature of the plate surface, and the residual temperature is higher than the ambient temperature for resin plug holes; The resin plug hole is plugged in such a waythat resin ink flows into the back hole from the through hole of the plate, and the whole back hole and the through hole are filled. The invention increases the plumpness of the plug hole of the backhole with the special structure, and improves the uniformity and reliability of the plug hole of the back hole with the special structure.

Owner:ANHUI SUN CREATE ELECTRONICS

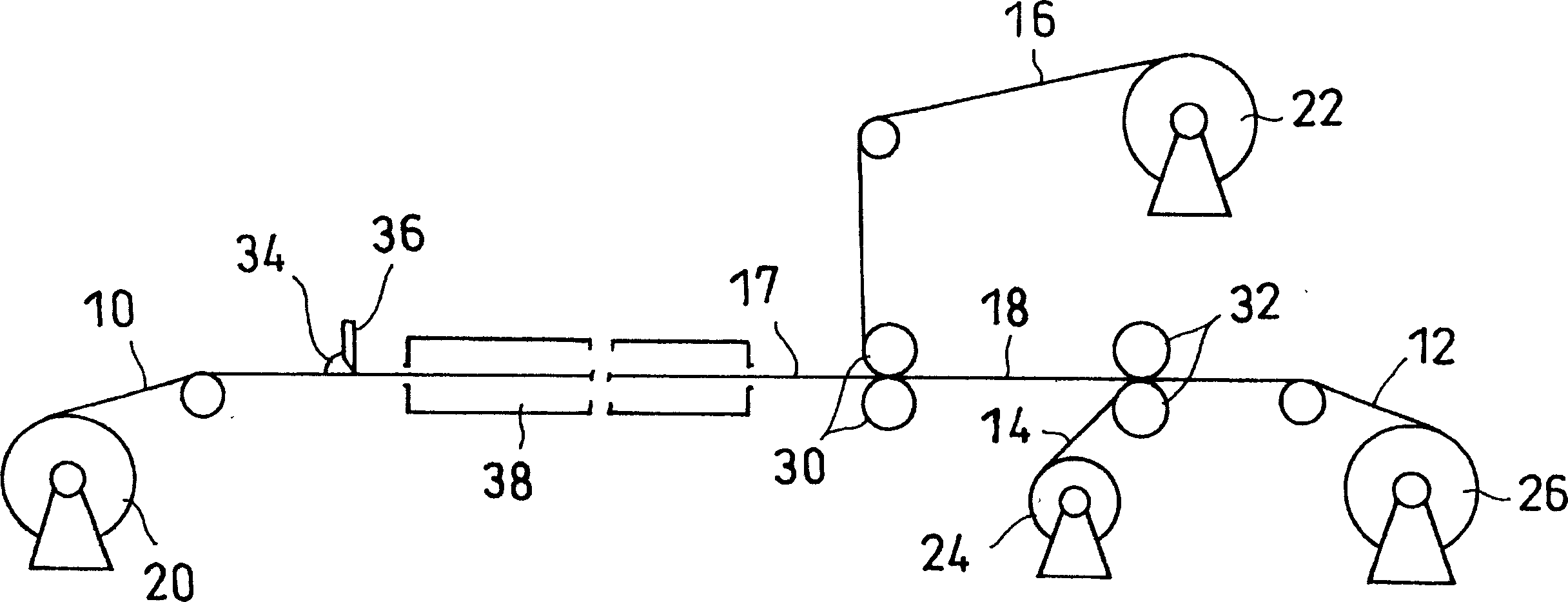

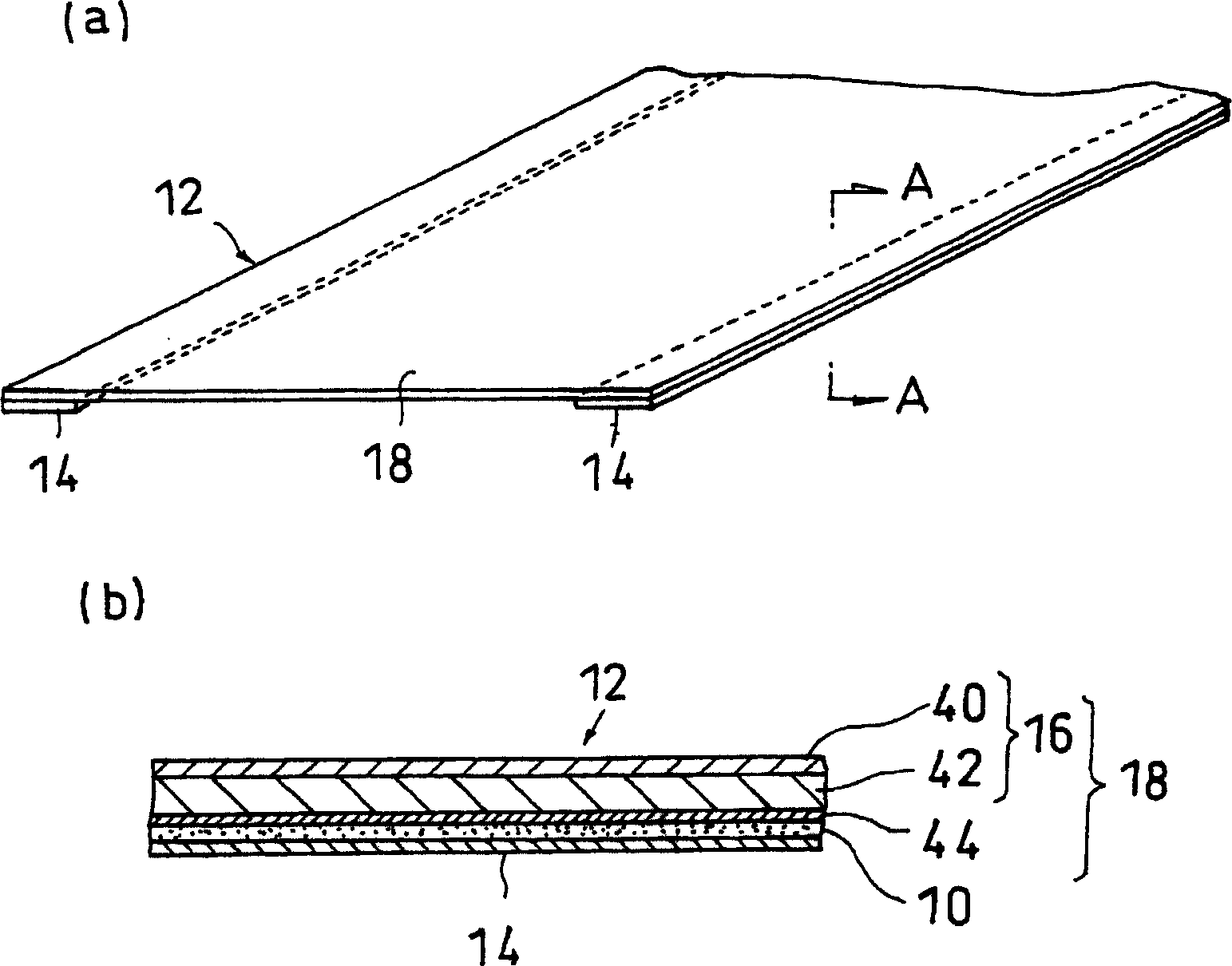

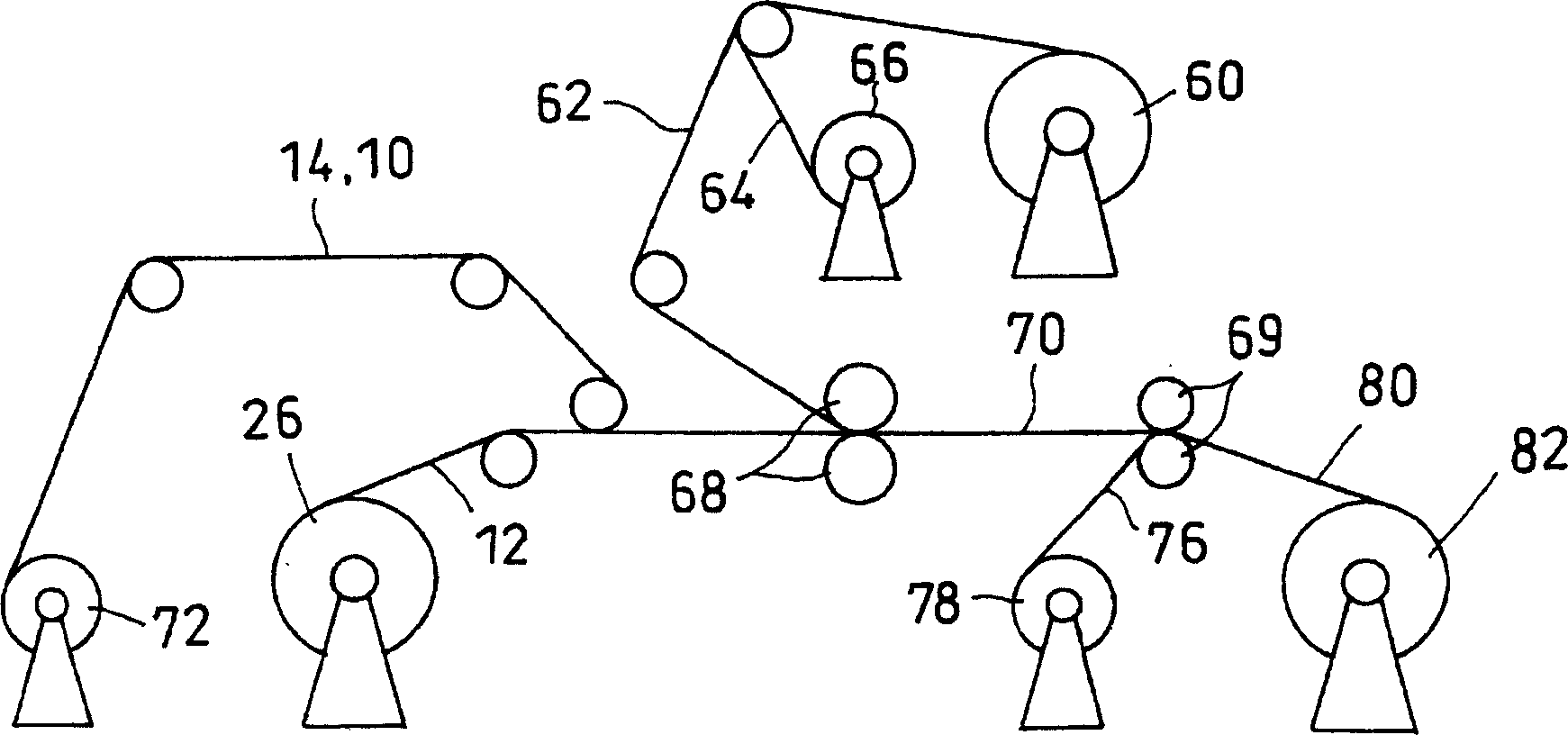

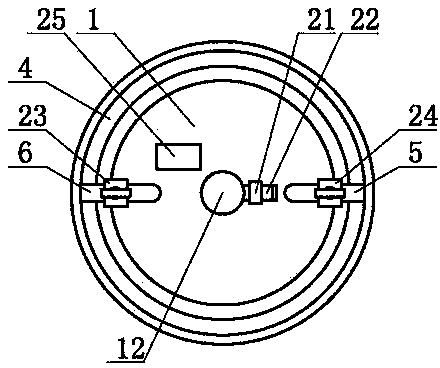

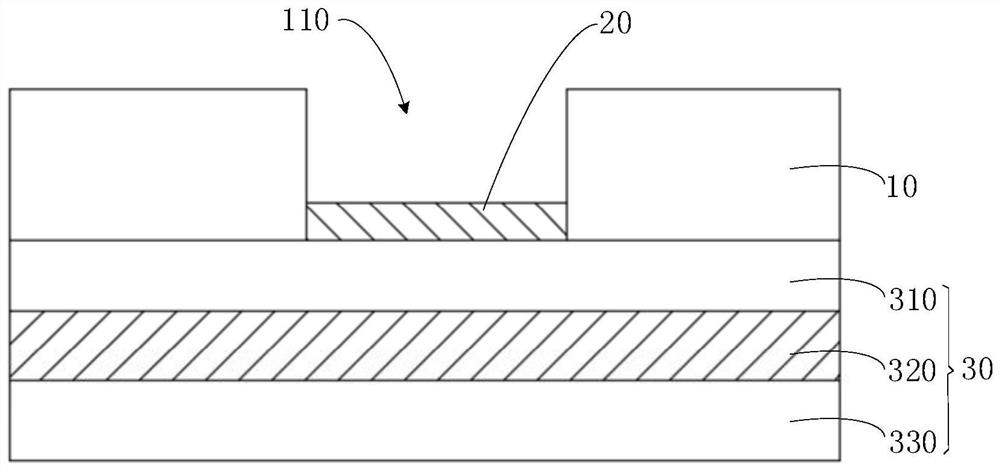

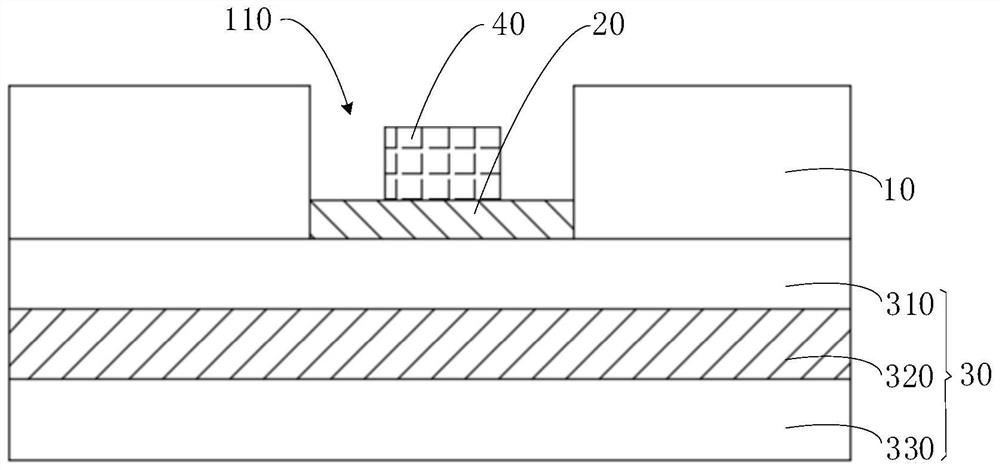

Method for producing transparent conductive film

InactiveCN1617087ANo dentsNo deformationConductive layers on insulating-supportsLayered productsDisplay deviceEngineering

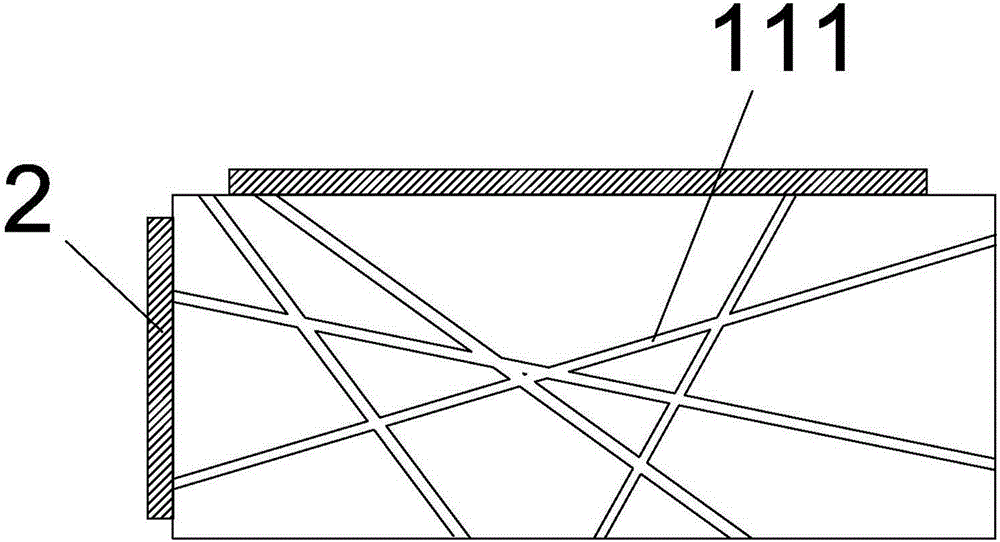

The present invention provides a method for producing a transparent conductive film for a touch panel that suppresses unevenness due to scratches, does not cause dents or deformation of images, and does not degrade display quality when used as a display. It is a kind of transparent conductive film ( 70) A manufacturing method comprising: providing spacers at both ends between the second surface of the spacer (10) of the first film (18) with an adhesive layer and the first film (16), and The process of simultaneously winding on a core to form a roll body of the first film with an adhesive layer, removing the spacer (10) while unwinding from the roll body of the first film (18) with an adhesive layer And a lamination process in which the second film (62) is supplied and adhered from the roll body wound on the core through the liner at both ends.

Owner:NITTO DENKO CORP

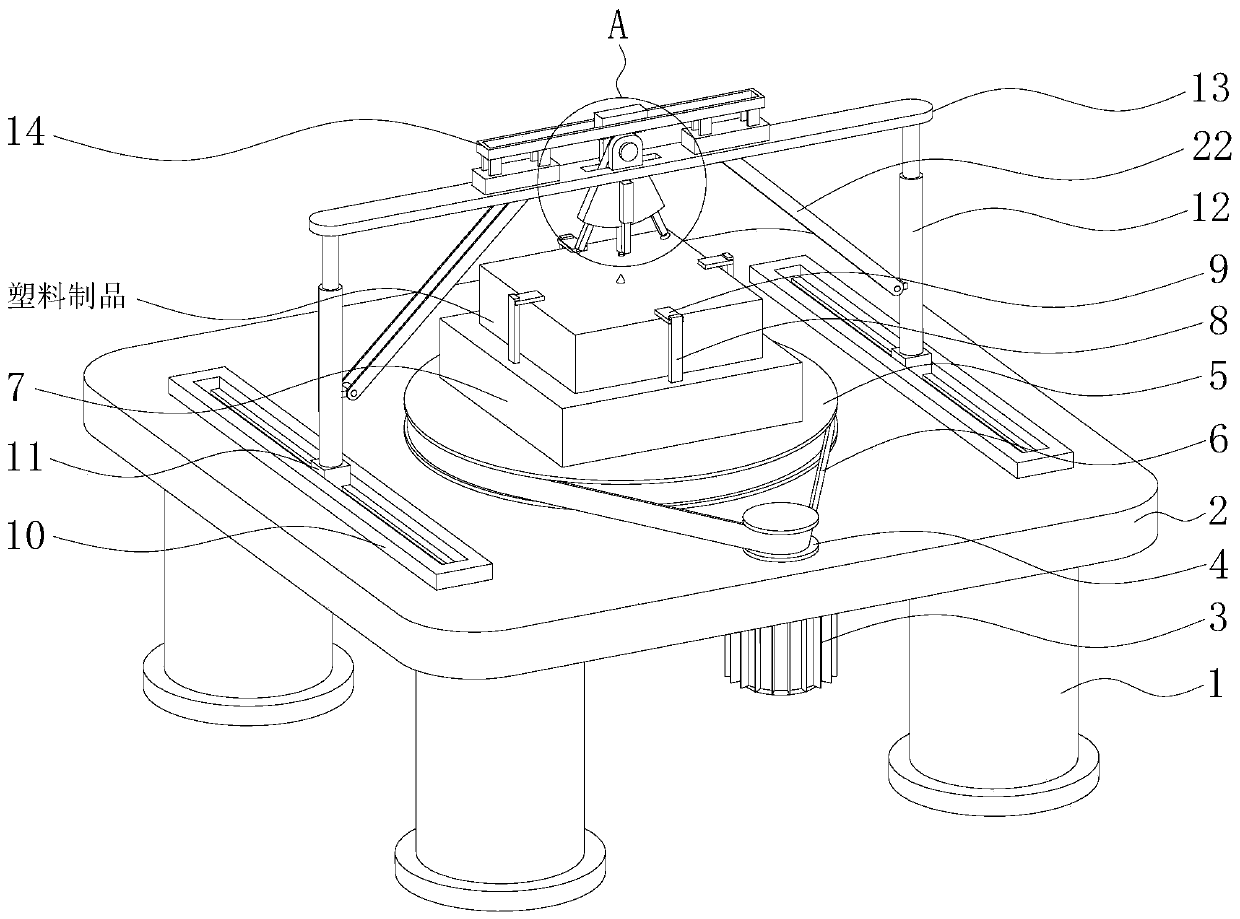

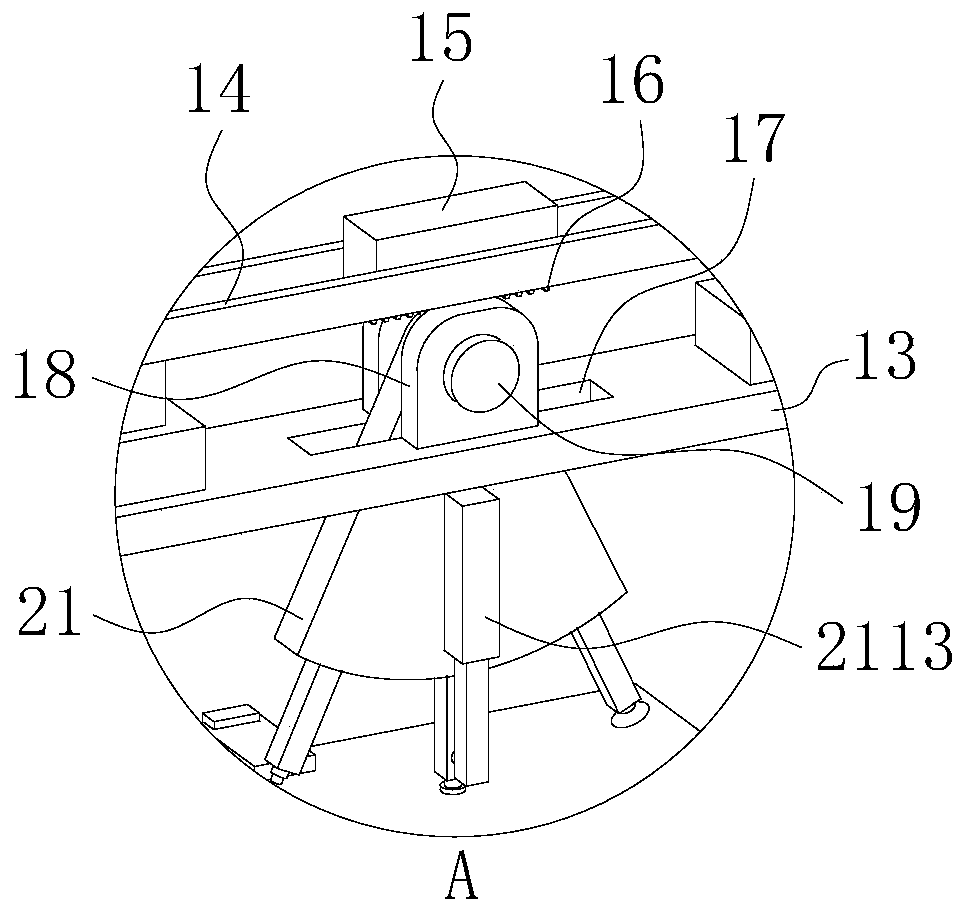

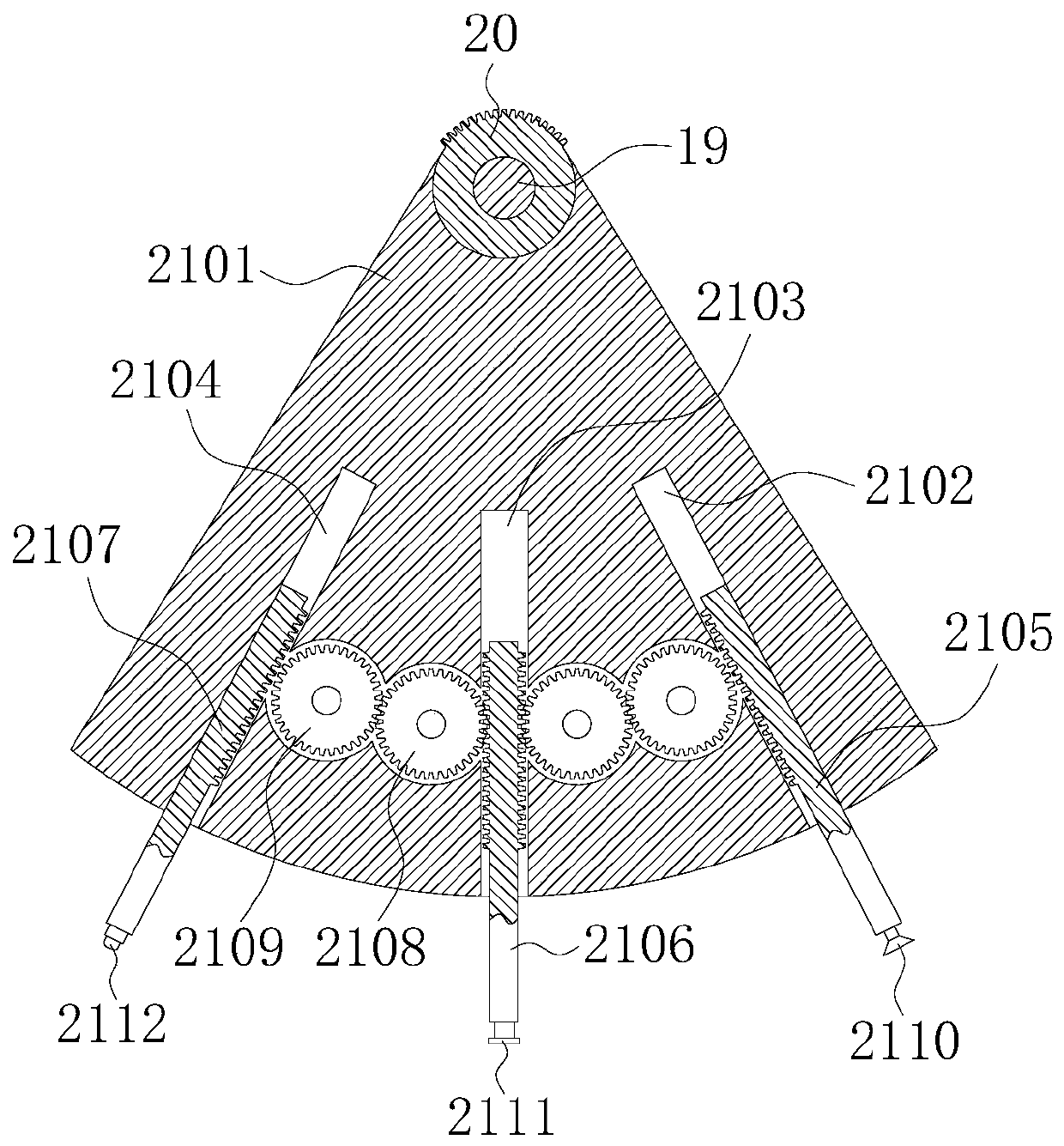

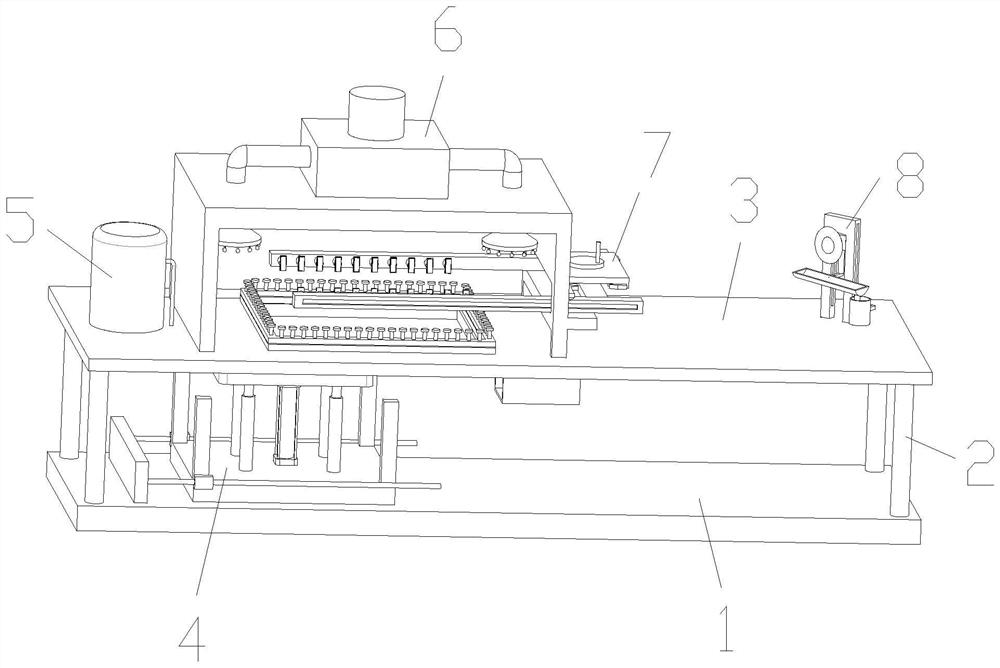

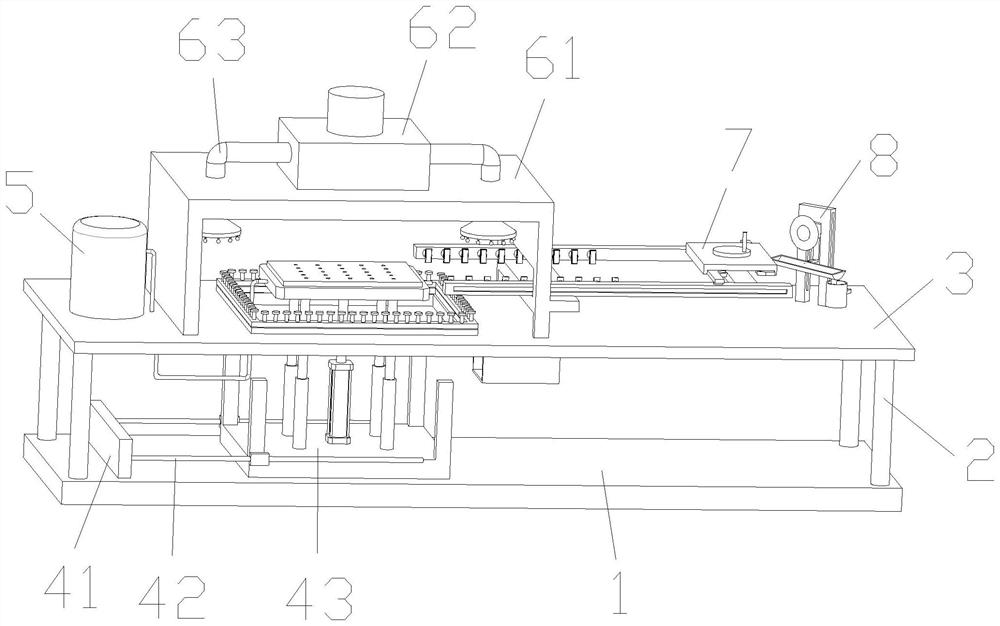

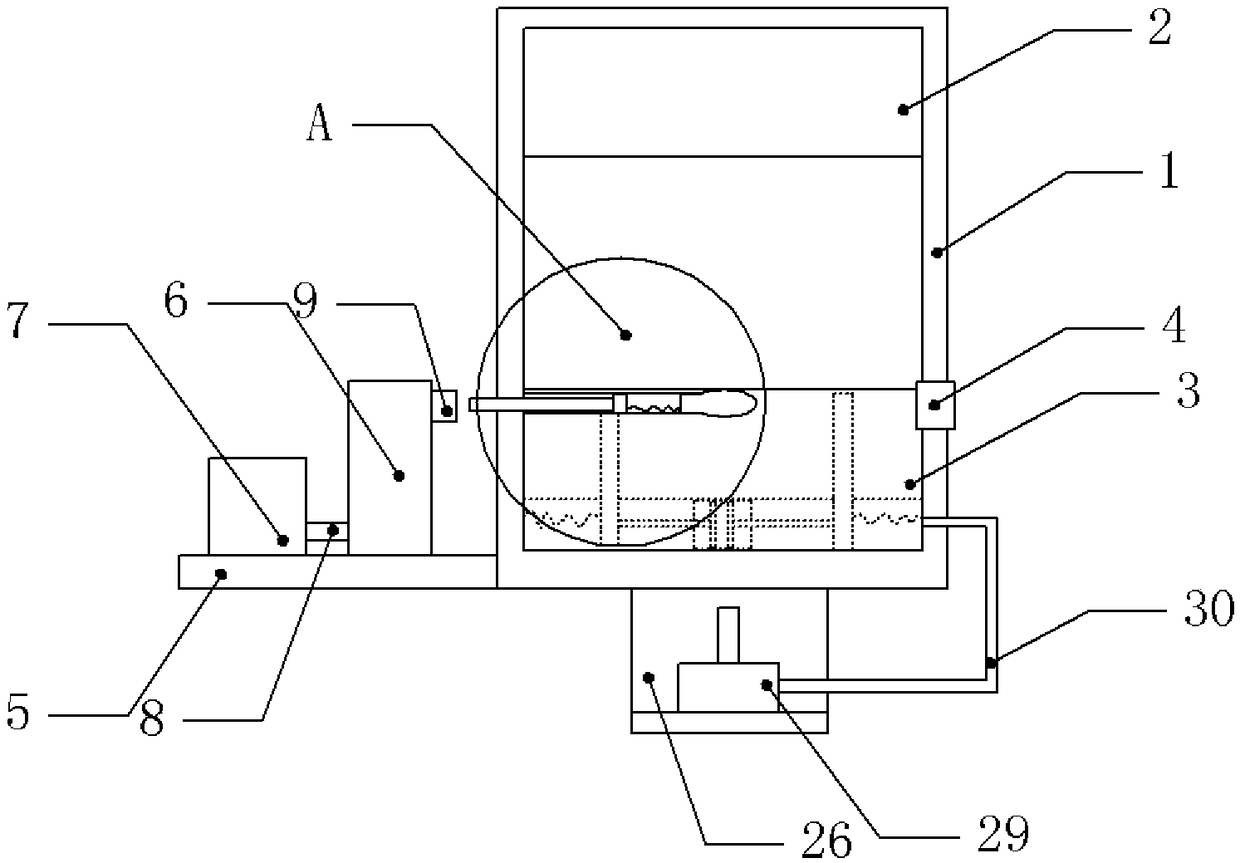

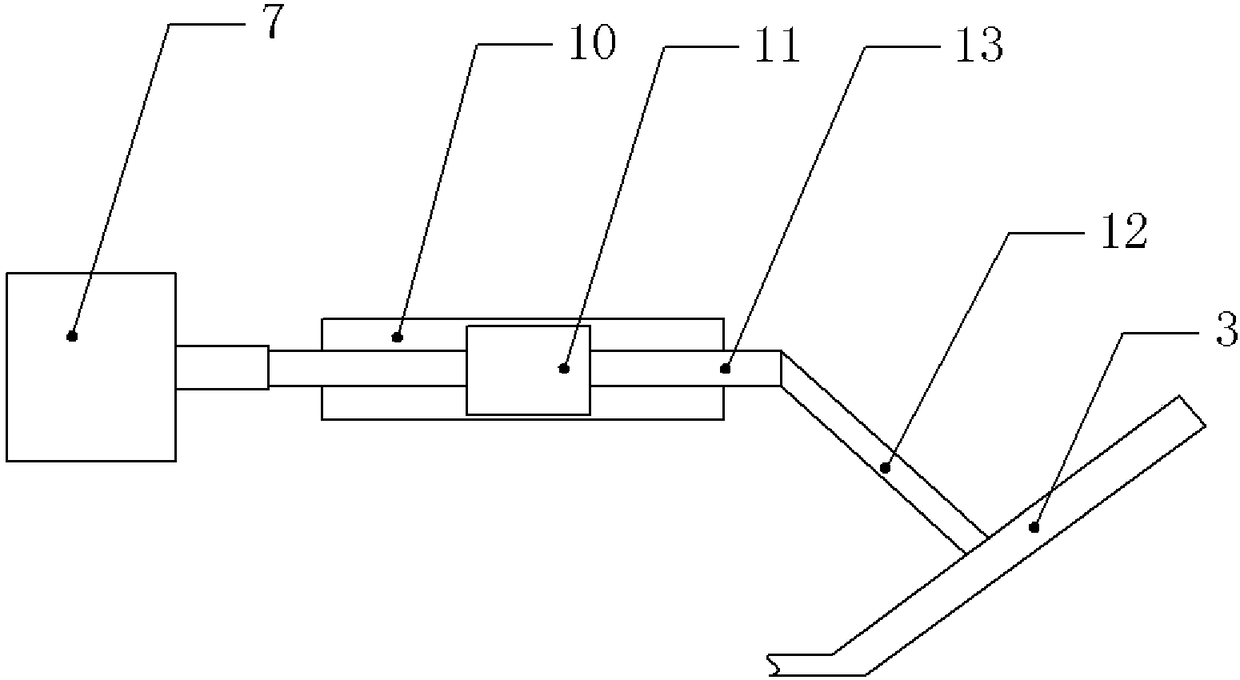

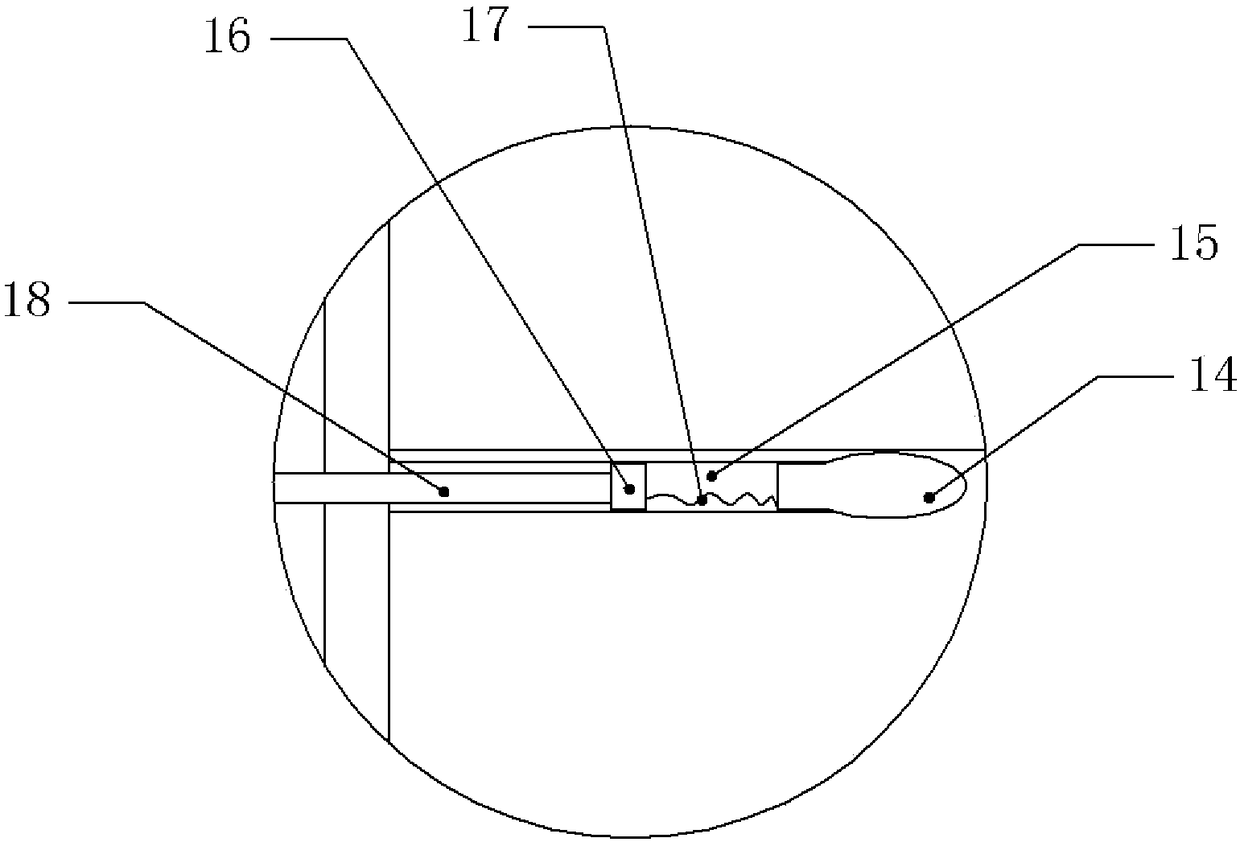

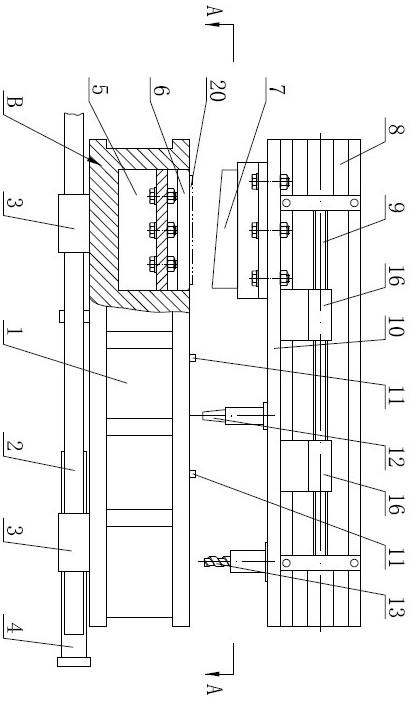

Automatic grinding processor for sprue gate of injection molding plastic product

ActiveCN110757290AEasy to operateQuality improvementEdge grinding machinesGrinding drivesElectric machineryGrinding

The invention relates to an automatic grinding processor for a sprue gate of an injection molding plastic product. The automatic grinding processor comprises a rack and a workbench, wherein a rotatingmotor is mounted below the workbench and connected with a first belt wheel; a second belt wheel and a first strip-shaped sliding rail are arranged on the workbench; a first electric sliding block isarranged on the first strip-shaped sliding rail in a matched manner; a first hydraulic cylinder is mounted on the first electric sliding block; the top of the first hydraulic cylinder is fixedly connected with a strip-shaped mounting plate; a second strip-shaped sliding rail is mounted on the upper surface of the strip-shaped mounting plate; a second electric sliding block is arranged on the second strip-shaped sliding rail in a sliding fit manner; a rack is fixedly mounted at the bottom of the second electric sliding block; a first rotating shaft is hinged to the strip-shaped mounting plate;the first rotating shaft is sleeved with an incomplete gear engaged with the rack; and a cutting and grinding mechanism is fixedly connected to the exterior of the incomplete gear. According to the automatic grinding processor, a grinding head does not need to be replaced, and the position of the grinding head does not need to be adjusted; and it can be guaranteed that the surfaces of the ground plastic product are positioned on the same plane.

Owner:东莞市美士富实业有限公司

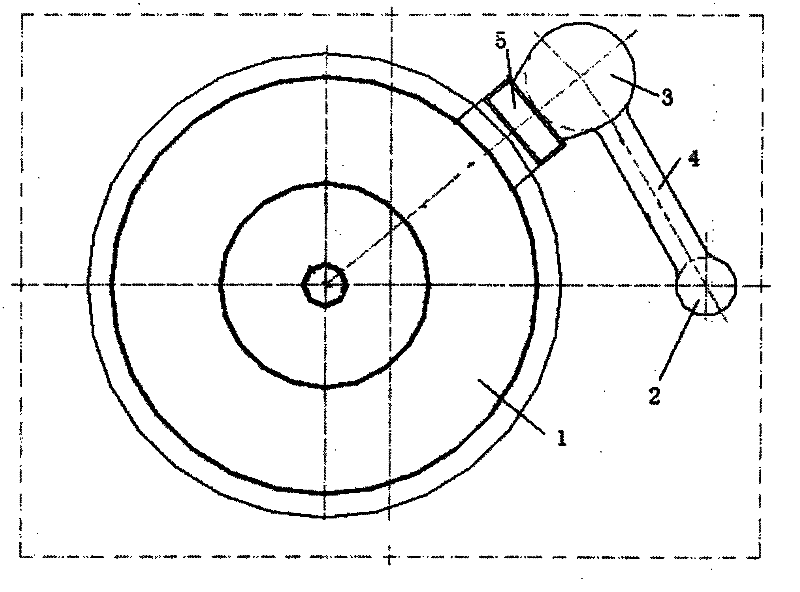

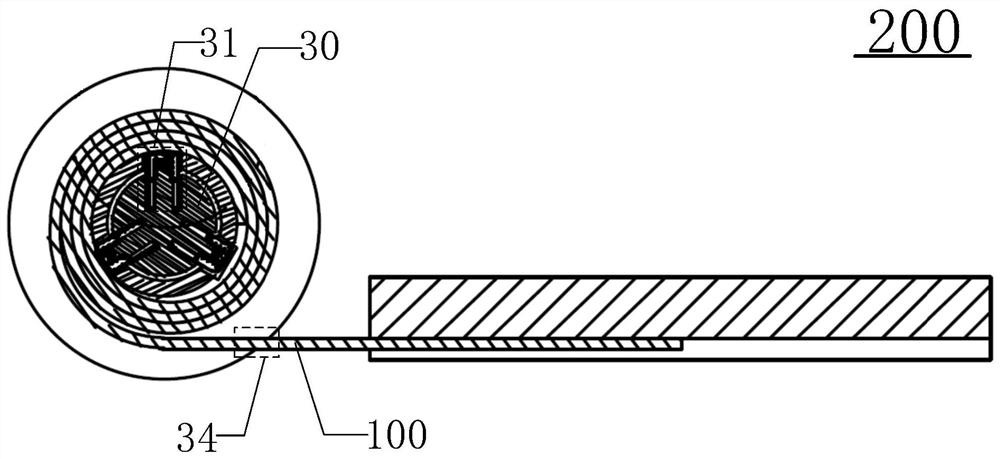

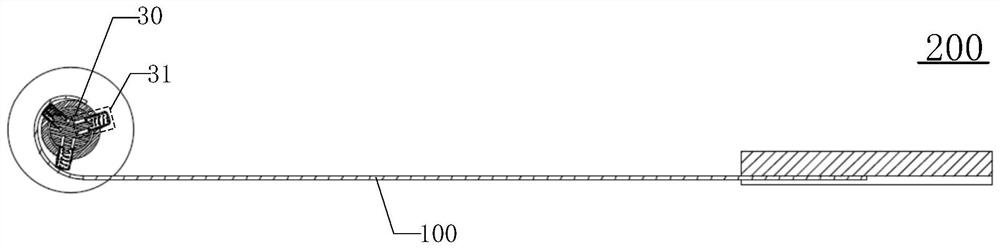

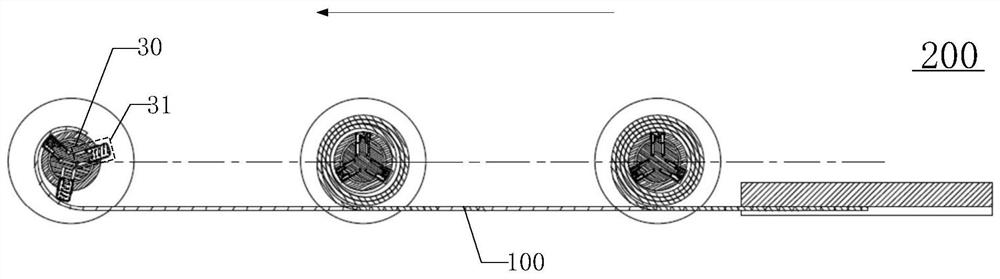

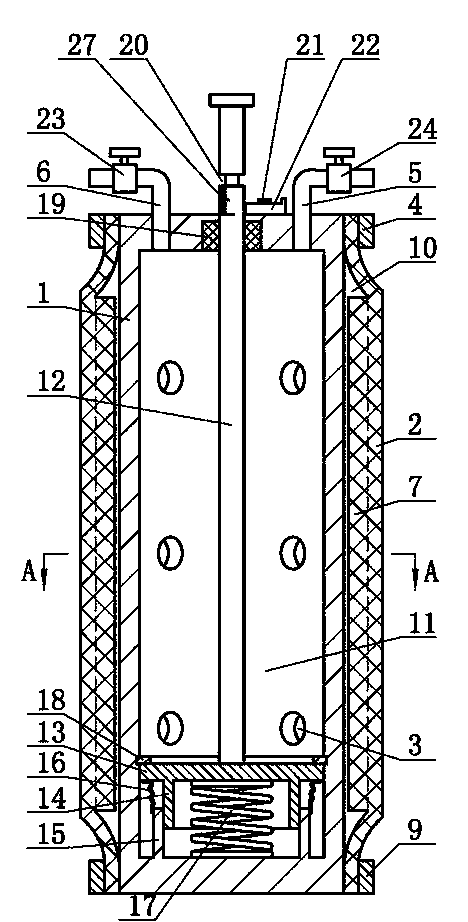

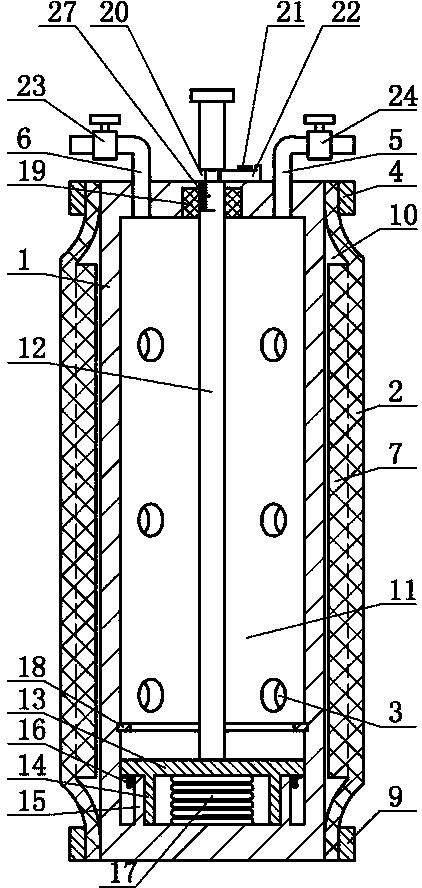

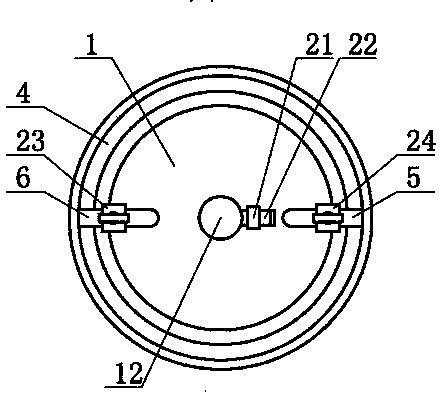

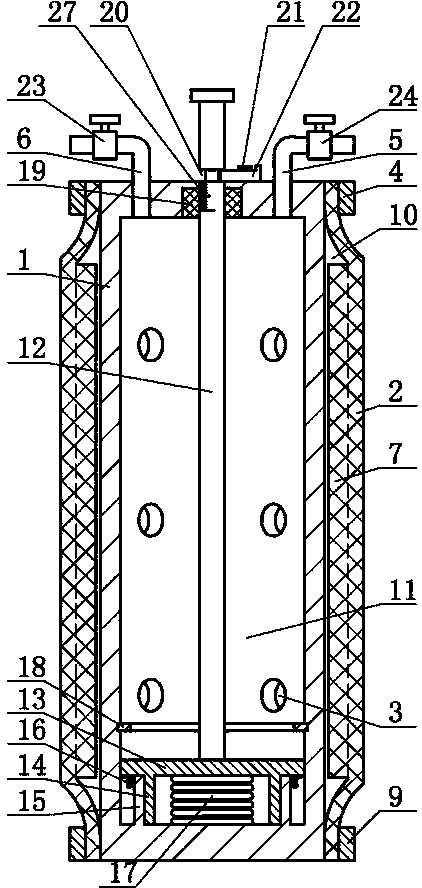

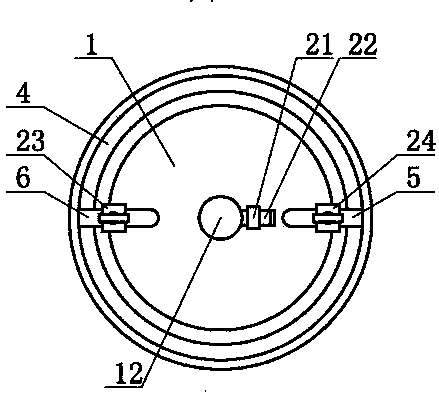

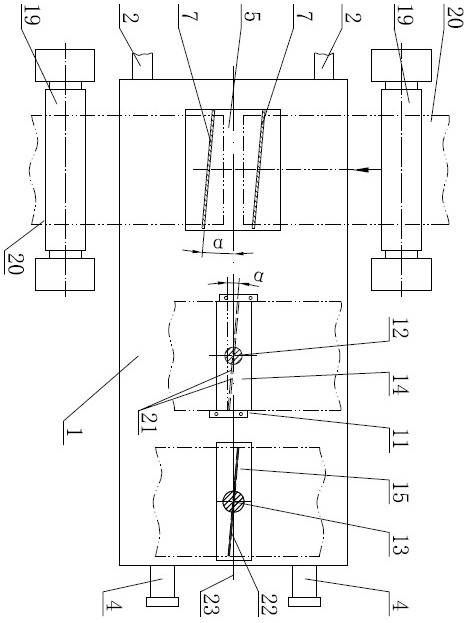

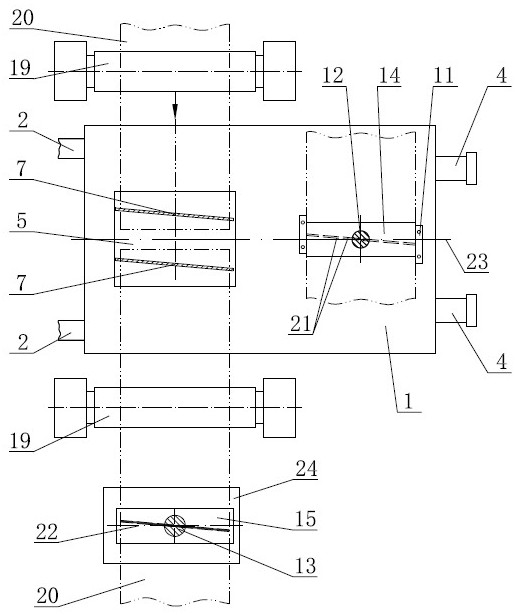

Centrifugal coating device and coating method for prefabricated insulator

The invention belongs to the field of insulator composite anti-pollution flashover coating equipment and method, in particular to a centrifugal coating device and a coating method applied to insulatorcoating. The invention adopts the centrifugal coating method with the rotating coating reagent of the workpiece insulator stationary, the coating thickness is uniform, smooth, free of bubble, bump, hanging flow, concave mark and other defects, and the coating process is convenient to disassemble and assemble. Compared with the traditional way of spraying by manipulator, the safety is greatly improved, and the quality and efficiency of the finished product are significantly improved compared with the artificial dip coating. The device and the coating method of the invention are suitable for coating outer umbrella insulators (single umbrella, double umbrella or multiple umbrellas), column insulators and other insulators.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

High-dosage lime stabilized soil subbase layer construction method

InactiveCN102839580AGuarantee the construction qualityReasonable designRoadwaysWater contentDigestion

The invention relates to a treatment method for treating roadbed, in particular to a high-dosage lime stabilized soil subbase layer construction method which is fast in construction speed, high in achieving quality, and stable in soil subbase layer. The high-dosage lime stabilized soil subbase layer construction method includes eight steps of construction preparation, measuring and setting out, material preparation, soil arrangement and ash distribution, stirring, reshaping, grinding and activity preservation, wherein the step of material preparation includes lime preparation and soil preparation. When lime is prepared, the lime is firstly digested for 7-10 days and then sieved through sieving holes of 10 millimeters, and the water usage for digestion is 500-800 kilograms / ton. When soil is prepared, the maximum size of the particle of the soil is not larger than 15 millimeters, and the quantity passing through sieving holes of 5 millimeters is larger than 60%. In the step of stirring, a stabilized soil mixer is matched with a ploughshare for stirring, and stirring depth is within the limit of infiltrating the subbase layer. When in construction, water content of the materials is detected timely, and the materials are watered when the water content is lower than -2% of the optimum water content and aired when the water content is larger than +2% of the optimum water content.

Owner:李应芝

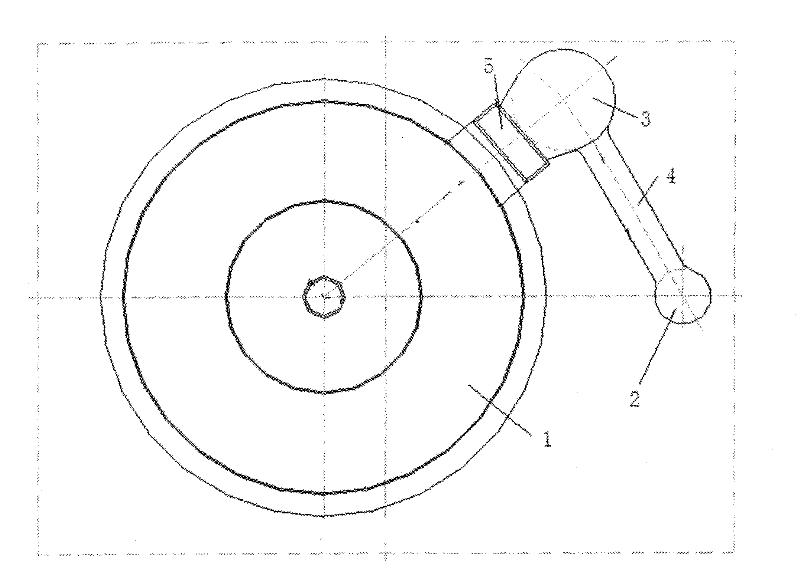

Automobile flywheel pouring system and pouring method

InactiveCN102259164AReduce internal shrinkageReduce shrinkage defectsFoundry mouldsFoundry coresFlywheelHead and neck

The invention provides an automobile flywheel pouring system and a pouring method thereof which can reduce the reject rate of castings and have a smooth surface. The automobile flywheel pouring system of the present invention comprises a sprue cup, a sprue, a runner, a riser with a riser neck, and an ingate; it also includes a riser neck chill, and the riser neck chill is located at below the riser neck. In the pouring system and pouring method for the automobile flywheel of the present invention, the riser neck cold iron is placed at the riser neck, which can not only make full use of the limited amount of liquid iron feeding of the riser, but also make the riser neck solidify in time, and give full play to the ductile ink. The expansion and self-feeding effect of cast iron graphitization greatly reduces the internal shrinkage cavity and shrinkage porosity defects of the flywheel casting, reduces the reject rate of the flywheel from 15% to less than 5%, and greatly improves the process yield.

Owner:湖北丹江口志成铸造股份有限公司

Electroless engraving thermocompression bonding gold stamping process

ActiveCN107323115AImprove aestheticsImprove bronzing effectDuplicating/marking methodsInksEngravingStamping process

The invention relates to the technical field of gold stamping, and concretely relates to an electroless engraving thermocompression bonding gold stamping process, which comprises the following steps of A, printing: printing gold stamping oil on the surface of an object to be subjected to gold stamping, and obtaining a print with a preset pattern to be subjected to gold stamping; B, curing: carrying out photocuring treatment on the print obtained through the step A, and obtaining a solid print with a preset pattern to be subjected to gold stamping; and C thermocompression bonding: covering a gold stamping film on the surface of the solid print obtained through the step B, using a soft edition for carrying out thermocompression bonding treatment on the solid print covered with the gold stamping film, and obtaining a gold stamping product with the preset gold stamping pattern. The gold stamping process provided by the invention does not need electronic engraving for gold stamping, and is convenient and fast in process operation, high in production efficiency and low in production cost, so that the prepared gold stamping product has the characteristics of high glossiness, high attractiveness, good hand feeling, excellent three-dimensional effect and the like, and is stable in quality and suitable for large-scale production.

Owner:缪秉强

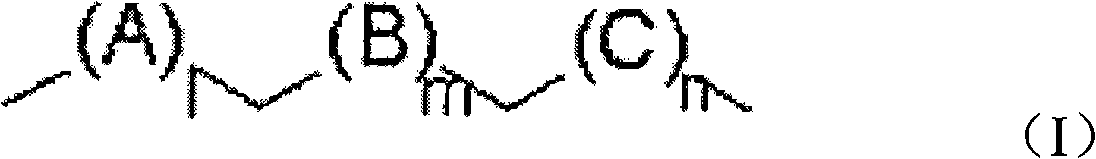

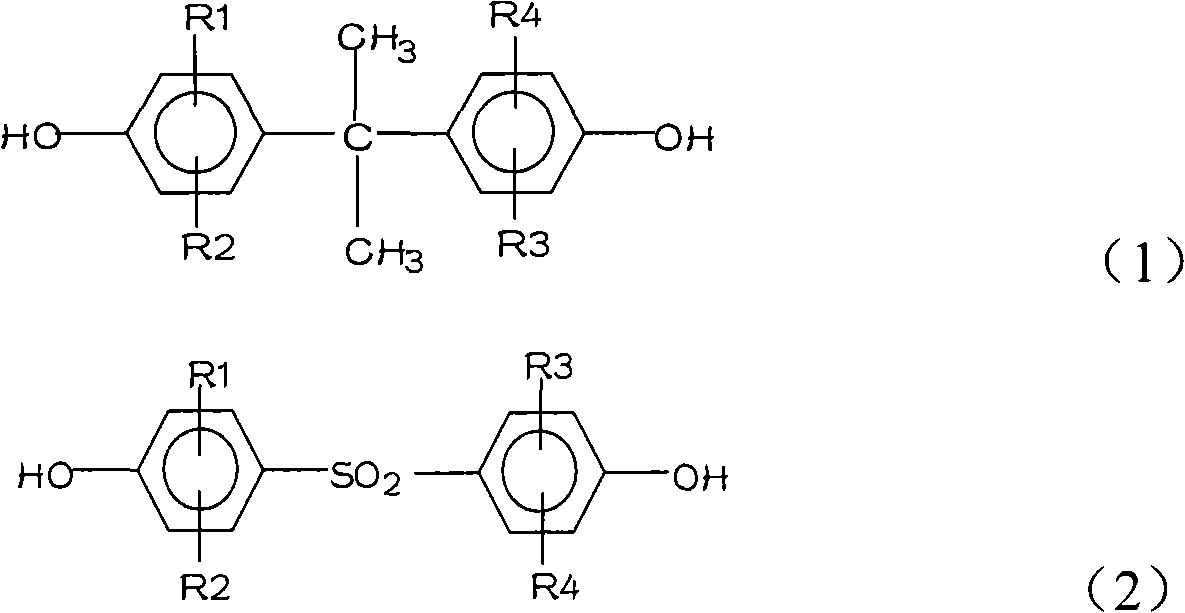

Film-forming resin and heat reactive resin compositions with the film-resin forming

InactiveCN101284891AHigh hardnessImprove heat resistanceNon-linear opticsOptical elementsTectorial membraneHeat resistance

The invention provides a film forming resin which comprises a unit formed by a monomer A and a unit formed by a monomer B, wherein, the monomer A is the methyl acrylate with an epoxide group, the monomer B is one or more than one of the (methyl) benzyl acrylate, the (methyl) acrylic acid phenethyl ester and the (methyl) acrylic acid phenyl ester, in the film forming resin, the mol ratio of the unit formed by the monomer A and the unit formed by the monomer B is between 1:1 and 8:1, the weight average molar mass of the film forming resin is between 5000 and 100000. The thermocuring resin compound greatly improves the hardness of a protective film for a colorful spectral filter and the heat-resistant polychromasia. In addition, the thermocuring resin compound has good storage stability; the protective film formed by the thermocuring resin compound has good heat resistance, leveling property, light-admitting quality, anti-ITO sputtering property, etching-proof characteristic, adhesive attraction and the uniformity of the film thickness.

Owner:BYD CO LTD

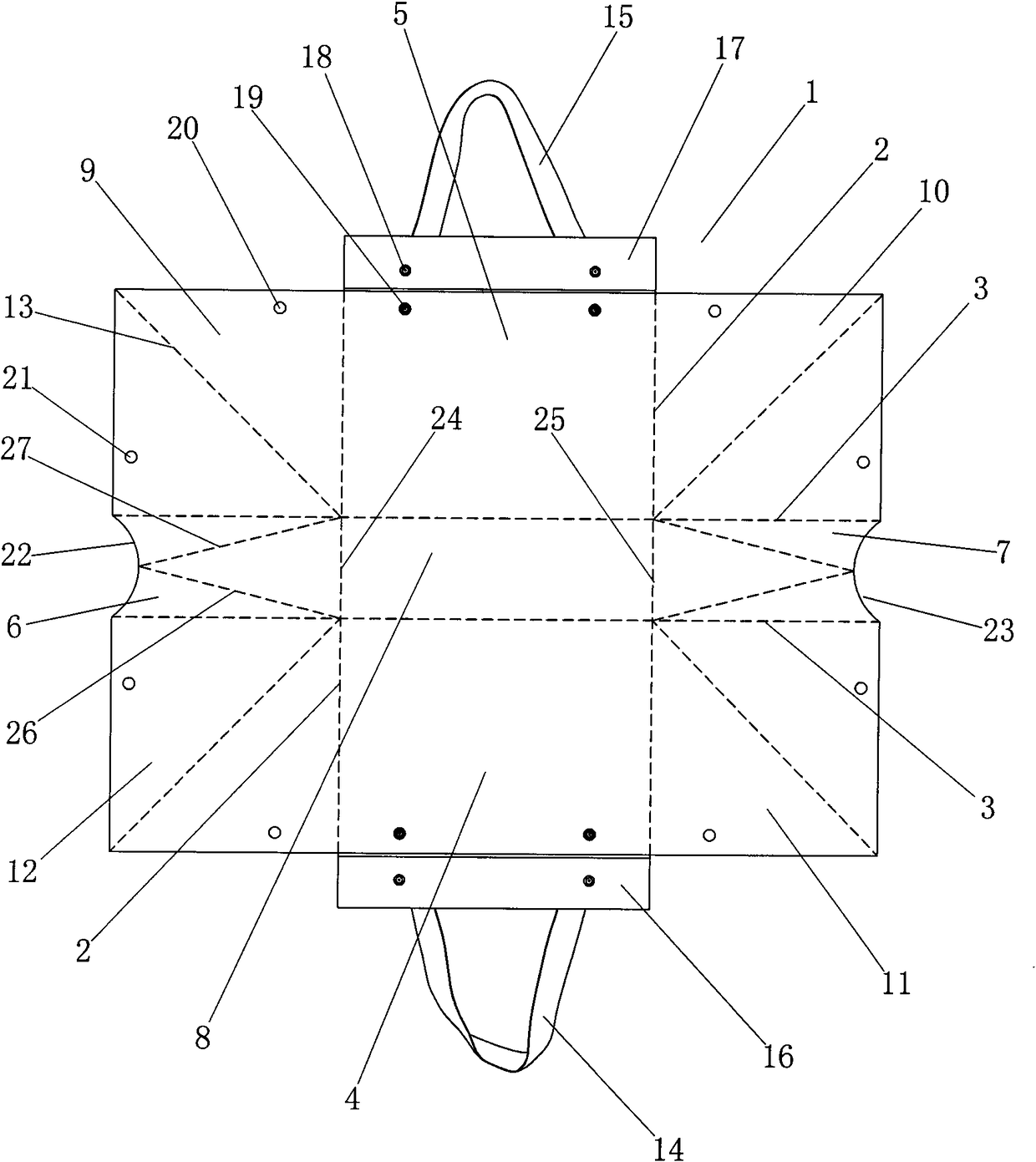

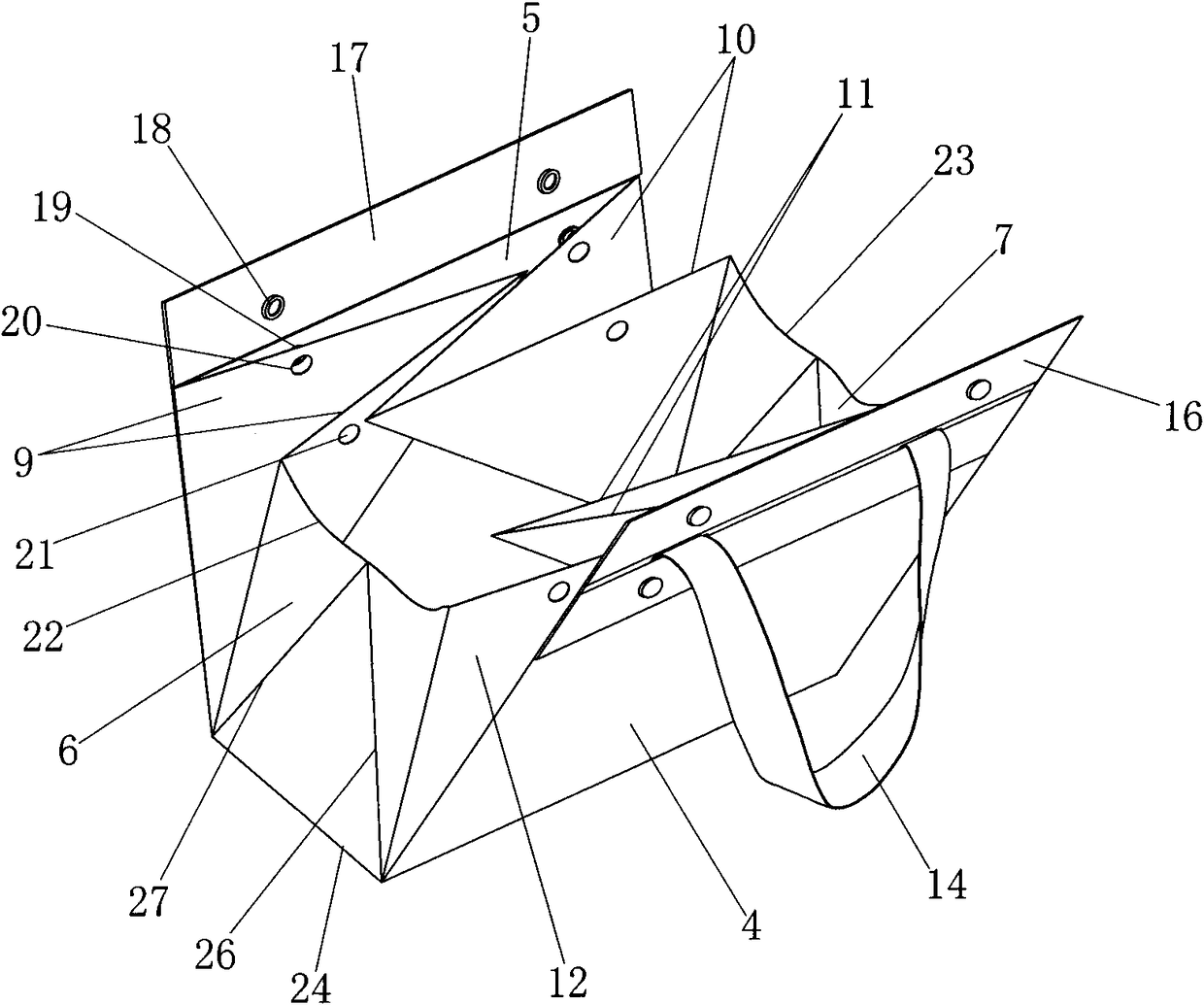

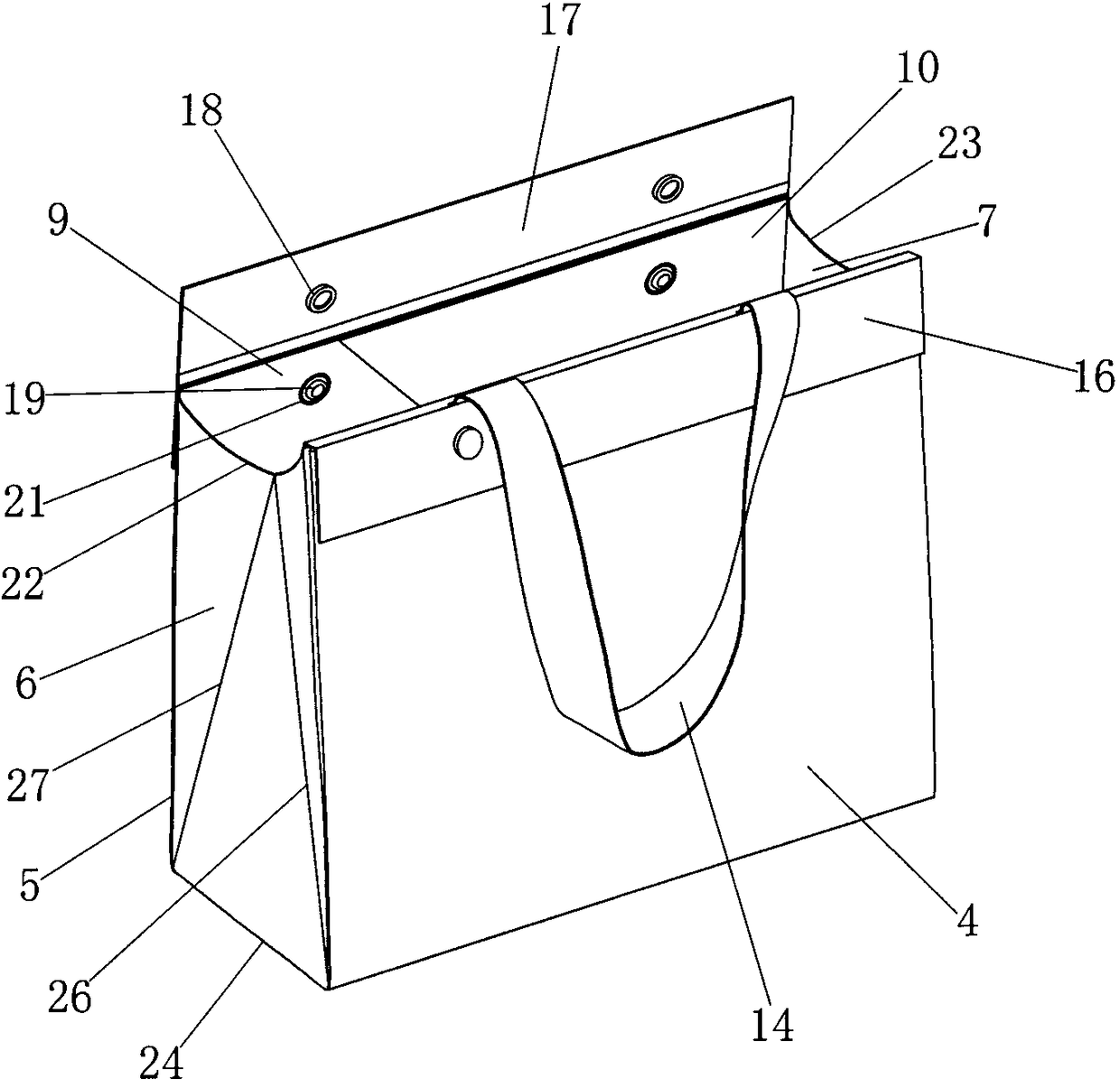

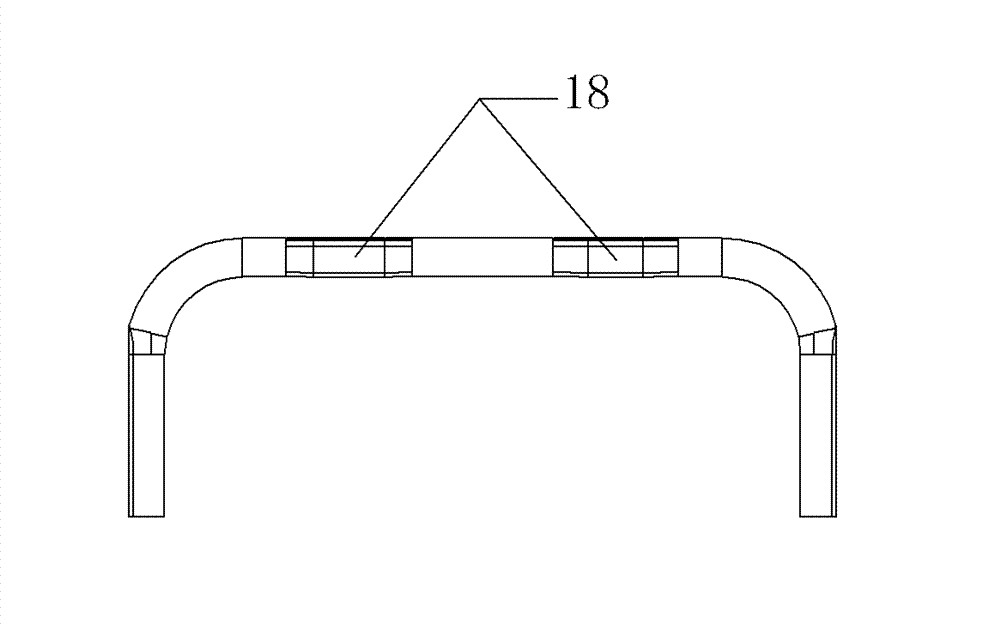

Folding buckle type portable square-bottom typical carry bag

The invention provides a folding buckle type portable square-bottom typical carry bag. In order to solve the problems that in the prior art, the firmness is poor, a handle is easy to damage, the appearance is affected by front and back folding press lines, lateral forms are complicated and the appearance of a bag opening is poor, the folding buckle type portable square-bottom typical carry bag ischaracterized in that a piece of paper capable of being spread is divided by folding press lines into areas of a front bag face, a rear bag face, a left lateral bag face, a right lateral bag face, a bottom bag face and four corners, the four corners are each provided with corner easily-folded press lines, the front bag face and the rear bag face are provided with handles and internal folding parts, the internal folding part of the front bag face and the internal folding parts of the rear bag face are provided with components A which are provided with snap fasteners through nails respectively,the upper portion of the front bag face and the upper portion of the rear bag face are provided with components B which are provided with snap fasteners through nails respectively, and the buckled parts of the components A and B are located on the internal lateral faces of the paper. Through holes aligned to the components B are formed in the four corners, recessed lines are arranged at the top edges of the left and right lateral bag faces, and lateral easily-folded press lines are arranged between the middle points of the top edges and the two end points of the bottom edges respectively.

Owner:郑烈森

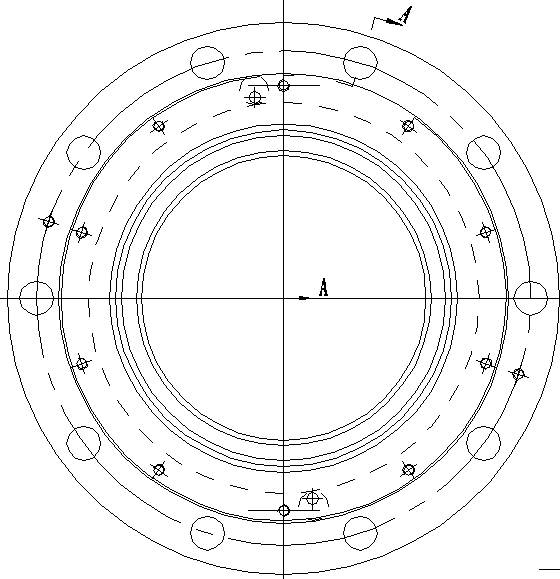

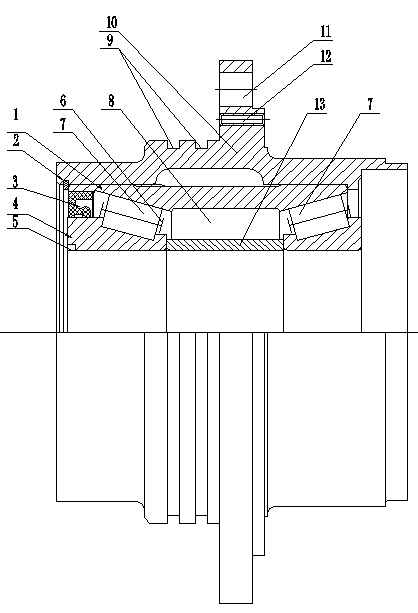

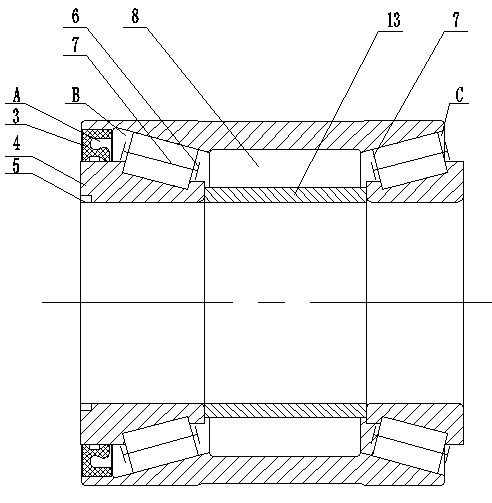

Heavy track rear hub bearing combination

InactiveCN104006075AImprove rigidityImprove carrying capacityRolling contact bearingsBearing componentsEngineeringMechanical engineering

The invention provides a heavy track rear hub bearing combination which comprises a hub and a bearing component arranged inside the hub, wherein the bearing component is of an integrated structure and comprises an outer ring, two inner rings, a partitioning ring, two holding racks and two rows of conical rollers; the two inner rings are arranged inside the outer ring at an interval through the partitioning ring; a chamber is formed among the outer walls of the inner rings, the inner wall of the partitioning ring and the inner wall of the outer ring; the chamber comprises a sealing part, a first mounting part, an oil channel and a second mounting part which are arranged in sequence; the two rows of conical rollers are respectively arranged at the first mounting part and the second mounting part through the two holding racks; the sealing part is internally provided with an oil seal for plugging the end opening of the chamber. The bearing combination has the advantages that the bearing combination is good in rigidity, is high inbearing capability, is long in service life, does not rotate relatively to the large outer diameter of the hub, cannot cause friction, and increases the contact area; the hub is not easy to abrade, and the hub is not concave.

Owner:济南普度重卡有限公司

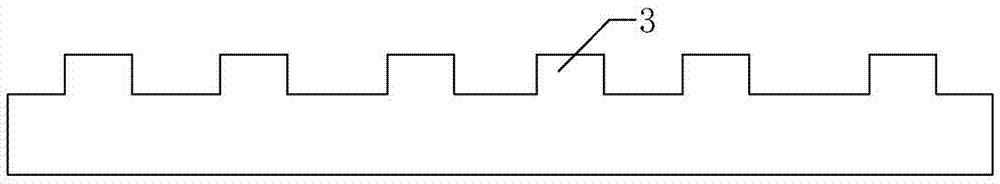

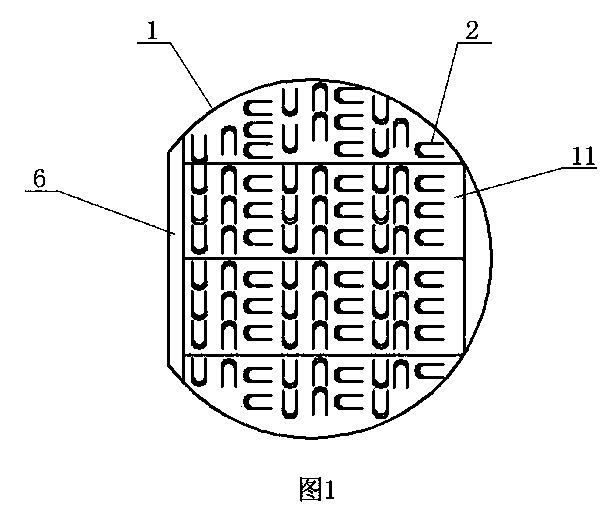

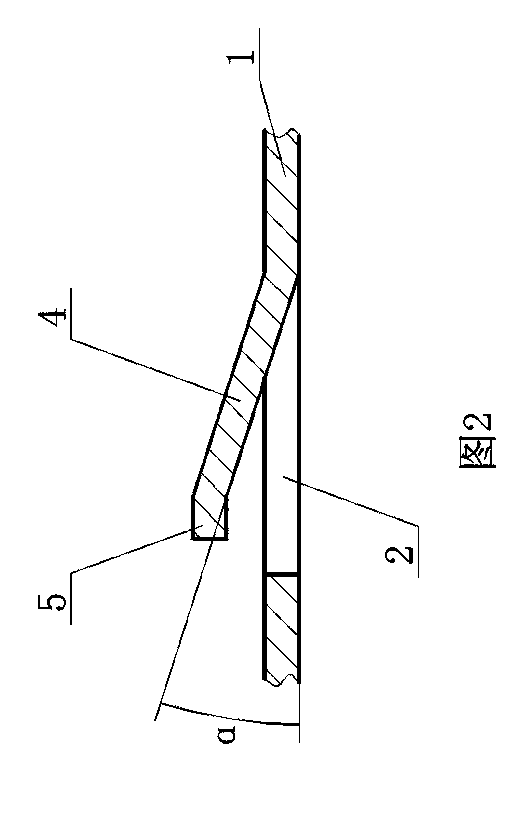

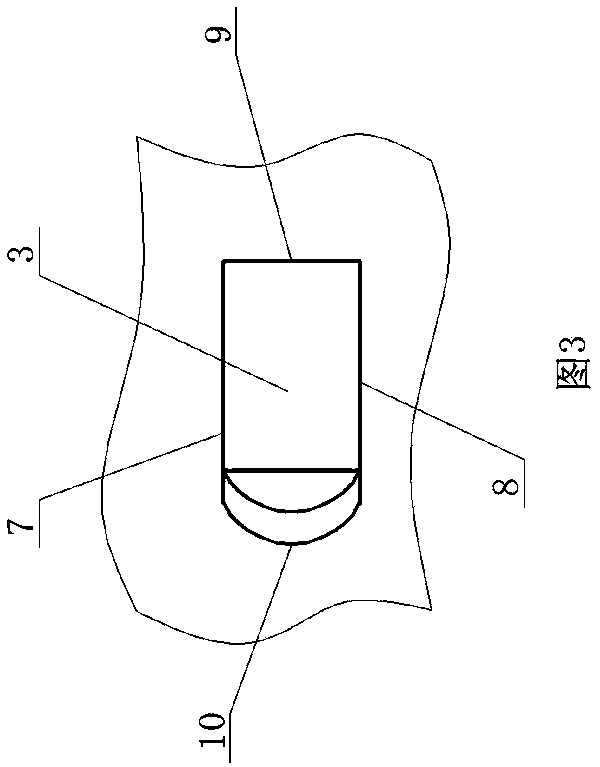

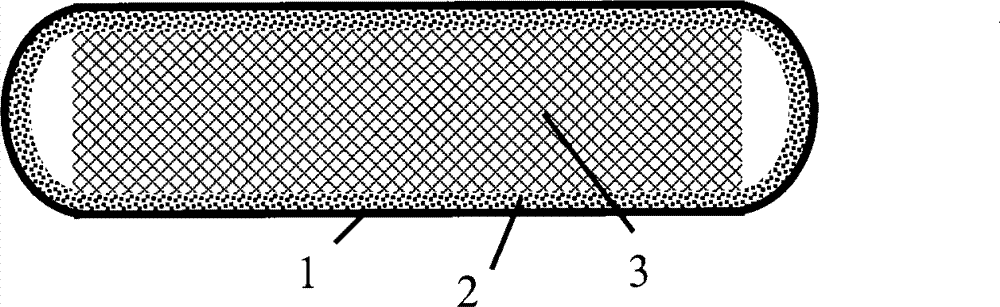

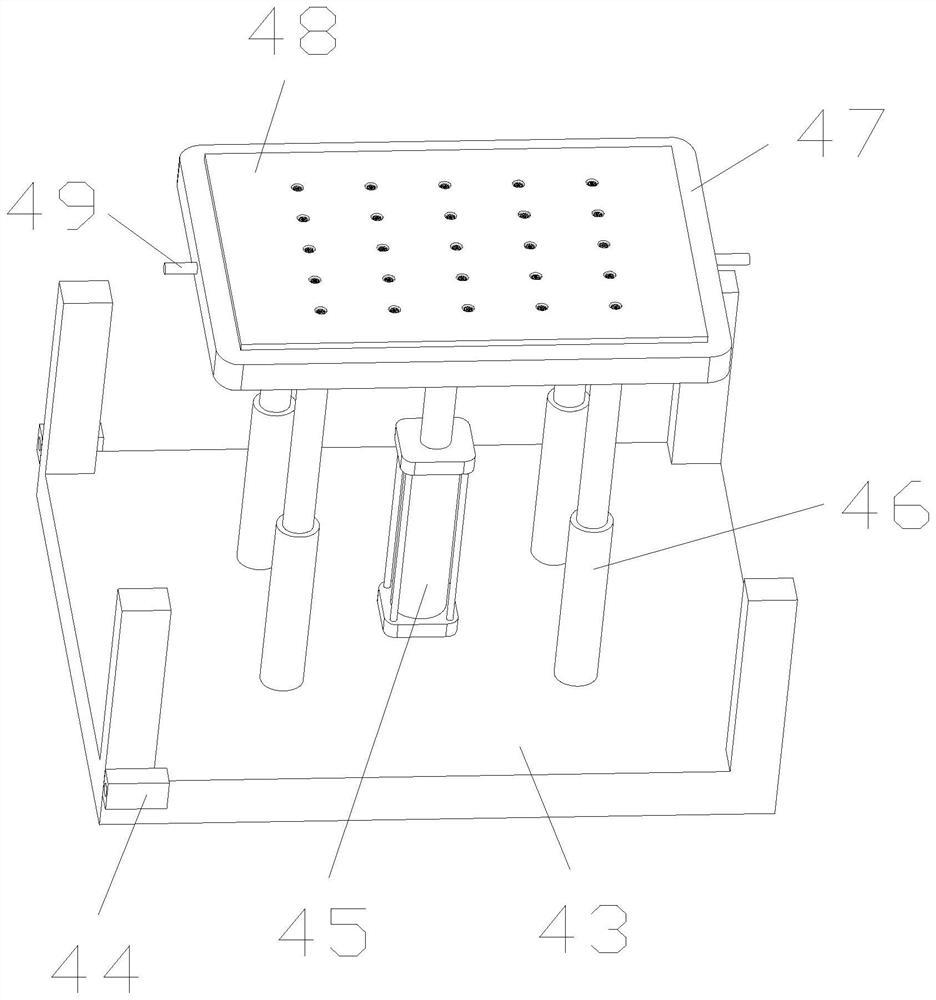

Inclined hole tray for distillation

ActiveCN103816692AImprove contact efficiencyShorten the timeDistillation separationGas phaseDistillation

The invention provides an inclined hole tray for distillation. The inclined hole tray comprises a liquid holding plate, wherein an overflow weir is arranged on the liquid holding plate; a plurality of tongue holes are formed in the liquid holding plate; a tongue plate is respectively arranged on one side of each tongue hole; the tongue plate on one side of each tongue hole comprises an inclined tongue plate and a horizontal tongue plate; one end of each inclined tongue plate is connected with the liquid holding plate; the other side of each inclined tongue plate is connected with each horizontal tongue plate; each horizontal tongue plate is in parallel with the liquid holding plate; the included angle alpha of each inclined tongue plate and the liquid holding plate is 15 to 30 degrees; the tongue holes are formed in the liquid holding plate in rows, each row is in parallel with the length direction of the overflow weir respectively; the row number of the tongue holes in the liquid holding plate is an integral multiple of 3. The inclined hole tray can effectively improve the contact efficiency of gas phase and liquid phase, reduces the time when the gas phase and the liquid phase are balanced, and enables the airflow resistance to keep in a relatively lower level.

Owner:JIGANG INT ENG & TECH CO LTD

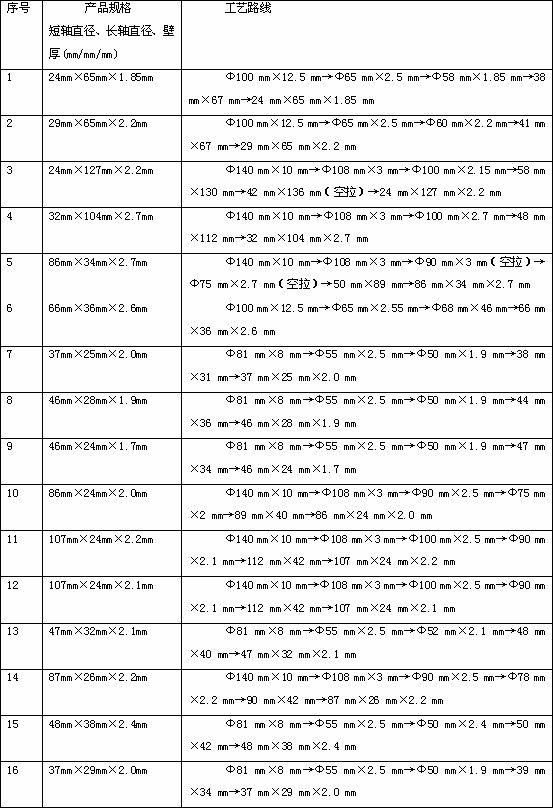

Preparation method of copper and copper alloy oval tube

The invention discloses a preparation method of a copper and copper alloy oval tube, which enables standard cathode copper to serve as a raw material to conduct smelting, ingot casting and saw cutting to obtain extrusion short ingot blanks of T2 phi 260mmX520mm or T2 phi 310mmX600mm. The extrusion short ingot blanks are heated on an induction heating-resistance soaking pit furnace, the heating temperature is 750-880 DEG C, the preheating temperature of a die is set to be 350-380 DEG C, and water sealing extrusion is carried out on the ingot blanks. The head and the tail of an extrusion tube blank are cut, acid washing, water scrubbing, alkali washing, hot water washing and rolling are carried out, and finally sizing saw cutting, head manufacturing and vertical bar stretching are carried out on the extrusion tube blank. Copper and aluminum composite busbars are produced by using the prefabricated oval tube, a large amount of the nonferrous metal is saved, and production cost is reduced. A molding stretching process guarantees that the upper big face and the lower big face of the oval tube are free of inside sinking phenomena.

Owner:JINCHUAN GROUP LIMITED

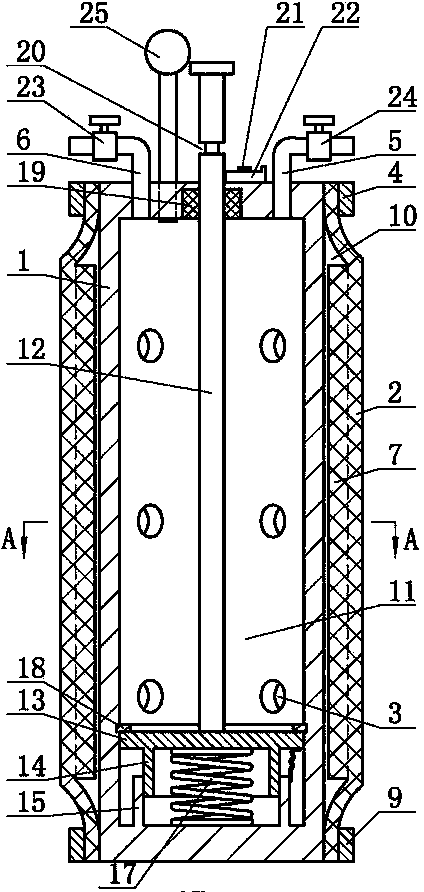

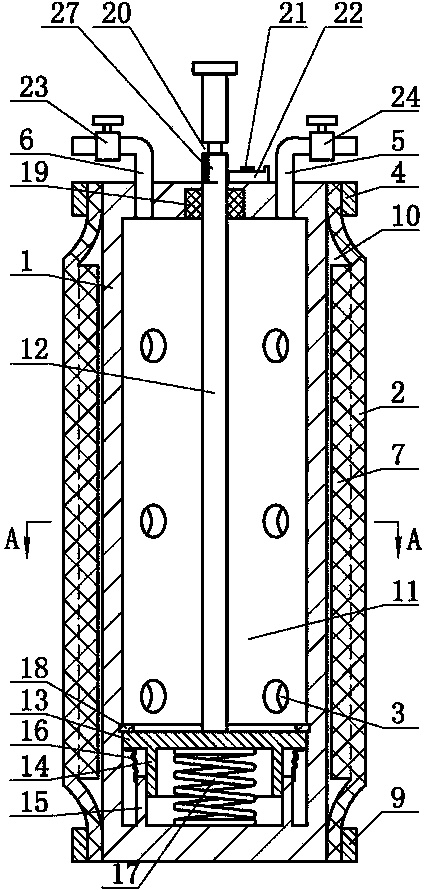

Method for pore forming in building member by using self-pressurized expansible mold and mold release

A method for pore forming in a building member by using a self-pressurized expansible mold and mold release comprises the following steps of pressing a push rod of the mold into a hard housing till a piston arrives at a lower-portion extreme position, remarkably compressing a spring, inserting a positioning pin into a positioning groove, and locking the position of the push rod; turning on a water inlet valve and a water outlet valve of the mold, filling water into a cavity and an expansion cavity through a water inlet pipe, meanwhile discharging air through a water outlet pipe, turning off the water outlet valve after the cavity and the expansion cavity are full of the water, enabling a soft casing to expand under the water pressure effect, and turning off the water inlet valve after water pressure in the mold and water pressure of a water source are balanced, wherein the soft casing is kept in an expanding state under the effect of water pressure in the mold. Therefore, technicians in the field provide multiple schemes for solving the problems. However, the disclosed methods have certain advantages.

Owner:南通汉腾建筑科技有限公司

Sintered soaking plate and manufacturing method thereof

ActiveCN101566440BReduce thermal contact resistanceReflow in timeIndirect heat exchangersWorking fluidThermal contact

Owner:ZHONGSHAN WEIQIANG TECH

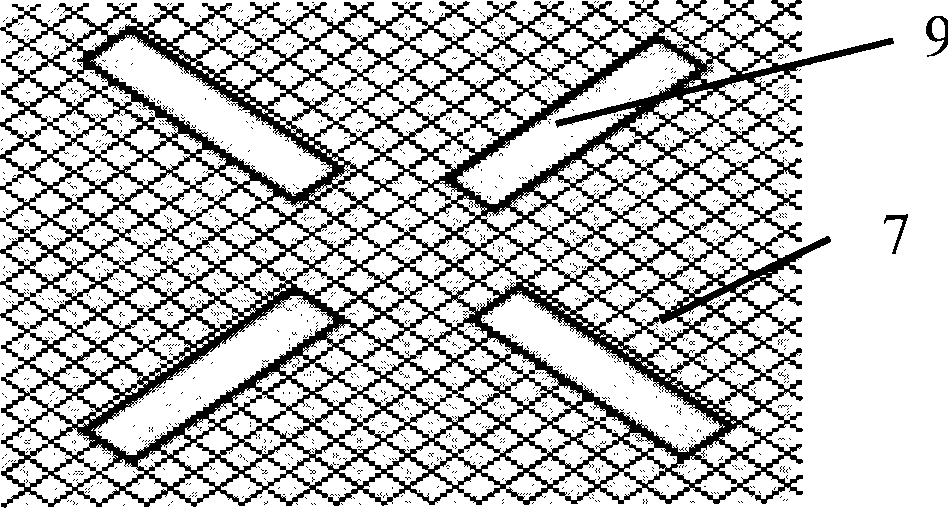

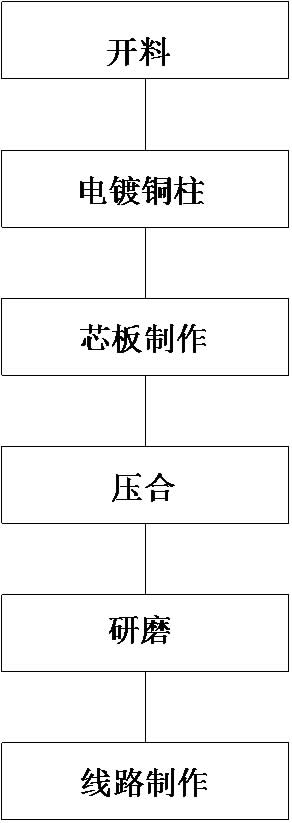

Method for manufacturing high-density interconnection circuit board

InactiveCN112752439AMade preciselyAccurate control of copper thicknessMultilayer circuit manufacturePrinted element electric connection formationHigh densityInterconnection

The invention discloses a method for manufacturing a high-density interconnection circuit board. The method comprises the steps of S1, cutting, S2, copper column electroplating, S3, core board manufacturing, S4, pressing, S5, grinding and S6, circuit manufacturing. According to the method for manufacturing the high-density interconnection circuit board, the manufacturing method is simple, conduction of any layer can be achieved, and the production efficiency is improved; and the method for electroplating the copper column has the advantages of no generation of recesses, easy realization of a structure of combining holes on holes and hole discs, high alignment precision, and realization of accurate control of the copper thickness of each layer of circuit by adopting a semi-additive method to manufacture the pattern circuit, realization of more precise circuit manufacture, and guarantee of the product quality.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH

Display device

The invention discloses a display device, and relates to the technical field of display. The display device comprises a flexible display panel which comprises a winding state and a flattening state; a reel assembly used for winding the flexible display panel and comprising an adjusting component used for adjusting the radius length of the flexible display panel supported by the reel assembly in the process that the flexible display panel is converted from the winding state to the flattening state. The mode that the flexible display panel is rolled in the reel assembly is adopted, the reel assembly comprises the adjusting component, and the adjusting component provides supporting force for the flexible display panel and is used for adjusting the radius length of the flexible display panel supported by the reel assembly, so that the flexible display panel has a better user experience effect.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

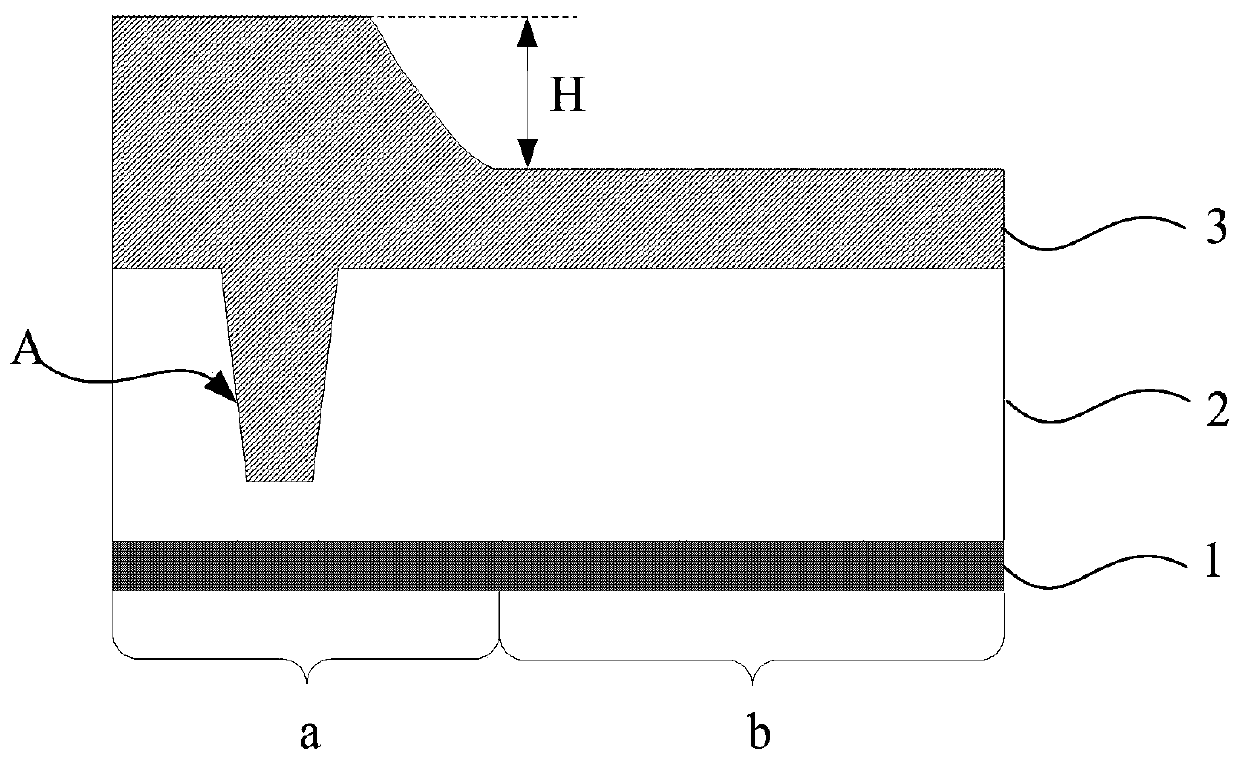

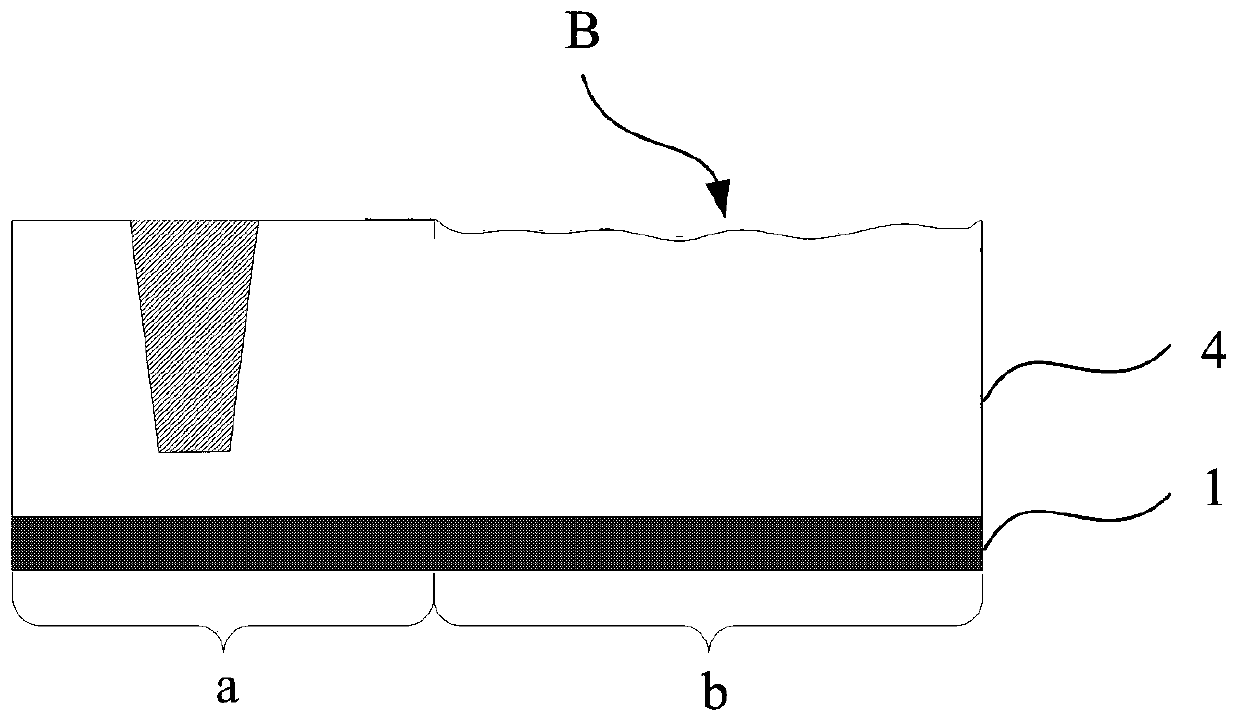

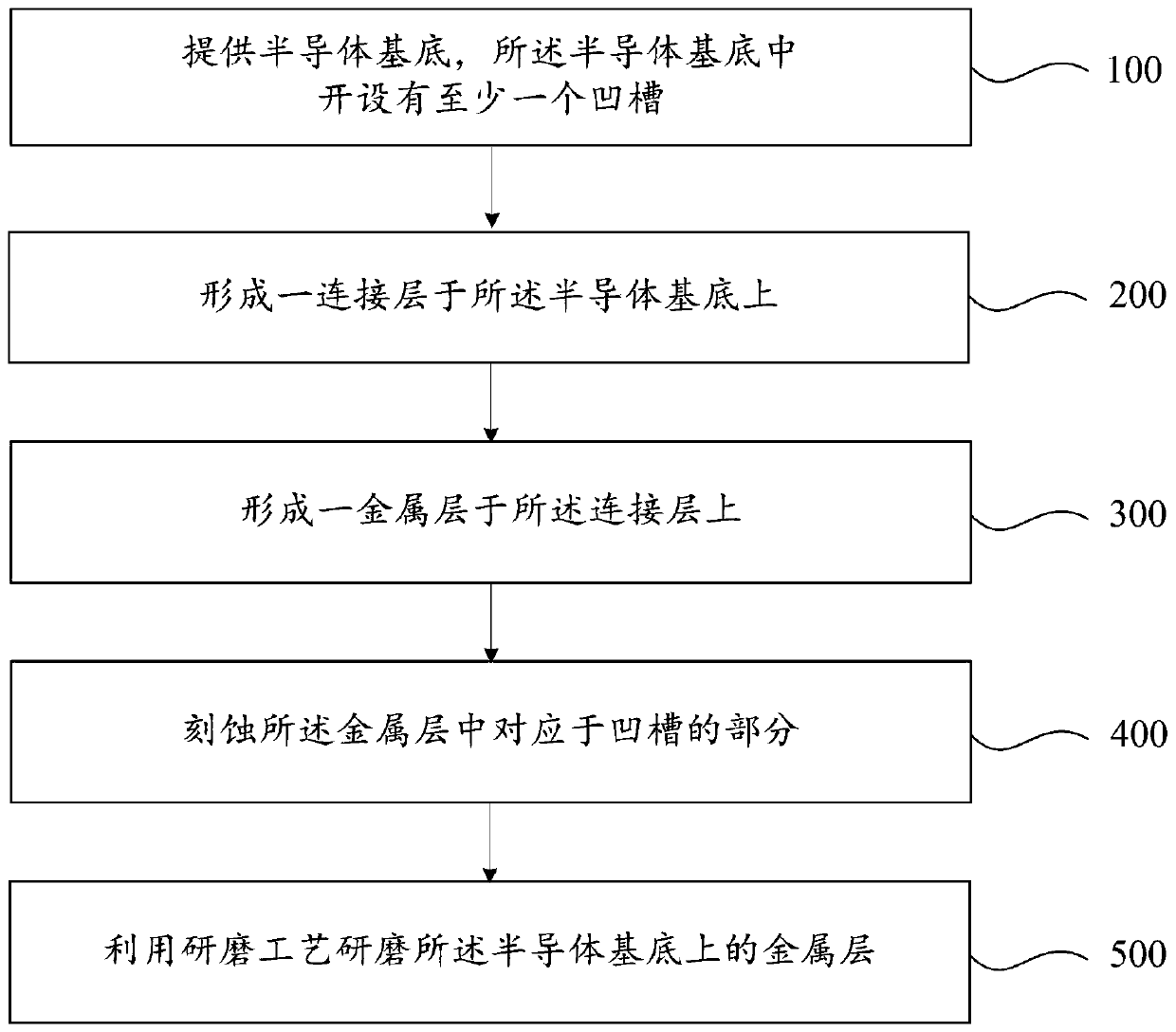

Manufacturing method for metal interconnection layer

InactiveCN111312595AGuarantee stabilityGuaranteed stabilitySemiconductor/solid-state device manufacturingMetal interconnectEngineering

The invention provides a manufacturing method for a metal interconnection layer, and the method comprises the steps: providing a semiconductor substrate which is provided with at least one groove; forming a metal layer on the semiconductor substrate, the metal layer filling the groove and protruding upwards from the groove to a first height, the metal layer also covering the top surface of the semiconductor substrate, the top position of the top surface of the semiconductor substrate covered in the metal layer corresponding to the position of the second height, and the first height being higher than the second height; and etching at least the part, corresponding to the upper part of the groove, of the metal layer so that the top position of the part, corresponding to the upper part of thegroove, of the metal layer is lowered to the position of a third height, and the height difference between the third height and the second height is smaller than the height difference between the first height and the second height. According to the manufacturing method for the metal interconnection layer, the resistance characteristic and the stability of the finally manufactured metal interconnection layer can be ensured.

Owner:NEXCHIP SEMICON CO LTD

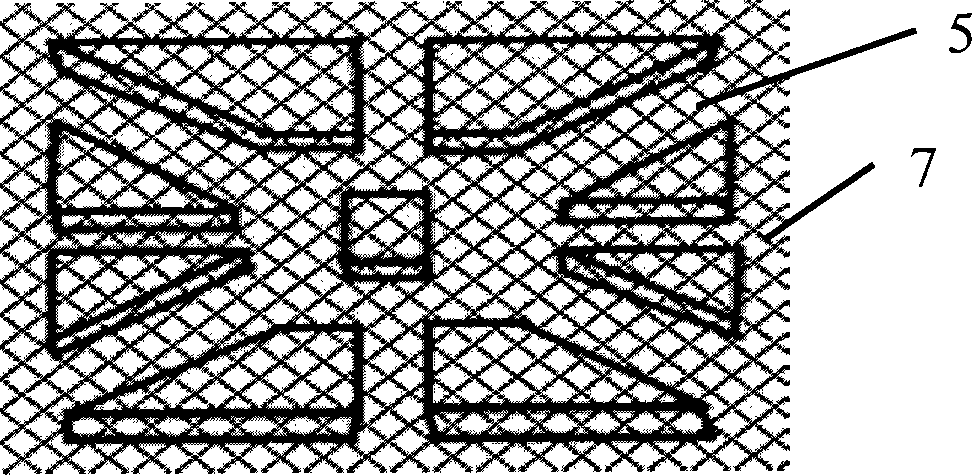

Building component self-pressurization expansion type pore-forming die

A building component self-pressurization expansion type pore-forming die comprises a hard shell. A cavity is formed in the hard shell, a soft sleeve is arranged on the periphery of the side wall of the hard shell, the two ends of the soft sleeve are connected with the hard shell through a first hoop and a second hoop respectively, an expansion cavity is formed between the inner wall of the soft sleeve and the outer wall of the hard shell, through holes are formed in the side wall of the hard shell, the cavity is communicated with the expansion cavity through the through holes, and a piston is arranged in the cavity. One side of the piston is connected with an inner sleeve pipe, an outer sleeve pipe is arranged outside the inner sleeve pipe, the outer sleeve pipe is connected with the hard shell, a spring is arranged between the piston and the hard shell, the other side of the piston is connected with one end of a push rod, and the other end of the push rod penetrates out of the top of the hard shell. Accordingly, technicians in the field provide multiple schemes to solve the problems, however, even though public methods have some advantages, the public methods can not solve the problems.

Owner:苏州盛泽科技创业园发展有限公司

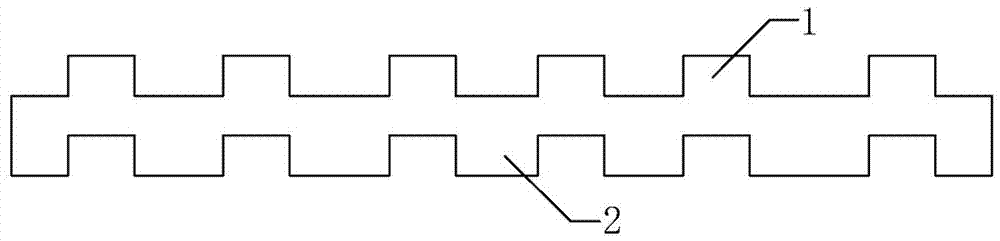

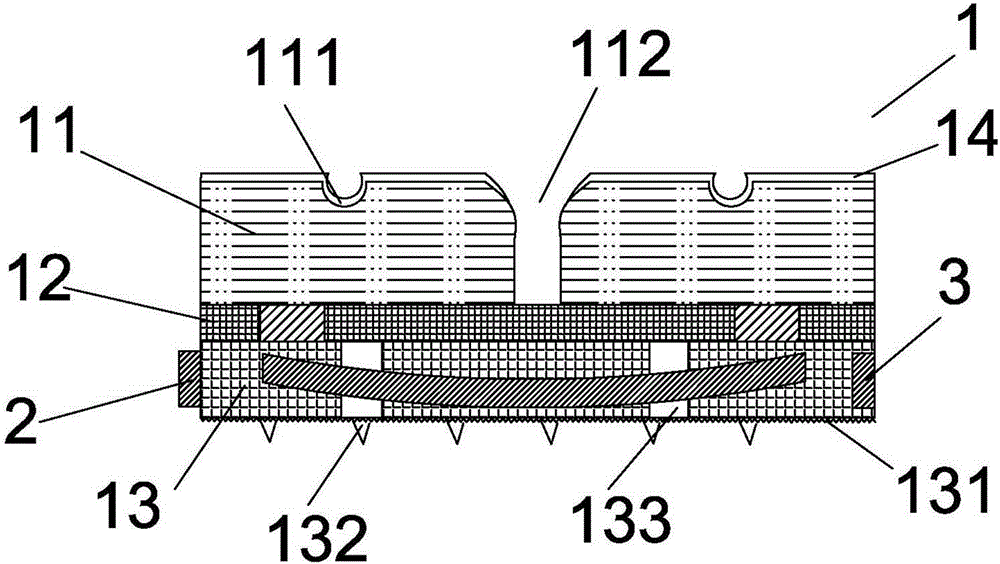

Connecting structure for wear-resistant floor tiles

ActiveCN105200884AGuaranteed smoothNo dentsSingle unit pavingsPaving gutters/kerbsWear resistantEarth surface

The invention relates to a connecting structure for wear-resistant floor tiles and belongs to the technical field of building materials. The connecting structure for the wear-resistant floor tiles comprises a floor tile body, flanges and grooves, wherein the floor tile body is arranged by layer, and the flanges and the grooves are arranged around the bottommost layer of the floor tile body; the flanges and the grooves are matched in shape; the surface of the floor tile body is provided with a greening body is a wear-resistant layer. The connecting structure for the wear-resistant floor tiles is suitable for tiles with multi-layer structures, is firm in connection and is capable of avoiding the irregularity of a floor surface paved with the floor tiles.

Owner:深圳市科建建设集团有限公司

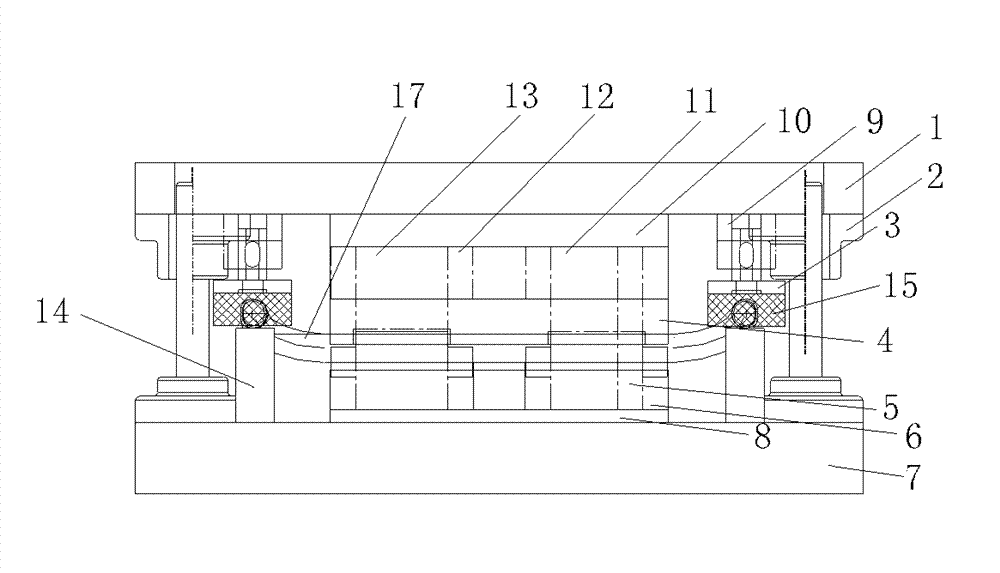

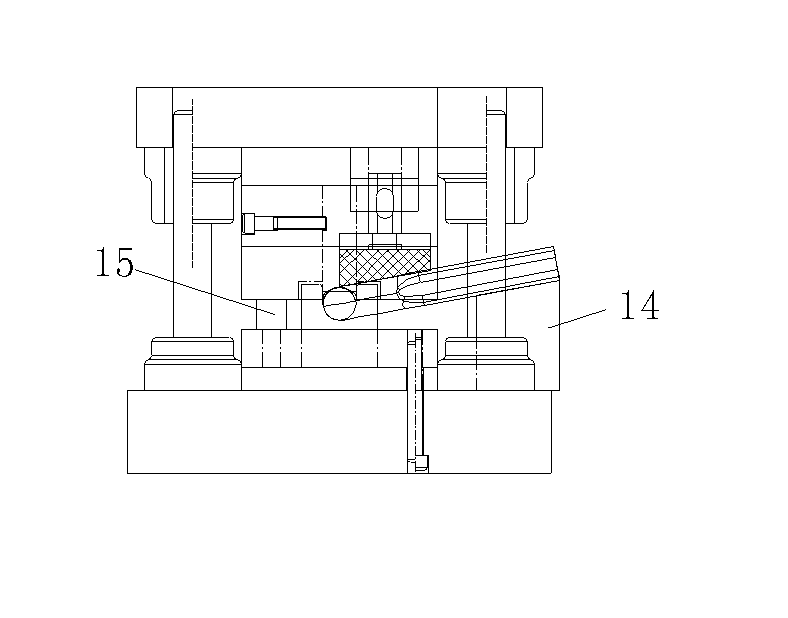

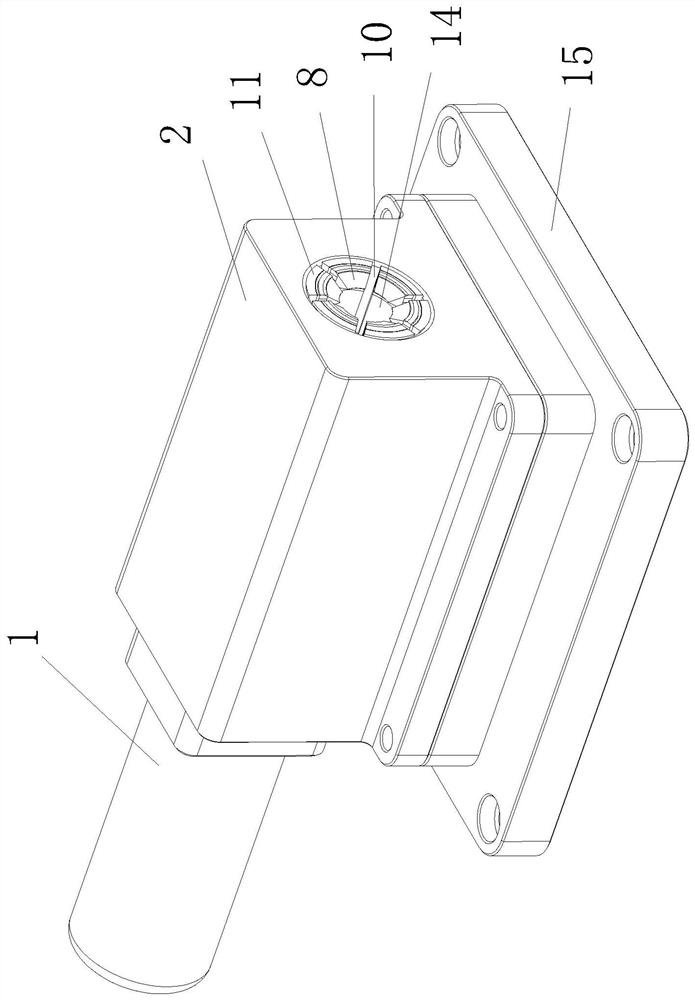

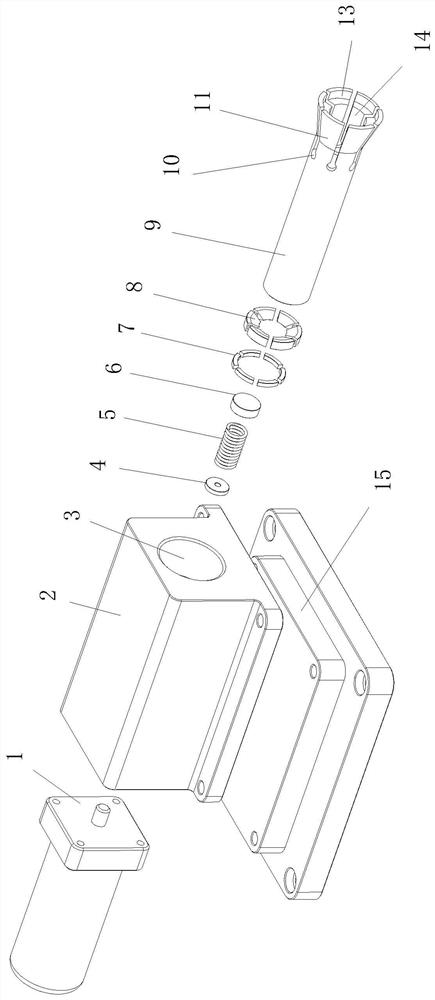

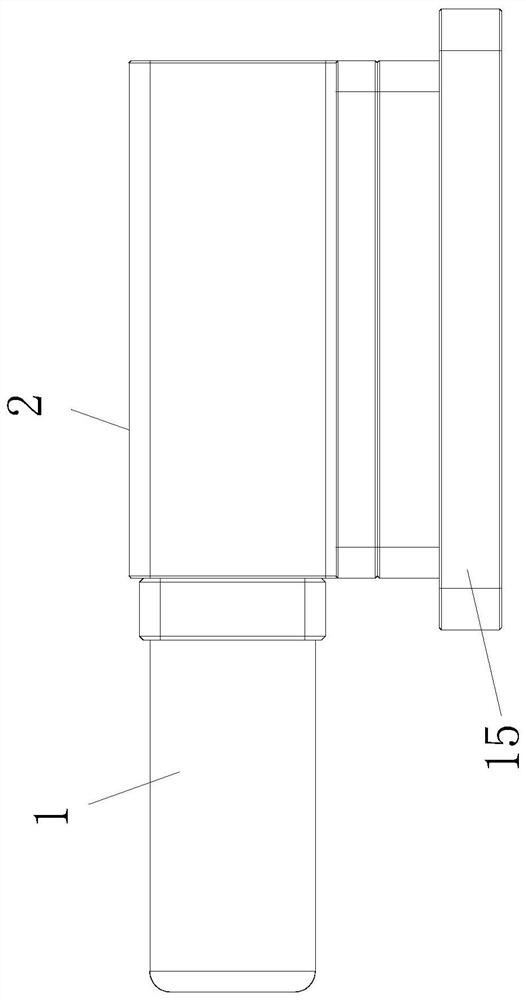

Beating and shaping die of annular pipe fitting

The invention provides a beating and shaping die of an annular pipe fitting, which can effectively solve the problems that two ends are bent when common die stamps the pipe fitting, and prevent the edge of a groove from generating a pit. The beating and shaping die comprises a top die structure and a lower die structure, wherein the top die structure comprises a top template of which the lower part is provided with an upper base plate, the lower part of the upper base plate is provided with an upper fixed plate, and a beating terrace die is installed in the upper fixed plate which is providedwith an upper pressure plate; the lower die structure comprises a lower template; and the lower template is provided with a lower fixed plate which is provided with a shaping die. The invention is characterized by also comprising a pressing device which is installed on the top template.

Owner:泰州市海通资产管理有限公司

PVC pipe cutting device for decoration construction

ActiveCN111702816AReduce distortionNo dentsMetal working apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of devices for decoration construction, and particularly relates to a PVC pipe cutting device for decoration construction. The PVC pipe cutting device fordecoration construction comprises a base, a cutting base, a collect, a conical groove, a hydraulic cylinder, cutter mounting grooves, a clearance groove, a positioning groove, a strip-shaped notch, arc-shaped cutters, a through groove, a semiconductor heating part and a material bouncing assembly, and the material bouncing assembly comprises a magnetic conductive block, an installation groove, anelectromagnet and an elastic piece. The PVC pipe cutting device has the beneficial effects that a PVC pipe is limited and clamped through the positioning groove of the elastic chuck, so that the PVC pipe does not deform, sink and the like during cutting, damage to the PVC pipe is avoided, the hydraulic cylinder is arranged to drive the elastic chuck to move in the cutting base, through elastic contraction of a circular truncated cone part, the cutters synchronously cut PVC pipe together, due to the fact that the cutters are used for cutting together, the cutting resistance during cutting is small, the cutting acting force borne by the PVC pipe acts on all positions of the surface of the PVC pipe evenly, deformation of the PVC pipe is further reduced, and the cutting blind area is small.

Owner:泉州台商投资区品新装潢设计工作室

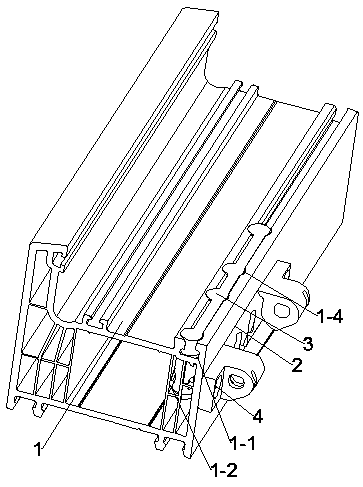

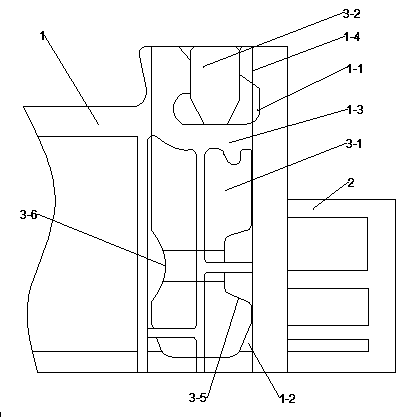

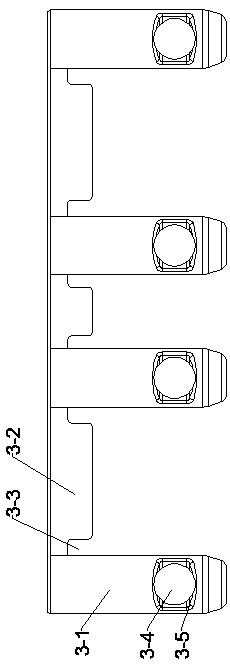

Door and window profile mechanism with hinge fixing reinforcing piece and mounting method thereof

PendingCN108915496AHigh strengthReduce the chance of saggingWindow/door framesWing framesSash windowEngineering

Owner:河南科饶恩门窗有限公司

Liquid-state sintering anti-sticking method for silicon carbide ceramics

The invention provides a liquid-state sintering anti-sticking method for silicon carbide ceramics. The method comprises the following steps: placing one or more layers of flint paper on a graphite load bearing board; placing a silicon carbide blank body on the flint paper; feeding the graphite load bearing board into a sintering furnace to be sintered, wherein if stacking of products is required, the flint paper can be placed between the products. The liquid-state sintering anti-sticking method can prevent silicon carbide ceramic products from cementation during high-temperature sintering, optimizes the production procedures, and is simple to operate and relatively low in manufacturing cost.

Owner:LUOYANG MINGLI TECH DEV

Method for forming hole in building component with self-pressurization expansion type die and die stripping

The invention provides a method for forming a hole in a building component with a self-pressurization expansion type die and die stripping. The method comprises the following steps that a push rod of the die is pressed into a hard shell until a piston reaches the lower limiting position, a spring is greatly compressed, a locating pin is inserted into a locating groove, and the position of the push rod is locked; a water inlet valve and a water outlet valve of the die are opened, water is fed into an empty cavity and an expansion cavity through a water inlet pipe, air is discharged out through a water outlet pipe, after the empty cavity and the expansion cavity are filled with water, the water outlet valve is closed, and a flexible sleeve expands under the action of water pressure; after the water pressure in the die is balanced with the water pressure of a water source, the water inlet vale is closed, and the flexible sleeve is kept in the expansion state under the action of the water pressure in the die.

Owner:苏州盛泽科技创业园发展有限公司

A pc/abs trolley case shell blister molding device and molding process

ActiveCN113733528BQuick fixImprove absorption efficiencyDirt cleaningDomestic articlesBlow moldingWater storage

The invention discloses a PC / ABS trolley case shell plastic-absorbing molding device and a molding process, which relate to the technical field of trolley case production, and include a base. A workbench is welded, the upper surface of the base is provided with a cooling assembly, the upper surface of the workbench is provided with a water storage bucket, and the plastic absorbing device of the present invention generates cold water during blow molding and extrusion after the box shell is blow molded. Spraying cold water to cool the box quickly fixes the shape of the box and improves production efficiency. At the same time, the box shell is prone to produce a lot of plastic smell during the blow molding process and is sucked away by the suction component, and the suction component can adjust the angle according to the blowing of the wind. To increase the absorption efficiency of the suction component, the operator selects the station according to the rotation angle of the suction component to ensure the health of the operator; it is more stable during the clamping process and does not cause dents, and at the same time, a large amount of debris is generated during the cutting process Slag can be cleaned up in time.

Owner:嘉兴市通雅旅游用品股份有限公司

Feeding device for shot blasting machine

ActiveCN108466182AFrame structure is stableStructure does not affectAbrasive machine appurtenancesHydraulic cylinderEngineering

The invention relates to the field of tools for grinding, polishing or sharpening, and discloses a feeding device for a shot blasting machine, the feeding device comprises a feeding port, an upper baffle and a lower baffle, and the lower baffle is divided into an inverting plate from the outside to the inside. The supporting mechanism is fastened in a groove to form a whole; the outer side of thefeeding port is provided with a driving mechanism for pushing the inverting plate to be turned up and down, the supporting mechanism comprises a first sliding slot and an adjusting box, the adjustingbox is provided with two relatively-disposed pistons, a first cavity is formed between the two pistons, a piston rod is fixedly connected to one side, away from the first cavity, of each piston, the free end of the piston rod is connected with a first slider matched with a first sliding g, the top of the first slider is flushed with the top of the inverting plate, the first slider is connected tothe inner wall of the feeding port through a first spring; a second platform is arranged below the feeding port, a hydraulic cylinder is arranged on the second platform, and the hydraulic cylinder isin communication with a hydraulic pipe by the first cavity. The feeding device supports the inner wall of the feeding port to avoid depressed deformation of the casing at the feeding port.

Owner:重庆博创知识产权运营有限公司

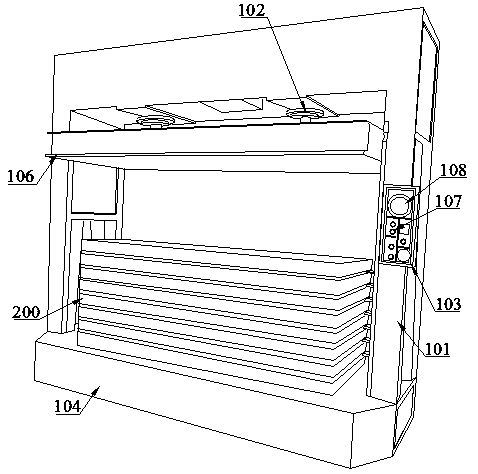

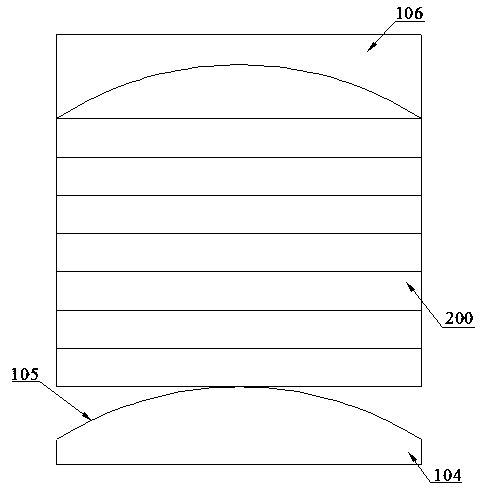

Processing technology of furniture plate material

InactiveCN107627432AQuality improvementImprove performanceWood compressionEngineeringMechanical engineering

The invention discloses a processing technology of a furniture plate material. Equipment for conducting cold pressing processing on the furniture plate material is included, and comprises a machine frame, an upper die, a lower die, a hydraulic lifting mechanism and a control panel. The upper end face of the lower die is arranged to be an arc-shaped hook face arching upwards, and the upper die andthe lower die are cooperatively used. The processing technology comprises the steps that firstly a plate material is cut, a plurality of well-cut plate material bodies are placed on the lower die, thehydraulic lifting mechanism drives the upper die to move downwards to conduct die closing operation, the plate material bodies are extruded and clamped between the upper die and the lower die after die closing is conducted, and extrusion is conducted at a normal temperature for 5-6 hours; die unloading is conducted, the plate material with the plate face arching upwards is obtained after cold pressing molding is conducted, finally painting and smoothing treatment is conducted on the upper end face of the plate material, the furniture plate material with the upper end face being level, smooth,flat and durable is obtained, and packing and storing can be conducted after oil paint is dry. The processing technology of the furniture plate material achieves the positive effects of being simplein technology, convenient to operate, low in manufacturing cost and the like, and the processed furniture plate material is good in quality, stable in performance and long in service life.

Owner:中山市一利办公家具有限公司

Display module, manufacturing method of display module, display panel and display device

The invention provides a display module, a manufacturing method of the display module, a display panel and a display device. The display module comprises a supporting layer, a bearing layer and a display function layer, and the supporting layer comprises a through hole; the bearing layer is positioned in the through hole, is fixedly connected with the side wall of the through hole and blocks one end of the through hole; the display function layer is arranged on the side, where the through hole is blocked, of the supporting layer; the bearing layer is in contact with the display function layer,and the bearing layer is used for supporting the display function layer. According to the display module provided by the invention, a die mark phenomenon can be avoided.

Owner:BOE TECH GRP CO LTD +1

Strip head shearing and butt welding method and shearing and butt welding platform

PendingCN114055169AReduce saggingPrevent outflowOther manufacturing equipments/toolsButt weldingMilling cutter

The invention discloses a strip head shearing and butt welding method and a shearing and butt welding platform. The strip heads of a front coil steel strip and a rear coil steel strip are sequentially subjected to shearing, welding blocking and milling treatment; in the shearing step, the strip heads of the front and rear coil steel strips are sheared by adopting a cutter to form shear lines; the shear lines are subjected to butt joint and then subjected to blocking welding, and during blocking welding, during welding, molten steel is intercepted at the two open ends of the butt-joint shear lines through blocking structures; and in the milling step, a milling cutter is used for milling a welding seam formed by welding. According to the method, the strip head of the front coil steel strip and the head of the rear coil steel strip are treated by adopting a beveling-plugging welding-milling method, so that on the basis of reducing sinking of the opening ends, the two opening ends are intercepted by adopting the stop blocks to form plugging welding, the collapse of the opening ends of welding seams is avoided, and it is ensured that the butt joint position of the steel strips does not have the sinking phenomenon; and therefore, pits cannot be formed after the steel strip is subsequently welded and formed, raw materials are saved, the cost of the raw materials is reduced, and the yield of the raw materials is improved.

Owner:龚海涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com