Connecting structure for wear-resistant floor tiles

A technology for connecting structures and floor tiles, which is applied to pavements, roads, side ditches/curbstones paved with prefabricated blocks, etc. It can solve the problems of difficult access, water accumulation, uneven unevenness, and achieve the effect of difficult connection and firm connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

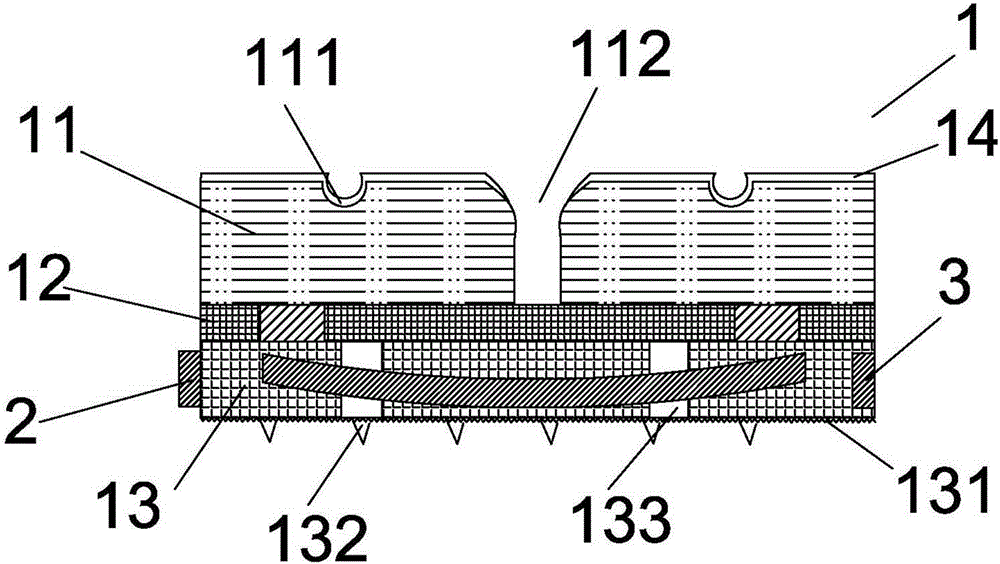

[0028] Embodiment 1: A connection structure of wear-resistant floor tiles, including a floor tile body 1 arranged in layers and a flange 2 and a groove 3 arranged around the bottom of the floor tile body 1, the shape of the flange 2 and the groove 3 match.

[0029] The floor tile body 1 is a cube, and there are two flanges 2 and two grooves 3 respectively, which are respectively arranged on two adjacent sides of the bottommost floor of the floor tile body 1 .

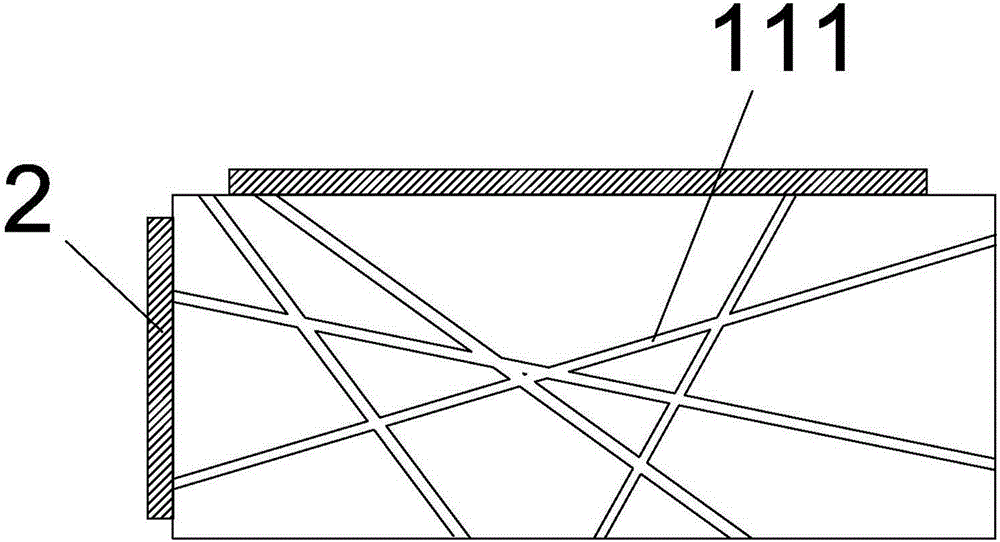

[0030] The floor tile body 1 includes a water-conducting layer 11, an aquifer 12 and a connecting layer 13 connected sequentially from top to bottom; 12 connected water guide holes 112; the water storage layer 12 is made of porous material; the bottom surface of the connecting layer 13 shown is provided with continuous protrusions 131, and the floor tile body 1 also includes a water-resistant layer above the water guide layer 11 Grinding layer 14.

Embodiment 2

[0031] Example 2: Reference figure 1 and image 3 , a connection structure of wear-resistant floor tiles, including a floor tile body 1 arranged in layers and a flange 2 and a groove 3 arranged around the bottommost layer of the floor tile body 1, the shape of the flange 2 and the groove 3 match.

[0032] The floor tile body 1 is a cube, and there are two flanges 2 and two grooves 3, which are respectively arranged on the two adjacent sides of the bottommost layer of the floor tile body 1. The flange 2 is a curved surface when viewed from the side of the floor tile body 1. , the groove 3 is located on the curved surface of the flange 2 when viewed from the side of the floor tile body 1 .

[0033] The floor tile body 1 includes a water-conducting layer 11, an aquifer 12 and a connecting layer 13 connected sequentially from top to bottom; 12 connected water guide holes 112; the water storage layer 12 is made of porous material; the bottom surface of the connecting layer 13 sho...

Embodiment 3

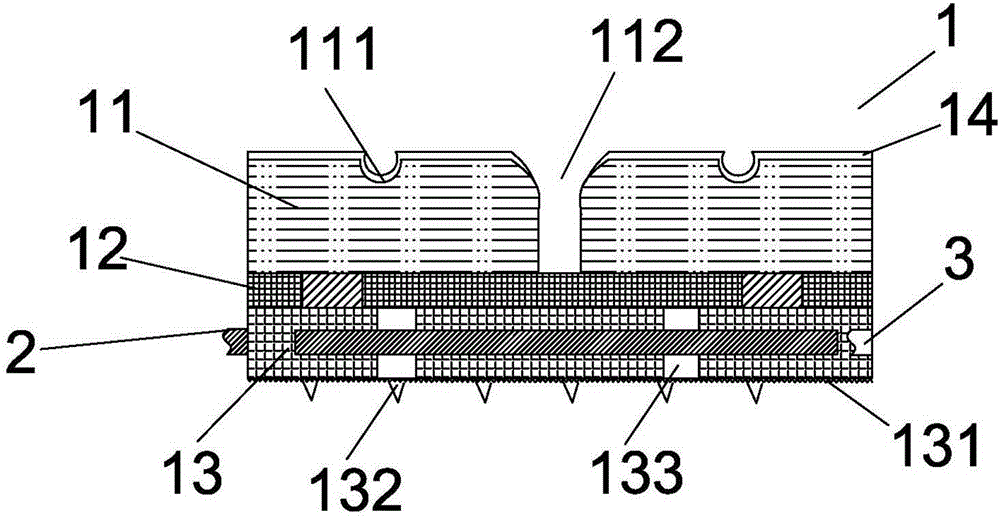

[0037] Example 3: Reference figure 2 and Figure 4 , a connection structure of wear-resistant floor tiles, including a floor tile body 1 arranged in layers and a flange 2 and a groove 3 arranged around the bottommost layer of the floor tile body 1, the shape of the flange 2 and the groove 3 match.

[0038] The floor tile body 1 is a cube, and there are two flanges 2 and two grooves 3 respectively, which are respectively arranged on two adjacent sides of the bottommost layer of the floor tile body 1. The end surface of the flange 2 is an S-shaped curved surface, The contact surface between the groove 3 and the end of the flange 2 is an S-shaped curved surface.

[0039] The floor tile body 1 includes a water-conducting layer 11, an aquifer 12 and a connecting layer 13 connected sequentially from top to bottom; 12 connected water guide holes 112; the water storage layer 12 is made of porous material; the bottom surface of the connecting layer 13 shown is provided with continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com