Automobile flywheel pouring system and pouring method

A pouring system and pouring method technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of surface depression of castings, increase cleaning procedures and cleaning workload, and uneconomical problems, so as to improve the process yield and reduce the cost. The effect of small internal shrinkage cavities and shrinkage defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are as follows:

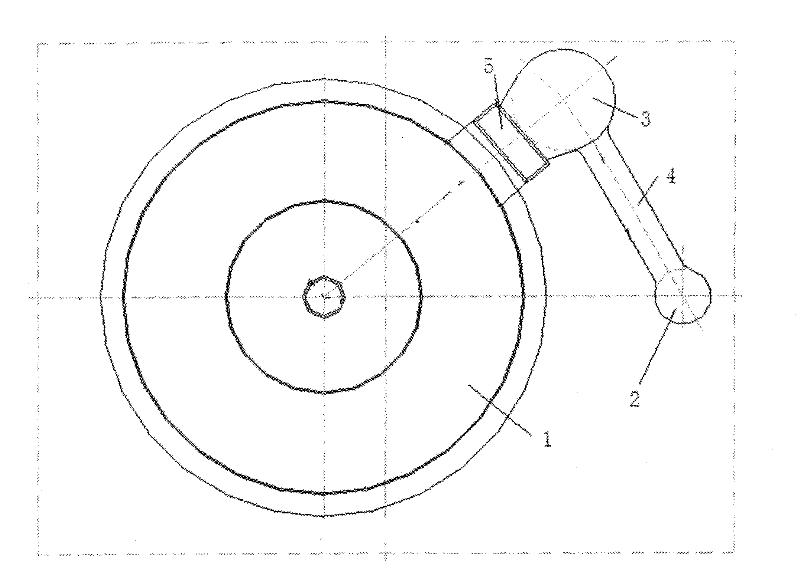

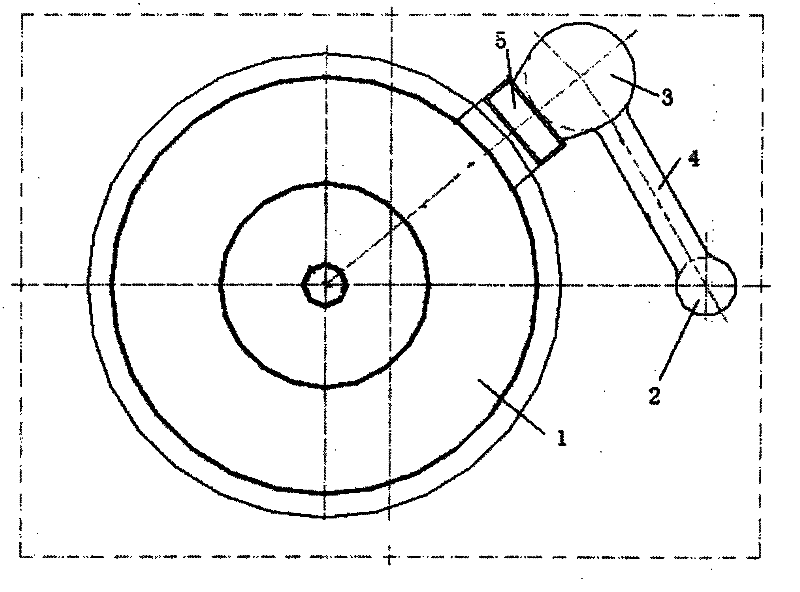

[0013] Such as figure 1 Shown, the automobile flywheel pouring system of the present invention comprises a sprue cup, a sprue, a runner 4, a riser 3 and an ingate with a riser neck; also includes a riser neck cold iron 5, the The riser neck cold iron 5 is located below the riser neck. The molten iron is introduced from the pouring cup, enters the runner 4 through the pouring cup base 2, then enters the riser 3, and then flows into the ingate through the riser neck and enters the casting 1.

[0014] The automobile flywheel pouring method of the present invention comprises:

[0015] (1) Inject molten iron into the riser,

[0016] (2) When the molten iron flows through the riser neck, the molten iron is cooled.

[0017] The method of cooling molten iron can be to place cold iron under the riser neck, and other cooling methods can also be used.

[0018] In the pouring method of the automobile flywheel of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com