Method for overcoming casting bolt shrinkage porosity defect

A technology for castings and bolts, applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of difficulty, increase casting cost, and high cost, and achieve the effect of reducing quality, reducing casting cost, and low free phenol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

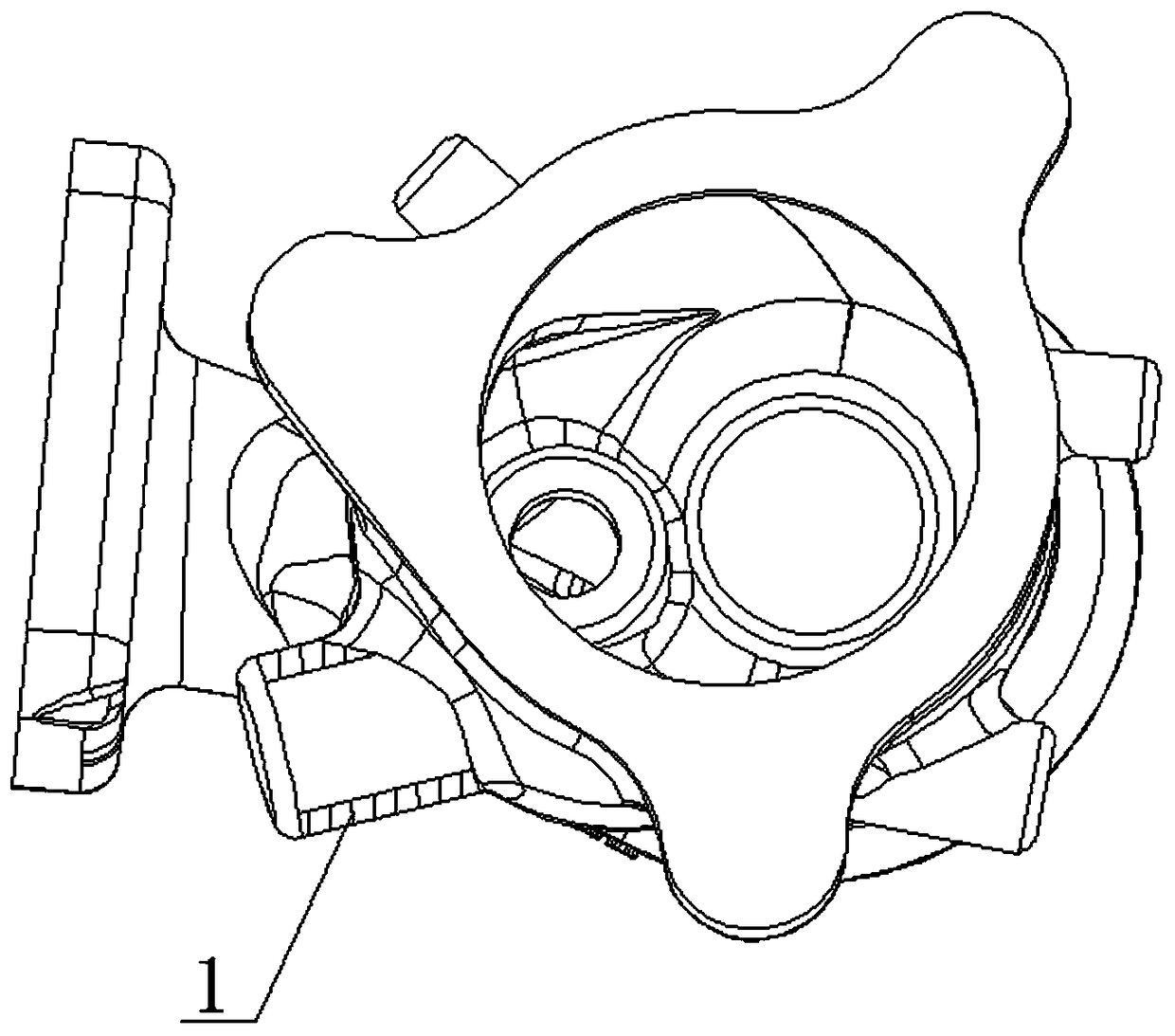

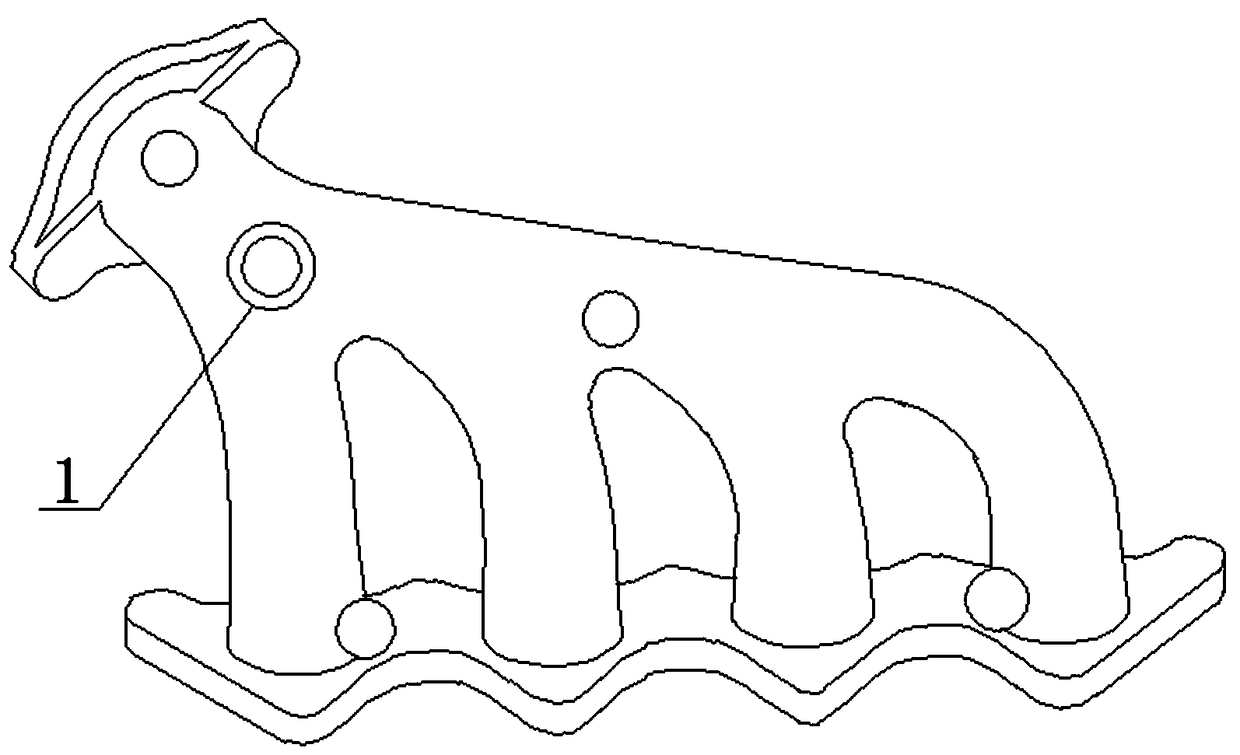

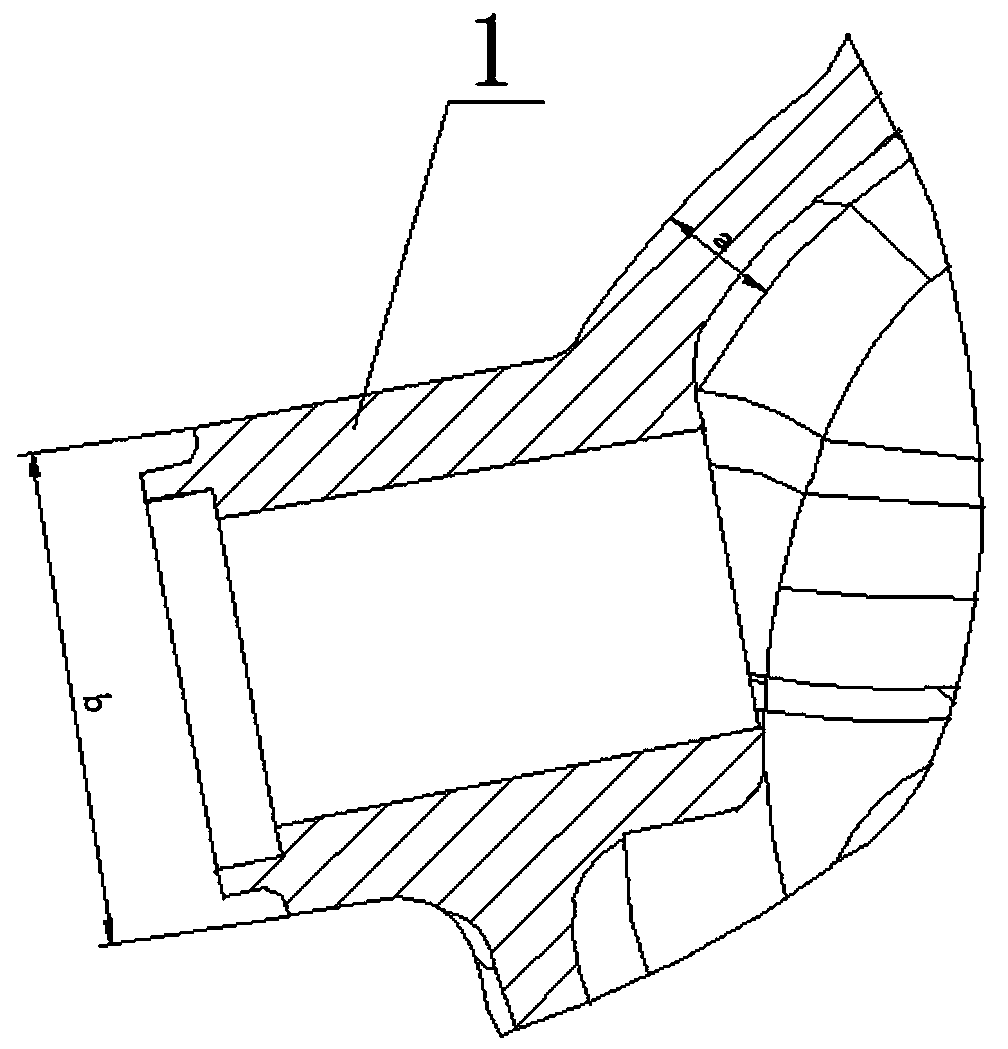

[0035] Such as figure 1 and figure 2 As shown, the diameter of the bolt 1 on the volute and the exhaust pipe casting is 20-30mm, and threaded holes need to be processed on the bolt 1 to facilitate subsequent installation and fixing. The conventional processing method is to fill up the processing hole, cast the blank, and then machine the threaded hole, or use blind hole casting, but from the attached image 3 It can be seen that the thickness a of the pipe wall of the casting is 4-5mm, while the diameter b of the bolt is 26mm, and there is an area where the thickness is connected, thus forming a T-shaped hot node area; when the molten iron is cast, the thickness of the casting is uneven, and the thin-walled part The solidification time is less than that of the thick part, and the heat of the thick part is large, and finally the solidification shrinks, and the bolts have defects such as shrinkage and shrinkage.

[0036] Therefore the present invention discloses a method for ...

Embodiment 2

[0047] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0048] The sand core is prepared from the following raw materials in parts by weight: 100 parts of silica raw sand, 1.8 parts of polyethylene resin, 2.2 parts of curing agent and 1.4 parts of calcium stearate.

[0049] Wherein the curing agent is urotropine.

[0050] Sand cores are prepared by the following steps:

[0051] 1) Sand mixing step: mix and stir the above raw materials to form uniform mixed sand;

[0052] 2) Core box design, installation and heating: Design the core box mold according to the drawings, such as Figure 7 As shown, the upper part is the movable mold 5, and the lower part is the static mold 6. After adding the tooling, install it on the core shooter and heat it. The dynamic and static molds are heated to 240 and 220 °C respectively;

[0053] 3) Sand filling step: inject the mixed sand into the dynamic and static mold core boxes respectively throug...

Embodiment 3

[0057] The structure of embodiment 3 is basically the same as that of embodiment 1, the difference is:

[0058] The sand core is prepared from the following raw materials in parts by weight: 100 parts of silica raw sand, 2.0 parts of polyethylene resin, 2.2 parts of curing agent and 1.3 parts of calcium stearate.

[0059] Wherein the curing agent is urotropine.

[0060] Sand cores are prepared by the following steps:

[0061] 1) Sand mixing step: mix and stir the above raw materials to form uniform mixed sand;

[0062] 2) Core box design, installation and heating: Design the core box mold according to the drawings, such as Figure 7 As shown, the upper part is the movable mold 5, and the lower part is the static mold 6. After adding the tooling, install it on the core shooter and heat it. The dynamic and static molds are heated to 240 and 220 °C respectively;

[0063] 3) Sand filling step: inject the mixed sand into the dynamic and static mold core boxes respectively throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com