Local extrusion method used for high-pressure casting

A technology of high-pressure casting and extrusion method, which is applied in the field of casting, which can solve the problems of uneven wall thickness, short solidification time, complex structure, etc., and achieve the effects of improving the economic benefits of enterprises, reducing shrinkage defects, and reducing the production scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Test group 1

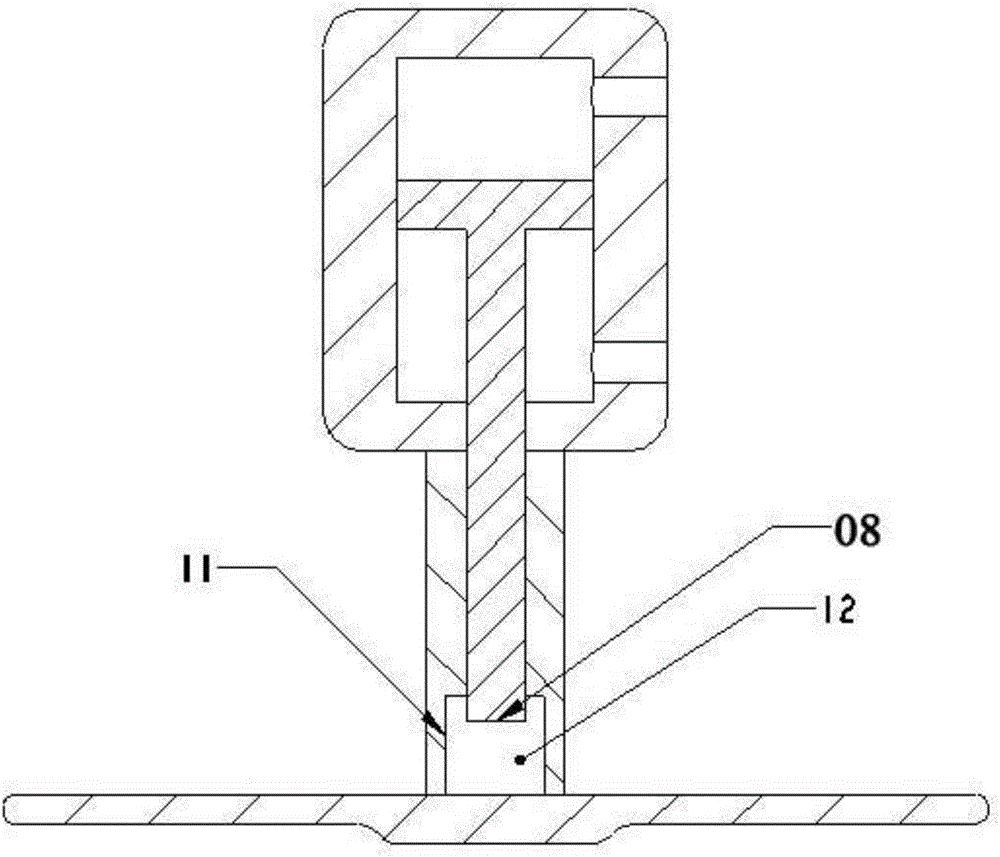

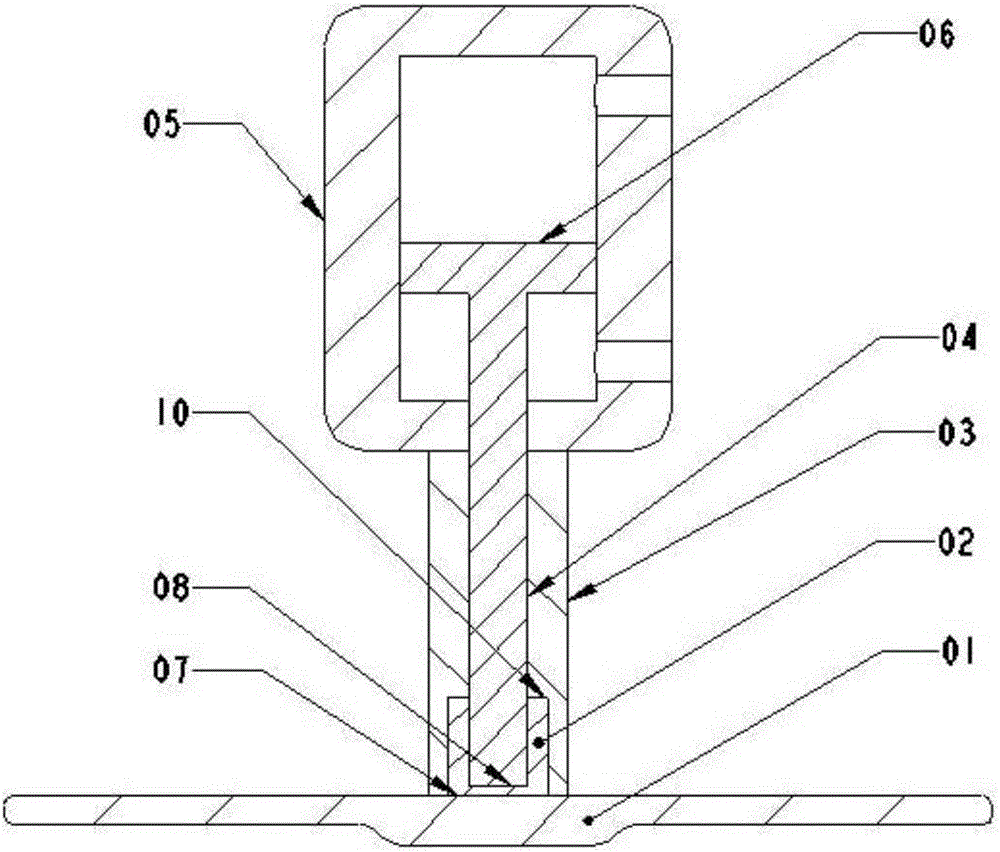

[0024] Partial extrusion structure for aluminum alloy high pressure casting includes extrusion boss (02), extrusion core sleeve (03), extrusion rod (04), extrusion cylinder (05), extrusion cylinder piston (06) . The cross-sectional area ratio of the extrusion cylinder piston (06) to the extrusion rod (04) is 12 to ensure sufficient extrusion force. When the cylinder piston is not squeezed (at zero position), the front end of the extrusion rod (08) is 10mm higher than the end surface of the extrusion sleeve (10), and at the same time the front end of the extrusion rod (08) is in contact with the inner wall of the lower cavity of the extrusion core sleeve Cavity (12) is formed between (11); in the extruding process of extruding rod, the gap between the lower cavity inner wall (11) of extruding core sleeve and extruding rod (04) outer contour is within 10mm ( That is, the extrusion boss (02) wall thickness range). In order to ensure that the local extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com