High-wear-resistant oriented Fe2B compact block and preparation method thereof

A high anti-wear and dense technology, applied in the field of anti-wear materials, can solve the problems of no patent reports, etc., and achieve the effects of improving smelting efficiency, high purity, high hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

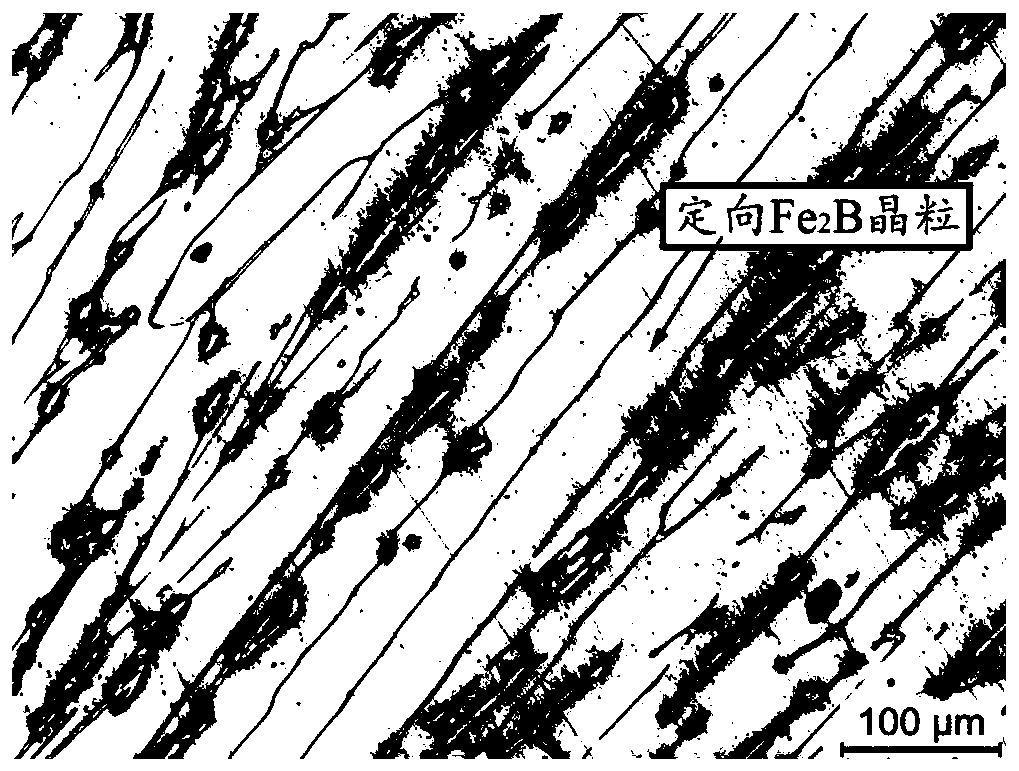

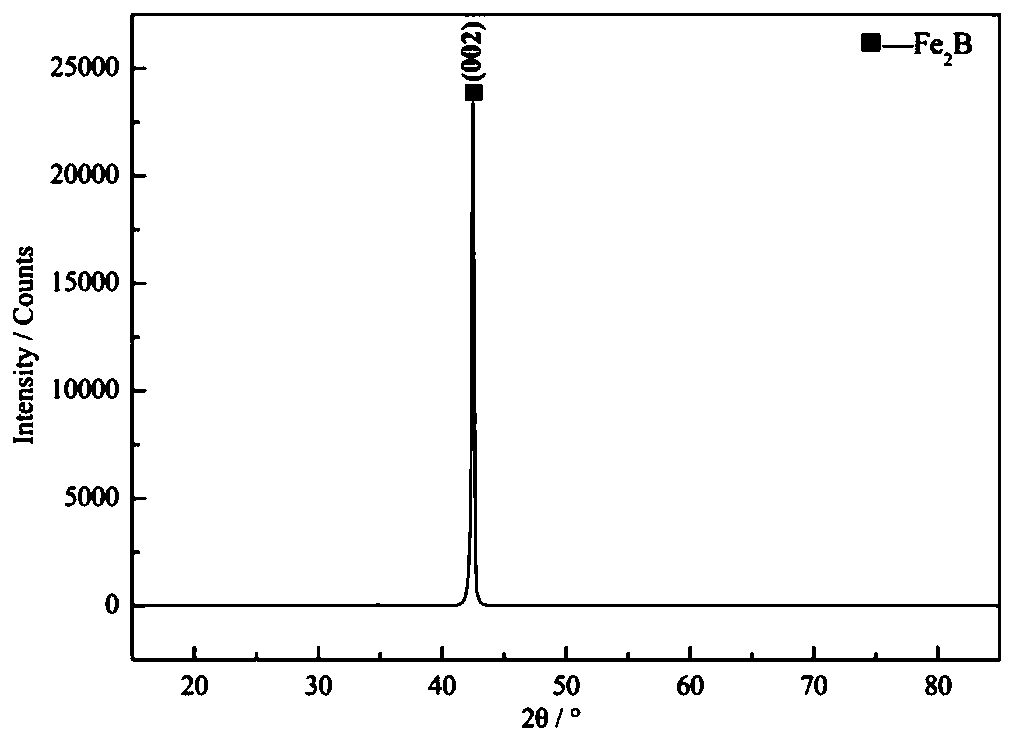

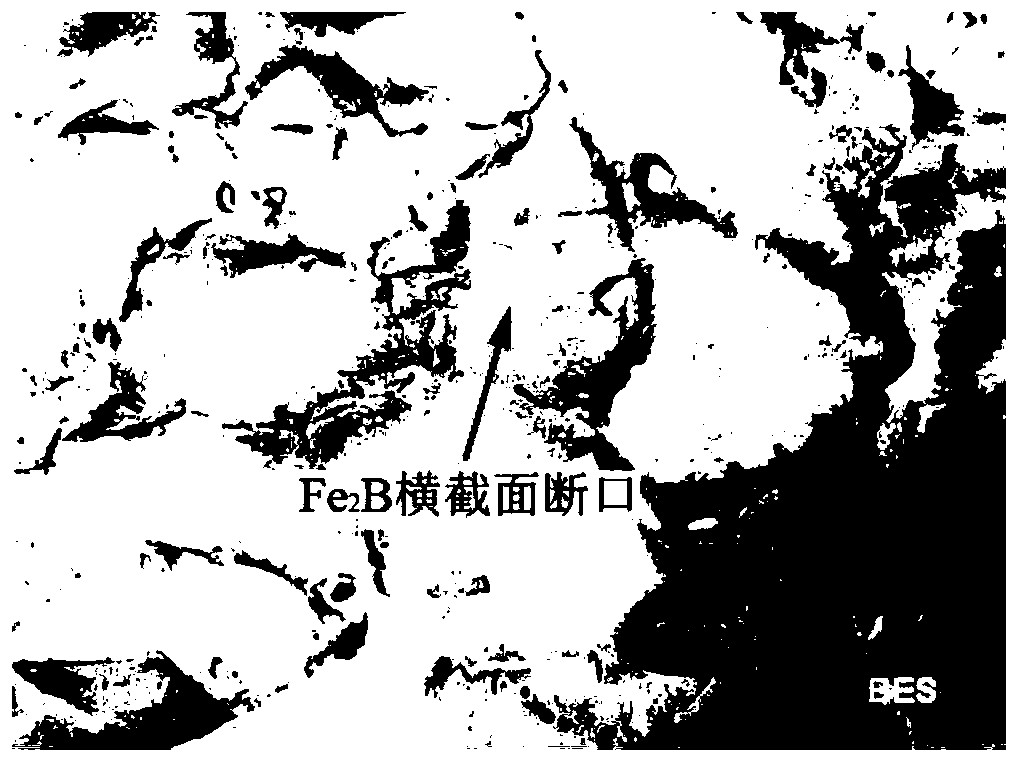

[0035] The present invention is a kind of high wear resistance oriented Fe 2 B dense block preparation method, comprises the following steps:

[0036] S1. Ingredients

[0037] Pure iron and ferroboron are batched according to the mass ratio Fe:B=91.2:8.8;

[0038] The content of Fe in the pure iron block is higher than 99.8%, and the surface oxide and pollution layer are removed; the B content in the boron iron is 10% to 25%, and the impurity elements other than B and Fe are lower than 1.2%.

[0039] S2, charging

[0040] Put the pure iron block and ferroboron particles into the corundum crucible in turn to ensure that the ferroboron particles fill the gap around the pure iron block and distribute tightly;

[0041] The pure iron block is placed in the center of the corundum crucible, surrounded by ferroboron particles.

[0042] S3, smelting

[0043] Place the crucible with the raw material in a vacuum induction melting furnace for vacuum melting. The melting parameters ar...

Embodiment 1

[0051] Using industrial pure iron (Fe content of 99.8wt%) and boron iron (B content of 19.8wt%) as raw materials, according to the weight ratio Fe:B=91.2:8.8, weigh 111.34g of pure iron and boron iron 88.89 g; Then, put the weighed pure iron and ferroboron into the melting crucible in turn, to ensure that the pure iron is in the middle of the crucible, and the ferroboron fills the space around the pure iron block and compacts it; put the crucible with raw materials into In the vacuum induction melting furnace, the pouring water glass sand mold is placed on the water-cooled copper block, and then the furnace door is closed to vacuumize; when the vacuum degree in the furnace cavity is lower than 10 -2 At Pa, turn on the heating button and control the heating rate to 50°C / min. When the melt temperature reaches 1600°C, turn down the heating power to keep the metal melt warm for 15 minutes, then turn off the heating program and observe the temperature of the metal melt in real time;...

Embodiment 2

[0053] With industrial pure iron (Fe content is 99.8wt%), boron iron (B content is 19.8wt%) and high-purity Cr particles (Cr content is 99.9wt%) as raw materials, according to the weight ratio Fe:Cr:B=89.2: 2:8.8 for batching, weighing 107.34g of pure iron, 88.89g of ferroboron and 4g of high-purity Cr particles; The iron is in the middle of the crucible, and ferroboron and high-purity Cr particles fill the space around the pure iron block and compact it; put the crucible with raw materials into the vacuum induction melting furnace, and place the pouring water glass sand mold on the water-cooled copper block , and then close the furnace door for vacuuming; when the vacuum degree in the furnace chamber is lower than 10 -2 At Pa, turn on the heating button and control the heating rate to 35°C / min. When the melt temperature reaches 1600°C, reduce the heating power to keep the metal melt warm for 20 minutes, then turn off the heating program and observe the temperature of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com