Casting model structure for differential mechanism shell with thick and large flange plate surface

A technology for casting models and differentials, which is applied to casting molding equipment, casting molds, cores, etc., and can solve problems such as the overall thickness of the flange surface and the side bushing area, the heavy weight of the vehicle, and unfavorable energy saving and emission reduction. , to achieve the effects of reducing product shrinkage defects, reducing shock absorption requirements, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

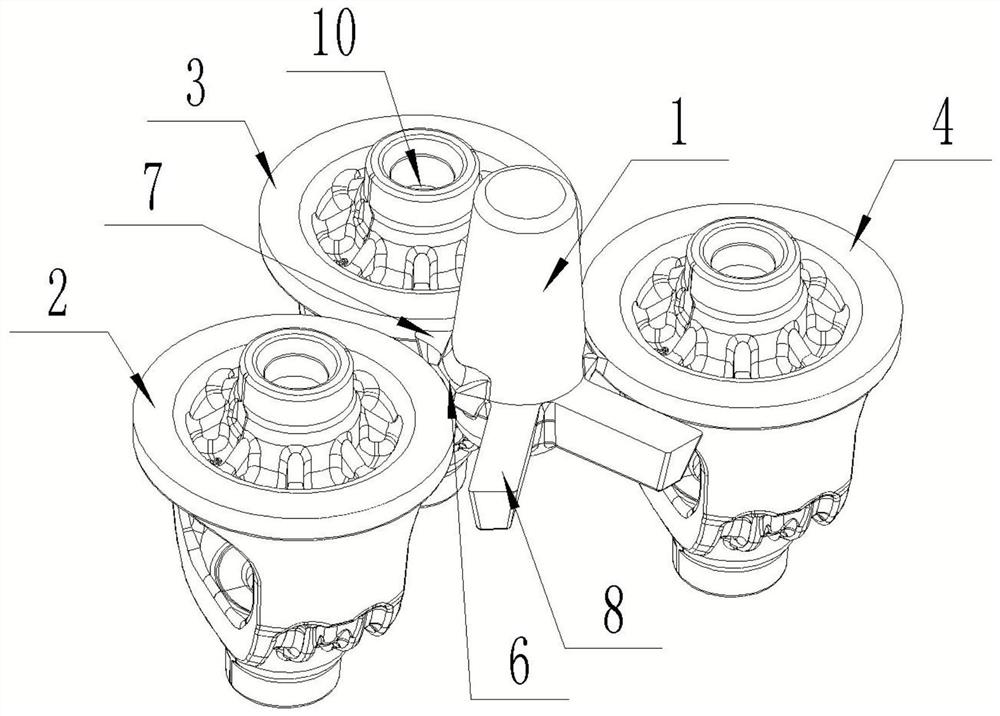

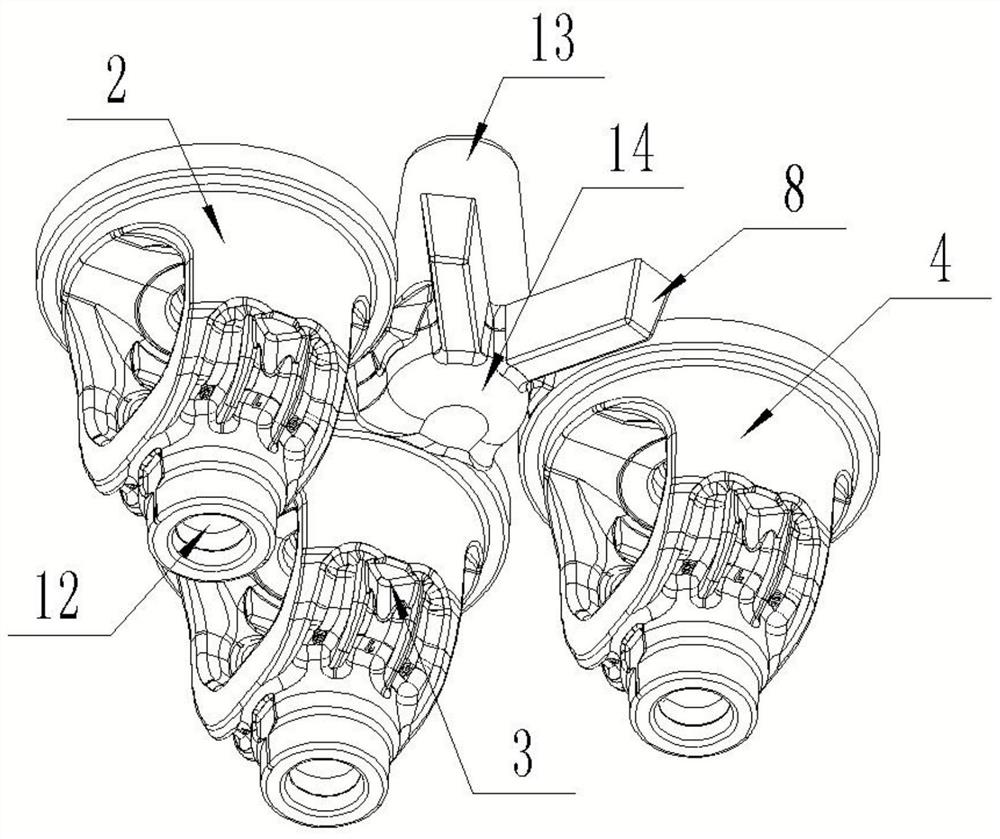

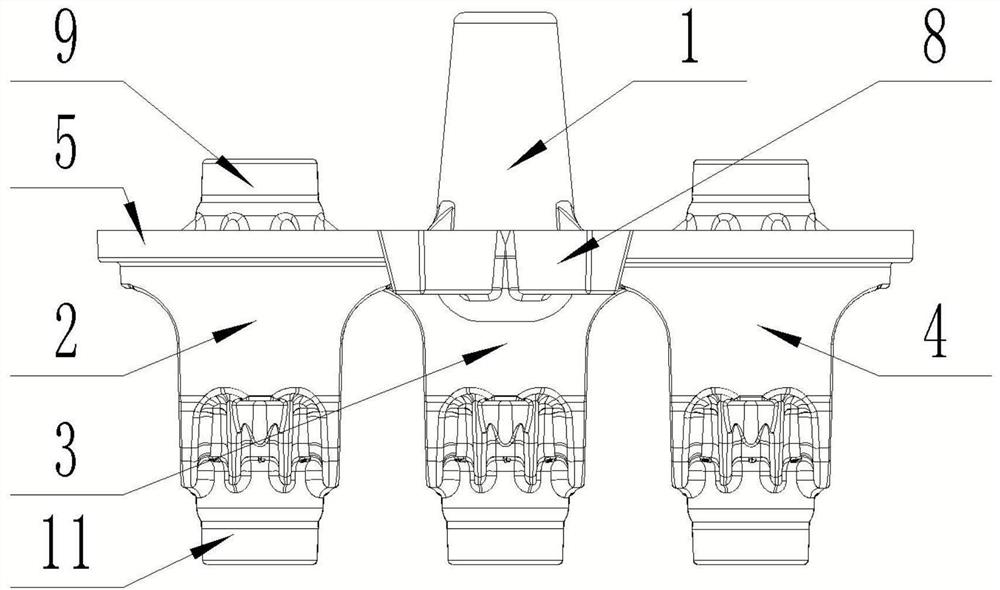

[0022] Such as Figure 1 to Figure 5 As shown, a casting model structure for a differential case with a thick and large flange surface includes a central riser column 1, and A casting 2, B casting 3 and C casting are arranged around the riser column 1. The casting 4, the A casting 2, the B casting 3, and the C casting 4 all include a flange 5 in the middle, an upper shaft sleeve 9 positioned at the top of the flange 5, and a lower shaft sleeve 11 positioned at the bottom of the flange 5, wherein A casting 2 and C casting 4 are respectively symmetrically distributed on both sides of the riser column 1, B casting 3 is on the perpendicular bisector of the line connecting the centers of A casting 2, riser column 1, and C casting 4, and the A casting 2, B casting 3 and C casting 4 are located on the same circle with the riser column 1 as the center, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com