Process and equipment for improving the quality of coal slurry and lignite through drying same

A drying and technological technology, applied in the drying of peat, petroleum industry, solid fuel, etc., can solve the problems of dehydration and drying failing to achieve the expected effect, equipment failing to operate normally, and mechanical dehydration being ineffective, and achieving dehydration and quality improvement. Good effect, safe and reliable use, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

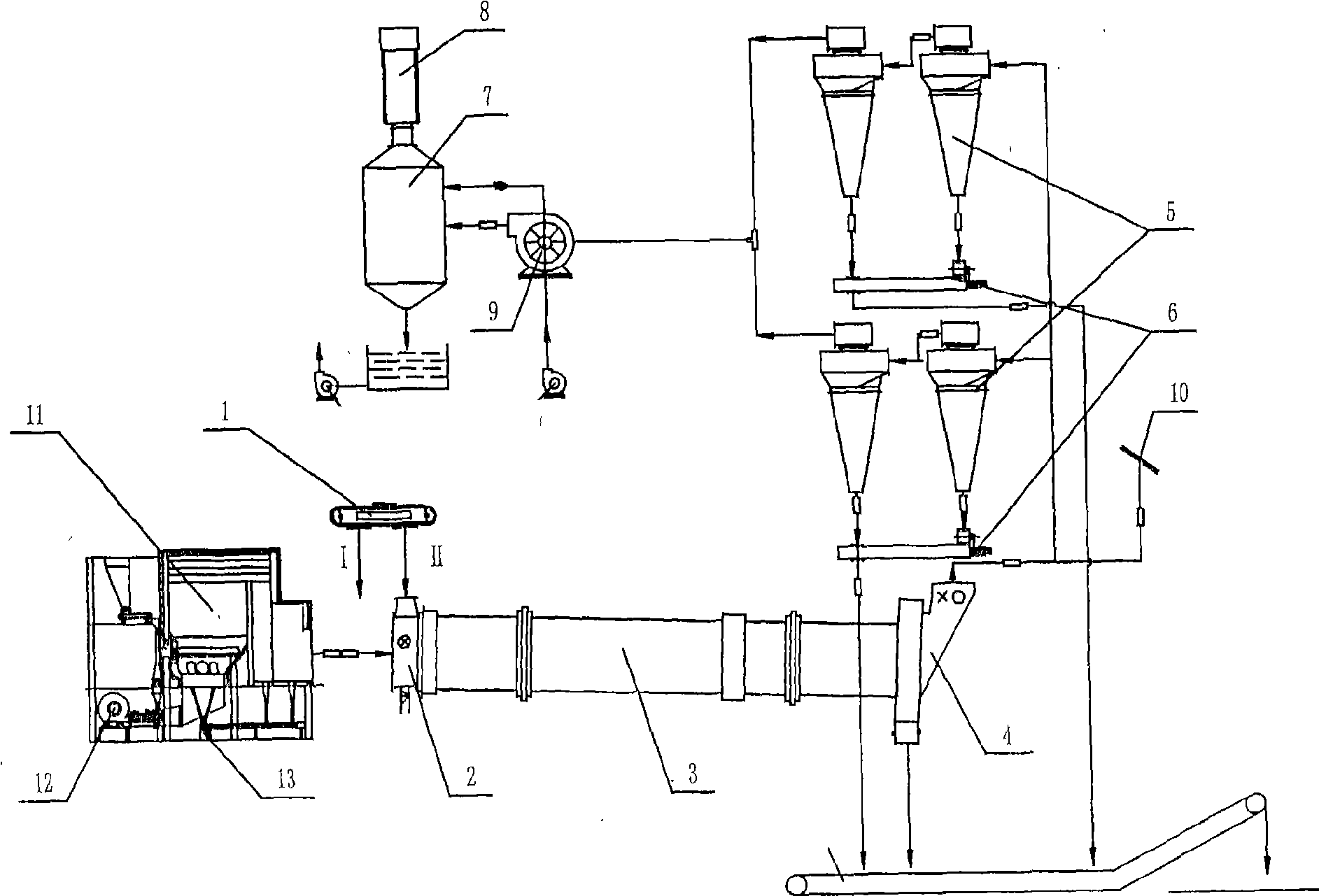

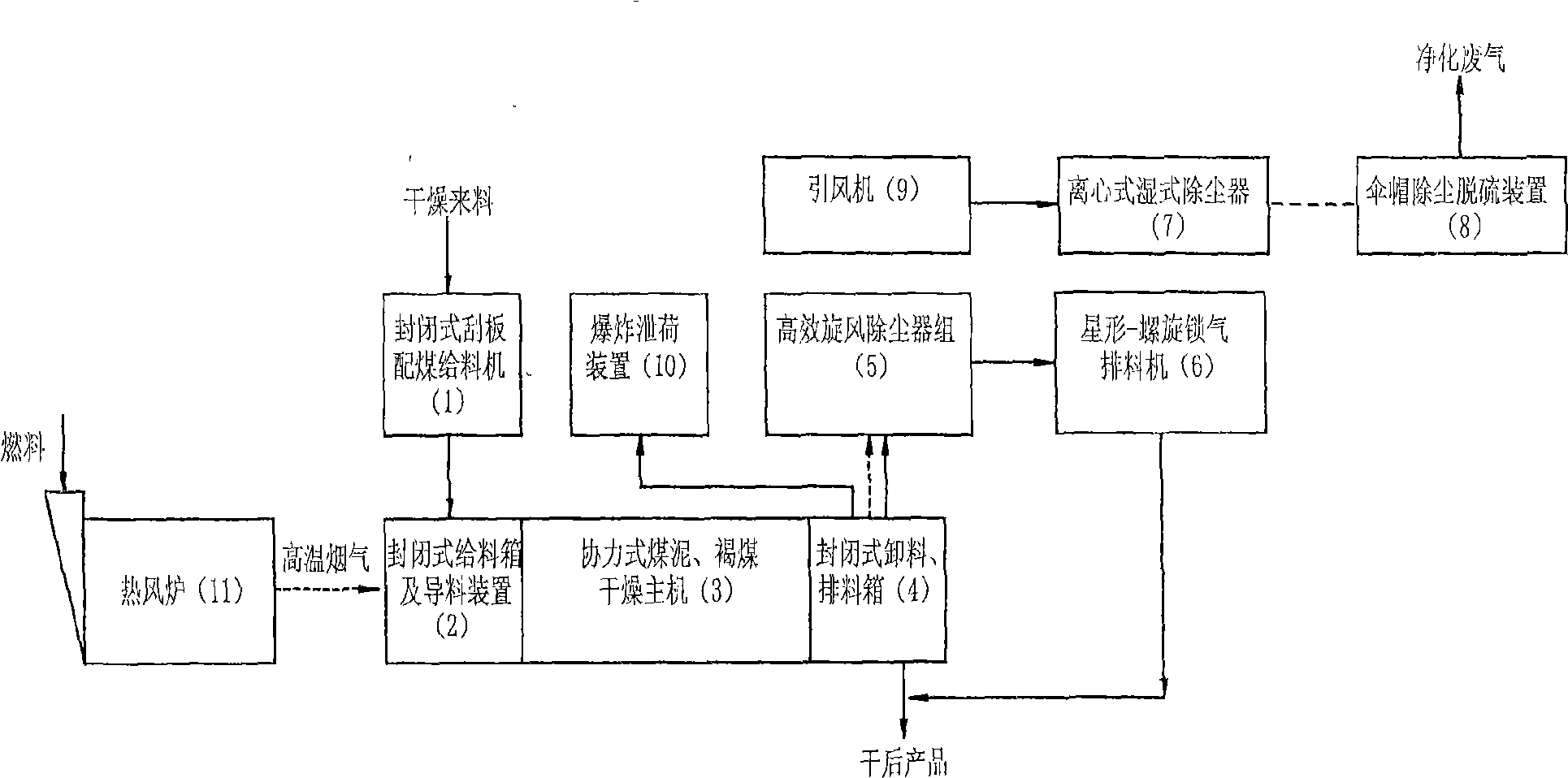

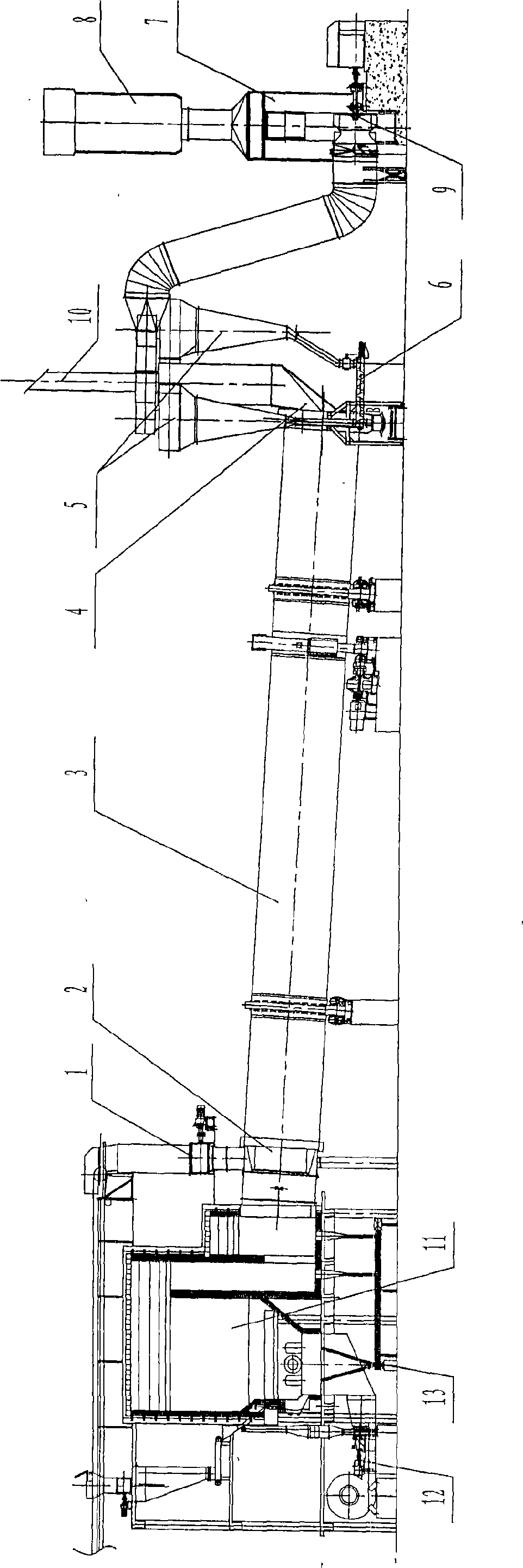

[0046] Embodiment one, with reference to the attached Figure 4 , 6 , 7.

[0047] The closed scraper coal blending quantitative feeder includes a body 53, a material inlet 58, a material outlet 59 and 60, a closed scraper 58, a chain 54, a head wheel group 51, and a tail wheel group 52. Two lower wheels are arranged below the body. The feed port and the two feed ports are fed by a closed scraper with air separation, and a flap gate 76 is set above the feed port. The flap gate is connected to the feed port through a chute, and the incoming material is evenly distributed to the scraper feeder. The two feeding ports are controlled by the flip gate to control the feeding state of the feeding port, so that one scraper feeder can match two material drying systems, and can feed materials to two material drying systems at the same time; it can also be turned over The plate gate only feeds to one material drying system. The chute set under the flap gate adopts the inverted cone type...

Embodiment 3

[0053] Embodiment 3, refer to accompanying drawing 8.

[0054] The feeding device includes a feeding box 21 and a material guiding device. The feeding box is provided with a material inlet 29, and the material guiding device is arranged in the feeding box. Several pieces of material guiding plates 22 form an angle of 40-80° with the center line of the drying machine. , evenly distributed for a week, and firmly connected together to form a tight overall hollow material guide cone structure, and the high-temperature flue gas passes through the hollow of the material guide cone.

[0055] The said feed box can have two structures, one is a double-layer structure, the outer layer is a straight box, the inner layer is a cone, the cone is matched with the hollow guide cone, and the inner layer of the feed box is The periphery of the cone bottom of the truncated cone is fixedly connected with the circumference of the straight box body, and the cone top of the truncated cone is fixedly...

Embodiment 4

[0060] Embodiment four, with reference to the attached Figure 9 .

[0061] The hollow material guide cone is still composed of several material guide plates 22 at an angle of 60° to the center line of the drying main machine. The hollow material guide cone is fixedly connected with the wall of the drying main machine through a ring frame, and its inner edge is guided by a ring frame and a reinforcing ring. The sheets 22 are secured together. In order to avoid the phenomenon of returning materials, a semicircular arc-shaped plate 26 is added at the feed end of the feed box 21 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com