Preparation process of intermediate alloy containing volatile element

An intermediate alloy and preparation technology, which is applied in the field of alloys, can solve the problems that the intermediate alloy cannot be continuously added to the smelting process, quantitative addition is inaccurate, etc., and achieve the effects of improving the production and working conditions of workers, reducing waste, and having strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

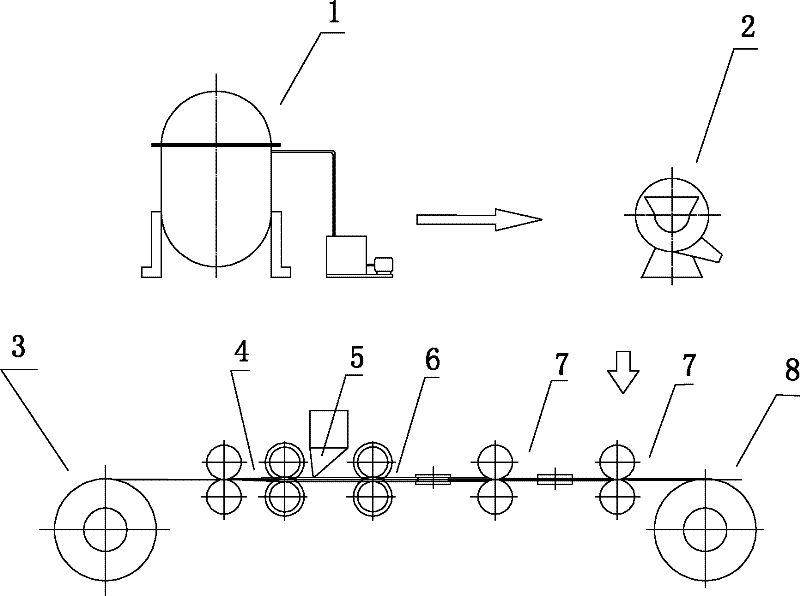

[0030] The invention will be further described below in conjunction with the accompanying drawings and preferred embodiments, which should not be used as limitations on the invention.

[0031] to combine figure 1 , a new process for the preparation of master alloys containing volatile elements, is to better meet the requirements of aluminum alloy and copper alloy melting and casting, so that the addition of master alloys with volatile alloy elements is more convenient, more accurate and more efficient Reduce burning loss of volatile elements, reduce environmental pollution, improve yield and reduce labor intensity of workers. The steps are as follows:

[0032] 1) The volatile alloying elements and parent metal are proportioned and loaded into a vacuum induction furnace; the temperature is raised to the melting temperature of the metal by vacuuming; due to the vacuuming, elements such as H, O, and N in the metal escape during the heat preservation process; After the smelting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com