Patents

Literature

130results about How to "Solve elusive problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for detecting and tracking obstacles in front of vehicle

InactiveCN102508246ASolve problems that are difficult to classify and identify at the same timeSolve elusive problemsPhotogrammetry/videogrammetryCharacter and pattern recognitionCamera imageImaging processing

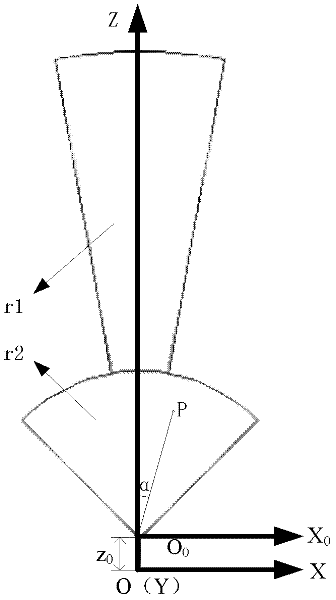

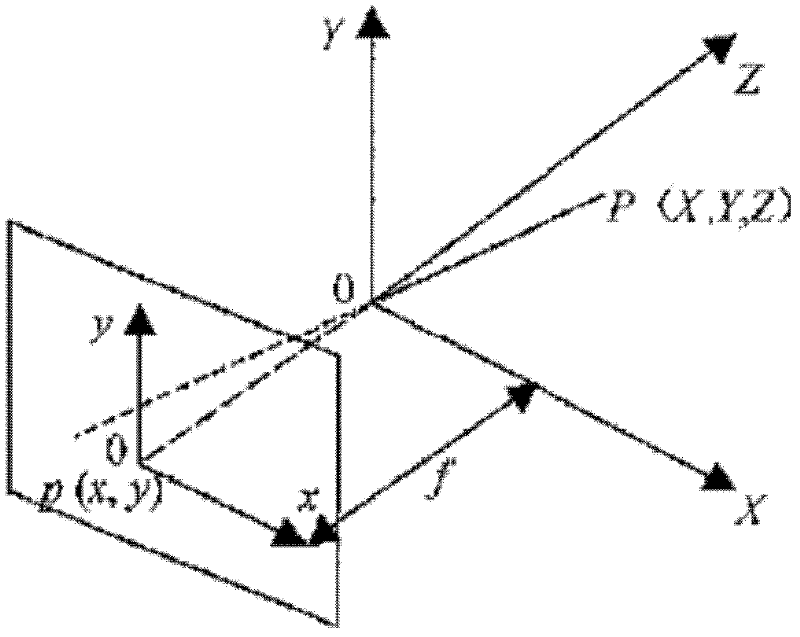

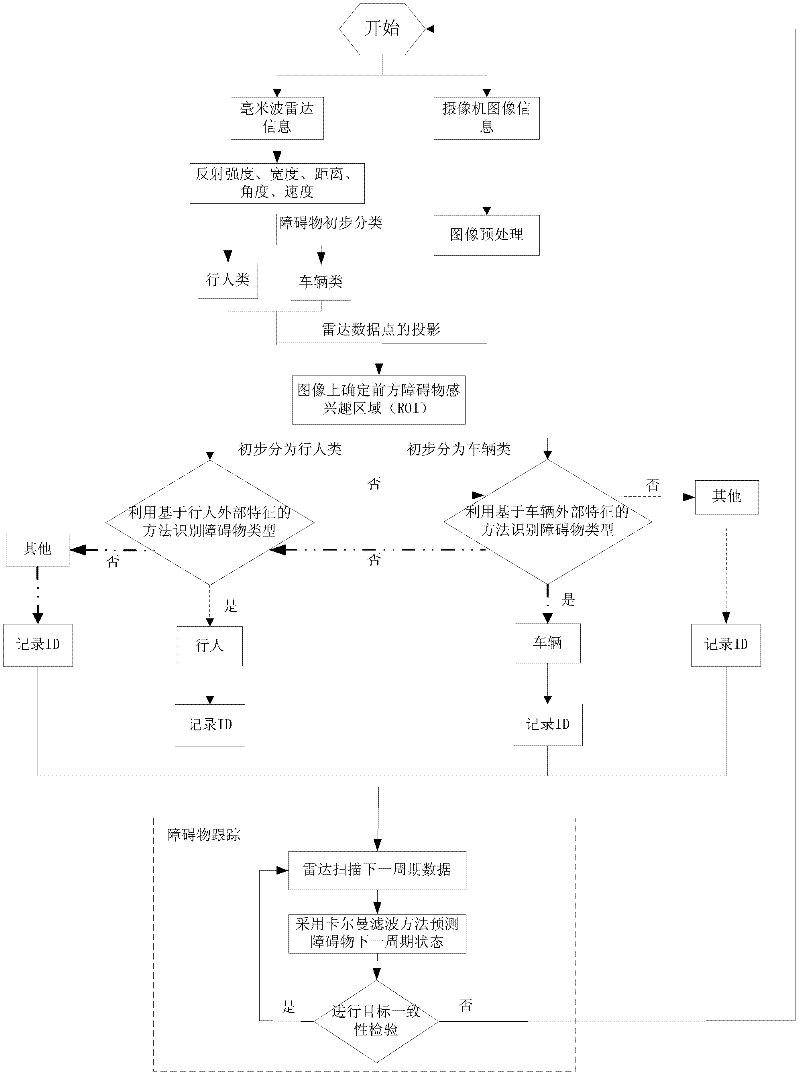

The invention discloses a method for detecting and tracking obstacles in front of a vehicle, aiming to overcome the defect and shortage in detection and tracking of obstacles in front of the vehicle by using a single-type sensor. The method comprises the following steps of: 1. establishing a relation for realizing data conversion between a millimeter wave radar coordinate system and a camera coordinate system; 2. receiving, resolving and processing the millimeter wave radar data, and carrying out preliminary classification on the obstacles; 3. synchronously collecting a camera image and receiving millimeter wave radar data; 4. classifying the obstacles in front of the vehicle: 1) projecting scanning points of the millimeter wave radar data on a camera coordinate system by combining the methods of millimeter wave radar and monocular vision, and establishing a region of interest (ROI) of the obstacles on the image; 2) carrying out preliminary classification on different obstacles in theROI established on the image, and confirming the types of the obstacles by using different image processing algorithms; and 5. tracking the obstacles in front of the vehicle.

Owner:JILIN UNIV

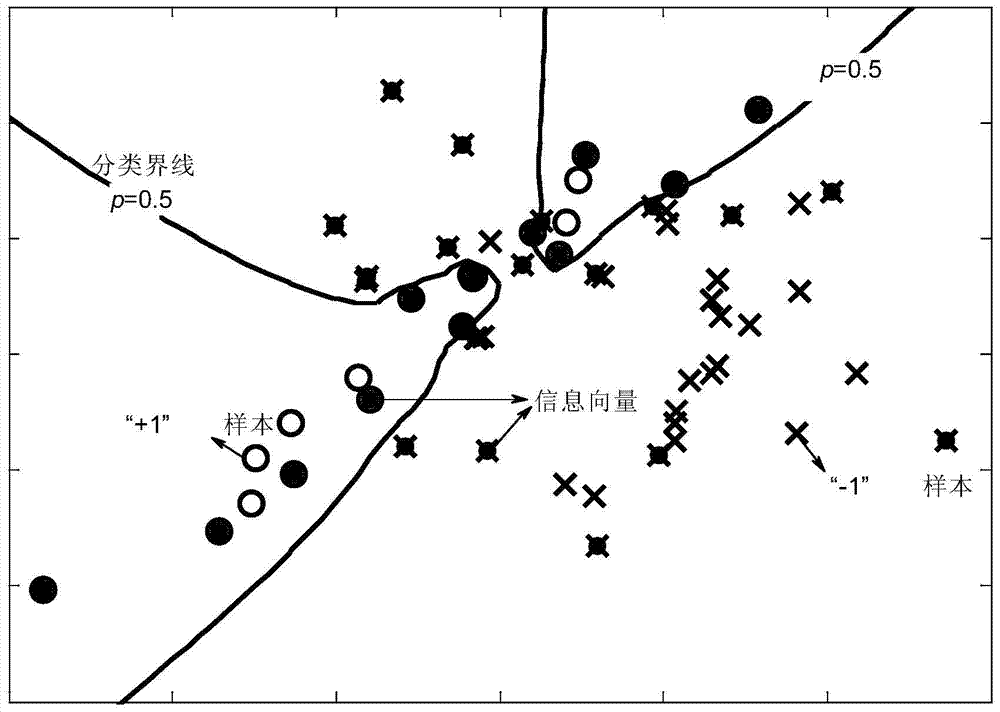

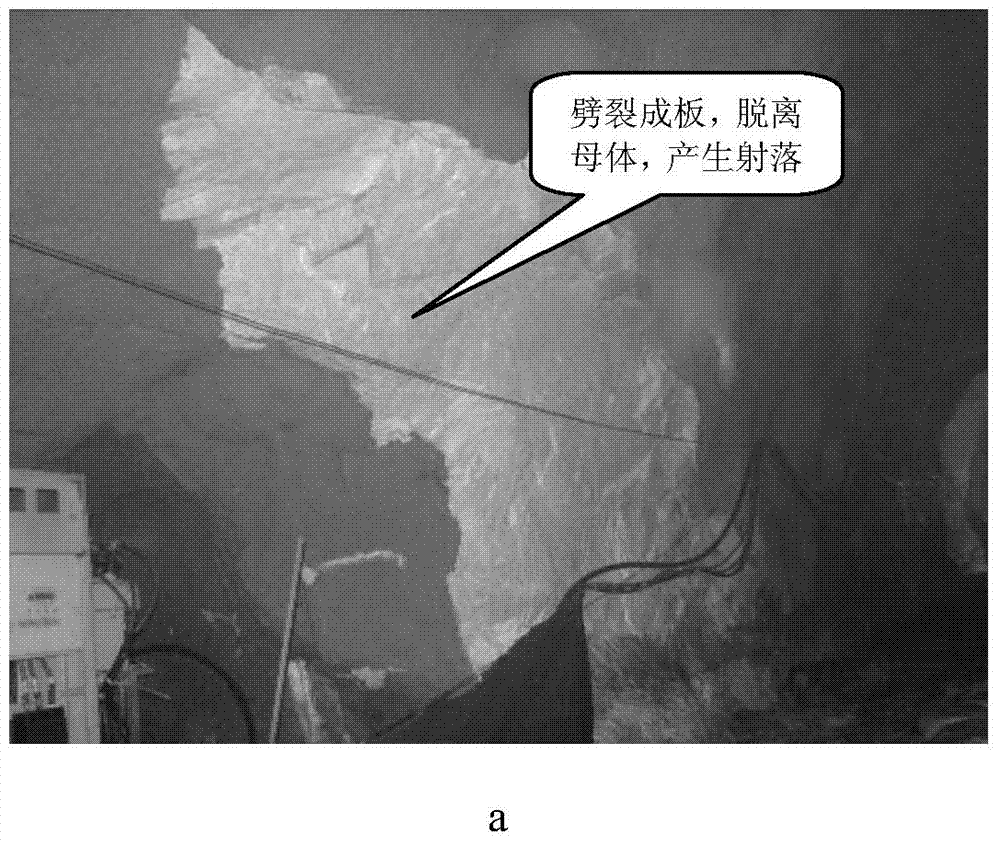

Rockburst grade predicting method based on information vector machine

ActiveCN104732070AOvercoming the lack of low forecasting accuracyGuaranteed credibilityCharacter and pattern recognitionSpecial data processing applicationsFeature vectorRock engineering

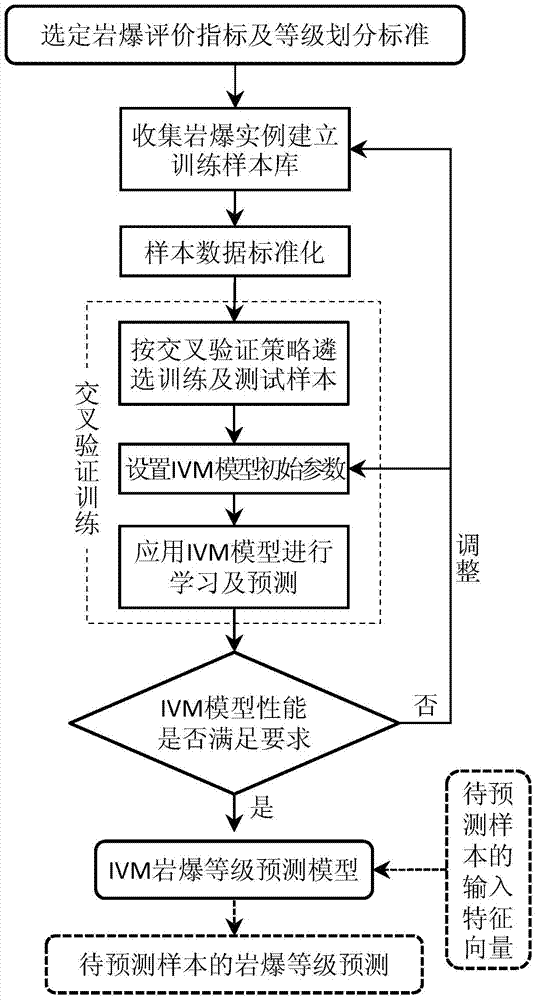

The invention discloses a rockburst grade predicting method based on an information vector machine to mainly solve the problem that in the current underground engineering construction process, the rockburst geological disaster prediction effect is not good. A rockburst evaluation index and a grading standard are selected, and domestic and overseas great deep rock engineering rockburst instances are widely collected to establish an abundant training sample library. A cross validation strategy is utilized for training an IVM model with the superior statistics mode recognition performance, accordingly, a nonlinear mapping relation between the rockburst evaluation index and the rockburst grade is established, model initial parameter setting and the training sample library are adjusted according to the training result, and the IVM model predicting the rockburst grade is finally established. By means of the method to predict the rockburst grade, the complex mechanical analysis or calculation is not needed, only the input feature vector of a sample to be predicted needs to be input in the prediction model, and then the prediction value of the rockburst grade can be obtained. The method is economical, efficient and high in prediction precision and has good engineering application prospects.

Owner:GUANGXI UNIV

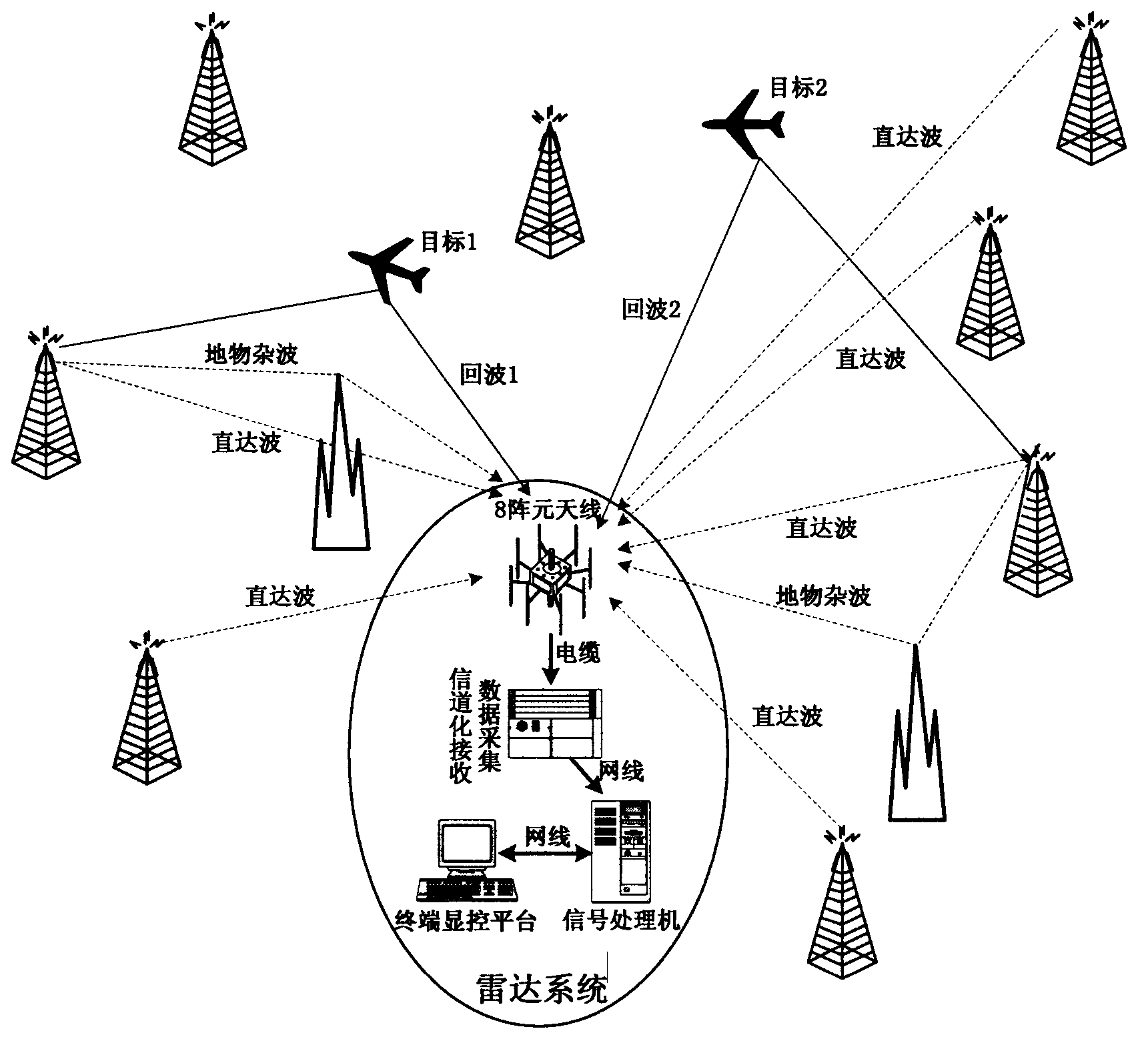

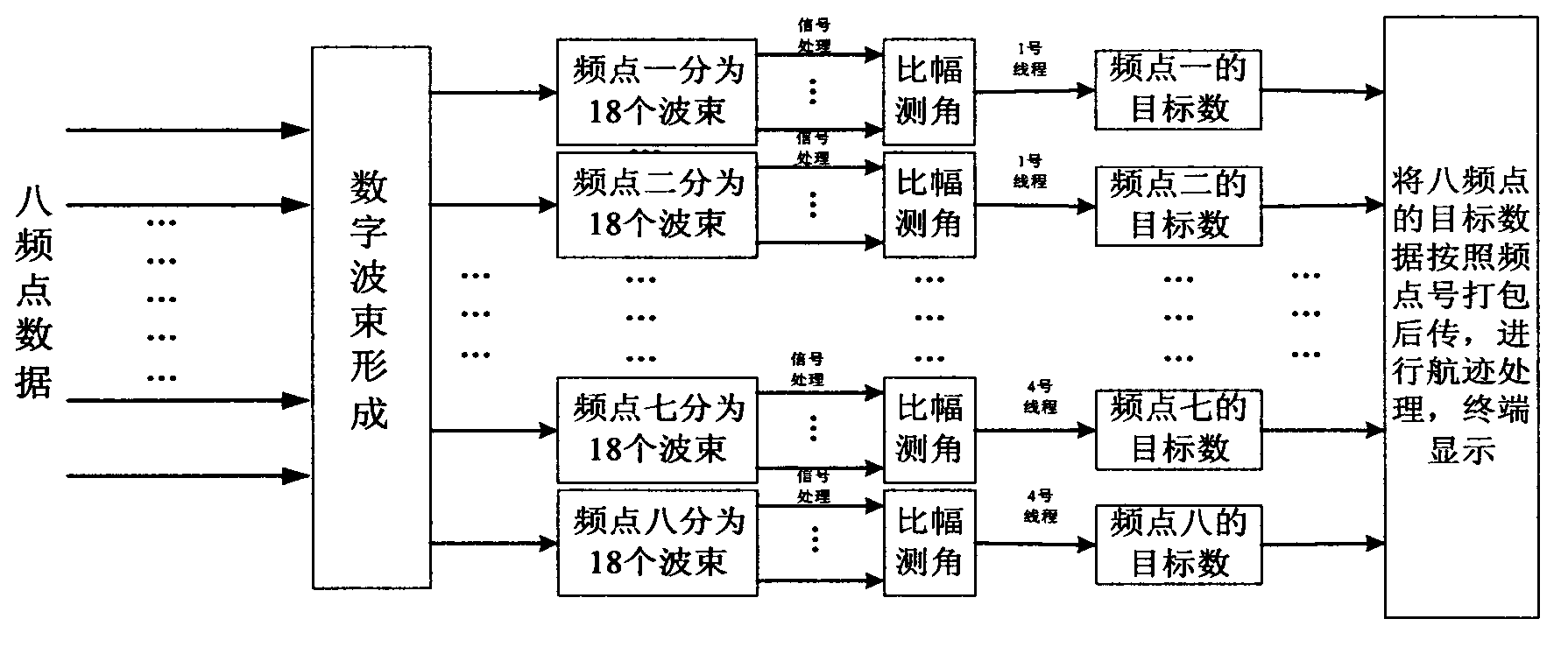

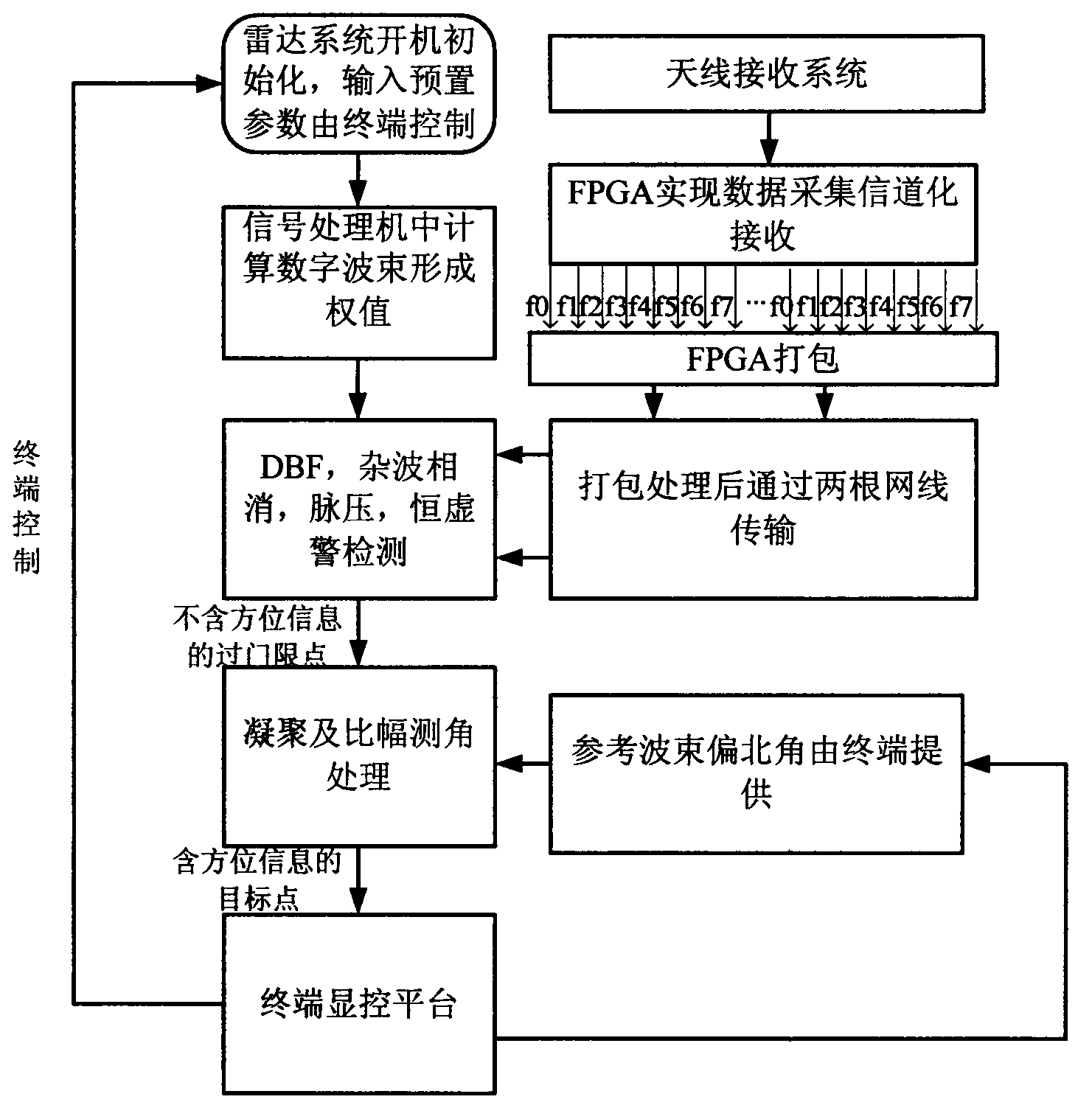

CPU (Central Processing Unit) realizing method based on amplitude-comparison direction finding of multi-frequency point omnibearing passive radar

InactiveCN102841333AGood choiceImprove detection accuracyRadio wave finder detailsRadio wave direction/deviation determination systemsHigh anglePassive radar

The invention discloses a CPU (Central Processing Unit) realizing method based on amplitude-comparison direction finding of a multi-frequency point omnibearing passive radar. A CPU and GPU (Graphic Processing Unit) heterogeneous hardware platform is adopted; a processing module with strong parallelism and the processing module with strong logicality are respectively realized on the GPU and the CPU; the platform is simple and high in use ratio; a system is simple in operation and strong in flexibility when being expanded; the coagulation and the angle measurement are carried out in the CPU; specifically, a coagulating-while-comparing amplitude angle measuring method is adopted; trace point coagulation is combined with amplitude-comparison angle measurement, so that the time for recombining the data after coagulation is omitted; the coagulation and angle measurement processes are embedded in multithreading, so that the time is further saved; and a target point containing the angle information is transferred to a terminal display control platform. According to the CPU realizing method provided by the invention, the problems that a target positioning effect of a single-frequency passive radar detecting system is inferior, the multi-frequency precision is high but the calculated quantity is large and the consumed time is long are solved. The CPU realizing method has the advantages of high processing speed, high angle measuring precision, and wide angle measuring scope, and can be applied to the target detection and positioning for the passive radar.

Owner:XIDIAN UNIV

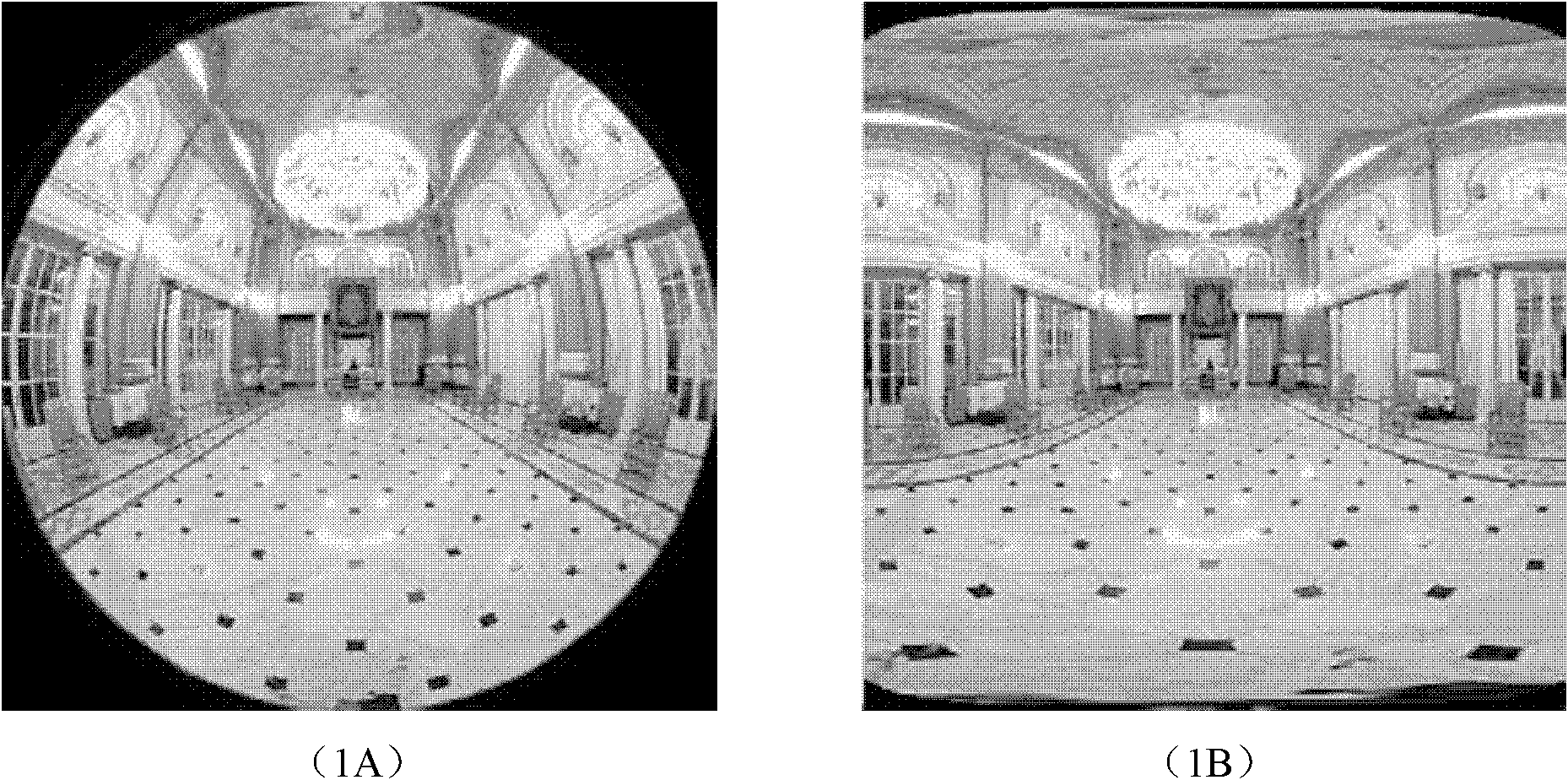

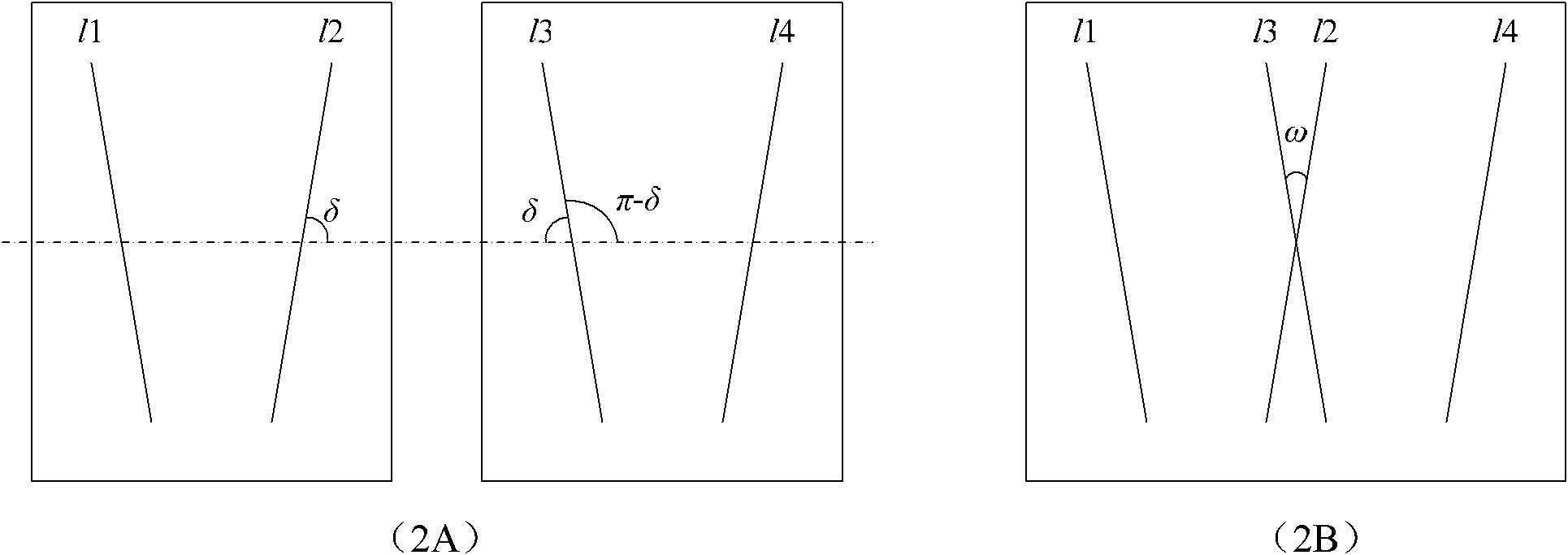

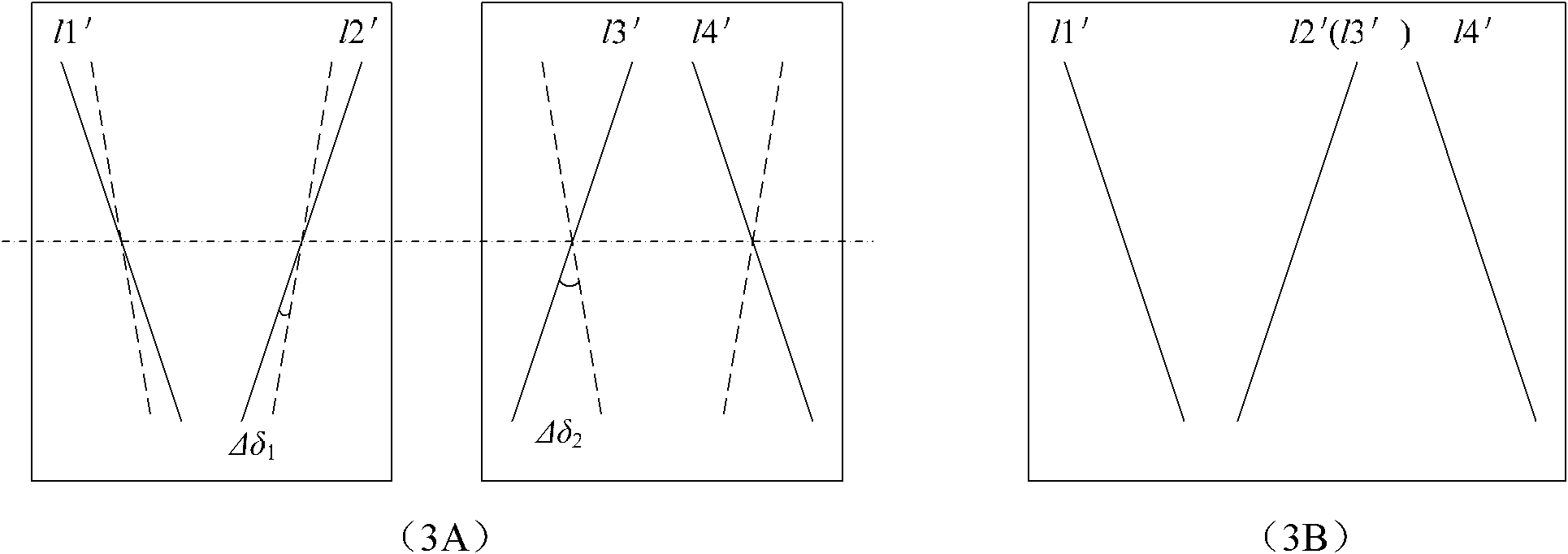

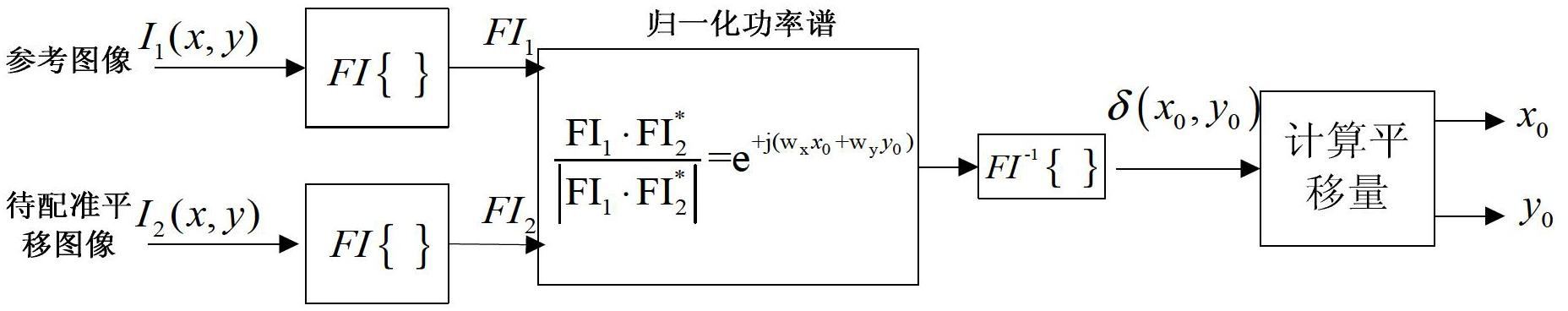

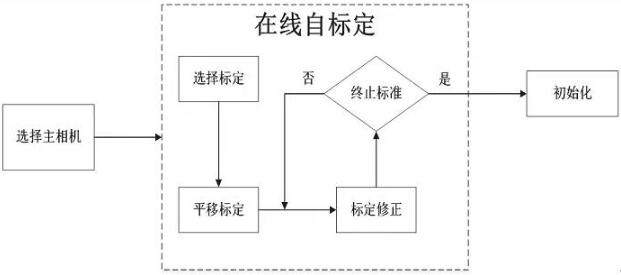

Fisheye image correcting method for image stitching

The invention provides a fisheye image correcting method for image stitching. The method corrects two fisheye images partially overlapped with each other through a computer, and finds out a splicing angle of stitching caused by pitch angles during shooting between the two fisheye images by adopting an unique correction principle and utilizing matched pixels in the two fisheye images so as to obtain the pitching angle formed during the shooting of the two fisheye images through backstepping; and the method also avoids adverse impacts, such as inclination, ghosting, and the like, of errors of the pitch angles formed during the shooting on the panorama stitching of the fisheye images through pitching conversion mapping treatment, and has the advantages of better robustness and high accuracy in computation.

Owner:CHONGQING UNIV

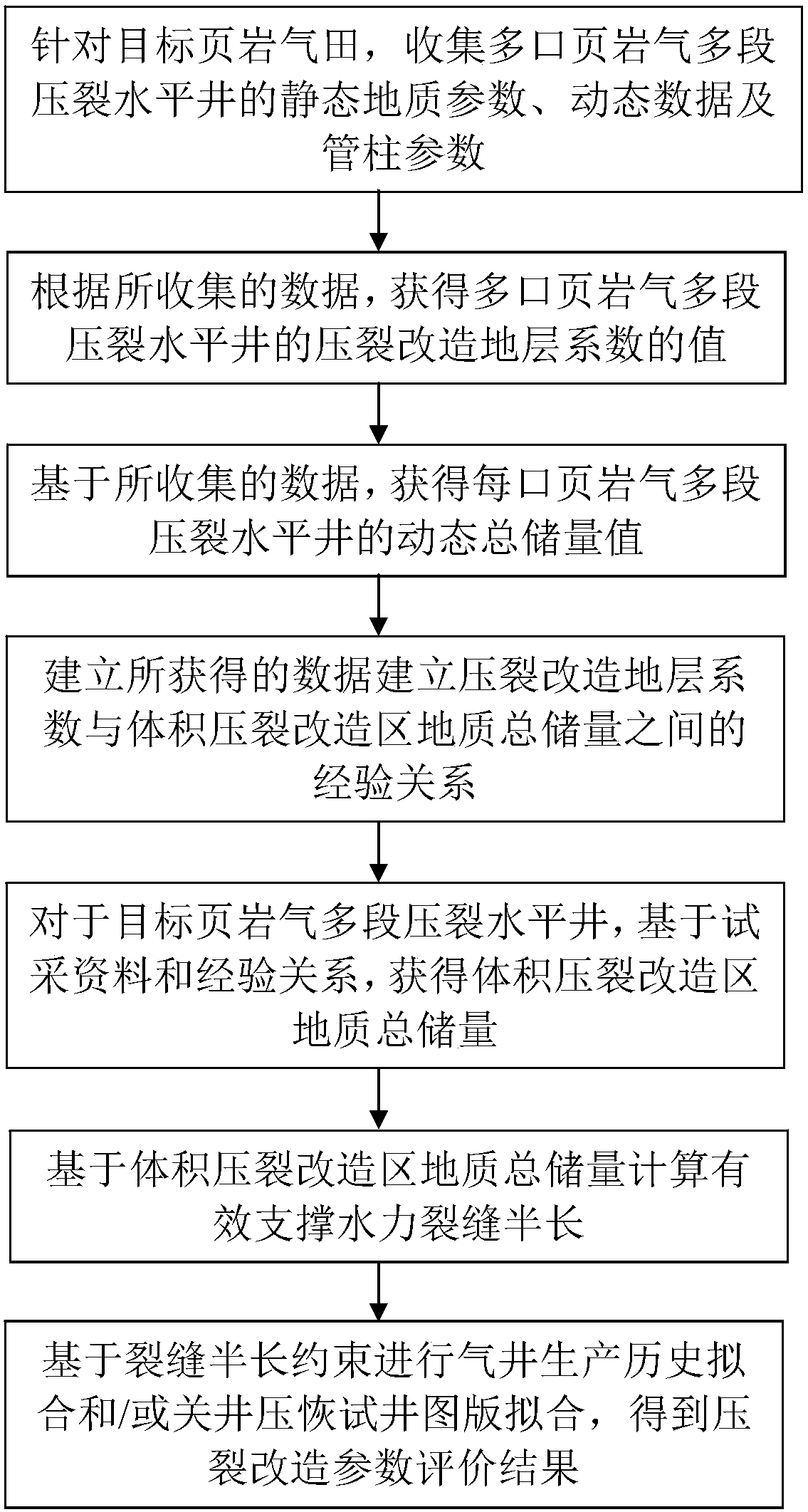

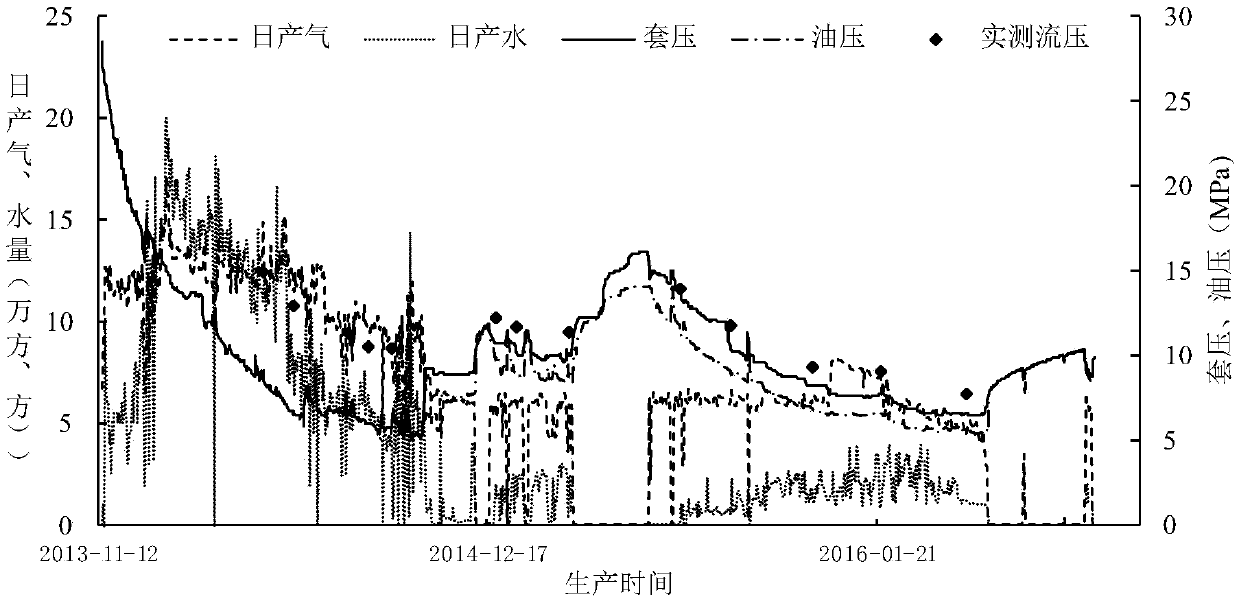

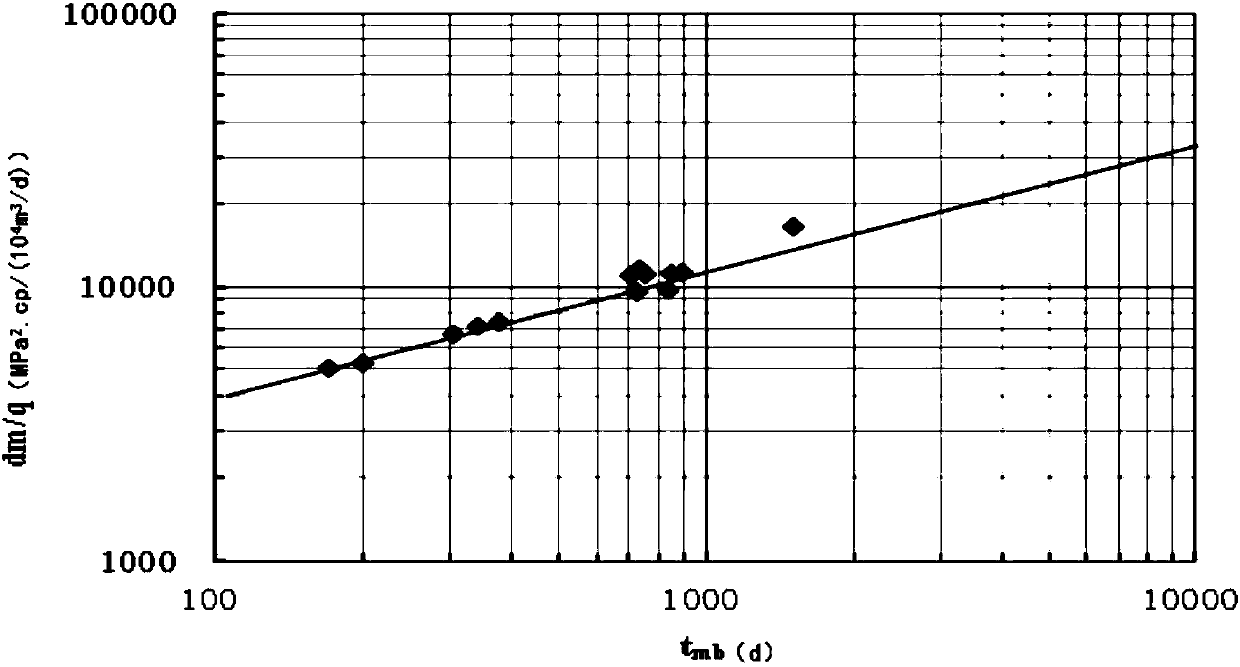

A shale gas multi-stage fractured horizontal well post-fracturing crack parameter evaluation method and system

ActiveCN109594968AReliable interpretation of resultsSolve elusive problemsSurveyFluid removalHorizontal wellsTransformation parameter

The invention discloses a shale gas multi-stage fracturing horizontal well post-fracturing crack parameter evaluation method and system. The method comprises the following steps: 1) aiming at a targetshale gas field, collecting static geological parameters, dynamic data and pipe column parameters of a plurality of shale gas multi-stage fractured horizontal wells; 2) obtaining values of fracturingtransformation stratum coefficients of the plurality of wells; 3) obtaining a dynamic total reserve value of each well; 4) establishing an empirical relationship between the fracturing transformationstratum coefficient and the total geological reserve of the volume fracturing transformation area according to data obtained in the steps 2 and 3; 5) obtaining the total geological reserve of the volume fracturing reconstruction area; 6) calculating the half length of the effective support hydraulic fracture; and 7) performing gas well production history fitting and / or shut-in pressure recovery well test chart fitting based on the crack half-length constraint to obtain a fracturing transformation parameter evaluation result. According to the method, the problem of high historical fitting multiplicity can be solved, a more reliable fracturing transformation parameter interpretation result is obtained, and a basis is provided for predicting the gas well productivity and making a reasonabledevelopment technical policy in the next step.

Owner:CHINA PETROLEUM & CHEM CORP +1

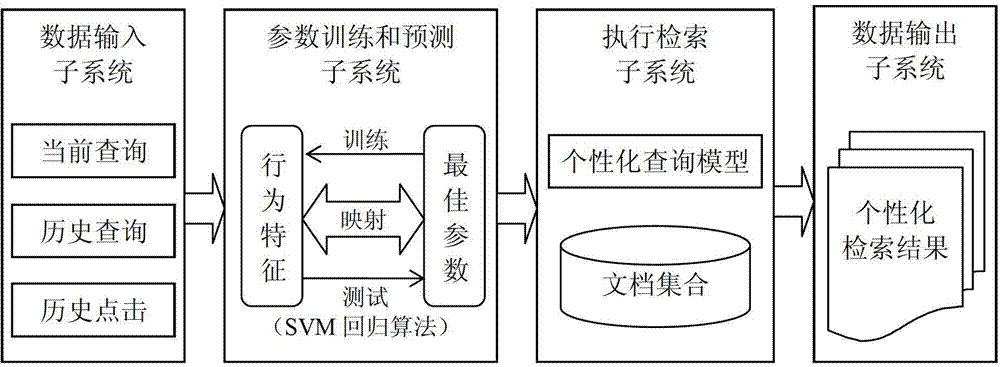

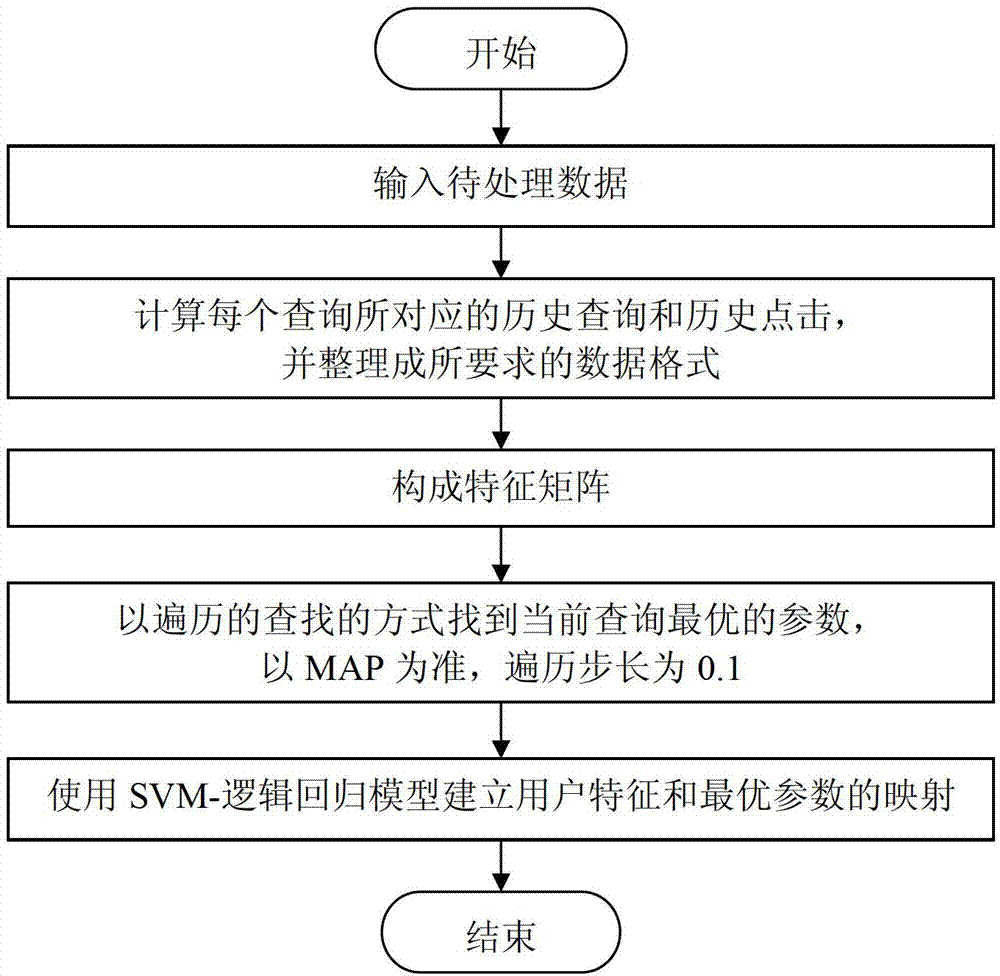

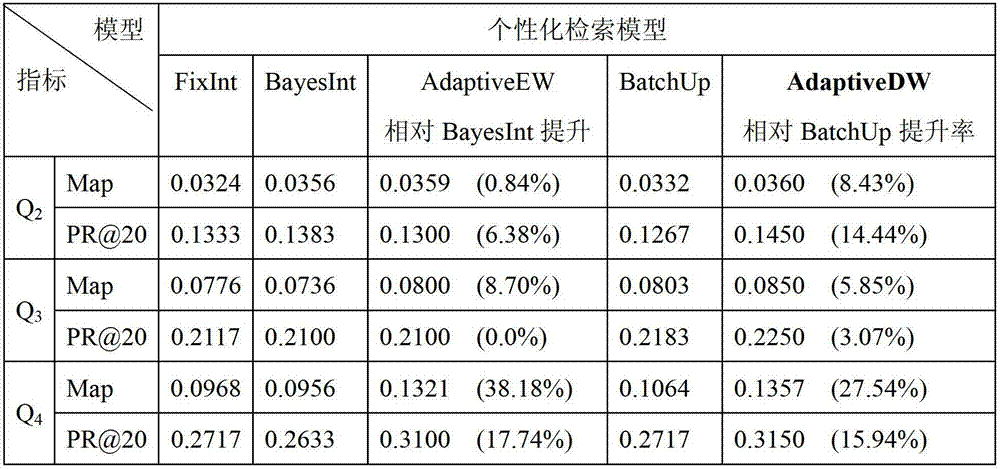

Self-adaptive personalized information retrieval system and method

ActiveCN102779193AFlexible handlingIncrease flexibilitySpecial data processing applicationsPersonalizationSelf adaptive

The invention discloses a self-adaptive personalized information retrieval system and method. For timely catching irregularly distributed dynamic retrieval requirements of a user, a retrieval module is timely updated through interaction of the user and a search engine. The system comprises a data input sub system, a parameter training and predicating sub system, a retrieval performing sub system and a data output sub system, wherein the data input sub system is used for combining historical inquiry information and historical click information to form a characteristic matrix according to the current inquiry information, and acquiring a training parameter predicating module according to the characteristic matrix; the parameter training and predicating sub system is used for training and applying the parameter predicating module to acquire the predicated parameters according to the characteristic matrix; the retrieval performing sub system is used for predicating the parameters to organize the current inquiry and the historical inquiry, and combining the user module and the inquiry module to form a personalized inquiry module; and the data output sub system is used for searching a document matched with the personalized inquiry from the document to be retrieved as a primary retrieved result, and sequencing the primary retrieved result according to the correlation to obtain the final retrieved result for outputting.

Owner:哈尔滨工业大学高新技术开发总公司

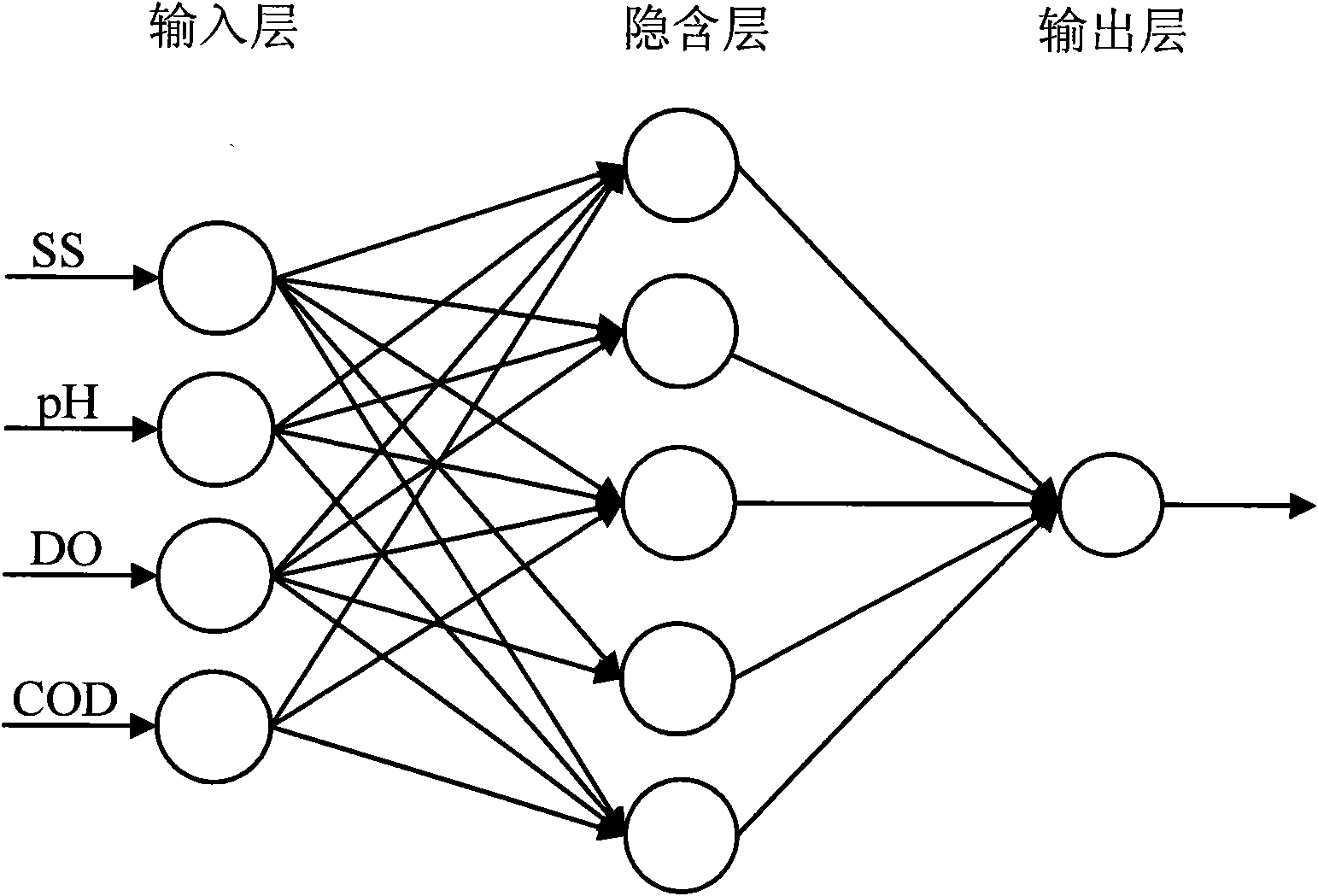

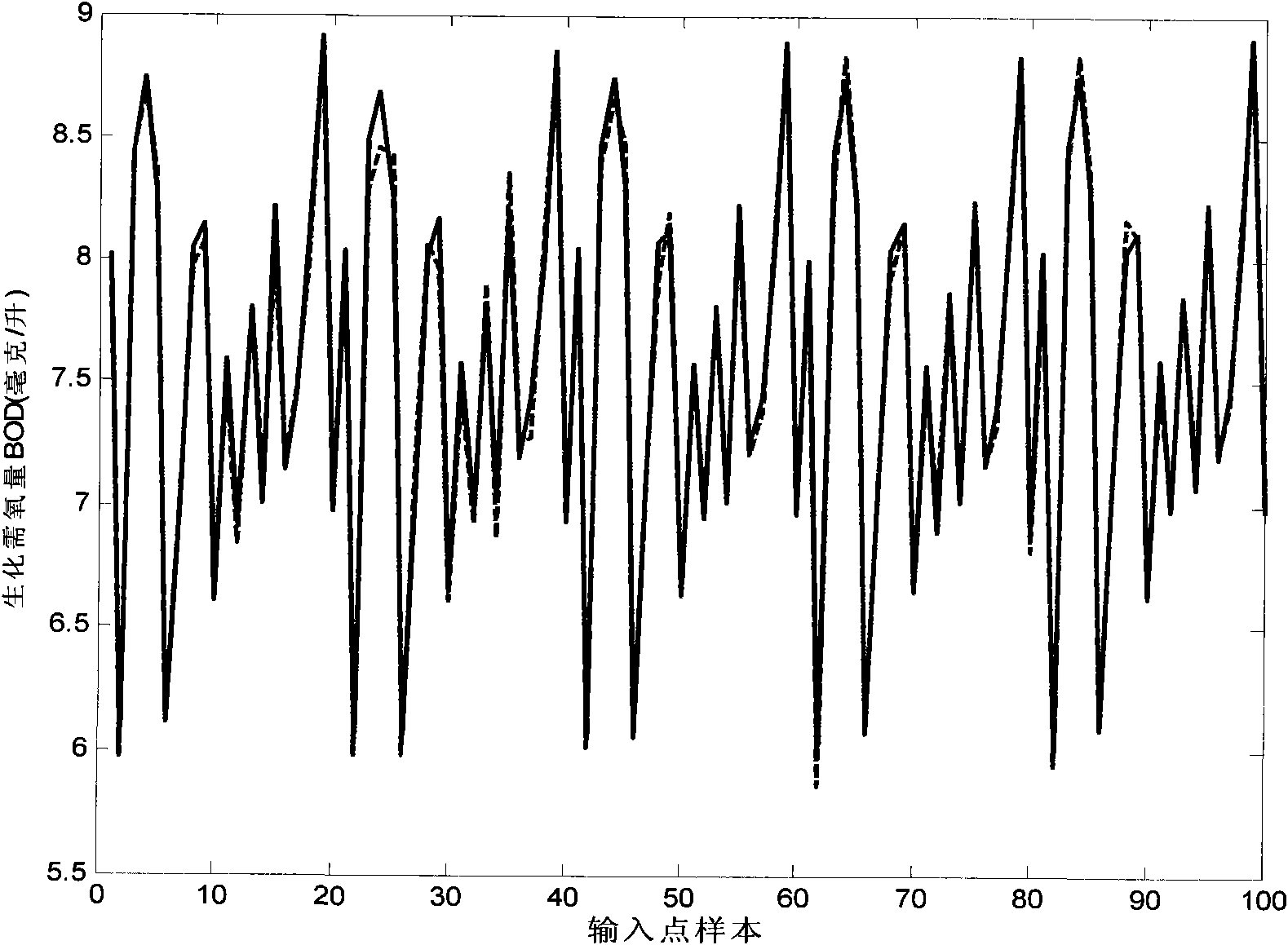

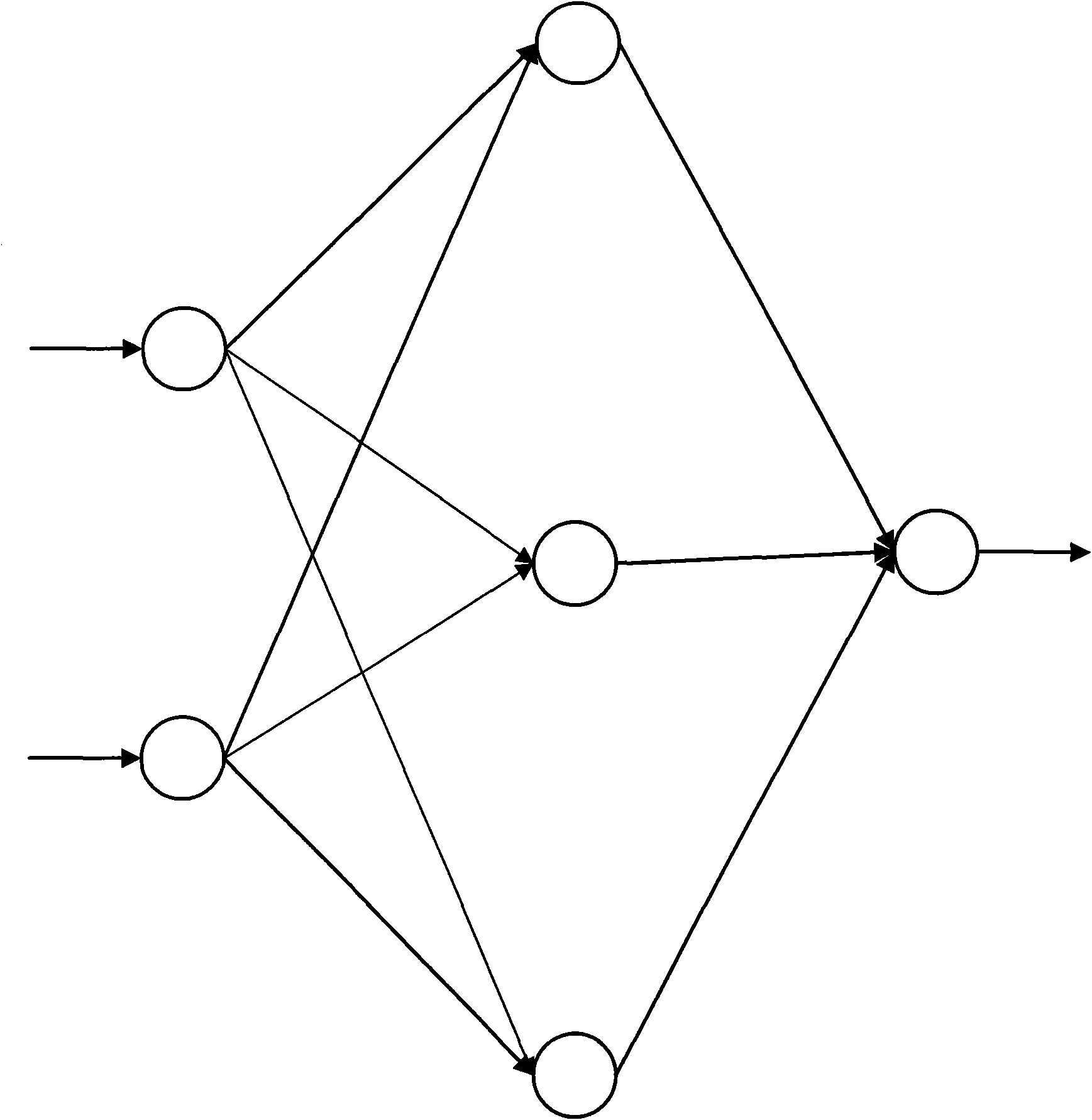

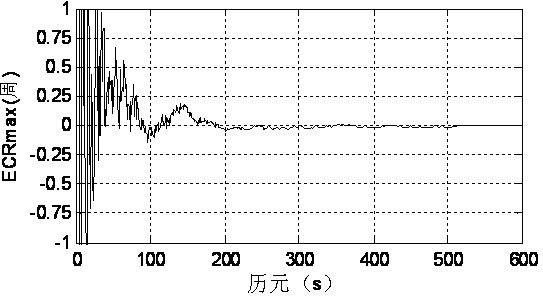

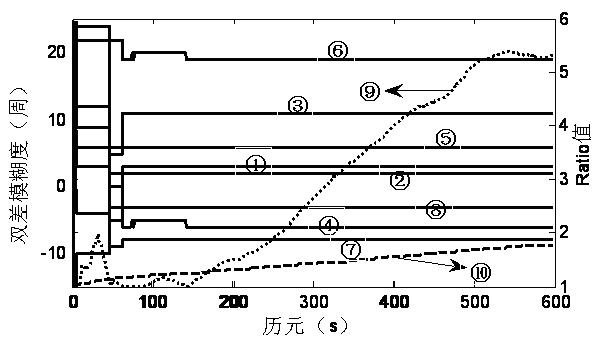

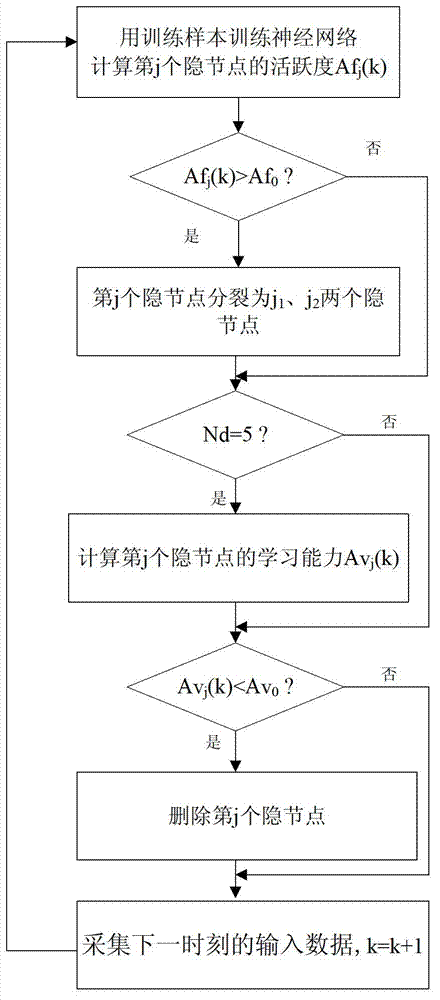

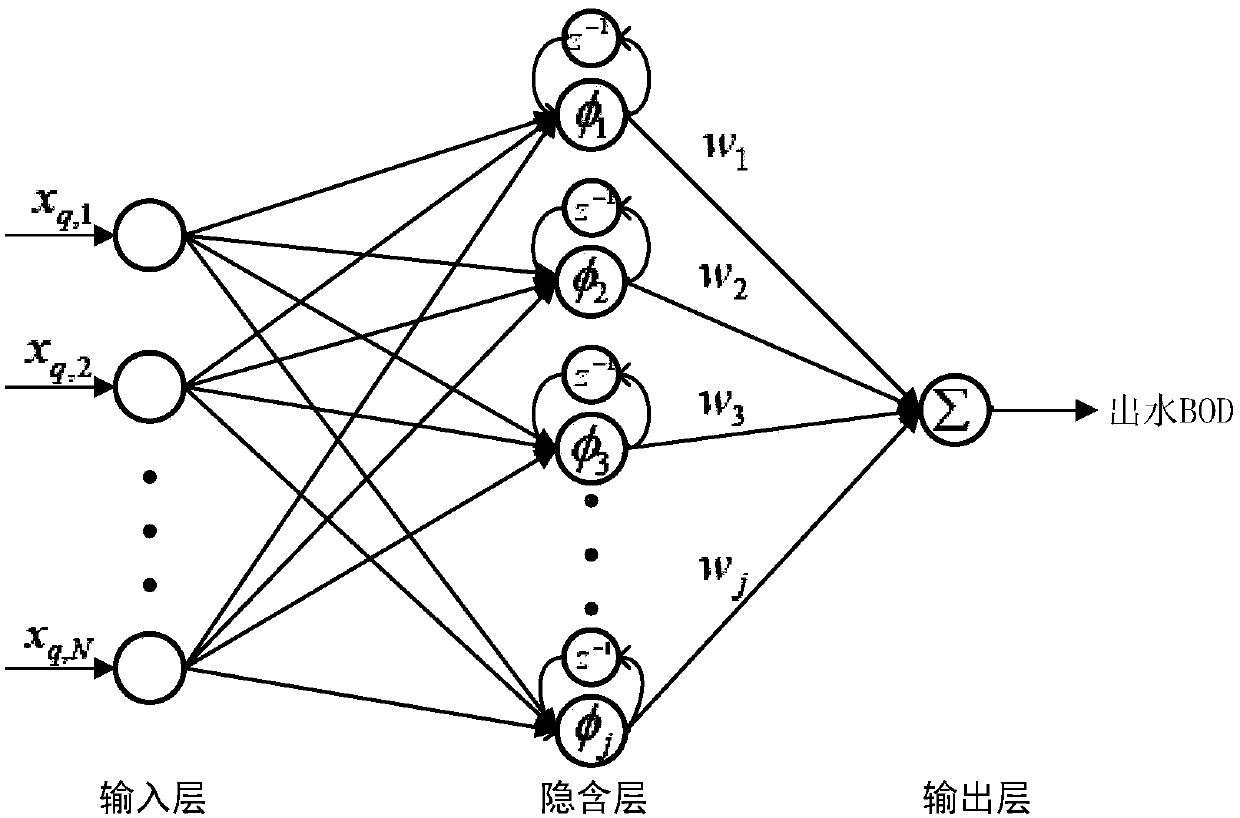

Biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network

ActiveCN101957356AGuaranteed uptimeSave investment costBiological neural network modelsTesting waterMathematical modelWater quality

The invention discloses a biochemical oxygen demand BOD soft measurement method based on elastic radical basis function neural network, belonging to the technical field of detection. The sewage processing process has severe production condition and serious random disturbance, has the characteristics of strong nonlinearity, large time varying and serious lag and is hard to build a precise mathematical model by mechanism analysis. The invention utilizes the liveness function of an RBF neuron to judge the activeness of the neuron, and divides the neuron with strong activeness; then, joint strength between the hidden layer neuron and the output layer neuron of an RBF neuron network is analyzed by calculating a mutual information dependency function so as to revise the neural network structureaccording to the mutual information intensity; and finally, the parameter of the neural network is adjusted until the network structure satisfies the requirement on processing information. The invention improves the quality and the efficiency of sewage processing, lowers sewage processing cost and provides in-time water quality and relevant parameter monitoring for realizing closed loop control for the sewage processing process so as to accelerate sewage treatment plants to efficiently and stably operate.

Owner:BEIJING UNIV OF TECH

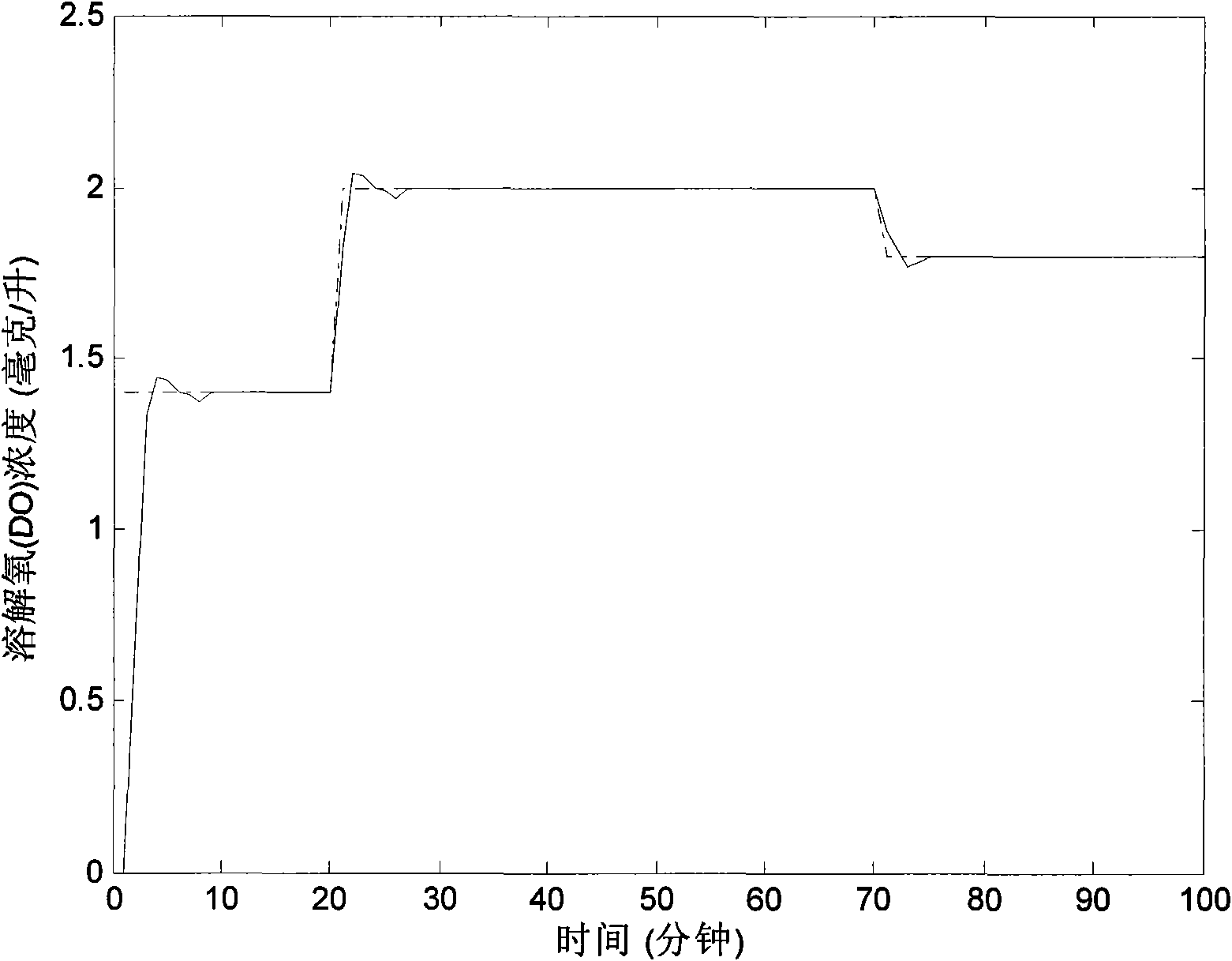

Dissolved oxygen control method based on dynamic radial basis function neural network

InactiveCN101576734AImprove real-time performanceImprove stabilitySustainable biological treatmentAdaptive controlFrequency changerAeration rate

The invention discloses a dissolved oxygen control method based on a dynamic radial basis function neural network, which adopts the following steps of: determining a control object; designing a dynamic RBF neural network topology structure used for a dissolved oxygen DO controller during sewage treatment; correcting sample data; training a neural network by using part of the corrected data, controlling dissolved oxygen (DO) by using the trained RBF neural network, and taking an error between anticipant DO concentration and actually output DO concentration and an error change rate as the input of the RBF neural network, wherein the output of the RBF neural network is the input of a frequency transformator, and the frequency transformator achieves the purpose of controlling a blower by adjusting the rotating speed of an electromotor so as to finally control aeration rate. The output of the whole control system is the actual DO concentration; the control effect of the controller is improved; the dissolved oxygen meets the anticipant requirements quickly and accurately; and the problem of poor self-adaptive capability based on switch control and PID control is solved.

Owner:BEIJING UNIV OF TECH

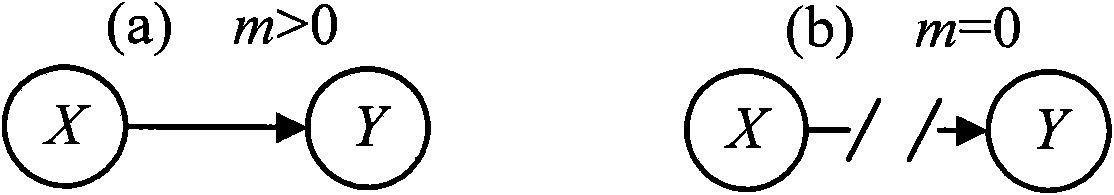

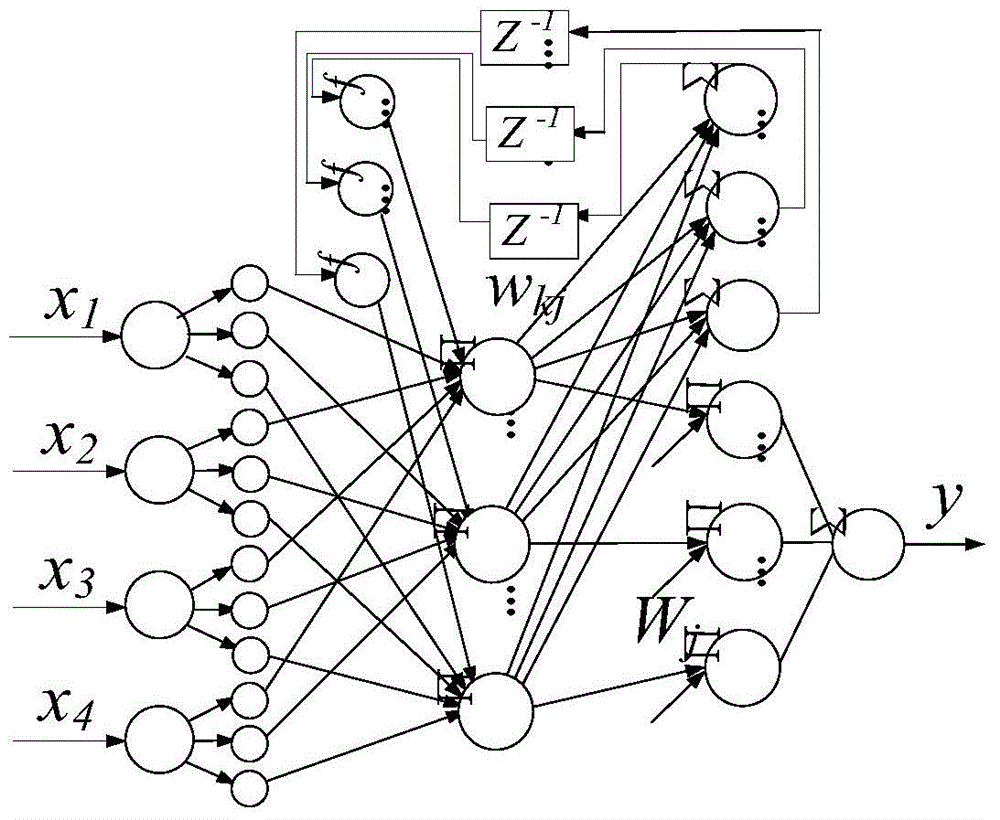

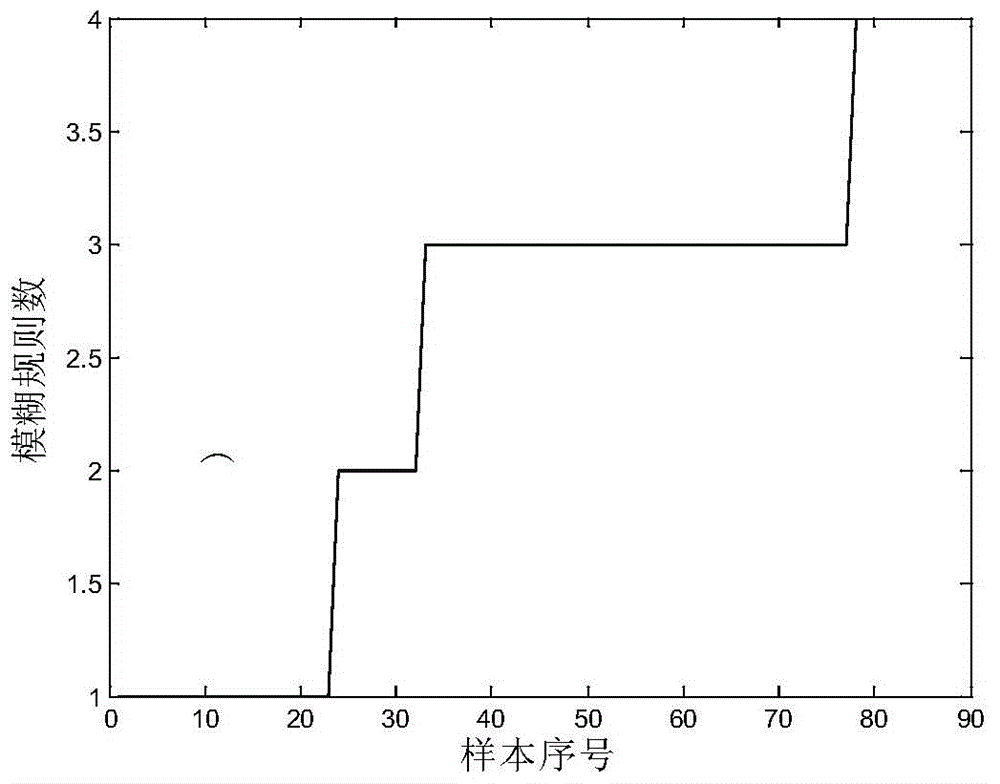

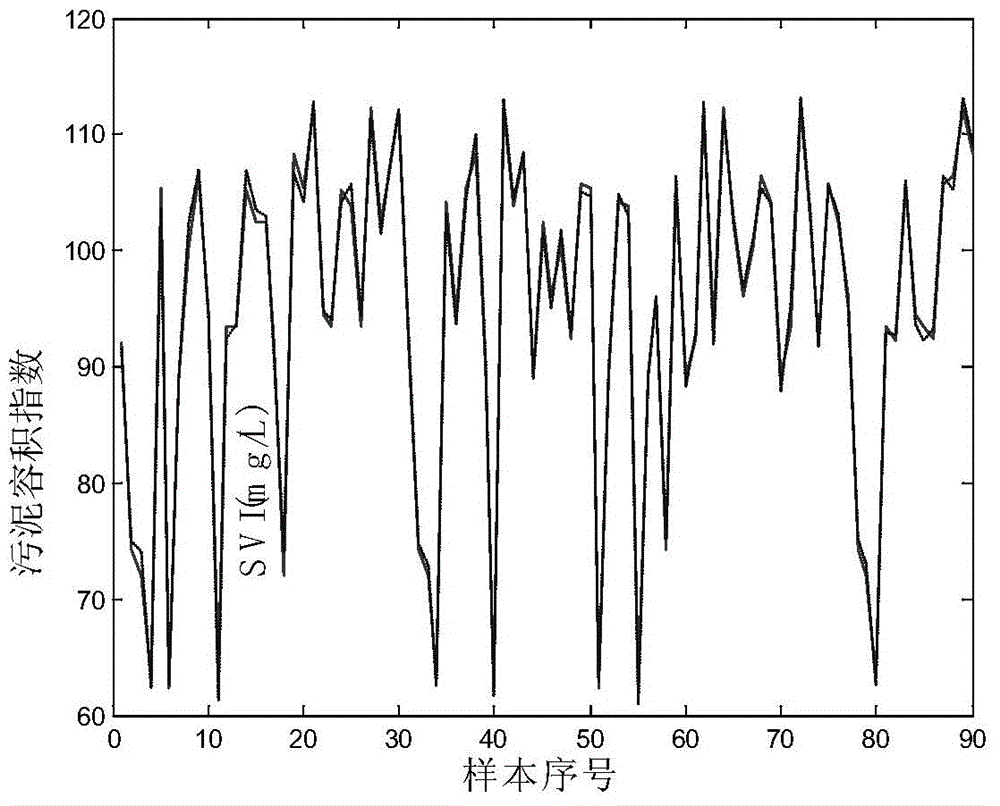

Sludge volume index (SVI) soft measuring method based on self-organized T-S fuzzy nerve network

ActiveCN103606006AInhibit swellingRealize online detectionNeural learning methodsMaterial analysisSewage treatmentRecurrent neural nets

The invention discloses a sludge volume index (SVI) soft measuring method based on a self-organized T-S fuzzy nerve network and belongs to both the field of control and the field of sewage treatment. The accurate prediction of an SVI is the guarantee for normal operation of a sewage treatment process. The method comprises: first of all, taking the output quantity of a rule layer, i.e., the space activation intensity of the rule layer as a basis for determining whether a fuzzy rule is increased; secondly, on the basis of generating a new fuzzy rule, taking the output quantity of a membership function layer as a basis for determining whether a fuzzy set is increased; and finally obtaining a self-organized T-S fuzzy recursion nerve network by using a gradient decrease algorithm to adjust the weight value parameter of a model and the center value and width of a Gauss function, and establishing an SVI on-line soft measuring model based on an SOTSFEN such that real-time detection of the SVI is realized, and an effective method is provided for preventing sludge expansion.

Owner:BEIJING UNIV OF TECH

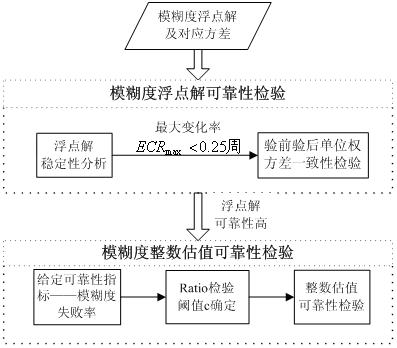

Phase integer ambiguity reliability checking method in GPS positioning technology

InactiveCN102426375AGuaranteed accuracySolve elusive problemsSatellite radio beaconingLeast squaresDependability

The invention discloses a phase integer ambiguity reliability checking method in a GPS positioning technology. Based on a mathematical statistic characteristic of an ambiguity resolution, examinations are performed successively to the reliability of an ambiguity floating point solution and an integer solution. The method is characterized by: firstly, examining floating point solution stability through a least square parameter valuation maximum variation rate so as to ensure the statistic characteristic of the floating point solution, on that basis, using a variance posteriori inspection method to examine the reliability of the floating point solution; secondly, based on an ambiguity success rate examination theory, establishing a function relation between an ambiguity integer valuation failure rate and a traditional ratio examination threshold c so that a given reliable index-the ratio examination threshold c determined by the ambiguity integer valuation failure rate is used and the traditional ratio examination threshold is easy to be determined; finally, through the ratio inspection method, realizing the reliability examination of the ambiguity integer valuation and obtaining anambiguity accuracy value.

Owner:SOUTHEAST UNIV

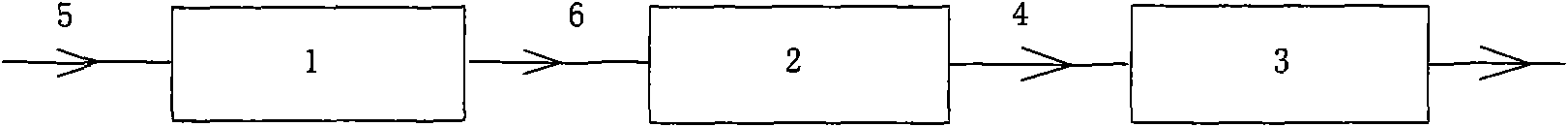

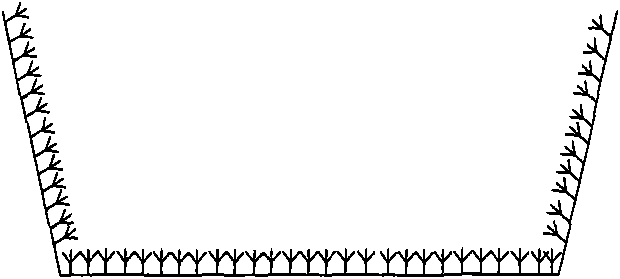

Combinational processing technique and device of deck radial flow

InactiveCN101624251AStrong oil separation abilityHigh efficiency in retaining suspended solidsFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesConstructed wetlandEnvironmental engineering

The invention relates to a combinational processing technique of deck radial flow, comprising the following steps: firstly, performing oil removal and sedimentation processing on the collected deck radial flow, then, introducing the processed radial flow to a planting slope, and introducing the radial flow to an artificial wet land for biochemical treatment. The processing device comprises an oil removing tank, a sedimentation tank and the artificial wet land, wherein a water outlet of the oil removing tank is connected with a water inlet of the sedimentation tank; the planting slope is arranged between the sedimentation tank and the artificial wet land; the water outlet of the sedimentation tank is higher than the slope top of the planting slope; and the bottom of the planting slope is opposite to the water inlet of the artificial wet land so that the radial flow flowing down from the planting slope enters from the water inlet of the artificial wet land to the artificial wet land through the bottom of the planting slope. The invention can improve the efficiency of processing the pollution of deck radial flow.

Owner:SOUTHEAST UNIV

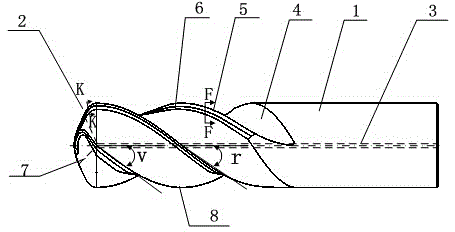

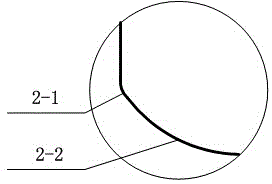

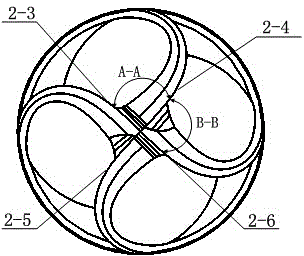

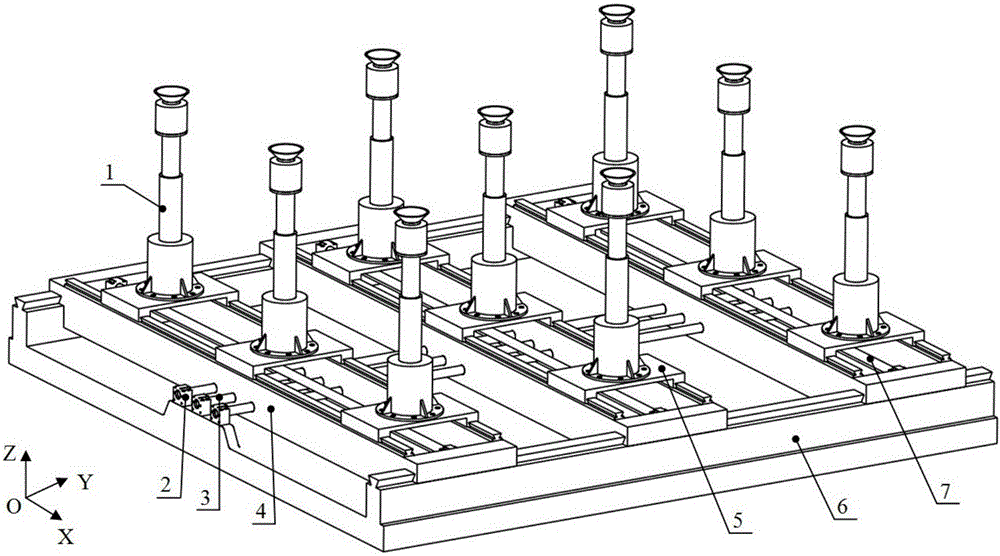

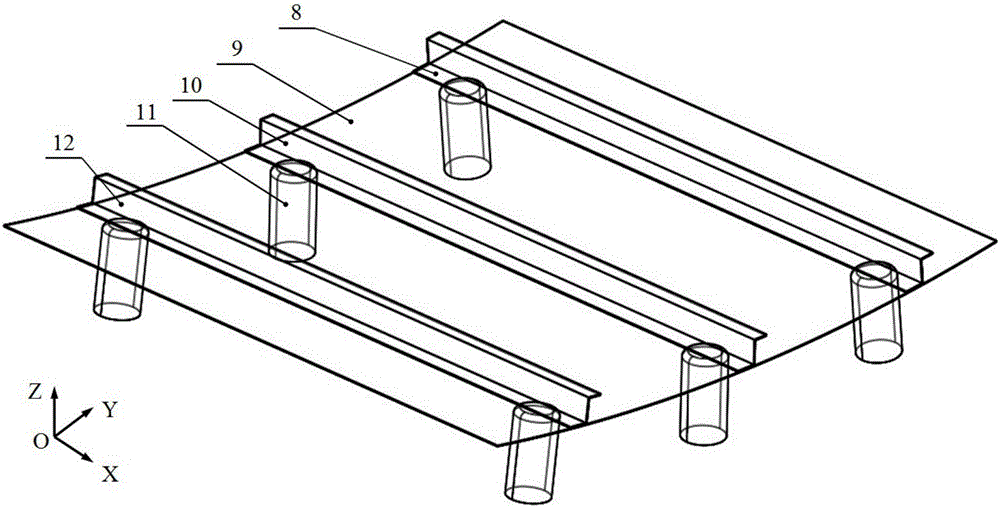

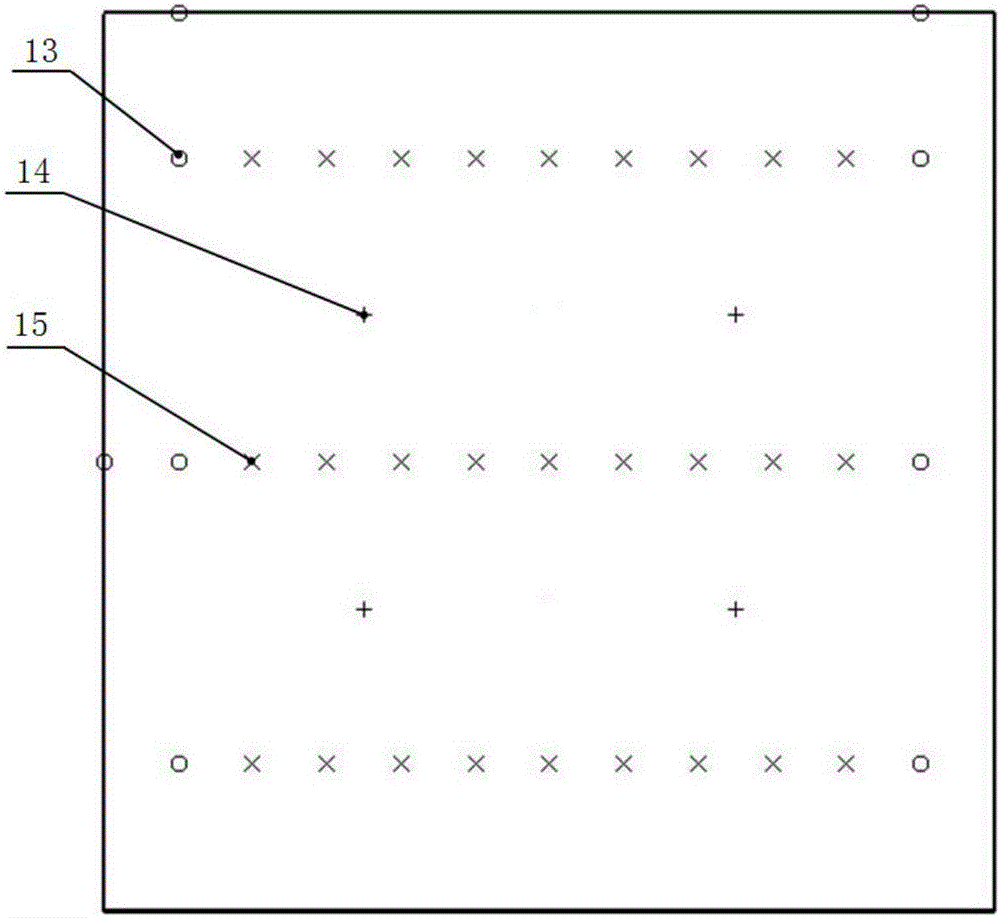

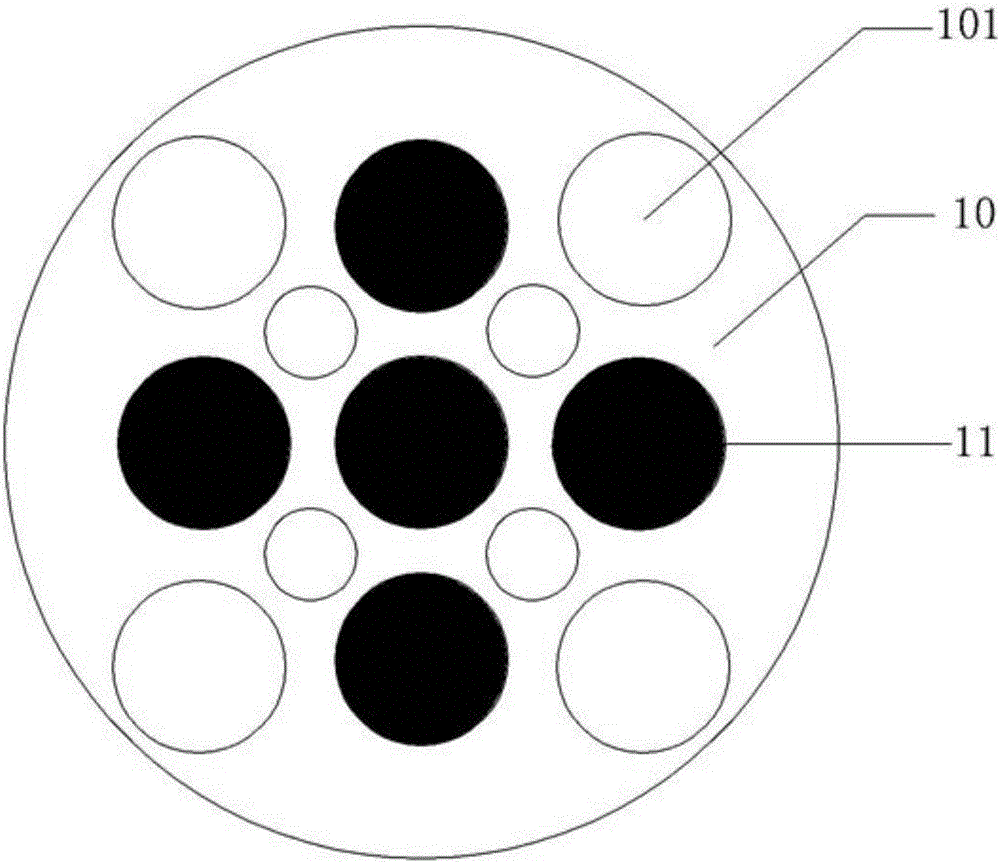

Milling cutter provided with equidistant arc head on eccentric shape flank surface and grinding method

InactiveCN104959667AAvoid vibrationExtend your lifeMilling cuttersWorkpiecesMilling cutterEngineering

The present invention relates to a milling cutter provided with an equidistant arc head on an eccentric shape flank surface and a grinding method, the cutter can reduce the vibration during the process of processing of different hardness of hardened steels for splicing of a mould, the cutter life and workpiece surface quality can be improved, the flank surface shape can be changed, and the cutter tip strength can be improved. The milling cutter is an overall hard alloy end milling cutter. The milling cutter includes a cutter shank (1) and the arc head (2), the arc head includes a large curvature arc (2-1) and a small curvature arc (2-2). Tooth-spacing angles are 87 degrees, 93 degrees, 87 degrees, and 93 degrees, tooth-spacing vertical angles are equal, helix angle (r) is 38 degrees, helix angle (v) is 40 degrees, and cutter end cutting edge flank surface (10) and circumferential cutting edge (6) are in eccentric shape. Front angle is in the range of 0-3 degrees, first clearance angle is in the range of 8-10 degrees, and second clearance angle is in the range of 15-22 degrees. The center position of the cutter is provided with cooling channels (3), the number of the cooling channels is four, and the four cooling channels respectively are located four cutting edge end tooth chip pockets. The present invention also provides a reference for the grinding of the cutter of the type.

Owner:HARBIN UNIV OF SCI & TECH

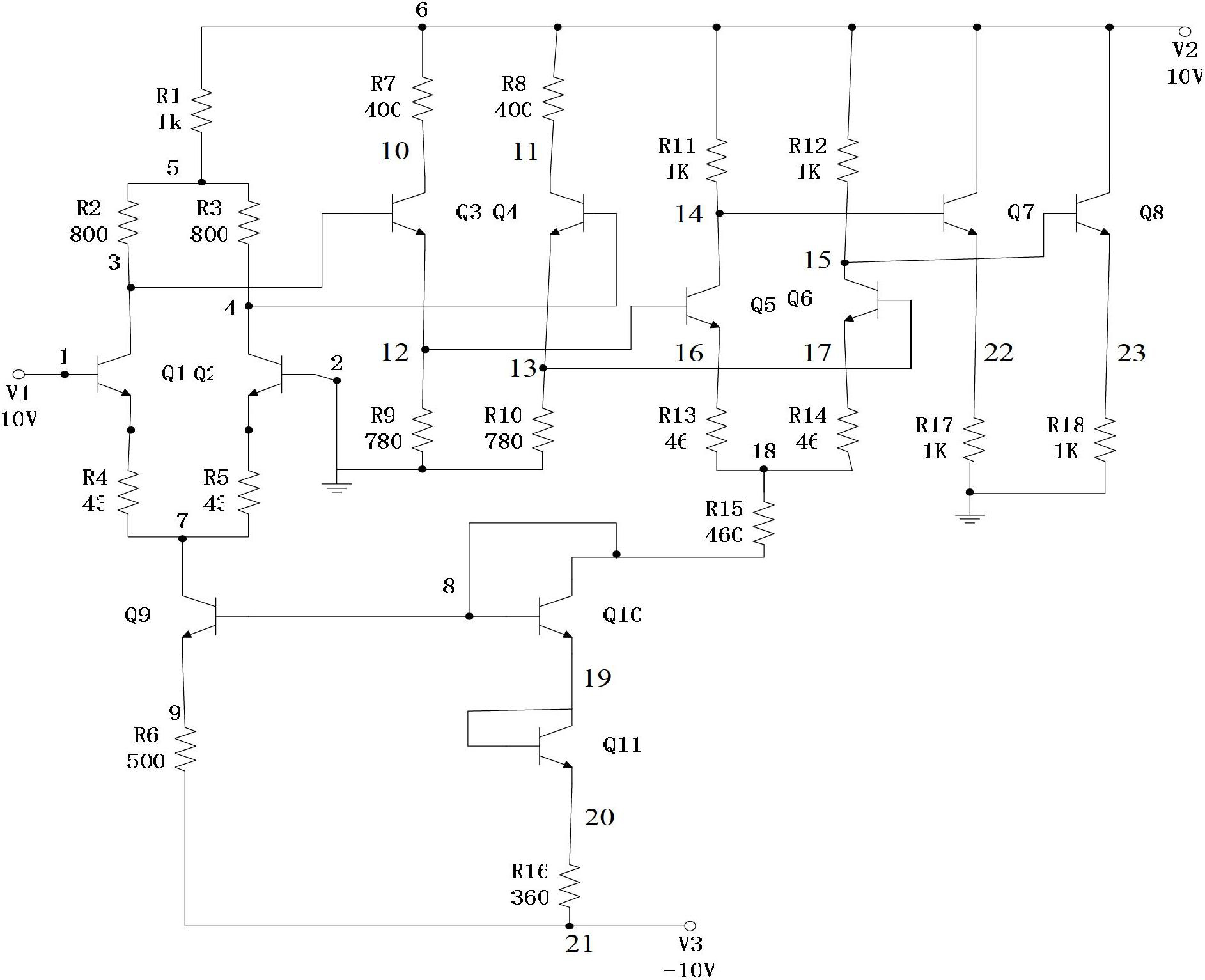

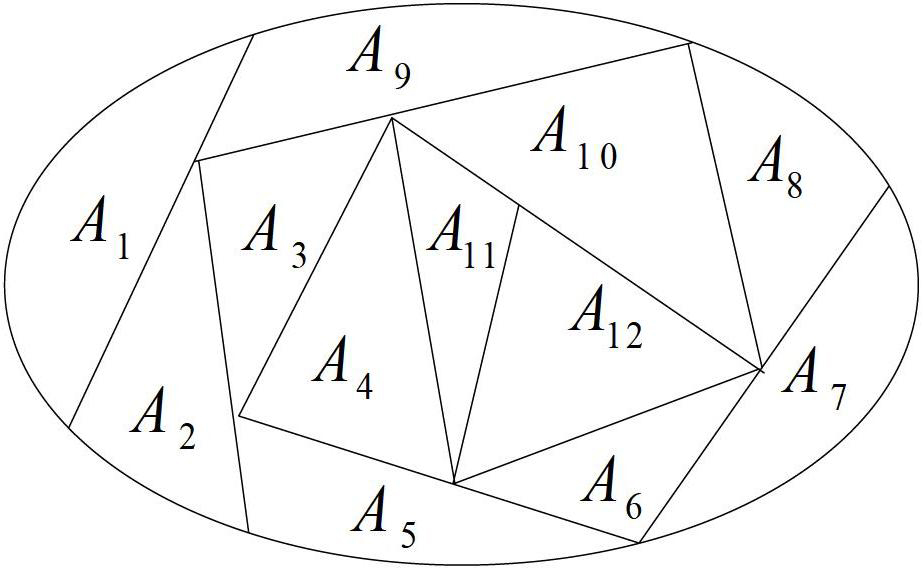

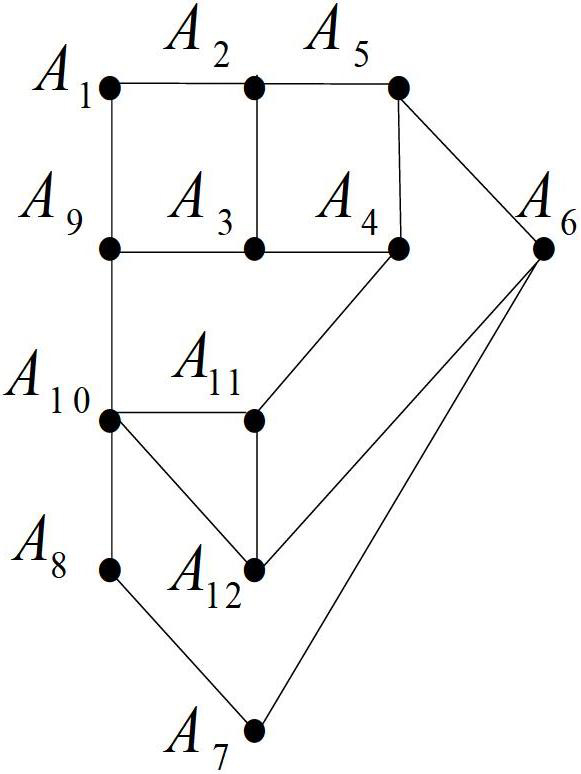

Large-scale analogue circuit fault diagnosis method based on wavelet neural network

ActiveCN102636742AReduce inputSimple structureElectronic circuit testingBiological neural network modelsVoltageReal-time computing

The invention discloses a large-scale analogue circuit fault diagnosis method based on a wavelet neural network. The method comprises the following steps: dividing functional modules on a to-be-tested circuit, and performing at least twice intersected-tearing on the to-be-tested circuit so that every two functional modules can be respectively contained in different sub networks at least once in the intersected-tearing, and determining each torn node; sampling a voltage of a sample torn node to obtain a fault feature vector; respectively establishing a wavelet neural network corresponding to each tearing, inputting the voltage feature vectors of the to-be-tested circuit in a normal state and different fault states to the wavelet neural network, and training all wavelet neural networks; and performing the logic diagnosis on the output of the wavelet neural network so as to position a fault module. The method provided by the invention can be used for rapidly and accurately positioning the modular fault about hard fault, soft fault and multi-fault state of the large-scale analogue circuit, and is high in engineering application value.

Owner:宁波力斗智能技术有限公司

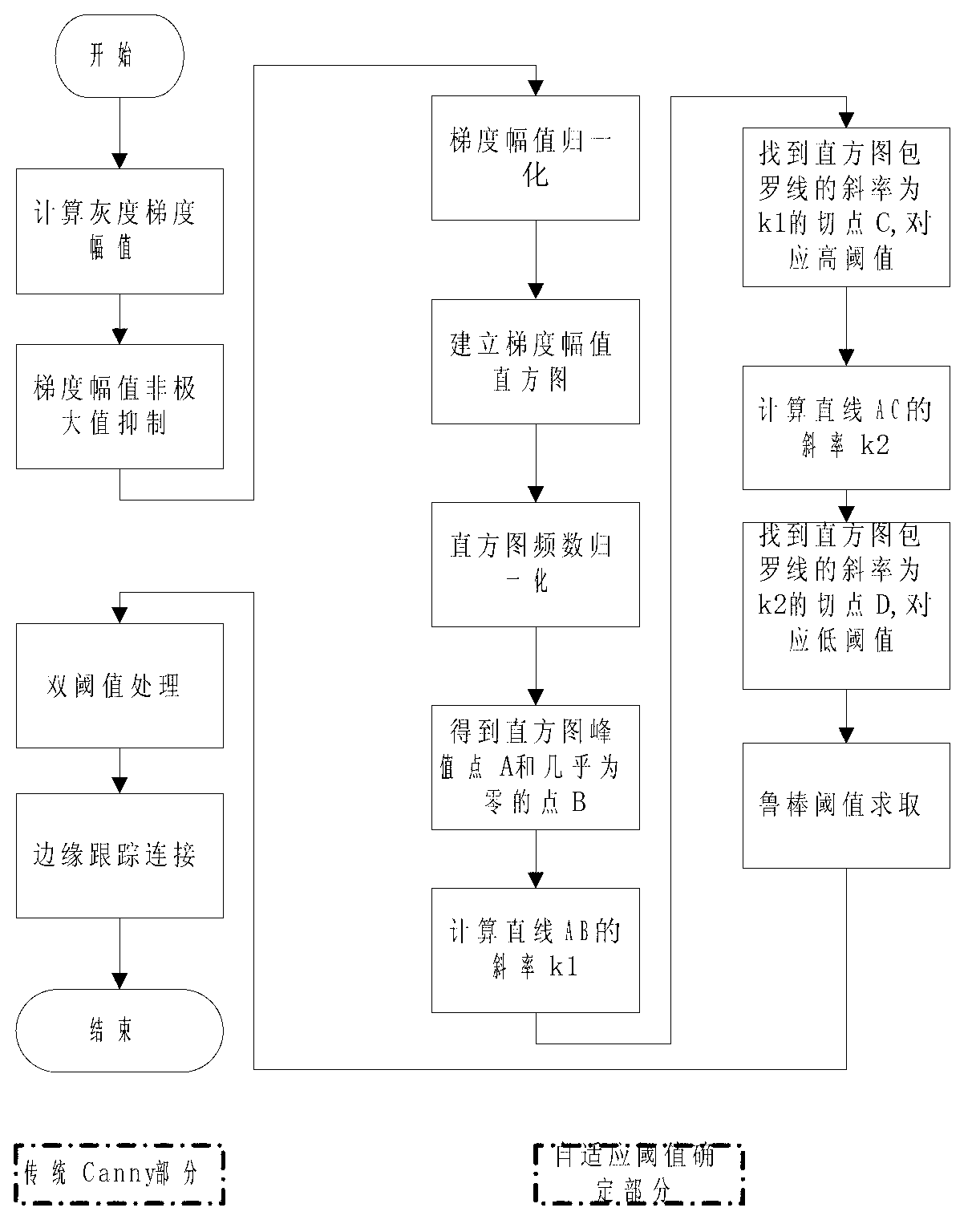

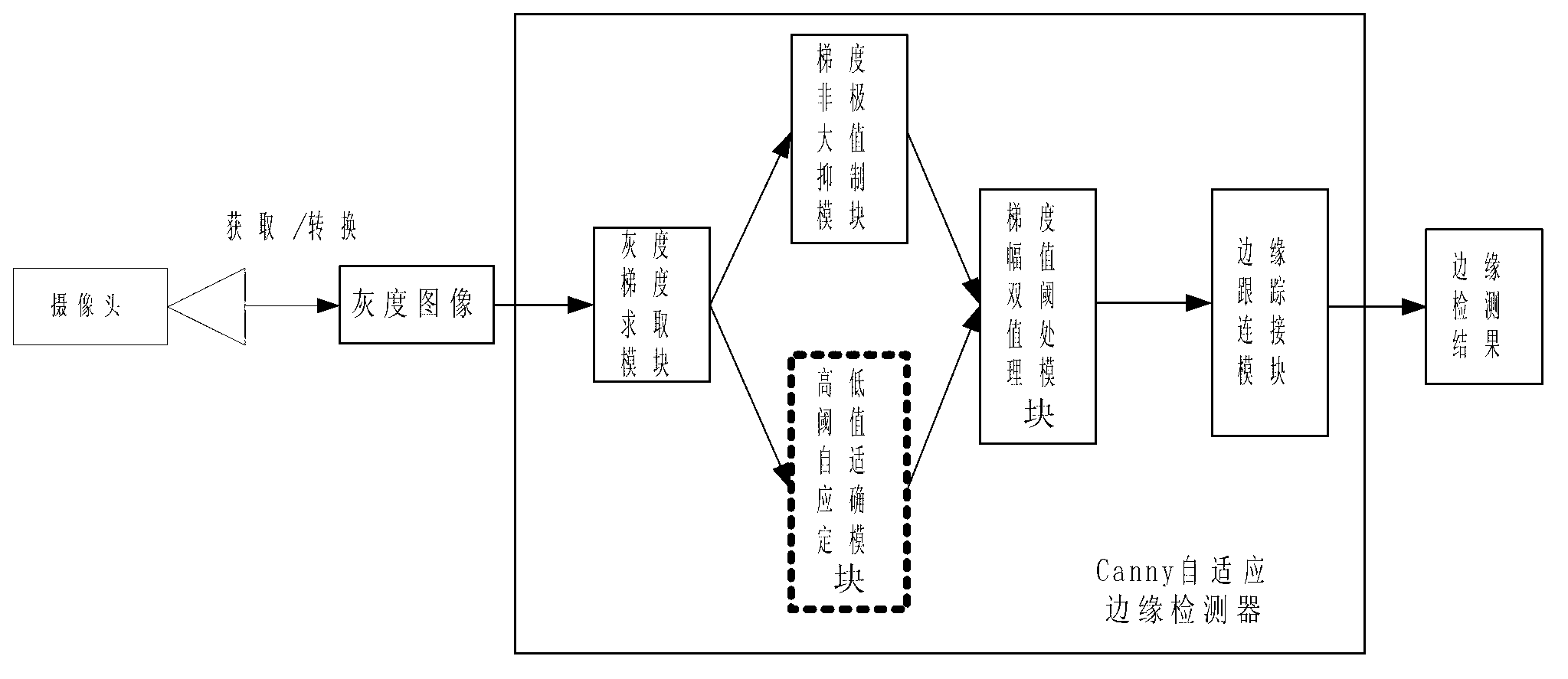

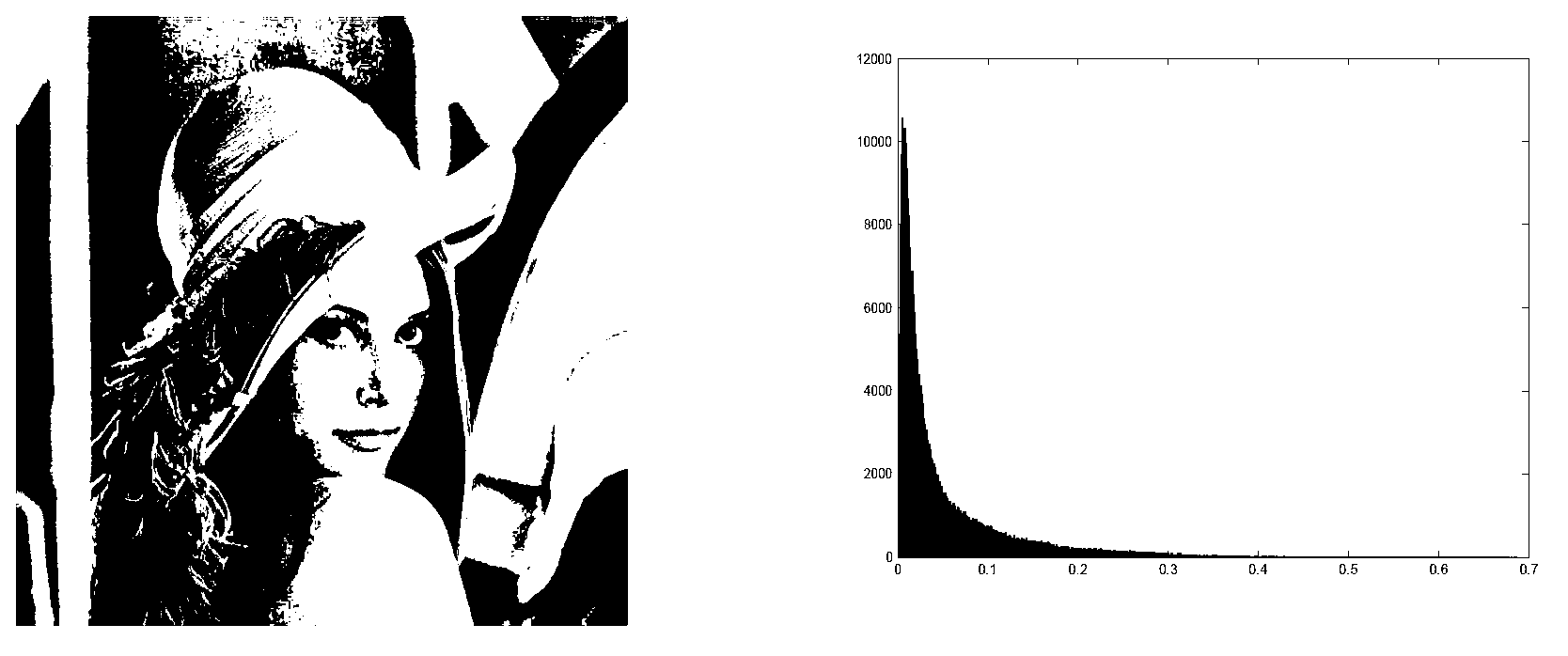

Canny edge detection dual threshold acquiring method based on chord line tangent method

The invention relates to a canny edge detection dual threshold acquiring method based on a chord line tangent method and belongs to the technical field of the digital image processing. The canny edge detection dual threshold acquiring method based on the chord line tangent method comprises only operations of add, subtract, multiply, divide and comparison and facilitates fast confirmation of a threshold. Compared with a histogram non-curve fitting method and method adopting local features, such as a histogram extreme point and a zero crossing point, the canny edge detection dual threshold acquiring method based on the chord line tangent method acquires the threshold by using a long chord line and a short chord line which can represents a integral shape feature of the histogram and are stable based on the integral shape feature of the histogram and stability and reliability of threshold acquiring are guaranteed. Meanwhile, influence to the threshold determination by different class numbers of the histograms is eliminated by adopting a mean value of a plurality of thresholds acquired from different class numbers of the histograms and the stability and the reliability of threshold acquiring are further improved. The canny edge detection dual threshold acquiring method based on the chord line tangent method has the advantages of being fast, stable and self-adaptable and facilitating the further widespread use of a canny edge image edge detection method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

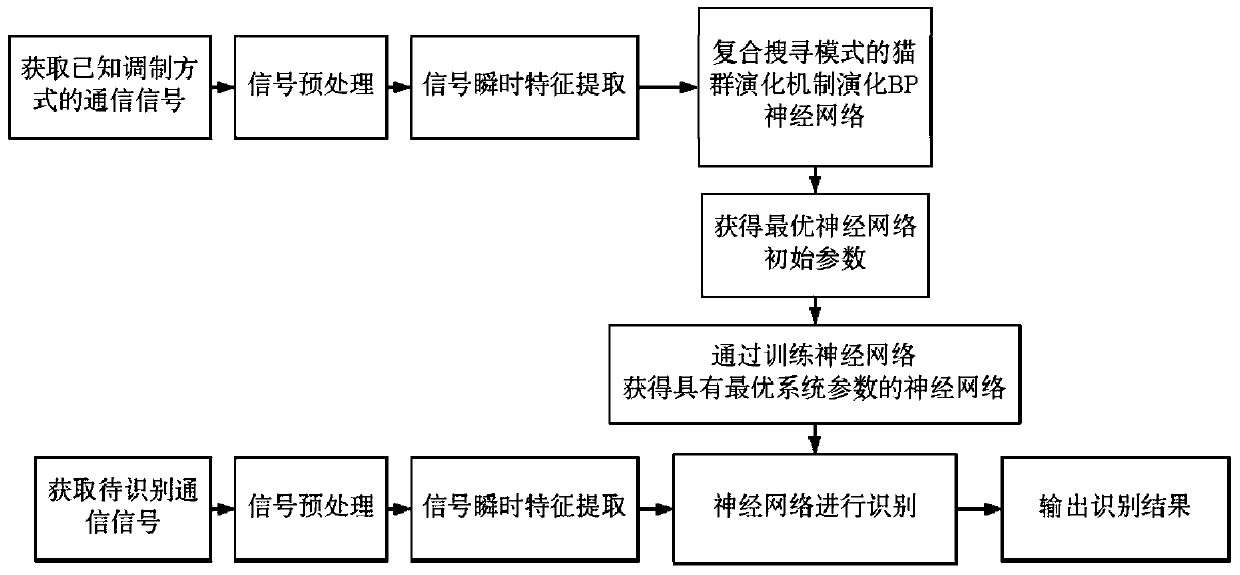

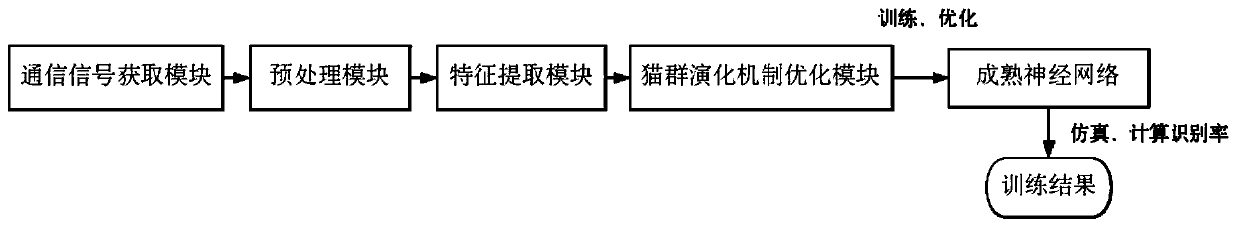

Communication signal modulation mode identification method based on evolved BP neural network

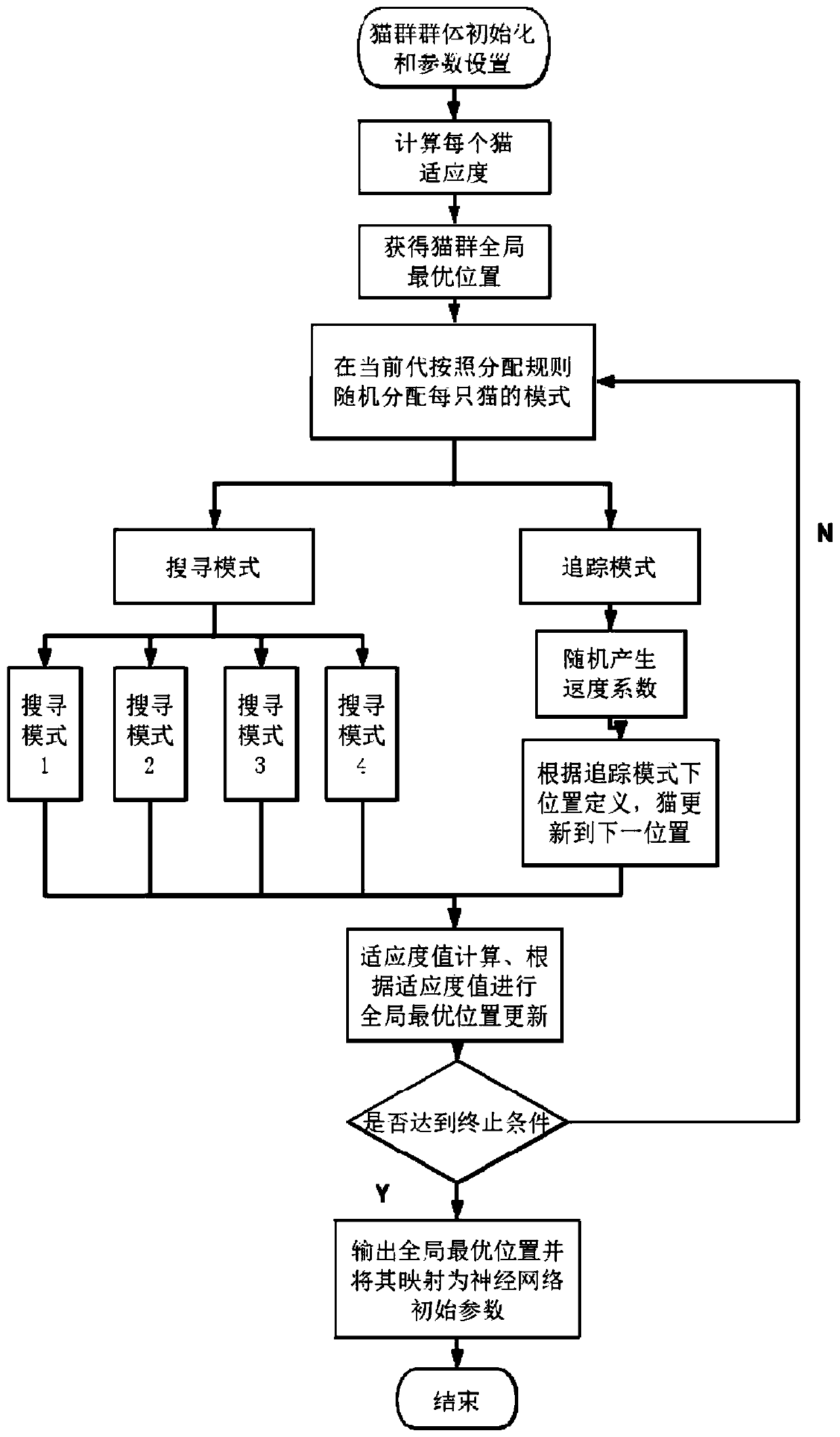

ActiveCN110120926ASolve the problem that the initial weight structure is difficult to determineSolve elusive problemsModulation type identificationLocal optimumFeature extraction

The invention provides a communication signal modulation mode identification method based on an evolution BP neural network, and the method comprises the steps: carrying out the preprocessing and feature extraction of obtained communication signals with different known modulation modes, and enabling an extraction result to serve as an input feature parameter of the neural network; optimizing the initial weight value and threshold value of the BP neural network by using a cat swarm evolution mechanism of a composite search mode and using the recognition rate as an objective function; and obtaining an optimal parameter as an initial parameter of the neural network for later recognition, and then training the BP neural network by using the input characteristic parameter and the optimal initial parameter to obtain the BP neural network with the optimal system parameter; acquiring a communication signal with an unknown modulation mode, and identifying the communication signal with the unknown modulation mode by using the BP neural network with the optimal system parameter to obtain an identification result. Compared with a traditional BP neural network for modulation recognition, the method has higher recognition rate under the same signal-to-noise ratio, and the situation that a local optimal solution is caught in the training process is avoided as much as possible.

Owner:HARBIN ENG UNIV

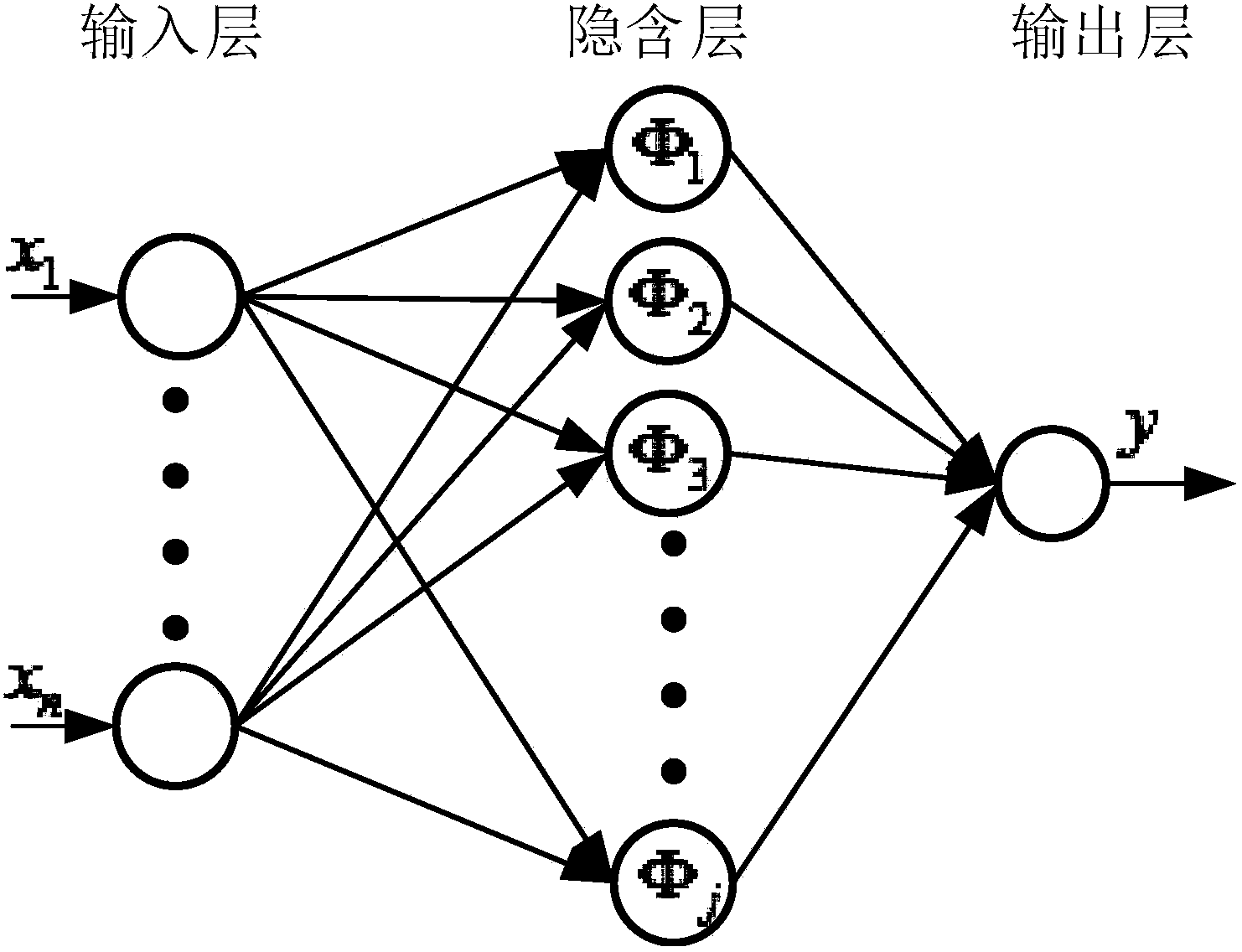

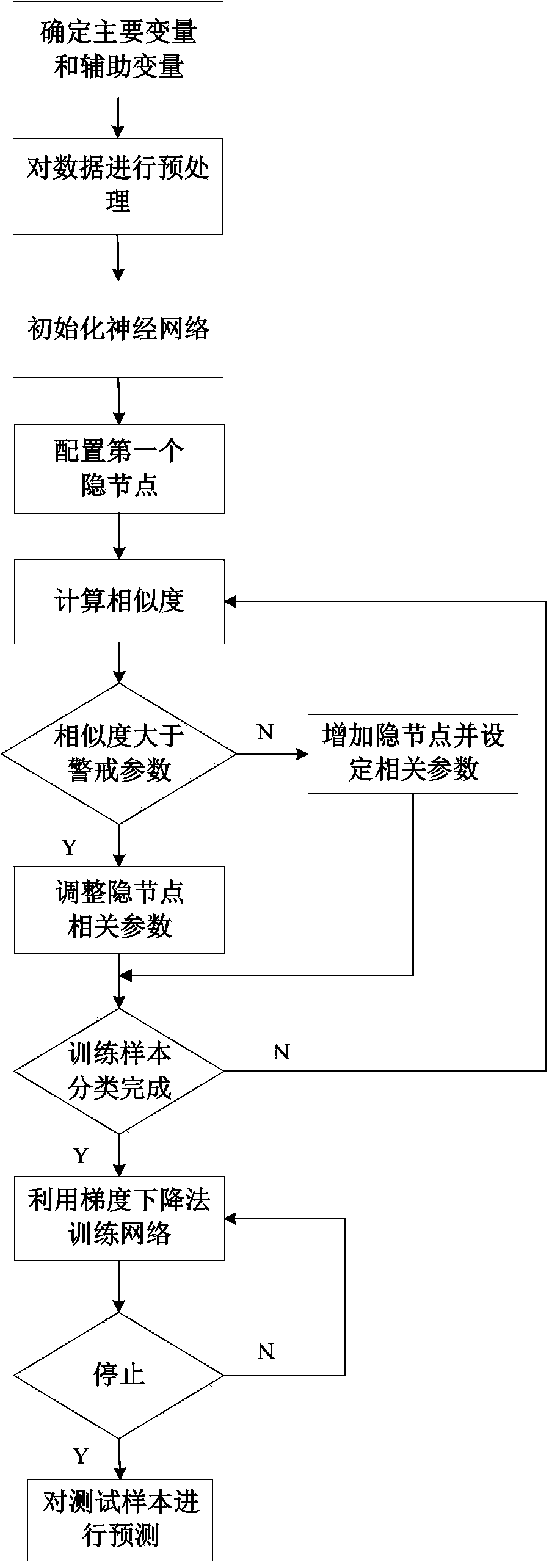

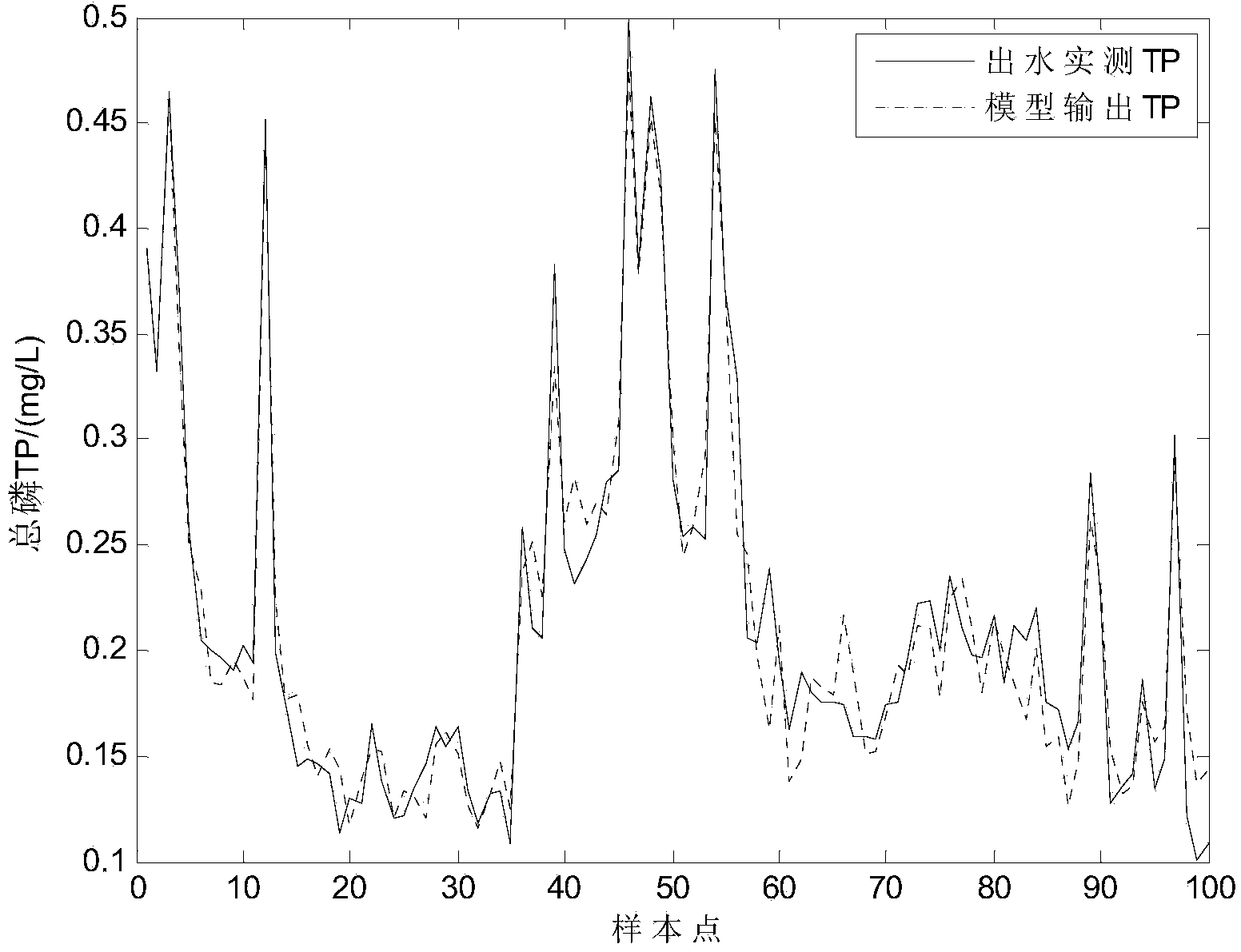

Method for soft measurement of effluent total phosphorus in sewage disposal process based on neural network

ActiveCN104182794AImplement soft sensingStrong non-linear mapping abilityTesting waterNeural learning methodsSewage treatmentSewage disposal plants

The invention provides a method for soft measurement of the effluent total phosphorus (TP) in the sewage disposal process based on the neural network, and belongs to the field of sewage disposal field. The mechanism is complex in the sewage disposal process, and to enable a sewage disposal system to be in a good running working condition and to obtain the higher effluent quality, the procedure parameters and the water quality parameters in the sewage disposal system need to be detected. The invention provides a soft measurement model established based on the self-organization radial-based neural network to solve the problem that the effluent total phosphorus of a current sewage disposal plant cannot be obtained in real time. The initial structure and the initial parameters of the neural network are determined according to the self-organization method, the structure of the neural network is simplified, and real-time soft measurement is carried out on the effluent TP. According to the soft measurement result, the related control link in the sewage disposal process and materials in the biochemical reaction are adjusted, the quality of the effluent obtained after sewage disposal is improved, and a theoretical support and a technological guarantee are provided for safe and stable running in the sewage disposal process.

Owner:BEIJING UNIV OF TECH

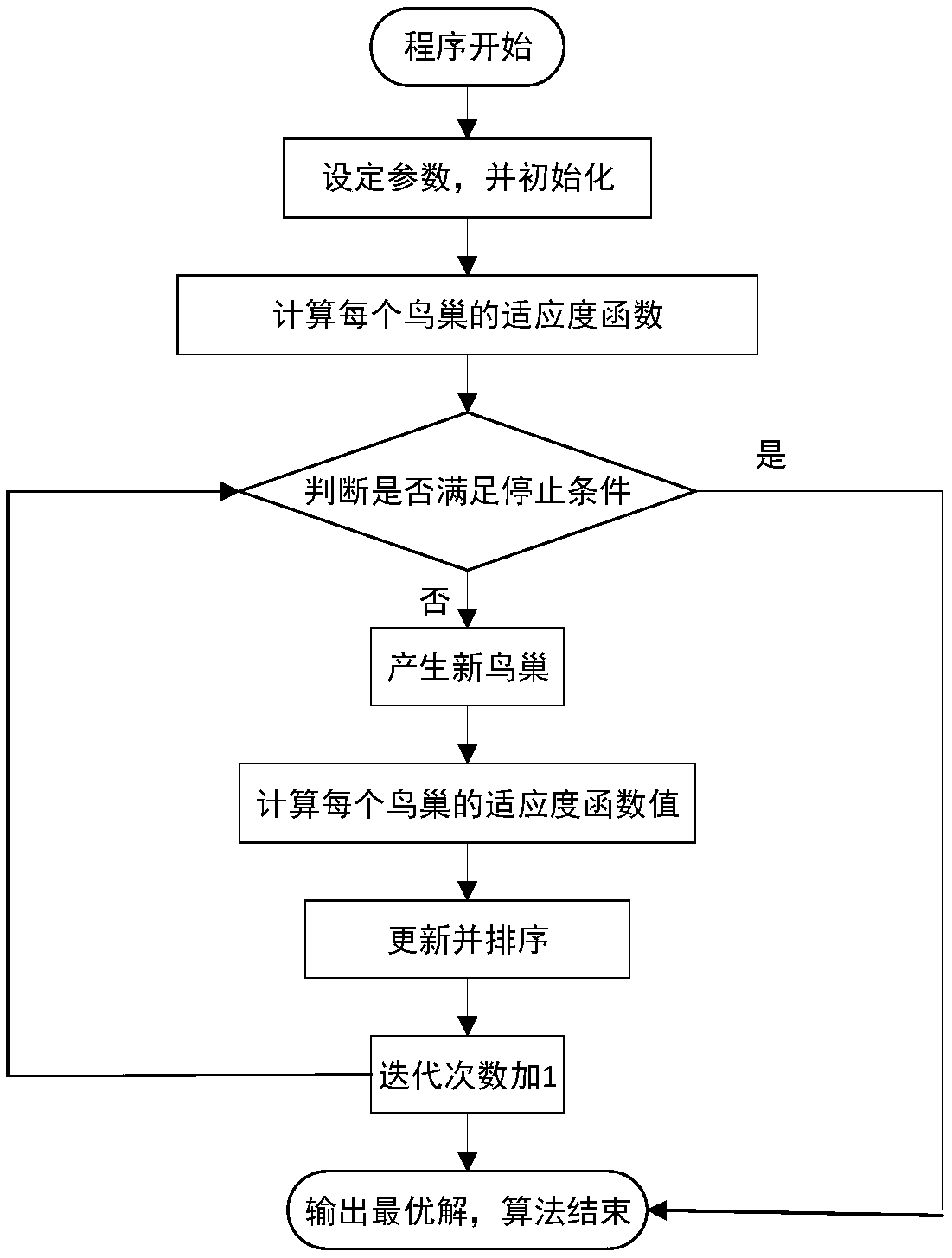

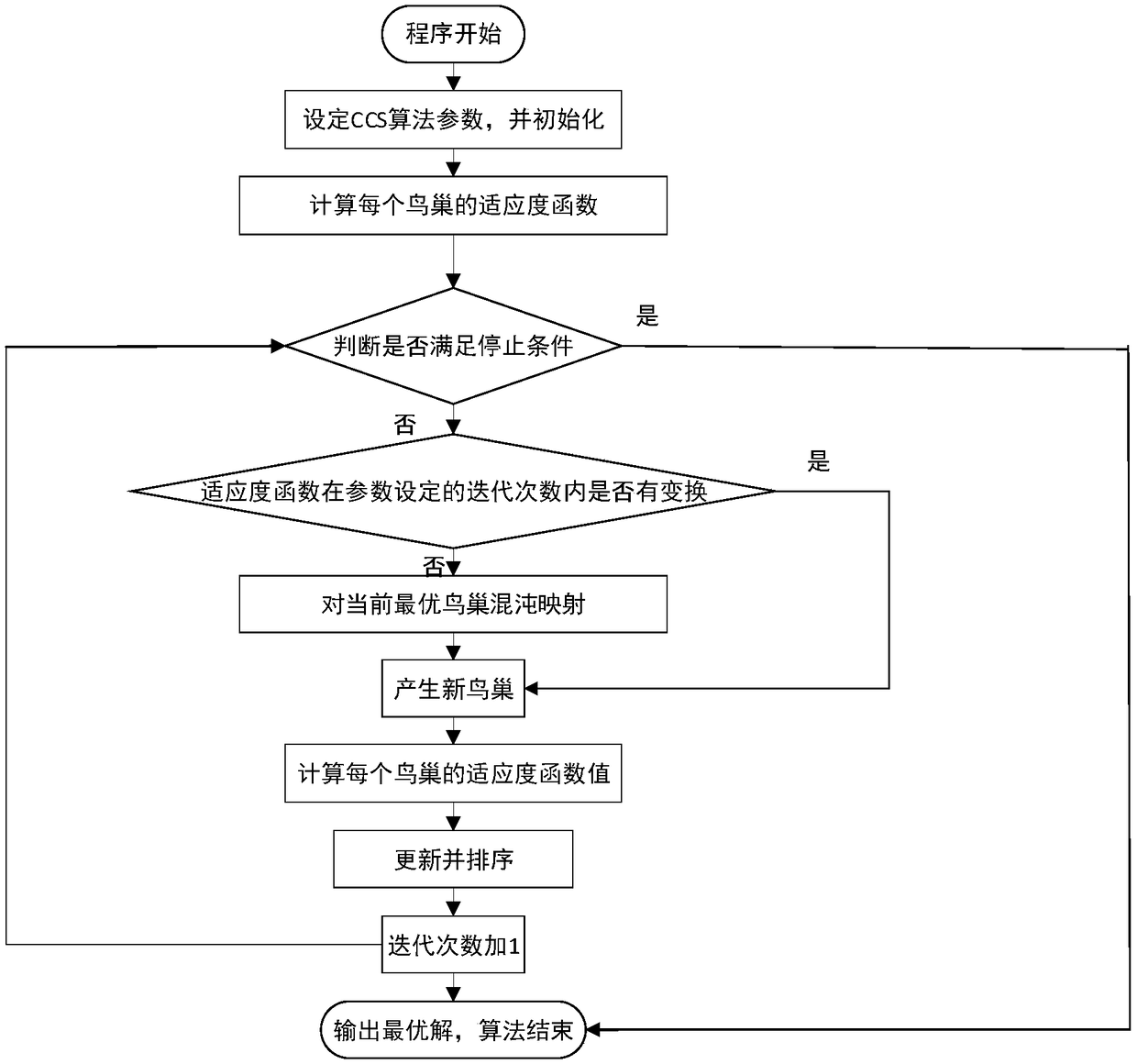

GIS mechanical fault diagnosis method and system based on chaotic cuckoo algorithm

InactiveCN108663202AAvoid mechanical failureIncrease signal decomposition rateMachine part testingFeature vectorDiagnosis methods

The invention discloses a GIS mechanical fault diagnosis method and system based on the chaotic cuckoo algorithm. For two common GIS mechanical faults of screw loosening and metal particle vibration,a VMD parameter is optimized with the chaotic cuckoo algorithm; GIS normal vibration signals and fault signals are subjected to VMD decomposition, and feature vectors with different fault type signalsare extracted; feature vector sets of training samples are clustered with the K-means clustering algorithm optimized through linearly decreasing weight PSO, and different clustering centers are obtained; feature vector sets of test samples are identified through the minimum euclidean distance rule, and diagnosis of GIS mechanical faults is achieved.

Owner:STATE GRID CORP OF CHINA +1

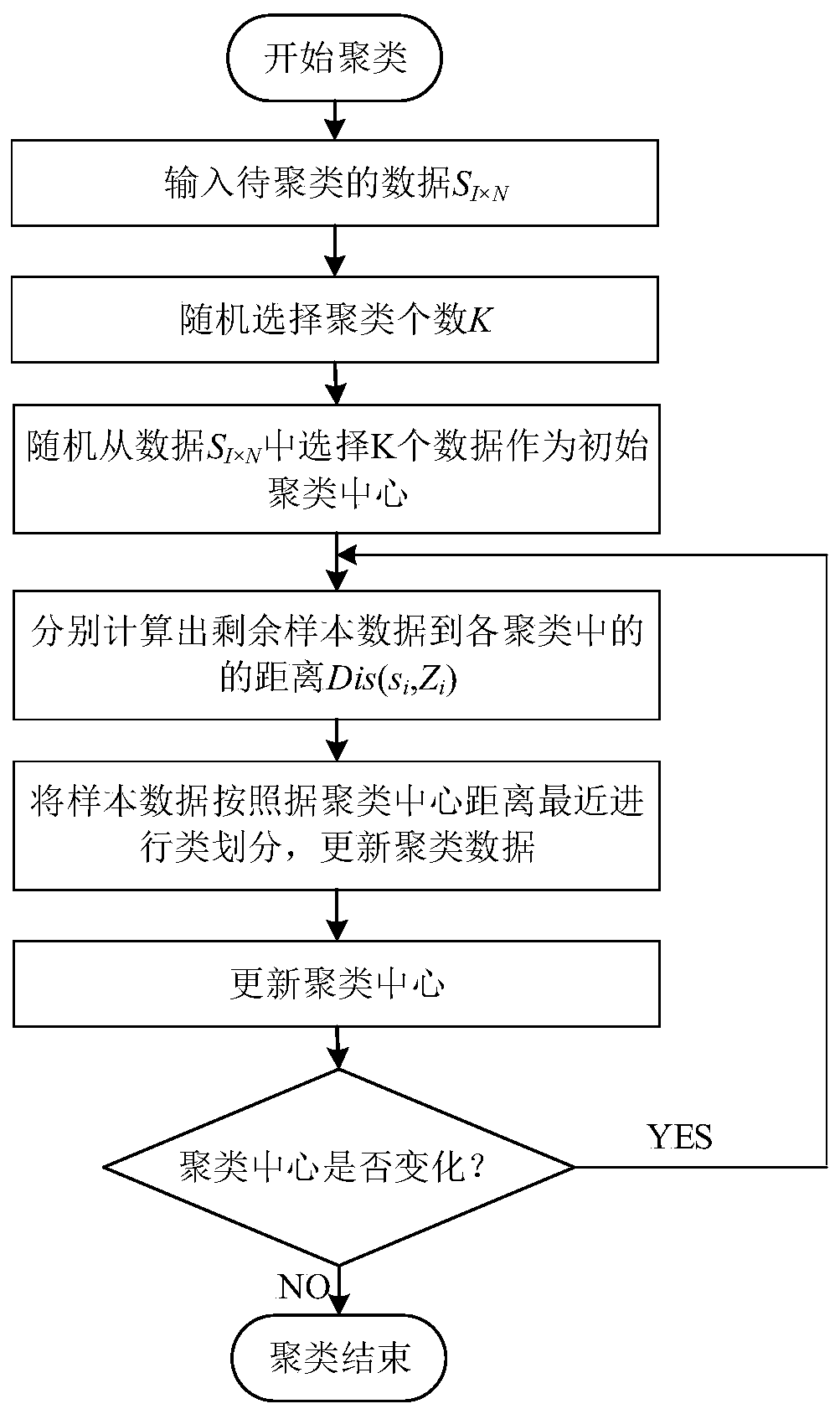

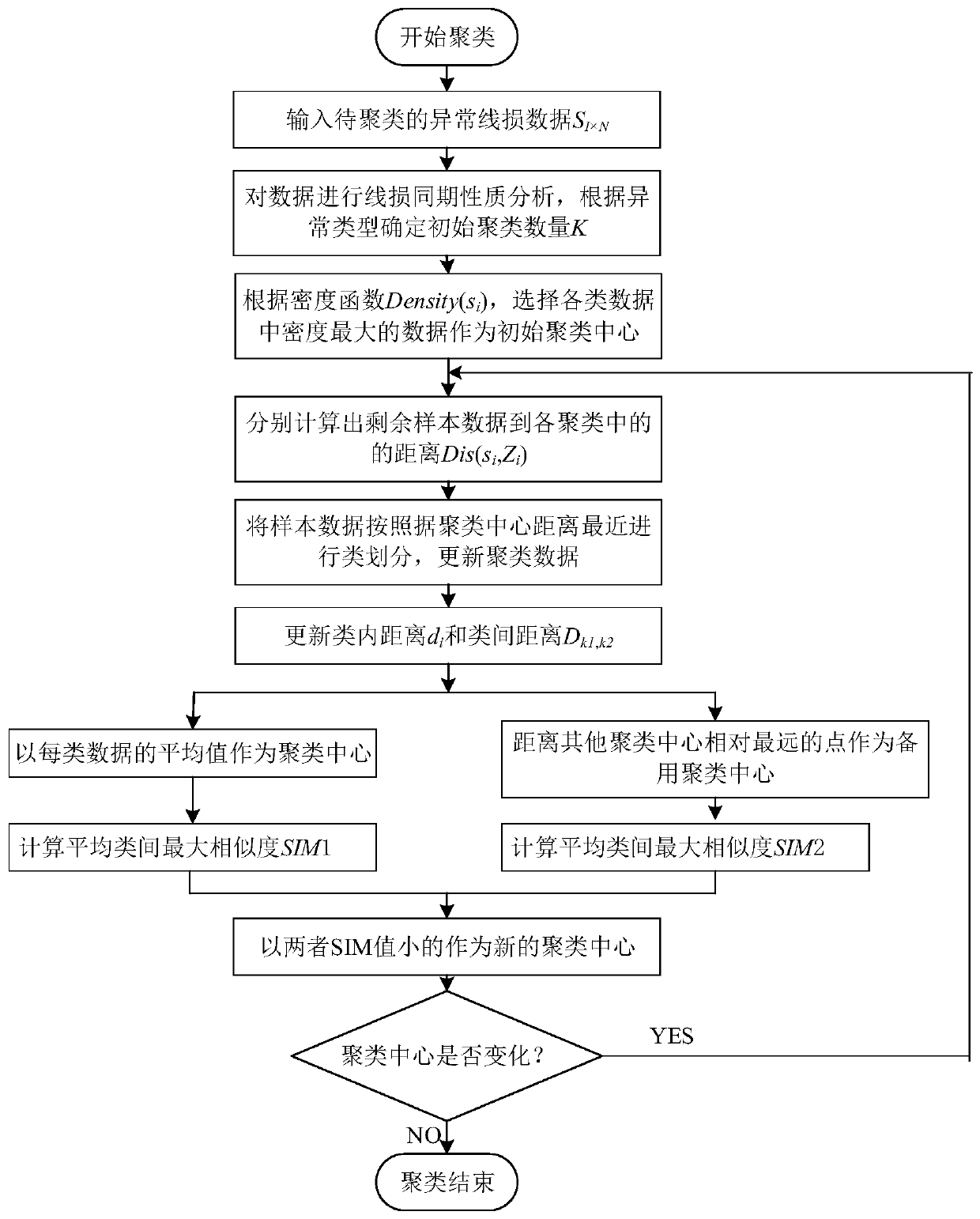

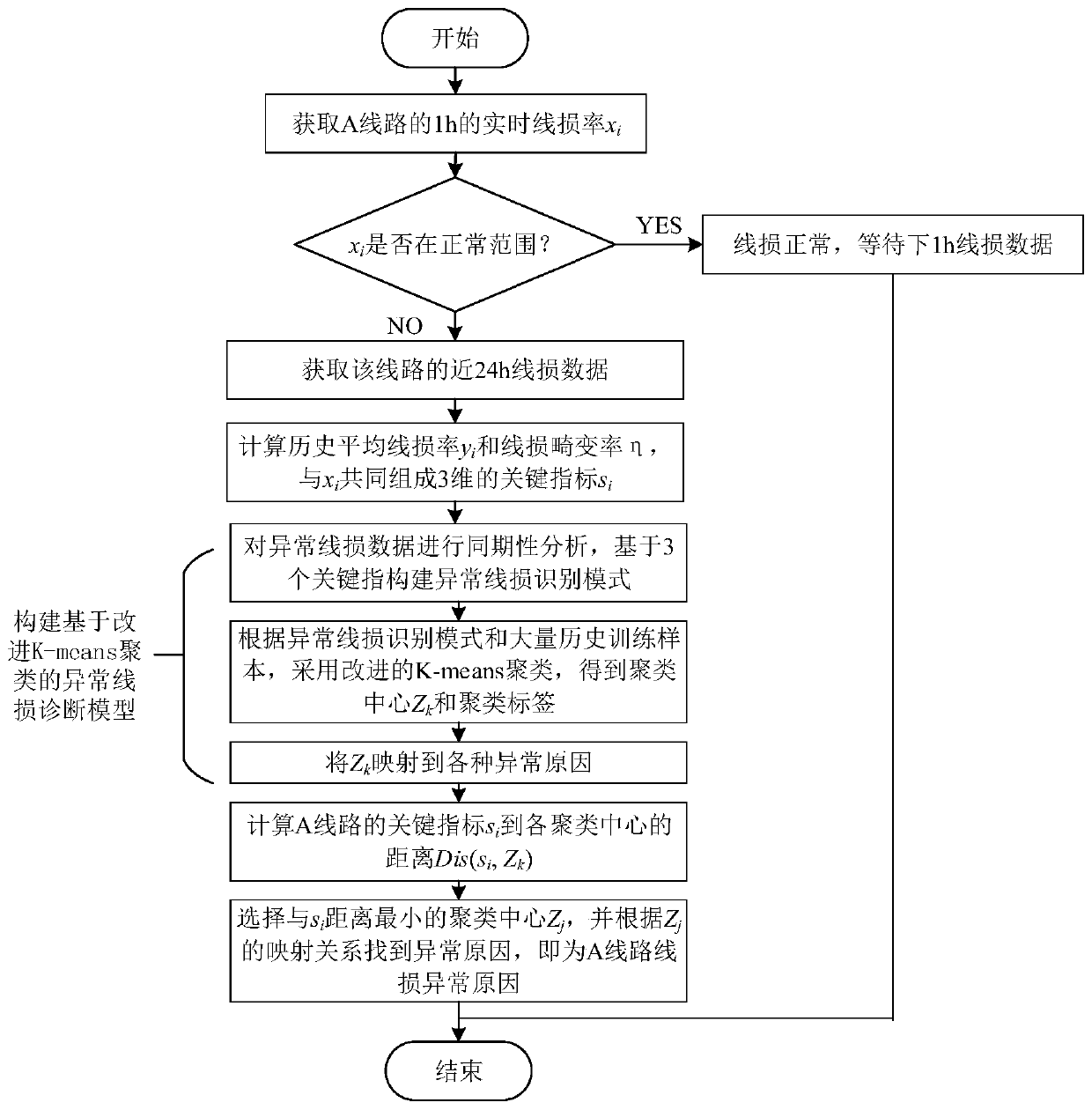

Power distribution network abnormal line loss diagnosis method based on synchronous characteristics and improved K-means clustering

ActiveCN111123039AImprove efficiencyStrong independenceCharacter and pattern recognitionFault locationEngineeringArtificial intelligence

The invention discloses a power distribution network abnormal line loss diagnosis method based on synchronous characteristics and improved K-means clustering. The method comprises: 1, collecting lineloss data of a certain line of a power distribution network; constructing three key indexes capable of reflecting abnormal reasons, namely a real-time line loss rate, an average line loss rate in nearly 24 hours and a line loss distortion rate; 2, classifying the features and reasons of the abnormal line loss, and preliminarily establishing a line loss abnormality diagnosis mode; 3, determining the number of clusters by adopting an improved K-means clustering method, and training the clustering model by using a large amount of sample data to obtain a clustering center; 4, mapping the labels ofthe clustering center to various abnormal reasons; and 5, finally, automatically diagnosing the newly acquired real-time line loss data of a certain line of the power distribution network according to the clustering center to obtain an abnormal reason. The method can quickly, effectively and automatically diagnose the abnormal reason of the regional line loss.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

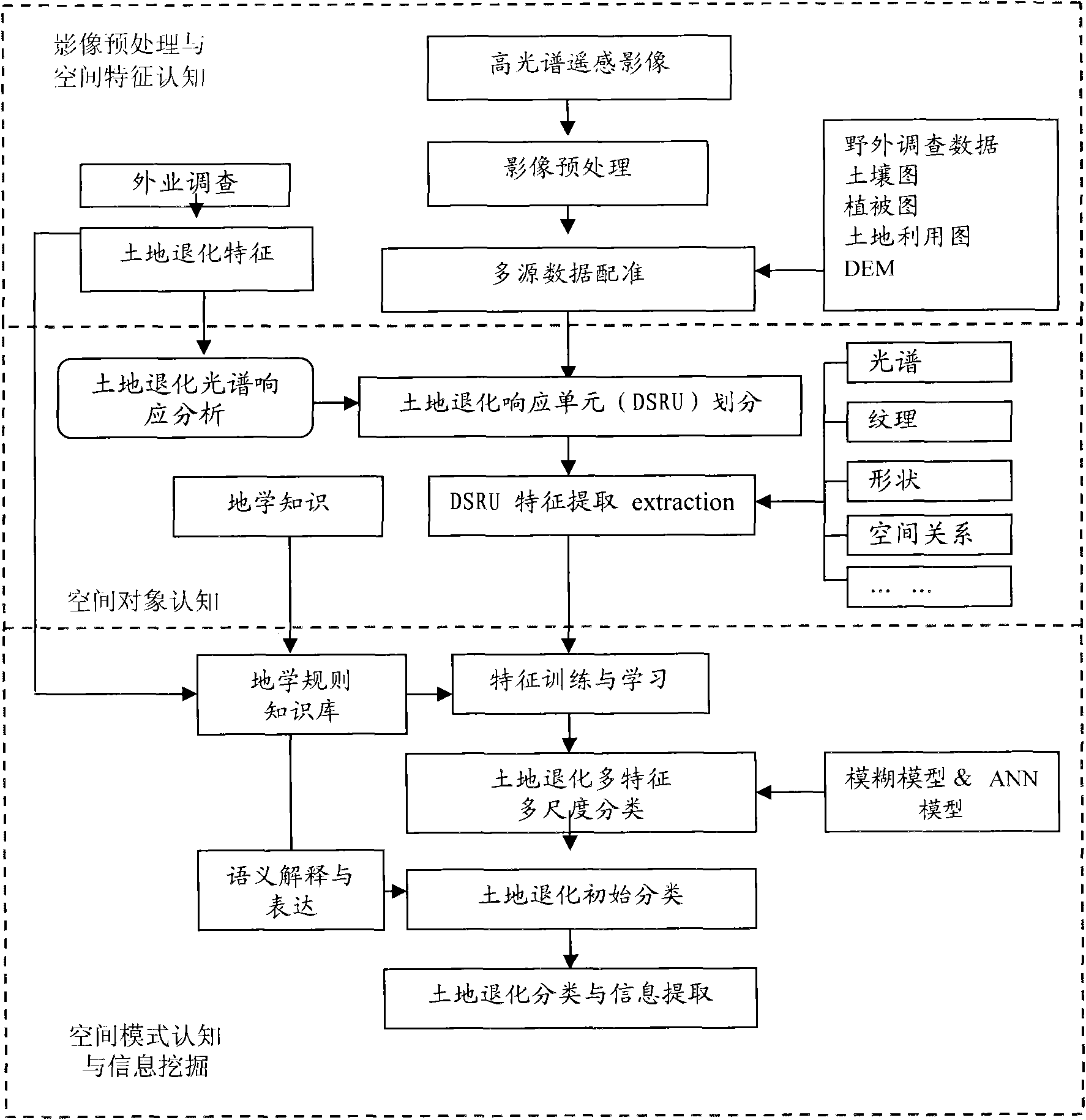

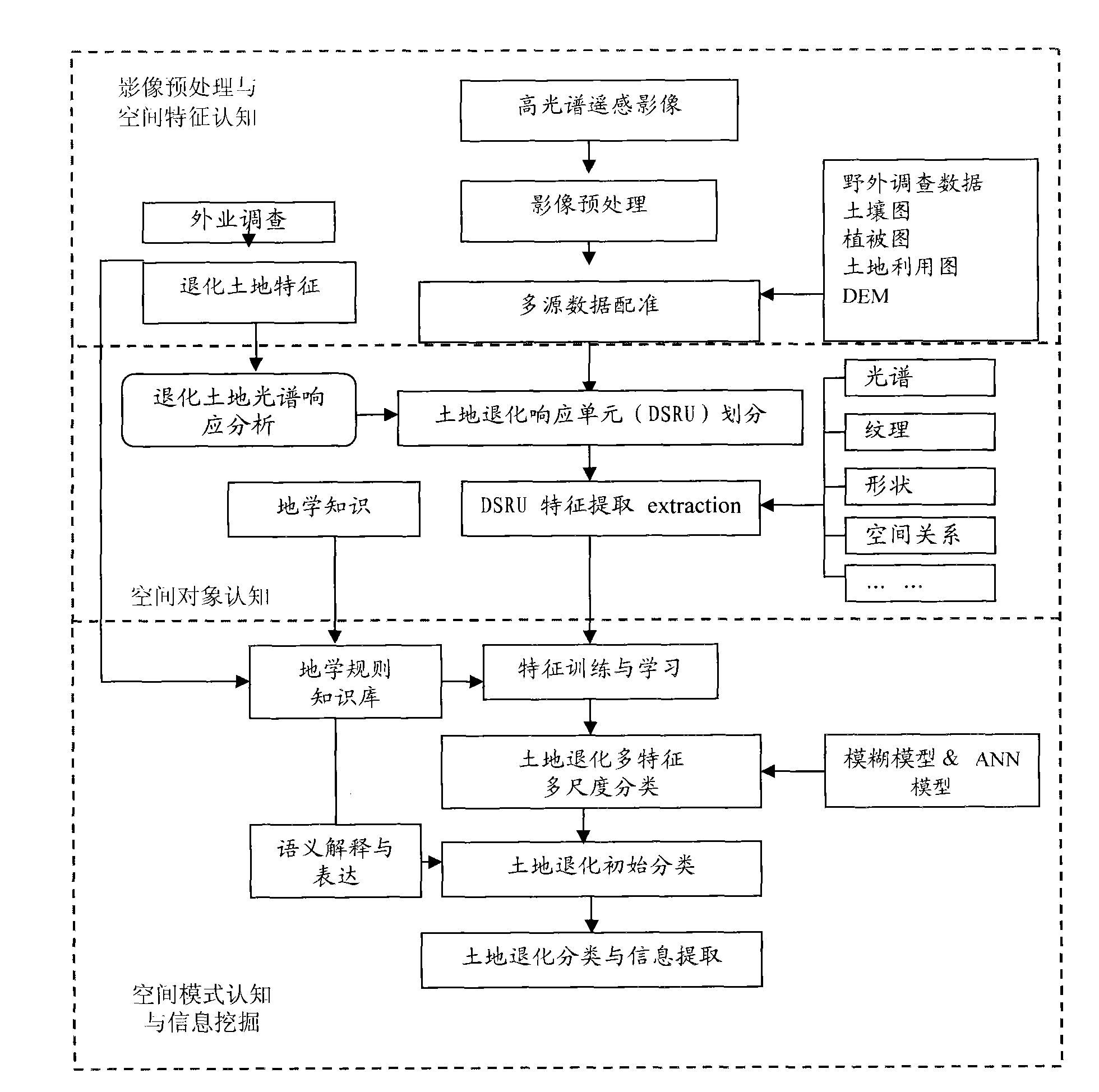

Land degradation response unit-oriented high-spectrum land degradation information extracting method

InactiveCN101788664AEasy accessSolve elusive problemsWave based measurement systemsSpectral responseInformation mining

The invention discloses a land degradation response unit-oriented high-spectrum land degradation information extracting method, which comprises three processes of image pre-processing and spatial characteristic cognition, spatial object cognition, and spatial mode cognition and information mining. The method comprises the following steps: pre-treating a high-spectrum image; integrating multi-source data of high-spectrum remote sensing image, soil, vegetation, basic geographic information, geoscience knowledge, field survey information and the like to divide a land degradation response unit based on degraded land spectrum characteristic analysis and spectrum response analysis; synthesizing information of spectrum, texture, shape, spatial relationship and the like to extract the characteristics of the land degradation response unit; and performing multi-dimensional classification of land degradation types by adopting a land degradation response unit-oriented image analyzing method based on a fuzzy model and an ANN model under the guidance of a geographic knowledge base and a rule base so as to evaluate the land degradation and extract the land degradation information. The method solves the problem that an evaluation unit in the traditional land degradation remote sensing monitoring and evaluating method is difficult to determine, and can quickly acquire the land degradation information.

Owner:中国土地勘测规划院

N-2-1 positioning based skin and stringer assembling deviation analyzing method of airplane

InactiveCN105912823AImprove assembly qualitySolve elusive problemsGeometric CADSpecial data processing applicationsAirplaneBiomedical engineering

The invention discloses an N-2-1 positioning based skin and stringer assembling deviation analyzing method of an airplane. The method comprises the following steps: positioning and clamping a skin based on the N-2-1 positioning principle; calculating the value of assembling clearances, at riveting points, of the skin and stringers; building a contact force model to solve the contact force; analyzing the influence of the contract force applied to the skin at a positioning and clamping point on a sensitivity matrix and a sub-assembly stiffness matrix; calculating the deformation of corresponding key feature points on the skin after the riveting of each stringer when a plurality of stringers are riveted on the skin; analyzing the influence of different stringer assembling sequences on the final assembling deformation; and evaluating different stringer assembling sequences to obtain the optimal assembling sequence. According to the method, the influence of the contact force and different stringer assembling sequences on the skin and stringer assembling deviation is analyzed in detail, so that the airplane wallboard assembling deviation can be accurately predicted, and as a result, the airplane assembling quality can be improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

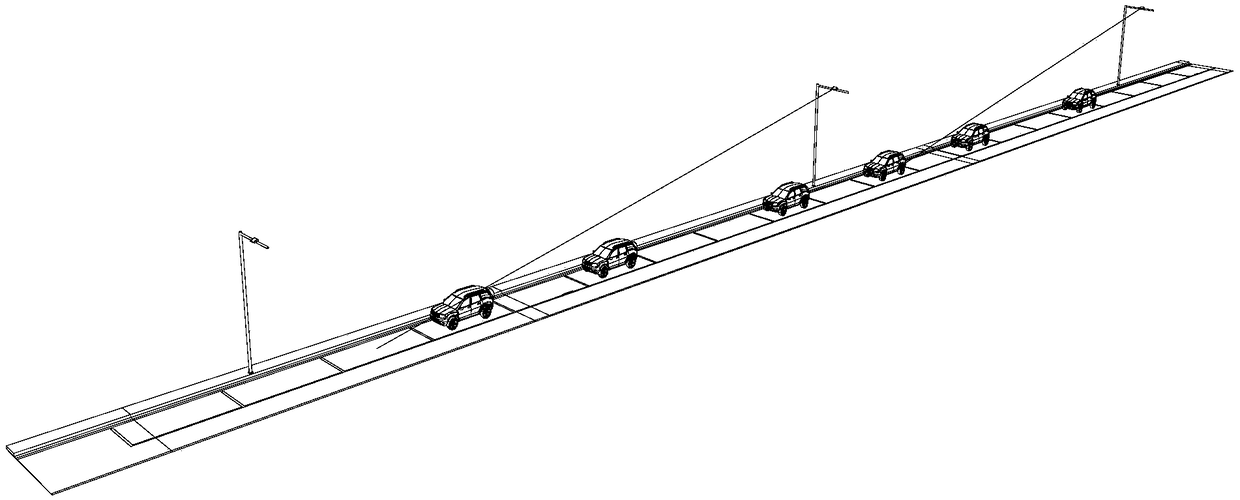

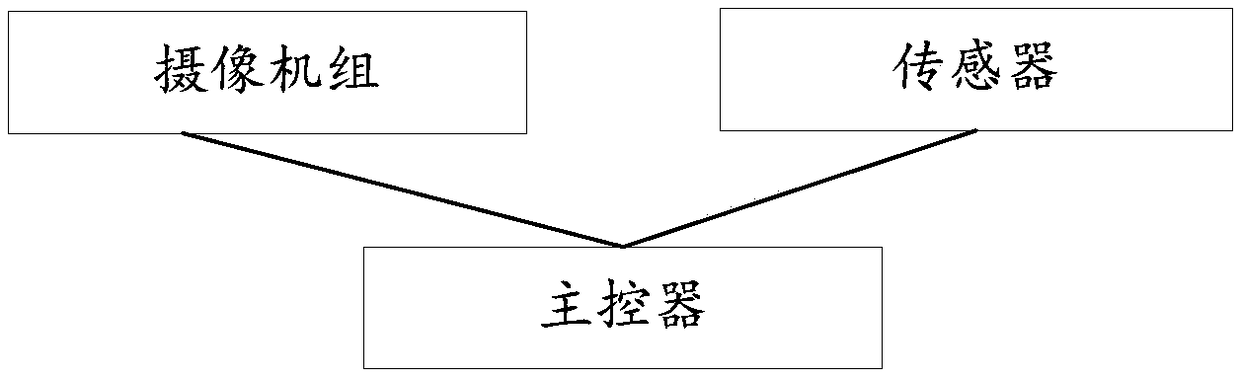

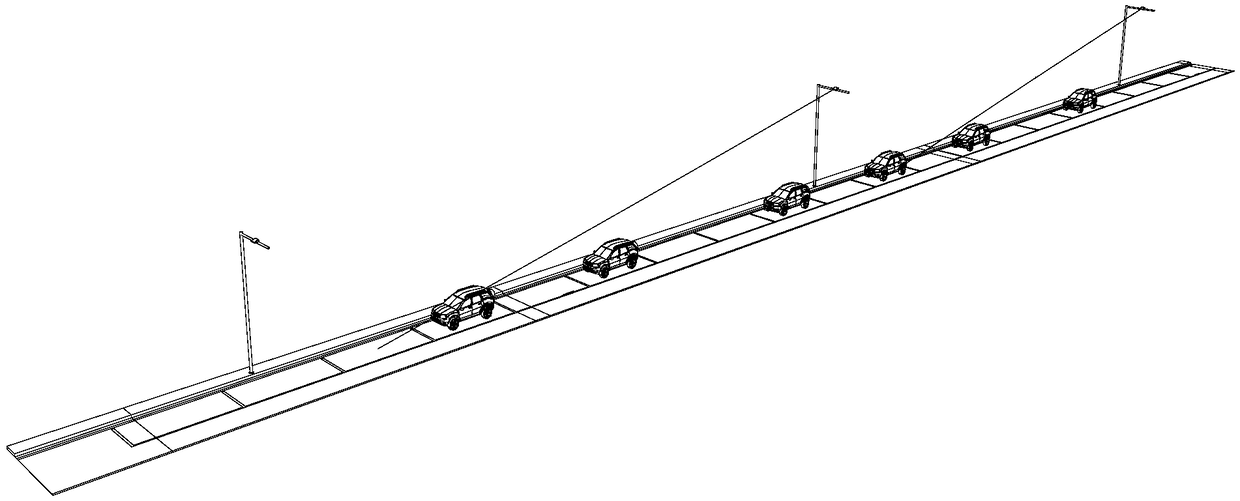

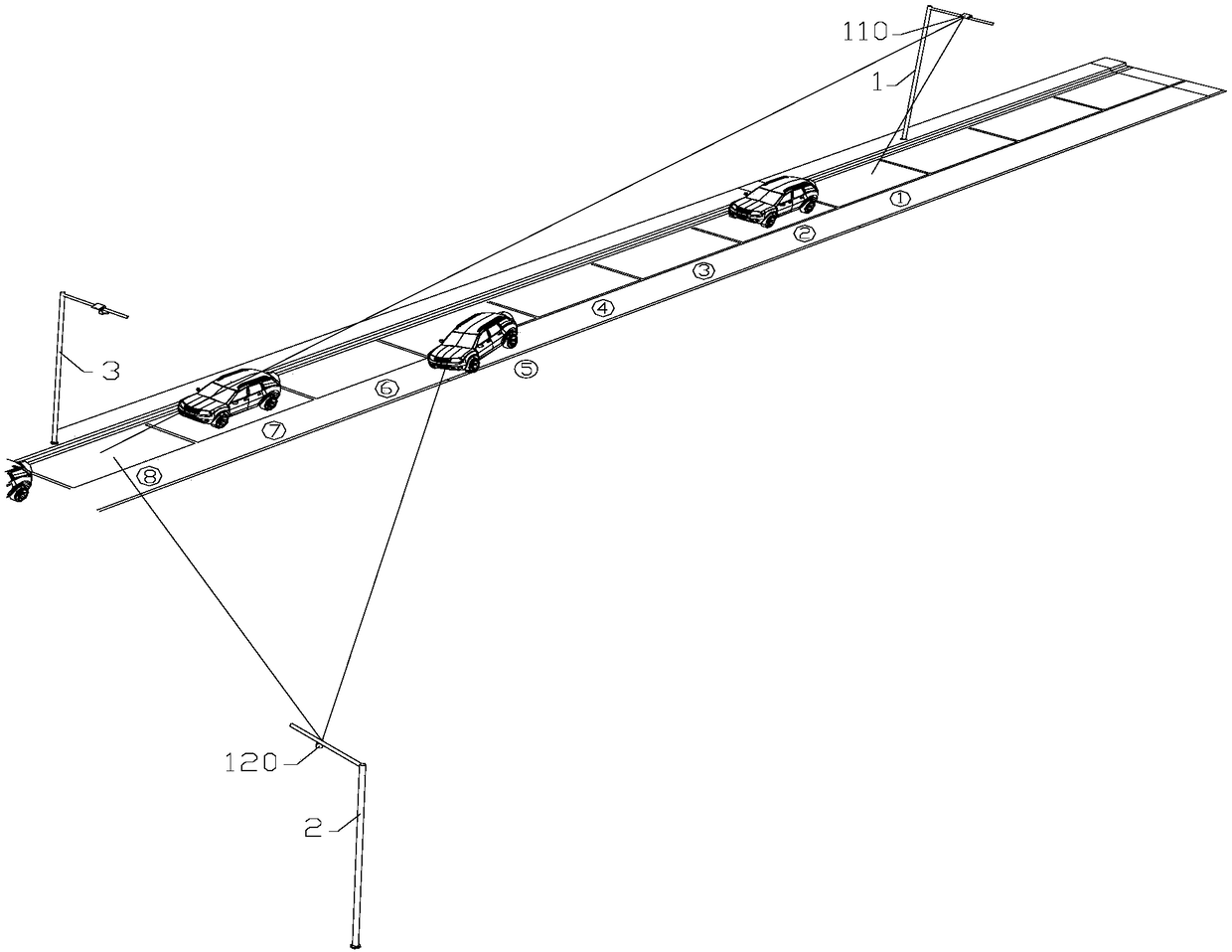

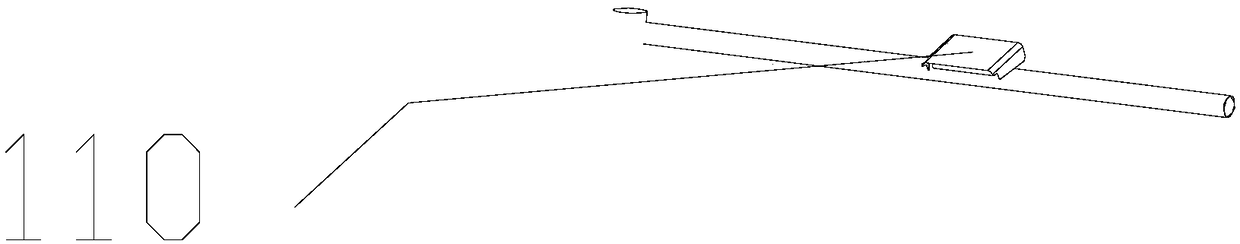

Roadside parking management system based on sensor signal and monitored image between rods

PendingCN109035852AImprove accuracyRich choiceDetection of traffic movementIndication of parksing free spacesJoint analysisParking space

The invention discloses a roadside parking management system based on a sensor signal and a monitored image between rods. The system comprises a camera set, a sensor and a master controller; the camera set is arranged on a first mounting rod or mounting position, and the sensor is arranged on a second mounting rod or mounting position; the camera set is used for acquiring an image of a monitoringarea; the sensor is used for acquiring a sensor signal of at least one parking space in the monitoring area; and the master controller is used for determining parking event information of each parkingspace in the monitoring area according to the sensor signal of at least one parking space in the monitoring area and the image of the monitoring area. The system disclosed by the invention jointly analyzes and determines the parking event information of each parking space, especially a far-end parking space, in the monitoring area by virtue of the signal acquired by the sensor arranged on the second mounting rod or mounting position and the image, acquired by the camera set arranged on the first mounting rod or mounting position, of the monitoring area and can improve accuracy of determination on the parking event information in roadside parking management.

Owner:INTELLIGENT INTER CONNECTION TECH CO LTD

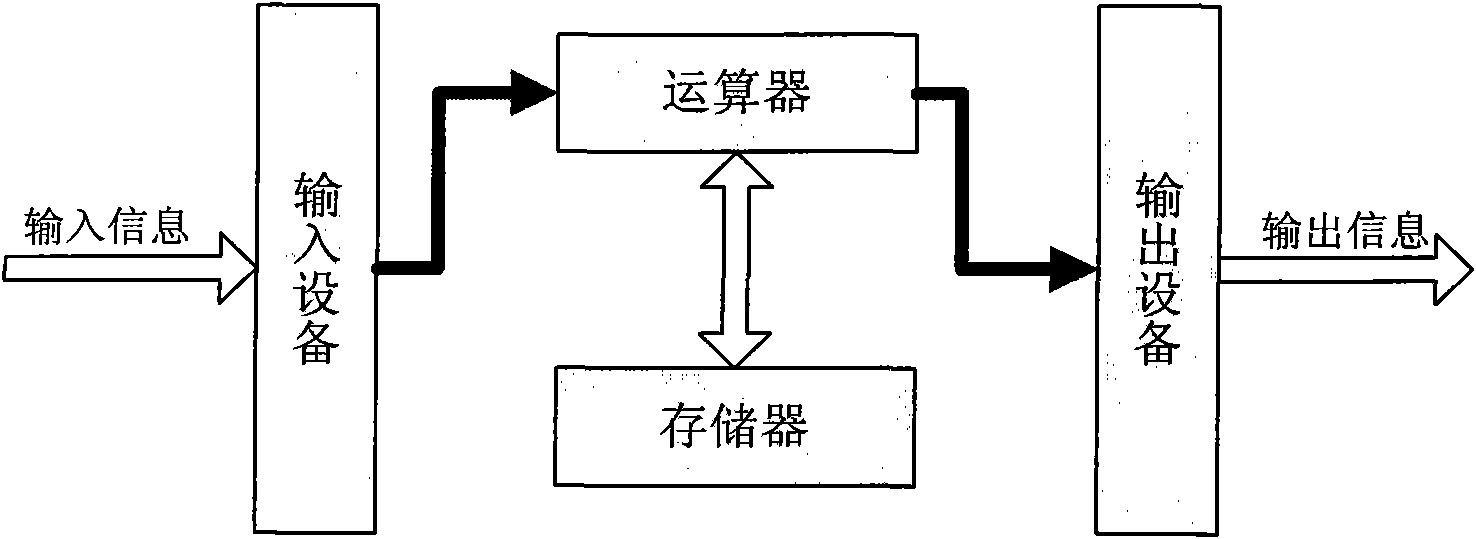

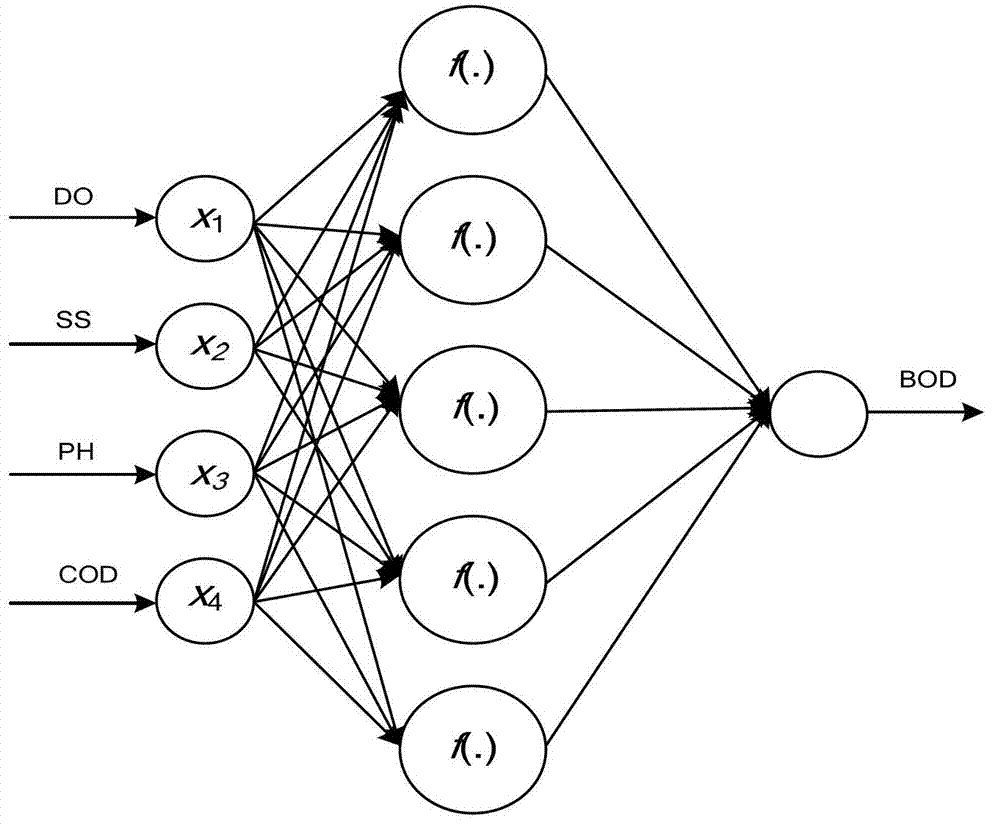

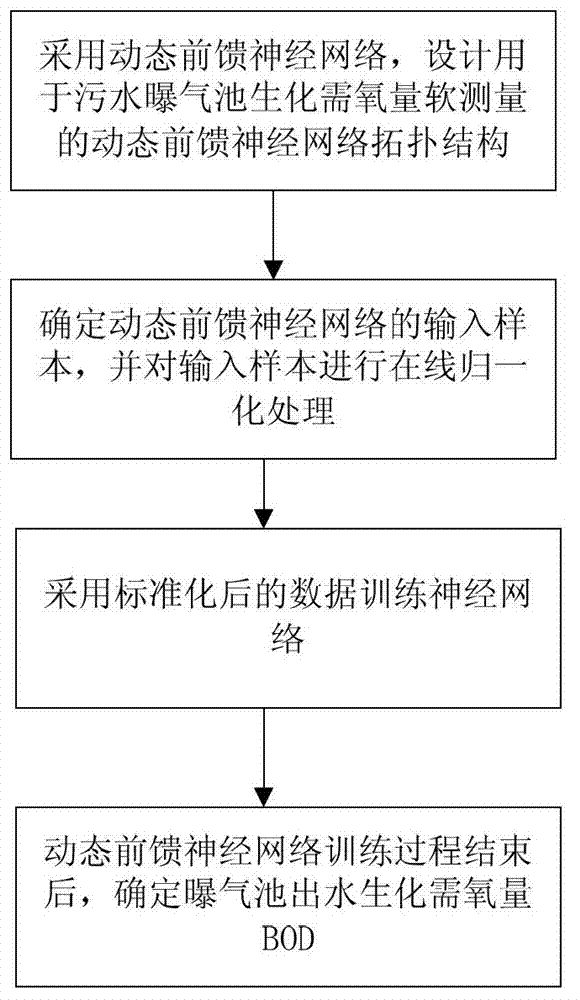

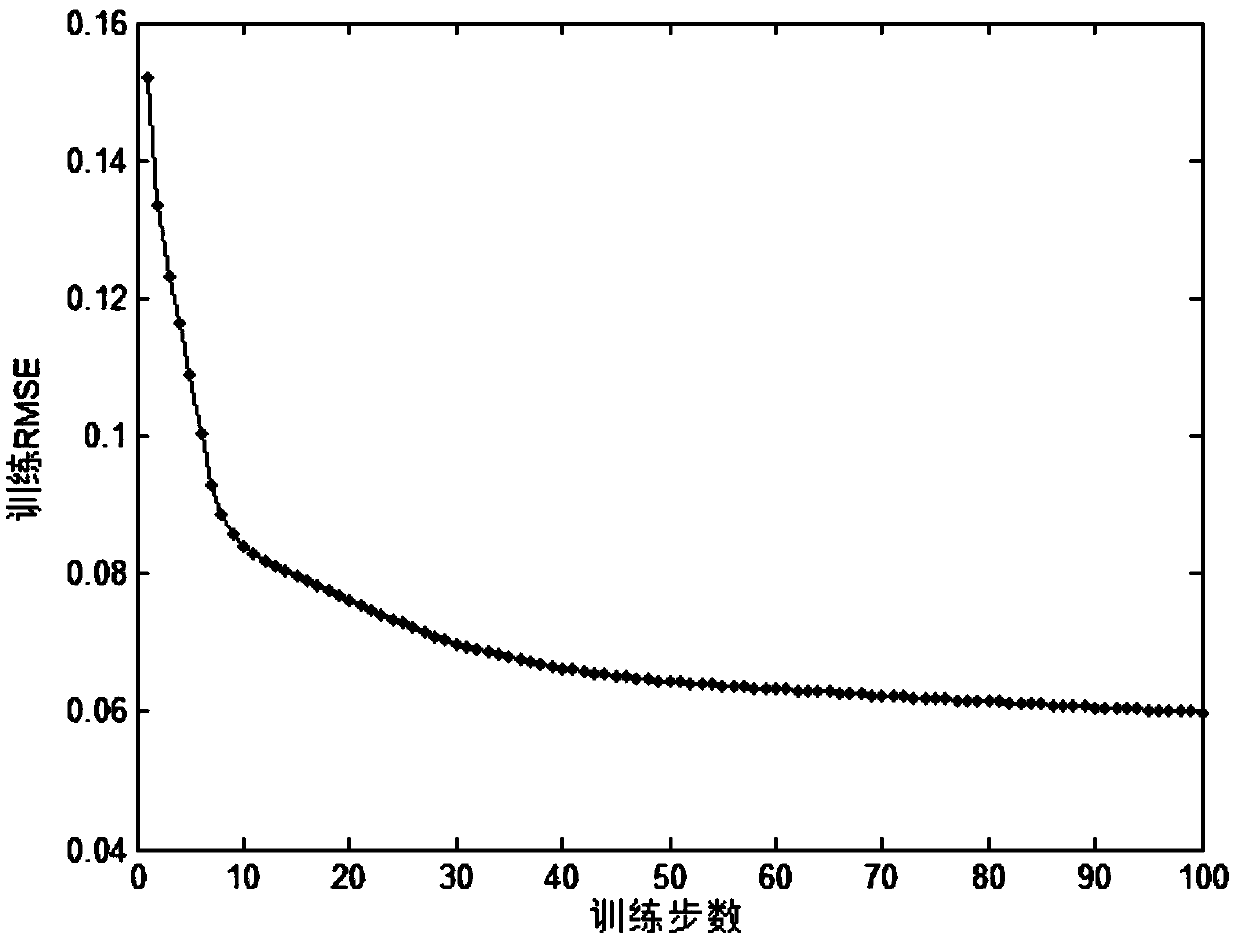

Online biochemical oxygen demand (BOD) soft measurement method based on dynamic feedforward neural network

InactiveCN102879541AImprove real-time performanceImprove stabilityBiological neural network modelsTesting waterNeural network topologySewage

The invention discloses an online biochemical oxygen demand (BOD) soft measurement method based on a dynamic feedforward neural network. The method comprises the following steps of: designing a dynamic feedforward neural network topological structure for BOD soft measurement of a sewage aeration tank, determining an input sample of the dynamic feedforward neural network, and performing online normalization processing on the input sample; calculating the variation condition of an ownership connection value connected with a hidden node in the neural network in each training process by employing a standardized data training neural network, judging the activeness of the hidden node, and splitting the hidden node with high activeness; judging the capacity of learning information of the hidden node by calculating the absolutely output variation condition of the hidden node in the training process, and deleting a hidden node without the learning capacity; adjusting parameters of the neural network; and determining the BOD of effluent of the aeration tank after the training process of the dynamic feedforward neural network is ended. The method has the advantages of high real-time property, high stability, high precision and high neural network generalization ability.

Owner:LIAONING TECHNICAL UNIVERSITY

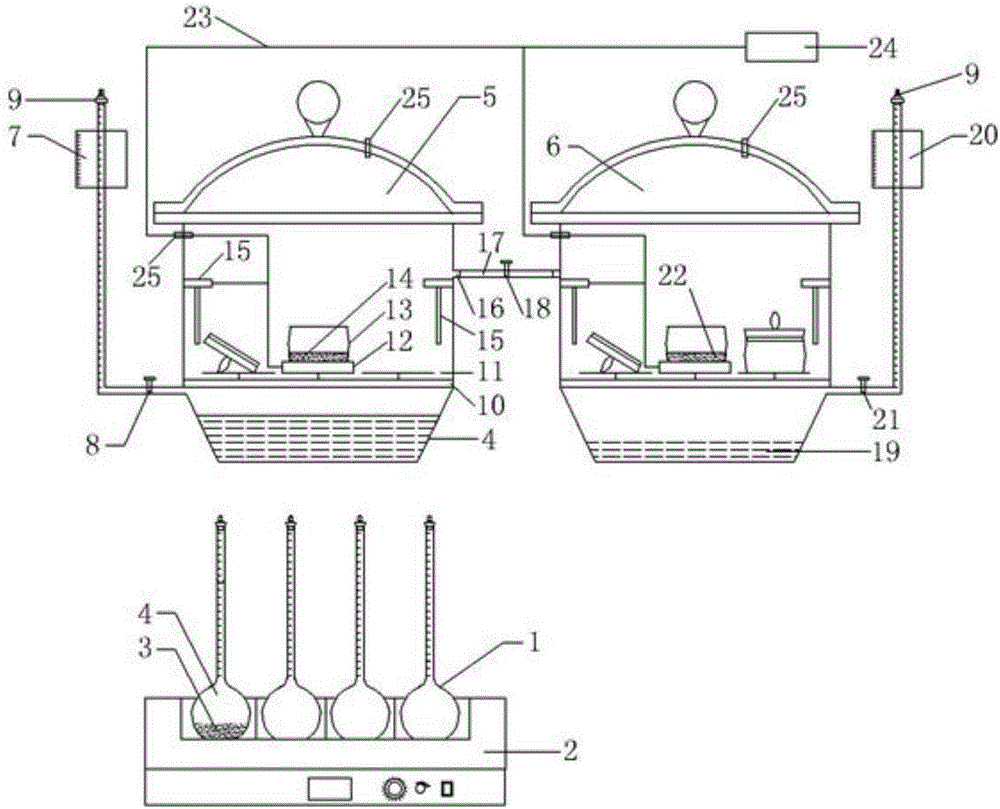

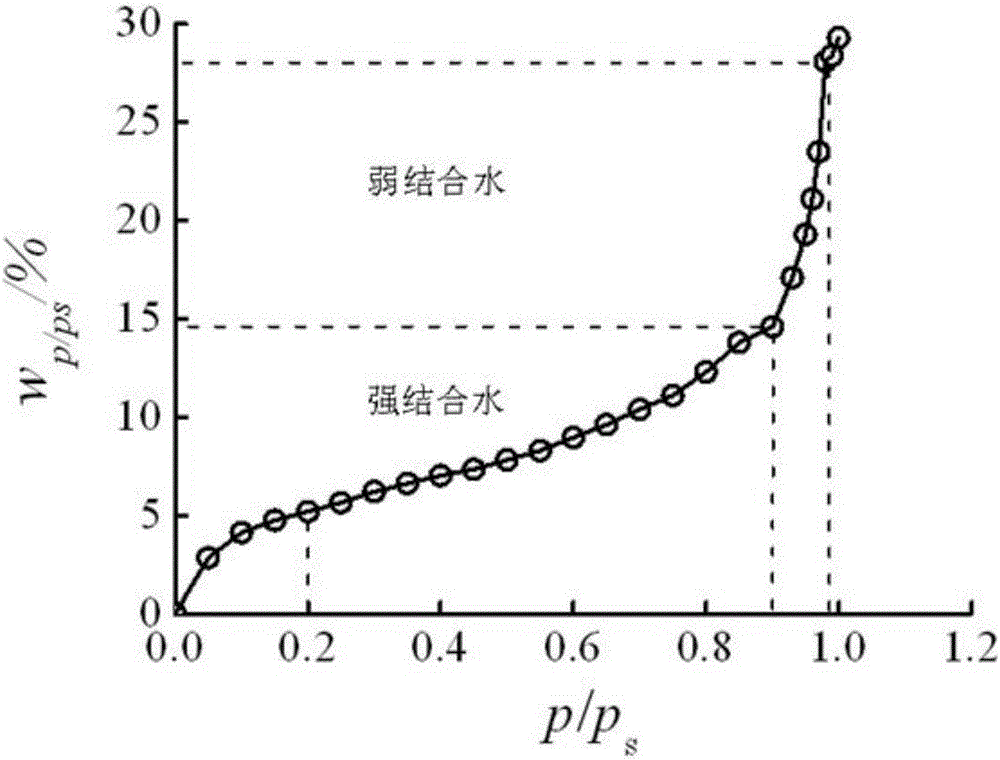

Combined determination device and method for combined water content of soft clay

InactiveCN106644805ALow costLow environmental requirementsWeighing by absorbing componentWater contentChemistry

The invention discloses a combined determination device and method for combined water content of soft clay. The combined determination device comprises a hydration system, an isothermal adsorption system and a measuring system; dry clay is sufficiently hydrated by a volumetric method; the water-air equilibrium pressure in a humidifying adsorption dryer can be adjusted by vapor provided by a moisture preserving dryer and sulphuric acid in an acid inlet pipe. A control system obtains test data through a weight sensor and a temperature and humidity sensor. Through the adoption of the combined determination device disclosed by the invention, the clay which is just sufficiently hydrated is obtained; the water content adsorbed on clay surface is measured under different water-air equilibrium pressure; the content of strong and weak combined water in the soft clay is obtained by an adsorption isotherm; the content of free water is obtained by the combination with an oven drying method. The combined determination device disclosed by the invention is simple, highly integrated, and safe and convenient to operate.

Owner:JILIN UNIV

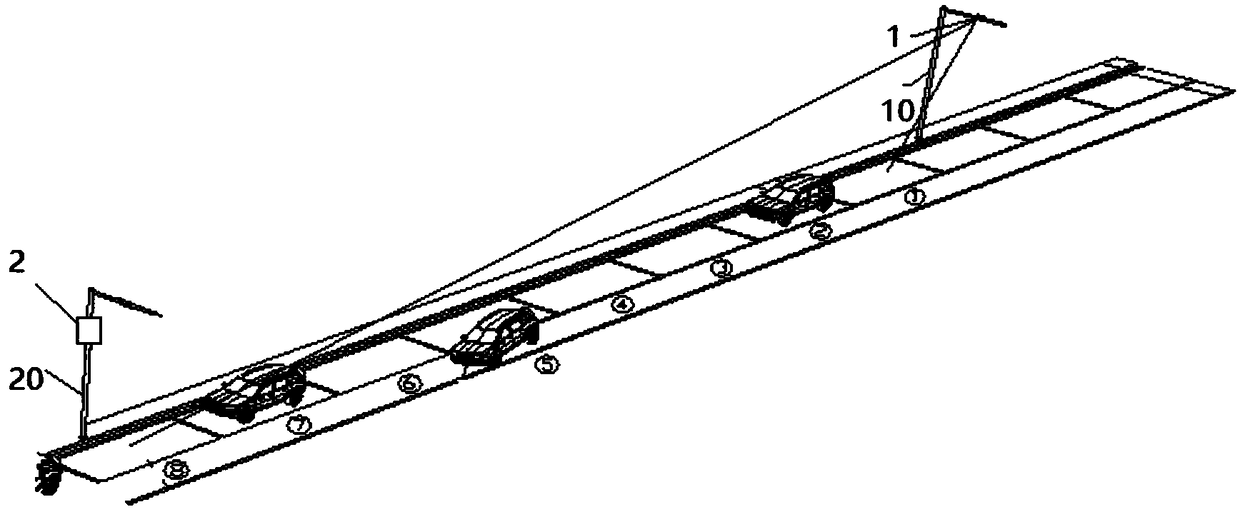

Roadside parking management system based on opposite visual angle complementation

ActiveCN108765973AQuality improvementImprove accuracyDetection of traffic movementIndication of parksing free spacesParking areaControl system

The invention discloses a roadside parking management system based on opposite visual angle complementation. The system comprises a first camera group, a second camera group and a main control system.The first camera group is mounted on a first monitor pole; the second camera group is mounted on a second monitor pole beyond a parking area. The first camera group and the second camera group capture images of monitoring areas from different angles. The main control system performs recognition processing on the images of the monitoring areas captured by the first camera group and the second camera group, and determines parking event information on the parking space jointly managed by the first camera group and the second camera group. The second monitoring rod added by the invention can be selectively installed at a position where the second camera group can cover all the parking spaces between adjacent pole positions, and by appropriately selecting the installation position of the second monitoring pole, the vehicle overlap degree and the license plate inclination in the monitoring image can be reduced, so as to improve the quality of the monitoring image and the accuracy of the master control system for the parking space status and / or license plate recognition.

Owner:INTELLIGENT INTER CONNECTION TECH CO LTD

Method for adaptively determining optimal polarization orientation in polarization vision system

InactiveCN102663768AReduce consumptionSolve elusive problemsImage enhancementImage analysisPolarizerComputer vision

The invention discloses a method for adaptively determining the optimal polarization orientation in a polarization vision system. The method comprises the following steps of: compositing polarization images in any polarization orientation by means of any three polarization images in the known polarization orientation; and evaluating the definition of the polarization images so as to determine the optimal polarization orientation for the polarization vision system. The invention provides the inexpensive, objective and convenient method, so that the problem that the orientation of a polarizer in the conventional polarization vision system is difficult to determine is solved; and after the optimal polarization orientation is determined, the influence of stray light can be eliminated to the greatest extent, and the imaging quality is greatly improved.

Owner:HEFEI UNIV OF TECH

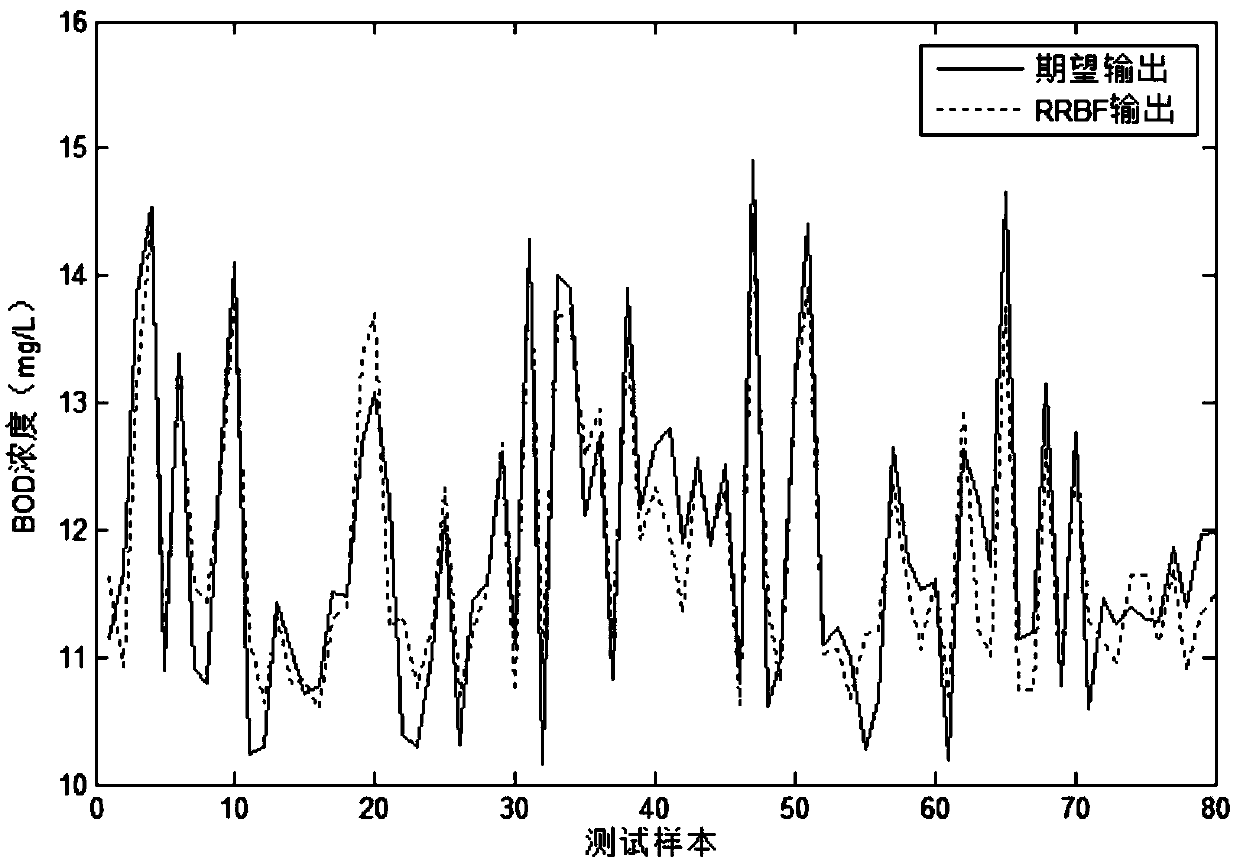

PSO-based recursive RBF neural network effluent BOD prediction method

ActiveCN109657790AImprove stabilityImprove real-time performanceArtificial lifeTesting waterWater qualitySewage treatment

The invention discloses a PSO-based recursion RBF neural network effluent BOD prediction method, which is an important branch in the advanced manufacturing technology field of realizing BOD concentration online prediction, and belongs to the control field and the water treatment field. According to the invention, PSO-is designed; The RRBF neural network realizes real-time measurement of the BOD concentration according to the data collected in the sewage treatment process, solves the problem that the BOD concentration of the effluent in the sewage treatment process is difficult to measure in real time, and improves the real-time monitoring level of the water quality of an urban sewage treatment plant.

Owner:BEIJING UNIV OF TECH

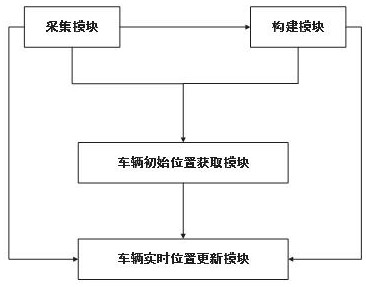

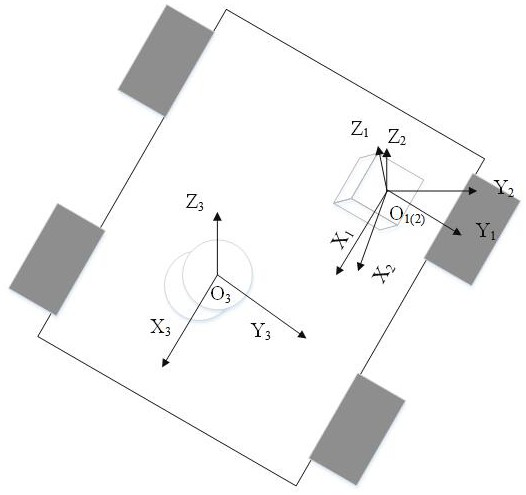

Two-dimensional code, laser radar and IMU (Inertial Measurement Unit) fusion positioning system and method without GPS (Global Positioning System) signal

ActiveCN114199240AGuaranteed accuracyLow production costNavigation by speed/acceleration measurementsElectromagnetic wave reradiationInertial measurement unitLidar point cloud

The invention discloses a two-dimensional code, laser radar and IMU fusion positioning system and method without a GPS signal, and the method comprises the steps: taking a pre-collected high-precision map as a reference, carrying out the joint calibration of a camera, the laser radar and the IMU, and obtaining the initial position of a vehicle on the high-precision map through the recognition of a two-dimensional code and the combination of the detection distance of the laser radar; in the moving process, the IMU serves as a main part, the laser radar serves as an auxiliary part, navigation parameters calculated by the IMU are corrected through position data detected by the laser radar, then the navigation parameters, laser radar point cloud data and lane line images are matched with a high-precision map, and updating of the real-time position of the vehicle is completed. According to the method, the problem that the initial position of the unmanned vehicle cannot be determined in a GPS-signal-free environment is solved, inertial navigation accumulative errors are corrected through multi-sensor data fusion in the movement process, the reliability, stability and precision of a positioning system are improved, and the method can be widely applied to various scenes such as mines and indoor and underground scenes with weak GPS signals.

Owner:WUHAN UNIV OF TECH

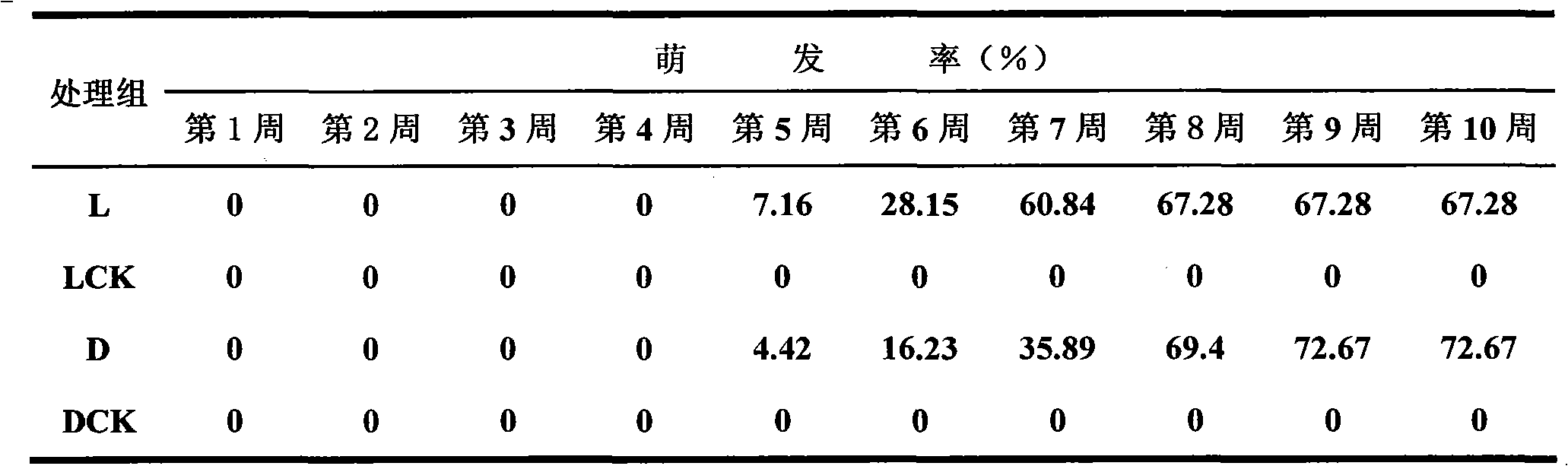

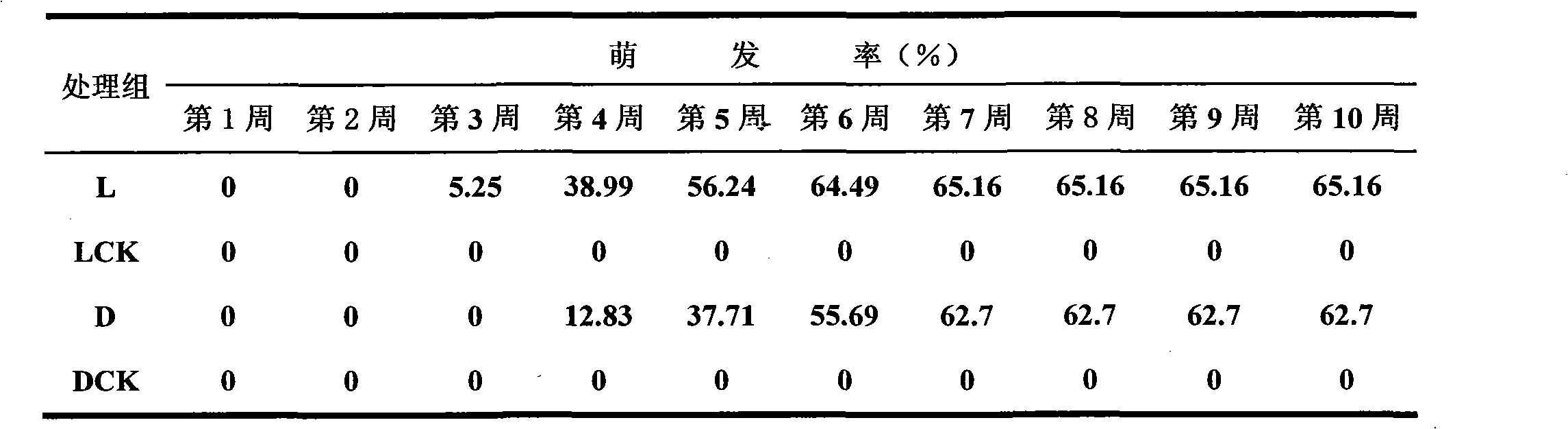

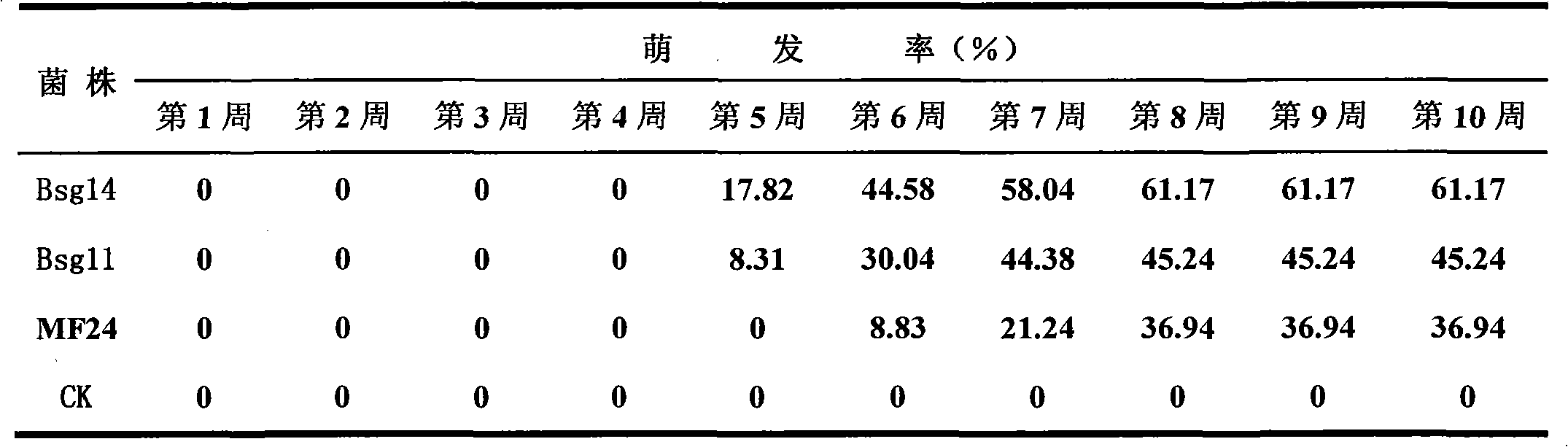

Fungus for promoting germination of bletilla striata seeds

InactiveCN101914457ASolve elusive problemsFungiMicroorganism based processesField cropBletilla striata

The invention discloses a fungus for promoting the germination of bletilla striata seeds. The fungus is named as Bsg11 and classified as Rhizoctonia sp. and has the preservation number of No.2450 in the CGMCC (China General Microbiological Culture Collection Center). The strain has an important significance on solving the problem of germination of the bletilla striata seeds, can be sown together with the bletilla striata seeds, is used for culturing seedlings by seedling-culturing pans or flowerpots or seedbeds and cultivating field crops on land and has the application value of replacing tissue culture to obtain plant seeds.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI

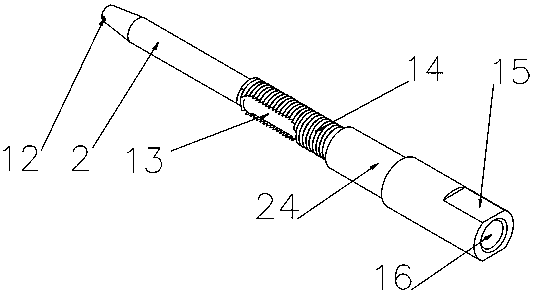

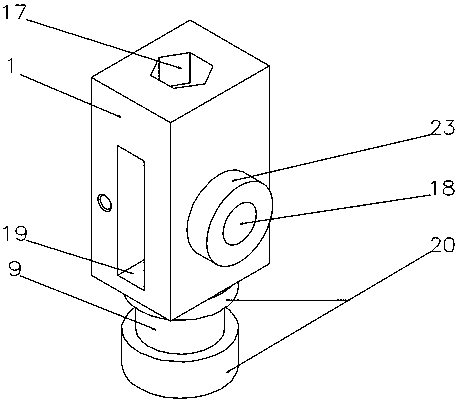

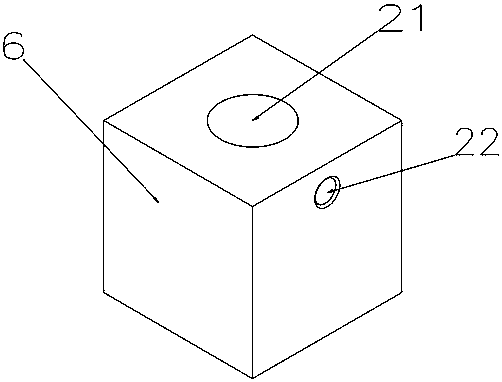

Adjustable oil-air lubrication nozzle kit

ActiveCN107795838APrecise adjustment of spray distancePrecise adjustment of spray angleConduits/junctionsEngineeringLubrication

An adjustable oil-air lubrication nozzle kit comprises a tubular nozzle body and a nozzle bracket used for supporting the nozzle body, wherein the nozzle bracket comprises a lower nozzle seat and an upper nozzle seat; the upper nozzle seat is horizontally and rotationally arranged on the lower nozzle seat; the nozzle body movably penetrates through the middle of the upper nozzle seat and can synchronously rotate along with the upper nozzle seat; an adjusting-fixing device used for pushing the nozzle body to axially move is arranged on the upper nozzle seat; and a locking device used for locking the upper nozzle seat is arranged on the lower nozzle seat. By adoption of the adjustable oil-air lubrication nozzle kit which comprises the adjustable oil-air lubrication nozzle body and nozzle bracket, the jet distance and angle for the oil-air lubrication of a bearing can be quickly adjusted, and then the optimum jet distance and angle of the oil-air lubrication nozzle body can be quickly determined.

Owner:HENAN UNIV OF SCI & TECH

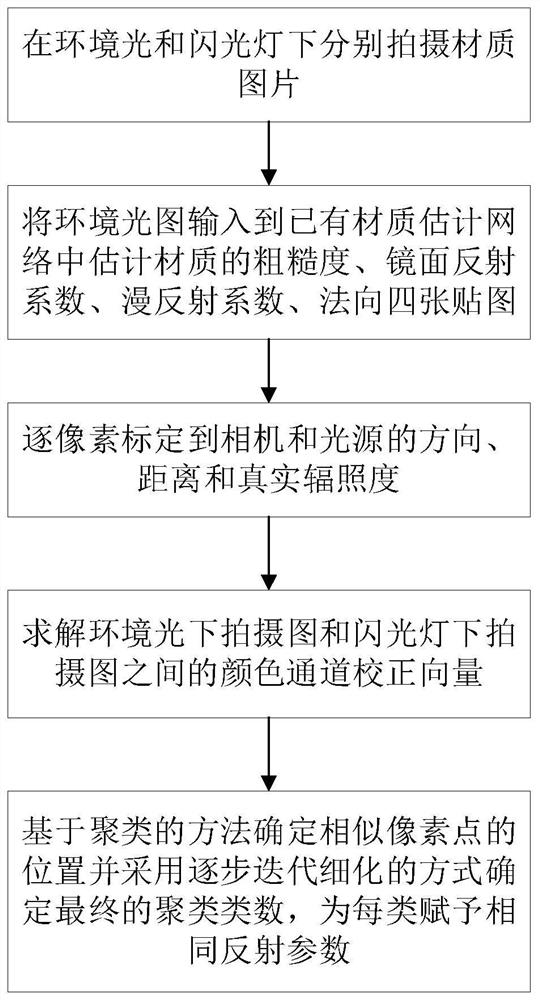

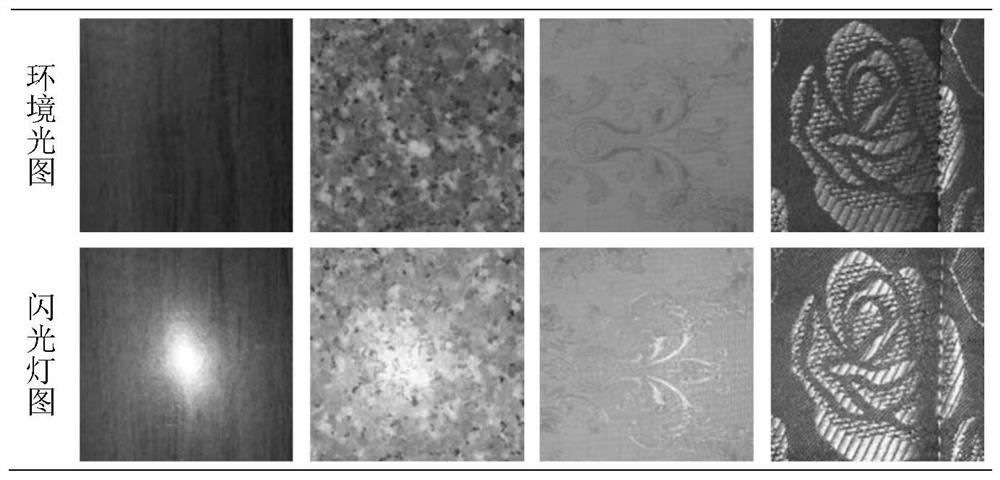

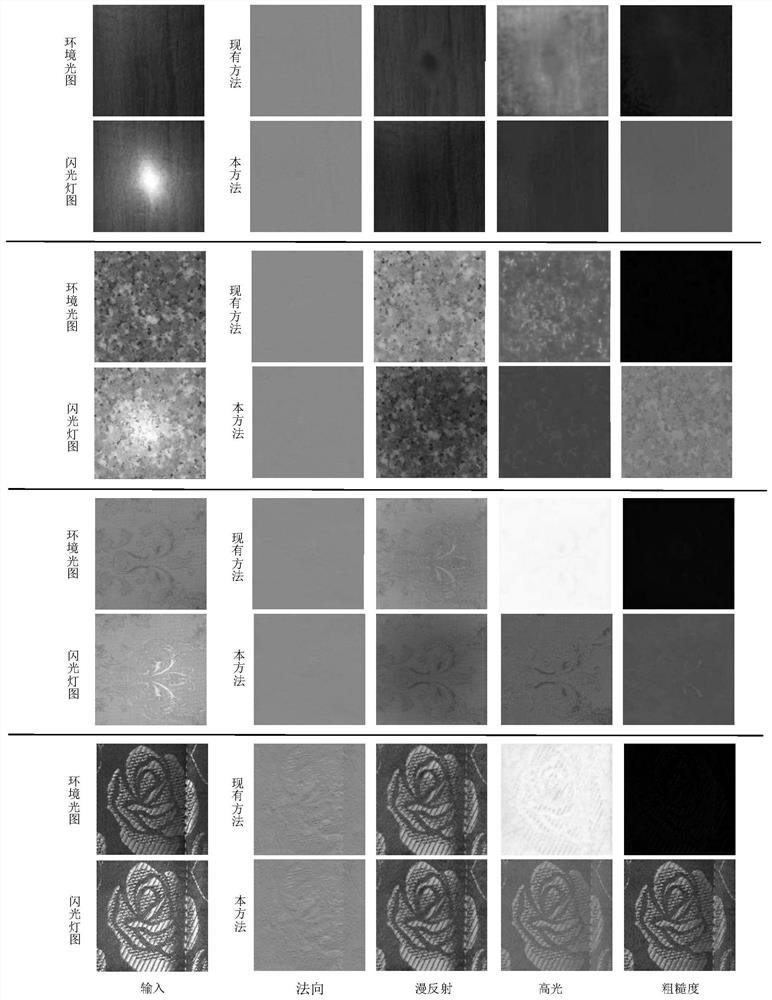

Method for estimating material reflection parameters based on images acquired by portable equipment

ActiveCN112634156APlay the role of white balanceSolve elusive problemsImage enhancementImage analysisComputer graphics (images)Image estimation

The invention discloses a method for estimating a material reflection parameter based on images acquired by portable equipment. The method comprises the following steps: shooting a material ambient light image and a flash lamp image; estimating the material roughness, the specular reflection coefficient, the diffuse reflection coefficient and the normal map according to the ambient light image; calibrating the direction, the distance and the real irradiance to the camera and the light source in a per pixel manner; solving a color channel correction vector between the ambient light image and the flash light image; and determining the positions of similar pixel points based on clustering, determining the final cluster number by adopting a gradual iterative refinement mode, and endowing points in each class with the same reflection parameters. The method can be used for conveniently estimating the SVBRDF parameters of the material; and aiming at the phenomenon that some material maps estimated by a neural network at present have serious halo and the like, the method can re-estimate the reflection parameters of the material by shooting the material flash lamp image andthe ambient light image, so that the sense of reality of rendering is improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com