Combinational processing technique and device of deck radial flow

A treatment process and combined technology, which is applied in the field of bridge deck runoff combined treatment process and its devices, can solve the problems of inapplicability, poor comprehensive treatment capacity of various pollutants, and poor interception of small particle pollutants, etc., to achieve Overcome the effects of affecting senses and vision, high efficiency of intercepting suspended solids, and achieving environmental coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A combined treatment process for bridge deck runoff, which is characterized in that the collected bridge deck runoff is first subjected to oil separation and sedimentation treatment, and then the runoff after the above treatment is led to the grass planting slope, and then the runoff is flowed into the artificial Biochemical treatment of wetlands.

Embodiment 2

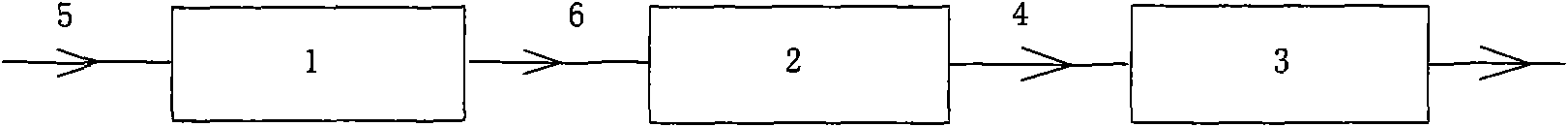

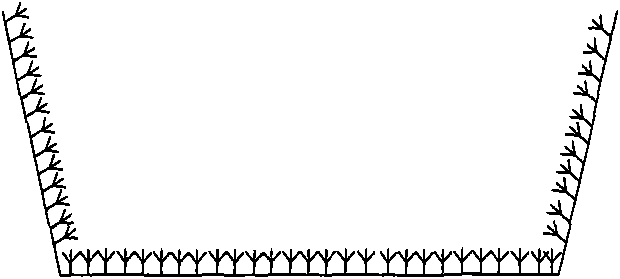

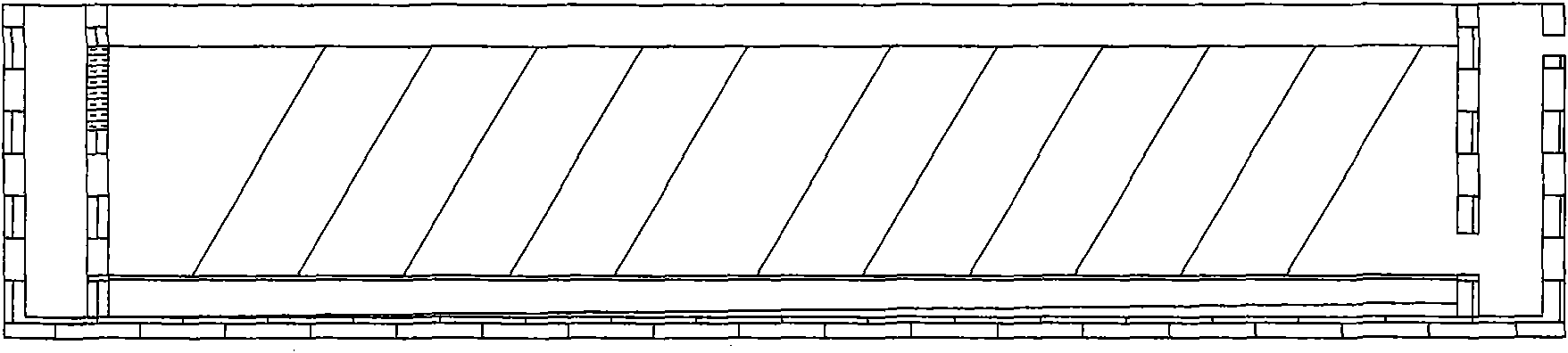

[0039] A device for realizing a combined treatment process of bridge deck runoff, comprising: a grease trap 1, a sedimentation tank 2 and an artificial wetland 3, the outlet of the grease trap 1 is connected to the water inlet of the sedimentation tank 2, and the sedimentation tank 2 is connected to the artificial wetland A grass planting slope 4 is arranged between the wetlands 3, the outlet of the sedimentation tank 2 is higher than the top of the grass planting slope 4, and the bottom of the grass planting slope 4 is opposite to the water inlet of the artificial wetland 3, so that the runoff flowing down the grass planting slope 4 passes through the grass planting slope The bottom of 4 enters the constructed wetland 3 from the water inlet of the constructed wetland 3 .

[0040] In this embodiment, the water inlet of the grease trap 1 is connected with the first grass planting ditch 5; the grass planted on the first grass planting ditch 5, the second grass planting ditch 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com