Oil-water separation device for leakage drainage system in hydropower station

A technology for oil-water separation device and drainage system, applied in liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of increasing the maintenance workload of the power station and reducing the reliability of the system, and achieves strong capabilities, reliable work, and high capacity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

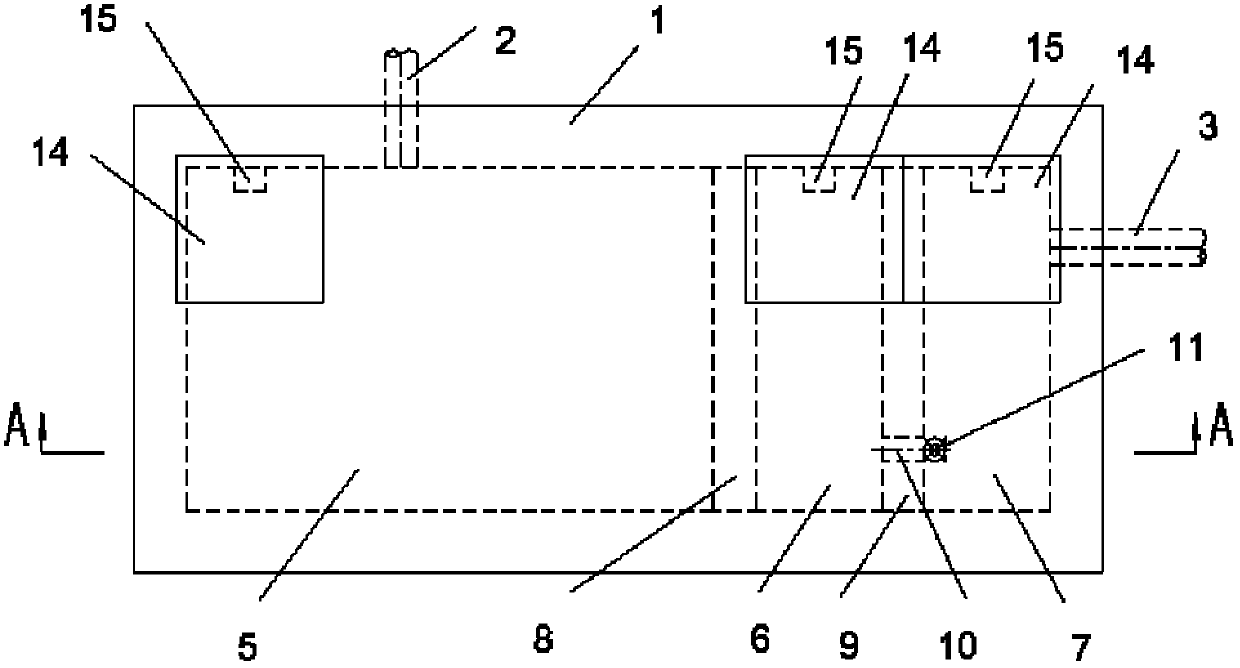

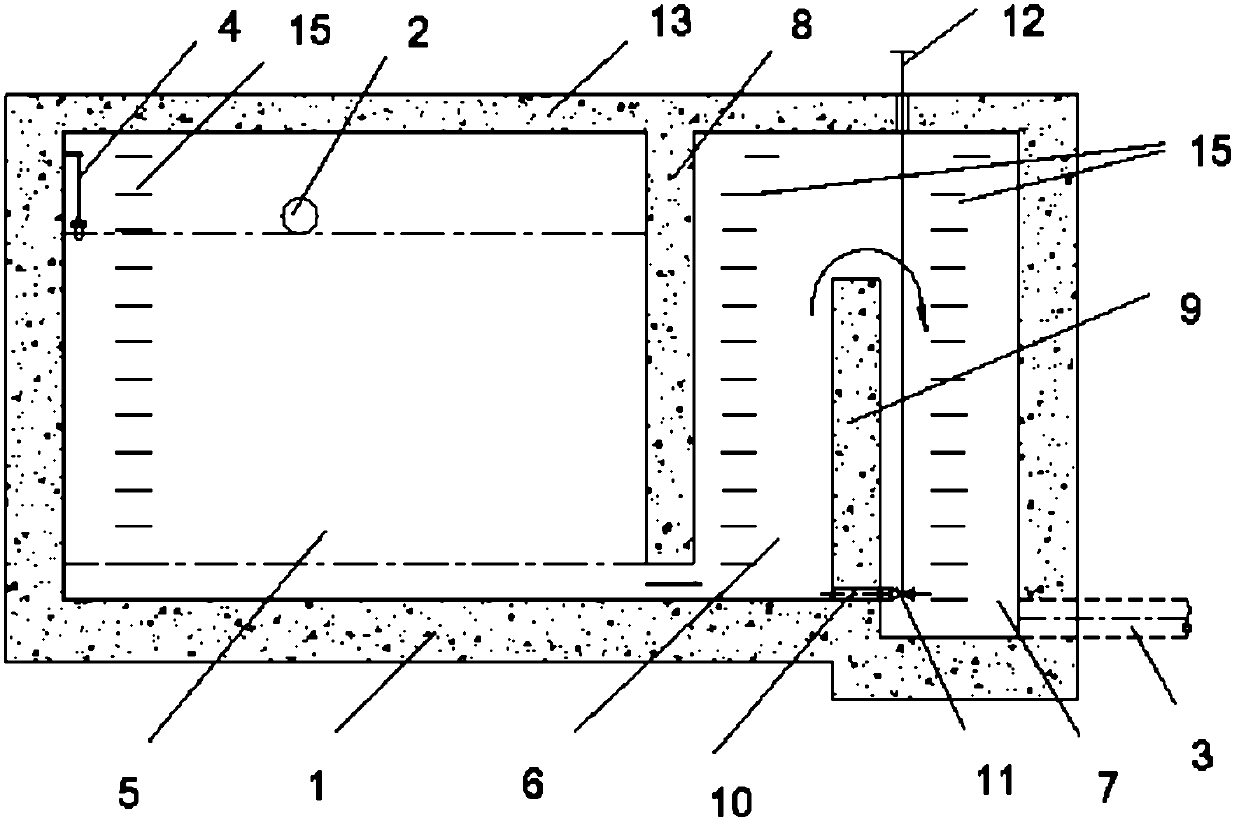

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0016] Such as figure 1 , 2 As shown, the oil-water separation device for the seepage and drainage system of a hydropower station of the present invention includes a pool 1, an oily sewage inlet pipe 2, a drain pipe 3 and a float alarm switch 4, and the inner space of the pool 1 is vertically partitioned by a first partition 8 The oil-water separation tank 5, the buffer tank 6 and the drain tank 7 which are connected to each other by the vertical second partition 9 are successively divided into the bottom of the oil-water separation tank 5 and the buffer tank 6 which are divided by the first partition 8, and are separated by the second partition 9 The divided buffer tank 6 is connected to the top of the drain tank 7; the oily water inlet pipe 2 is located at the upper part of the oil-water separation tank 5 and is higher than the top of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com