N-2-1 positioning based skin and stringer assembling deviation analyzing method of airplane

A technology of aircraft skinning and analysis methods, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as poor accuracy, immature modeling methods for assembly deviation of aircraft panel components, and no mature analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

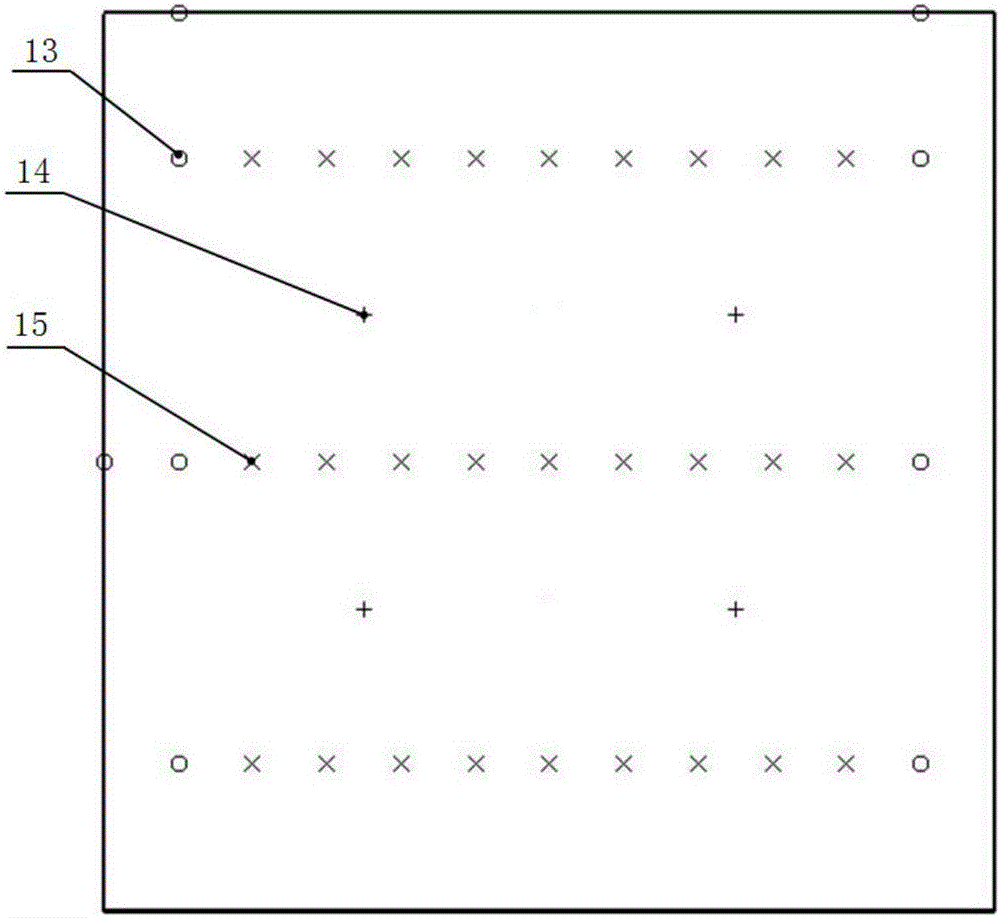

[0047]In this embodiment, the deviation analysis method provided by the present invention is described in detail with the assembly process of a small piece of skin 9 and three stringers on the aircraft panel assembly.

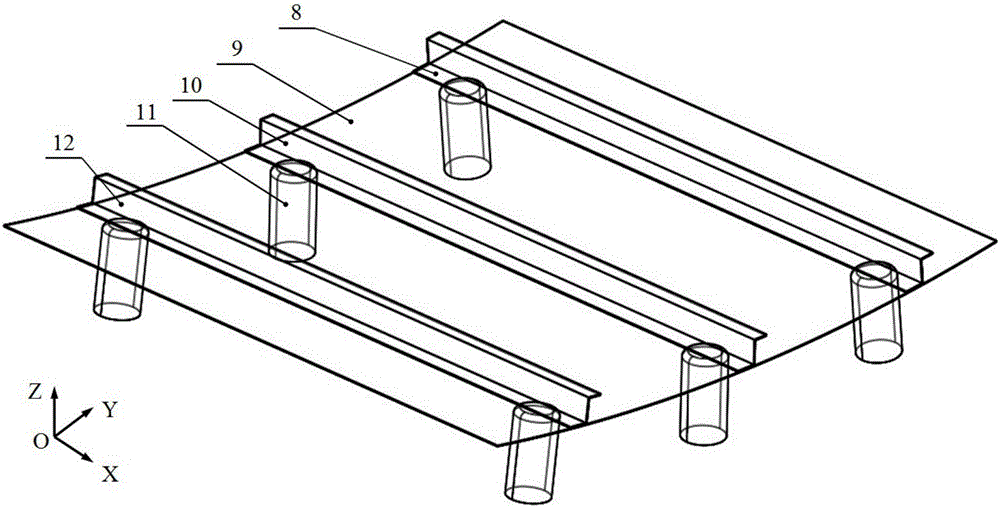

[0048] Such as figure 2 As shown, the simplified model of the skin 9, the stringer and the positioning clamping element 11 in this embodiment. The three long stringers, that is, the first stringer 8 , the second stringer 10 and the third stringer 12 are positioned on the inner surface of the skin 9 .

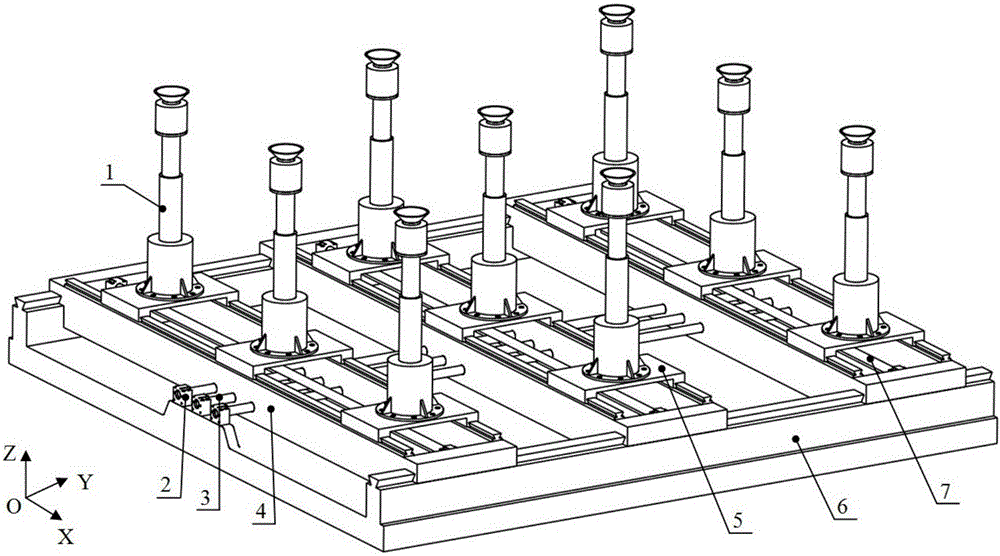

[0049] In this embodiment, the positioning and clamping element 11 comes from a multi-lattice vacuum chuck type flexible tooling. Such as figure 1 As shown, the multi-lattice vacuum chuck type flexible tooling is mainly composed of an adjustable column 1, a support seat 2, a Y-direction screw 3, a bent frame 4, an X-direction transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com