Rotary disk type full-automatic bearing assembly machine

A fully automatic, turntable technology, used in bearing components, shafts and bearings, machinery and equipment, etc., can solve the problems of slow production rhythm, unguaranteed assembly quality, low production efficiency, etc., to eliminate potential safety hazards, improve efficiency and assembly. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

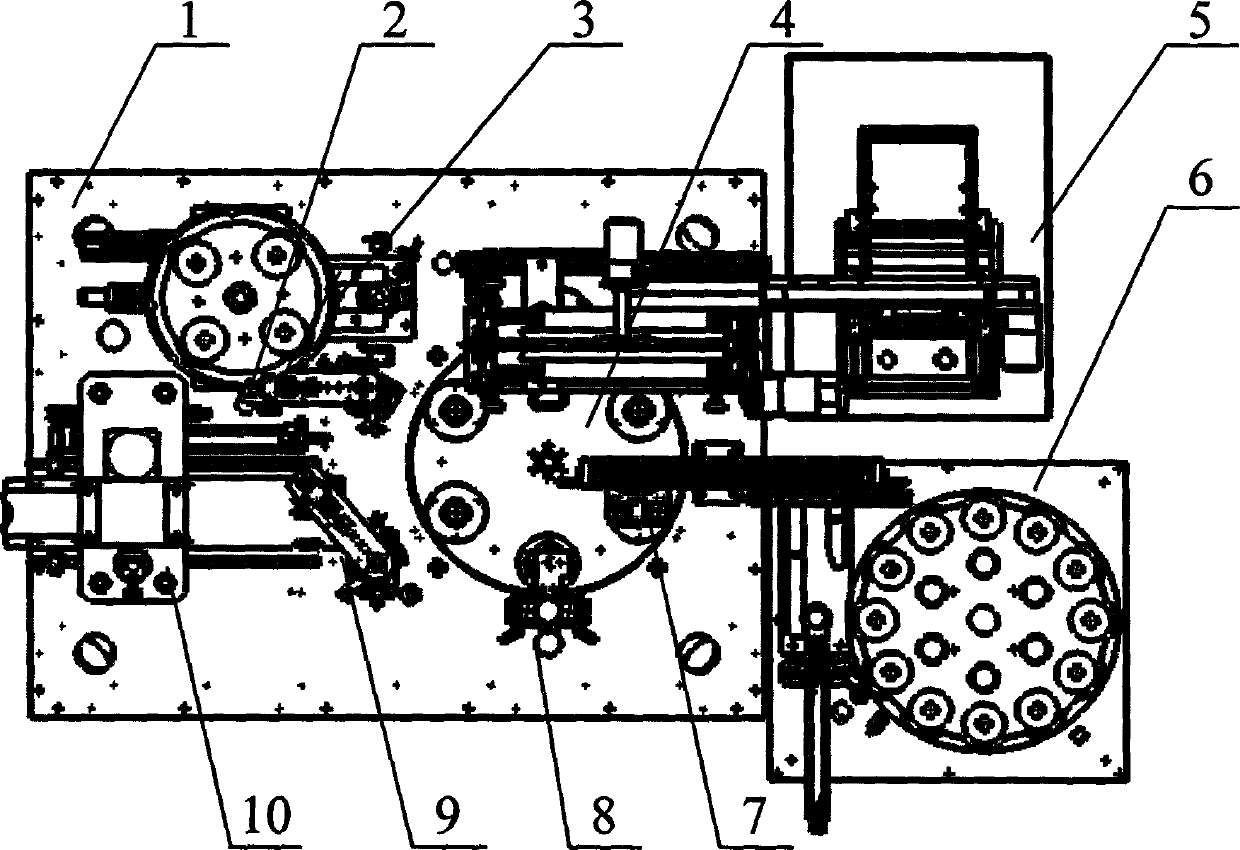

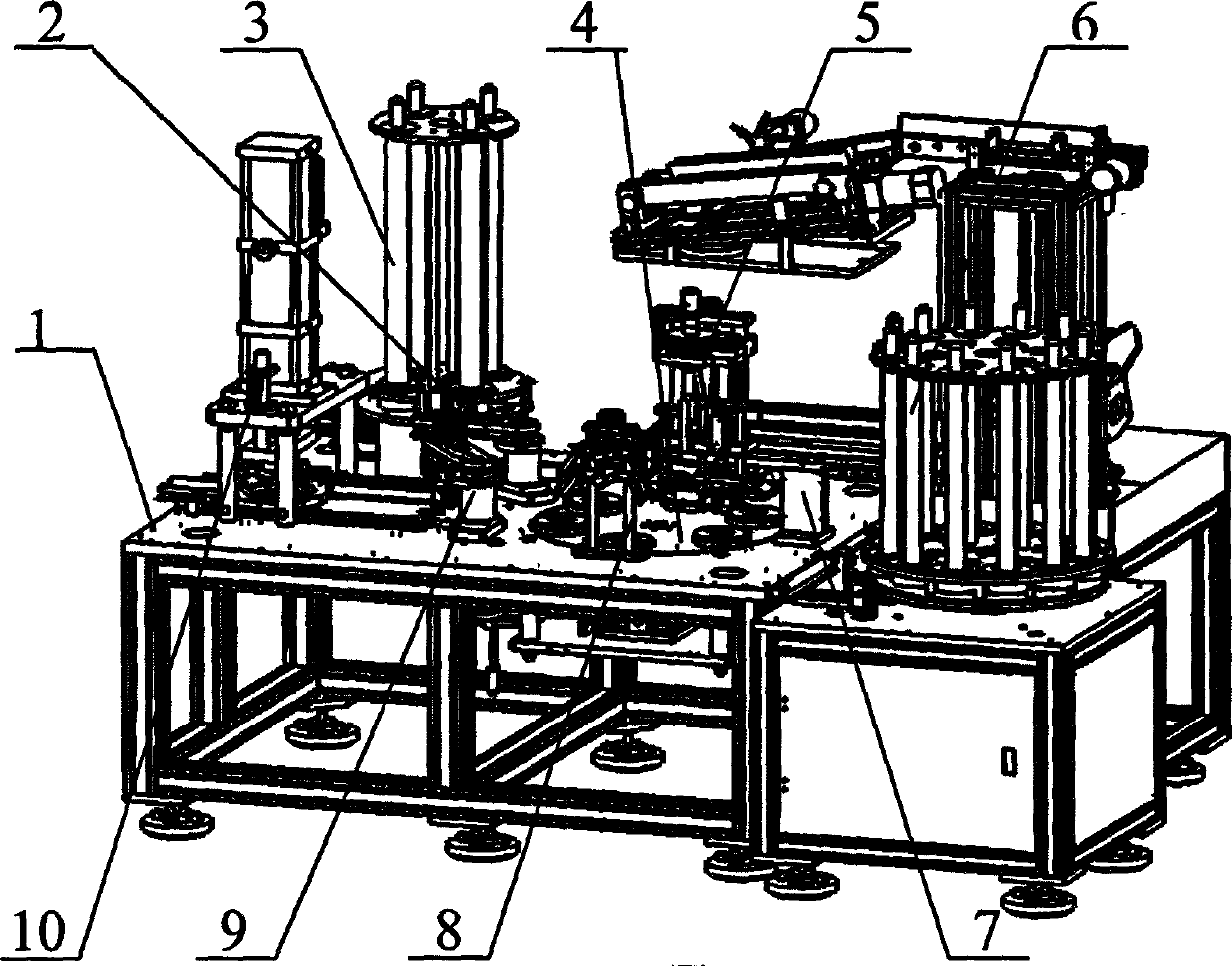

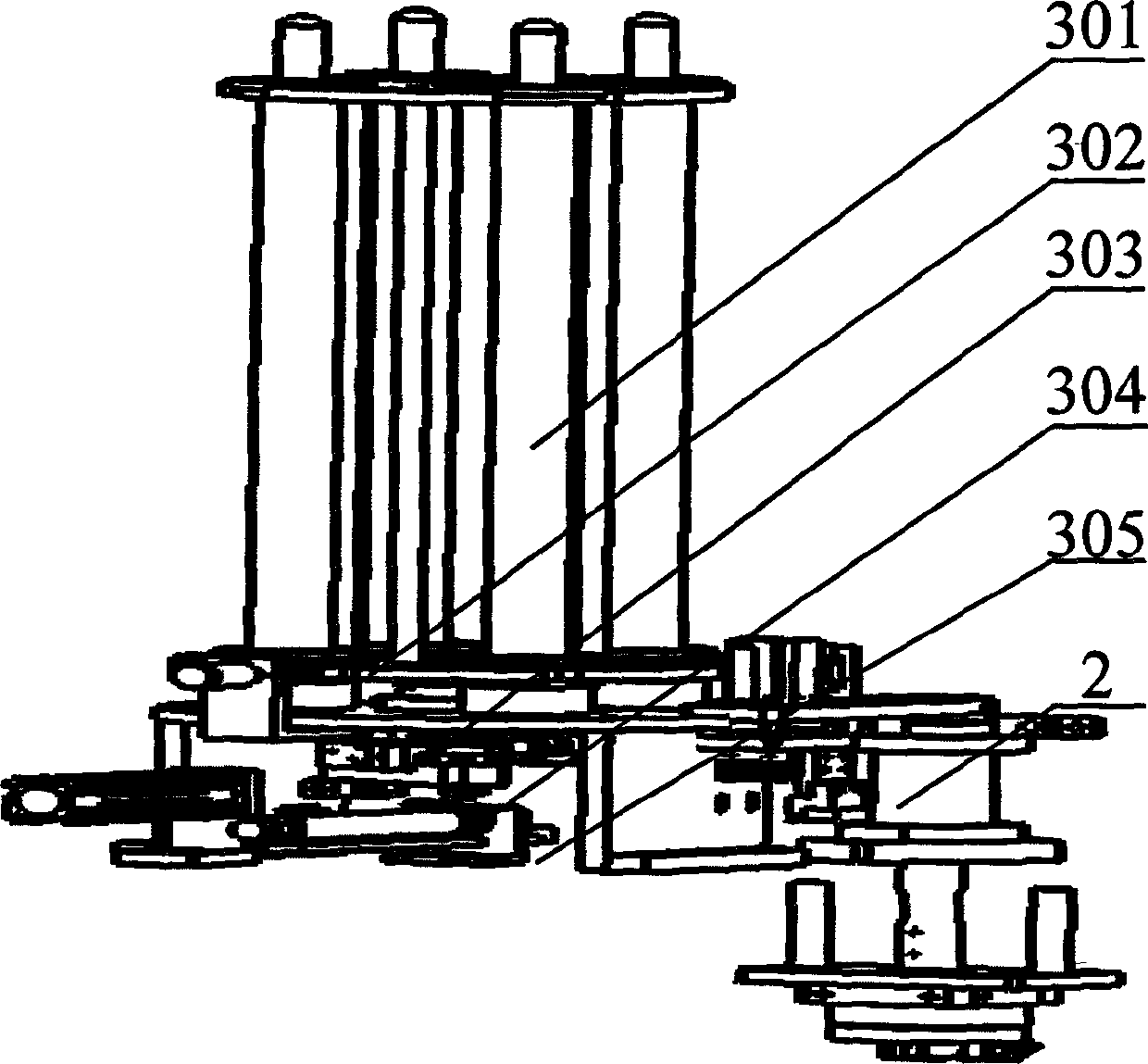

[0023] Such as Figure 1 to Figure 8 As shown, a turntable type automatic bearing assembly machine includes a worktable 1, a turntable assembly 4 arranged on the worktable 1, and a cage feeding assembly 3 and a roller assembly assembly are evenly arranged around the turntable assembly 4 in sequence. 5. The inner ring feeding component 6, image leak detection component 8 and press-fit component 10 are arranged in the same order as the turntable rotation direction, and the operating sequence of each component is consistent with the production process sequence of the product.

[0024] The turntable assembly 4 includes a turntable 401 arranged on the workbench 1, a fixture 403 evenly arranged on the turntable 401, and a sextant 402 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com