Automatic loading pricking device for automobile ceiling and carpet production line

An automatic feeding and acupuncture device technology, applied in the direction of thin material processing, transportation and packaging, conveyor objects, etc., can solve the problems of inability to pick up the quality of soft materials such as carpets, the reduction of production efficiency of automatic assembly lines, positioning efficiency and positioning Low precision and other problems, to achieve the effect of reducing labor intensity of workers, simple structure, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

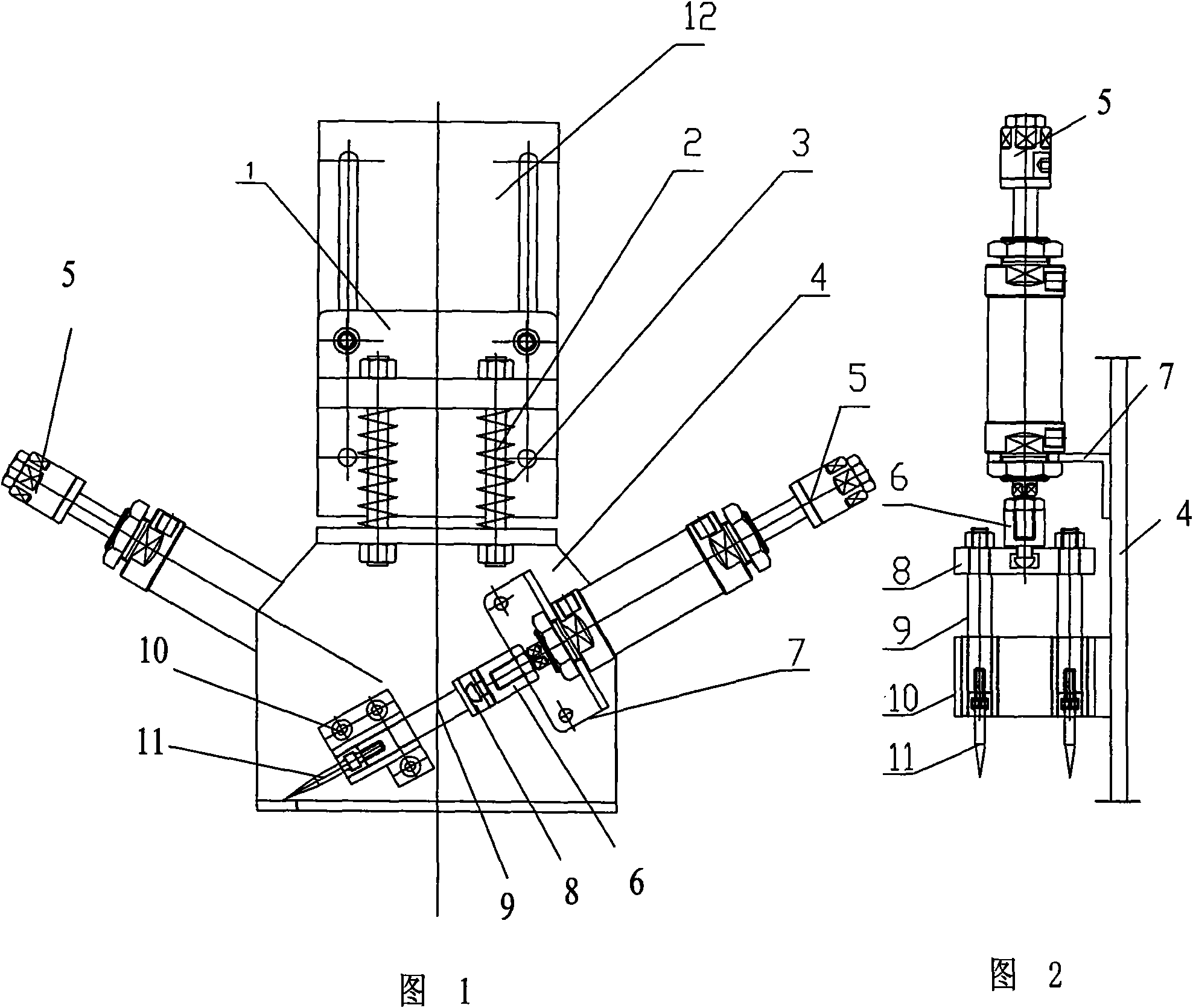

[0009] As shown in the figure, there is a connecting plate 1 above the frame 4, and a first guide post 2 on the connecting plate 1. The lower end of the first guide post 2 is connected to the upper end of the frame 4, and the There is a spring 3 on the first guide post 2; there is a cylinder bracket 7 on the frame 4, an adjustable stroke cylinder 5 is installed on the cylinder bracket 7, the piston rod of the stroke adjustable cylinder 5 and the second guide post 9 is connected, and a needle 11 is provided at the end of the second guide post 9.

[0010] A guide post bottom plate 8 is provided at the end of the piston rod, and the second guide post 9 is mounted on the guide post bottom plate 8. The axis of the adjustable-stroke cylinder 5 and the axis of the first guide post 2 obliquely intersect. There are two first guide posts 2 arranged in parallel. There are two second guide posts 9 arranged in parallel. A guide sleeve 10 is provided on the frame 4, and the acupuncture needle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com