Reflux rotating household garbage pyrolysis carbonization furnace system and garbage disposal process

A technology for domestic waste and carbonization furnace, applied in coke oven, petroleum industry, fixed bed gasification and other directions, can solve the problems of pipeline treatment system not running continuously and stably, investment and operation cost, pyrolysis tar blockage, poor heat transfer effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

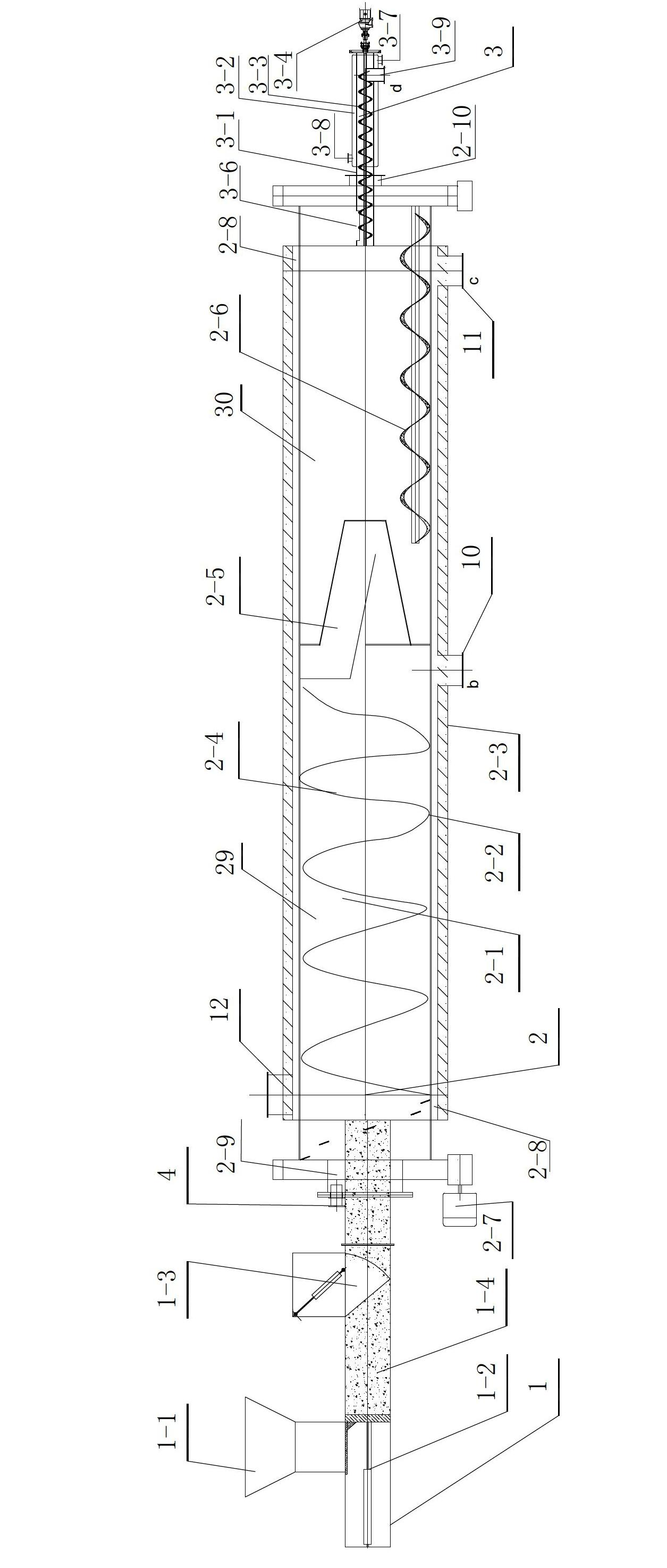

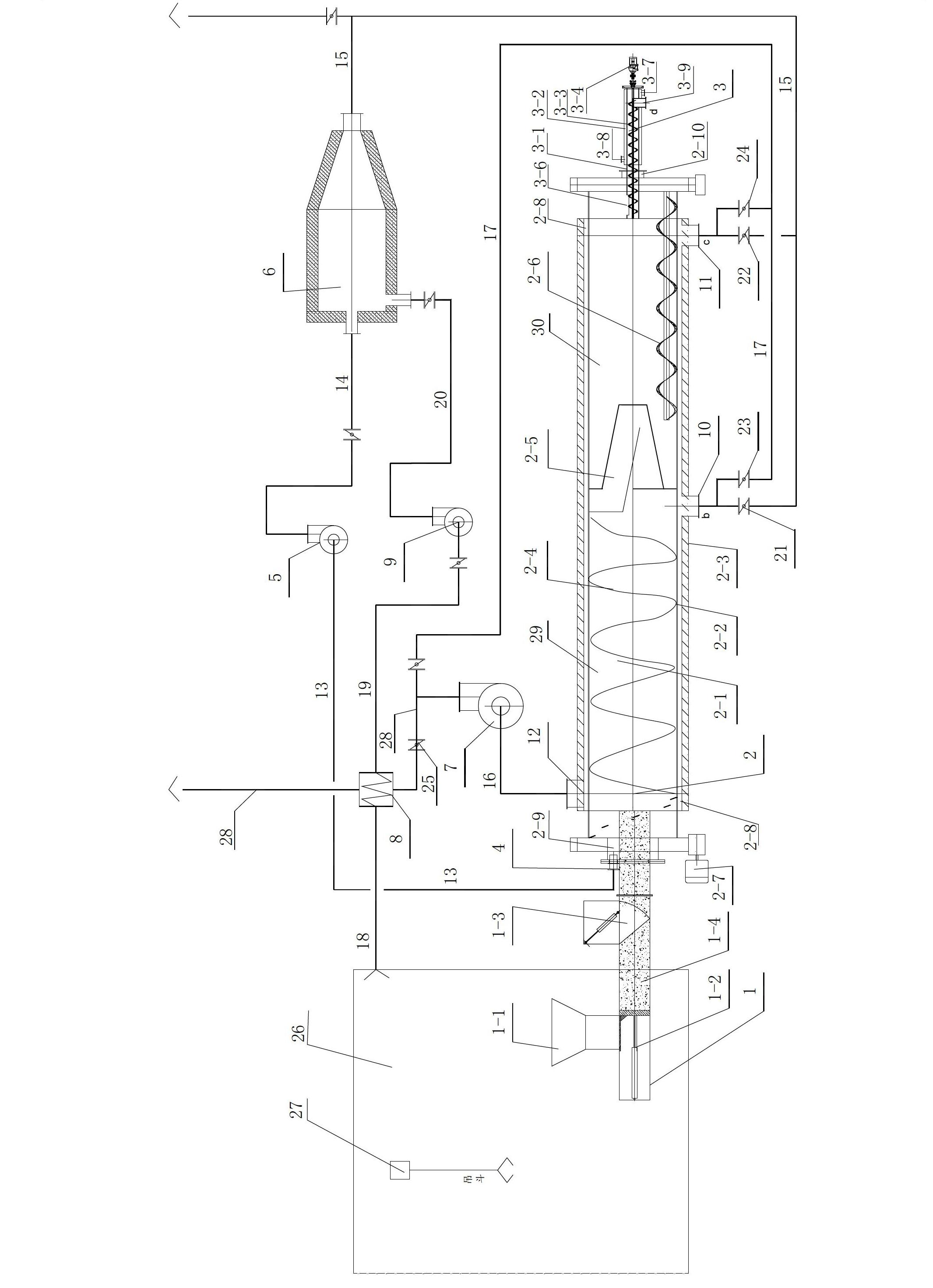

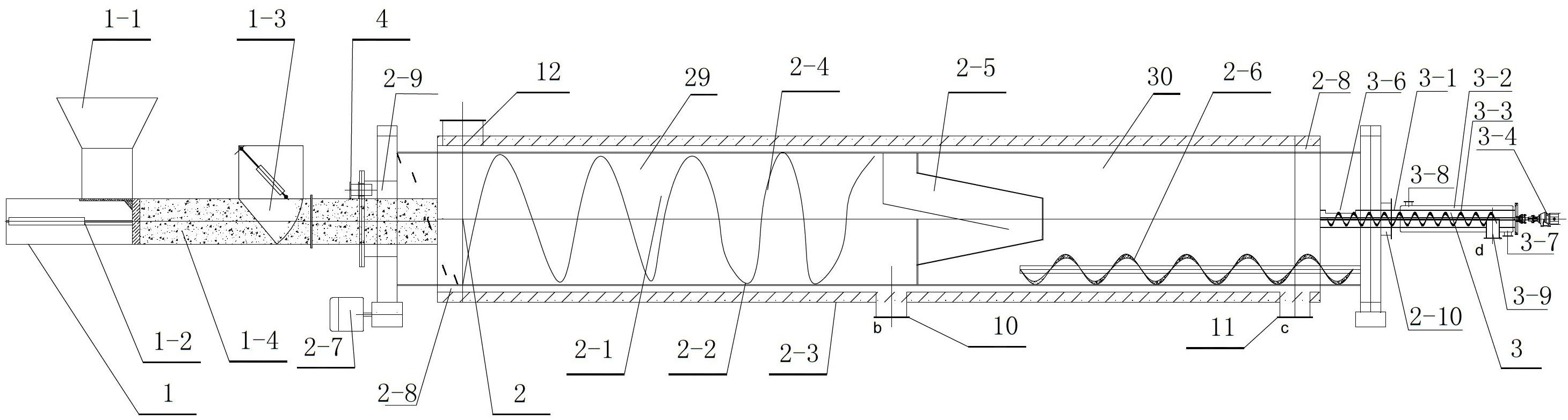

[0015] Such as figure 1 As shown: it is composed of feeding device 1, pyrolysis and carbonization furnace body 2, and slag discharge screw 3, which are arranged and connected in sequence;

[0016] The feeding device 1 is composed of a feeding port 1-1, an extrusion chamber 1-4, a pusher 1-2, and a solid material check valve 1-3. The extrusion chamber 1-4 is a cylindrical channel, The feed port 1-1 is connected to the front side wall of the extrusion chamber, the pusher 1-2 is located in the extrusion chamber 1-4 below the feed port 1-1, and the solid material check valve 1-3 is located in the extrusion chamber. In the chamber in the middle and back section of chamber 1-4; during use, the garbage passes through the solid material check valve of the feeding device and the compression and propulsion of the pusher, so that the garbage layer is compressed and compacted to reduce the air being brought into the pyrolysis furnace, and at the same time Push the garbage into the pyroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com