Patents

Literature

65results about How to "Reduce shrinkage defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold work die steel and preparation method thereof

The invention provides cold work die steel. The cold work die steel comprises C, Si, Mn, Cr, Mo, W, V, P, S, Cu, Mg, Ti, Sr, Zr, B, Zn, Re, Sn, Pb, Be, Sc, Li, Ni, La, Al and the balance iron, wherein the sum of the mass percentages of the components is 100%. The nodular cast iron comprises multiple kinds of nonmetal, metal and transition metal elements. Because the elements are added and cooperate with one another, the oxidation resistance, the corrosion resistance, the abrasion resistance, the compression resistance and the shock resistance of a compressor cylinder block of an air conditioner are improved, and the service life of the compressor cylinder block of the air conditioner under severe working conditions is prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Production process for weaving all-cotton cutting motif fabric by air-jet loom

The present invention discloses a production process for weaving all-cotton cutting motif fabric by an air-jet loom. The production process comprises the following steps of winding process, warping process, sizing process, drawing-in process, weft preparation, and weaving process. The cutting motif fabric is usually weaved by a rapier loom and is not suitably weaved by a high-speed air-jet loom. According to production process, the cutting motif fabric is weaved by the air-jet loom, product quality and production efficiency are ensured, and enterprises gain considerable benefits. Ground warp threads are drawn in front zones of heald frames, and droppers are drawn in back zones, thereby facilitating reduction of tension force of the ground warp threads. Colored warp threads are drawn in the back zones of the heald frames, droppers are drawn in the front zones, and tension force of the colored warp threads is relatively small, thereby facilitating increase of the tension force of the colored warp threads and reduction of knees defects. When the former processes are performed for production, the winding and warping processes are performed at a low speed, air splicing is configured to the winding process so as to reduce yarn hairiness, coating is important in the sizing process, the weaving process is assisted by early opening, large tension force and late weft insertion and the like, and the problem of weft stop is solved.

Owner:NANTONG HONGJINBEI ELECTRONICS TECH CO LTD

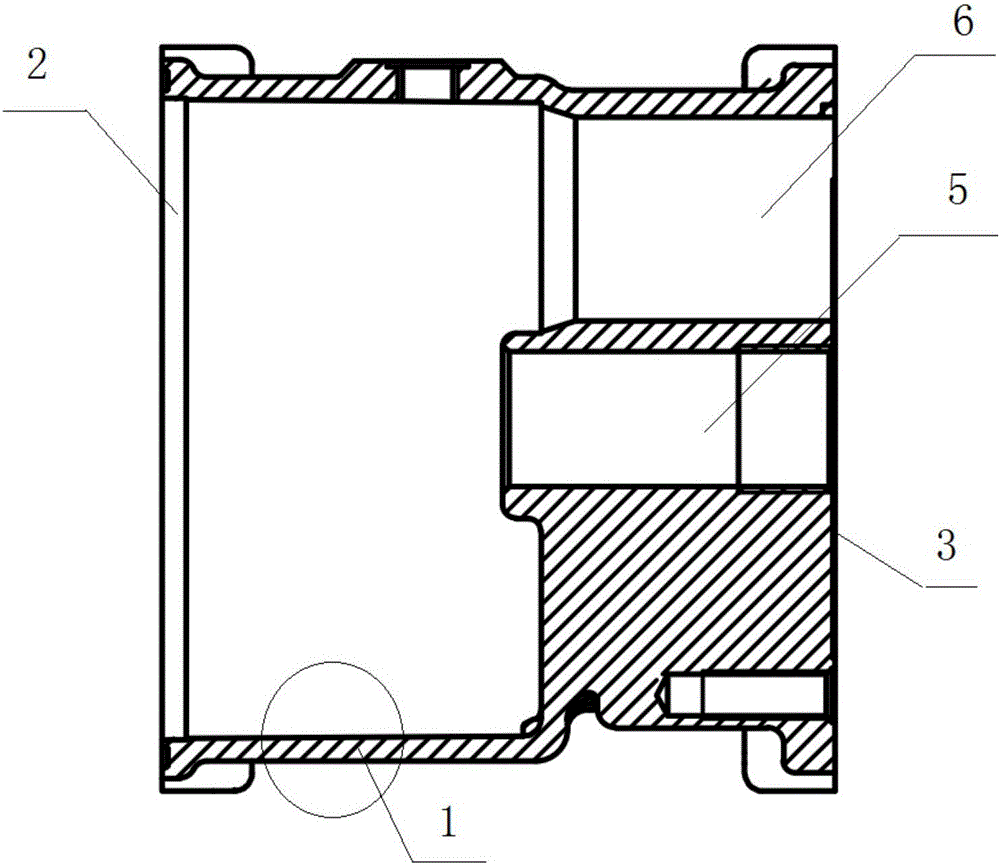

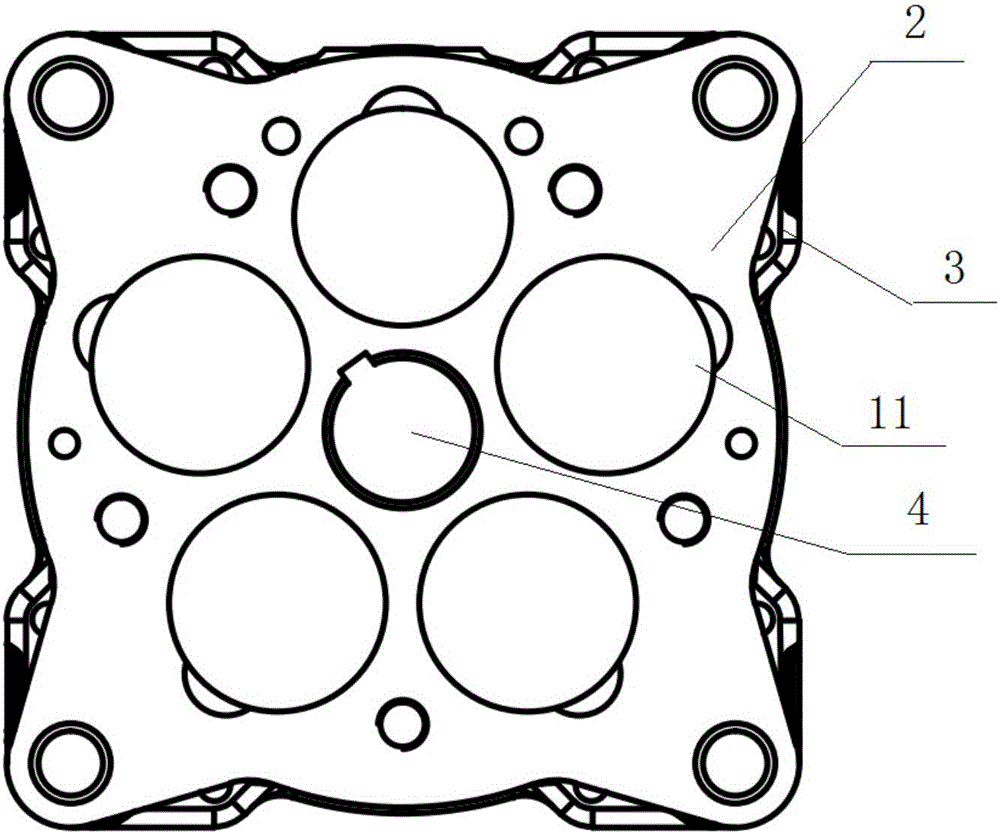

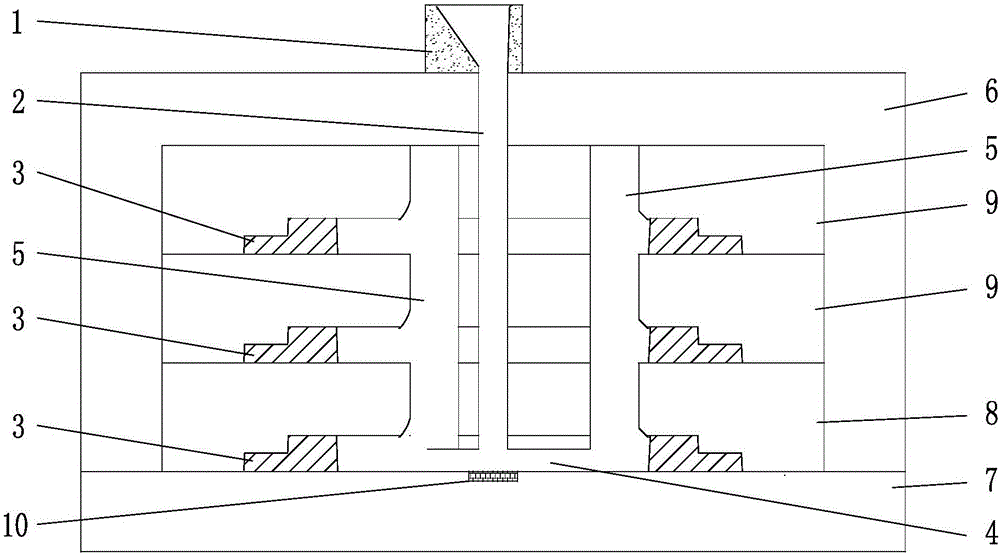

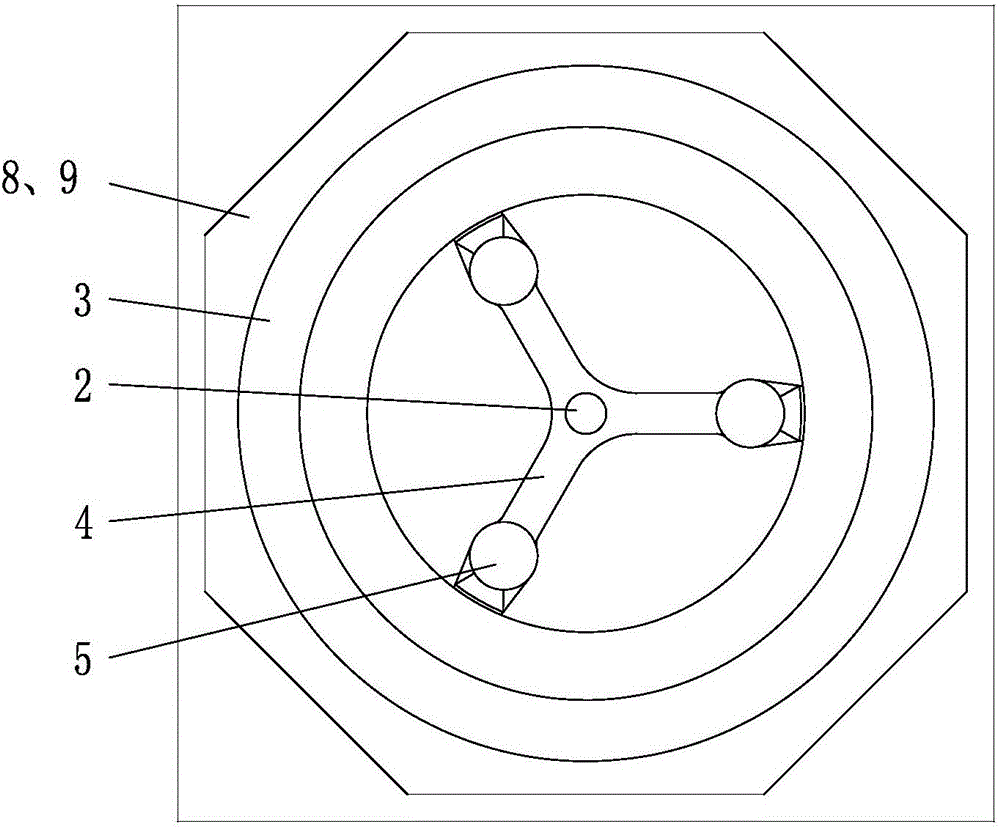

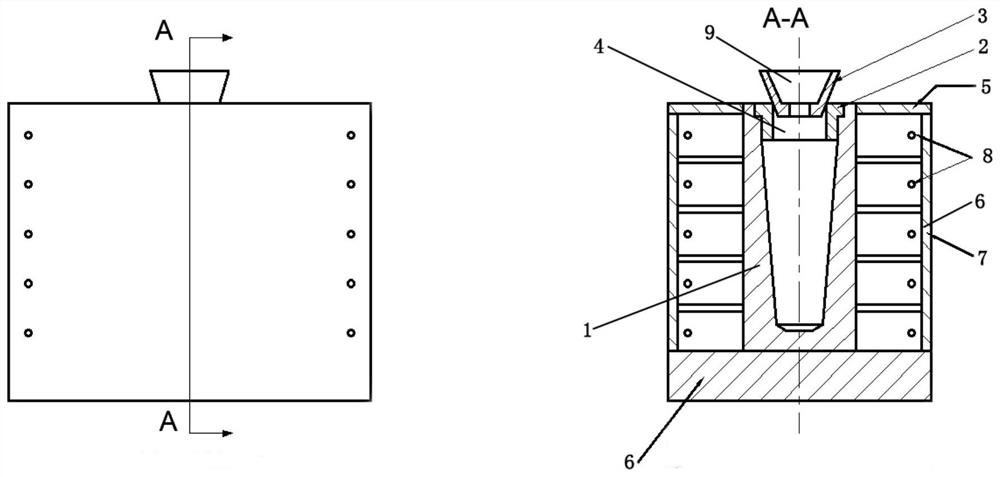

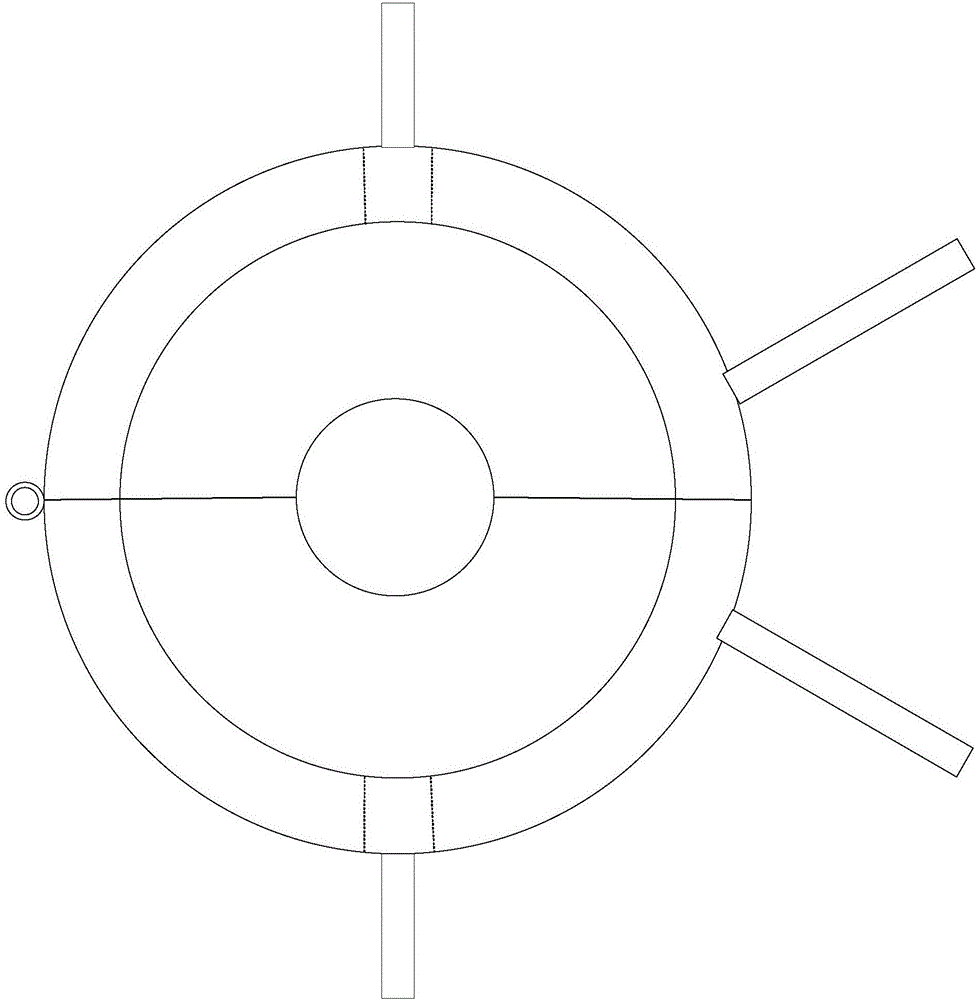

Casting mold and casting method of high aluminum zinc alloy annular casting parts

The invention discloses a casting mold of high aluminum zinc alloy annular casting parts. A metal outer mold of the casting mold is positioned on a metal bottom plate, a metal core mold is positioned in the center of the metal bottom plate, a casting mold cavity with an annularly opened upper opening is formed by a cavity among the upper side of the metal bottom plate, the inner edge of the metal outer mold and the outer edge of the metal core mold, a casting mold sand core is fixed on the upper side of the metal core mold, a metal cover plate is covered on the upper side of the metal outer mold, and knurling is arranged on the bottom surface of the casting mold cavity. The invention also discloses a casting method for the high aluminum zinc alloy annular casting parts. The method includes 1) injecting liquid-state high aluminum zinc alloys into the casting mold cavity until the high temperature liquid level rises to the upper side of the metal outer mold; 2) lifting the metal cover plate to the upper side of the metal outer mold, continuing casting, compensating cooled the upper lateral surfaces of casting parts until the casting parts are formed finally. The casting mold and casting method reduces dendrite segregation and pinholes among dendrites, improves mechanical property of the casting parts and greatly increases qualified rate of the casting parts.

Owner:镇江汇通金属成型有限公司

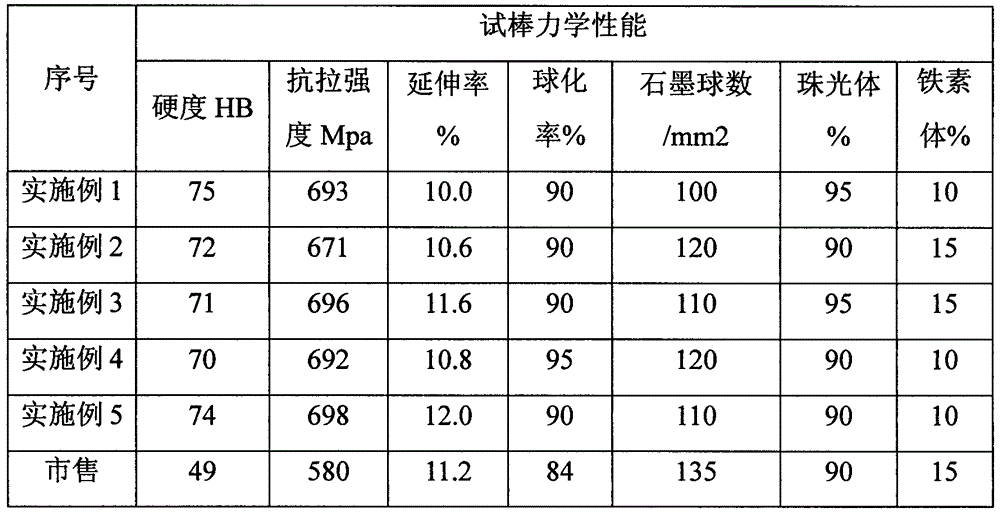

Nodular cast iron used for air conditioner compressor cylinder and preparing method of nodular cast iron

ActiveCN106048400AImprove antioxidant capacityImprove corrosion resistancePositive displacement pump componentsPositive-displacement liquid enginesDuctile ironMetal

The invention provides a nodular cast iron used for an air conditioner compressor cylinder. The nodular cast iron comprises, by weight percent, C, Si, Mn, P, S, Cu, Mg, Ti, Sr, Zr, Cr, B, V, Zn, Re, Sn, Pb, Be, Sc, Li, Ni, La and the balance iron, wherein the sum of the weight percent of all components is 100%; and the nodular cast iron comprises multiple nonmetal elements, metal elements and transition metal elements, the elements are added and matched, oxidization resistance, corrosion resistance, abrasion resistance and compressing and vibration resistance of the air conditioner compressor cylinder are improved, and accordingly, the service life of the air conditioner compressor cylinder under the poor working condition is prolonged.

Owner:江苏昊科汽车空调有限公司

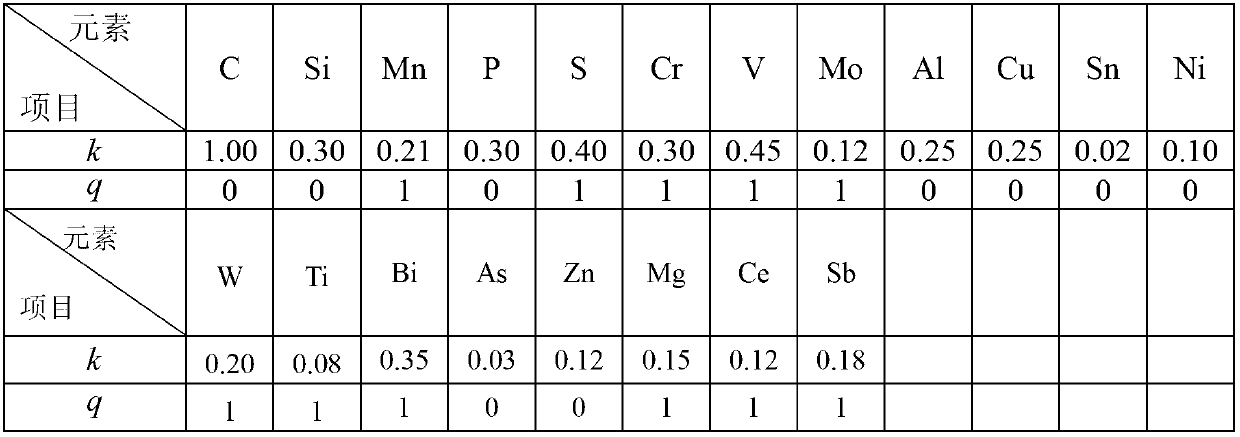

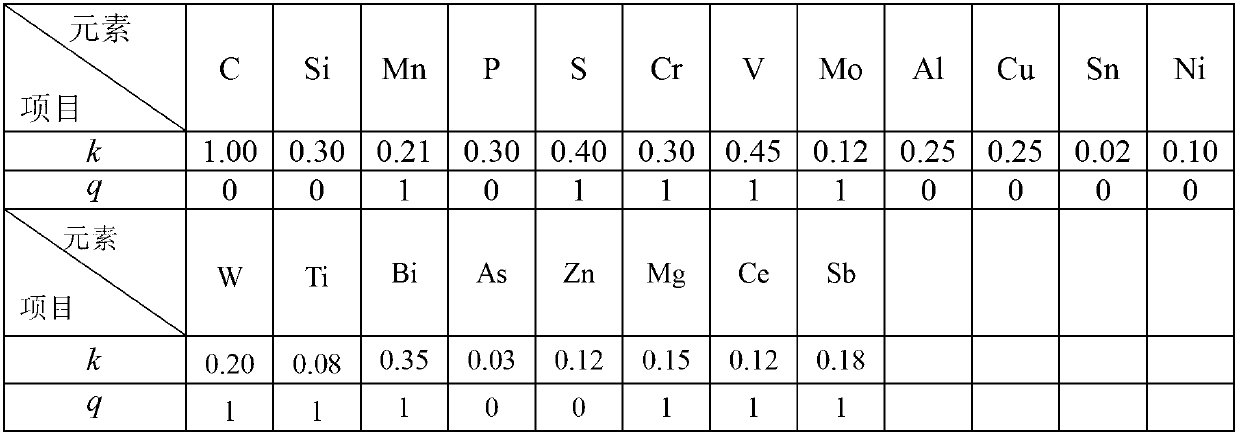

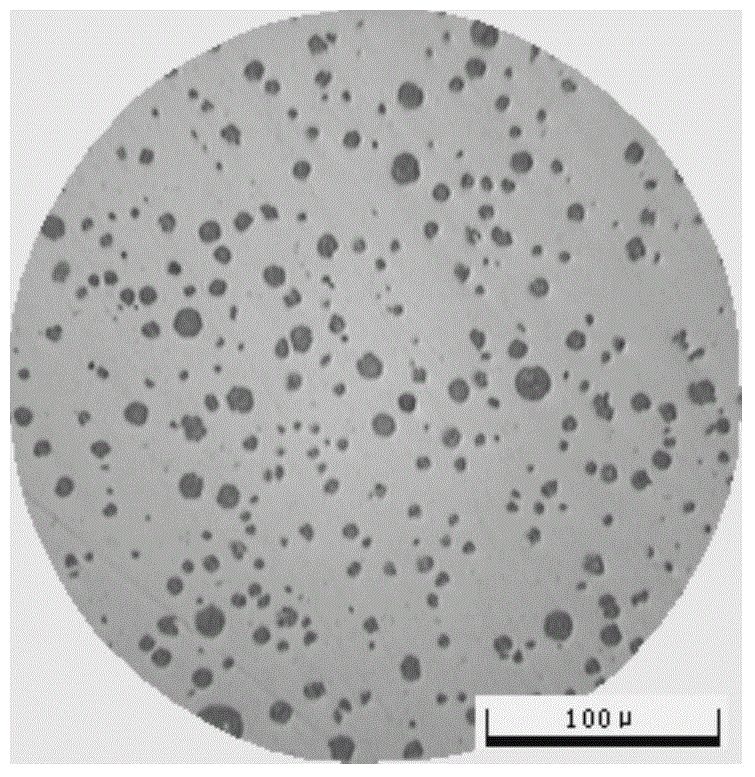

Method for computing accurate value of carbon equivalent of cast iron and application of method

InactiveCN102809538AImprove calculation accuracyEliminate genetic influencesColor/spectral properties measurementsSilicon ironCast iron

The invention discloses a method for computing an accurate value of a carbon equivalent of cast iron and the application of the method and belongs to the technical field of cast iron alloy. According to the invention, influence of carbon, silicon and microelements on the carbon equivalent is taken into simultaneous consideration, the actual carbon equivalent of iron liquid is quickly and accurately calculated by using a mathematical modeling method, errors of theory and practice are obviously reduced, and furnace charge proportion or silicon iron addition can be timely adjusted in the production process, so the carbon equivalent approaches an eutectic point, and the casting performance and casting quality of the cast iron are improved.

Owner:SHANDONG UNIV OF TECH

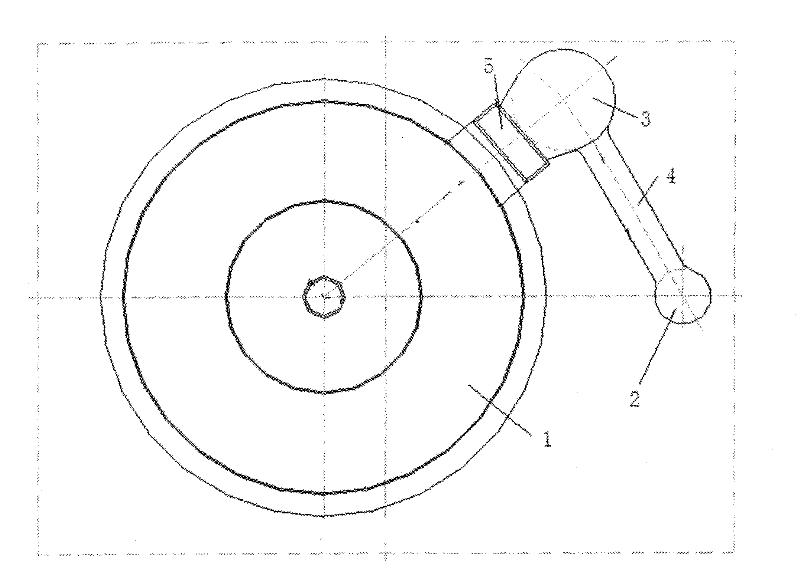

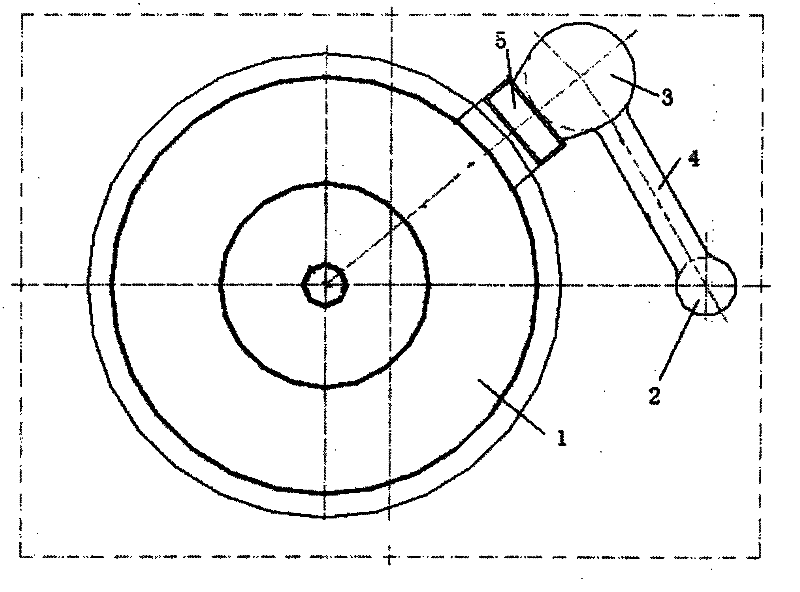

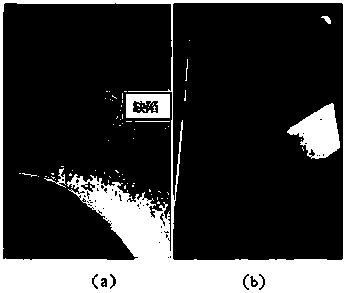

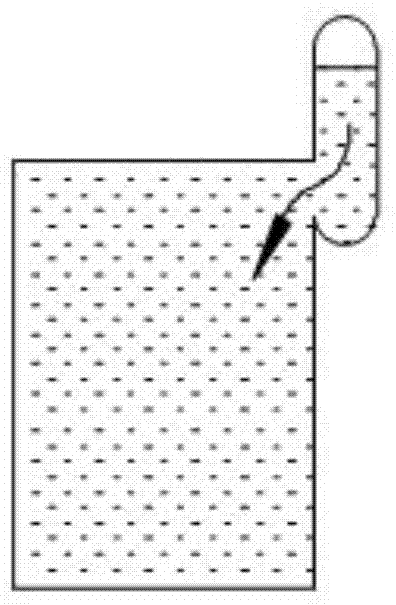

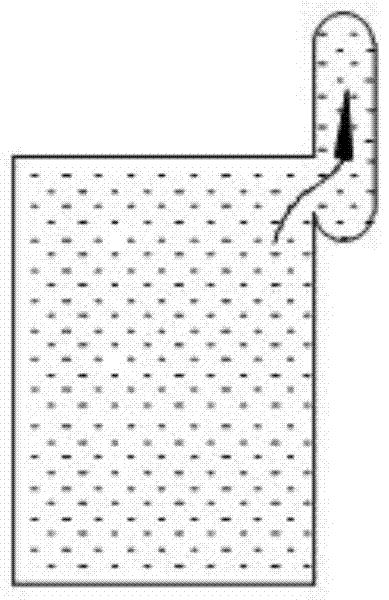

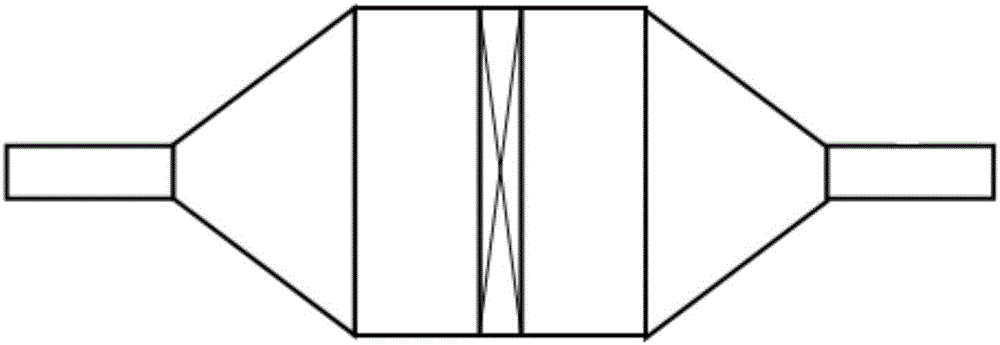

Automobile flywheel pouring system and pouring method

InactiveCN102259164AReduce internal shrinkageReduce shrinkage defectsFoundry mouldsFoundry coresFlywheelHead and neck

The invention provides an automobile flywheel pouring system and a pouring method thereof which can reduce the reject rate of castings and have a smooth surface. The automobile flywheel pouring system of the present invention comprises a sprue cup, a sprue, a runner, a riser with a riser neck, and an ingate; it also includes a riser neck chill, and the riser neck chill is located at below the riser neck. In the pouring system and pouring method for the automobile flywheel of the present invention, the riser neck cold iron is placed at the riser neck, which can not only make full use of the limited amount of liquid iron feeding of the riser, but also make the riser neck solidify in time, and give full play to the ductile ink. The expansion and self-feeding effect of cast iron graphitization greatly reduces the internal shrinkage cavity and shrinkage porosity defects of the flywheel casting, reduces the reject rate of the flywheel from 15% to less than 5%, and greatly improves the process yield.

Owner:湖北丹江口志成铸造股份有限公司

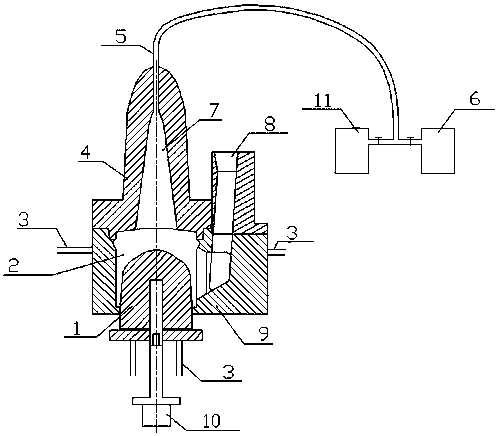

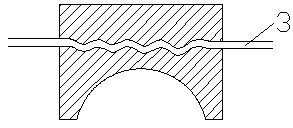

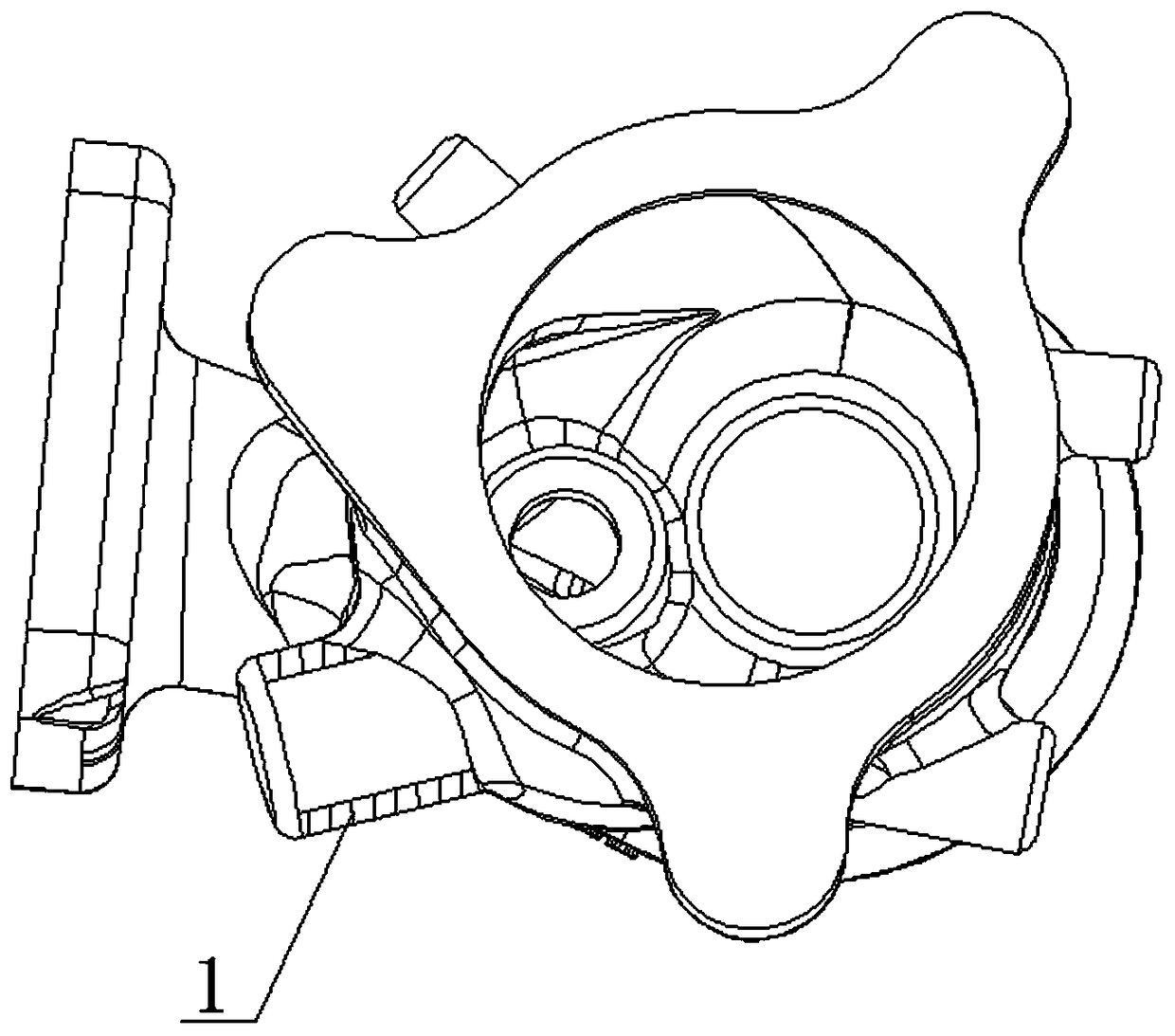

Preparation mold for piston for high-power engine and piston preparation method

ActiveCN108856653ASequential solidification accelerationEnhanced high temperature fatigue resistanceFoundry mouldsFurnace typesWave shapeEngineering

The invention provides a preparation mold for a piston for a high-power engine and a piston preparation method. In the prior art, the problems that the casting defects such as shrinkage porosity of the center of the top of a blank are more, more air hole defects exist on the top of a piston, and the performance difference between the skirt part of the piston and the top of the piston is relativelylarge exist. The provided preparation mold comprises a top mold, a side mold and a core mold, a pressure air channel and a dead head structure are arranged in the top mold, and a cooling water channel is formed in each of the side mold and the core mold; and the preparation mold is characterized in that a pressure adjusting device is connected to the pressure air channel in the mold, the coolingwater channel on the side mold is in a wave shape, and an emitting head of an ultrasonic generator is arranged on the core mold. The problems of shrinkage porosity, the air holes and the poor overallperformance consistency in the prior art are well solved.

Owner:XIAN KANGBO NEW MATERIAL TECH

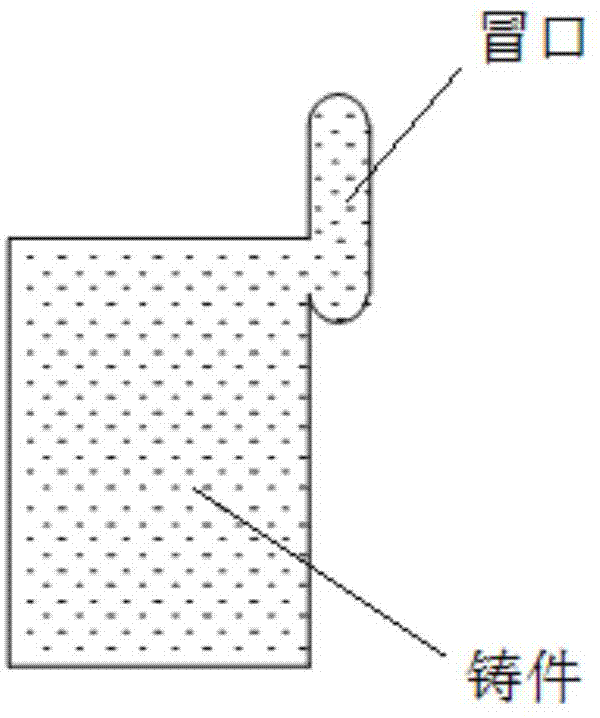

Method for setting riser on casting of ship diesel engine body

ActiveCN103658541APrevent concentrated shrinkageImprove self-feeding capabilityFoundry mouldsFoundry coresSelf compensationEngineering

The invention provides a method for setting a riser on a casting of a ship diesel engine body. The riser is arranged at a central line part between a bottom plate of the casting and a crankshaft, the riser and a riser neck are previously solidified on the casting, and the diameter of the riser and the diameter of the riser neck are calculated according to the modulus of the riser and the modulus of the riser neck. The method solves the problems that as a traditional technology adopts a casting method for compensating contraction by the riser and the riser neck, excessive molten iron is squeezed back to the riser when the casting enters a graphitization expansion period, and although the casting is prevented from a concentrated contracted hole under the gravity action of the molten metal column of the riser when secondary contraction occurs in a solidifying later period, micro contracted loosening among eutectic colonies cannot be overcome. According to the application, the riser and the riser neck are previously solidified on the casting, and pressure is built in the casting through the utilization of all or part of eutectic expansion quantity. The contraction self-compensation capability is improved, and contracted loosening flaws are reduced.

Owner:CSIC NO 12 RES INST

Production method for machine tool guide rail casts

ActiveCN102941316AUnique feeding abilityImprove feeding capacityFoundry mouldsFoundry coresMold fillingSlag

The invention relates to a production method for thick large casts with large plane, in particular to a production method for machine tool guide rail casts. The method is characterized by including the following steps: system pouring, mould manufacturing, core manufacturing, core assembly and pouring. The production method is unique, strengthens feeding capability of the casts in the mold filling and solidification processes, reduces shrinkage porosity shortcomings, reduces slag inclusion shortcoming at the large plane position of the casts, saves production cost, improves production efficiency and improves product quality of the casts.

Owner:KOCEL EQUIP

Method for casting annular thin-wall castings by means of feeding stack box of gating system

ActiveCN106694808AFlexible control quantityCompact distributionFoundry mouldsFoundry coresMaterials scienceThin walled

The invention relates to a method for casting castings, in particular to a method for casting annular thin-wall castings by means of a feeding stack box of a gating system. The method is characterized in that firstly, a mould is designed and manufactured; secondly, a core box containing a detachable cross pouring gate, a detachable feeding pouring gate and a casting mould is manufactured; thirdly, a corresponding lower-form and shrinkproof loam core is manufactured, and the loam core and the feeding pouring gate are manufactured according to the number of the castings; fourthly, the mould is matched, and castings are obtained by pouring molten iron after the mould is matched; and fifthly, the qualified castings are obtained after grinding, cleaning and detecting are completed. According to the pouring method of the annular thin-wall castings, the mould is easy to manufacture, a plurality of parts can be manufactured through one box according to needs, the number of the castings through the box can be flexibly adjusted according to needs, the finally formed castings are good in structure and performance, the probability of the shrinking defect is obviously lowered, the cost is low, and the percent of pass of the products is high.

Owner:JIANGSU FAW FOUNDRY

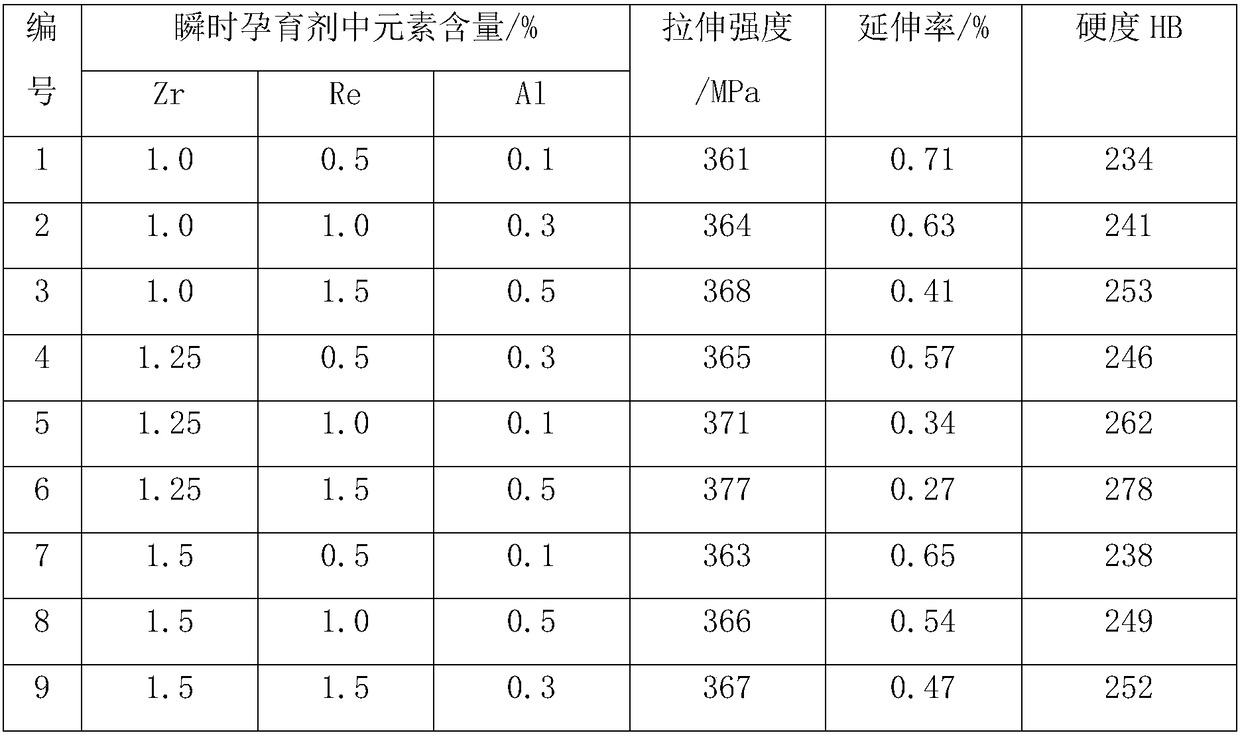

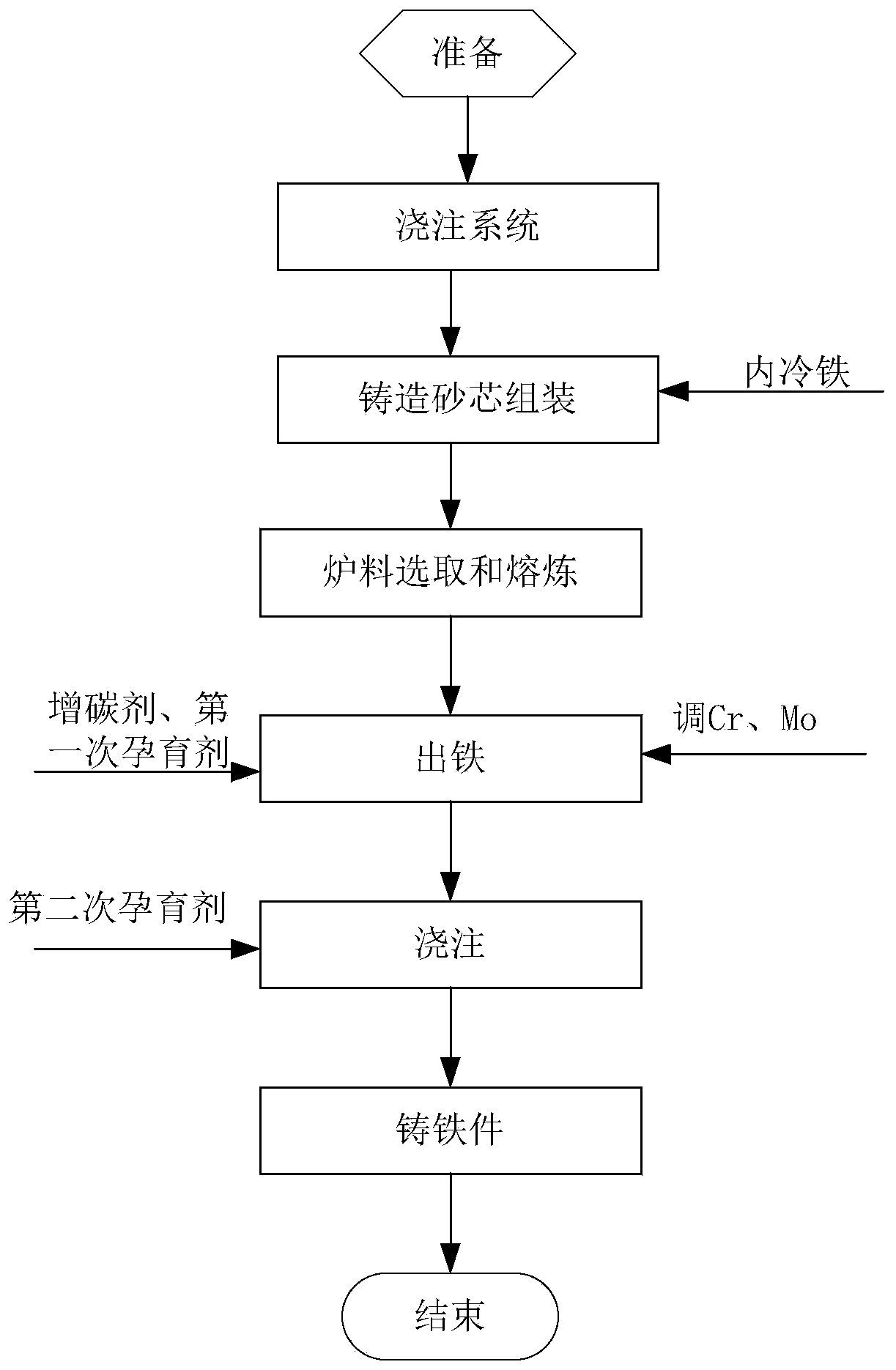

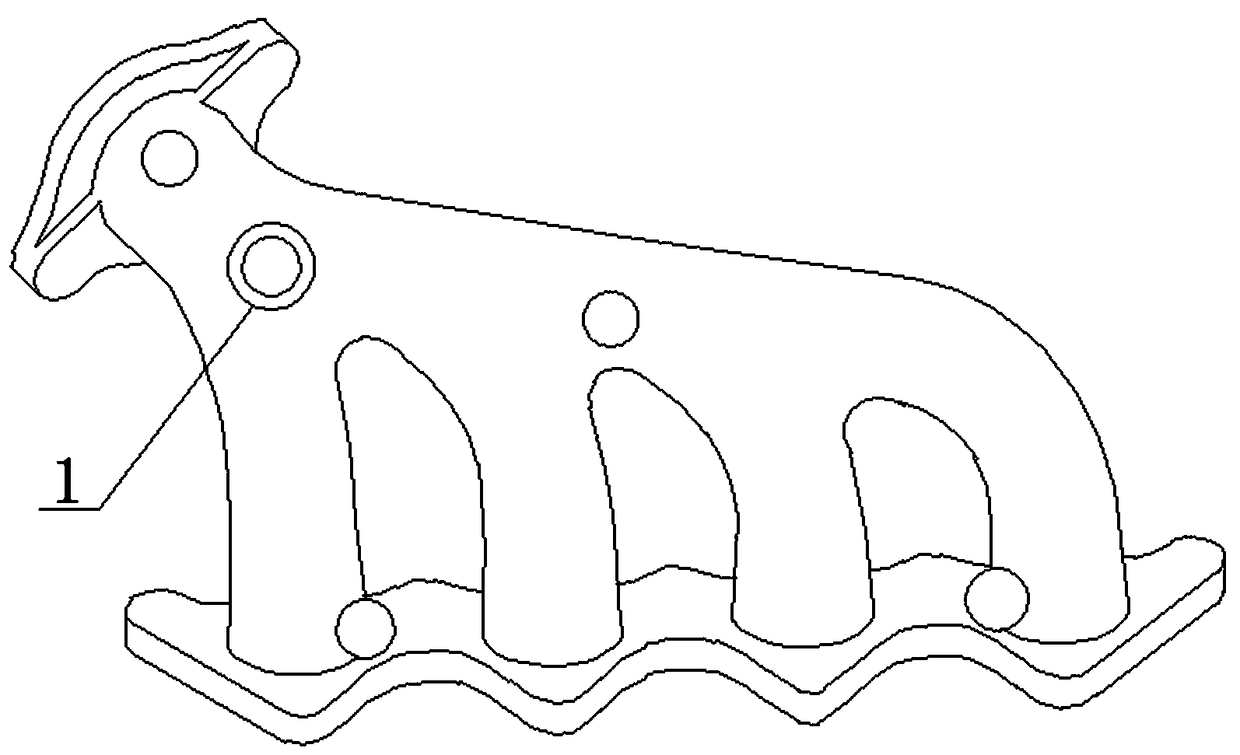

Production technology of multi-alloy cylinder cover

The invention discloses a production technology of a multi-alloy cylinder cover. The production technology comprises the following steps that preparation is conducted, specifically, a stream inoculantincluding 60-65% of Si, 1.0-1.5% of Zr, 0.5-1.5% of Re, 0-0.5% of Al, 2.0-3.0% of Ba and the balance Fe and inevitable impurities is prepared; smelting is conducted, a molten iron raw material is putinto an electric furnace, and machine starting is conducted for melting; a ladle transfer inoculant is added 5-8 min before molten iron is discharged from a trough, and primary inoculation is conducted; and pouring and steam inoculation are conducted, specifically, when the temperature of molten iron is lowered to 1400-1440 DEG C, pouring is conducted for 6 min, secondary inoculation is conductedwhen the stream inoculant is added into the molten iron fluid in the pouring process, cooling is carried out stage by stage, the white cast and shrinkage defects can be decreased through an instant inoculant, the form and distribution situation of graphite in a cylinder cover casting piece are perfected, the strength and hardness of the cylinder cover casting piece are improved, the service lifeis prolonged, and the elongation percentage is reduced.

Owner:宁波力古机械制造有限公司

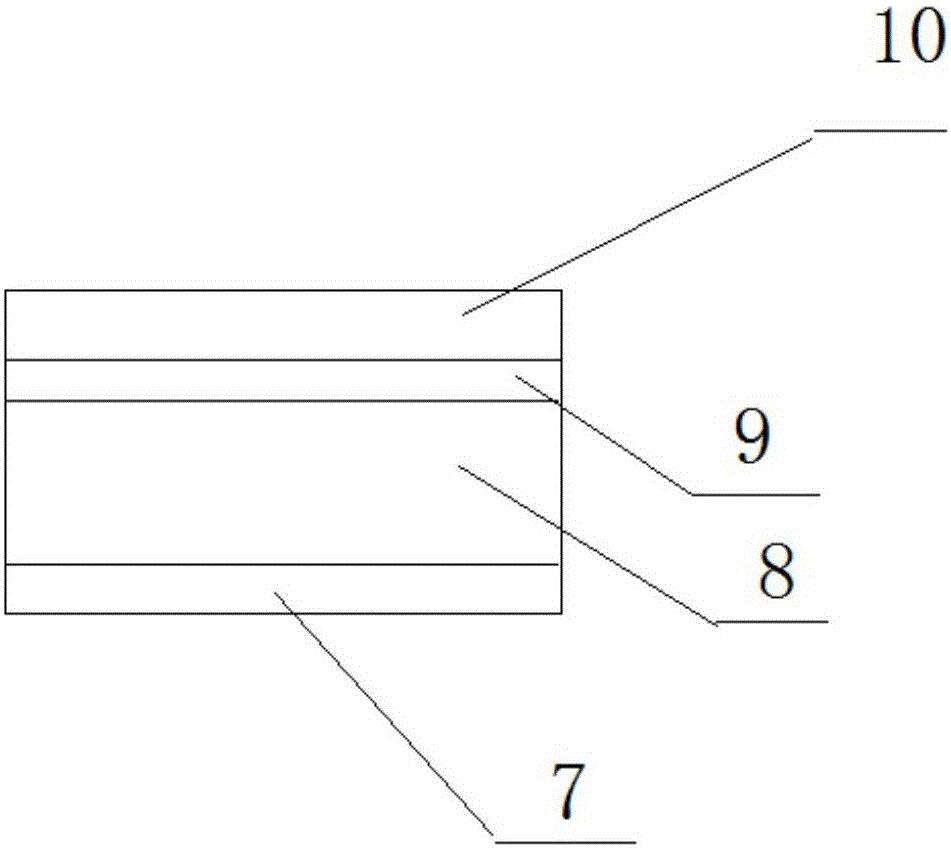

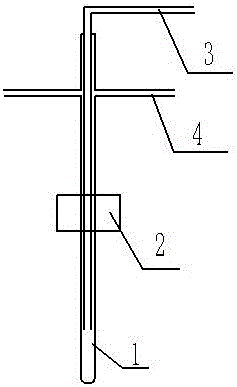

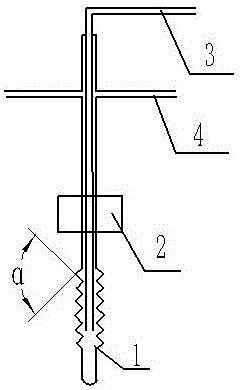

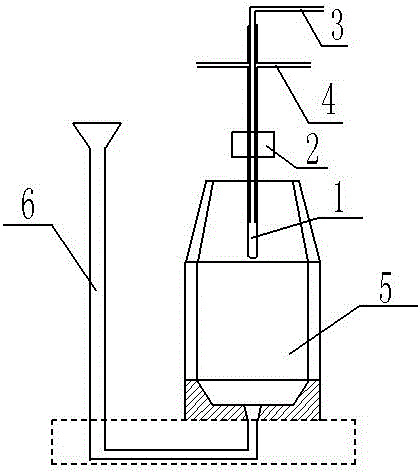

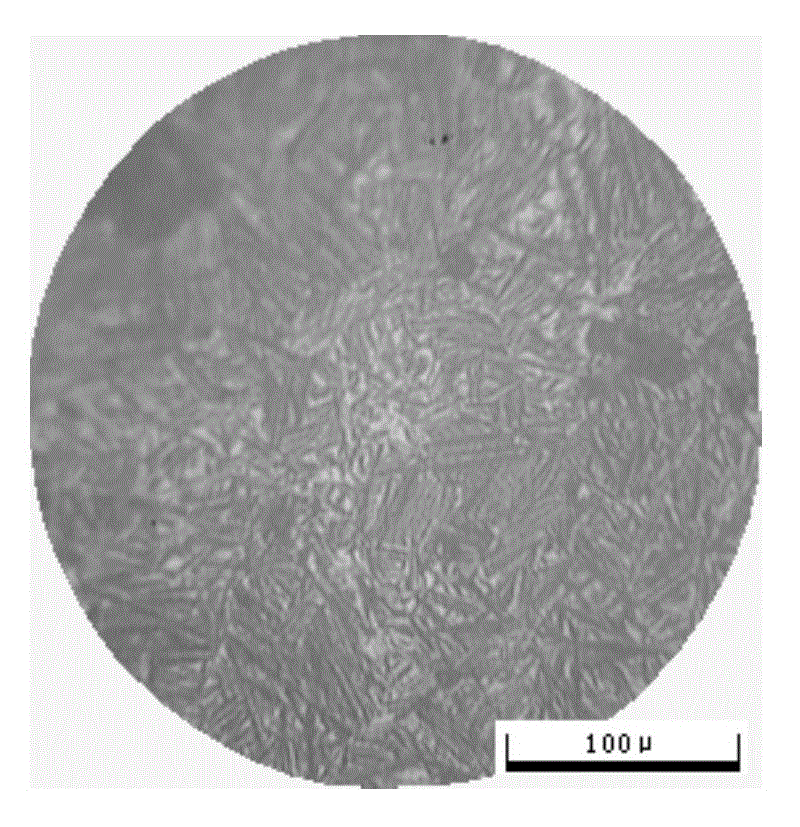

Device for refining grain structure and application method

The invention discloses a device for refining grain structure and an application method, and belongs to the technical field of metallurgy. The device comprises a vibration device inserted in a steel ingot mold; the vibration device includes a vibration rod making direct contact with molten steel; the vibration rod is provided with a vibration generation source for driving the vibration rod to move; an introduction pipe for circulating a cooling medium is arranged in the center of the vibration rod; and discharge pipes for circulating the cooking medium are arranged on two sides of the upper end of the vibration rod. A steel ingot is vibrated in the solidification process to urge fusing and breakage of dendrites; and the number of free cold crystals is increased to inhibit growth of columnar crystals, so that the isometric crystal rate is increased, the solidification structure is refined, and the purpose of relieving segregation is achieved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Casting method of aluminum alloy castings

The invention relates to a casting method of aluminum alloy castings. The casting method of aluminum alloy castings comprises the following steps of firstly, making a cope flask and a drag flask according to the shape of one casting, and carrying out coating treatment on the cope flask and the drag flask; secondly, carrying out mold assembly on the cope flask and the drag flask to form a cavity, and carrying out fastening treatment; thirdly, carrying out vacuum pumping treatment on the cavity; fourthly, filling the cavity with aluminum alloy molten metal with the injection speed ranging from 2m / s to 6m / s; fifthly, increasing the pressure of the cavity to 5 Mpa to 10 Mpa, and carrying out pressure maintaining treatment; sixthly, relieving the pressure of the cavity to the normal pressure after the casting formed in the cavity completely solidifies, separating the cope flask from the drag flask, and taking out the casting, namely, the aluminum alloy casting. The aluminum alloy castings prepared with the preparation method is good in surface quality and low in preparation cost.

Owner:益阳仪纬科技有限公司

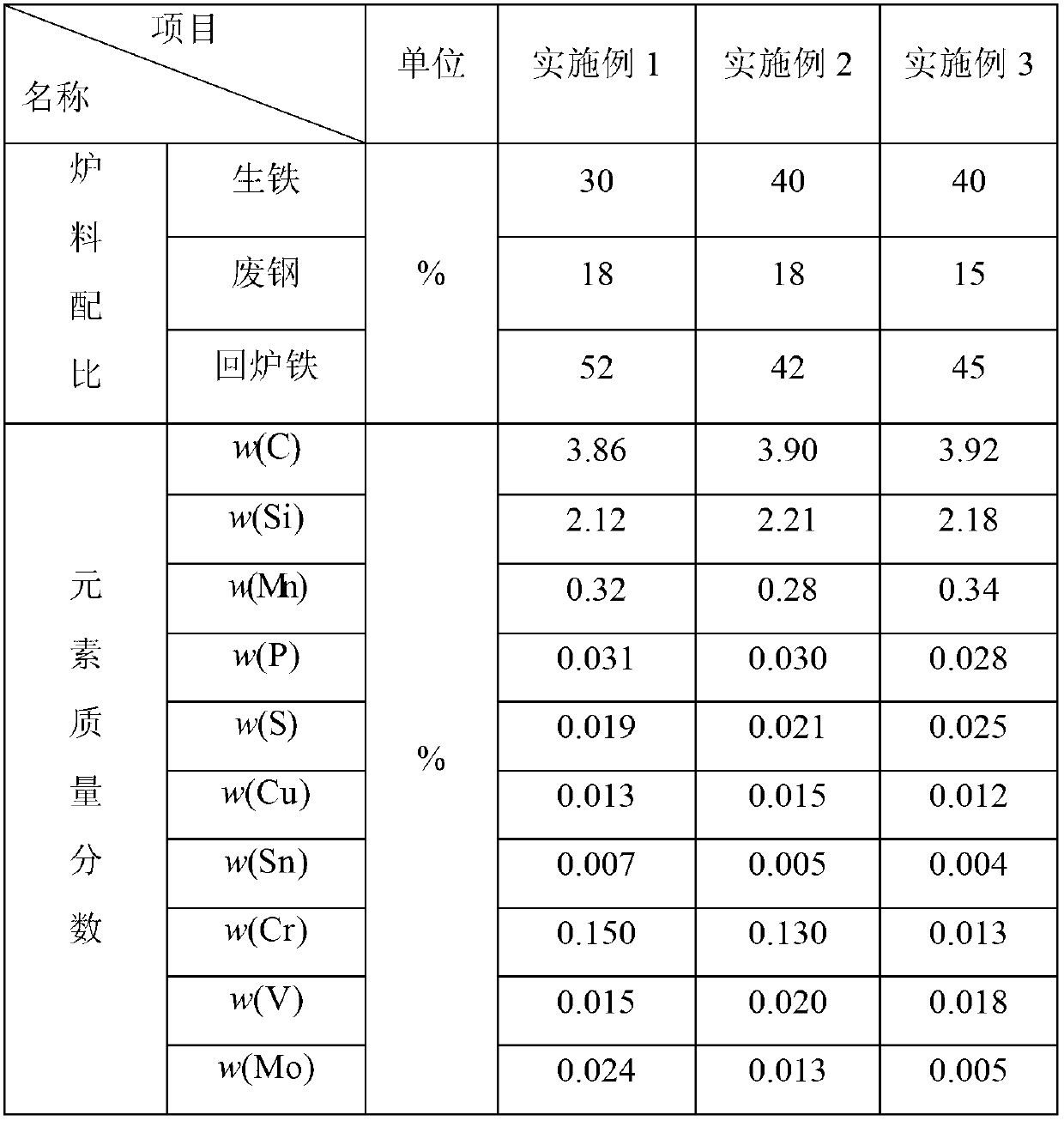

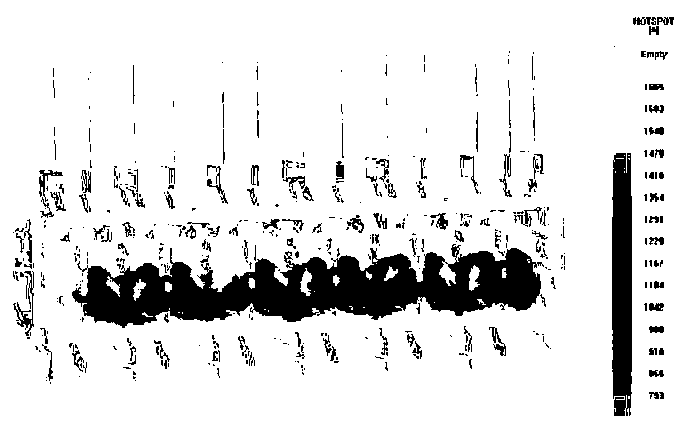

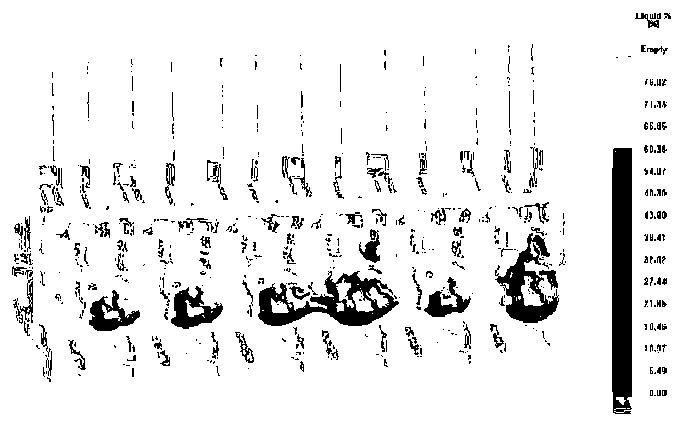

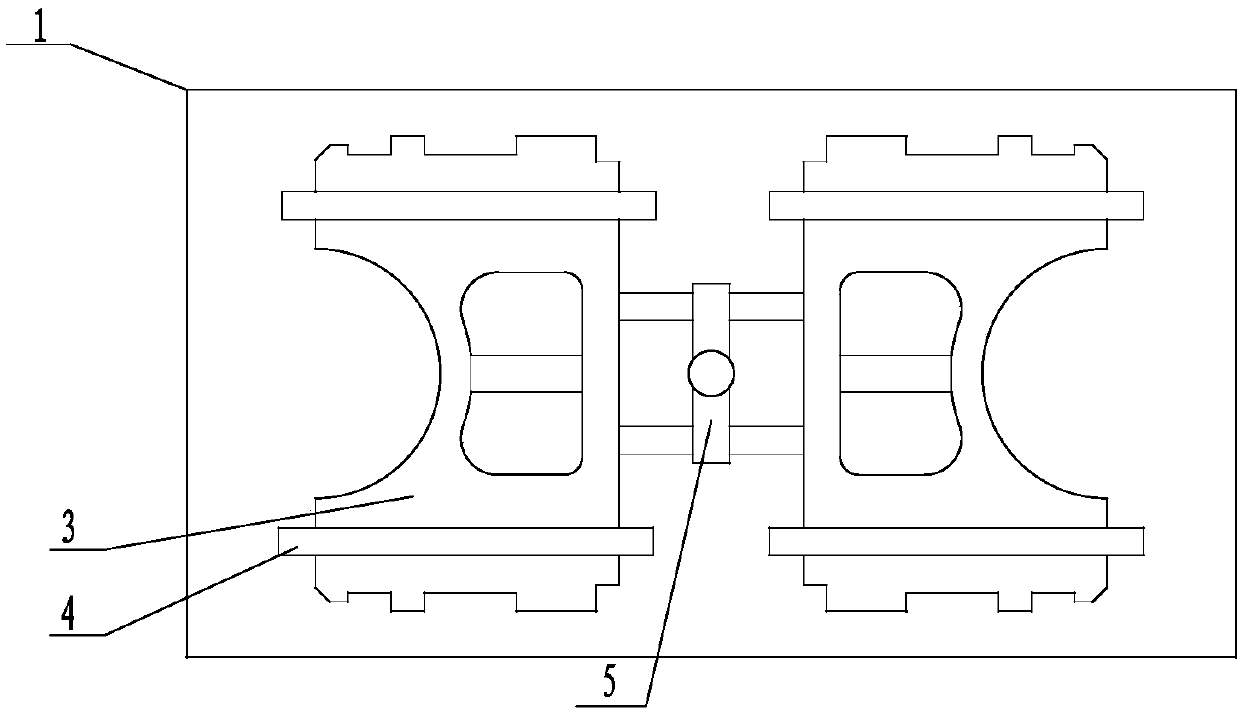

Technological control method for iron casting shrinkage porosity defect

ActiveCN110640088AHigh strengthShrinkage leakage waste rateFoundry mouldsFoundry coresEngineeringShrinkage porosity

The invention belongs to the technical fields of novel materials and casting and discloses a technological control method for an iron casting shrinkage porosity defect. According to the technologicalcontrol method for the iron casting shrinkage porosity defect, combination of vertical type pouring and stair pouring and a pouring system with a flat gate and position of the flat gate away from an isolated hot phase area are adopted; internal chill is placed in sand core assembling; steel scrap and recirculated iron are adopted and smelted at a high temperature according to the proportion of furnace burden; in the tapping process, a carburant and a first-time nucleating agent are added with the flow, and the content of alloy elements such as chromium and molybdenum is adjusted; and a second-time nucleating agent is added with the flow in the pouring process. According to the technological control method for the iron casting shrinkage porosity defect, higher strength is acquired by castings; and meanwhile, shrinkage porosity tendency of an area with shrinkage mending difficulty is controlled to be at a lower level, it is achieved that shrinkage porosity of complex-structure castings and the rejection rate caused by pore defects are lowered synchronously, and the shrinkage porosity leakage rejection rate is below 1%.

Owner:DEUTZ DALIAN ENGINE +1

Casting process for bolt hole of large-scale ductile iron main bearing cover casting process

The invention is mainly applied to the technical field of casting of the diesel engine bearing cover, in particular to a casting process for a bolt hole of a large-scale ductile iron main bearing cover. The casting process is characterized by comprising the steps that 1, a corundum mullite ceramic tube is selected; 2, a ceramic tube fixing core head is arranged, and resin sand is used for molding;3, the casting sand mold is coated with coatings and then is dried; 4, resin sand is filled in the middle of the dried ceramic tube; 5, the outer wall of the filled ceramic tube is coated with an alcohol-based fire-resistant coating and then is aired after being ignited; 6, the coated casting sand mold and the aired ceramic tube are dried again, and the dried ceramic tube is placed in the ceramictube fixing core head; and 7, mold assembling, pouring and cleaning are carried out. According to the casting process, the defects of using a sand core and a cast steel tube process such as penetration, deformation, blowholes, hard spots and the like are overcome; meanwhile, the operation of workers is simple, multiple pieces can be manufactured at the same time, the production efficiency is greatly improved, and the production cost of manufacturing a core box is also saved; and the ceramic tube has the advantages that the strength can be high, sand sticking and penetration can be prevented,and the defects of porosity and shrinkage can be overcome.

Owner:ZICHAI POWER CO LTD

Method for preparing ADI nodular cast iron capable of resisting impact of low temperature of 40 DEG C below zero

InactiveCN104805350AImprove mechanical propertiesEvenly distributedProcess efficiency improvementManganeseDuctile iron

A method for preparing an ADI nodular cast iron capable of resisting the impact of a low temperature of 40 DEG C below zero relates to a method for preparing a low-temperature-resistant ADI ductile iron, and solves the technical problem that the impact energy of a conventional ADI ductile iron 900 / 650 / 09 in a high-cold environment is relatively low. The method comprises the following steps: firstly, melting ductile cast iron Q10, low-manganese steel scrap and returns and a proper amount of nickel plates and then adding nickel plates and sheet copper for smelting so as to obtain an iron liquid; secondly, performing spheroidization and inoculation treatment; thirdly, adding a desulfurization agent; fourthly, casting to obtain a sample; fifthly, preserving heat of the sample twice, then placing the sample into a nitrate medium, and discharging to obtain the ADI nodular cast iron. The ADI nodular cast iron has the yield strength of 660-690 MPa, the tensile strength of 910-950 MPa and the elongation of 9-11%, and the unnotched impact value of the ADI nodular cast iron prepared at the temperature of 40 DEG C below zero is 105-120 J. The method is applied to the field of nodular cast iron preparation.

Owner:齐齐哈尔市精铸良铸造有限责任公司

Method for improving internal quality of cast ingot and heating insulation box

The invention relates to the technical field of ferrous metallurgy, and discloses a method for improving the internal quality of a cast ingot and a heating insulation box. The method comprises the following steps that (1) a baked steel ingot mold, a riser brick and a sprue brick are sequentially placed in the heating insulation box from bottom to top, the steel ingot mold and the riser brick are heated to 600-800 DEG C, then heating is stopped, and heat preservation is conducted; (2) molten steel obtained after smelting is poured into the steel ingot mold; in the pouring process, the pouring speed is controlled in a segmented mode; and after the molten steel is completely poured, the amount of the molten steel in a riser is 10-30 wt% of the weight of the cast ingot; and (3) cooling is conducted after pouring is completed, and demolding is conducted after the molten steel is solidified in the steel ingot mold. According to the method and the heating insulation box, the steel ingot mold and the riser brick are heated to the proper temperature before pouring, then the pouring speed is controlled in the segmented mode, the amount of the molten steel in the riser is controlled, and the problems of internal defects such as shrinkage cavities, looseness and segregation generated by the steel ingot during pouring through an upper pouring method are solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

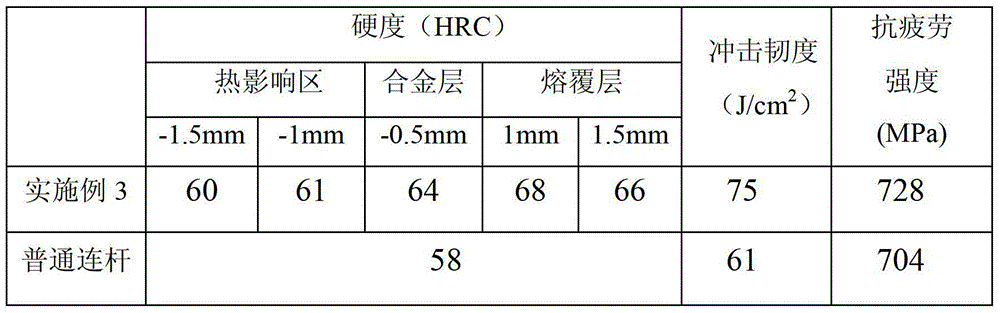

Special nickel-base metal ceramic alloy powder for connecting rod laser cladding

InactiveCN103334103AHigh hardnessEnsure toughness and strengthMetallic material coating processesManganeseAlloy

The invention discloses a special nickel-base metal ceramic alloy powder for connecting rod laser cladding, which comprises the following components in percentage by weight: 10-12% of titanium carbide, 0.8-1.4% of carbon, 2-4% of calcium fluoride, 2-4% of silicon nitride, 9-12% of germanium, 18-24% of chromium, 2-4% of silicon, 5-7% of iron, 5-8% of molybdenum, 0.1-0.4% of manganese and the balance of nickel. The nickel-base metal ceramic alloy powder is specially used for connecting rod laser cladding, and can form a cladding layer on the connecting rod surface by a laser cladding technique. The nickel-base metal ceramic alloy powder can reduce bubbles, cracks and shrinkage void defects on the cladding layer, and enhances the fatigue resistance, toughness and hardness of the connecting rod.

Owner:张家港和昊管理咨询有限公司

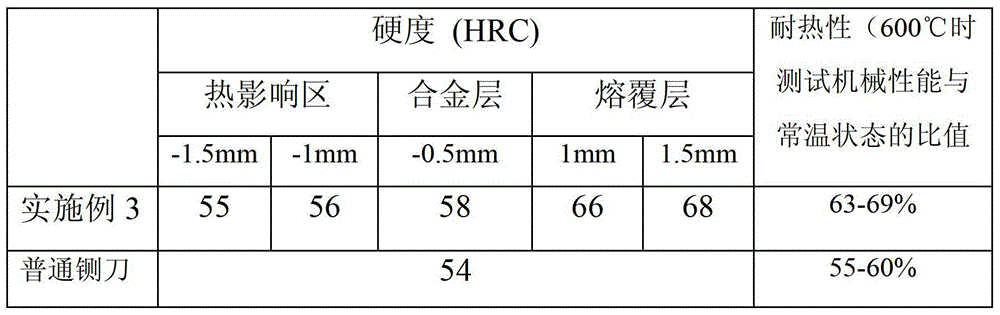

Special cobalt-base metal ceramic alloy powder for guillotine laser cladding

The invention discloses a special cobalt-base metal ceramic alloy powder for guillotine laser cladding, which comprises the following components in percentage by weight: 11-13% of titanium carbide, 0.1-0.4% of carbon, 4-6% of calcium fluoride, 1-3% of silicon nitride, 6-9% of iron, 5-7% of chromium, 2-4% of zirconium, 1-3% of vanadium, 2-4% of silicon, 0.8-1.2% of manganese and the balance of Co. The cobalt-base metal ceramic alloy powder is specially used for guillotine laser cladding, reduces bubbles, cracks and shrinkage void defects on the cladding layer, and enhances the hardness, strength and shock resistance of the guillotine.

Owner:张家港和昊管理咨询有限公司

Sand mold casting method

InactiveCN110834069AHigh mechanical strengthUnbreakableFoundry mouldsMould handling/dressing devicesMold fillingSlag

The invention discloses a sand mold casting method, and belongs to the technical field of metal material casting. The sand mold casting method comprises the following steps that S1, a mold is manufactured and made of non-magnetic materials; S2, in parts by weight, 100 parts of metal sand and 2-4 parts of a water glass binder are evenly mixed to prepare molding sand; S3, the mold is placed in a sand box, then the molding sand is filled until the sand box is full, and thus a casting mold is formed; S4, a sprue and a riser are formed, and the box is closed; S5, the sand box is heated; and S6, metal liquid is injected into the casting mold, and after the metal liquid is solidified to form a casting, shakeout and shot blasting treatment are conducted. According to the sand mold casting method,the metal sand casting mold and inclined pouring are adopted, a mold cavity is high in stability, mold filling is stable, generation of slag inclusion can be reduced, casting mold exhaust is facilitated, the defect of air holes is overcome, and mechanical properties of the casting are high.

Owner:湖北谷城锐丰机械有限公司

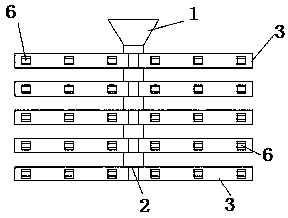

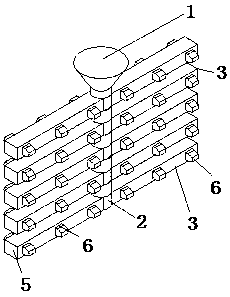

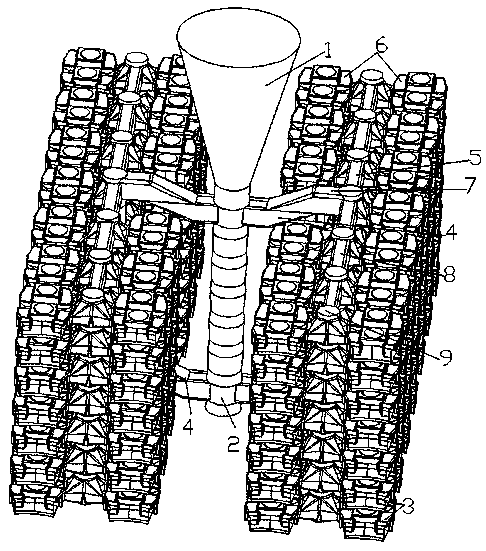

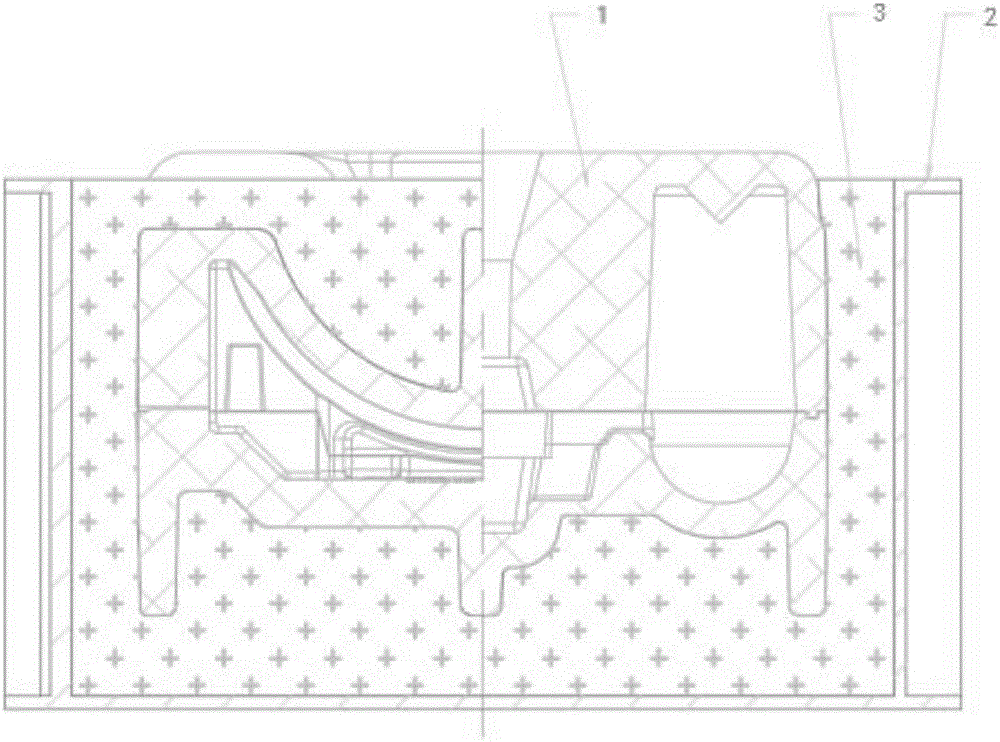

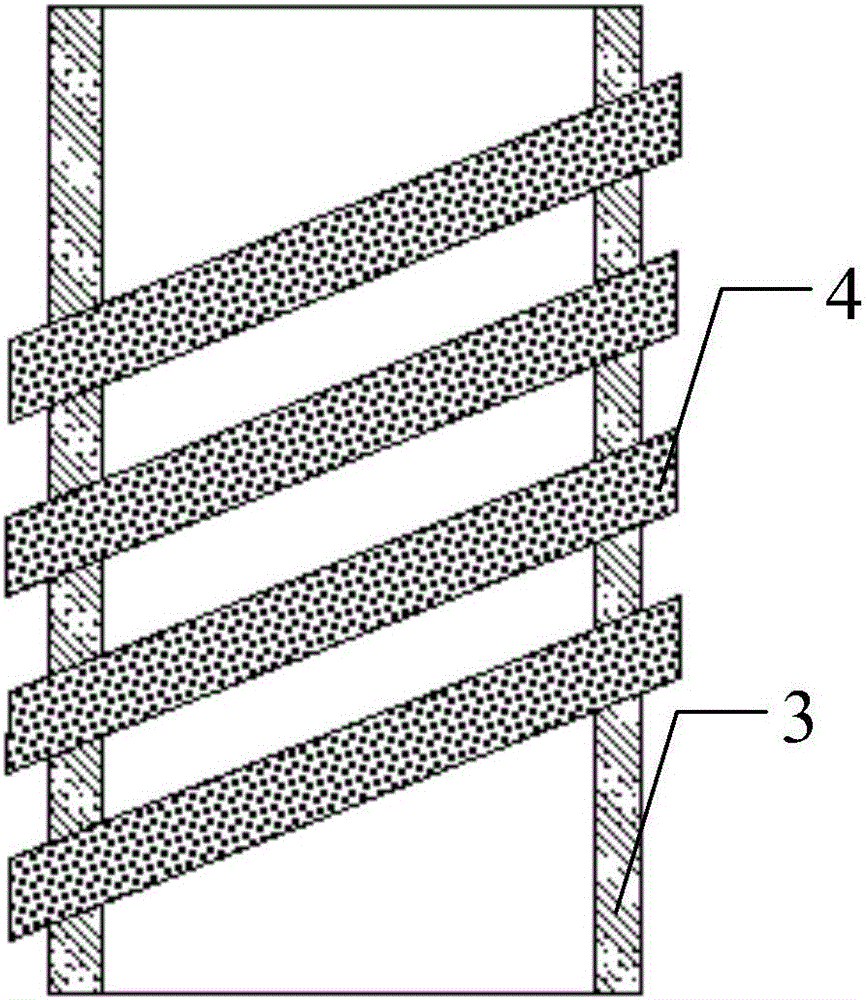

Casting device and method for precoated sand stacking type product

ActiveCN110340299AAvoid cold barrier defectsImprove production efficiencyFoundry mouldsFoundry coresCasting

The invention discloses a casting device and method for a precoated sand stacking type product. The casting device comprises a casting frame; the casting frame comprises a sprue cup, a straight pouring gate and a plurality of parallel casting layers; the sprue cup is arranged on the top of the casting frame; the straight pouring gate communicates with the sprue cup; at least a flow dividing transverse pouring gate located on the bottommost layer is included, and the flow dividing transverse pouring gate forms a flow guiding segment; during casting, the flow guiding segment is used for guidingcasting liquid at the bottommost layer to flow to an upper casting layer; the two sides of the flow guiding segment are correspondingly connected with the straight pouring gate and the transverse pouring gate; the transverse pouring gate forms the plurality of casting layers; each casting layer is provided with a plurality of inner sprues, and each inner sprue is connected with a to-be-cast casting; and the height of the casting frame is 800-1000 mm. The casting device makes casting start from the bottommost layer, the casting efficiency is improved, meanwhile, due to the casting manner, the flowing direction of molten iron is controllable, and cold insulating defects are reduced.

Owner:西安合力汽车配件有限公司

Coated sand shell mould and steel-coated sand solidification casting process

InactiveCN106807888AImprove the cooling environmentGood air permeabilityFoundry mouldsFoundry coresCasting defectCooling speed

The invention belongs to the field of casting and particularly relates to a coated sand shell mould and steel-coated sand solidification casting process. The casting process includes molding material preparation, molding, core making, metal smelting, pouring, solidification control and other technologies. The invention aims to make innovation on the aspects of molding and solidification control so that a casting can be superior to a casting tissue produced regularly. The casting process is characterized in that two types of materials are adopted for a molding process for compound molding, the two types of materials comprise surface sand and floor sand, and the surface sand and the floor sand are of different heat conductivity coefficients. Coated sand is selected as the surface sand, the consumption of the coated sand is reduced, and casting surface quality is improved; steel sand is adopted for the floor sand, the used sand regeneration cost is lowered, more importantly, the steel sand is served as conformal indirect cold iron, the casting modulus is lowered, and casting defects are reduced; and the two molding materials of different heat conductivity coefficients are matched, and the cooling speed is controlled to obtain the uniform casting tissue. The process is high in production flexibility, good in applicability and low in cost.

Owner:山东汇金股份有限公司

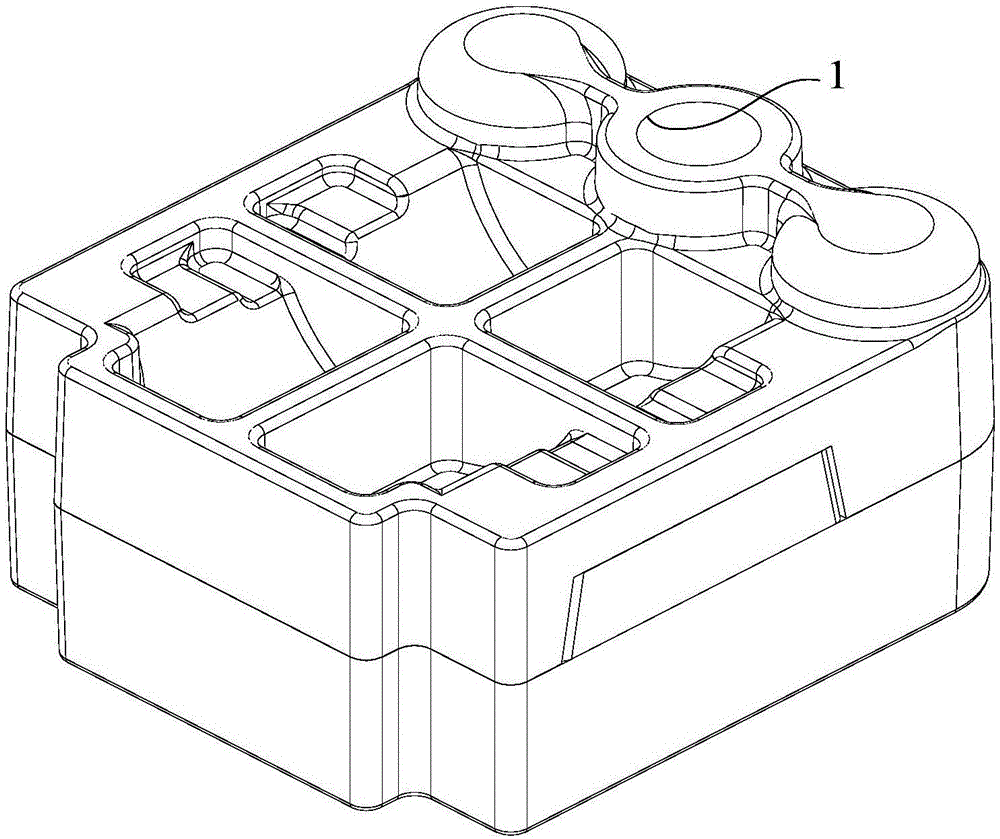

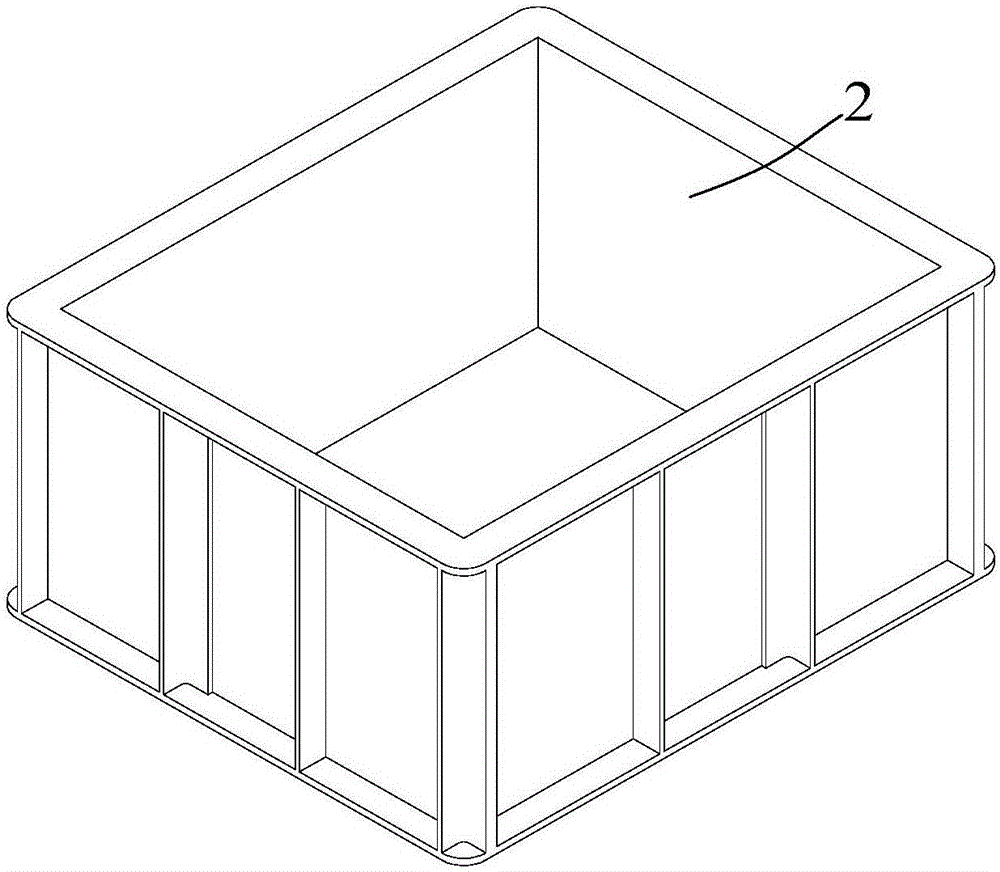

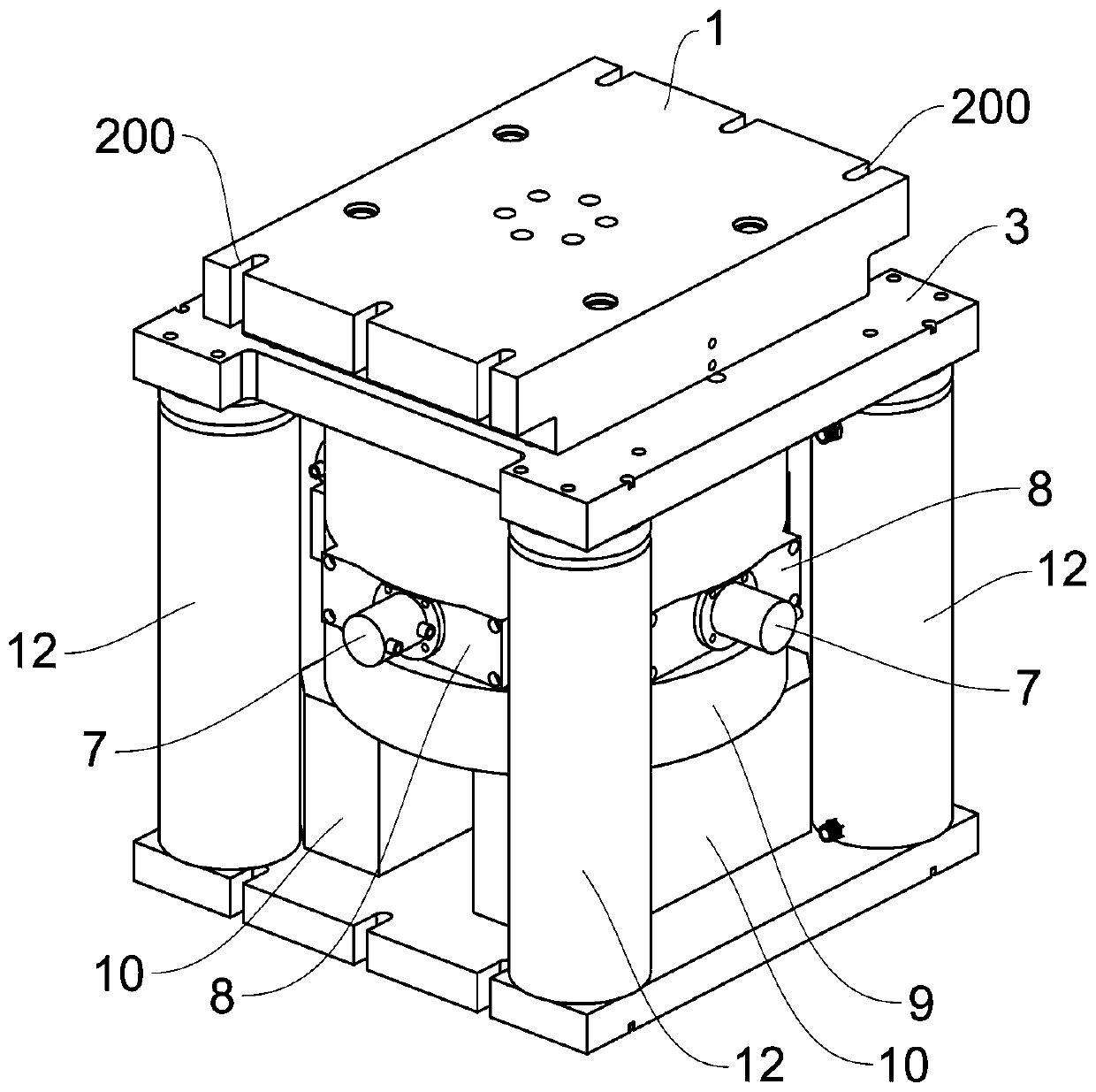

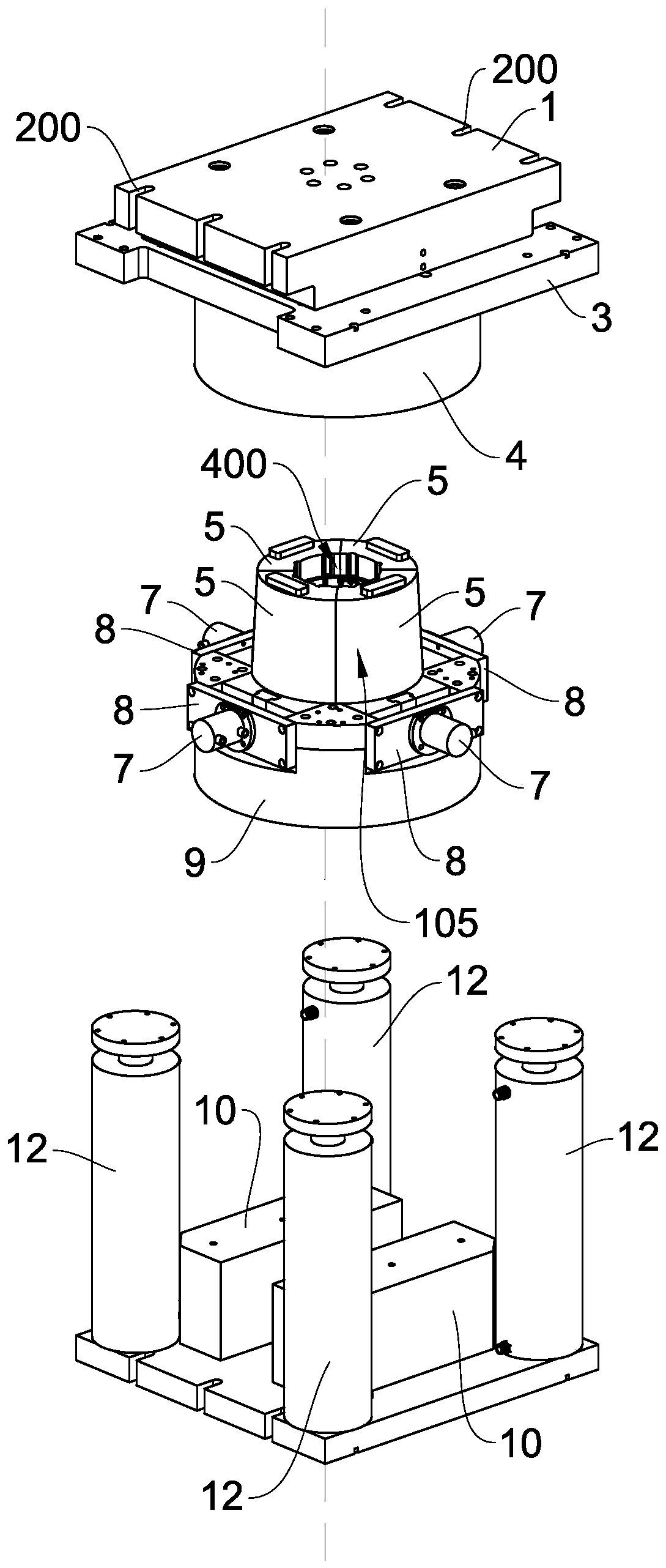

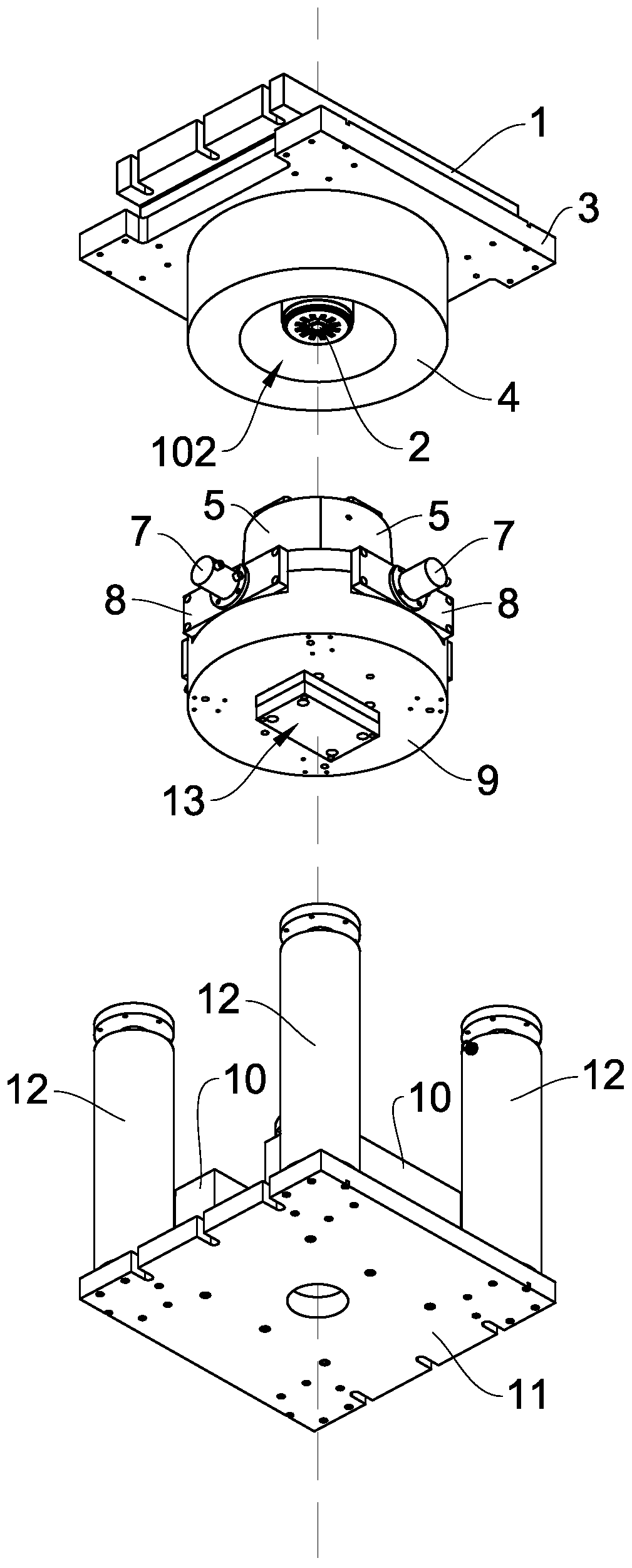

Production method of new energy automobile motor aluminum shell

ActiveCN110328348AImprove air tightnessAvoid crackingManufacturing dynamo-electric machinesNew energyNinetieth percentile

The invention relates to a production method of a new energy automobile motor aluminum shell. In the method, the following hardware devices are included: an outer shell die device, an inner shell diedevice and an end cover die device, wherein the outer shell die device and the inner shell die device are composed of a punch fixing plate, a punch, an upper die plate, a locking block, sliding blocks, a die core, core-pulling oil cylinders, a die frame, a die foots, a lower die plate, upright cylinders and the like; and the end cover die device is composed of a second upper die plate, an upper die frame, an upper die core, a lower die core, a lower die frame, a second die foot, a second lower die plate, a second sliding block, a second locking block, a second core-pulling oil cylinder, a locking block oil cylinder and the like. A motor aluminum outer shell, a motor aluminum inner shell and a motor aluminum end cover are obtained through a production process flow of raw material preparation, feeding, forging and pressure maintaining, and product forming. According to the production method, the production efficiency of the motor aluminum shell can be obviously improved, the yield reaches 95% or more, the energy consumption of casting is greatly reduced, the defects of pores and shrinkage few occur in the motor aluminum shell, the structure is compact, no crack is generated, the mechanical performance is good, and the stability is good.

Owner:广东银迪压铸有限公司

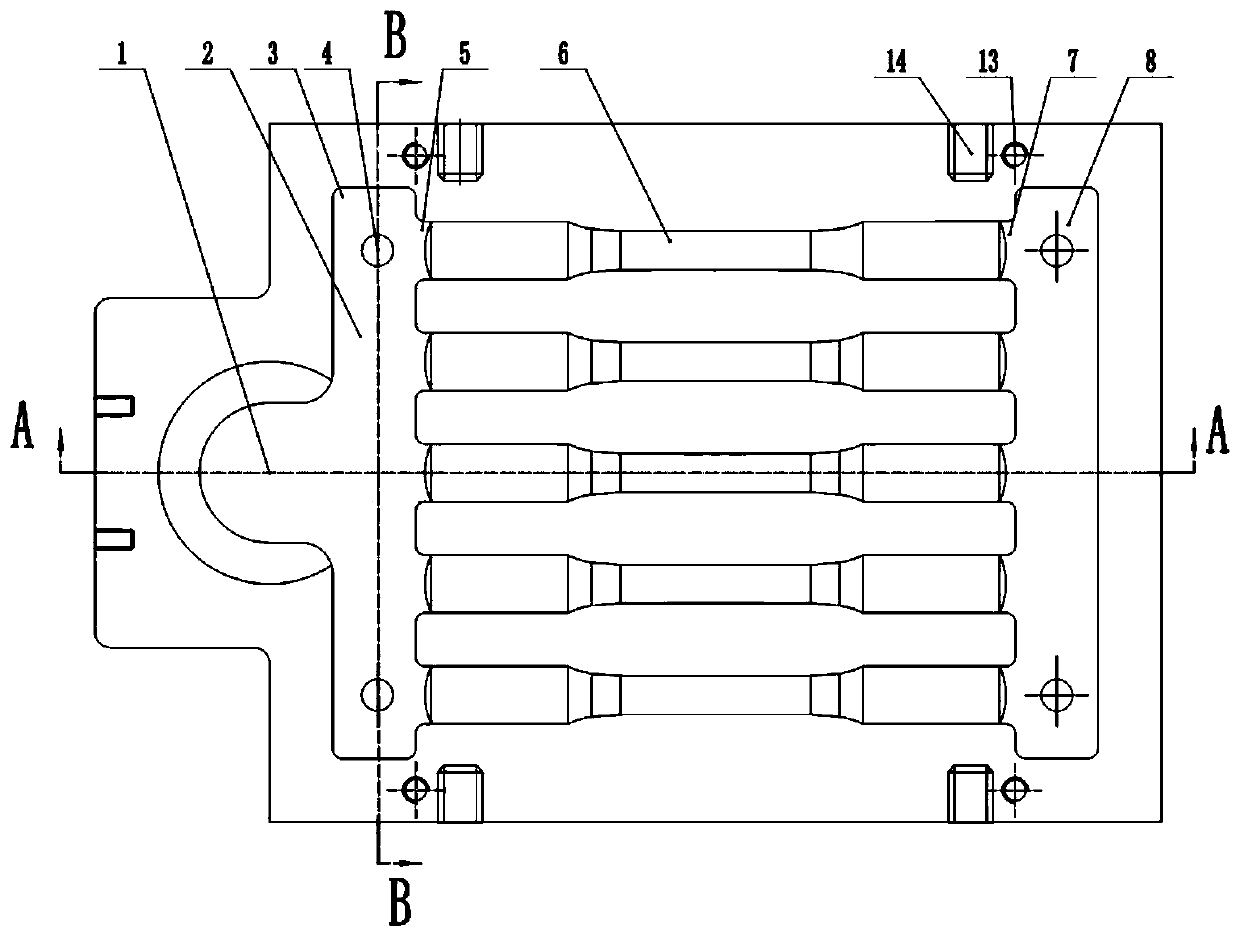

Novel multi-tension-testing-rod mould

InactiveCN110625072AImprove work efficiencyReduce entryFoundry mouldsFoundry coresSlagMaterials science

The invention discloses a novel multi-tension-testing-rod mould. The mould comprises an upper mould and a lower mould; the upper mould and the lower mould are positioned through a positioning pin andare precisely assembled; one end in the mould is provided with a pouring opening; one side of the pouring opening communicates with a horizontal runner; two axial ends of the horizontal runner are provided with slag collection blind passages; n cavities are sequentially formed in the other side of the horizontal runner in the vertical direction, and n is larger than or equal to 2; one end of eachcavity communicates to the horizontal runner through a direct runner, and the other end communicates with a feeding head through a feeding passage; and the horizontal runner, the direct runners, the cavities, the feeding passages and the feeding head are symmetrically distributed about a contact surface of the upper mould and the lower mould. By adopting the novel multi-tension-testing-rod mould,multiple tension testing rods can be poured at one step; working efficiency is improved, and operation is simple; defects of slag inclusion and pores in the tension testing rods are reduced through arrangement of the slag collection blind passages; two ends of the testing rods can be fed sufficiently through the horizontal runner and the feeding head; very good smoothness of end surfaces is ensured; the defect of shrinkage porosity is lowered; and the yield and mechanical performance of the tension testing rods are improved.

Owner:河北立中有色金属集团有限公司

Method for solving shrinkage of die-casting piece

InactiveCN101758187AReduce shrinkage defectsMolten metal pouring equipmentsMolten metal conveying equipmentsDie castingImproved method

The invention relates to an aluminium alloy die-casting improvement method, in particular to a method for solving shrinkage of the die-casting piece; the methods of reducing pouring temperature, improving the die-casting piece structure, increasing specific pressure, setting an alloy overflow groove, improving pressure chamber fullness degree and improving a running gate system are adopted, so as to effectively improve the shrinkage defect generation of the aluminium alloy die-casting piece.

Owner:WUJIANG TIANLONG MACHINERY

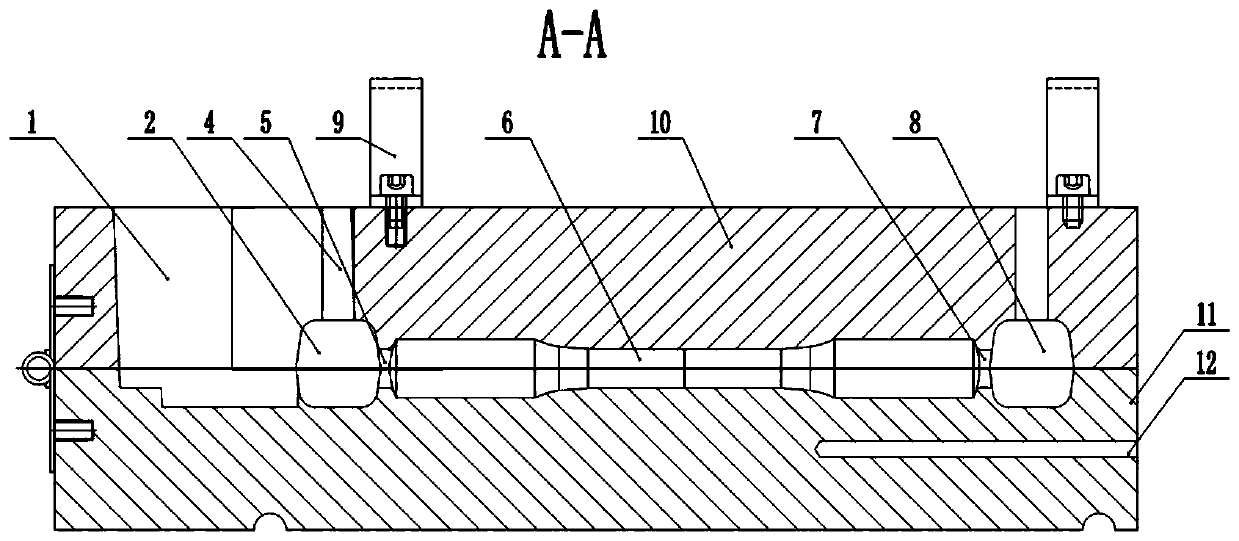

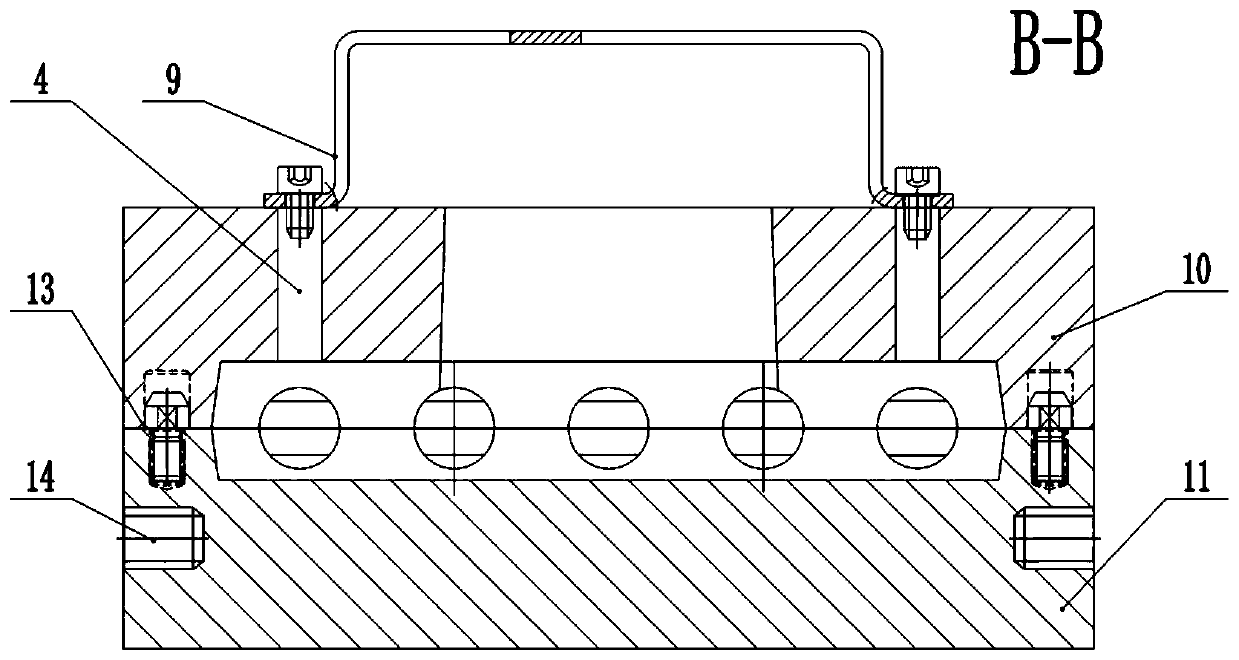

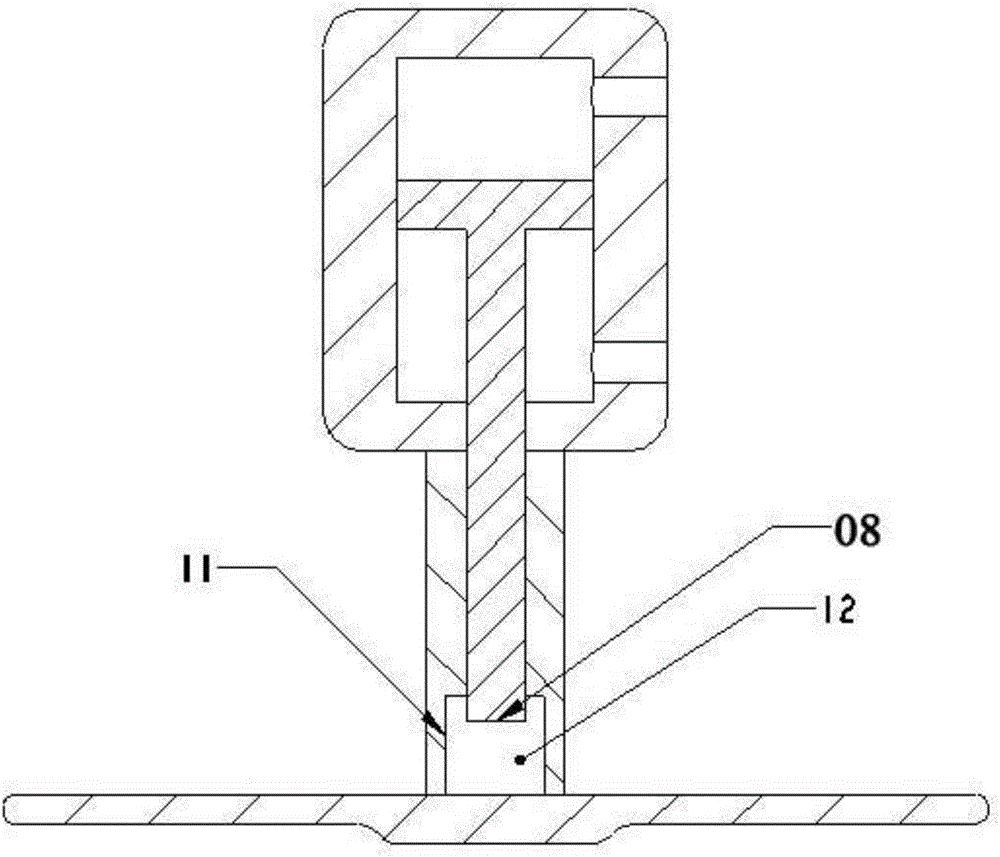

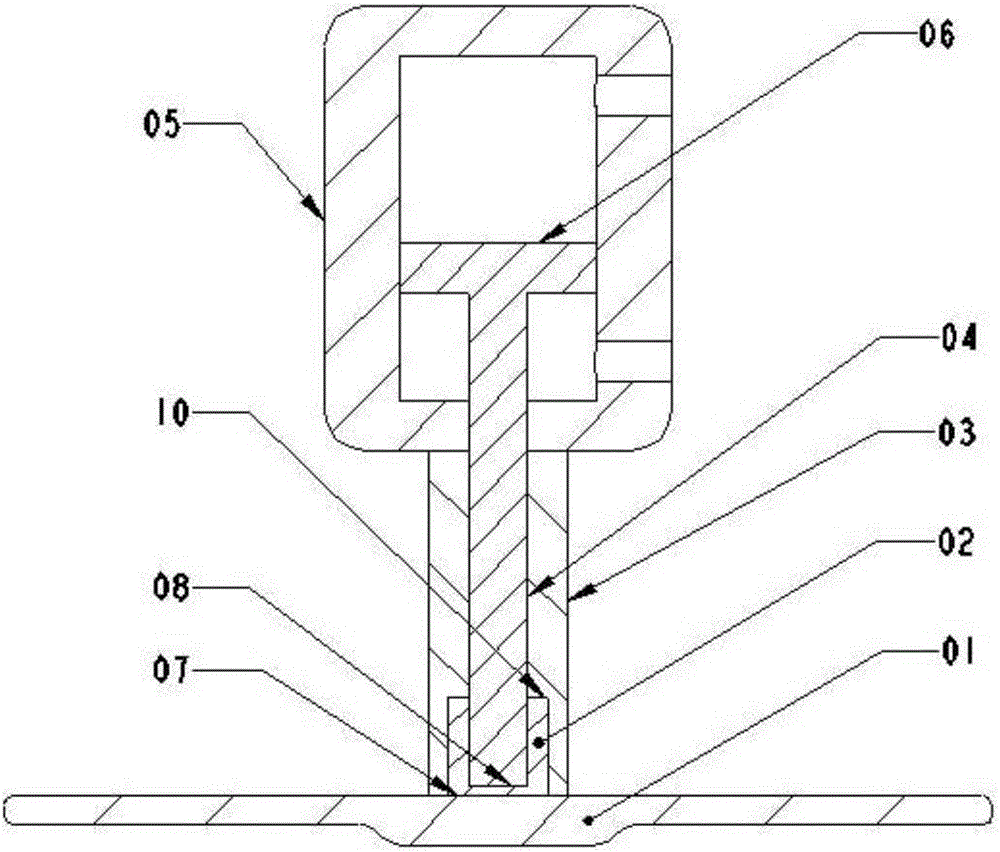

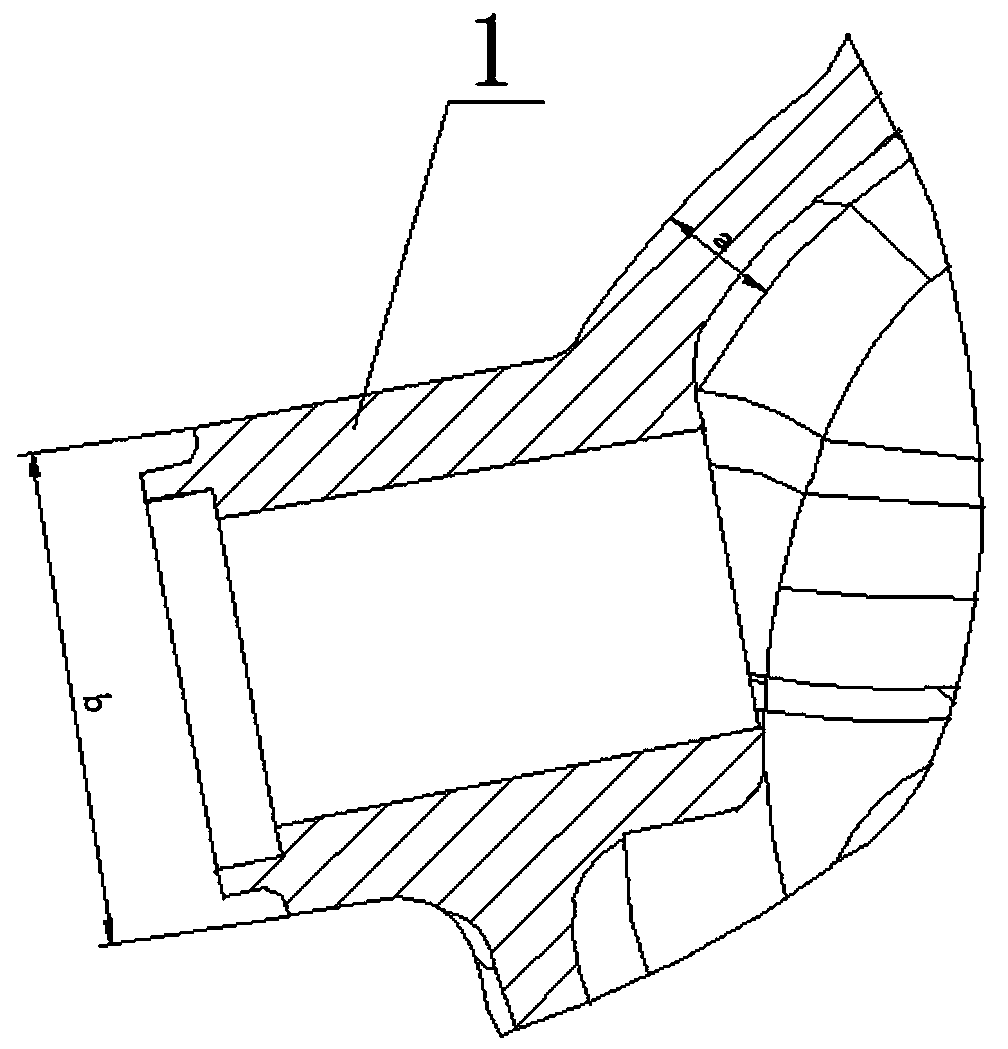

Local extrusion method used for high-pressure casting

InactiveCN106392033AGuaranteed Extrusion StrokeReduce shrinkage defectsEconomic benefitsHigh pressure

The invention provides a local extrusion method used for high-pressure casting. The method comprises the steps that a local extrusion device used for high-pressure casting is used for extruding the surface of a casting. The device is composed of an extrusion core sleeve (03), an extrusion rod (04), an extrusion oil cylinder (05) and an extrusion oil cylinder piston (06) and is characterized in that the extrusion oil cylinder (05) internally comprises the extrusion oil cylinder piston (06), the extrusion oil cylinder piston (06) is connected with the extrusion rod (04), the extrusion rod (04) is located in the extrusion core sleeve (03), and the extrusion core sleeve (03) and the extrusion oil cylinder (05) are fixed; the extrusion oil cylinder piston (06) is driven to drive the extrusion rod (04) to complete extrusion. The method has the beneficial effects that the extrusion stroke of the local extrusion process can be effectively ensured, meanwhile, the shrinkage defect of the large and thick portion of products is reduced, the production rejection rate is reduced, and the enterprise economic benefits are obviously improved.

Owner:CITIC DICASTAL

Method for preparing corrosion-resistant 410 stainless steel

ActiveCN106676379ASave resourcesEliminate harmful substancesMolten metal pouring equipmentsRecycling and recovery technologiesMolten steelMachinability

The invention provides a method which includes the steps of molten steel preparation, primary refining, secondary refining, mixing, pouring, electroslag ingot preparation and annealing. The invention further provides corrosion-resistant 410 stainless steel prepared through the method. The 410 stainless steel not only has the characteristics of being large in heat conductivity coefficient, small in dilatation coefficient, good in resistance to oxidation, high in strength, good in machinability, magnetic and the like just as those of common 410 stainless steel but also is good in forming resistance and corrosion resistance.

Owner:马鞍山市中桥金属材料有限公司

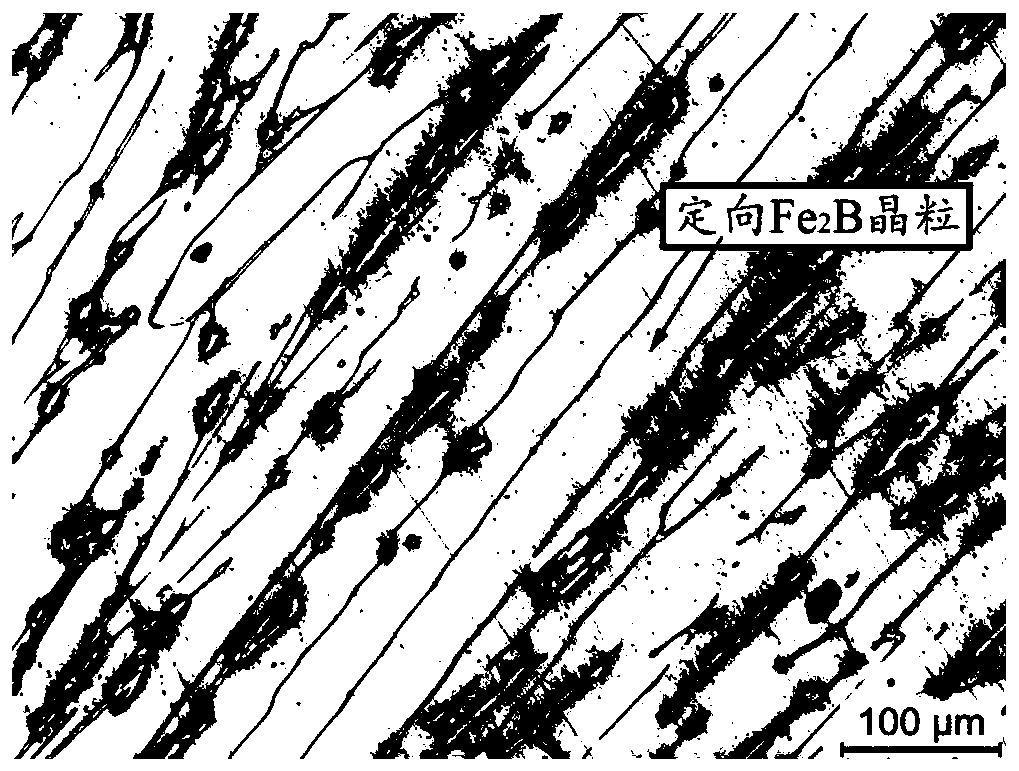

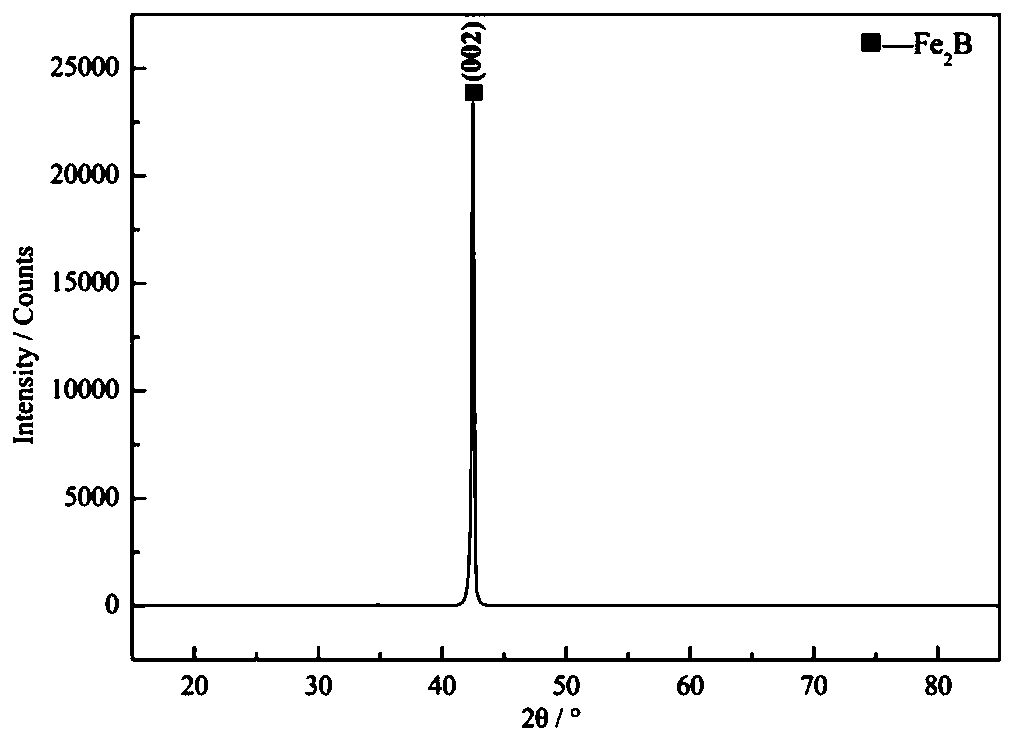

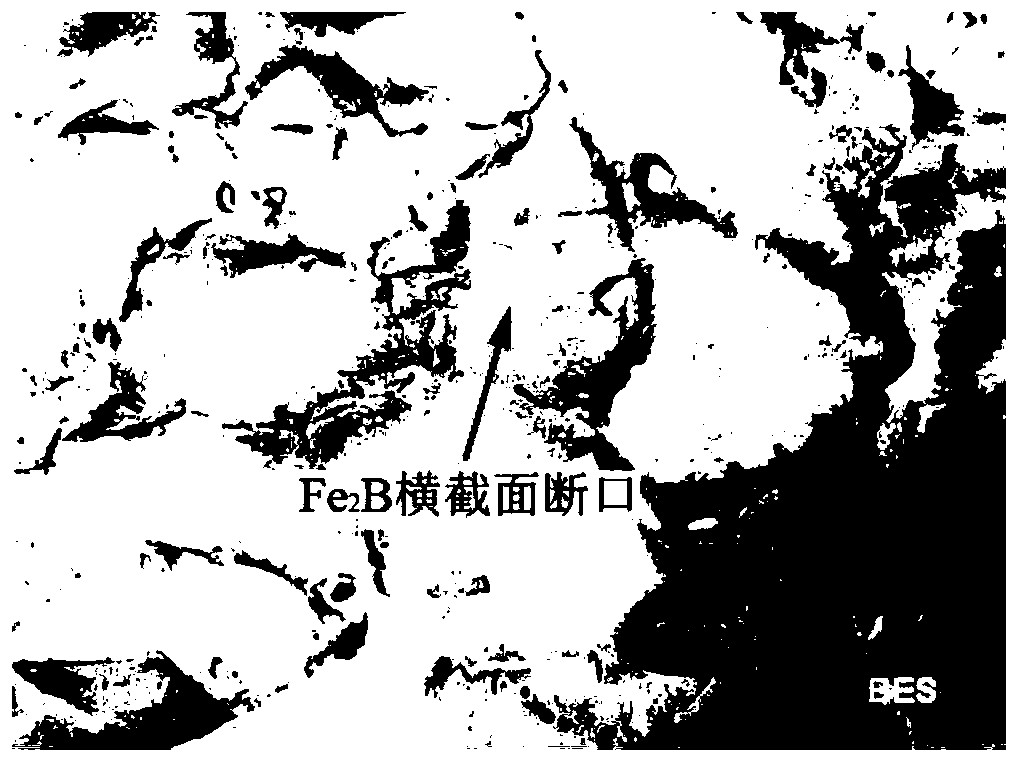

High-wear-resistant oriented Fe2B compact block and preparation method thereof

InactiveCN111074142AGood orientationGive full play to the wear resistanceFoundry mouldsFoundry coresCrucibleMaterials science

The invention discloses a high-wear-resistant oriented Fe2B compact block and a preparation method thereof. The method comprises the following steps that pure iron blocks and ferro-boron particles aretaken as raw materials, materials are prepared according to the mass ratio of Fe to B being 91.2: 8.8, the prepared mixed raw materials are put into a crucible, the crucible is put in a vacuum induction melting furnace for vacuum induction melting, after smelting is completed, metal melt is poured into a water glass sand mold cavity, and furnace cooling is conducted to a room temperature to obtain the oriented Fe2B block. The high-wear-resistant oriented Fe2B block prepared by the method has good purity and compactness, Fe2B crystal grains presents oriented arranged uniform columnar crystal form characteristics in a solidification direction, so that the high-hardness advantage of a cross section can be fully exerted, and the excellent wear-resistant performance is presented.

Owner:XI AN JIAOTONG UNIV

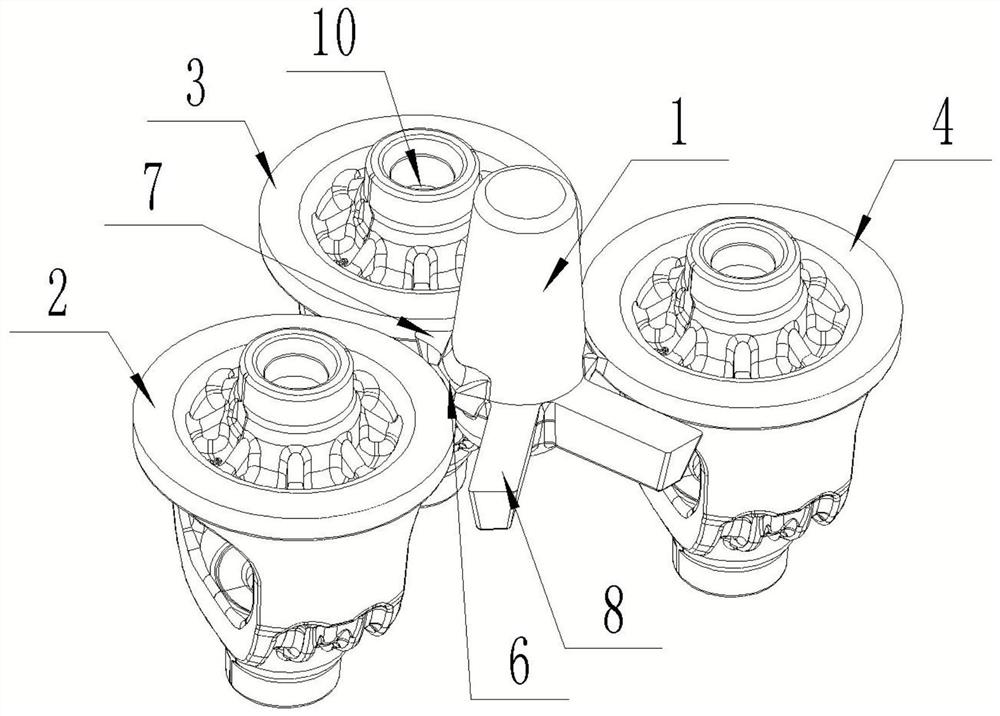

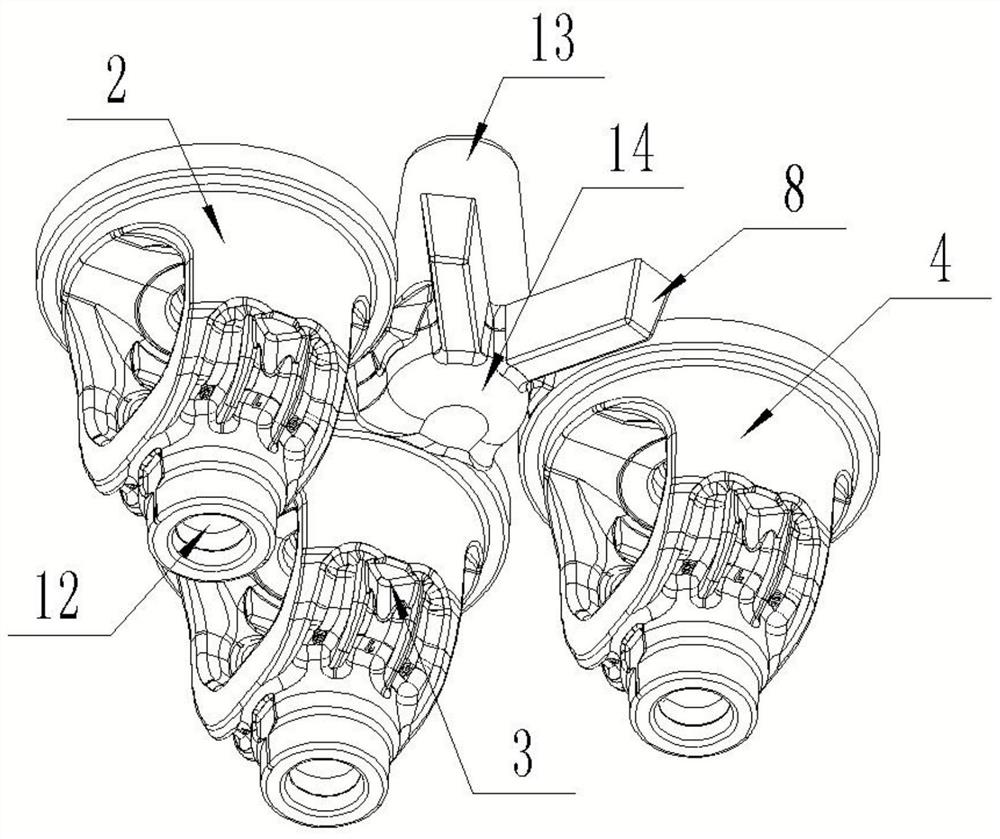

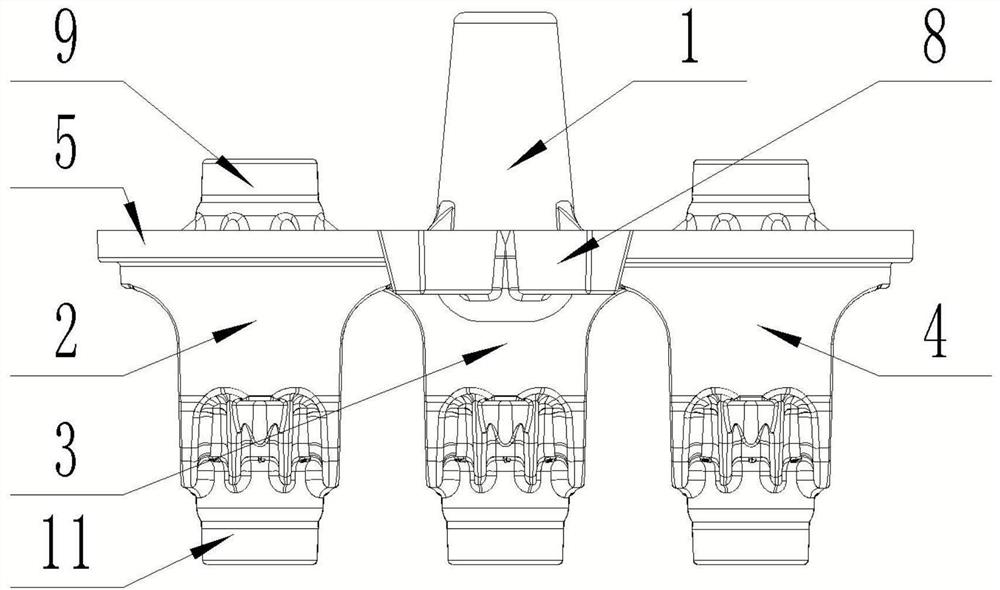

Casting model structure for differential mechanism shell with thick and large flange plate surface

PendingCN112371919ASmooth feedingReduce weightFoundry mouldsFoundry coresStructural engineeringMechanical engineering

The invention discloses a casting model structure for a differential mechanism shell with a thick and large flange plate surface. The casting model structure comprises a riser column, a casting A, a casting B and a casting C are arranged on the periphery of the riser column, the casting A and the casting C are symmetrically distributed on the two sides of the riser column respectively, and the casting B is located on the perpendicular bisector of the center connecting line of the casting A, the riser column and the casting C. Connecting blocks are arranged between the riser column and flange plates of the casting A, the casting B and the casting C. First heat preservation blocks are arranged in the positions, between the casting A and the casting B and between the casting C and the castingB, of the outer wall of the riser column. A plurality of second heat preservation blocks are arranged in the positions, between the casting A and the casting C, of the outer wall of a riser, and thelength of the second heat preservation blocks is larger than that of the first heat preservation blocks. Upper shaft sleeve heat preservation columns are arranged in upper shaft sleeves of the castingA, the casting B and the casting C. Lower shaft sleeve heat preservation columns are arranged in lower shaft sleeves of the casting A, the casting B and the casting C. According to the casting modelstructure, the upper shaft sleeves, the lower shaft sleeves and the flange plate surface are thick and large, and the areas of side shaft sleeves are weaker.

Owner:勤威(天津)工业有限公司

Method for overcoming casting bolt shrinkage porosity defect

ActiveCN109396357AReduce shrinkage defectsUniform wall thicknessFoundry mouldsFoundry coresQuenchingShrinkage porosity

The invention discloses a method for overcoming a casting bolt shrinkage porosity defect and relates to the technical field of casting. The method specially comprises the steps that when a casting sand core is prepared, a hole-forming boss is arranged at the corresponding position of the center of a casting bolt and is in a shape of a circular truncated cone, the hole-forming boss is removed aftera casting is formed through pouring, and a circular truncated cone shaped blind hole is formed in the center of the casting bolt and is machined into a threaded hole. According to the method, the hole-forming boss is arranged at the corresponding position of the center of the casting bolt, a feeding dead head added at the top of the bolt and a quenching chiller added at the bottom are not needed,and the process is simple, low in cost and can overcome the casting bolt shrinkage porosity defect.

Owner:西峡飞龙特种铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com