Production technology of multi-alloy cylinder cover

A production process and multi-alloy technology, which is applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of weakening the expansion and contraction effect of graphite, increasing the cost of castings, and fluctuations in alloy composition, so as to improve the shape and distribution , Improve the matrix strength and refine the matrix structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

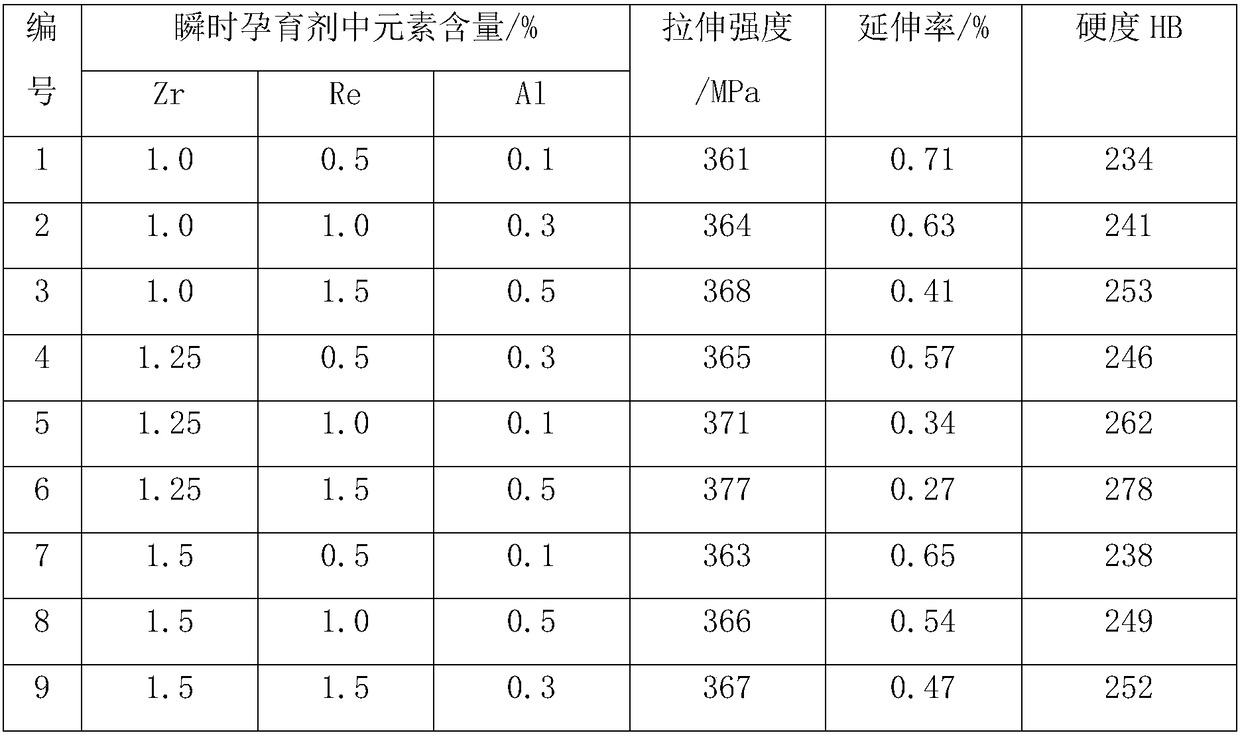

Embodiment 1

[0022] A production process of a multi-alloy cylinder head, comprising the following steps;

[0023] (1) Prepare raw materials: raw iron liquid: C 3.0%, Si 1.8%, Mn 0.7%, P 0.05%, S 0.06%, Cr 0.3%, Mo 0.35%, Cu 0.6%, the balance is Fe and unavoidable Impurities; flow inoculants: Si 65%, Zr1.0%, Re 0.5%, Al 0.1%, Ba 2.0%, the balance is Fe and unavoidable impurities;

[0024] (2) Molding, core making, and box closing: the molding process is carried out by iron mold sand-covered casting;

[0025] (3) Smelting: Take 100 parts of the original molten iron raw material and add it to the electric furnace, start the machine and melt it, and when the temperature of the molten iron reaches 1420°C, add the deslagging agent and stir evenly;

[0026] (4) Heating up: after the slag removal is completed, samples are taken for spectral analysis. After the temperature and chemical composition are qualified, the temperature of the molten iron is raised to 1450°C, and the molten iron is poured ...

Embodiment 2

[0031] A production process of a multi-alloy cylinder head, comprising the following steps;

[0032] (1) Prepare raw materials: raw iron liquid: C 3.0%, Si 1.8%, Mn 0.7%, P 0.05%, S 0.06%, Cr 0.3%, Mo 0.35%, Cu 0.6%, the balance is Fe and unavoidable Impurities; flow inoculants: Si 65%, Zr1.0%, Re 1.0%, Al 0.3%, Ba 2.0%, the balance is Fe and unavoidable impurities;

[0033] (2) Molding, core making, and box closing: the molding process is carried out by iron mold sand-covered casting;

[0034] (3) Smelting: Take 100 parts of the original molten iron raw material and add it to the electric furnace, start the machine and melt it, and when the temperature of the molten iron reaches 1420°C, add the deslagging agent and stir evenly;

[0035] (4) Heating up: after the slag removal is completed, samples are taken for spectral analysis. After the temperature and chemical composition are qualified, the temperature of the molten iron is raised to 1450°C, and the molten iron is poured ...

Embodiment 3

[0040] A production process of a multi-alloy cylinder head, comprising the following steps;

[0041] (1) Prepare raw materials: raw iron liquid: C 3.0%, Si 1.8%, Mn 0.7%, P 0.05%, S 0.06%, Cr 0.3%, Mo 0.35%, Cu 0.6%, the balance is Fe and unavoidable Impurities; flow inoculants: Si 65%, Zr1.0%, Re 1.5%, Al 0.5%, Ba 2.0%, the balance is Fe and unavoidable impurities;

[0042] (2) Molding, core making, and box closing: the molding process is carried out by iron mold sand-covered casting;

[0043] (3) Smelting: Take 100 parts of the original molten iron raw material and add it to the electric furnace, start the machine and melt it, and when the temperature of the molten iron reaches 1420°C, add the deslagging agent and stir evenly;

[0044] (4) Heating up: after the slag removal is completed, samples are taken for spectral analysis. After the temperature and chemical composition are qualified, the temperature of the molten iron is raised to 1450°C, and the molten iron is poured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com