Method for improving internal quality of cast ingot and heating insulation box

A technology of heating, heat preservation and internal quality, applied in the field of iron and steel metallurgy, can solve the problems of unsatisfactory shrinkage effect, difficult operation, porosity and segregation of ingots, and achieve shrinkage defects, good feeding effect, improvement of porosity and segregation. The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment is used to illustrate the ingot pouring process of superalloy GH4169 steel.

[0069] The specific operation steps are as follows:

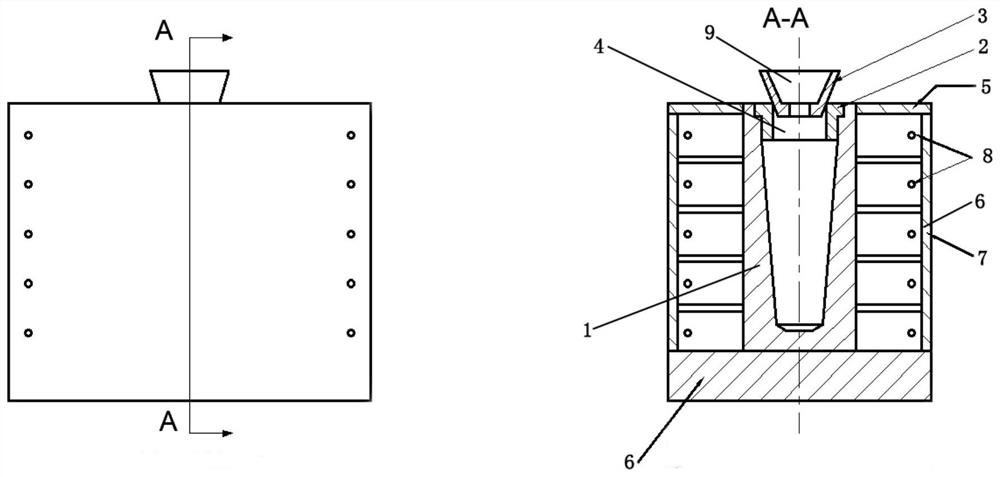

[0070] (1) The steel ingot mold 1, riser brick 2 and sprue brick 3 required for the pouring process are placed in a heating furnace, baked at 400°C for 5 hours and taken out, and then the steel ingot mold 1 is placed in a heating insulation box, Place riser brick 2 and sprue brick 3 on the upper end of steel ingot mold 1 in sequence, move the tapping trolley, move steel ingot mold 1, riser brick 2 and sprue brick 3 to the lower end of the crucible’s tapping gate, align the ingot mold 1 and riser brick 2 are heated to 650°C, then power off and keep warm, waiting for tapping;

[0071] (2) Heat and smelt the raw materials for smelting GH4169 steel in an induction furnace. After the molten steel is melted, deoxidize and refine the molten steel, then add alloys for alloying, and adjust the temperature of the molten steel until t...

Embodiment 2

[0077] This embodiment is used to illustrate the ingot pouring process of GH4065 steel.

[0078] The specific operation steps are as follows:

[0079](1) The steel ingot mold 1, riser brick 2 and sprue brick 3 required for the pouring process are placed in a heating furnace, baked at 450°C for 4.5 hours and then taken out, and then the steel ingot mold 1 is placed in a heating insulation box, Place riser brick 2 and sprue brick 3 on the upper end of steel ingot mold 1 in sequence, move the tapping trolley, move steel ingot mold 1, riser brick 2 and sprue brick 3 to the lower end of the crucible’s tapping gate, align the ingot mold 1 and riser brick 2 are heated to 670°C, then power off and keep warm, waiting for tapping;

[0080] (2) Heat and smelt the raw materials for smelting GH4065 steel in an induction furnace. After the molten steel is melted, deoxidize and refine the molten steel, then add alloys for alloying, and adjust the temperature of the molten steel until the co...

Embodiment 3

[0085] This embodiment is used to illustrate the ingot pouring process of GH2909.

[0086] The specific operation steps are as follows:

[0087] (1) The steel ingot mold 1, riser brick 2 and sprue brick 3 required for the pouring process are placed in a heating furnace, baked at 400°C for 5.5 hours and then taken out, and then the steel ingot mold 1 is placed in a heating insulation box, Place riser brick 2 and sprue brick 3 on the upper end of steel ingot mold 1 in sequence, move the tapping trolley, move steel ingot mold 1, riser brick 2 and sprue brick 3 to the lower end of the crucible’s tapping gate, align the ingot mold 1 and riser brick 2 are heated to 700°C, then power off and heat preservation, waiting for tapping;

[0088] (2) Heat and smelt the raw materials for smelting GH2909 steel in an induction furnace. After the molten steel is melted, deoxidize and refine the molten steel, then add alloys for alloying, and adjust the temperature of the molten steel until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com