Patents

Literature

37results about How to "Enough to enter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

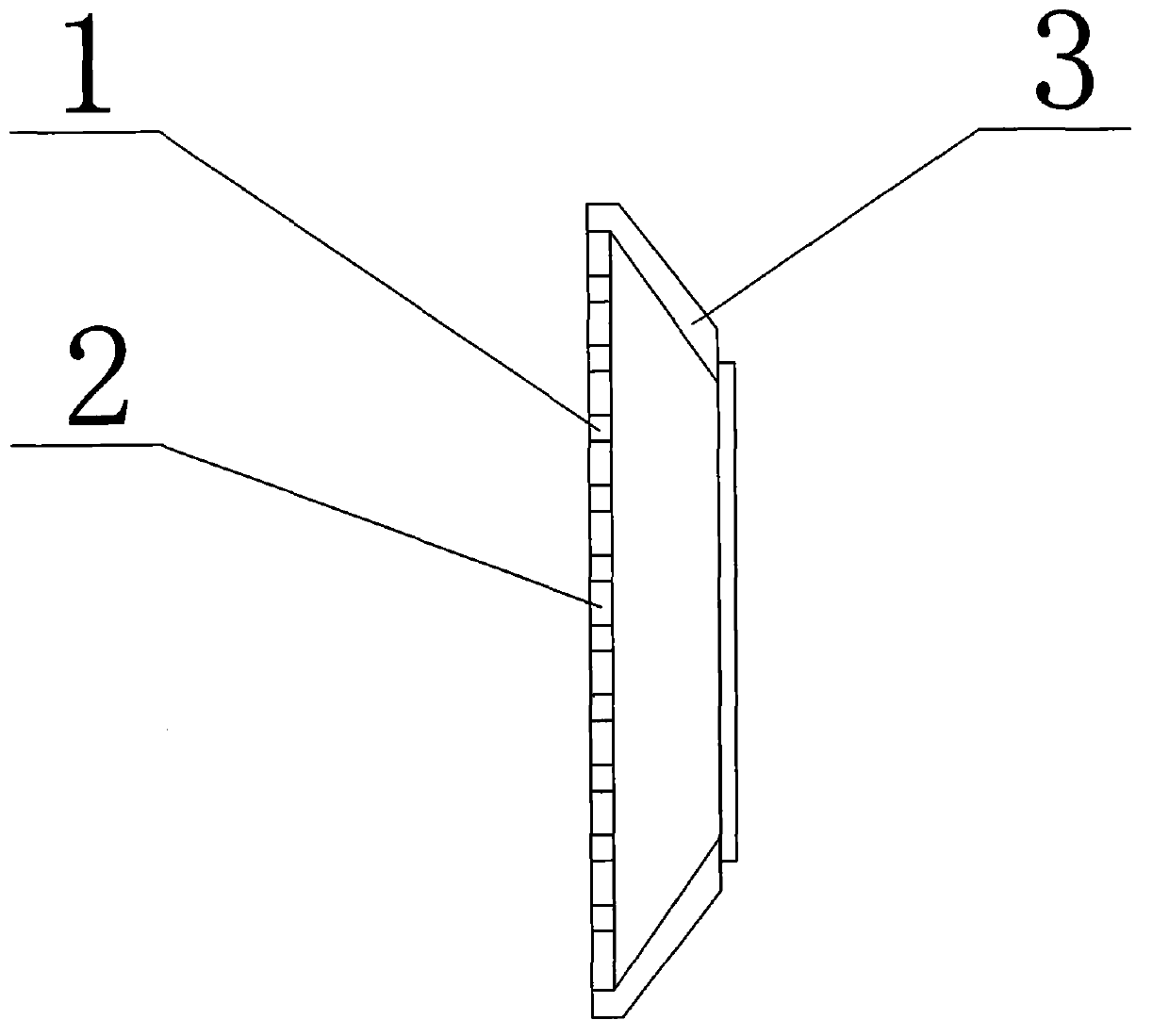

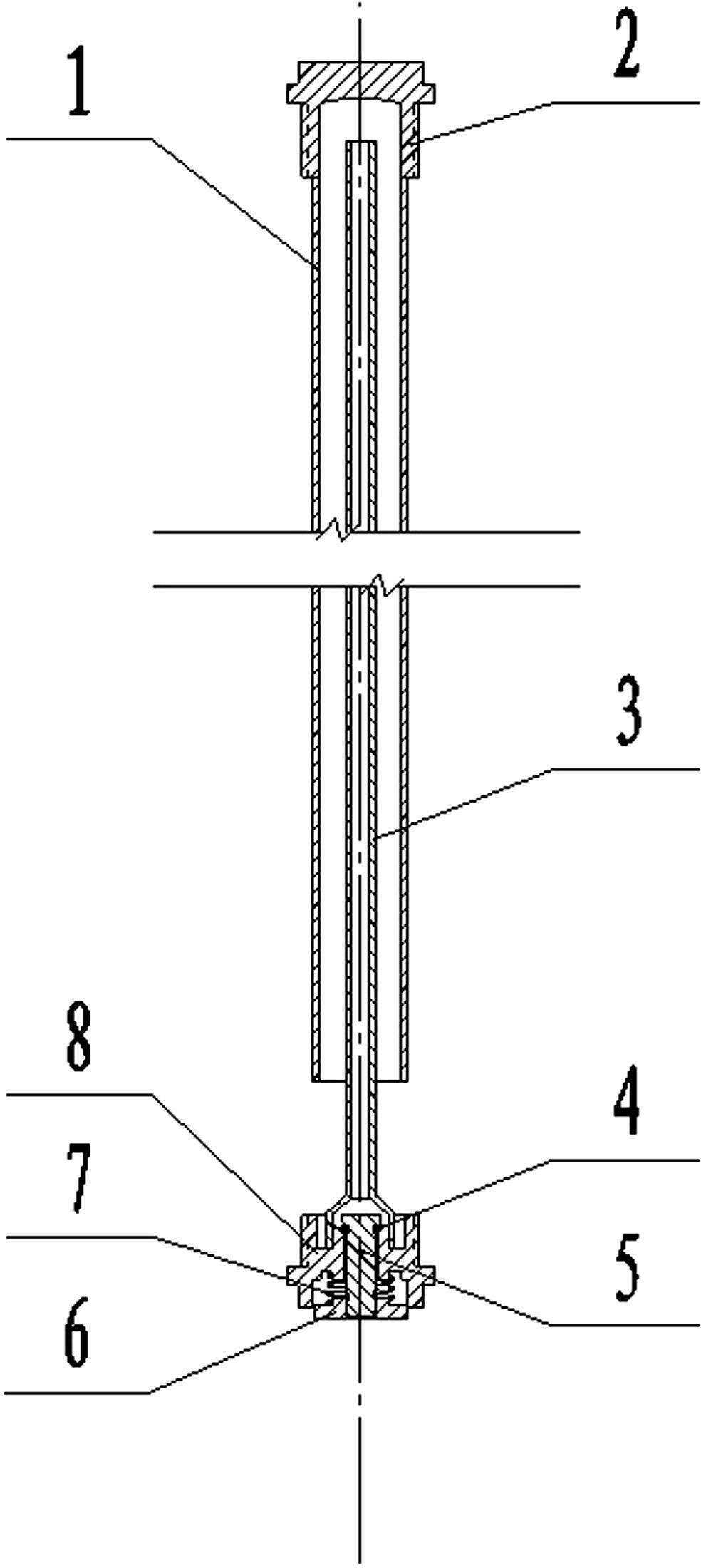

Warp-knitted base sun shading material and preparation method thereof

The invention relates to a warp-knitted base sun shading material and a preparation method thereof. The preparation method comprises the following steps of: (1) providing polyester warp-knitted base cloth; (2) coating PVC slurry on the polyester warp-knitted base cloth, and drying the polyester warp-knitted base cloth to obtain an intermediate material; and (3) coating surface treatment slurry to the surface of the intermediate material obtained in the step (2), and drying the intermediate material to obtain the finished sun shading material. The PVC slurry and the surface treatment slurry in the preparation method are special slurry of the invention. The sun shading material has high mechanical function, fireproof function, insulating performance, self-cleaning performance and weather resistance besides the functions of appearance, visual effect and the like of a common curtain material.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

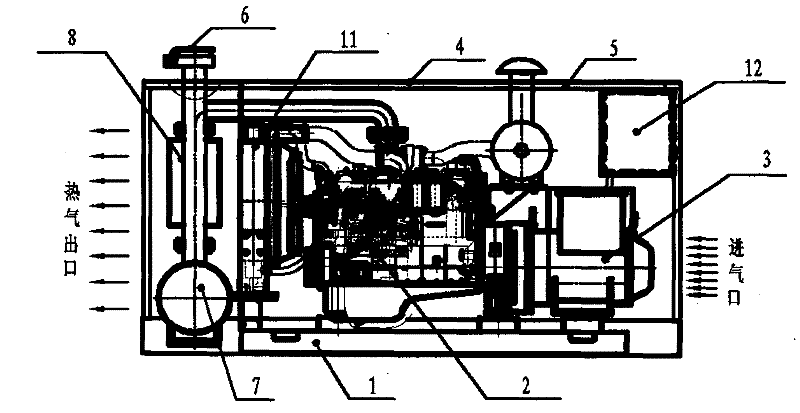

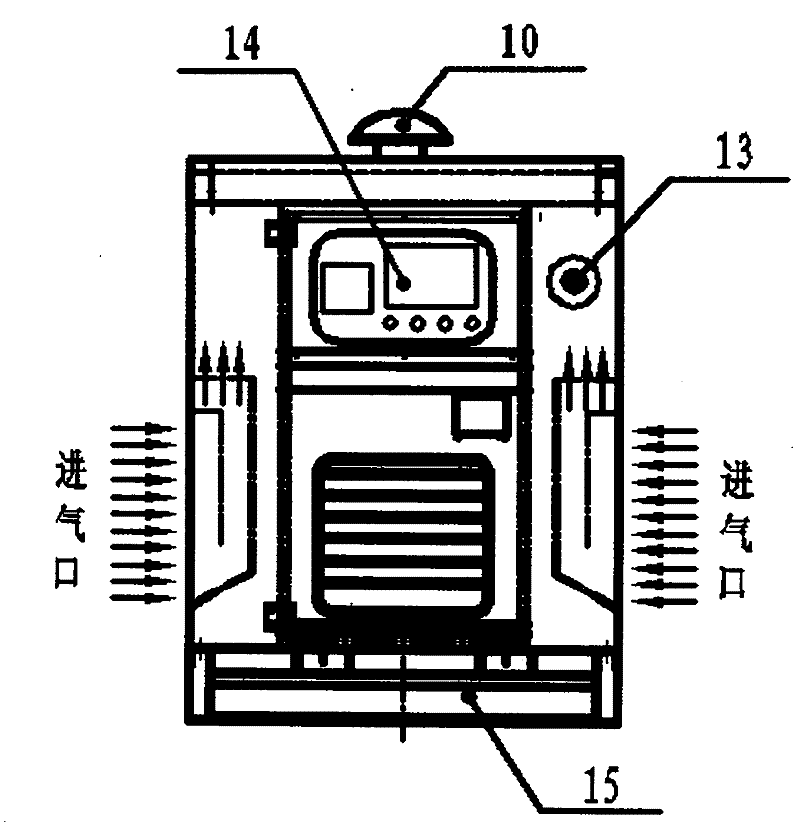

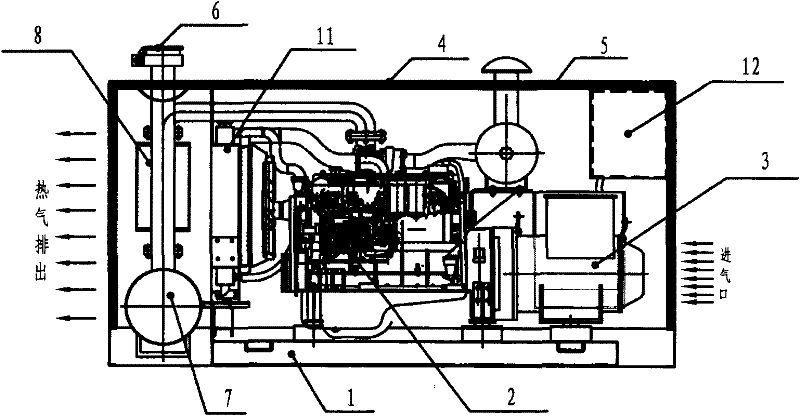

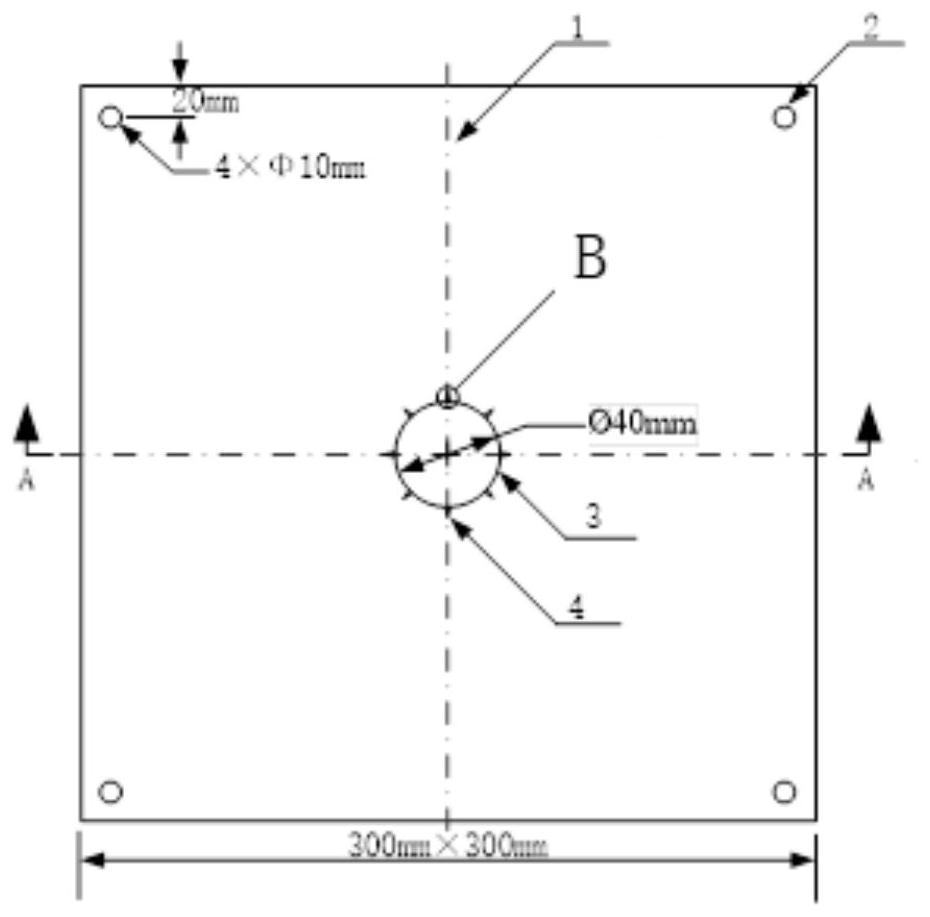

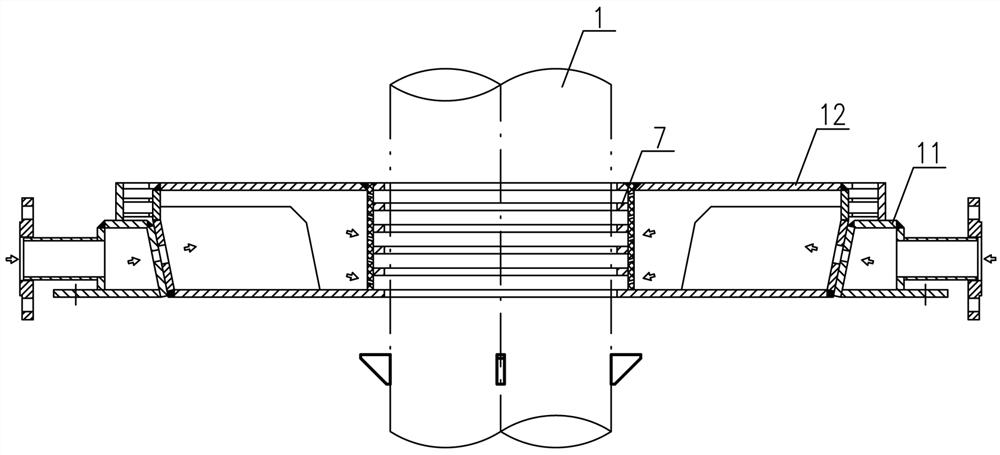

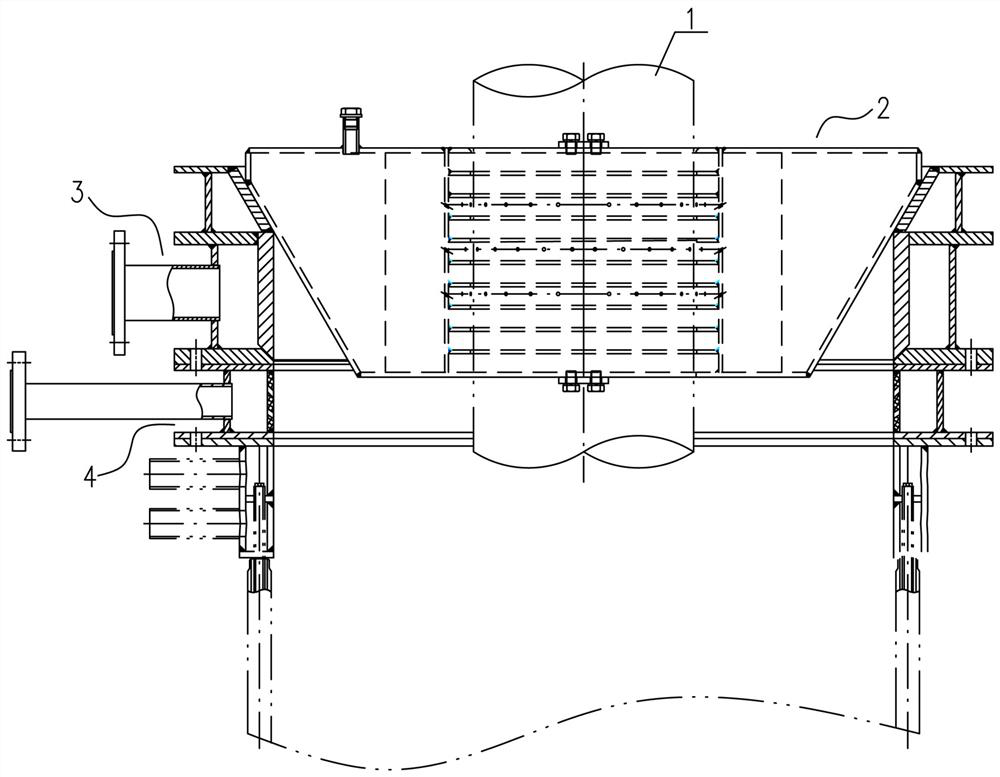

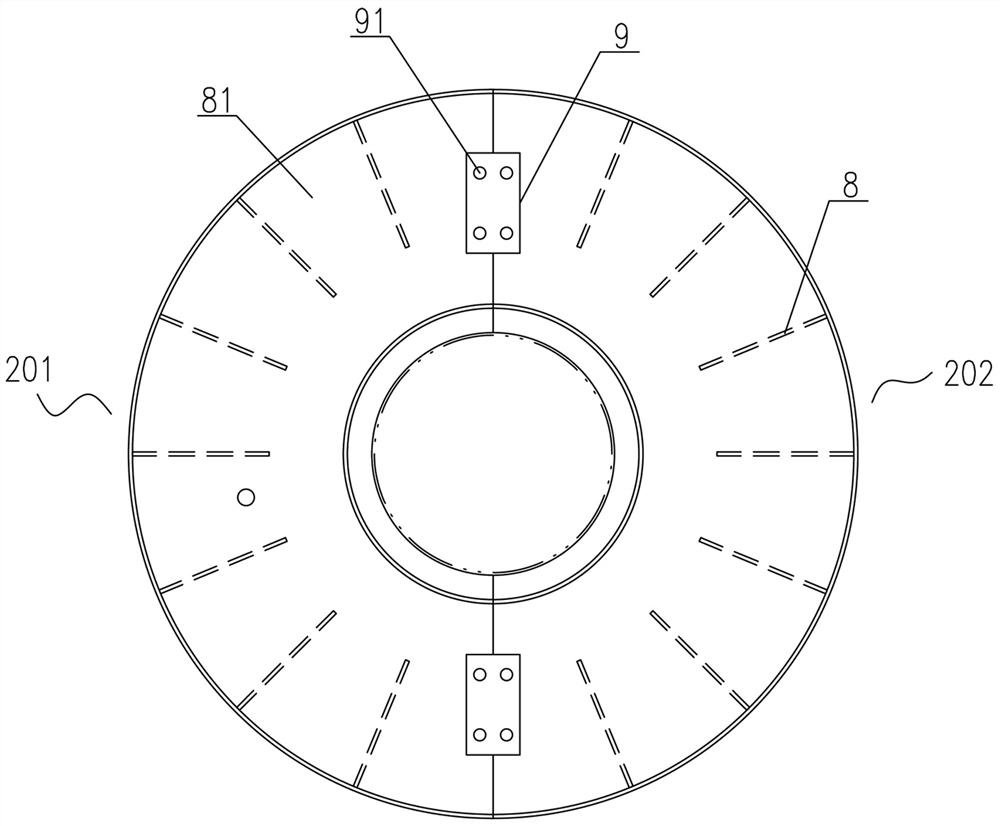

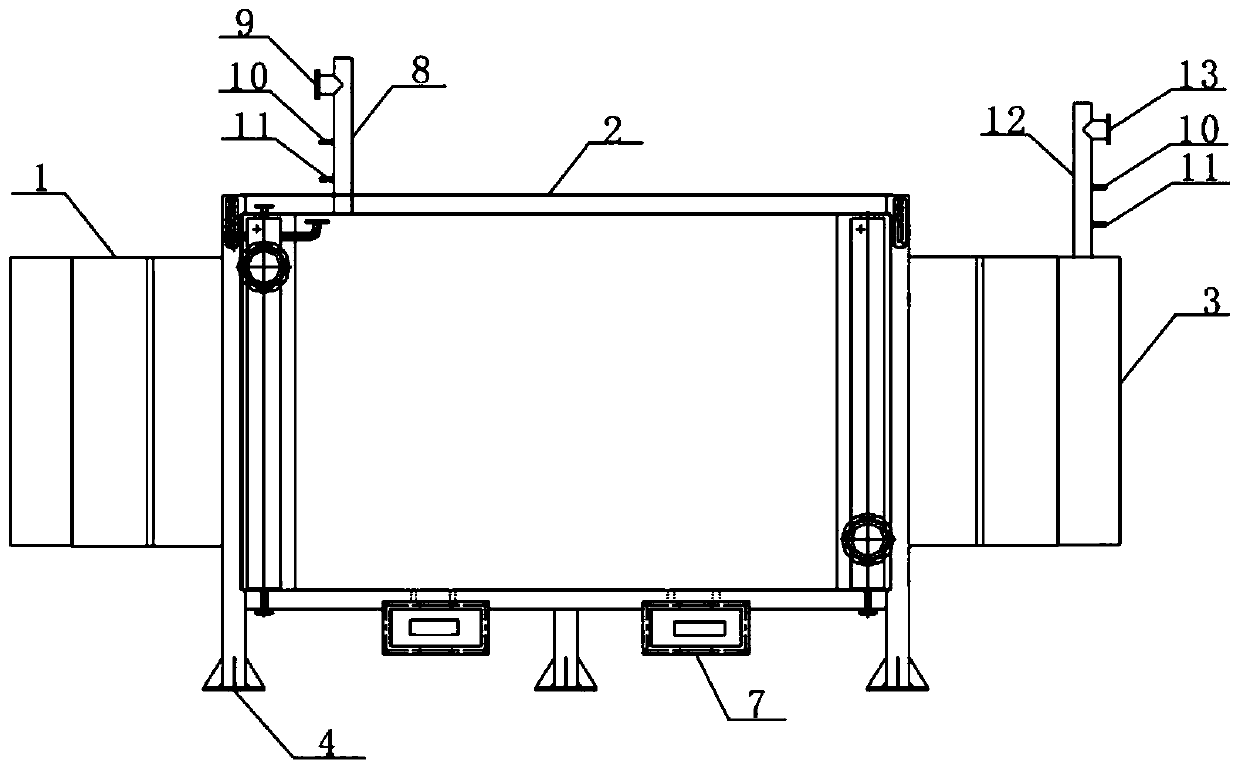

Novel energy-saving low noise diesel generator set

InactiveCN102182552AReduce noise sourcesReduce different noiseMachine framesInternal combustion piston enginesLow noiseDiesel generator

The invention discloses a novel energy-saving low noise diesel generator set. The diesel engine power is between 30kw and 130kw and the corresponding generator power is between 20kw and 100kw, the diesel engine is a supercharged intercooled diesel engine of which the rated rotary speed is 1000r / min and the fuel consumption is 205-210g / kw.h, thus obviously saving energy; the exhaust pipe adopts a divided exhaust pipe, 20mm space is reserved between the height of the baffle and the flange plane of the supercharger arranged on the exhaust manifold, thus effectively avoiding the influences on the supercharger efficiency due to excessively high temperature caused by the crossed exhaust gas of the engine; a silenced case body is added to the engine set, a high-performance shock absorber is adopted, an efficient PUR (poly urethane resin) type antiflaming sound absorbing sheet is pasted in the case body and a labyrinth type inlet air mulffer device made from a high-efficiency damping material is adopted to reduce the source of noises. Experimental results show that the energy-saving low noise diesel generator set can operate reliably for a long time with a controllable noise value of 65-70dB(A) at one meter).

Owner:LIUZHOU HENGDA POWER MACHINERY MFG

Vinegar for children promoting digestion and appetite and method of preparing the same

The present invention relates to digestion-promoting appetizing vinegar for children, which contains the materials with the following weight portions: 30 to 60 portions of premium mature vinegar, 30 to 60 portions of Chinese medicine extract, 2 to 5 portions of nutritional additive, 5 to 15 portions of honey and 2 to 5 portions of glucose. Ethanol solution is used to extract the mixture of the premium mature vinegar and the Chinese medicine extract, the nutritional additive, the honey and the glucose are then added into the dealcoholized extract liquor after filtration and ethanol removing, and thereby, the digestion-promoting appetizing vinegar is produced. The digestion-promoting appetizing vinegar for children, which is eaten as relish, can recuperate the spleen and the stomach and help digestion by the method of diet therapy, and substitute pharmacotherapy to prevent and cure the maldigestion and anorexia of children, so the digestion-promoting appetizing vinegar for children is a seasonend vinegar which has rich nutrition and a health-caring function and is particularly suitable for children to eat.

Owner:王建忠

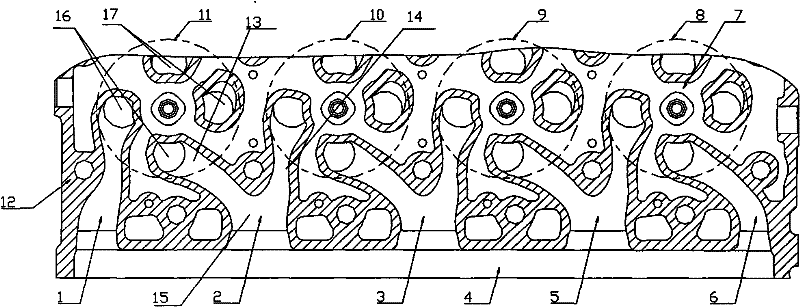

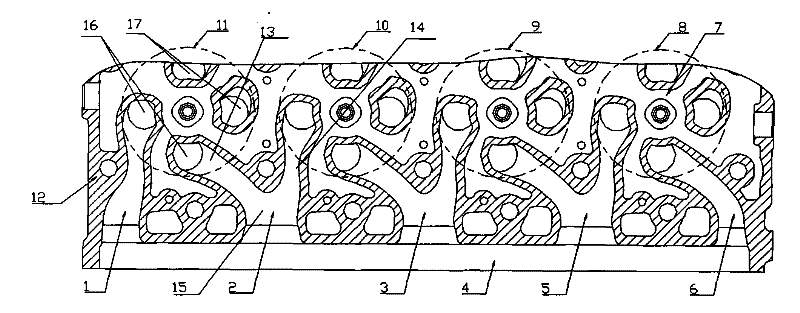

Air cylinder cover for four-valve diesel engine

InactiveCN102235263AGuaranteed cooling needsEnough to enterCylinder headsCylindersInlet channelInlet valve

The invention discloses an air cylinder cover for a four-valve diesel engine, comprising an air cylinder cover body. An air inlet channel structure is arranged on the air cylinder cover body and comprises a total air inlet channel arranged at one side of the air cylinder cover body; the total air inlet channel is provided with a single air inlet channel and parallel cylinder-spanning dual air inlet channels, wherein the single air inlet channel is only communicated with the total air inlet channel and one air inlet seat ring hole; the parallel cylinder-spanning dual air inlet channels are simultaneously communicated with the total air inlet channel and the air inlet valve seat ring holes of two adjacent air cylinders; the parallel cylinder-spanning dual air inlet channels comprise a first branch channel, a second branch channel and a shared channel; the first branch channel and the second branch channel are respectively and directly connected with the air inlet valve seat ring holes of the two air cylinders and are respectively communicated with the shared channel; and the shared channel is connected with the total air inlet channel. Compared with the prior art, with the unique air inlet mechanism, the air cylinder cover disclosed by the invention can ensure that enough air enters the air cylinder; meanwhile, more space can be saved for setting a water jacket space; and the cooling requirement on the air cylinder cover is satisfied.

Owner:GUANGXI YUCHAI MASCH CO LTD

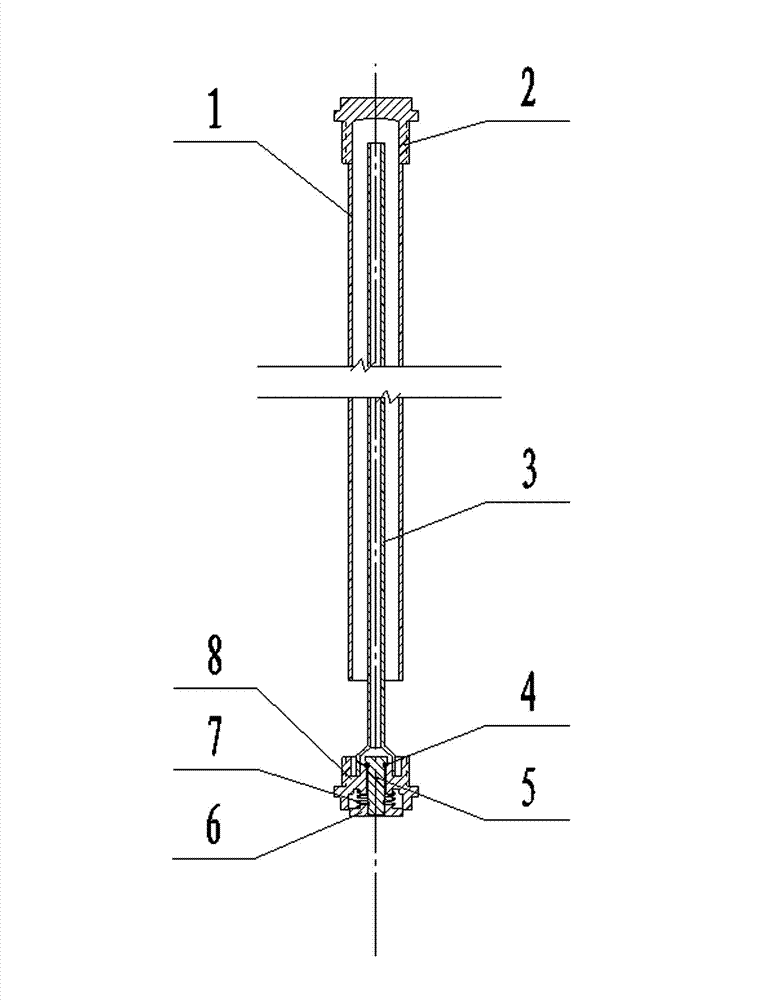

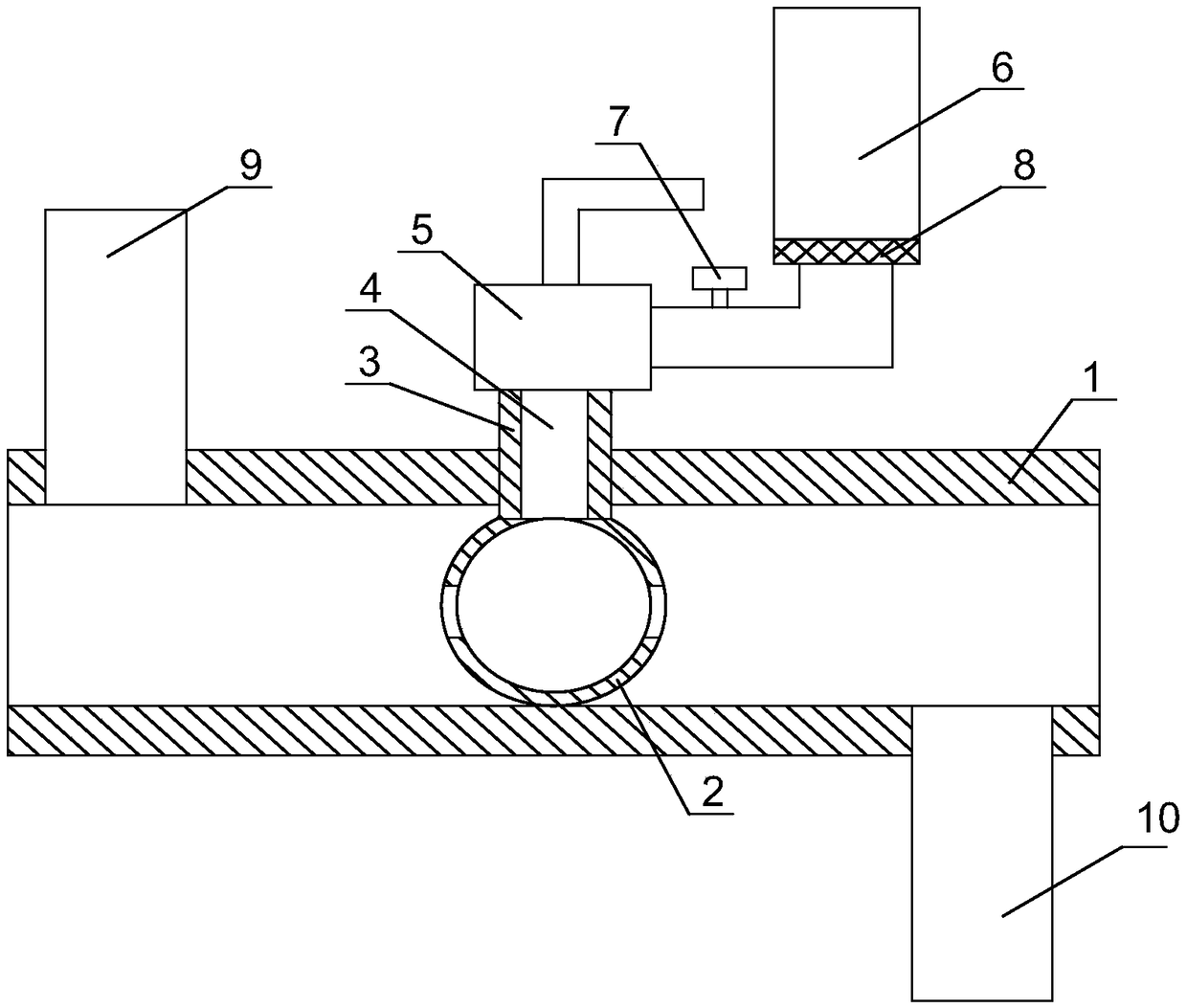

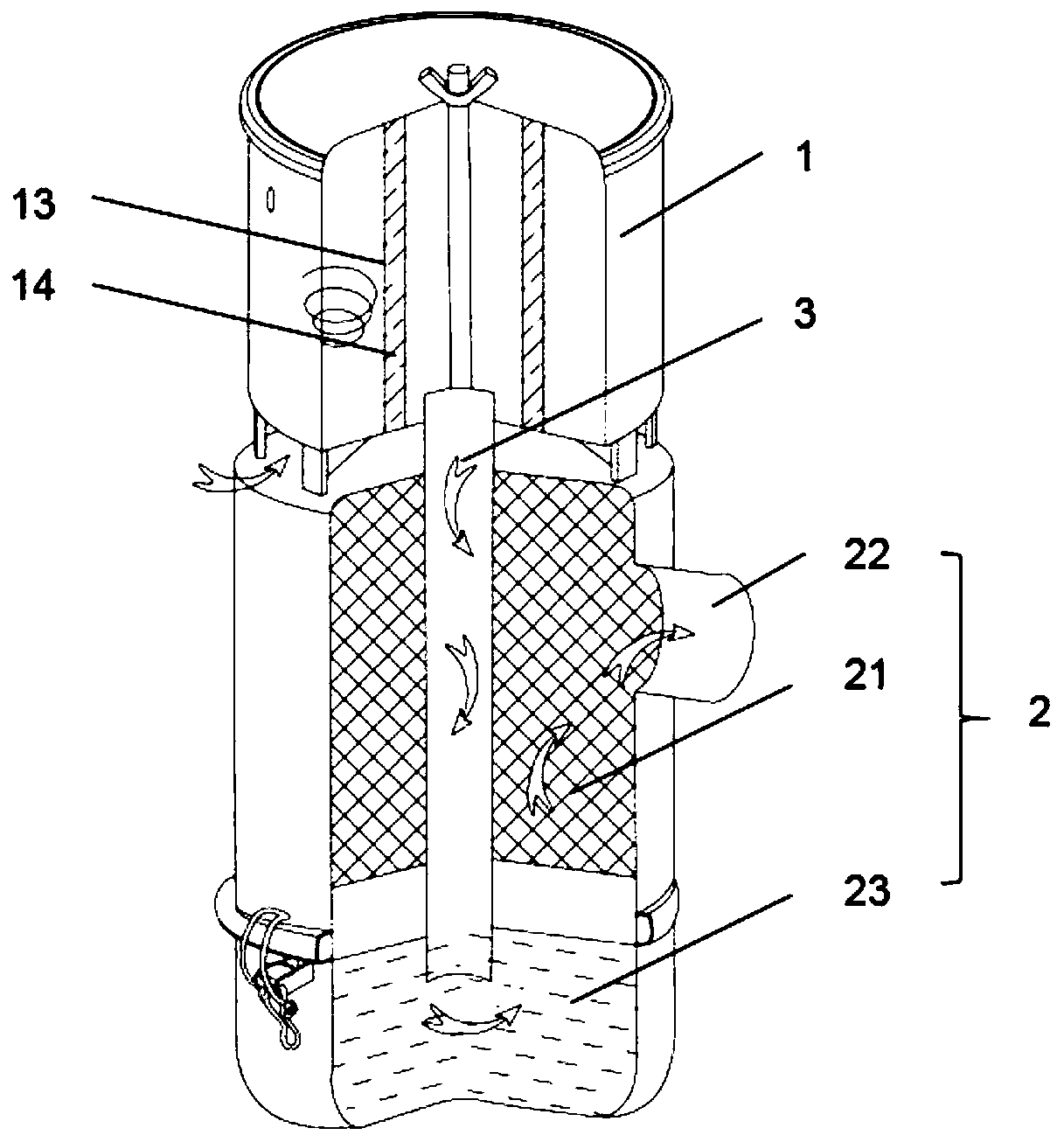

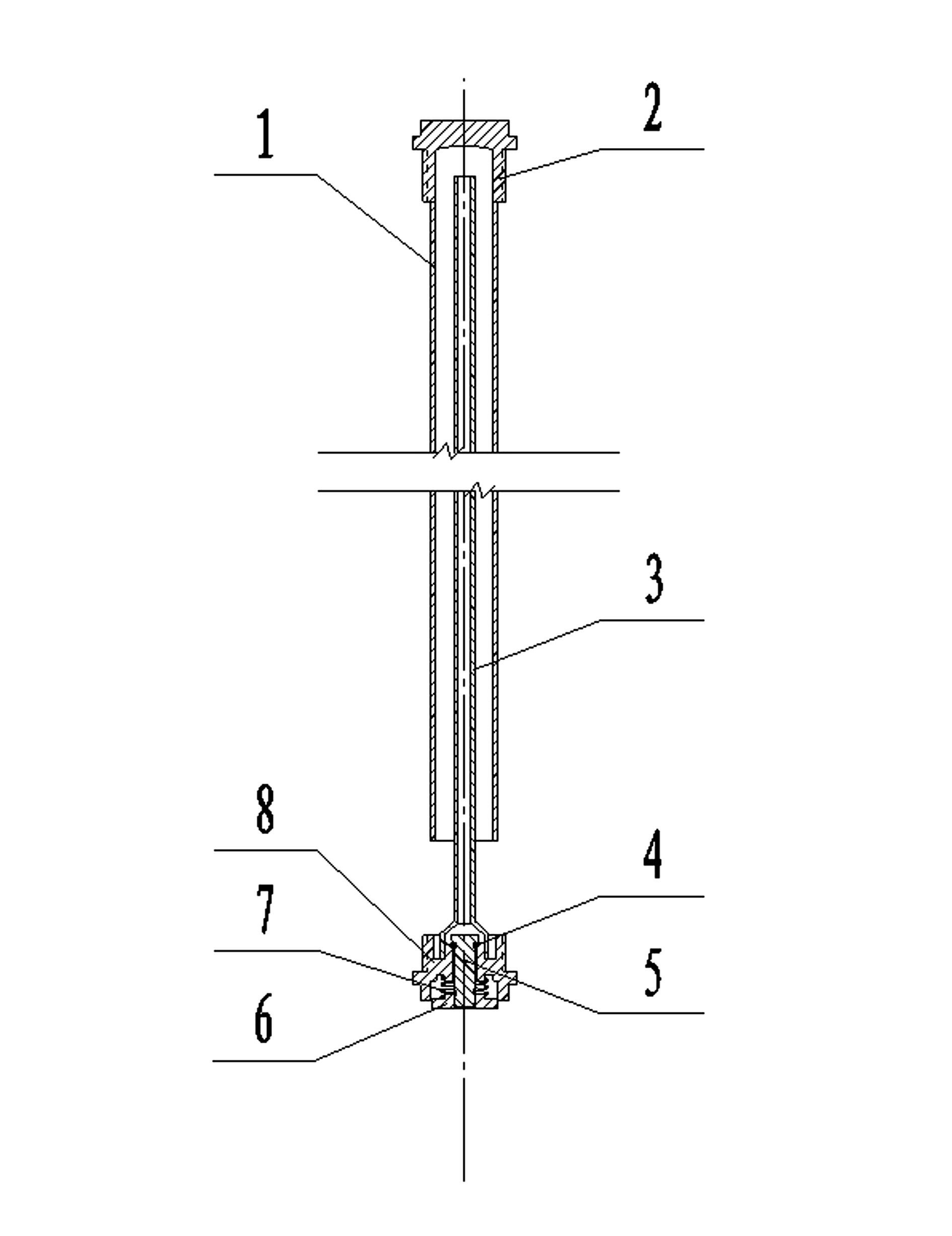

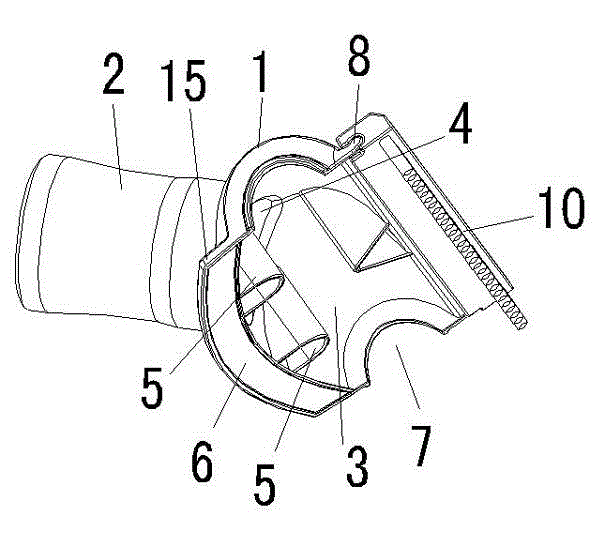

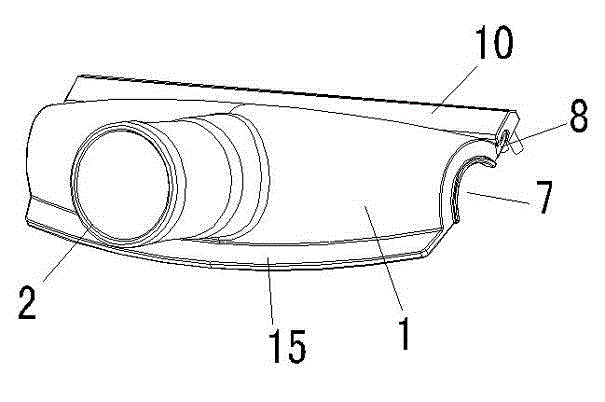

Special manual air inlet valve for device in bearing water storage equipment

InactiveCN102425696BRealize threaded connectionEnough to enterOperating means/releasing devices for valvesAerating valvesWater storageInlet valve

The invention relates to an air inlet valve, in particular to a special manual air inlet valve for a device in bearing water storage equipment, and solves the problem of incapability of automatic outlet water upon water supply cut-off of an external water supply system and formation of negative pressure at a high position of a pipeline system existing in the bearing water storage equipment. The special manual air inlet valve for the device in the bearing water storage equipment comprises an air collection pipe, an air collection pipe joint, an air inlet pipe, a seal ring, a push rod, a push button, a compression spring and a valve seat, wherein the lower end of the air collection pipe is provided with an opening; the air collection pipe joint is hermetically connected to the upper end of the air collection pipe; the upper end of the air inlet pipe extends into the inner cavity of the air collection pipe, and is close to the lower end face of the air collection pipe joint; and the lower end of the air inlet pipe extends out of the air collection pipe and is hermetically connected with a middle circular hole of the valve seat. Through the valve, the problem of incapability of automatic outlet water upon water supply cut-off of the external water supply system and formation of negative pressure at the high position of the pipeline system existing in the bearing water storage equipment is effectively solved; and the valve is suitable for various kinds of bearing water storage equipment.

Owner:王贵林

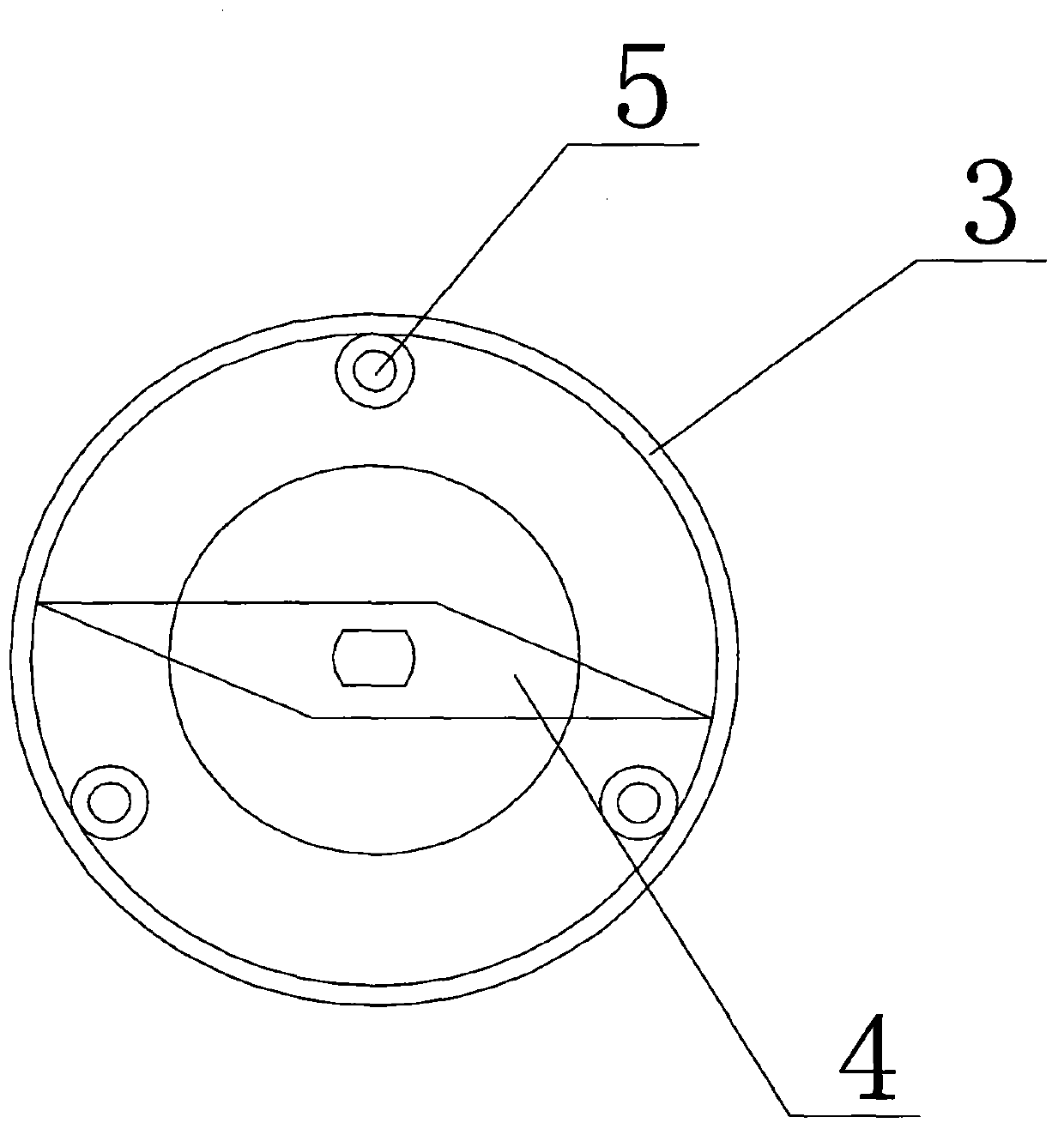

Water pump water inlet filter and flow divider of lotus root digging machine

InactiveCN103340057AInfluential areaAvoid peelingHarvestersFiltration separationEngineeringFlow divider

The invention discloses a water pump water inlet filter and flow divider of a lotus root digging machine. The water pump water inlet filter and flow divider of the lotus root digging machine comprise a water pump, wherein the water pump comprises a water pump body, a water inlet pipe and a water outlet pipe. The water pump water inlet filter and flow divider of the lotus root digging machine are characterized in that the filter is arranged on the water inlet pipe, the flow divider is arranged on the water outlet pipe, the filter comprises an outer shell, and a filtering device and a pulverizing device are arranged inside the outer shell. The water pump water inlet filter and flow divider of the lotus root digging machine have the advantages that sufficient water can enter the water pump, blocking caused by accumulation of impurities at the position of the water inlet of the water pump is avoided, rotary-cutting and separating of a rotary-cutter are facilitated, water capacity and pressure inside a water collecting barrel can be increased for a period of time, and the pressure of water inside the water collecting barrel can be balanced.

Owner:宋加龙

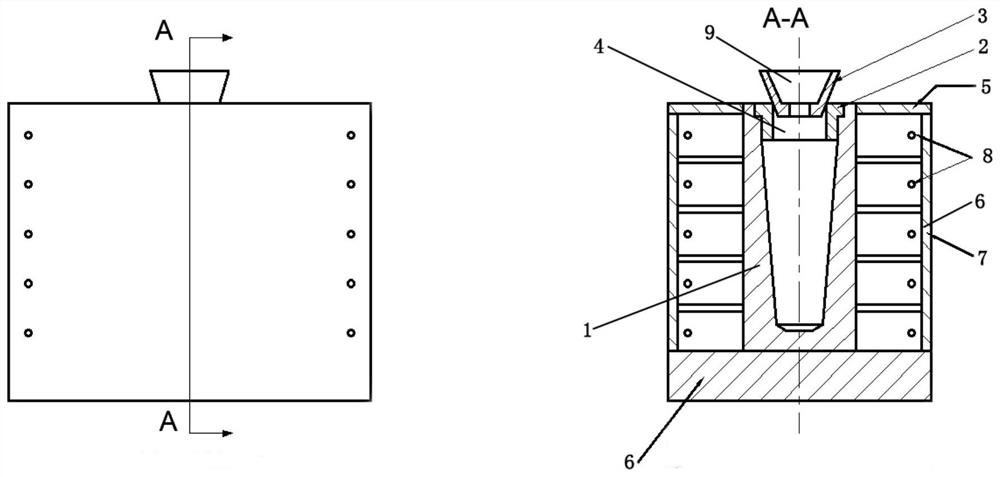

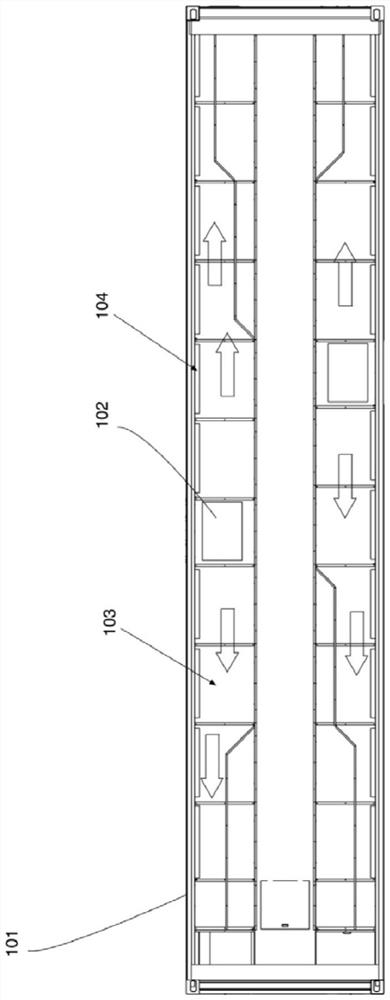

Method for improving internal quality of cast ingot and heating insulation box

The invention relates to the technical field of ferrous metallurgy, and discloses a method for improving the internal quality of a cast ingot and a heating insulation box. The method comprises the following steps that (1) a baked steel ingot mold, a riser brick and a sprue brick are sequentially placed in the heating insulation box from bottom to top, the steel ingot mold and the riser brick are heated to 600-800 DEG C, then heating is stopped, and heat preservation is conducted; (2) molten steel obtained after smelting is poured into the steel ingot mold; in the pouring process, the pouring speed is controlled in a segmented mode; and after the molten steel is completely poured, the amount of the molten steel in a riser is 10-30 wt% of the weight of the cast ingot; and (3) cooling is conducted after pouring is completed, and demolding is conducted after the molten steel is solidified in the steel ingot mold. According to the method and the heating insulation box, the steel ingot mold and the riser brick are heated to the proper temperature before pouring, then the pouring speed is controlled in the segmented mode, the amount of the molten steel in the riser is controlled, and the problems of internal defects such as shrinkage cavities, looseness and segregation generated by the steel ingot during pouring through an upper pouring method are solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

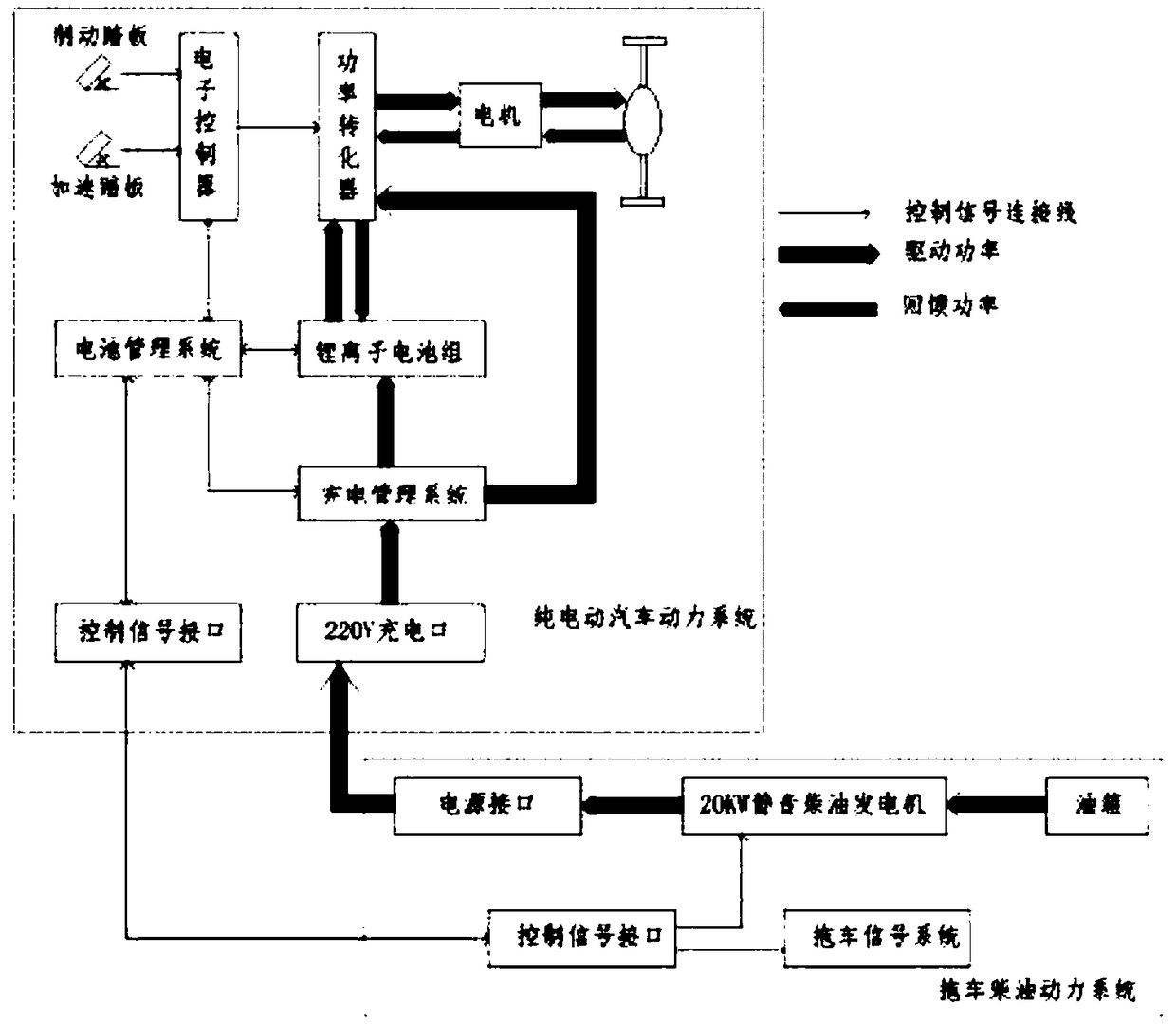

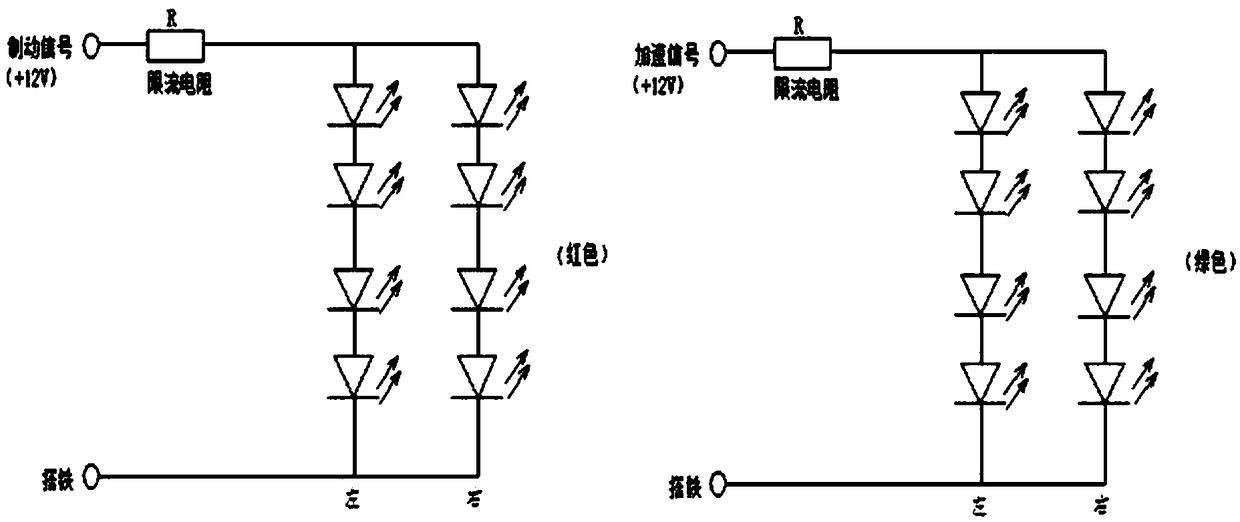

Trailer type electric automobile standby power supply based on 20KW diesel power generation

InactiveCN109398113AReduce noiseMature technologyCharging stationsPropulsion by batteries/cellsShortest distanceStandby power

The invention relates to the technical field of automobile power supplies, in particular to a trailer type electric automobile standby power supply based on 20KW diesel power generation. The trailer type electric automobile standby power supply based on 20KW diesel power generation comprises a pure electric automobile power system and a trailer diesel power system. The technical scheme is that a trailer mounted with a 20KW diesel silent power generator is hooked to a pure electric automobile when the pure electric automobile needs to run a long distance; the diesel power generator outputs 220V20 KW alternating current to provide running energy for the pure electric automobile; and as the pure electric automobile is continuously filled with diesel oil in a filling station like a fuel vehicle, long trips of the pure electric automobile can be realized. When the pure electric automobile runs in urban areas or in short distances, the pure electric automobile singly runs by taking off thetrailer.

Owner:毛琦

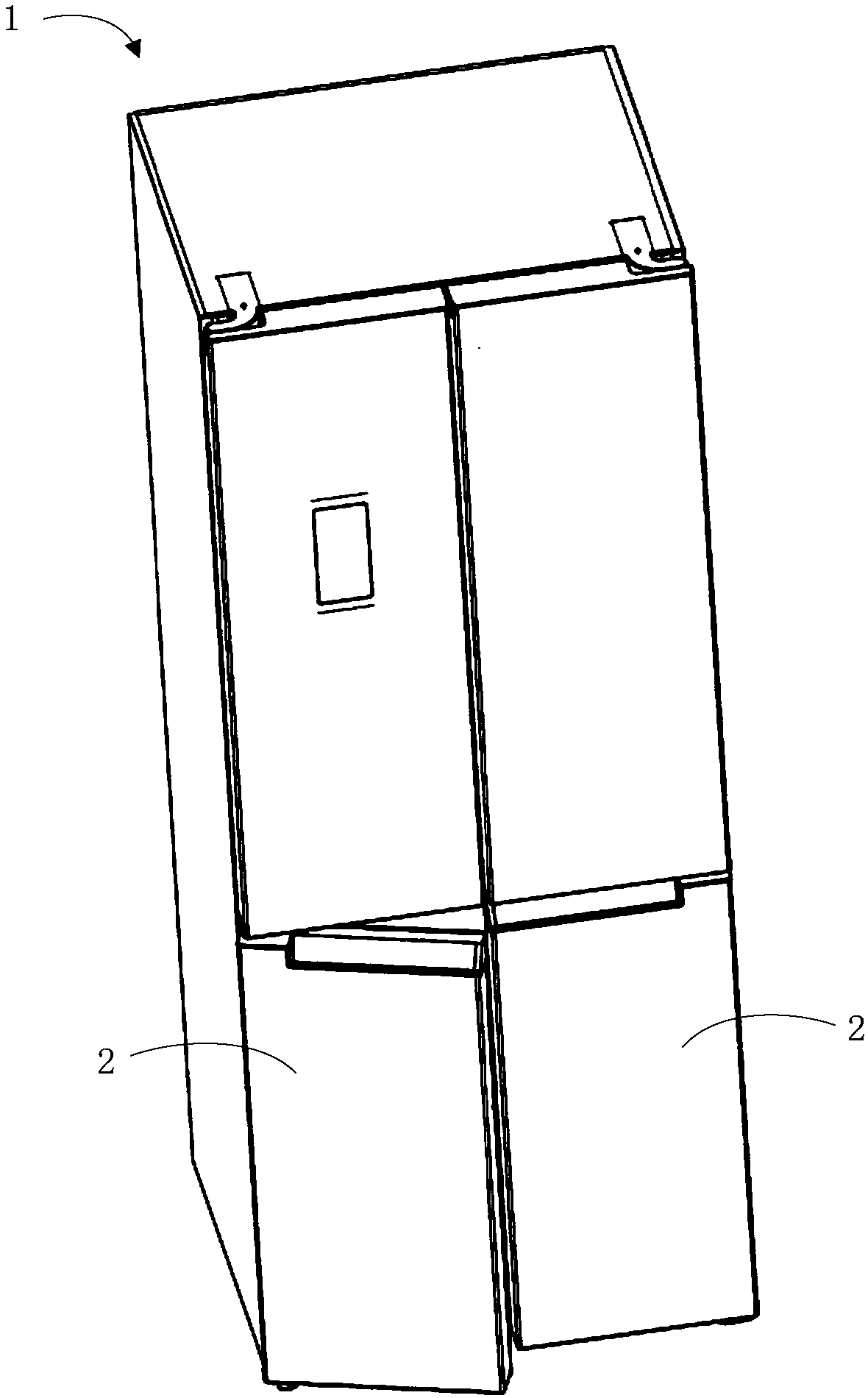

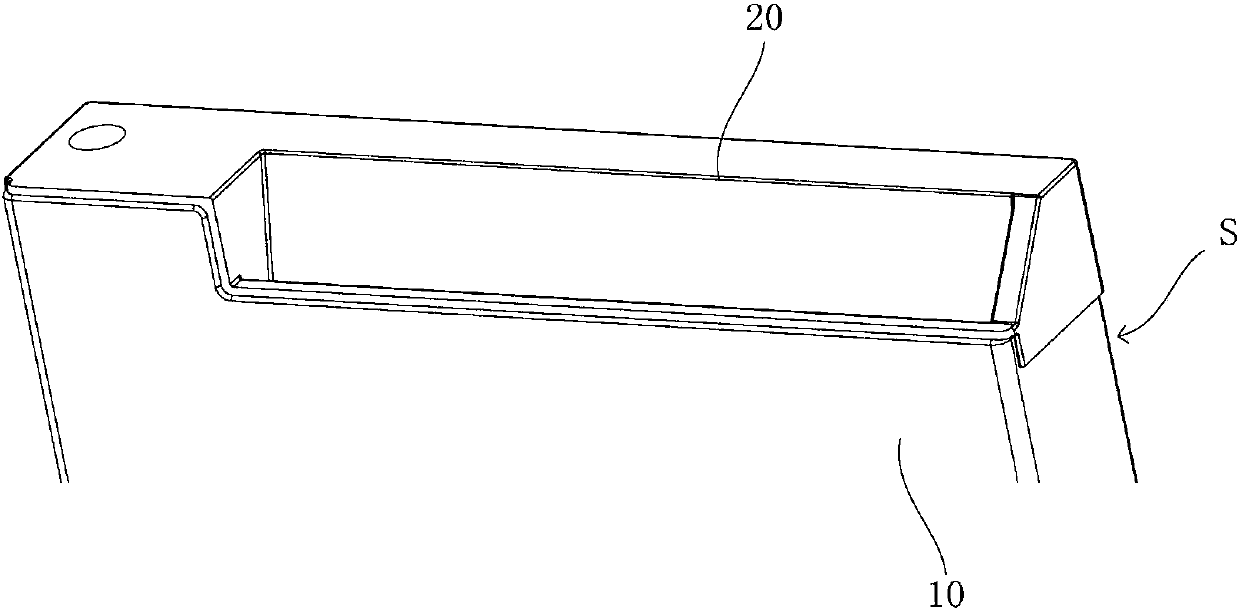

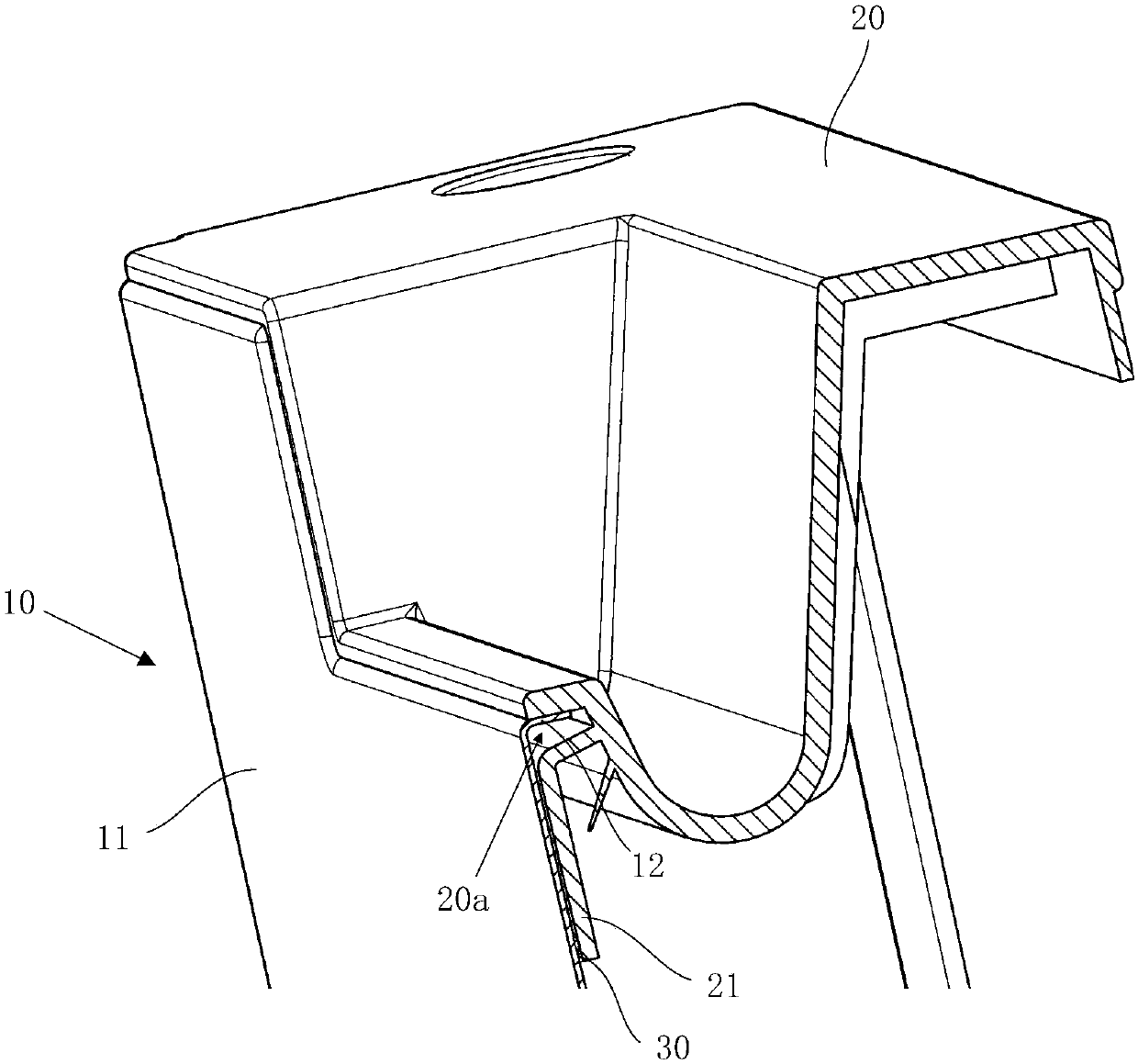

Refrigerator and door thereof

ActiveCN107687738AControl flowGuaranteed mating connectionLighting and heating apparatusCooling fluid circulationRefrigerated temperatureWell control

The invention discloses a refrigerator (1) and a door (2) thereof. The door (2) comprises a door shell (2) and an end cover (20) and further comprises a closing piece (30) located in a gap (d), wherein the door shell (2) and the end cover (20) are connected with each other. The door shell (2) comprises a door panel (11) and a flange (12); the end cover (20) is provided with a receiving groove (20a) used for inserting of the flange (12) and further comprises a baffle (21) which is arranged face to the surface, facing the inner wall (S), of the door panel (11); the gap (d) exists between the baffle (21) and the door panel (11), and the closing piece (30) at least partially closes an opening of the gap (d); and the baffle (21) is provided with a plurality of through holes (21a) used for allowing foaming liquid to pass through and being separated from the closing piece (30). According to the scheme, the quantity of the foaming liquid entering the gap can be well controlled, matching connection of the door shell and the end cover is ensured, and meanwhile bubble leakage is avoided.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Ball valve capable of prolonging service lifetime

InactiveCN108730559AEasy to useGood cleaning effectPlug valvesHollow article cleaningBall valveEngineering

The invention discloses a ball valve capable of prolonging service lifetime. The ball valve comprises a valve body, a valve core and a valve rod. The valve core is located in the interior of the valvebody. The valve rod is vertically connected on the valve body and fixedly connected with the valve core. The interior of the valve core is equipped with a cavity supplying forfluids to pass through.The interior of the valve rod is equipped with a channel communicating with the cavity in the interior of the valve core. The channel penetrates through the valve rod in the axial direction of the valve rod. The top of the valve rod is provided with a control valve communicating with the channel. An outlet of the control valve communicates with the channel. An inlet of the control valve is equipped with a container internally holding a cleaning agent in a communicating manner. The container is located on the side surface of the control valve and located above an inlet end of the control valve.A traditional ball valve structure is changed. The problem that the valve core is blocked is resolved.

Owner:四川威卡自控仪表有限公司

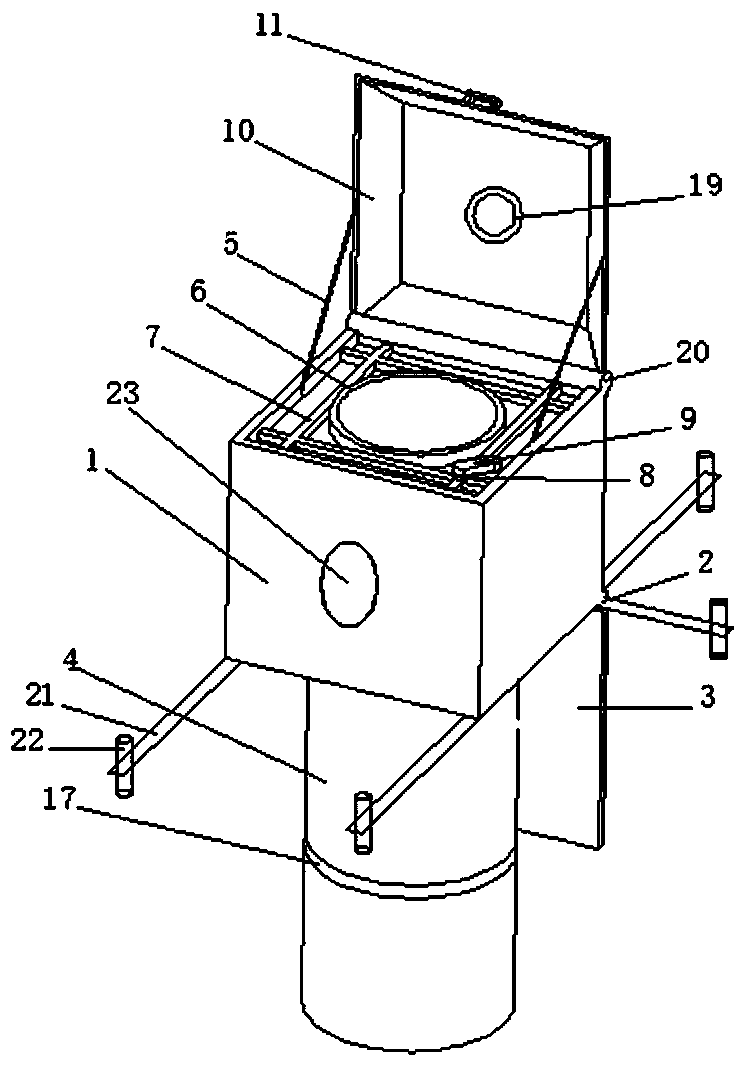

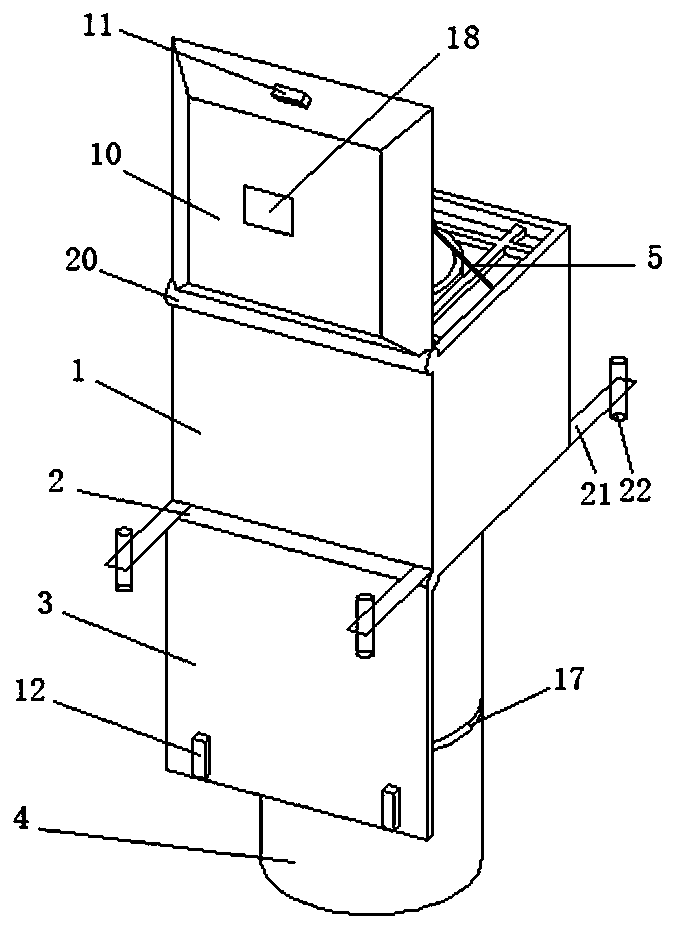

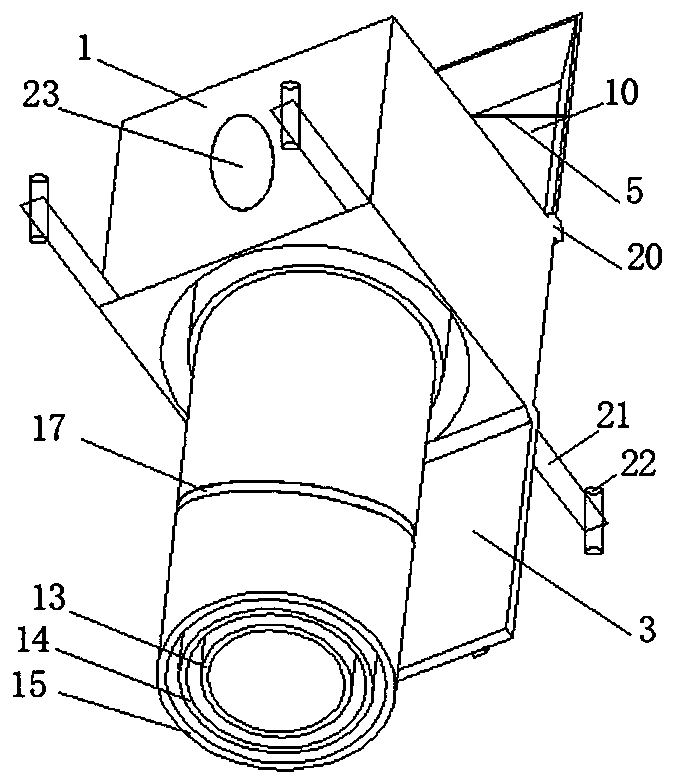

Escape rescue device

InactiveCN107648762AEnsure safetyImprove securityLighting elementsBuilding rescueGas springEngineering

The invention discloses an escape rescue device. The escape rescue device comprises an escape box, a first rotary shaft, an upper cover plate, a lower cover plate, an escape sliding way, a gas spring,a handle, a support ring, frame strips, a linkage rod and a rotary handle. The upper cover plate is arranged on the upper portion of the escape box. The escape box and the upper cover plate are connected through the gas spring. The handle is arranged on the upper portion of the upper cover. A baffle is arranged on the edge of the upper cover plate. The frame strips are arranged in the escape box.The support ring is arranged in the frame strips. The escape sliding way is arranged on the support ring. A man riding layer is arranged on the escape sliding way. A middle contraction layer is arranged outside the man riding layer. A fireproof layer is arranged outside the middle contraction layer. The linkage rod is arranged on the right side of the support ring. The rotary handle is arranged on the upper portion of the linkage rod. The lower cover plate is arranged on the lower portion of the escape box. The escape box is connected with the lower cover plate through the first rotary shaft.A fixing device is arranged on the lower cover plate.

Owner:杜洪

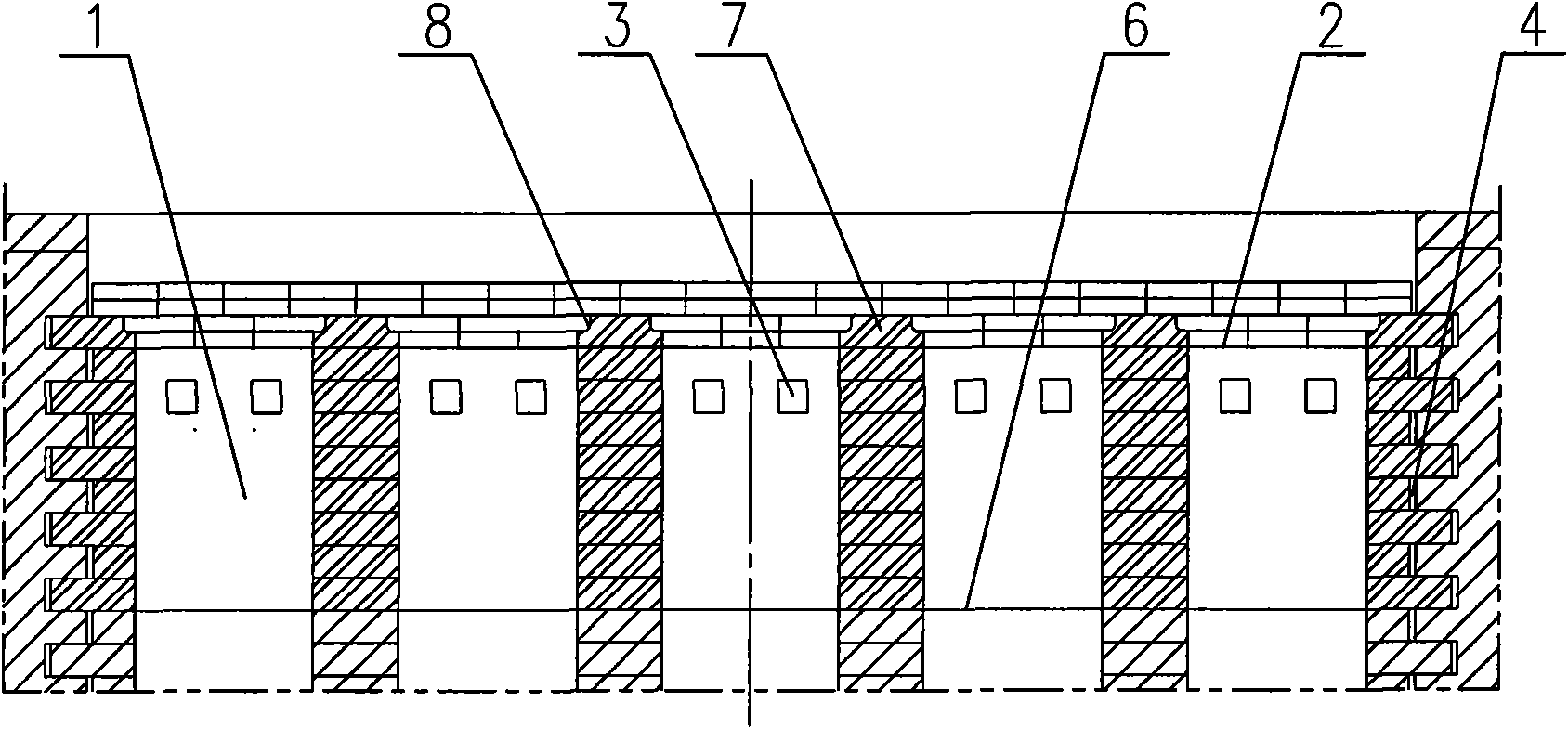

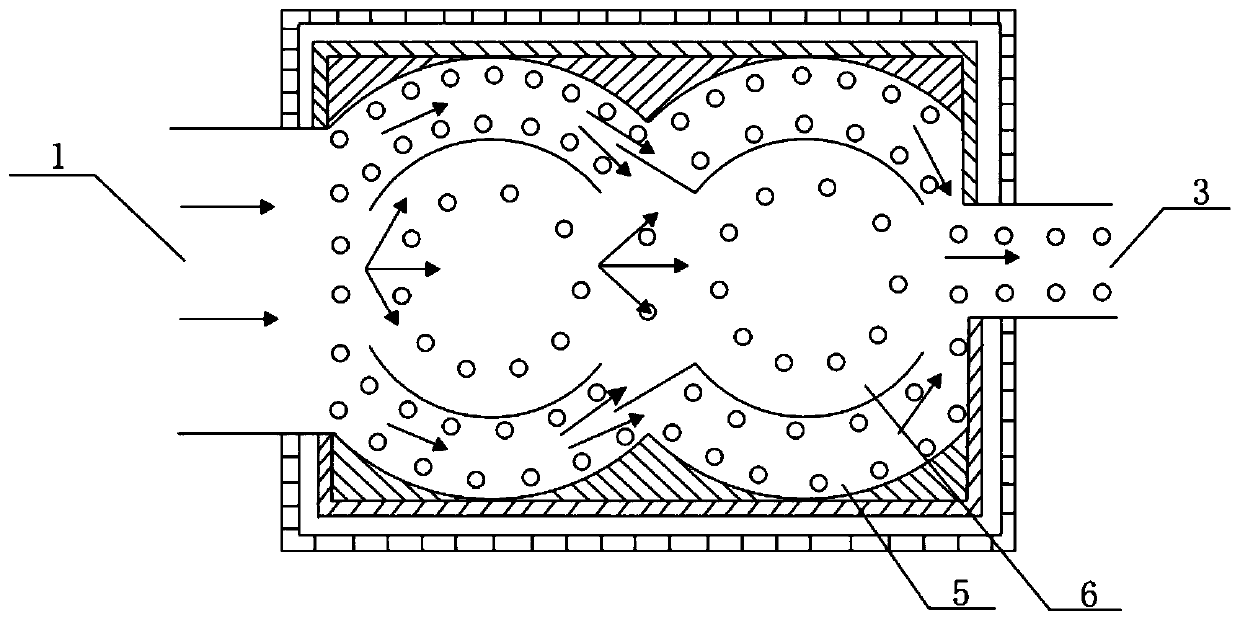

Gas well structure for electrode roasting furnace

InactiveCN101571353AOverall goodGood absorption of expansion stress performanceFurnace componentsFurnace temperatureGraphite electrode

The invention discloses an electrode roasting furnace in the field of graphite electrode production, in particular to a gas well structure for an electrode roasting furnace. The gas well structure is characterized in that a gas well building body is built by gas well shaped bricks, a gas well mouth is arranged at the top of the gas well and a combustion-supporting air inlet opening is arranged at the upper part of the gas well. The gas well has good integrity; because a plurality of dilatation joint structures are arranged in the gas well building body, the gas well building body has good swelling stress absorption property; the gas well ensures the reliable deformation resistance when being taken as the combustion space and sufficient combustion-supporting air enters during the fuel combustion to achieve the purpose of complete combustion and improves the utilization ratio of fuel and reduces the energy consumption; the gas well keeps the cross section basically unchanged, is favorable for keeping the reasonable distribution of the negative pressure in the flame system and the smooth smoke flowing and effectively ensures the compliance between the furnace temperature distribution and the baking curve and the quality of the baked products; and the gas well can effectively ensure the capability of the main smoke extraction system to provide the negative pressure to the electrode roasting furnace.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

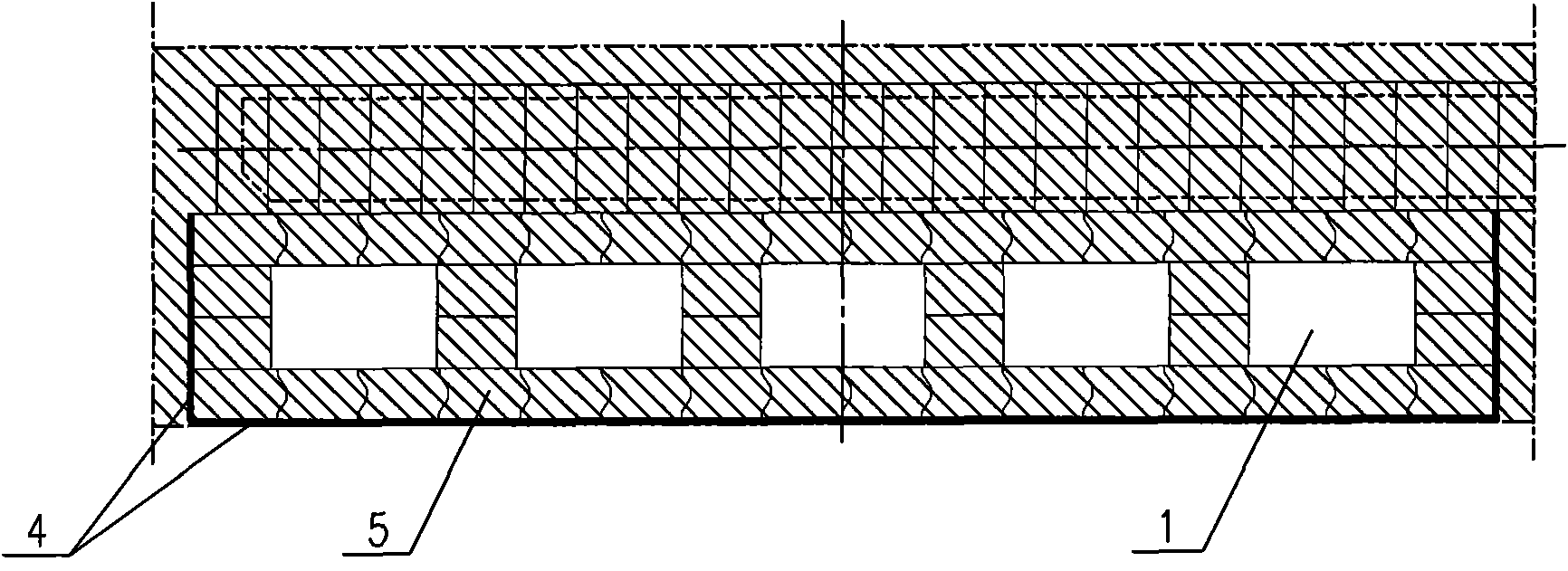

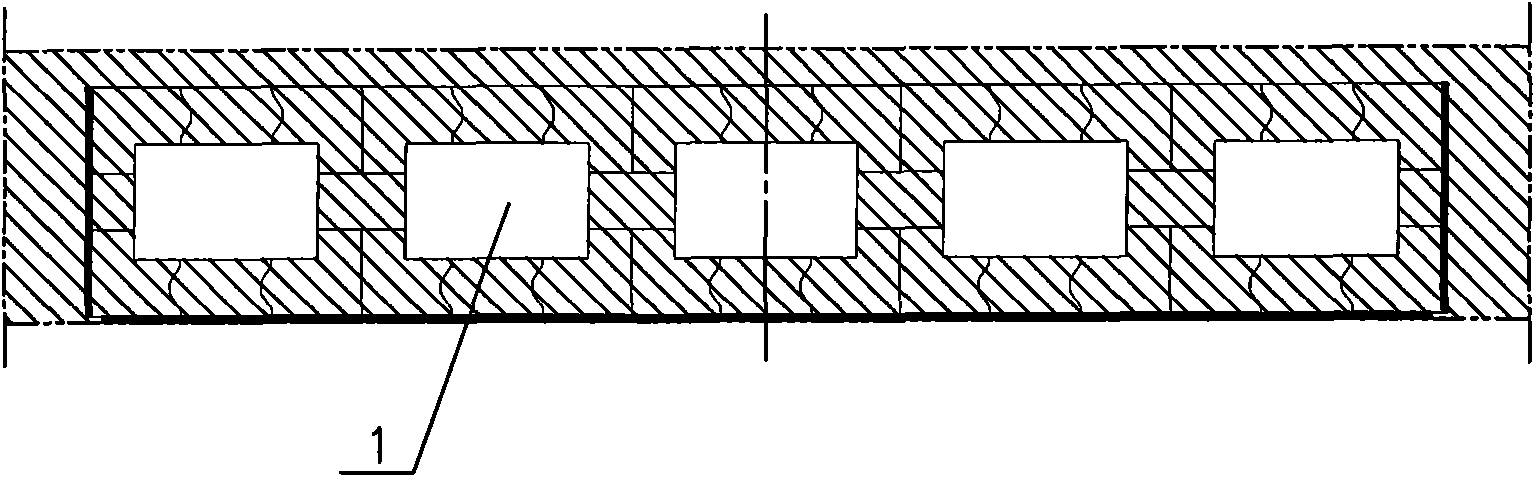

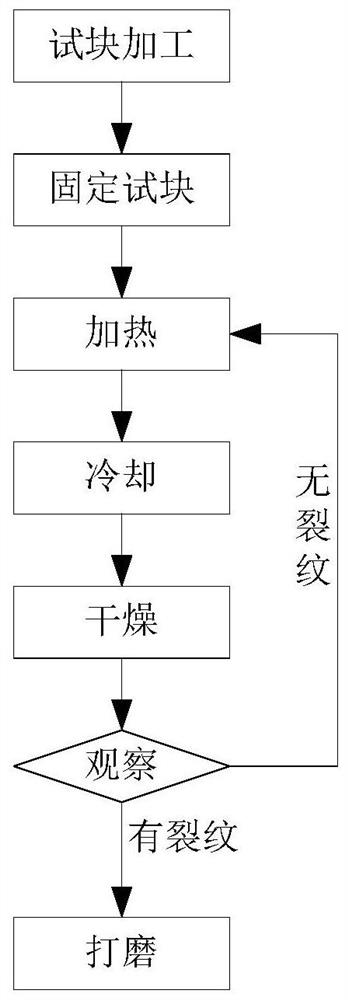

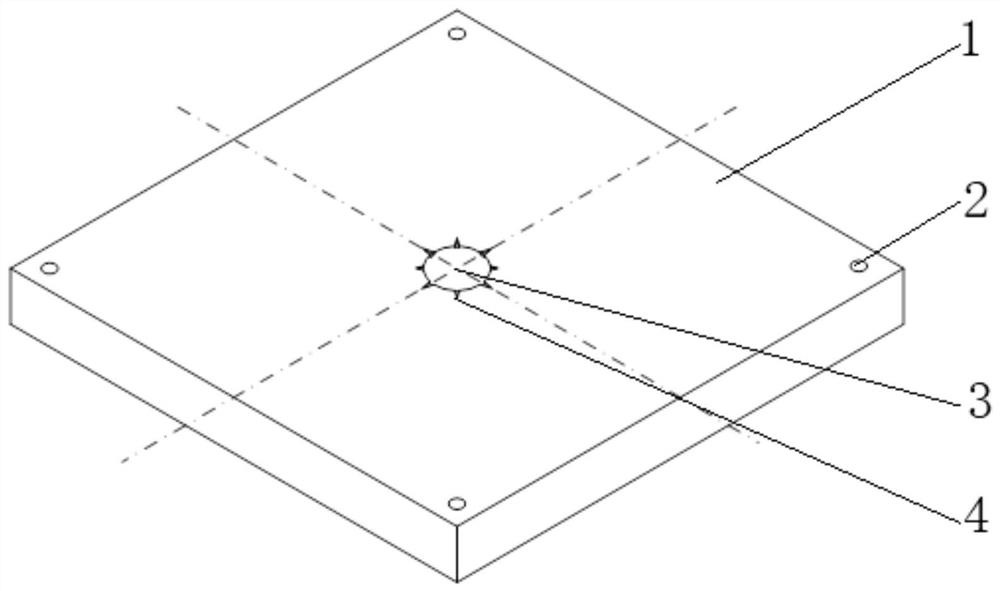

Preparation method of thermal fatigue crack simulation test block

PendingCN112903827AGenerate fastGuaranteed safe operationMaterial analysis using sonic/ultrasonic/infrasonic wavesThermal fatiguePower station

Owner:XIAN THERMAL POWER RES INST CO LTD

Oxygen lance opening sealing device in converter waste heat boiler

PendingCN114317875ATake advantage ofReduce energy consumptionManufacturing convertersProcess efficiency improvementNitrogen gasEnvironmental geology

The invention discloses an oxygen lance muzzle sealing device in a converter waste heat boiler, which comprises a sealing seat and a nitrogen sealing plug, at least one upper nitrogen inlet is arranged on the nitrogen sealing plug and distributed at the top of the nitrogen sealing plug, and each upper nitrogen inlet is hermetically connected with an upper nitrogen connecting pipe; the sealing seat is of a double-layer sealing seat structure composed of a steam sealing seat and a nitrogen sealing seat fixedly arranged at the bottom of the steam sealing seat. Double-layer sealing of an oxygen lance opening is achieved through first air curtain nitrogen sealing of the nitrogen sealing plug part and second nitrogen ring sealing of the nitrogen sealing seat part in the initial smelting stage, after operation is stable, nitrogen supply of the nitrogen sealing seat part is stopped, steam is supplied to the steam sealing seat part through steam generated by a converter waste heat boiler, and the oxygen lance opening is sealed. At the moment, double-layer sealing of the oxygen lance opening is achieved through first air curtain nitrogen sealing of the nitrogen sealing plug part and second steam ring sealing of the steam sealing seat part, and the oxygen lance opening sealing device has the advantages of being good in sealing effect, long in service life, low in operation cost and the like.

Owner:SUZHOU HAILU HEAVY IND

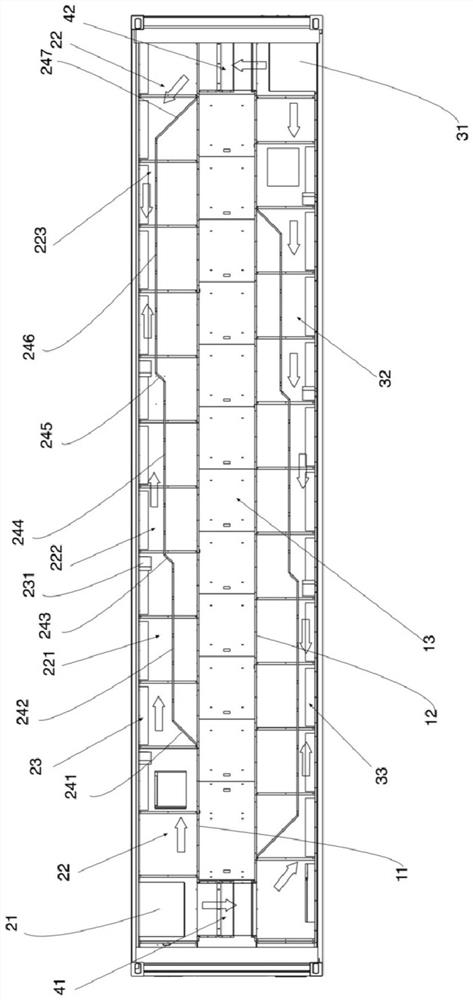

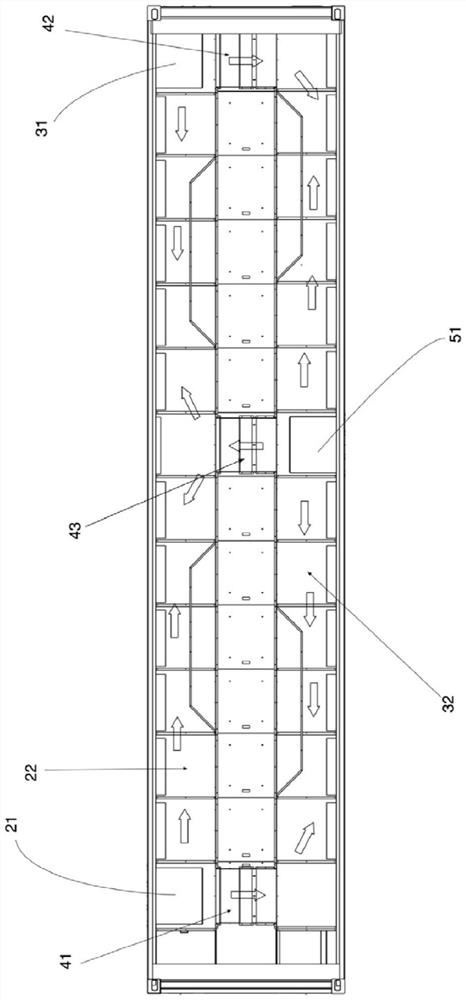

Machine room refrigerating system and energy storage machine room

PendingCN114786422AAvoid hitting the duct wallImprove cooling efficiencyCooling/ventilation/heating modificationsCold airEngineering

The invention discloses a machine room refrigerating system and an energy storage machine room, the machine room extends along a first direction and comprises two oppositely arranged machine cabinet columns, the refrigerating system comprises cold air ducts located above the machine cabinet columns, and the cold air ducts are provided with a plurality of lower air ports used for supplying air to the backs of the corresponding machine cabinet columns; the communicating air ducts are located at the first end and the second end of the machine room in the first direction, and the two ends of each communicating air duct communicate with the two opposite cold air ducts; the air conditioners are arranged in the machine room, air outlets of the at least two air conditioners are located at the first end and the second end of the machine room in the first direction, and the air conditioners are suitable for supplying air to the cold air duct and the communicating air duct; by opening the cold air duct, cold air can be shared under the condition that one air conditioner cannot refrigerate, and meanwhile, the cold air duct is matched with the position of the air conditioner, so that the refrigeration efficiency of the cabinet can be effectively improved, and the balance of the refrigeration effect of each cabinet can be improved.

Owner:厦门科华数能科技有限公司

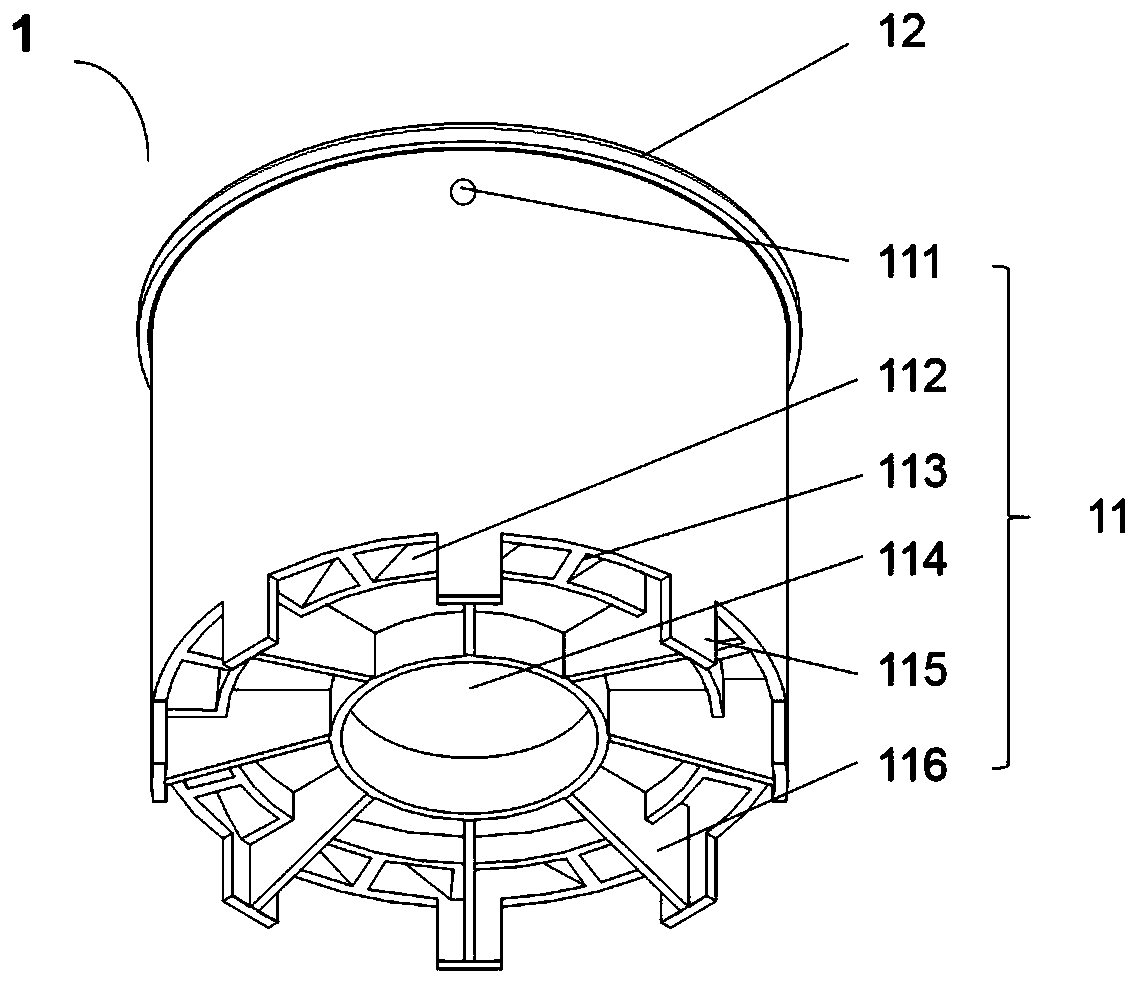

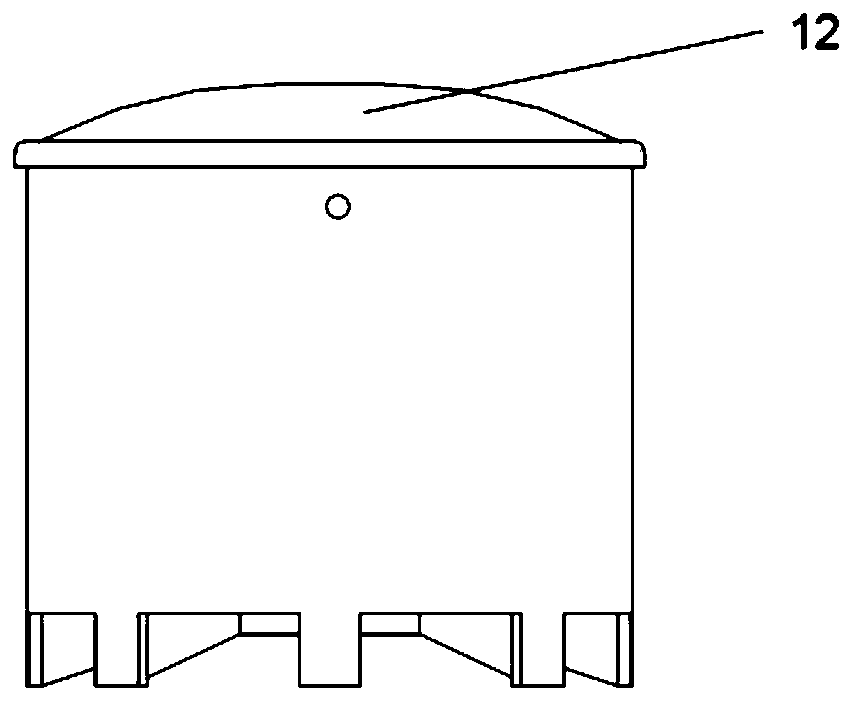

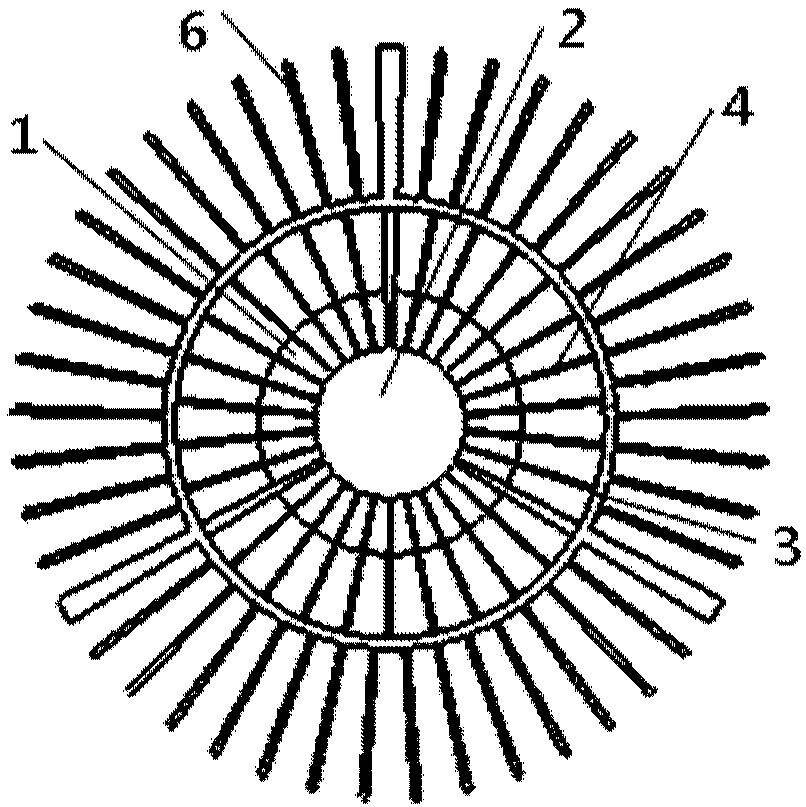

Air inlet and dust discharge device, air filter and micro-cultivator

PendingCN111412090AImprove performanceRelieve pressureMachines/enginesAir cleaners for fuelAir filterAcute angle

The invention discloses an air inlet and dust discharge device for an air filter, the air filter with the air inlet and dust discharge device and a micro-cultivator with the air filter. The air inletand dust discharge device for the air filter comprises an upper shell and a waterproof cover, wherein the upper shell is of a column-shaped structure with an opening in the upper end, the waterproof cover covers the opening, a dust discharging opening is formed at the position, close to the opening in the upper shell, of the side wall of the upper shell, a plurality of air inlets are formed in thebottom surface of the upper shell, are uniformly distributed in an annular array along the outer edge of the circumference of the bottom surface, and are provided with flow guide plates, the flow guide plates are inclined towards the interior of the upper shell in the circumferential direction, acute angles are formed between the flow guide plates and the bottom surface of the upper shell, and the inclination angles of all the flow guide plates are the same. Air with dust enters from the air inlets and is guided by the flow guide plates to form cyclone to rotationally rise in the upper shell,the dust can be discharged out of the upper shell when rotating to the dust discharging opening, the air subjected to primary dust discharging enters a filter device, so that the pressure of the filter device is reduced, and the performance of the air filter is further improved.

Owner:云南豪祥农业科技有限公司

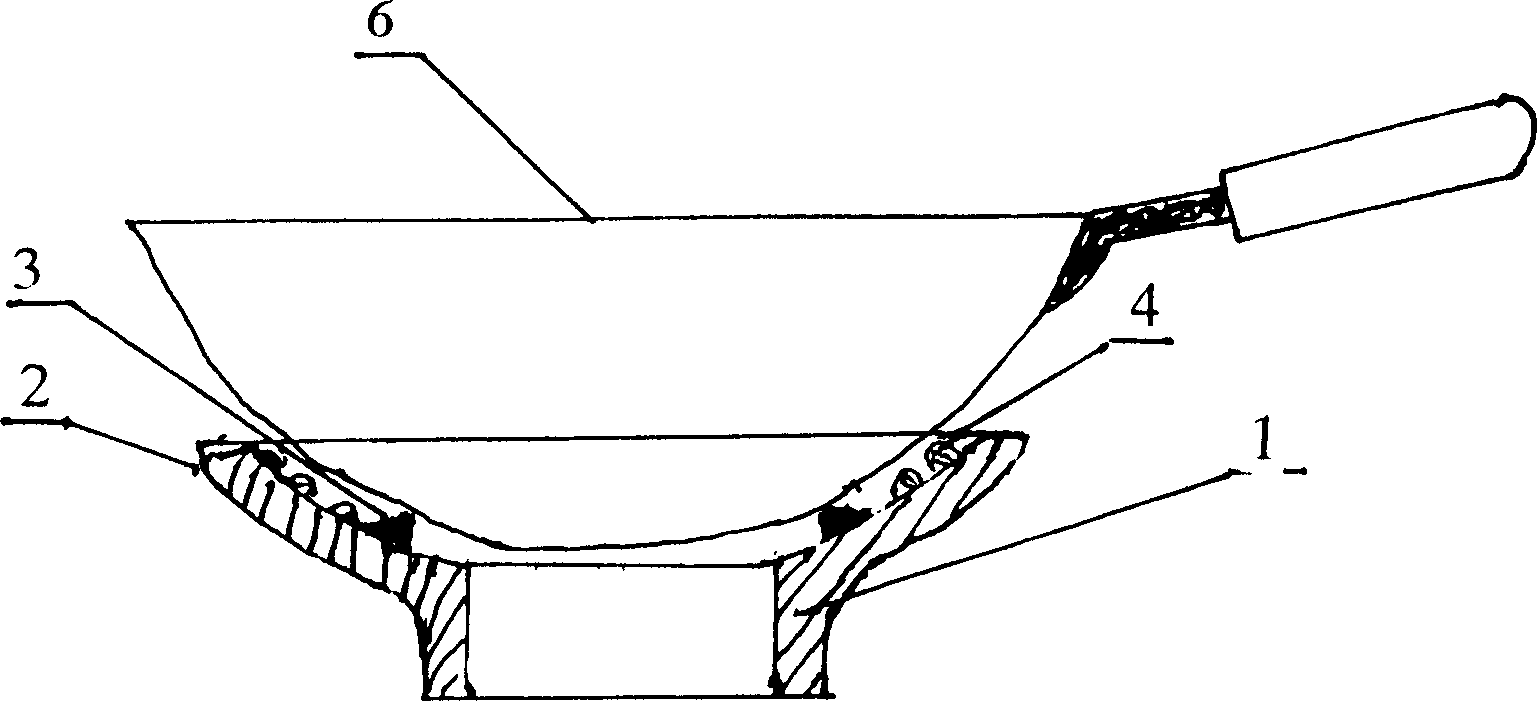

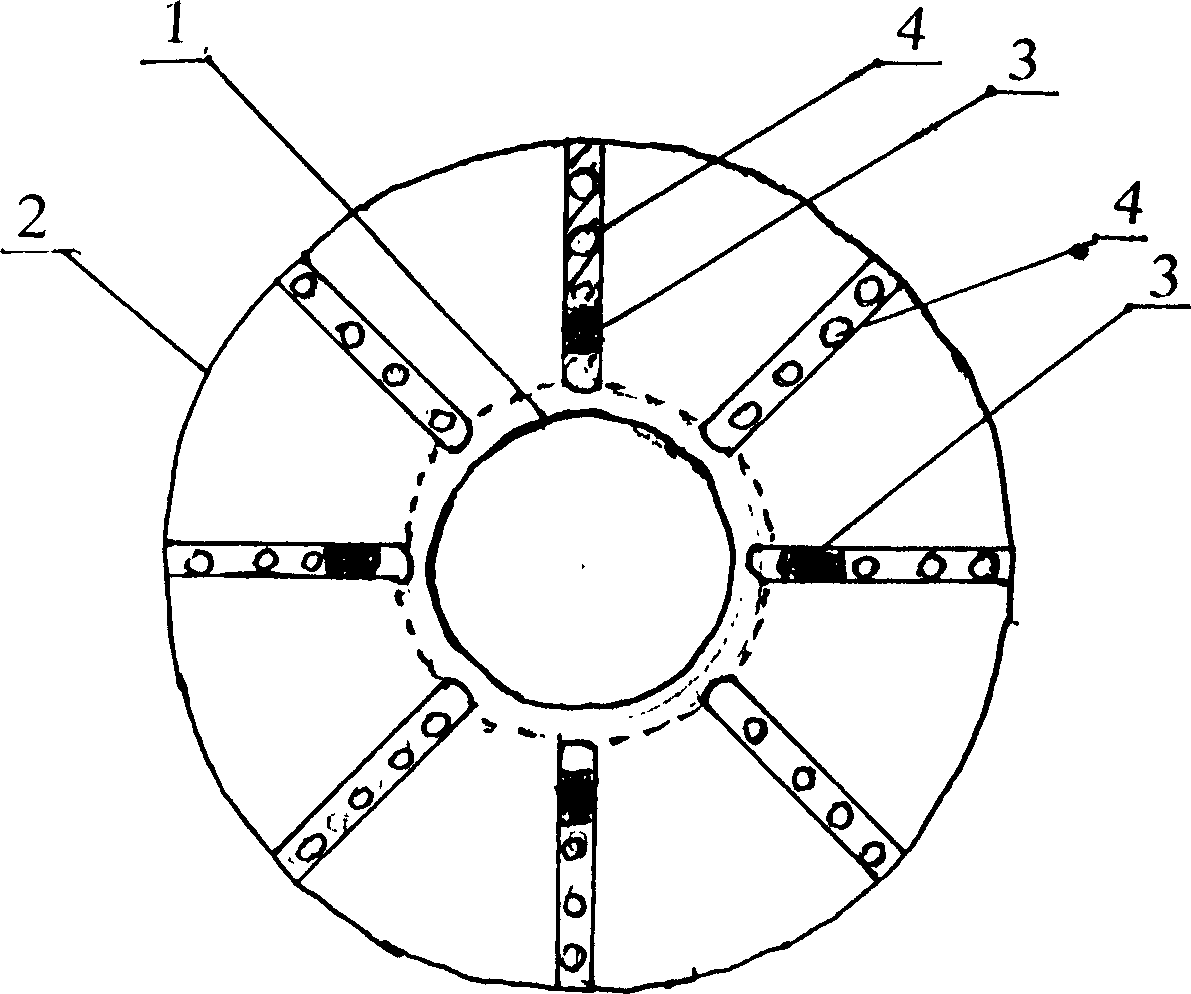

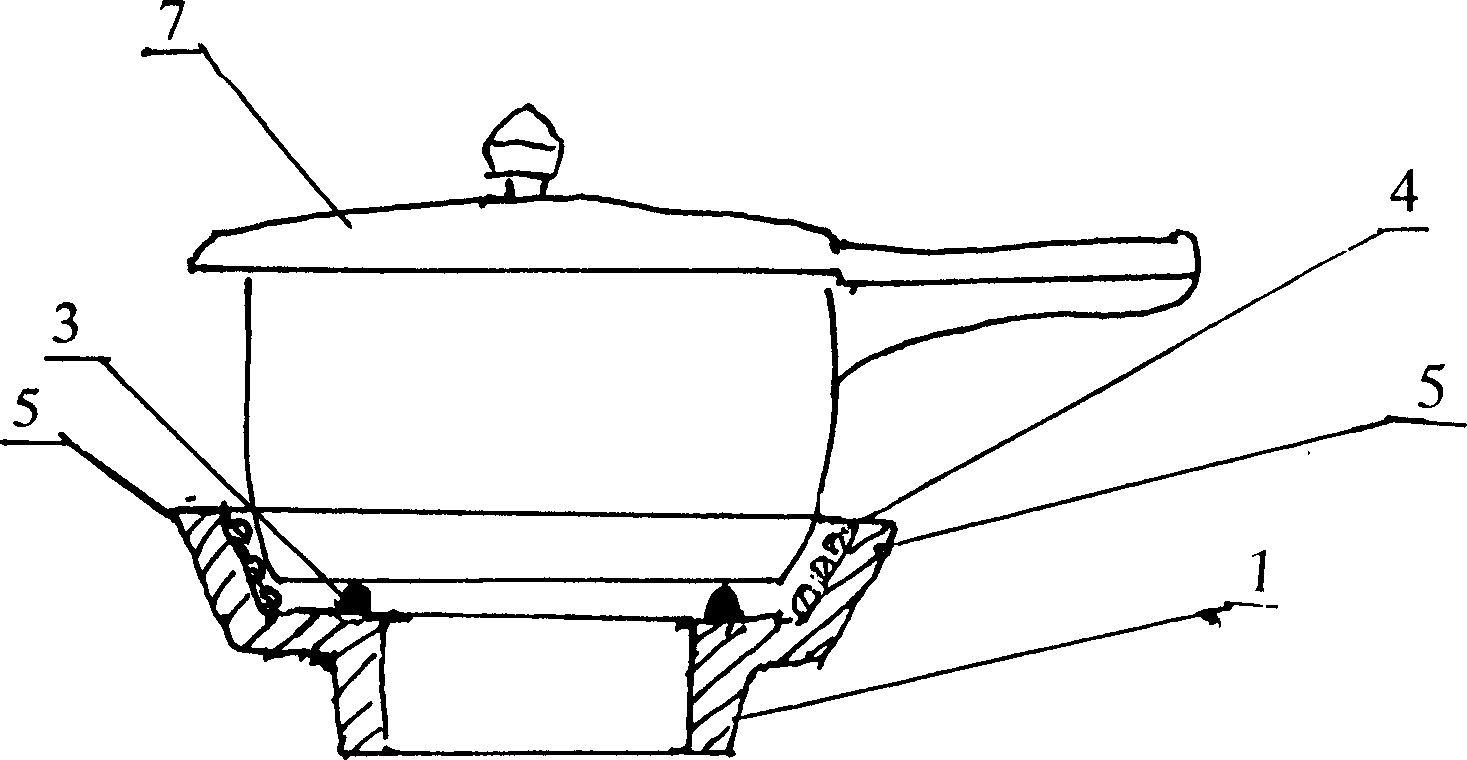

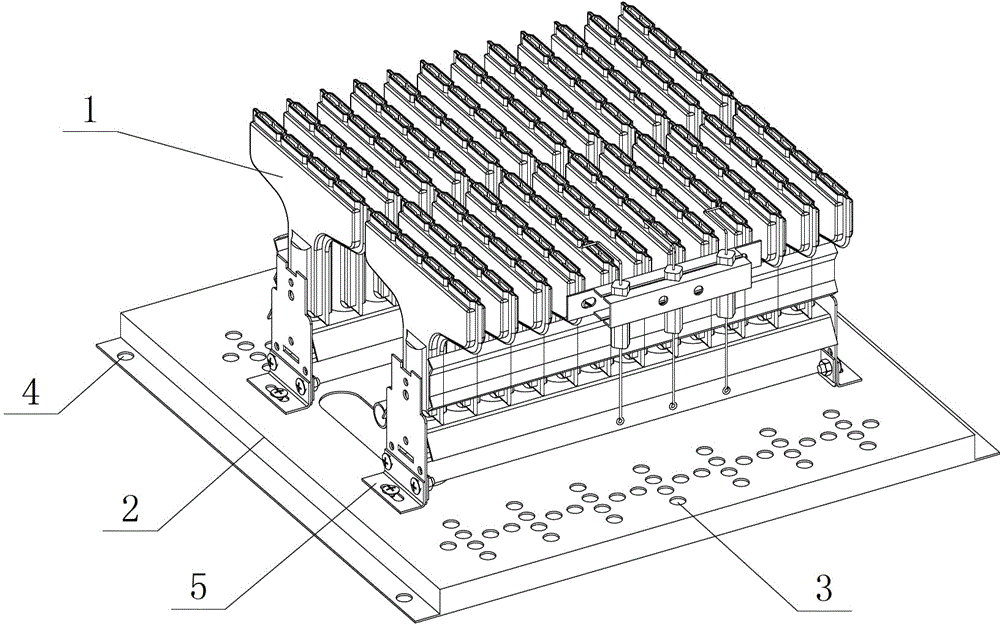

Gas water boiler

The utility model discloses a gas water boiler and is capable of effectively solving the problems of inconvenient arrangement of burners and wasting time and energy of the prior gas water boiler. The gas water boiler comprises a burner and a base plate, wherein the burner is fixed on the base plate, a plurality of air holes are formed on the base plate, fixing holes are formed at the rim of the base plate to fix the frame of the gas water boiler. The gas water boiler has the advantages that the burner is fixed on the base plate, and then the frame of the gas water boiler is fixed on the base plate, thereby greatly decreasing installation difficulty, improving installation efficiency, and simultaneously, the air holes enable to ensure enough oxygen gas to enter the burner.

Owner:ZHEJIANG XUSHI KITCHEN APP

Special manual air inlet valve for device in bearing water storage equipment

InactiveCN102425696ASolve the problem of not being able to automatically discharge waterRealize threaded connectionOperating means/releasing devices for valvesAerating valvesWater storageInlet valve

The invention relates to an air inlet valve, in particular to a special manual air inlet valve for a device in bearing water storage equipment, and solves the problem of incapability of automatic outlet water upon water supply cut-off of an external water supply system and formation of negative pressure at a high position of a pipeline system existing in the bearing water storage equipment. The special manual air inlet valve for the device in the bearing water storage equipment comprises an air collection pipe, an air collection pipe joint, an air inlet pipe, a seal ring, a push rod, a push button, a compression spring and a valve seat, wherein the lower end of the air collection pipe is provided with an opening; the air collection pipe joint is hermetically connected to the upper end of the air collection pipe; the upper end of the air inlet pipe extends into the inner cavity of the air collection pipe, and is close to the lower end face of the air collection pipe joint; and the lower end of the air inlet pipe extends out of the air collection pipe and is hermetically connected with a middle circular hole of the valve seat. Through the valve, the problem of incapability of automatic outlet water upon water supply cut-off of the external water supply system and formation of negative pressure at the high position of the pipeline system existing in the bearing water storage equipment is effectively solved; and the valve is suitable for various kinds of bearing water storage equipment.

Owner:王贵林

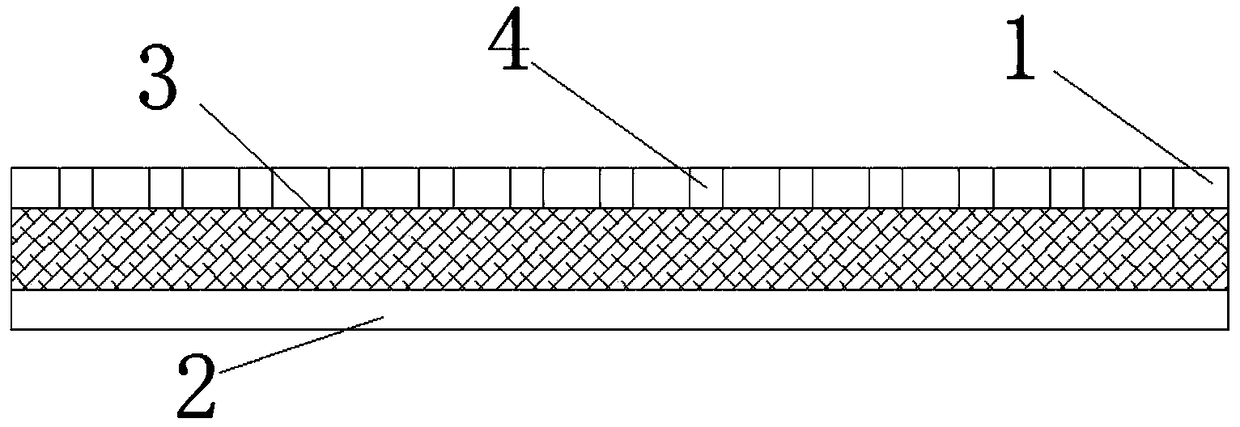

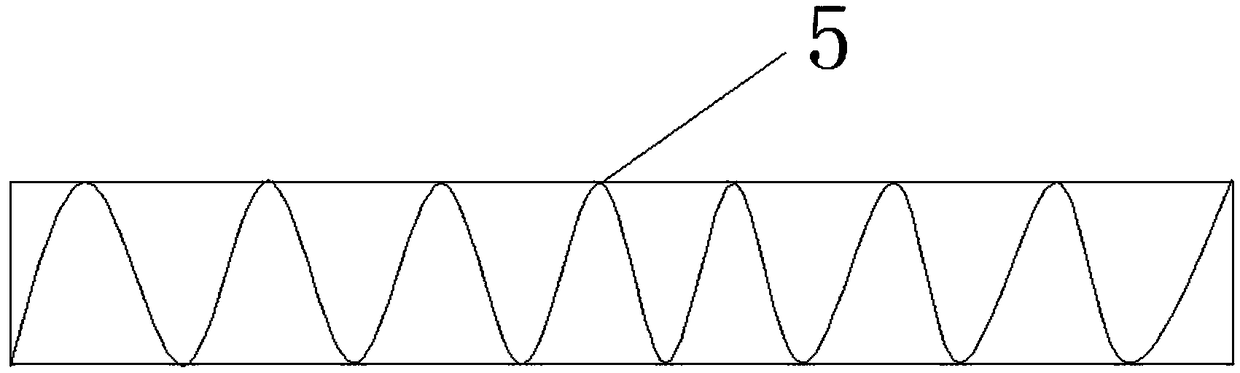

Lawn seed belt convenient for degradation

PendingCN108781600AInfluential impactAvoid spillingHops/wine cultivationTurf growingFluff pulpPulp and paper industry

The invention relates to a lawn seed belt convenient for degradation. The lawn seed belt comprises an upper fluff pulp belt and a lower fluff pulp belt, wherein glue is sprayed on the lower surface ofthe upper fluff pulp belt in an S shape, glue is sprayed on the upper surface of the lower fluff pulp belt in an S shape, and glue of the upper fluff pulp belt and glue of the lower fluff pulp belt are staggered with each other up and down; a seed mixture is evenly distributed between the upper fluff pulp belt and the lower fluff pulp belt, and comprises lawn seeds, high molecular water-absorbingparticles and fertilizers; and the upper fluff pulp belt is provided with a plurality of grass outlet holes. The lawn seed belt provided by the invention has the advantages of high seed survival rate, easy degradation of the seed belt and safe transportation.

Owner:杭州考拉之屋贸易有限公司

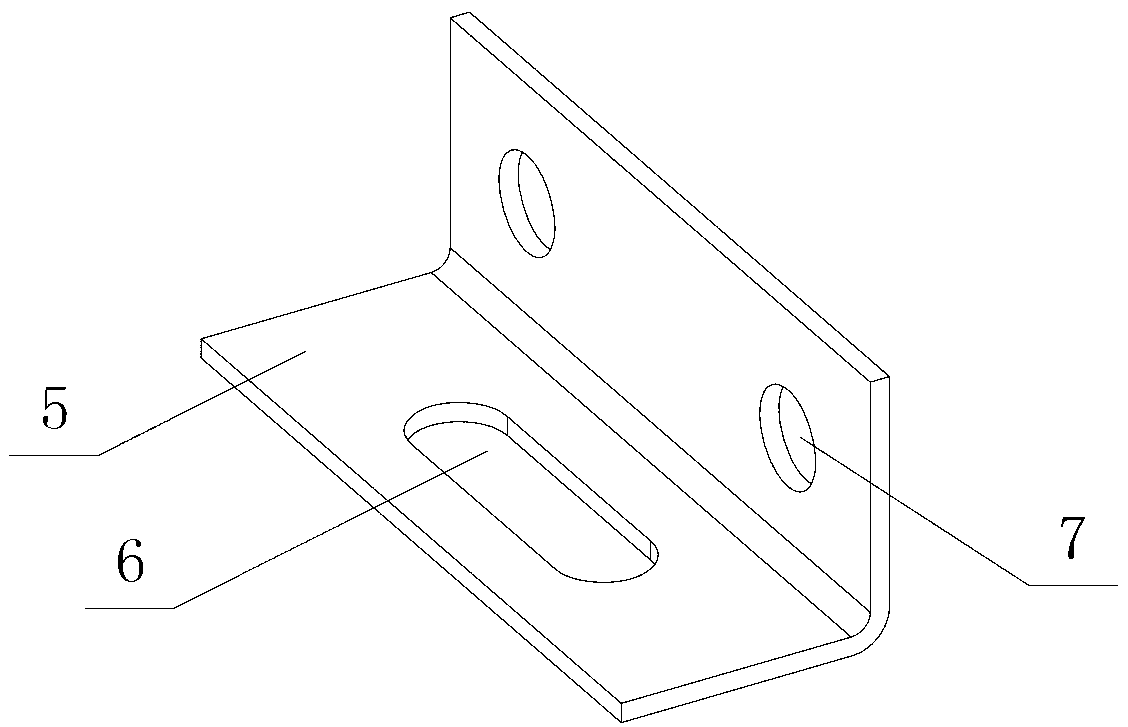

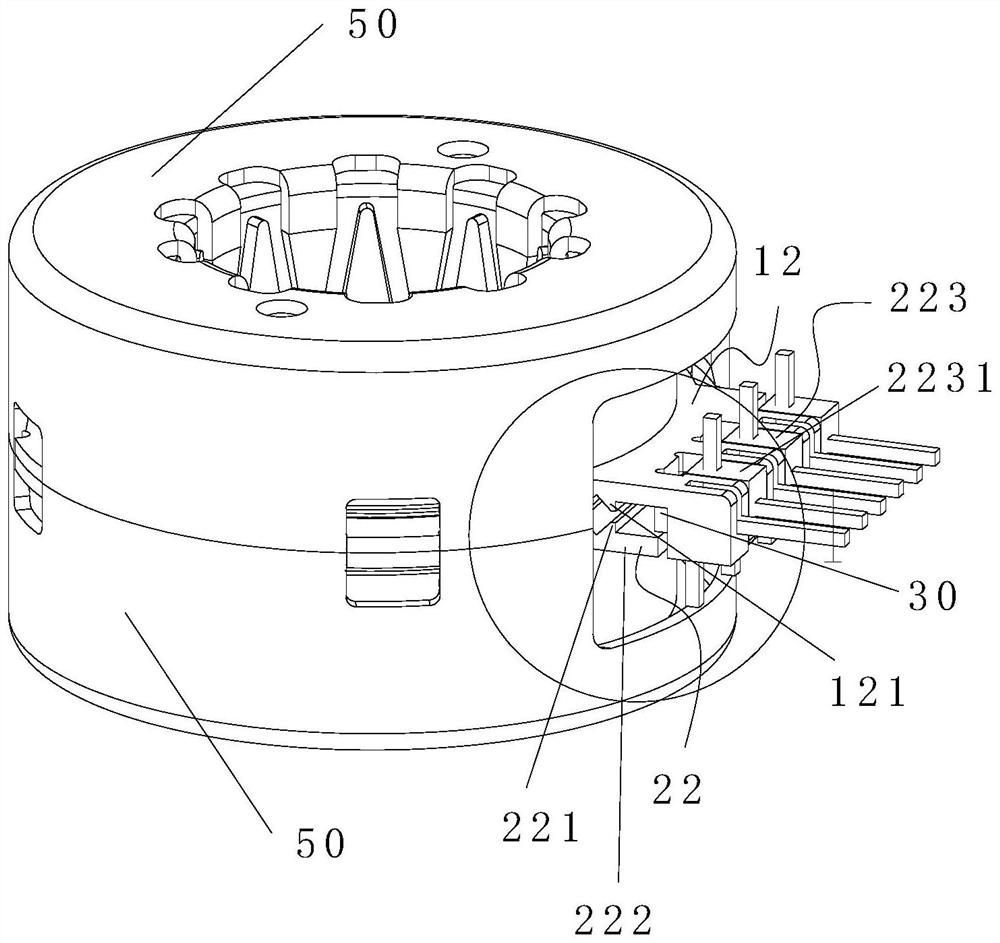

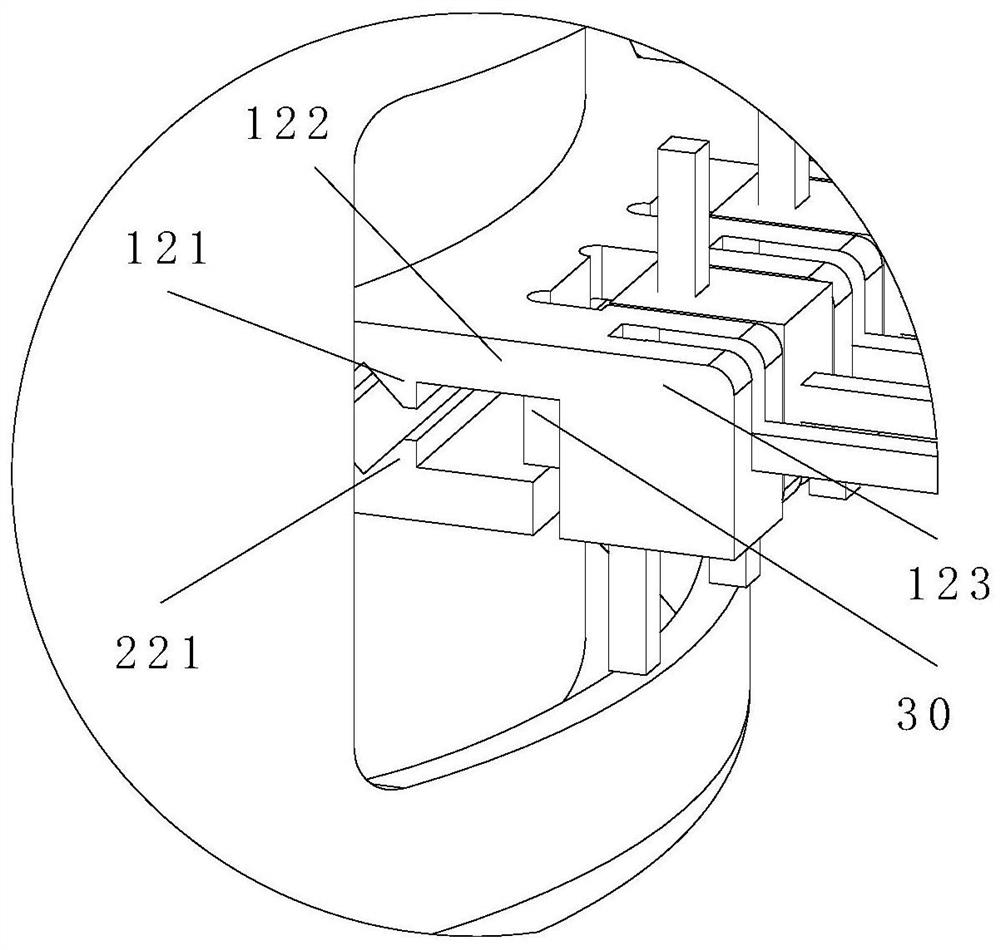

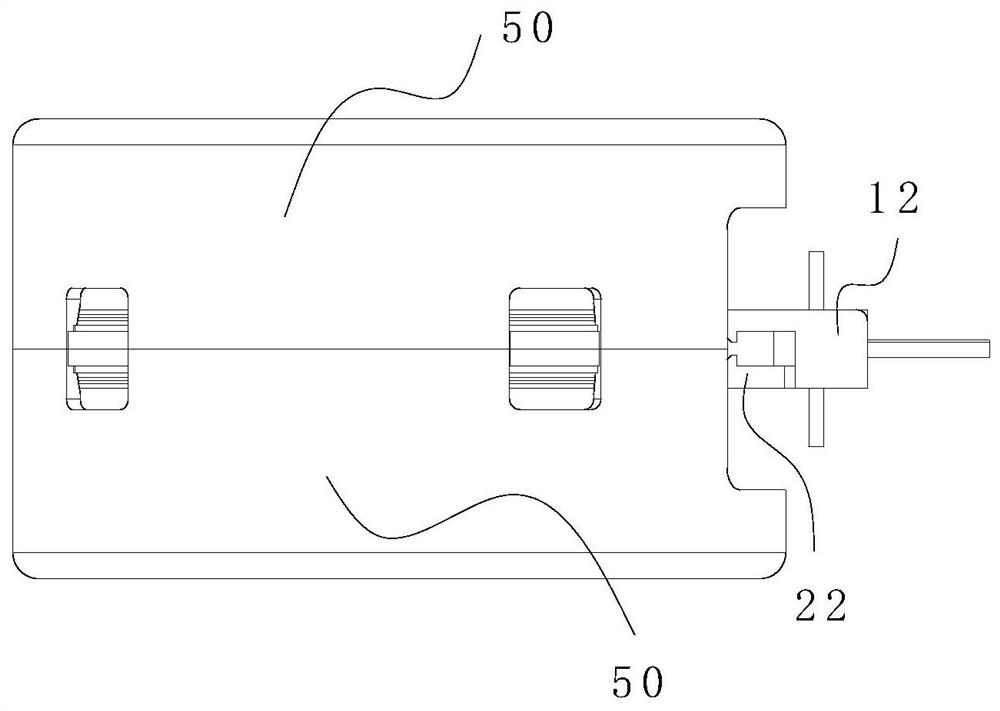

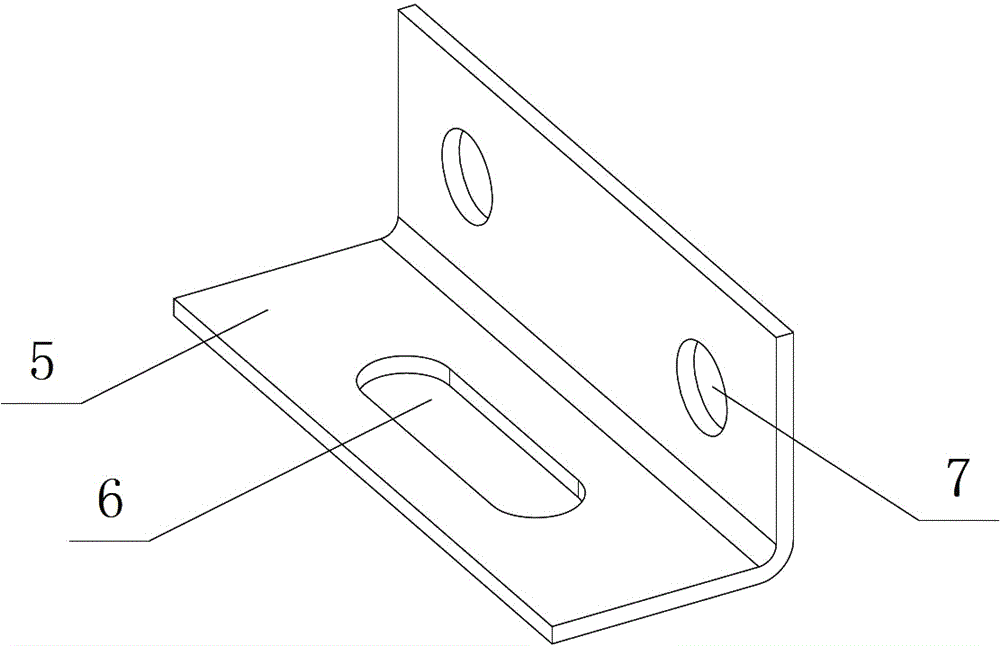

Framework structure and electronic expansion valve with framework structure

ActiveCN113357852AAvoid deformationAvoid situations where the distance decreasesMechanical apparatusPlastic packagingStructural engineering

The invention provides a framework structure and an electronic expansion valve with the framework structure. The framework structure is used for winding a coil, the framework structure comprises a first framework, a second framework and a supporting structure, the first framework comprises a first frame body and a first plug pin structure, the first plug pin structure is arranged on the first frame body, and the first plug pin structure comprises a first waterproof rib; the second framework comprises a second frame body and a second plug pin structure, the second plug pin structure is arranged on the second frame body, the second plug pin structure comprises a second waterproof rib, and the second waterproof rib and the first waterproof rib are arranged at an interval; and at least part of the supporting structure is arranged on the first plug pin structure, and the supporting structure is used for being matched with the second plug pin structure in an abutting manner. By means of the technical scheme, the technical problem that in the prior art, a framework structure of an electronic expansion valve is prone to deformation in the plastic packaging process can be solved.

Owner:DUNAN ENVIRONMENT TECH

Air supplying type thermal insulation gas kitchen range

InactiveCN1807991APromote combustionPrevent disseminationDomestic stoves or rangesLighting and heating apparatusHigh volume manufacturingThermal insulation

The invention relates to a wind feeding thermal-insulation gas kitchen range, which comprises a frame 14 as carrier, a wind adsorption cover 23, a fan 17, a wind tube 18 and a flameout protection device 27, which are inside the frame. Wherein, the gas fuel burner 16 is at the center of frame groove 21; the fuel gas channel 15, the fuel gas ignition switch 20 and the fan switch 19 are on the frame 14; the burning chamber 1 of frame thermal insulation gas kitchen range core is embedded into the chamber of range core support wall 11; the range core support can use the flame thermal insulation gas kitchen range core in any kinds. And the invention can be produced in batch.

Owner:娄金晶

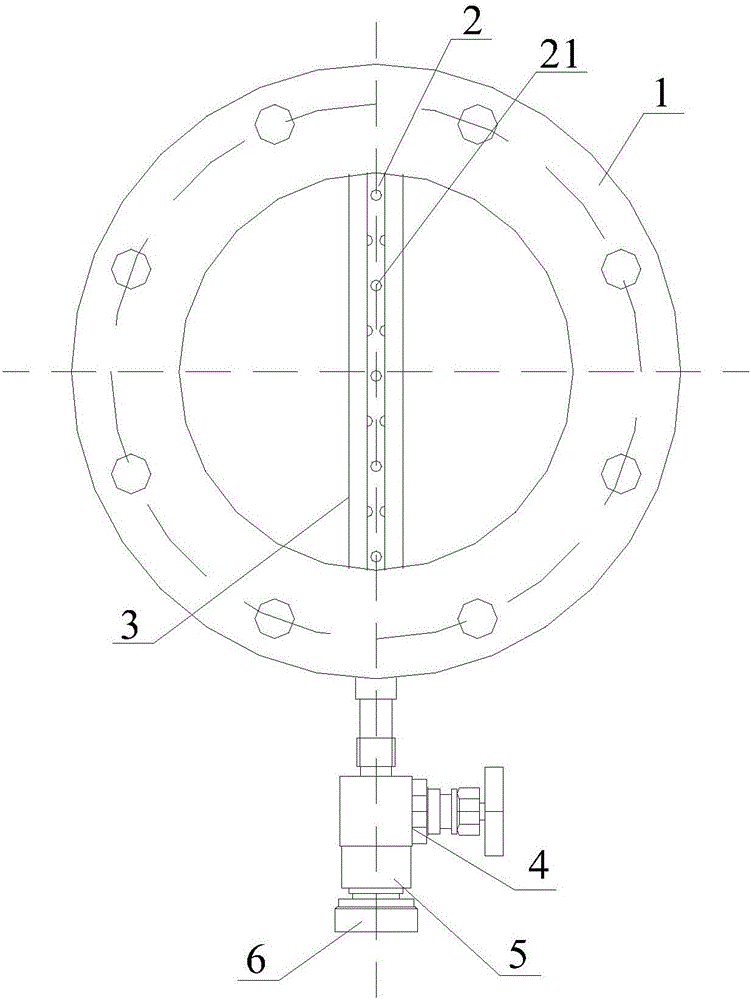

Fuel sampling device

The invention discloses a fuel sampling device. The fuel sampling device comprises a flange, a sampling tube and a needle valve, the sampling tube is mounted on the flange, a plurality of liquid taking holes are arranged in the sidewall of the sampling tube, one end of the sampling tube is fixed to the flange, the other end of the sampling tube traverses through the through hole of the flange and stretches out of the flange, and the needle valve is mounted at the end portion of the sampling tube stretching out of the flange; and the sampling device also comprises a fuel baffle plate, the fuel baffle plate is mounted on the flange, and sleeves the sampling tube, and one side of the fuel baffle plate is provided with an opening. The fuel sampling device has the advantages of simplicity in manufacturing, simplicity in mounting, easiness in operating and cleaning, wide application range, time and labor saving, and cost saving.

Owner:TAIZHOU SANFU SHIP ENG CO LTD

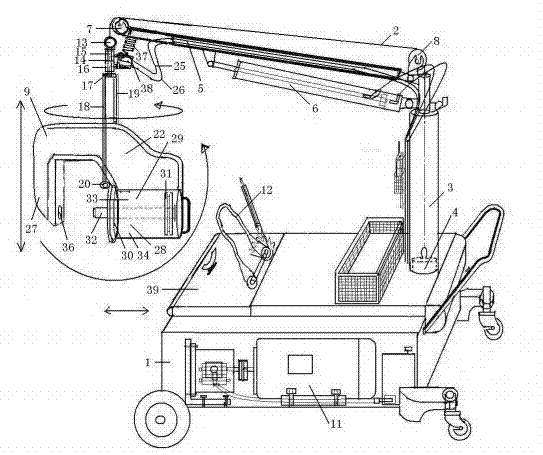

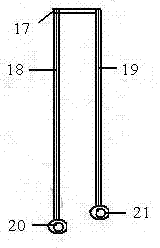

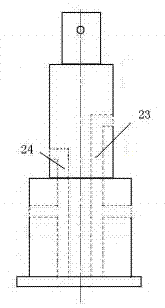

Automotive frame fold straightening machine

The invention discloses an automotive frame fold straightening machine which comprises a car body, a wire cable, a stand column, a clump weight, a swinging strut, an adjusting oil cylinder, a front fixed pulley and a rear fixed pulley. The automotive frame fold straightening machine further comprises an omnibearing rotation straightening device which can rotate 360 degrees in the horizontal direction and the vertical direction, a remote control receiver which is installed in the car body and used for controlling the omnibearing rotation straightening device, and a motor oil pump set which provides power for the omnibearing rotation straightening device through an oil pipe. The motor oil pump set is electrically connected with the remote control receiver. The omnibearing rotation straightening device is connected with one end of the wire cable through the front fixed pulley. The other end of the wire cable is connected with the clump weight through the rear fixed pulley. A holding frame used for stabilizing the omnibearing rotation straightening device is connected to the front end of the car body. By means of the automotive frame fold straightening machine, an automotive frame can be straightened at any position, as a result, repair difficulty is reduced, and repair efficiency is improved; since the omnibearing rotation straightening device is controlled remotely, the workload of manual intervention is small, and safety performance is higher.

Owner:曾柏林

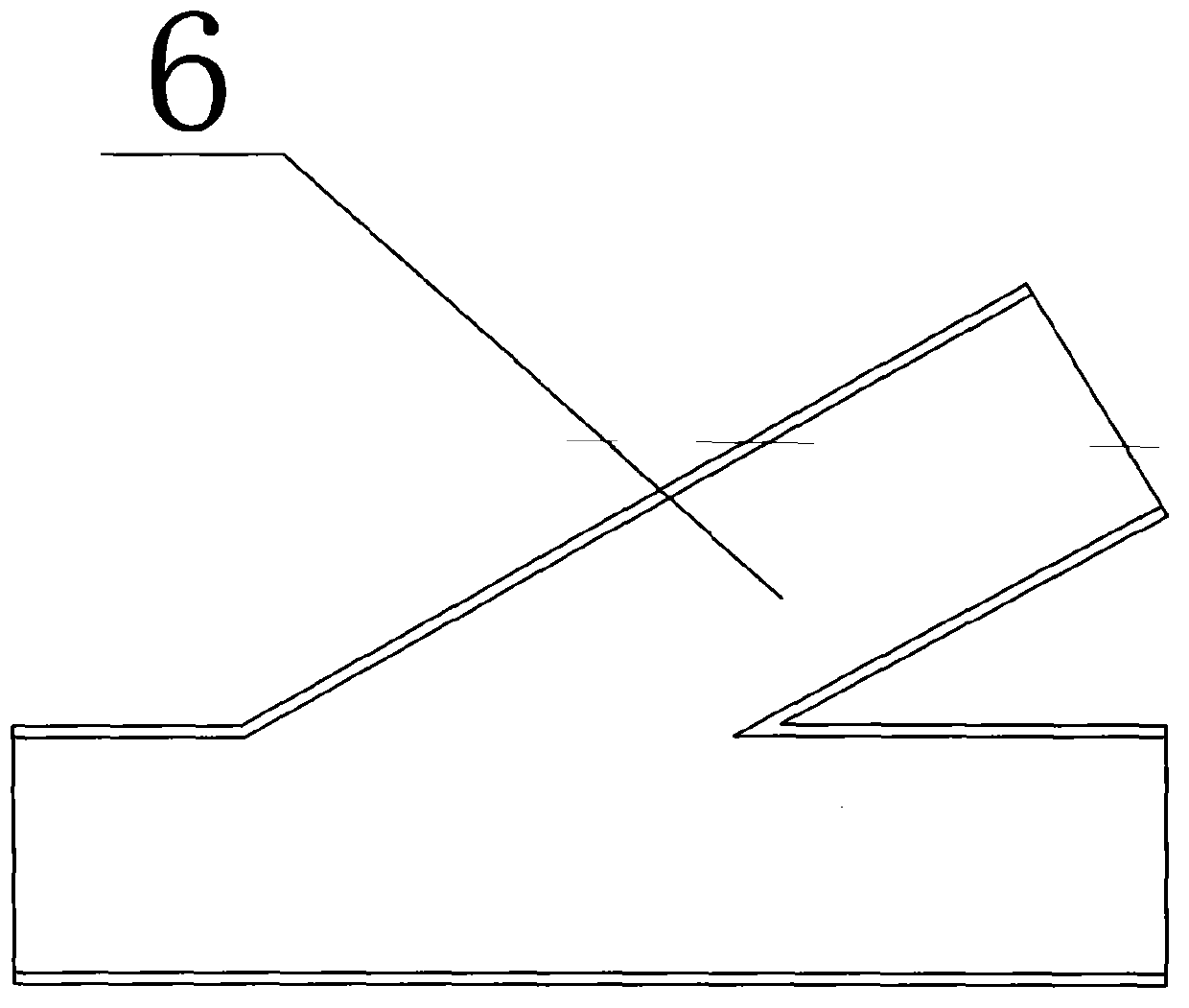

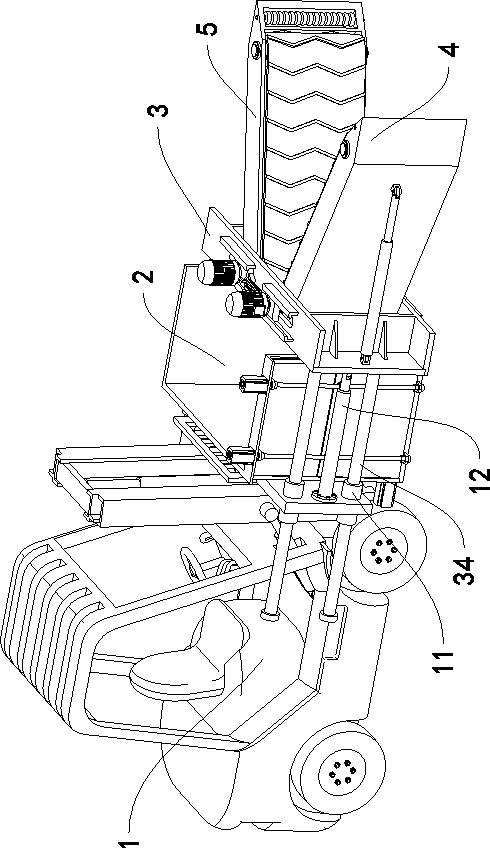

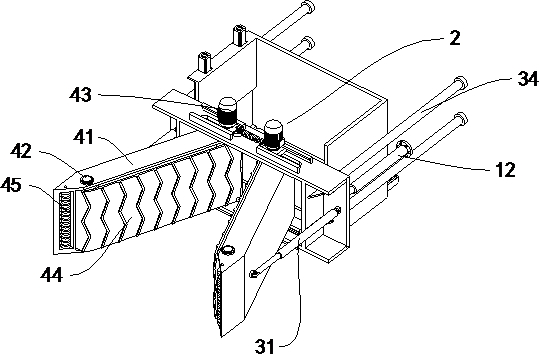

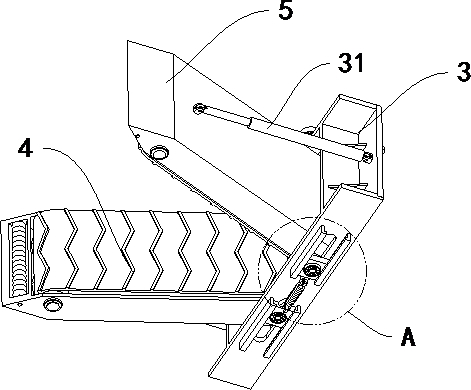

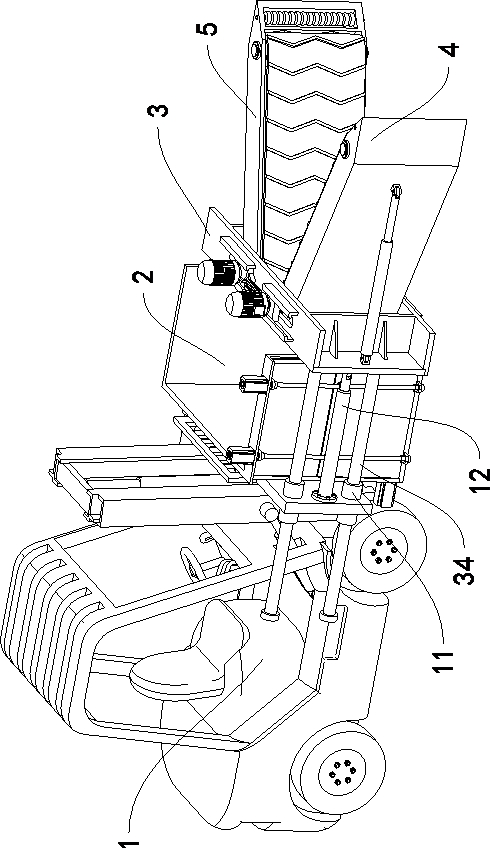

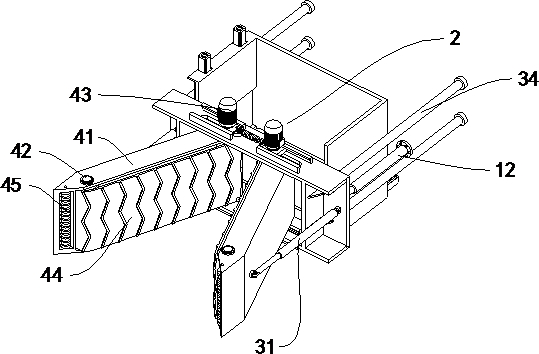

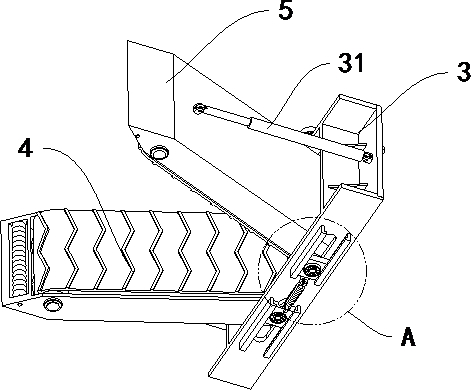

Cargo unloading platform for logistics transportation

ActiveCN111874666ASolve technical problems that are difficult to remove completelyIncrease the angleLoading/unloadingLogistics managementStructural engineering

The invention discloses a cargo unloading platform for logistics transportation, and relates to the technical field of unloading platform equipment. The cargo unloading platform comprises a forklift body, a cargo temporary storage mechanism, a connecting frame, a first material taking arm and a second material taking arm, the connecting frame is installed on the forklift body and located at the lifting end in the forklift body, and the cargo temporary storage mechanism is arranged on the connecting frame and located between the connecting frame and the forklift body; the first material takingarm and the second material taking arm are arranged on the connecting frame in a V-shaped manner, the opening position of the first material taking arm and the second material taking arm is located onthe opposite side of the forklift body, and an opening is formed in the ends, with the small distance, of the first material taking arm and the second material taking arm; and the opening position between the first material taking arm and the second material taking arm is located in the cargo temporary storage mechanism. According to the cargo unloading platform for logistics transportation, thefirst material taking arm and the second material taking arm can drive cargoes to move towards the interior of the cargo temporary storage mechanism through friction force generated by mutual contactof the cargoes and a material taking conveying belt, and therefore the cargoes are gathered towards the middle position in a centralized manner and collected.

Owner:GUANGDONG GENSHO LOGISTICS CO LTD

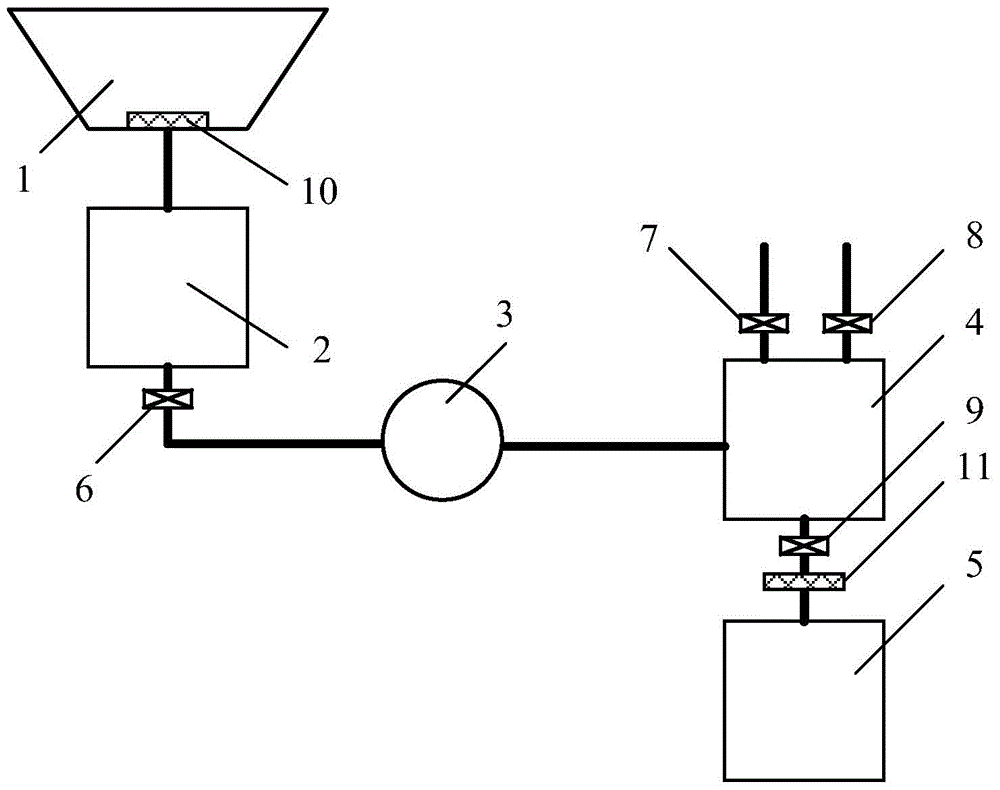

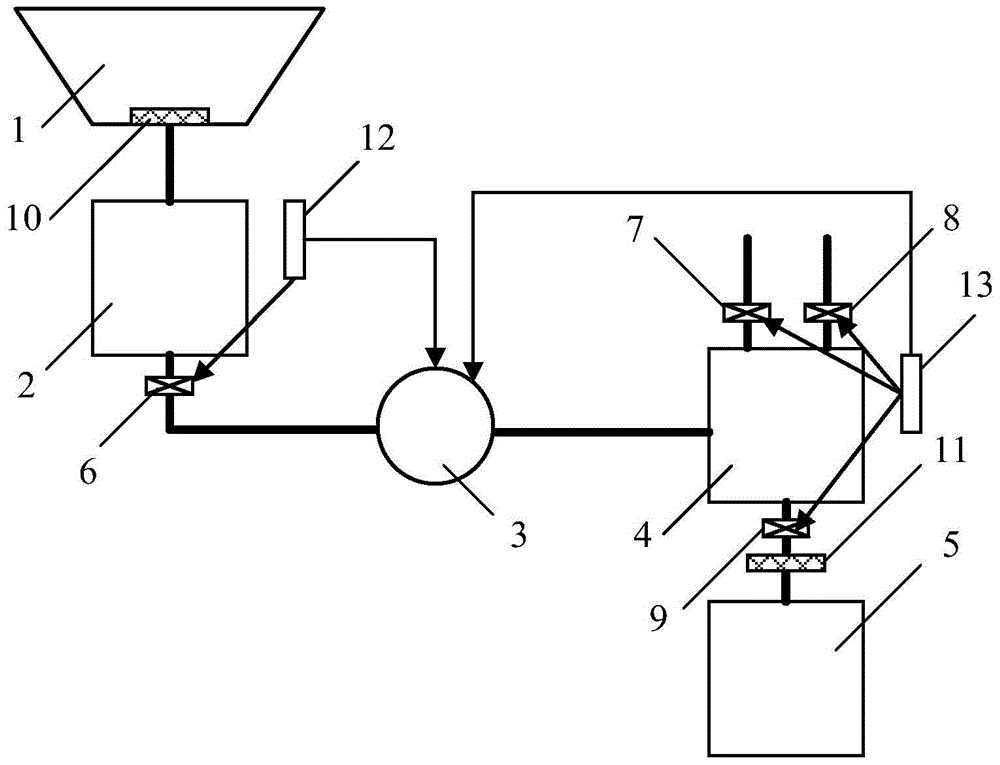

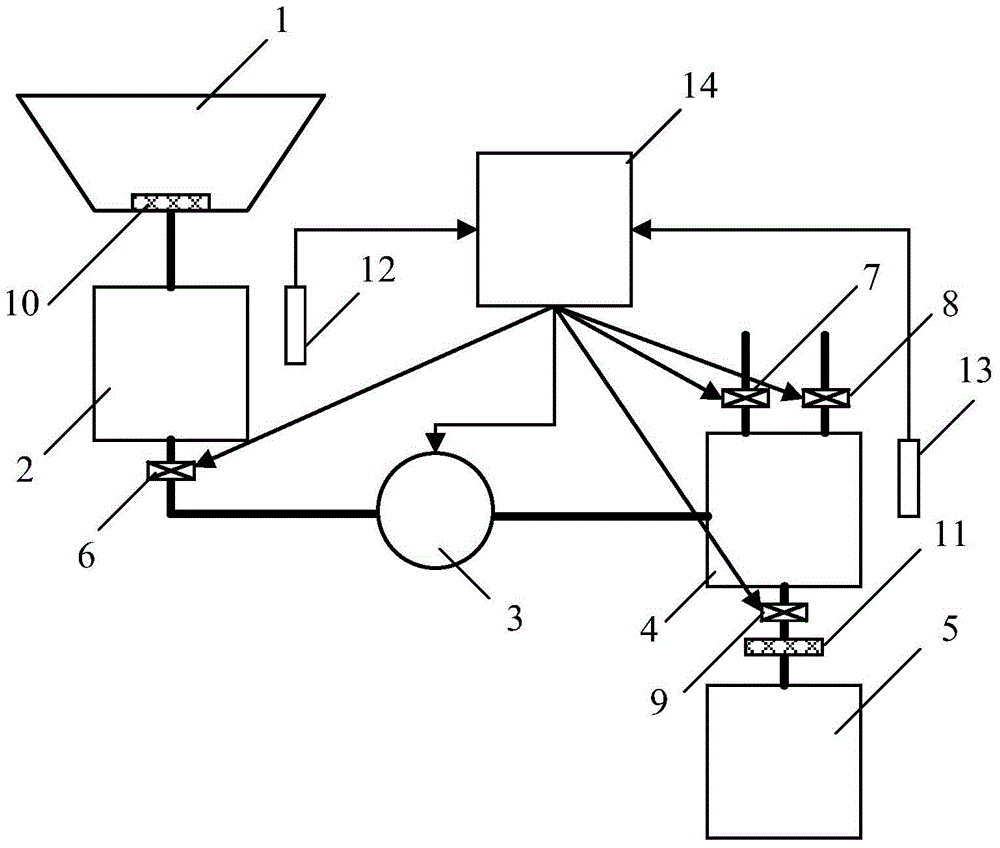

A photoresist recovery system

InactiveCN103769351BAchieve recyclingSufficient buffer timeLiquid surface applicatorsCoatingsEngineeringAtmospheric pressure

The invention discloses a photoresist recovering system which is used for solving the problems that the used photoresist exhausted from a photoresist coating machine is wasted. The system comprises a receiving device which is connected with the photoresist coating device, and a conveying device connected with a first buffer device and a second buffer device, respectively, and is used for conveying the photoresist in the first buffer device into the second buffer device, wherein the top of the second buffer device is connected with a dry and clean air source via a pipeline which is provided with a second control valve; the bottom of the second buffer device is connected with a pipeline which is provided with a fourth control valve; the second buffer device is used for containing the used photoresist conveyed by the conveying device and conveying the used photoresist to a photoresist barrel via the pipeline provided with the fourth control valve under the air pressure provided by the dry and clean air source. The used photoresist exhausted from the photoresist coating machine enters the photoresist barrel via the devices, in this way, the photoresist can be recycled, and consequently, the production cost is reduced.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

A gas water boiler

The utility model discloses a gas water boiler and is capable of effectively solving the problems of inconvenient arrangement of burners and wasting time and energy of the prior gas water boiler. The gas water boiler comprises a burner and a base plate, wherein the burner is fixed on the base plate, a plurality of air holes are formed on the base plate, fixing holes are formed at the rim of the base plate to fix the frame of the gas water boiler. The gas water boiler has the advantages that the burner is fixed on the base plate, and then the frame of the gas water boiler is fixed on the base plate, thereby greatly decreasing installation difficulty, improving installation efficiency, and simultaneously, the air holes enable to ensure enough oxygen gas to enter the burner.

Owner:ZHEJIANG XUSHI KITCHEN APP

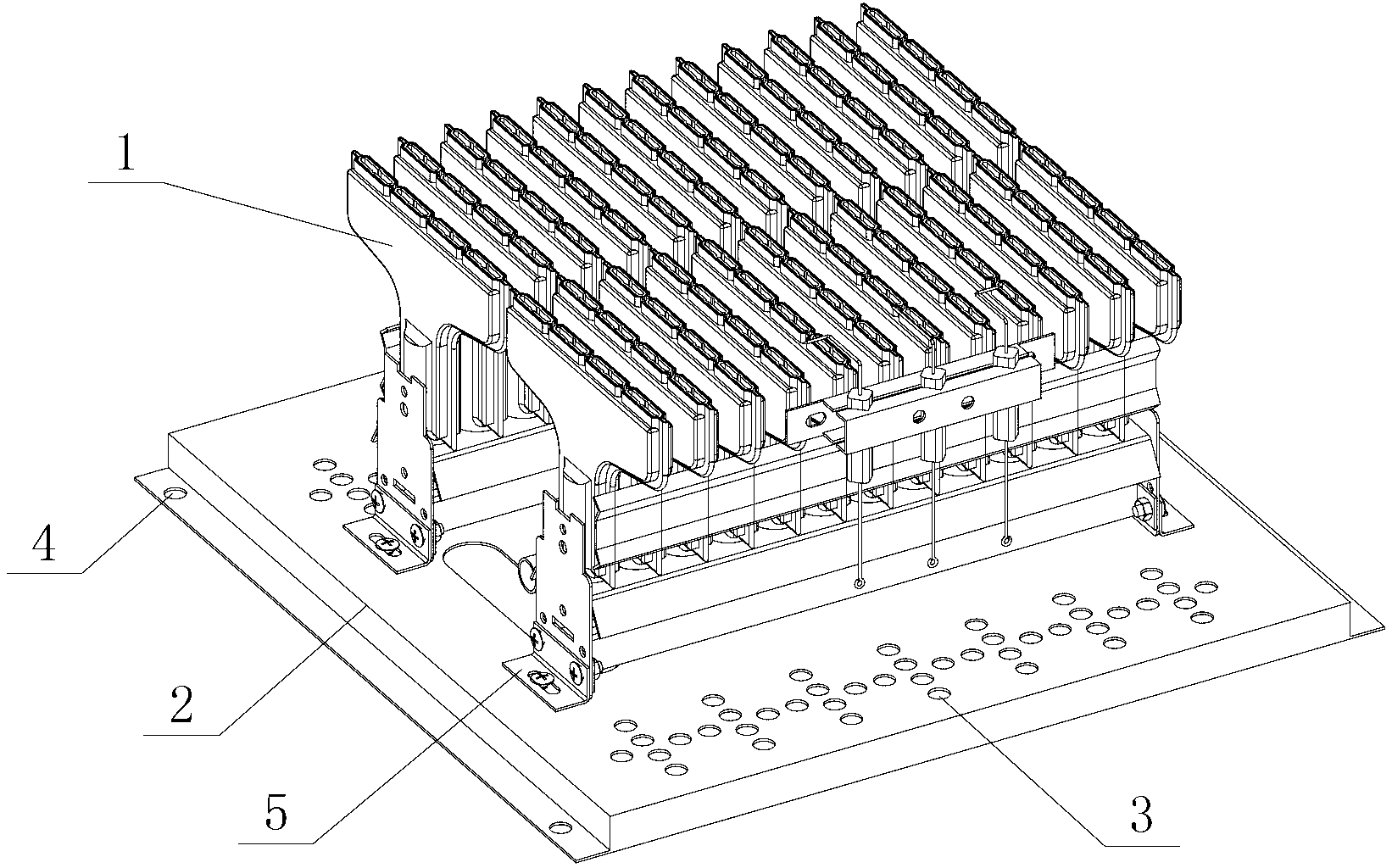

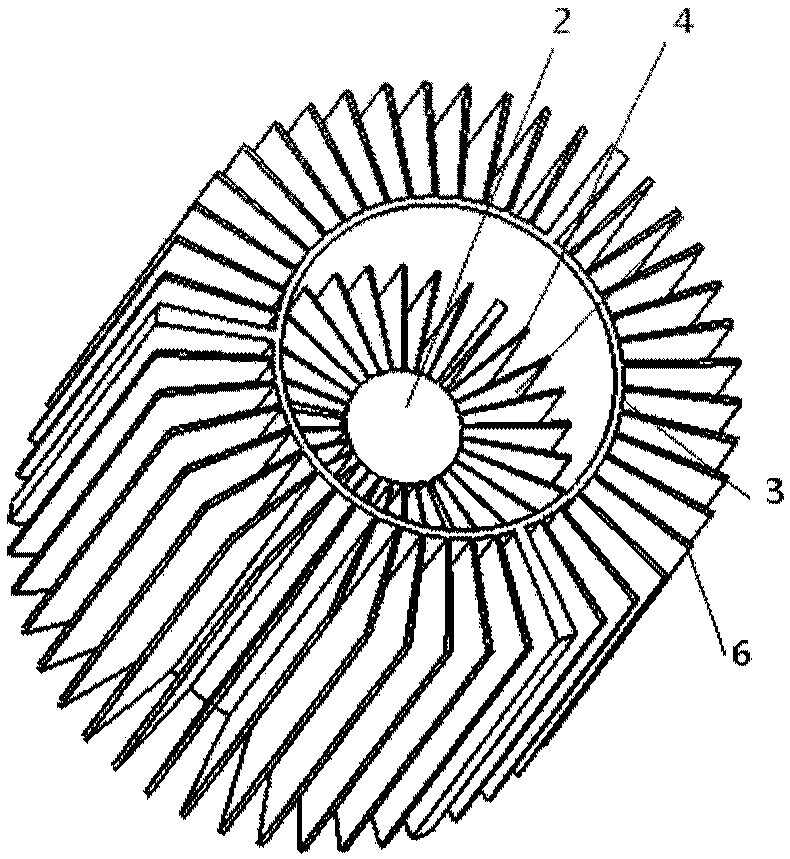

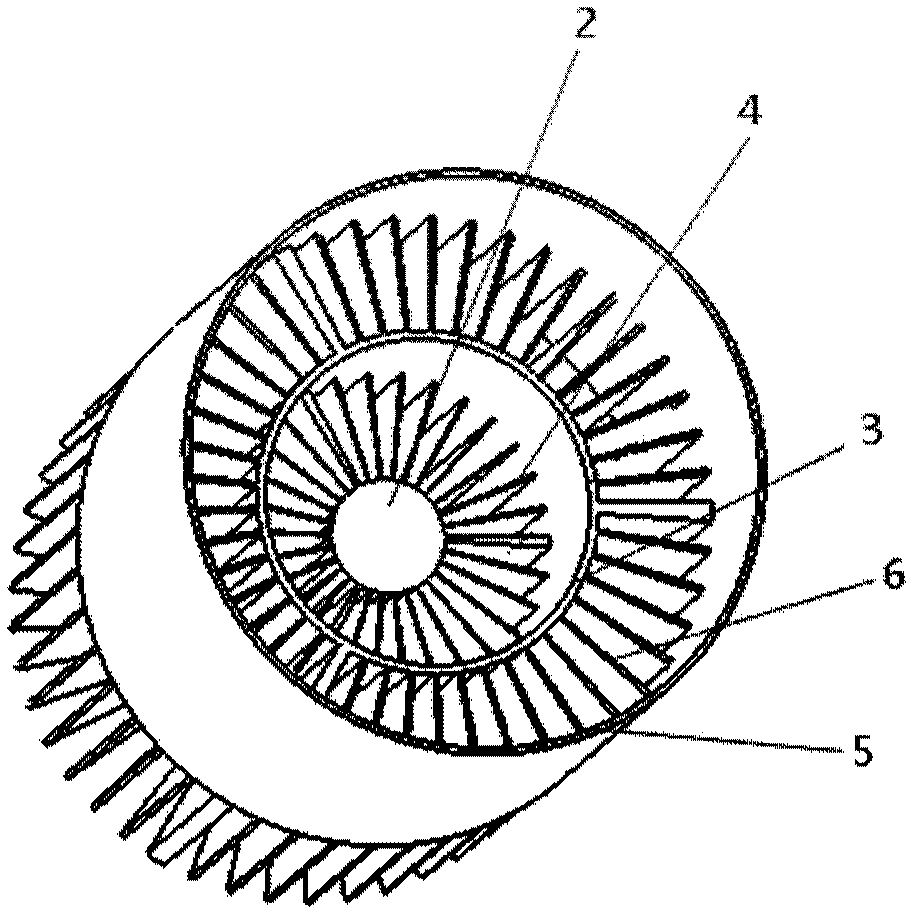

Heat sink based on chimney effect

PendingCN109855066ASpeed up the flowSpeed up heat dissipationLighting heating/cooling arrangementsSemiconductor devices for light sourcesSuction forceHeat conducting

The invention provides a heat sink based on the chimney effect. The heat sink comprises a heat source mounting substrate, a heat conducting column, a first thin-wall cylinder, N1 first-layer cooling fins, N2 second-layer cooling fins and a second thin-wall cylinder, wherein a first end of the heat conducting column is connected with the heat source mounting substrate; the first thin-wall cylinderis nested outside the heat conducting column; the N1 first-layer cooling fins are arranged between the heat conducting column and the first thin-wall cylinder radially; the N2 second-layer cooling fins are arranged outside the first thin-wall cylinder radially; the second thin-wall cylinder is nested outside the second-layer cooling fins; the overall structure is that a first-layer chimney air channel, a first thin-wall cylinder chimney air channel, a second-layer chimney air channel and a second thin-wall cylinder chimney air channel are sequentially formed in the radial direction from insideto outside to form a layer-by-layer chimney group structure. The heat sink based on the chimney effect has beneficial effects as follows: by means of multilayer flue nesting structure, horizontal diffusion of airflow is delayed, suction force of the chimney air channels is increased, heat is more effectively taken away from the heat source, and the rapid cooling effect is realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

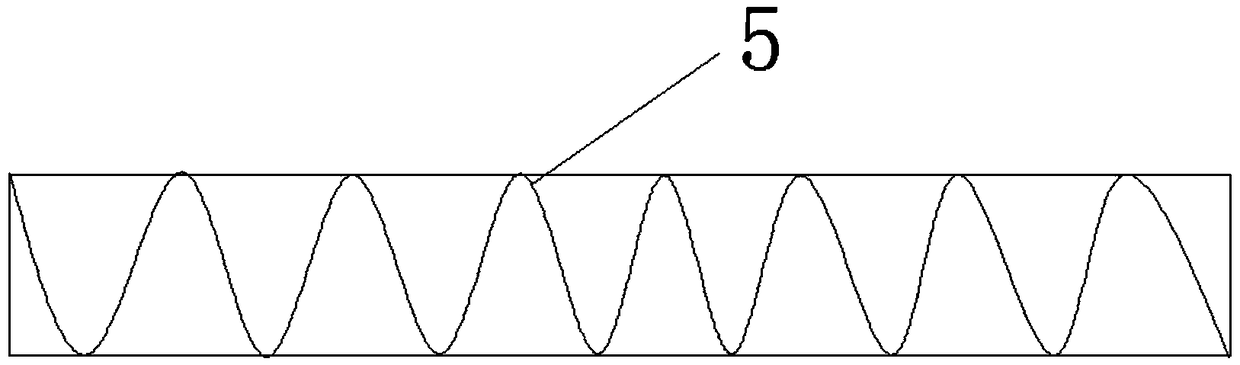

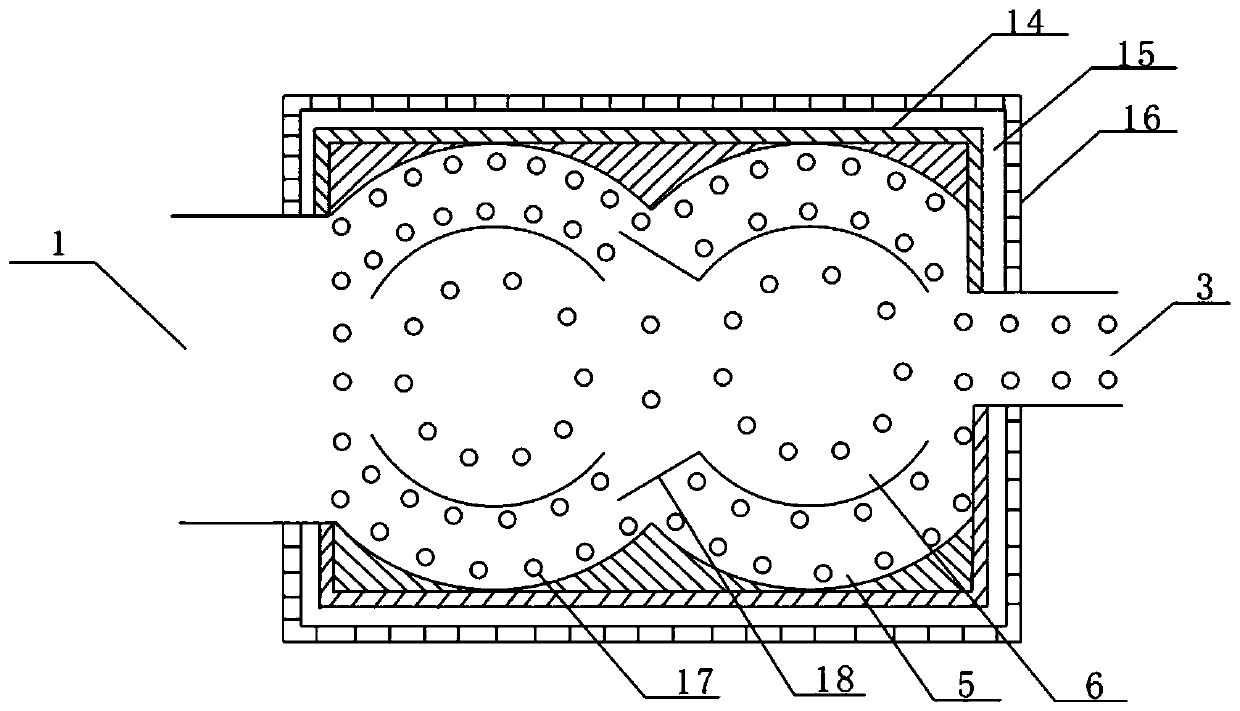

Smoke waste heat exchanger

PendingCN110081755AExtension of timeExtend heat exchange timeIncreasing energy efficiencyIndirect heat exchangersPlate heat exchangerEngineering

The invention discloses a smoke waste heat exchanger. The smoke waste heat exchanger comprises a smoke inlet formed in one end of a shell and a smoke outlet opposite to the smoke inlet. The smoke inlet and the smoke outlet communicate with a heat-exchange smoke cavity in the shell. The heat-exchange smoke cavity comprises inner circular smoke cavities and outer circular smoke cavities arranged around the inner circular smoke cavities. A plurality of heat-exchange water pipes are evenly distributed in the inner circular smoke cavities and the outer circular smoke cavities. The inner circular smoke cavities include the first inner circular smoke cavity and the second inner circular smoke cavity. The first inner circular smoke cavity comprises two first inner circular arc plates. A connectingline of upper endpoints A3 and A4 of the inner circular arc plate is parallel to a connecting line of B3 and B4, and a connecting line of upper endpoints A1 and A2 of the second inner circular arc plate is parallel to a connecting line of B1 and B2. The outer circular smoke cavities include the first outer circular smoke cavity and the second outer circular smoke cavity.

Owner:四川陆亨能源科技有限公司

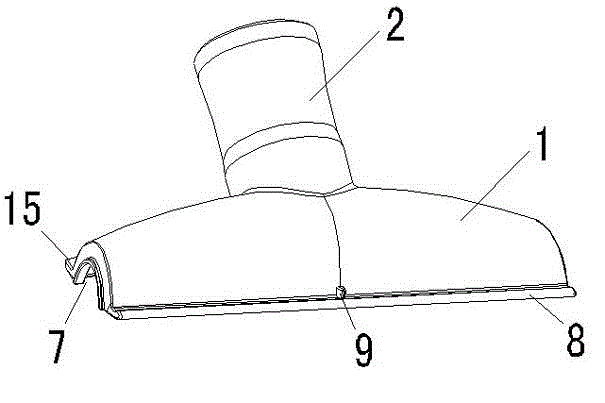

Sofa sucking device

InactiveCN104013353AAvoid blockingEnough to enterSuction nozzlesStructural engineeringMechanical engineering

Owner:SUZHOU ARIO ELECTRIC CO LTD

A cargo unloading platform for logistics transportation

ActiveCN111874666BSolve technical problems that are difficult to remove completelyIncrease the angleLoading/unloadingLogistics managementMarine engineering

The invention discloses a cargo unloading platform for logistics transportation, and relates to the technical field of unloading platform equipment. It includes a forklift body, a cargo buffer mechanism, a connecting frame, a first picking arm and a second picking arm, the connecting frame is installed on the forklift body and is at the lifting end of the forklift body, and the cargo buffering mechanism is arranged on the connecting frame and between the connection frame and the forklift body, the first and second reclaiming arms are arranged on the connection frame in a V shape and the openings of the first and second reclaiming arms are facing the forklift On the opposite side of the body, an opening is provided at the end where the distance between the first and second retrieving arms is small, and the opening between the first and second retrieving arms is located in the cargo buffer mechanism. In the present invention, the provided first and second retrieving arms can drive the goods to move toward the goods buffer mechanism through the mutual contact between the goods and the pick-up conveyor belt to generate friction, so that the goods are gathered and collected in the middle position.

Owner:GUANGDONG GENSHO LOGISTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com