A gas water boiler

A water boiler and gas technology, applied in the field of gas water boilers, can solve the problems of inconvenient installation of fire row, time-consuming and labor-intensive, etc., and achieve the effect of reducing installation difficulty and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

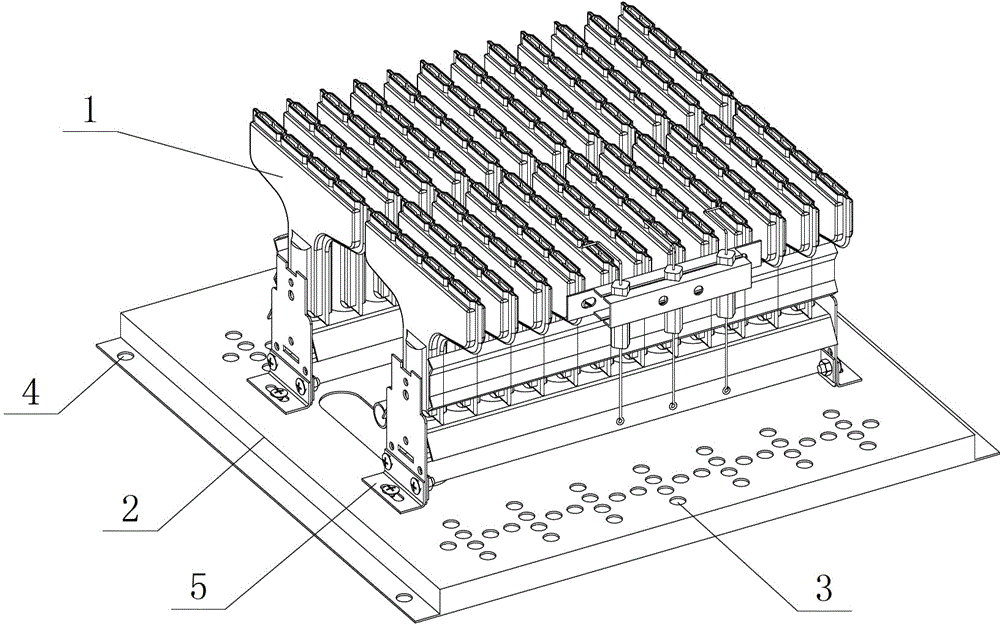

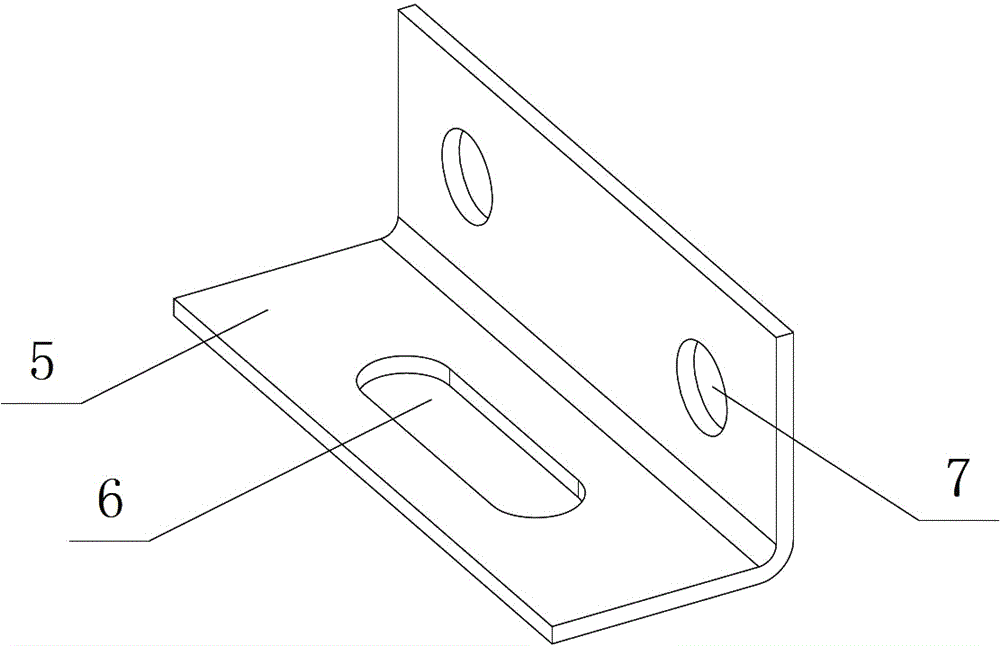

[0012] See figure 1 , figure 2 This is an embodiment of a gas water boiler of the present invention, a gas water boiler, comprising a fire row 1, a bottom plate 2, the fire row 1 is fixed on the bottom plate 2, the bottom plate 2 is provided with a plurality of vents 3, so The edge of the bottom plate 2 is provided with a fixing hole 4 that is fixed to the gas boiler frame. The fire row 1 is fixed on the bottom plate 2 by a connecting plate 5 with an L-shaped cross section. The connecting plate 5 includes a horizontal part and a vertical part. Straight part, the horizontal part is provided with a through groove 6, and the bottom plate 2 is provided with a first installation through hole. The bolt passes through the through groove 6 and the first installation hole and then cooperates with a nut to connect the connecting plate 5 and the bottom plate 2. Fixed connection; the vertical part is provided with two second mounting holes 7, the bottom of the side wall of the fire row 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com