Heat sink based on chimney effect

A technology of chimney effect and heat sink, which is applied in semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting and heating equipment, etc., which can solve the problem of inability to achieve fast and effective heat dissipation, smooth air flow, and unfavorable small size and light weight problems such as the development of modernization, to achieve the effect of increasing air flow speed, improving reliability and speeding up air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] In a first exemplary embodiment of the present disclosure, a chimney effect based radiator is provided.

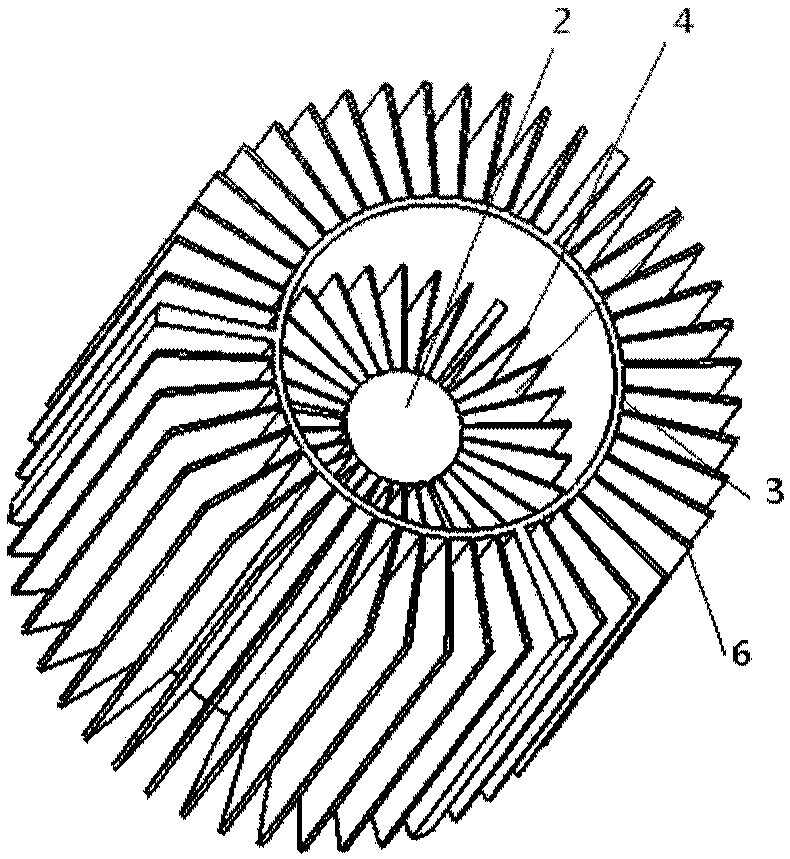

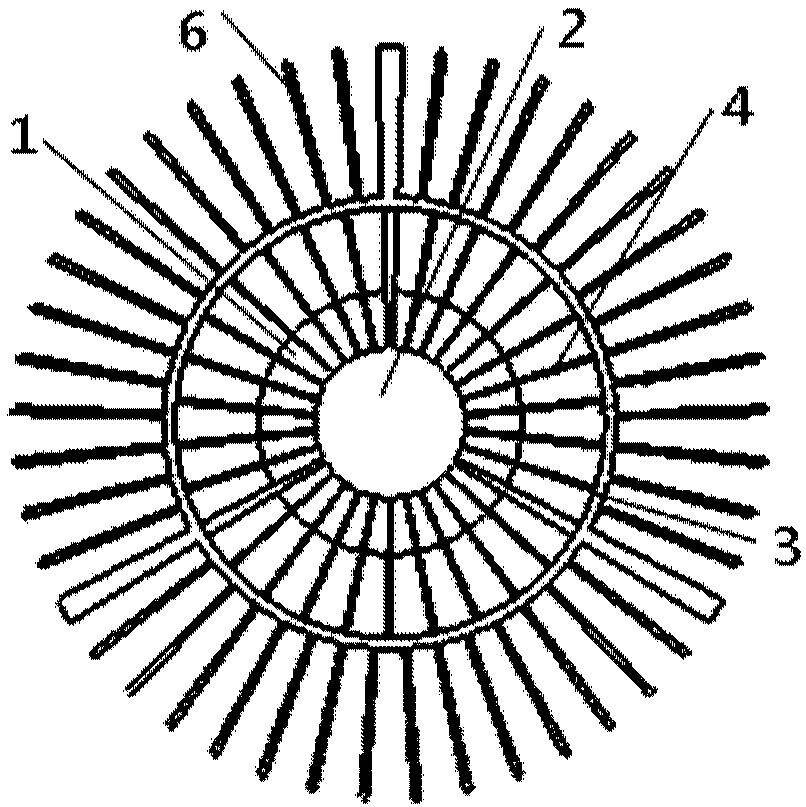

[0051] figure 1 It is a structural schematic diagram of a chimney effect-based radiator according to the first embodiment of the present disclosure. figure 2 for figure 1 A top view of a chimney-effect based radiator is shown. Such as figure 1 with figure 2As shown, this embodiment is a radiator based on the chimney effect comprising a layer of thin-walled cylindrical structure. It specifically includes a heat source mounting substrate 1; a heat conducting column 2, the first end of which is connected to the heat source mounting substrate 1; a first thin-walled cylinder 3, which is nested outside the heat conducting column 2; N1 first-layer heat sinks 4, It is radially arranged between the heat conduction column 2 and the first thin-walled cylinder 3; the extension surface of the plane where each first layer of heat sink 4 is located passes through the centra...

no. 2 example

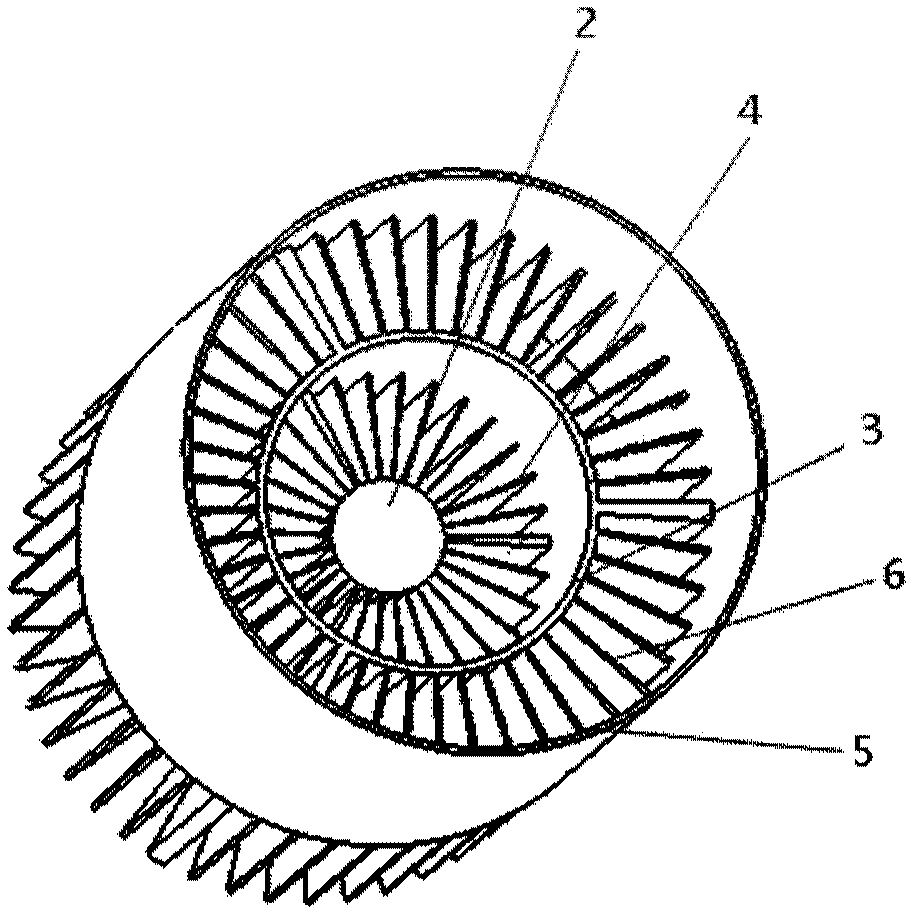

[0053] In a second exemplary embodiment of the present disclosure, a chimney effect based radiator is provided. Compared with the first embodiment, this embodiment differs in that a second thin-walled cylinder 5 is added on the basis of the first embodiment.

[0054] image 3 It is a schematic structural diagram of a radiator based on the chimney effect according to the second embodiment of the present disclosure. Figure 4 for image 3 A top view of a chimney-effect based radiator is shown. Such as image 3 with Figure 4 As shown, this embodiment is a radiator based on the chimney effect comprising a two-layer thin-walled cylindrical structure. The specific structure increases the second thin-walled cylinder 5 on the basis of the first embodiment, and the second thin-walled cylinder is nested outside the second layer of cooling fins 6; the first end of each of the second layer of cooling fins 6 is connected to The outer wall of the first thin-walled cylinder 3 is conne...

no. 3 example

[0056] In a third exemplary embodiment of the present disclosure, a chimney effect based radiator is provided. Compared with the first embodiment, this embodiment differs in that: on the basis of the first embodiment, a second thin-walled cylinder 5 with an extended thin-walled circular platform 7 is added.

[0057] Figure 5 It is a schematic structural diagram of a chimney effect-based radiator according to a third embodiment of the present disclosure. Image 6 for Figure 5 A top view of a chimney-effect based radiator is shown. Such as Figure 5 with Image 6 As shown, this embodiment is a radiator based on the chimney effect comprising a two-layer thin-walled cylindrical structure. The specific structure adds a second thin-walled cylinder 5 including an extended thin-walled circular platform 7 on the basis of the first embodiment, and the extended thin-walled circular platform 7 is connected to the second thin-walled cylinder 5 .

[0058] Compared with Embodiment 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com