Patents

Literature

453results about How to "Extend heat exchange time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

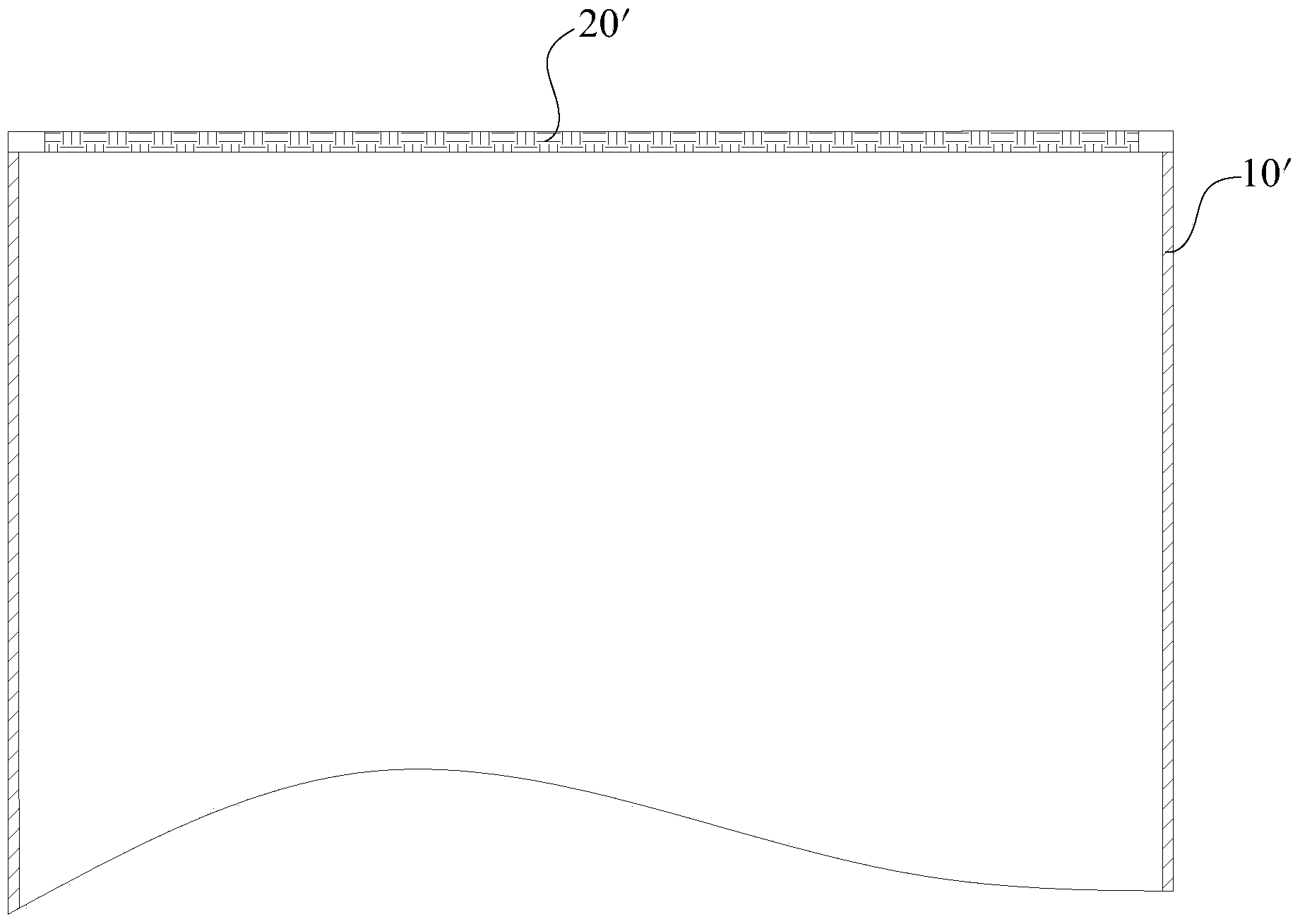

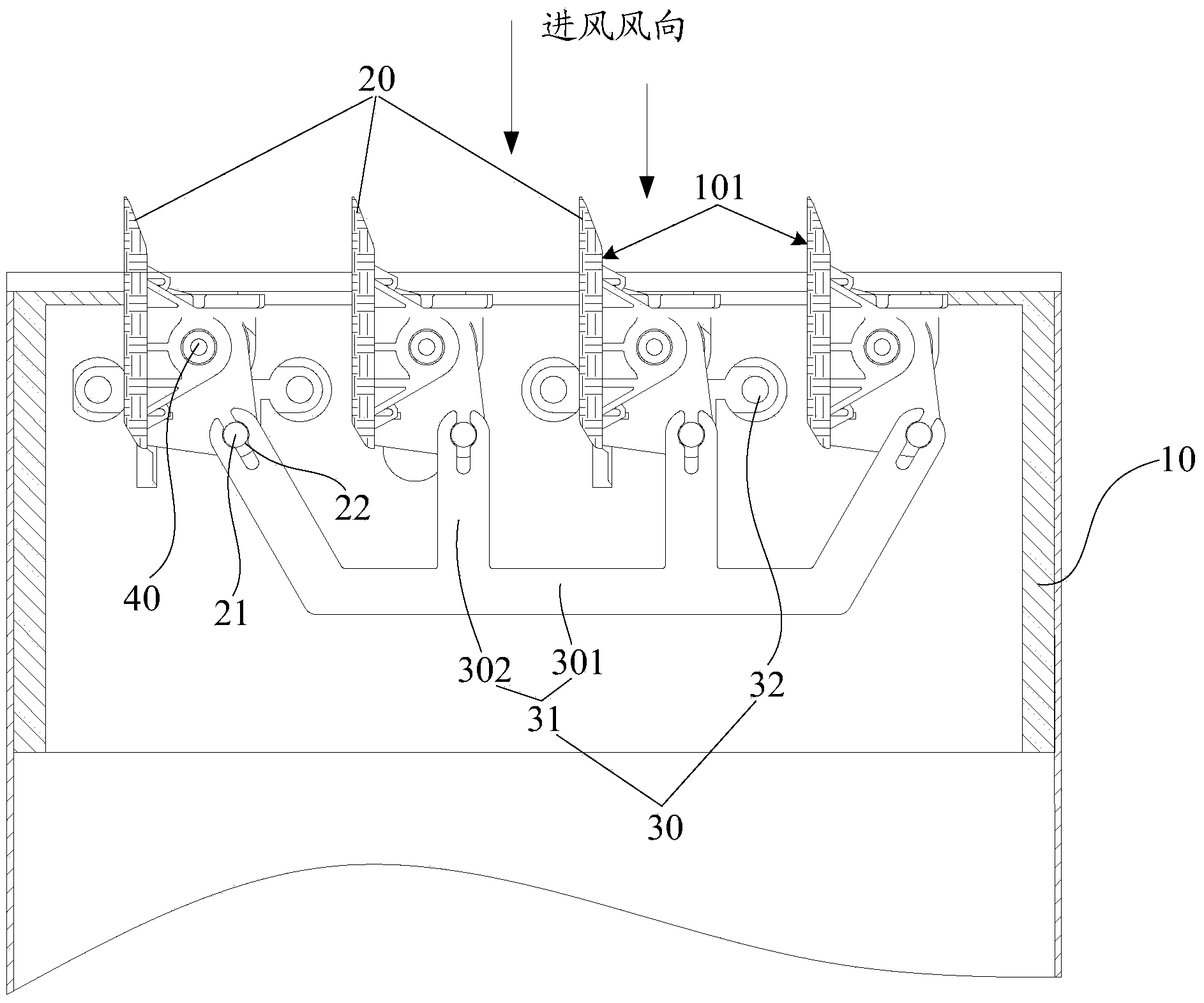

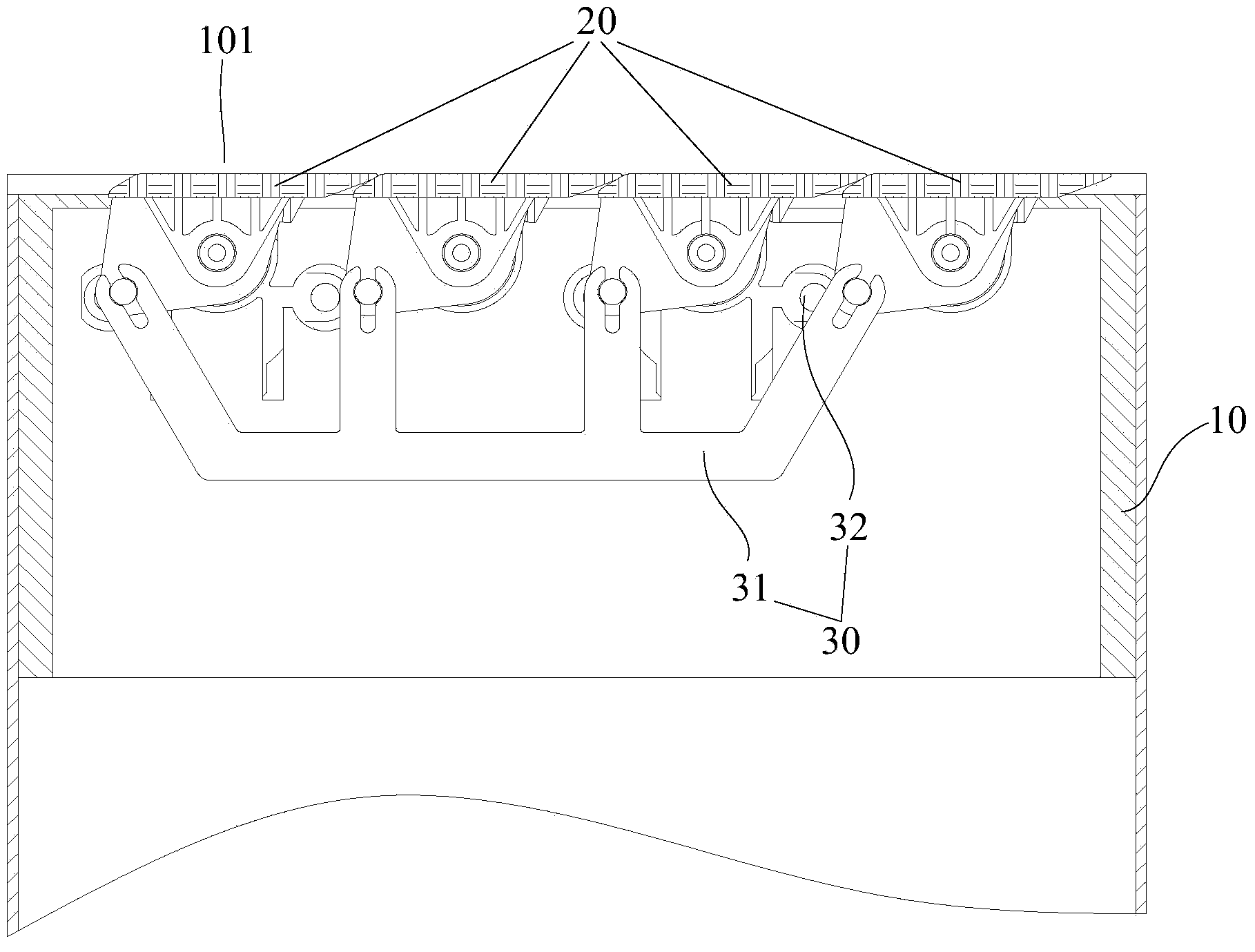

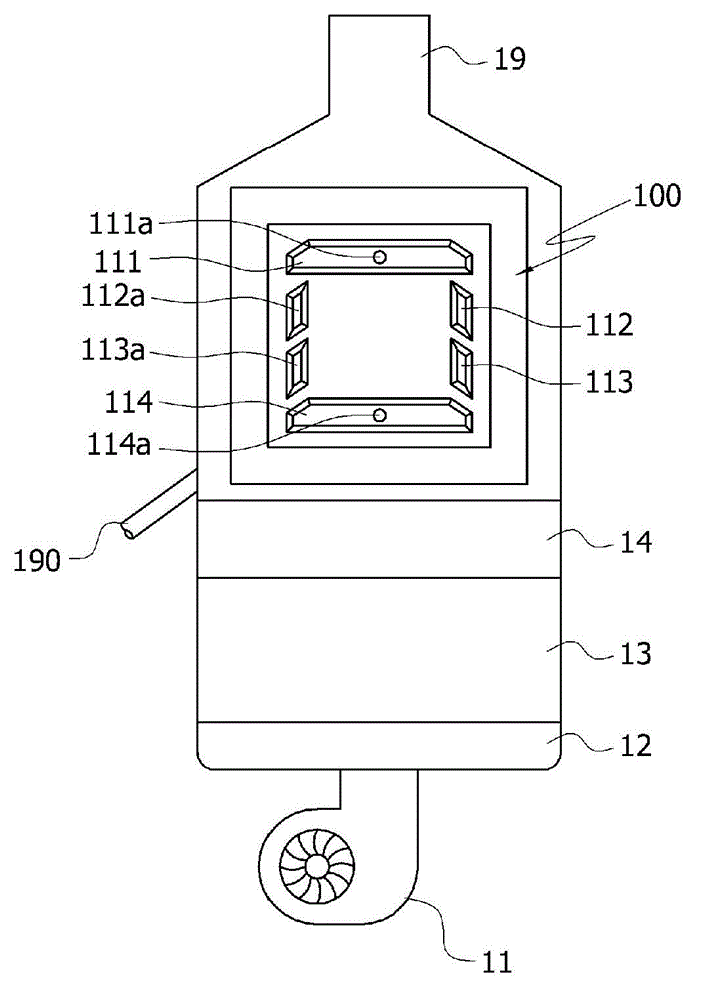

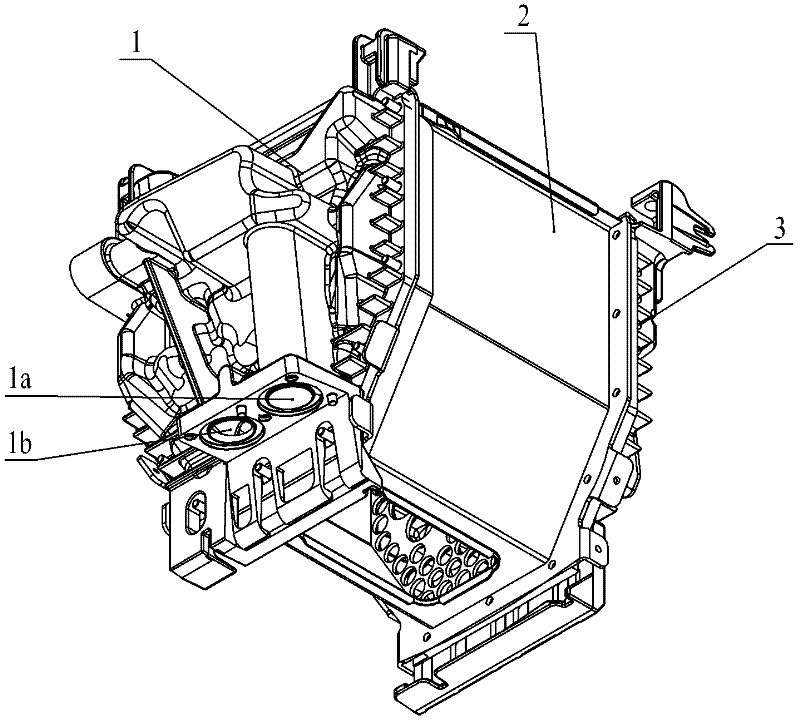

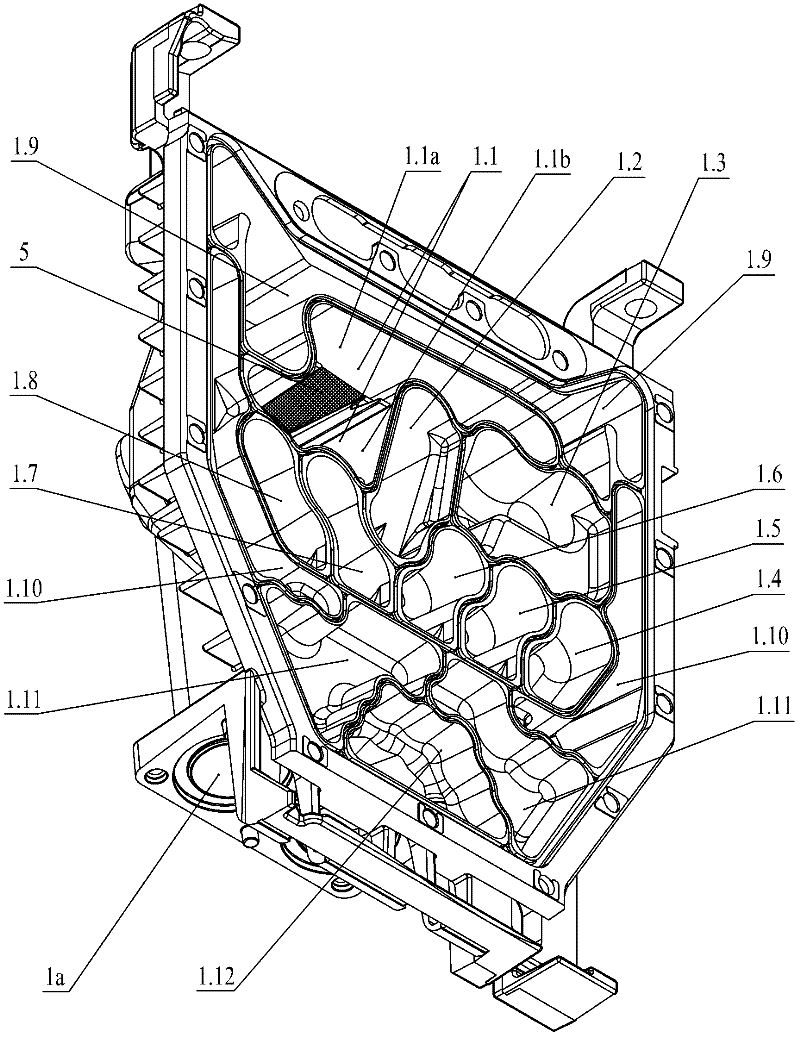

Air purifying assembly, air conditioner and control method of air conditioner

ActiveCN103759335ASmooth circulationTo achieve the purpose of filtering airSpace heating and ventilation safety systemsLighting and heating apparatusInlet channelButt joint

The invention discloses an air purifying assembly which comprises a support plate, multiple filtering screens and drive elements, wherein the filtering screens are rotatably arranged on the support plate, and the driving elements are used for driving the filtering screens to turn. Each drive element at least comprises a first drive position and a second drive position. When the drive elements drive the filtering screens to be at the first drive positions, the filtering screens are sequentially arranged in an end-to-end mode, in butt joint or stacked, and the end faces of the filtering screens achieve filtering in the air inlet direction. When the drive elements drive the filtering screens to be at the second drive positions, the head portions and the tail portions of the filtering screens are sequentially separated, the end faces of the filtering screens form air inlet channels in pairs and allow air to pass. The invention further discloses an air conditioner and a control method thereof. The aim of purifying the air is achieved, and smooth circulation of the air is not influenced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

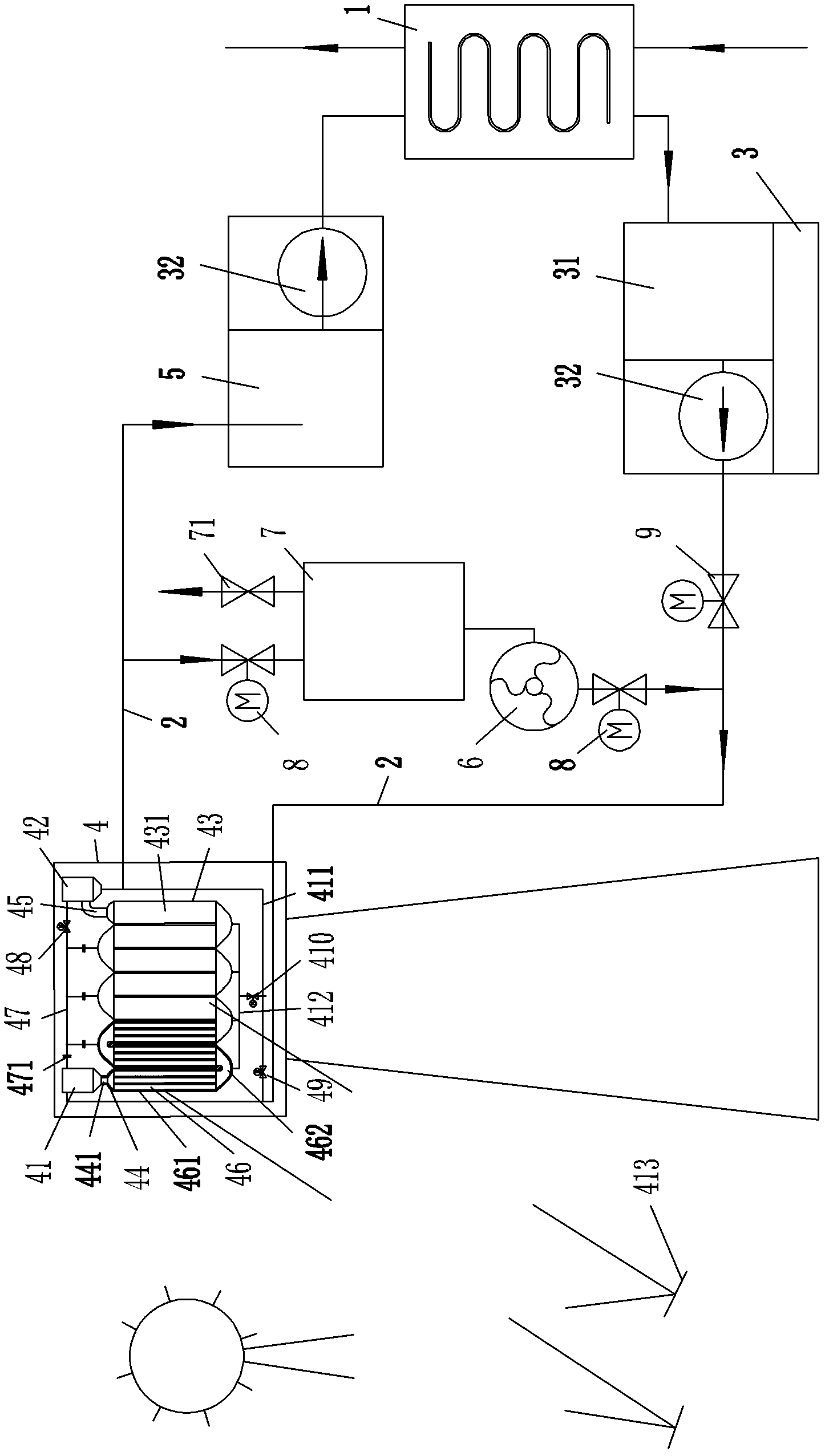

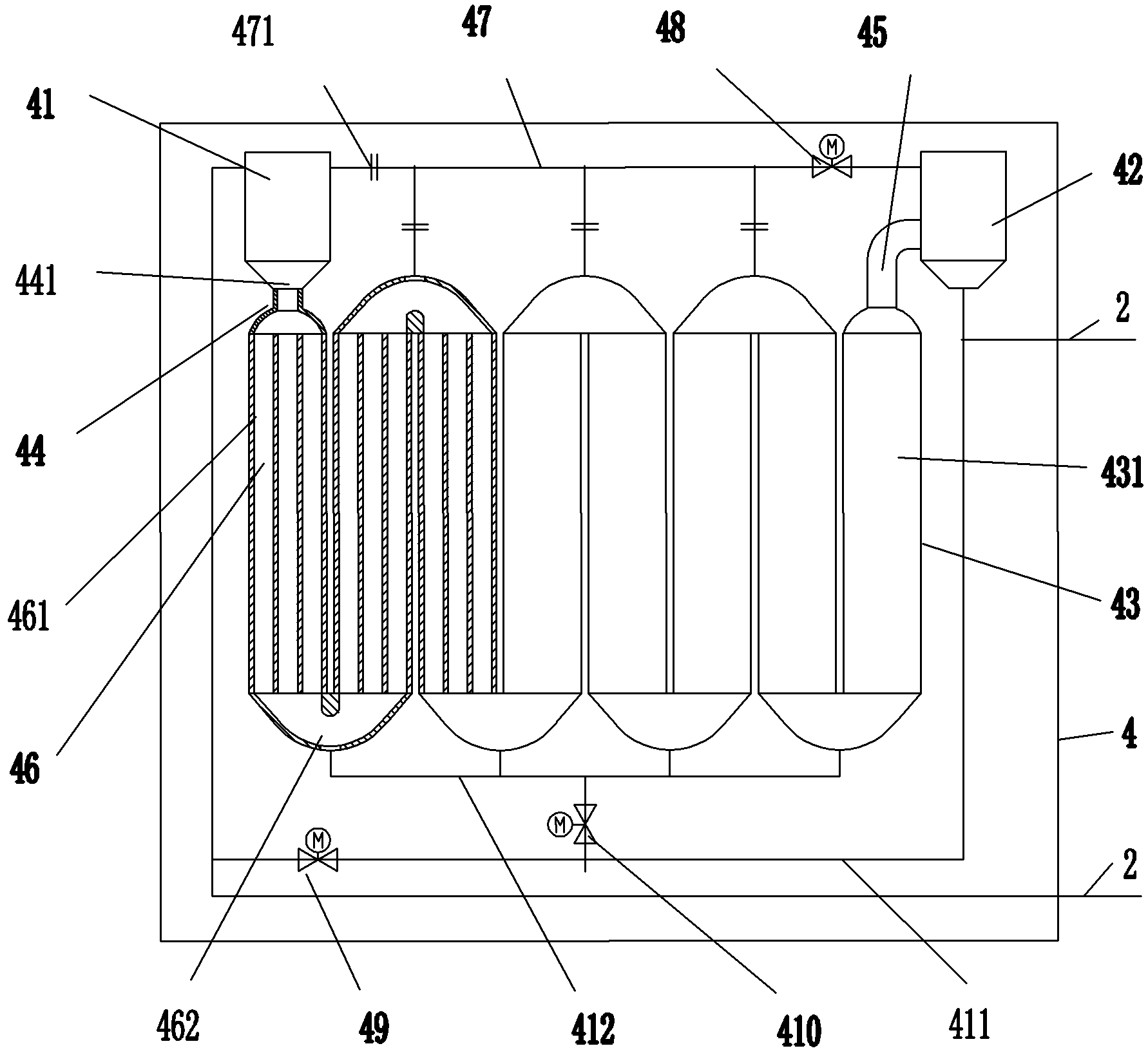

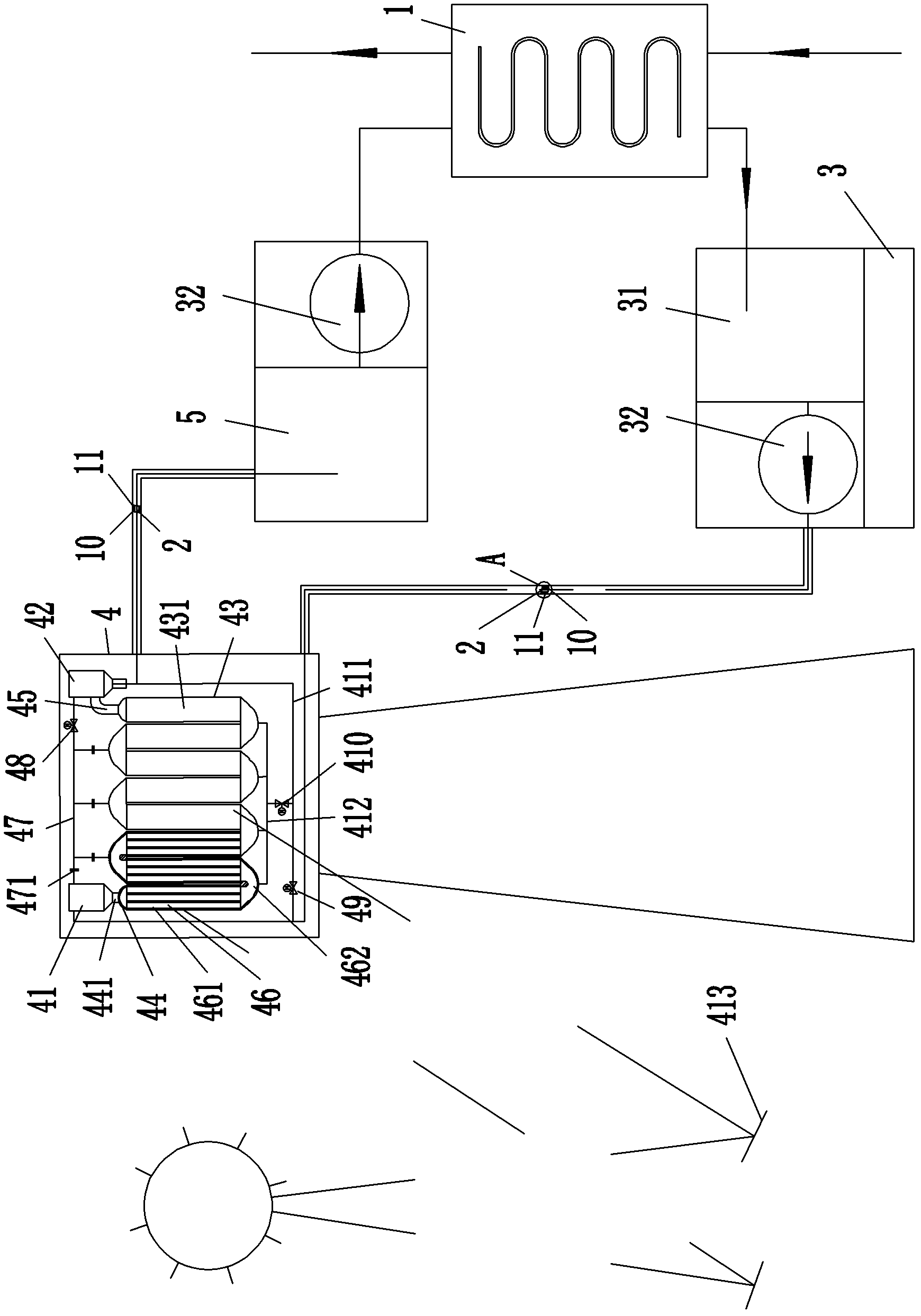

Solar-heating assisted salt melting system

ActiveCN102563867AReduce consumptionReduce flow rateSolar heat devicesStorage heatersMolten saltHot Temperature

The invention belongs to the field of the salt melting equipment and aims to provide a solar-heating assisted salt melting system which consumes less fuel and less affects the environment. The solar-heating assisted salt melting system comprises a salt melting furnace and a heating device, wherein the salt melting furnace is provided with a low-temperature salt storage tank with a salt melting pump; the solar-heating assisted salt melting system further comprises a solar heat absorbing device, two heating pipes and a high-temperature salt storage tank with a salt melting pump; the outlet of the salt melting pump of the low-temperature salt storage tank is communicated with the inlet of the solar heat absorbing device through a first heating pipe; the outlet of the solar heat absorbing device is communicated with the high-temperature salt storage tank through a second heating pipe; the outlet and the inlet of the heating device are communicated with the inlet of the low-temperature salt storage tank and the outlet of the salt melting pump of the high-temperature salt storage tank respectively; and the solar-heating assisted salt melting system is provided with a preheating device used for preheating the heating pipes. The solar-heating assisted salt melting system consumes less fuel and less affects the environment.

Owner:HANGZHOU BOILER GRP CO LTD

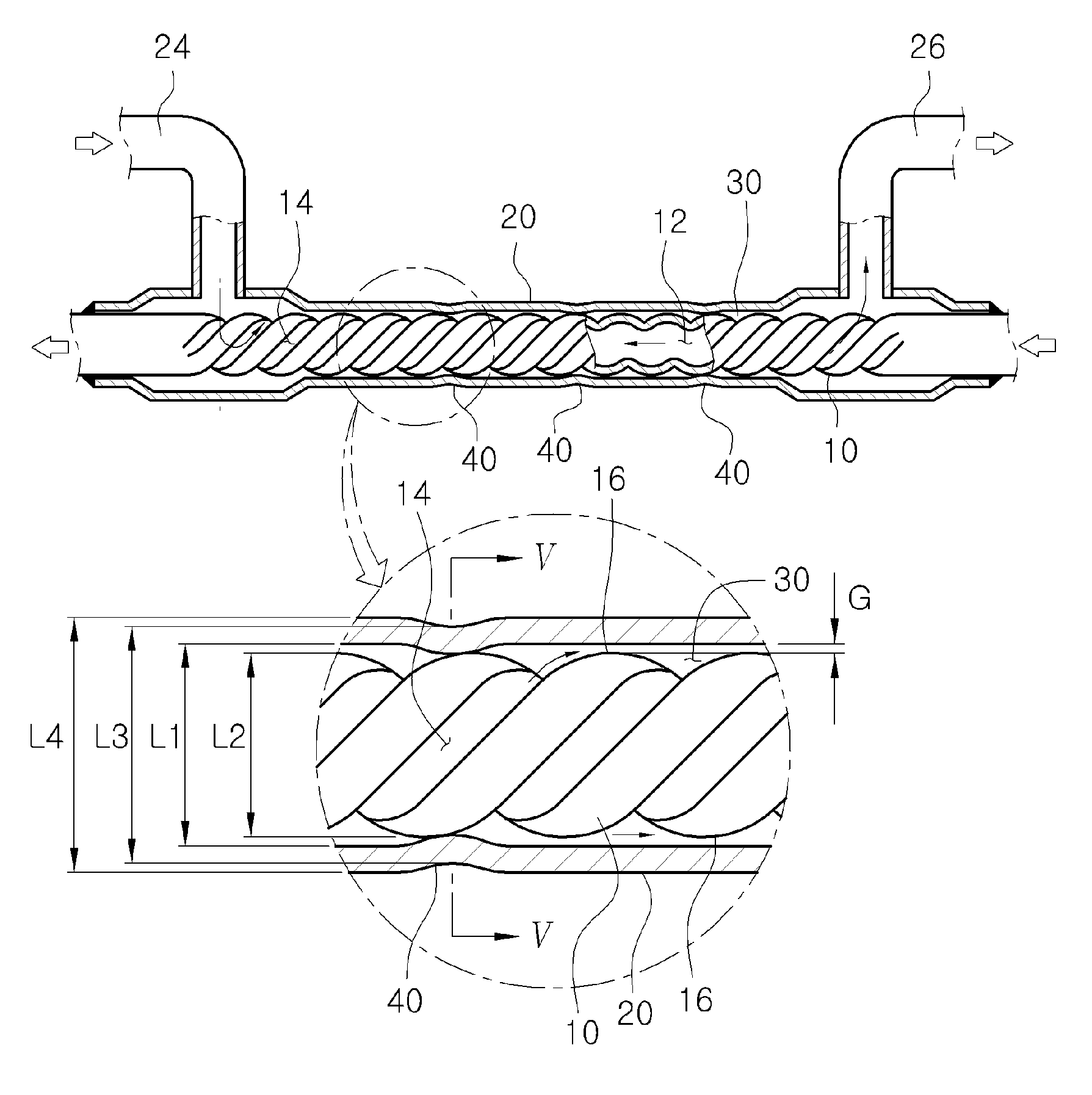

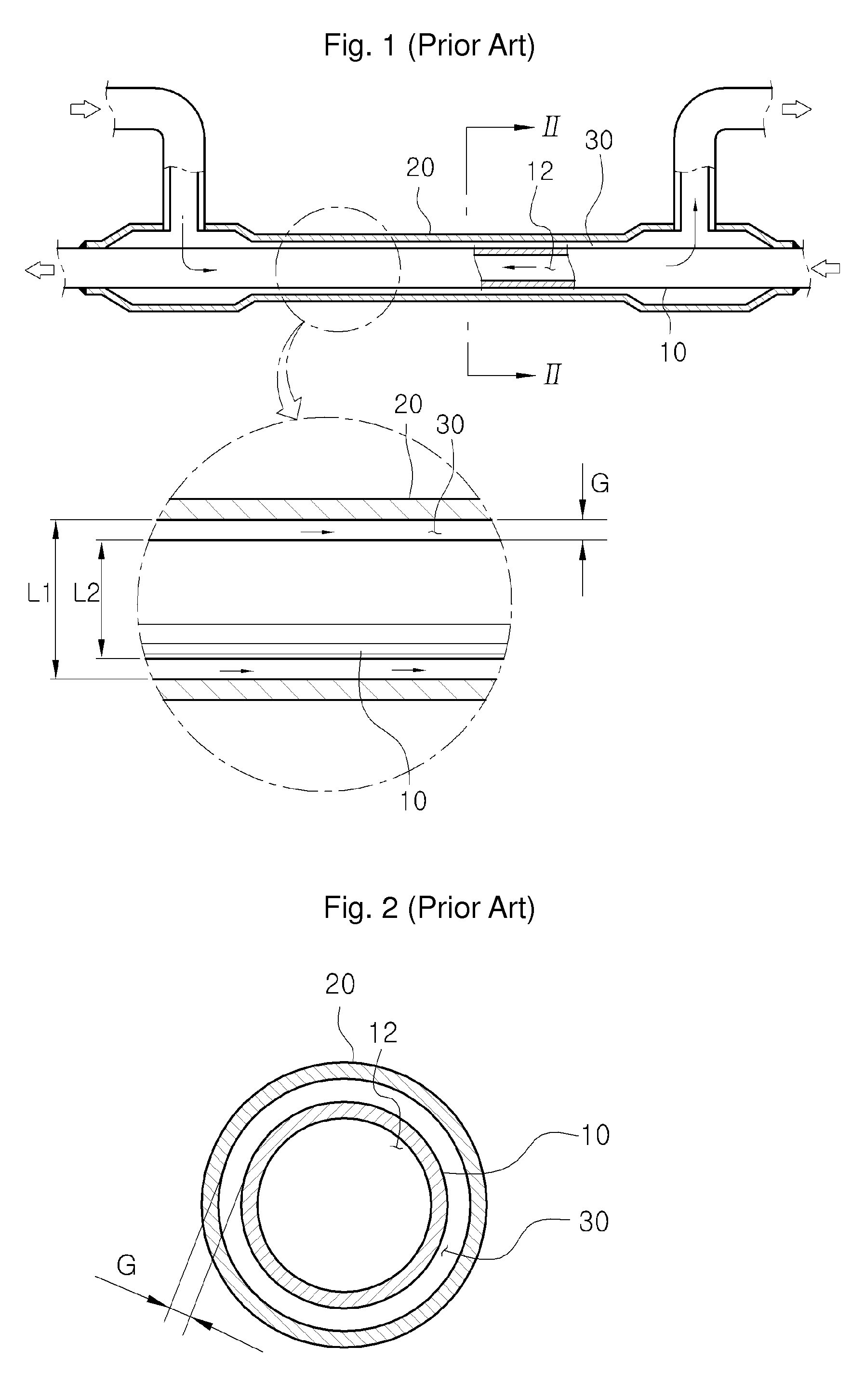

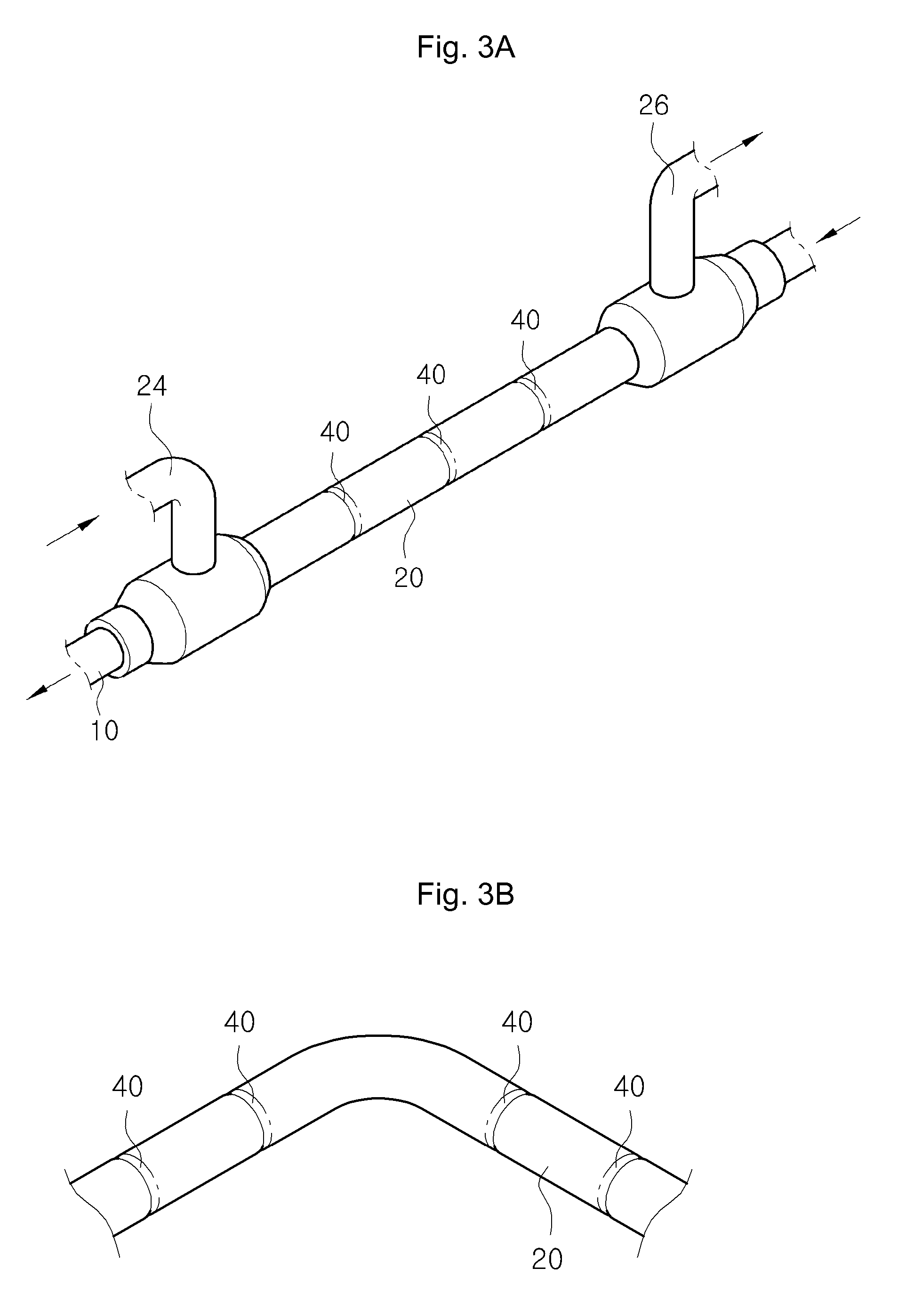

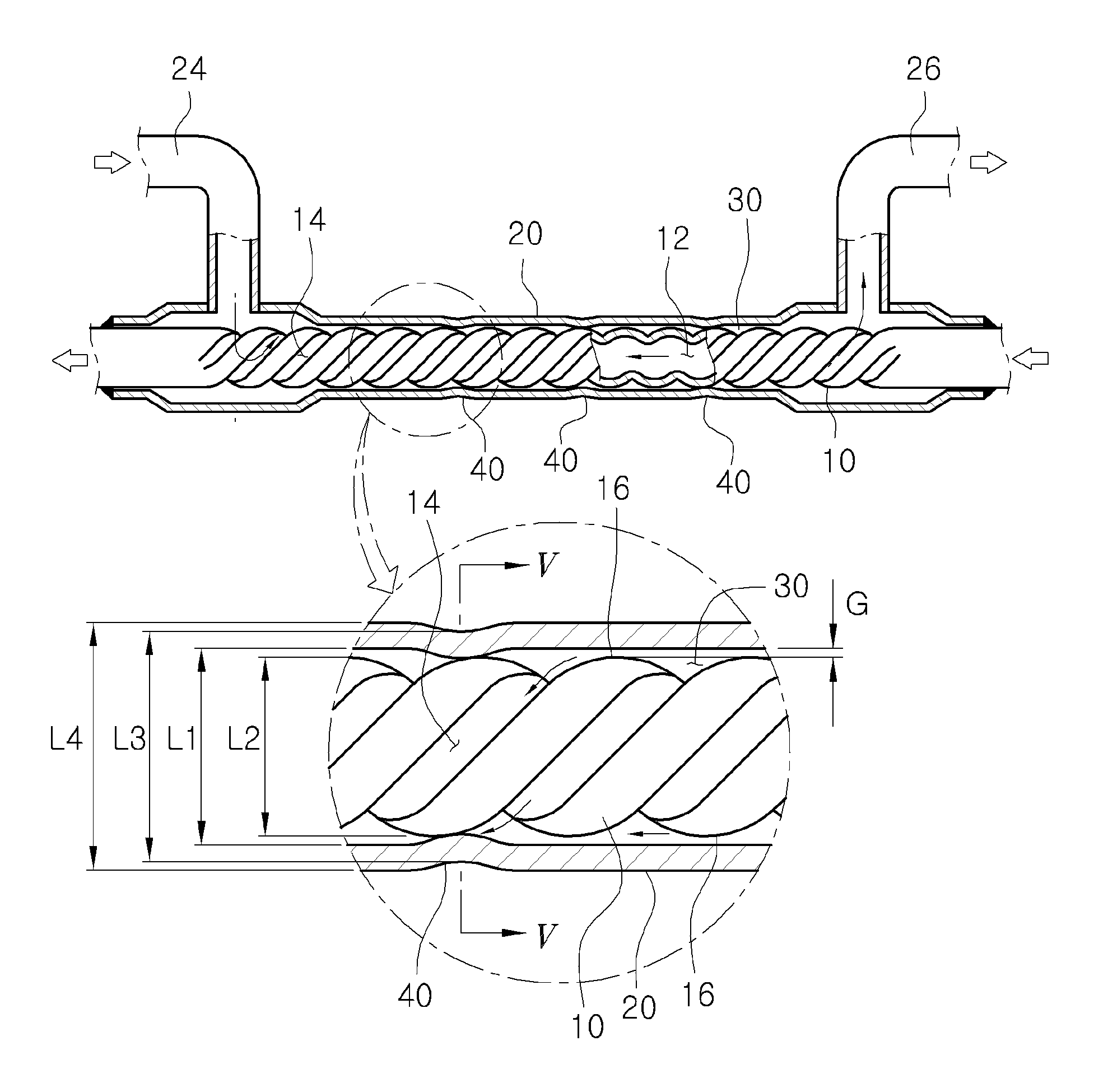

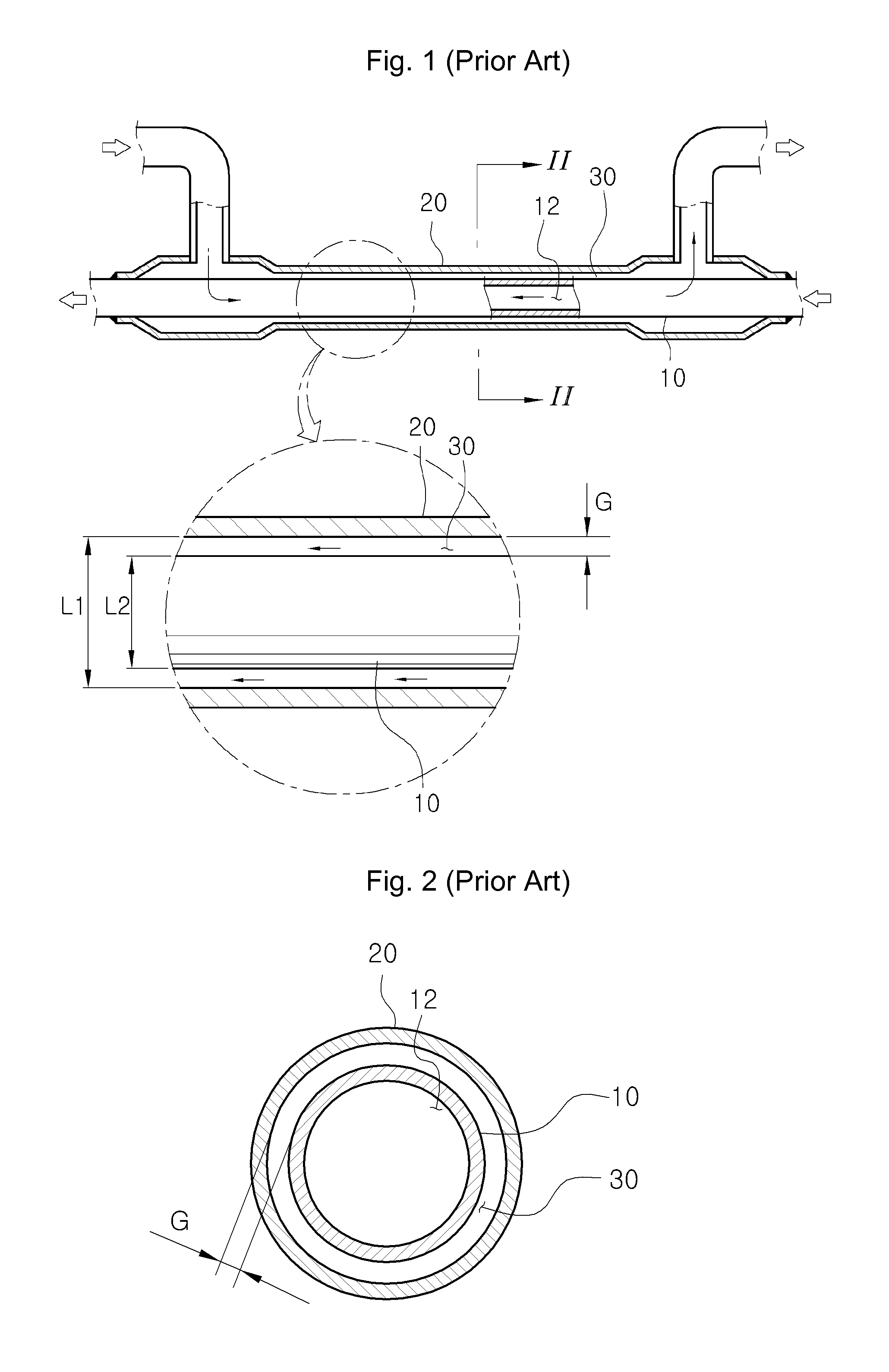

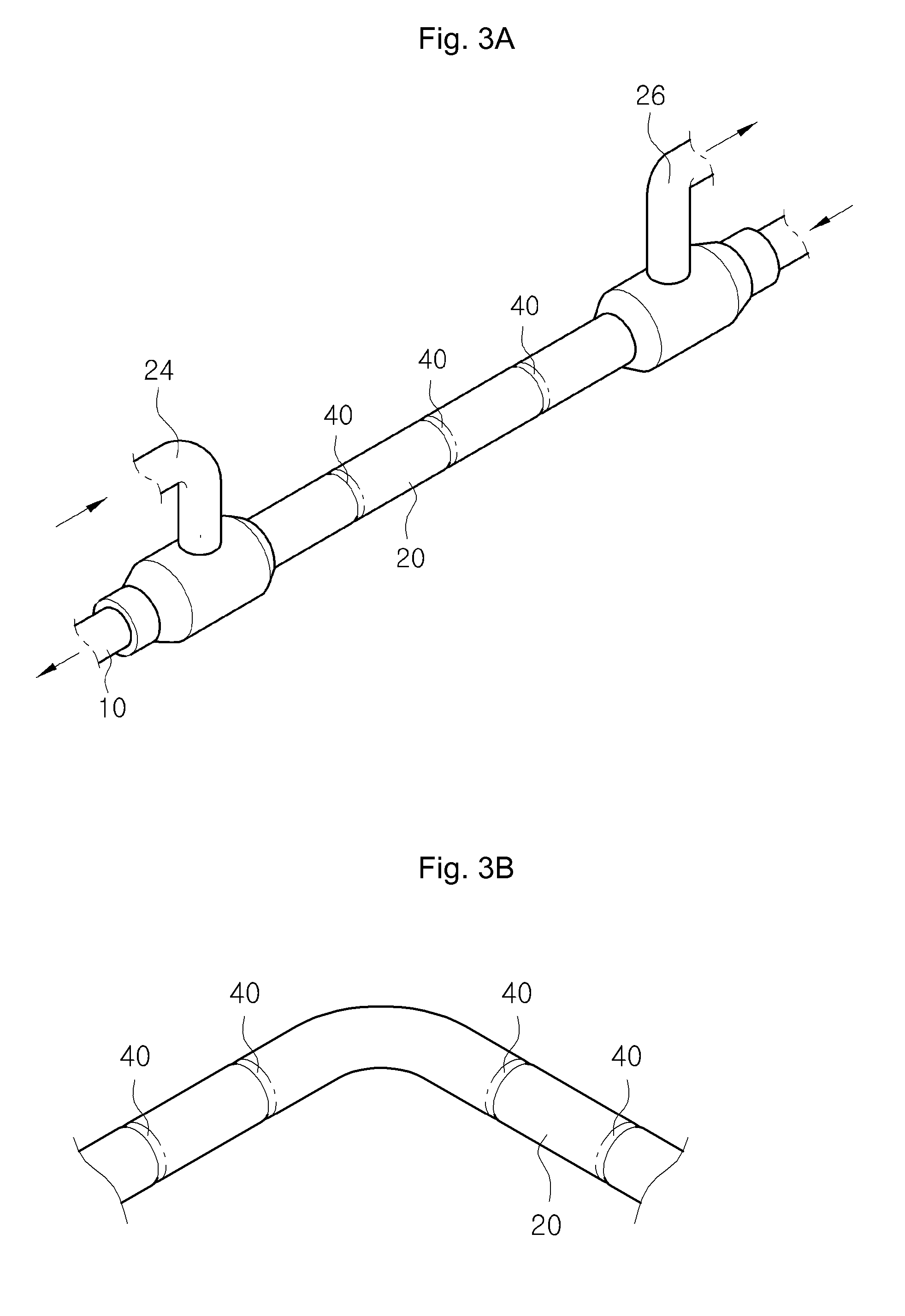

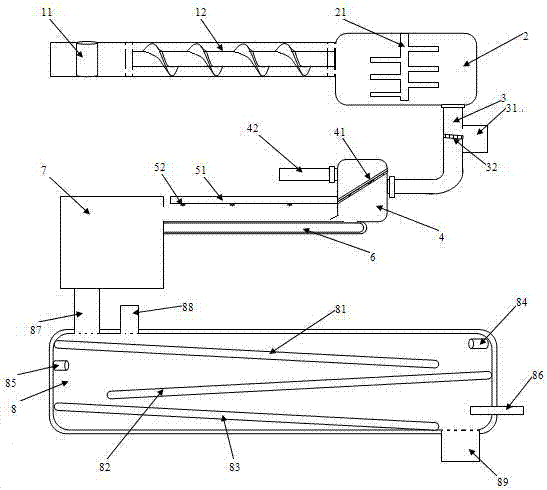

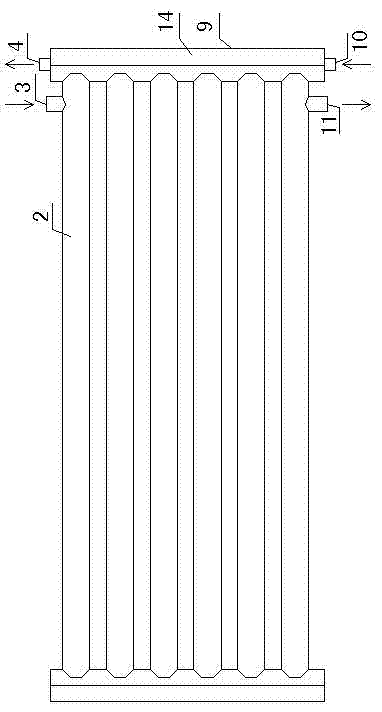

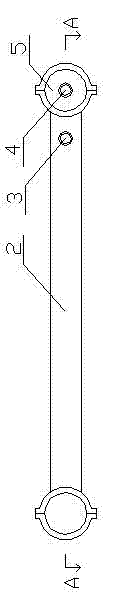

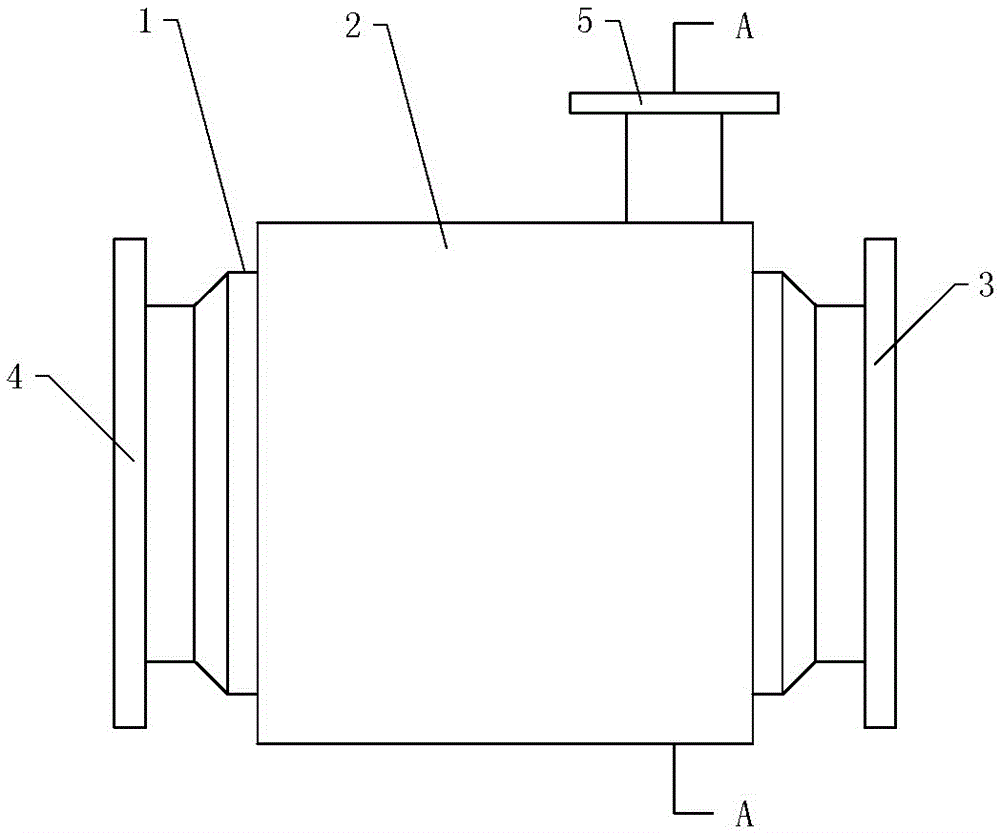

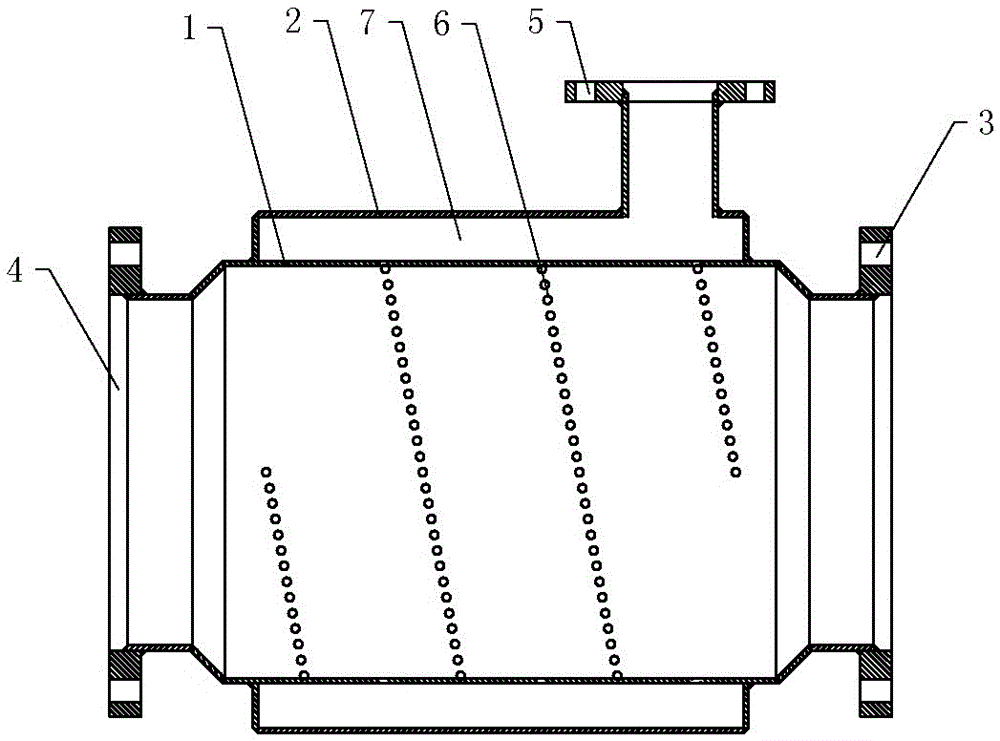

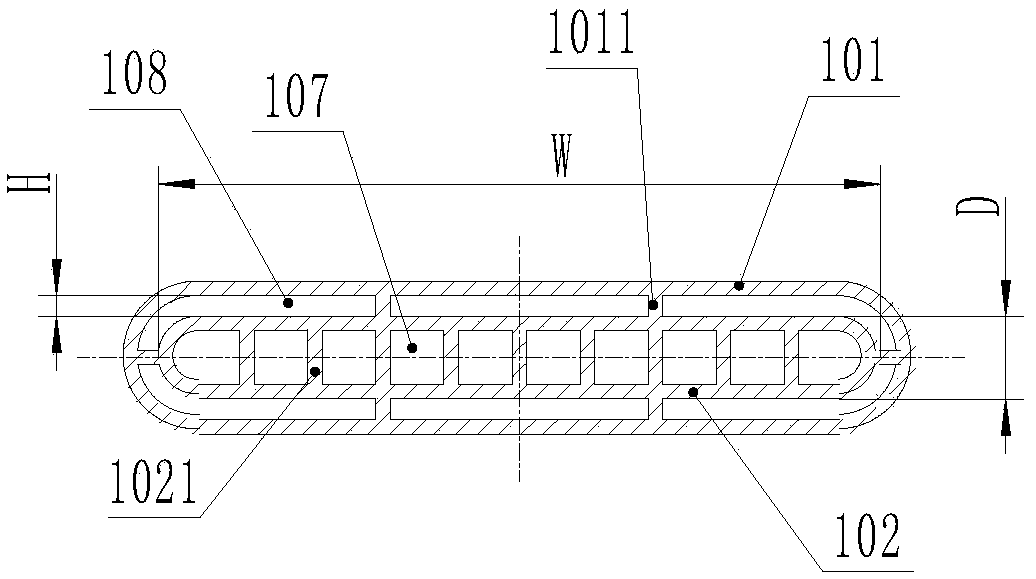

Double pipe type heat exchanger and method for manufacturing the same

ActiveUS9091487B2Extend heat exchange timeAvoid frictional contactSafety devices for heat exchange apparatusHeat exhanger conduitsEngineeringHeat exchanger

A double pipe type heat exchanger includes an inner pipe having a first flow path defined therein and an outer pipe arranged around the inner pipe to define a second flow path between the inner pipe and the outer pipe. The inner pipe includes a spiral groove formed on an outer circumferential surface of the inner pipe to extend along a longitudinal direction of the inner pipe. The outer pipe includes a reduced diameter portion protruding inwardly so that the inner surface of the outer pipe is intermittently contacted with the outer circumferential surface of the inner pipe.

Owner:HANON SYST

Double Pipe Type Heat Exchanger and Method for Manufacturing the Same

ActiveUS20120043055A1Efficiently exchange heatImprove performanceSafety devices for heat exchange apparatusHeat exhanger conduitsEngineeringHeat exchanger

A double pipe type heat exchanger includes an inner pipe having a first flow path defined therein and an outer pipe arranged around the inner pipe to define a second flow path between the inner pipe and the outer pipe. The inner pipe includes a spiral groove formed on an outer circumferential surface of the inner pipe to extend along a longitudinal direction of the inner pipe. The outer pipe includes a reduced diameter portion protruding inwardly so that the inner surface of the outer pipe is intermittently contacted with the outer circumferential surface of the inner pipe.

Owner:HANON SYST

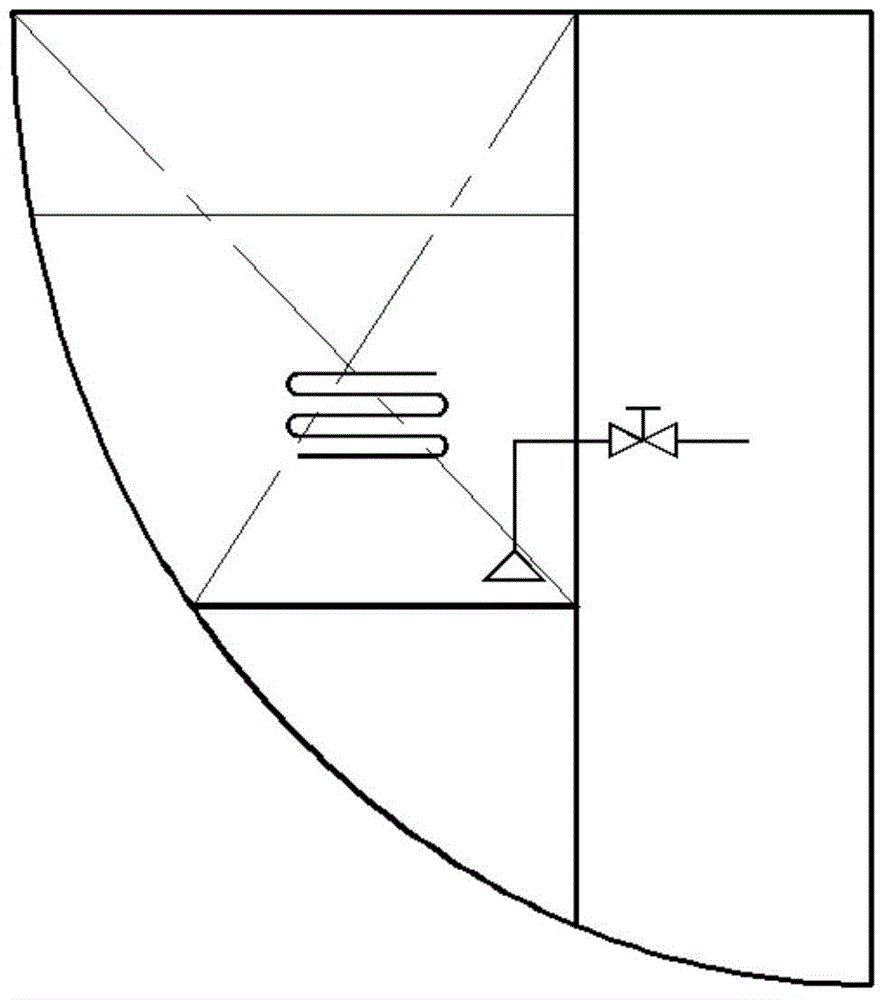

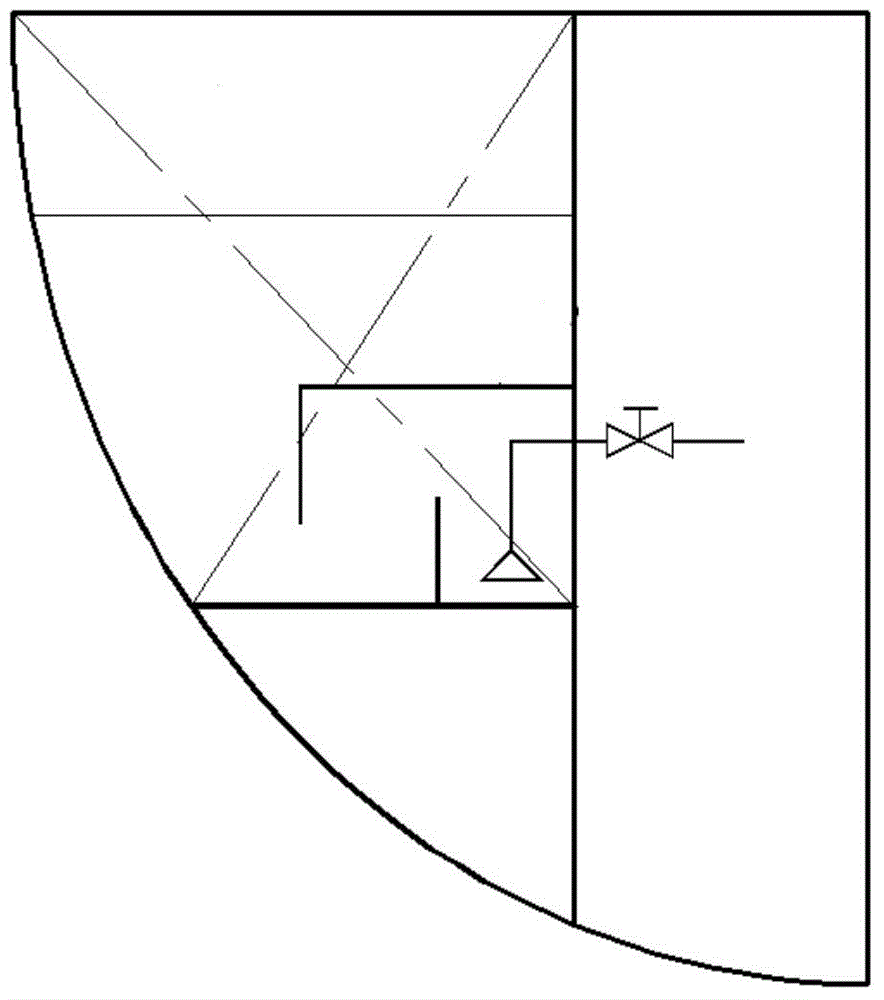

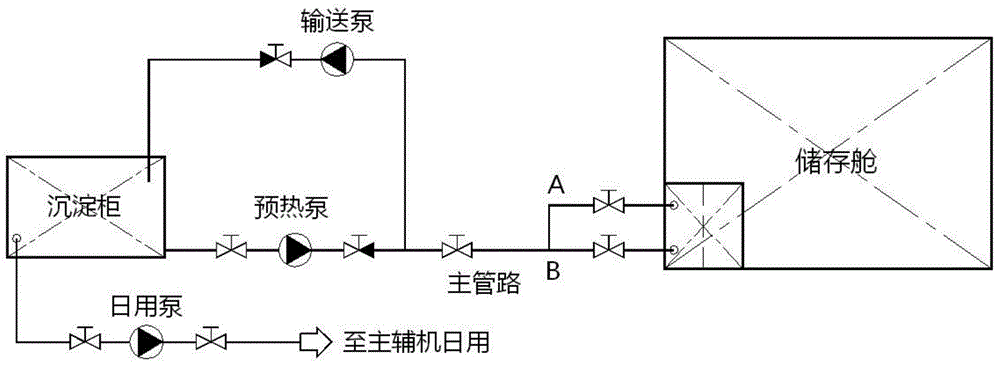

Ship fuel preheating system and preheating method

ActiveCN104819080AReduce operating costsEfficient use ofHull interior subdivisionElectrical controlFuel oilEngineering

The invention relates to a ship fuel preheating system. The ship fuel preheating system is characterized in that a fuel preheating branch pipeline and a fuel conveying branch pipeline are arranged between a storage bin and a sedimentation cabinet. A main pipeline is shared and is divided into two branches near the sedimentation cabinet, a preheating pump is arranged on one branch and provides high temperature fuel for the storage bin, a transfer pump is arranged on the other branch and conveys heated heavy oil to the sedimentation cabinet, and the two branches are provided with stop check valves in the corresponding directions so as to avoid pipeline direction malposition. A small compartment is arranged at one corner of the storage bin, and a first partition plate is arranged in the middle of the small compartment and divides the compartment into two parts in the X direction. A pipe A and a pipe B are arranged in a first sub-compartment, the upper right corner of the first partition plate is provided with a hole, the lower left corner of a second partition plate is provided with a hole, and the two holes are in opposite angle arrangement. Small holes are formed at the bottoms of partition plates to be used for sweeping. An upper plate of the compartment is provided with a plurality of air holes, so as to guarantee timely overflow of generated steam. The pipe A and the pipe B are communicated with the main pipeline and provided with regulating valves respectively.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

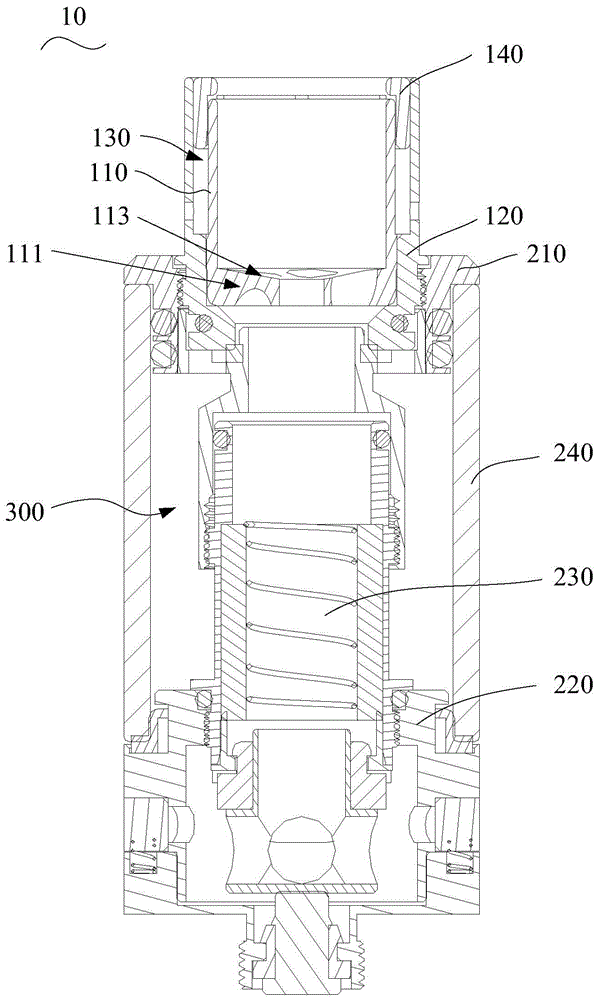

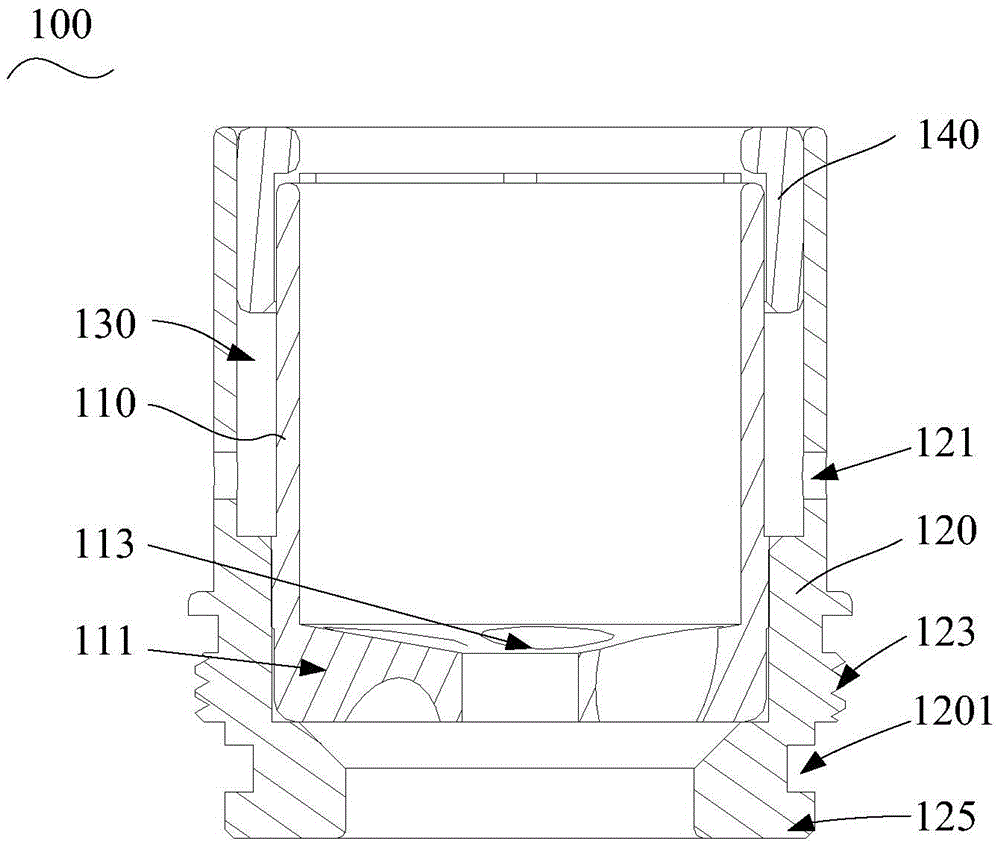

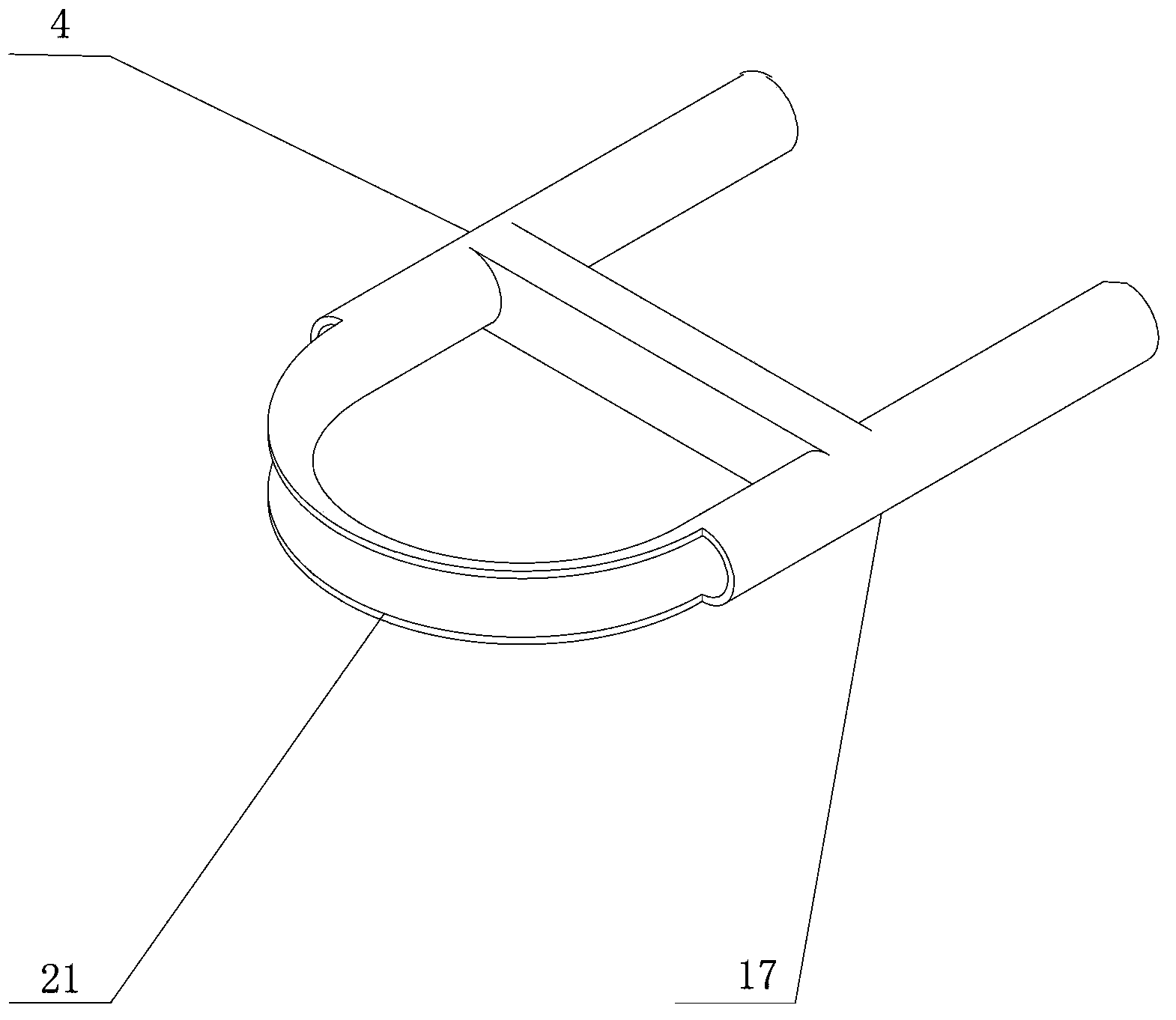

Electronic cigarette atomizer

The invention relates to an electronic cigarette atomizer, comprising a suction nozzle assembly and an atomization assembly connected with the suction nozzle assembly by airflow. The suction nozzle assembly comprises a suction nozzle base and a suction nozzle sleeve. The suction nozzle base is held in the suction nozzle sleeve. The bottom end of the suction nozzle base is provided with a slope-shaped venthole. The atomization assembly comprises an upper base, a lower base, an atomization core, and a sleeve housing. The sleeve housing is connected with the upper base and the lower base in an airtight manner. A tar storage cavity is formed among the upper base, the lower base, the atomization core, and the sleeve housing, and is used for storing tobacco tar. The atomization core is installed on the lower base. The atomization core is connected with the upper base by airflow. The suction nozzle sleeve is installed on the upper base. When smoke generated by the atomization core flows through the suction nozzle base, the smoke rotates and detours and rises in circles through the slope-shaped venthole, so that the smoke is mixed uniformly. The slope-shaped venthole can prolong heat exchange time of the smoke, the suction nozzle base, and the suction nozzle sleeve, so as to reduce temperature of the smoke, and reduce temperature of the electronic cigarette atomizer, and prolong service life.

Owner:SHENZHEN HANGSEN STAR TECH +1

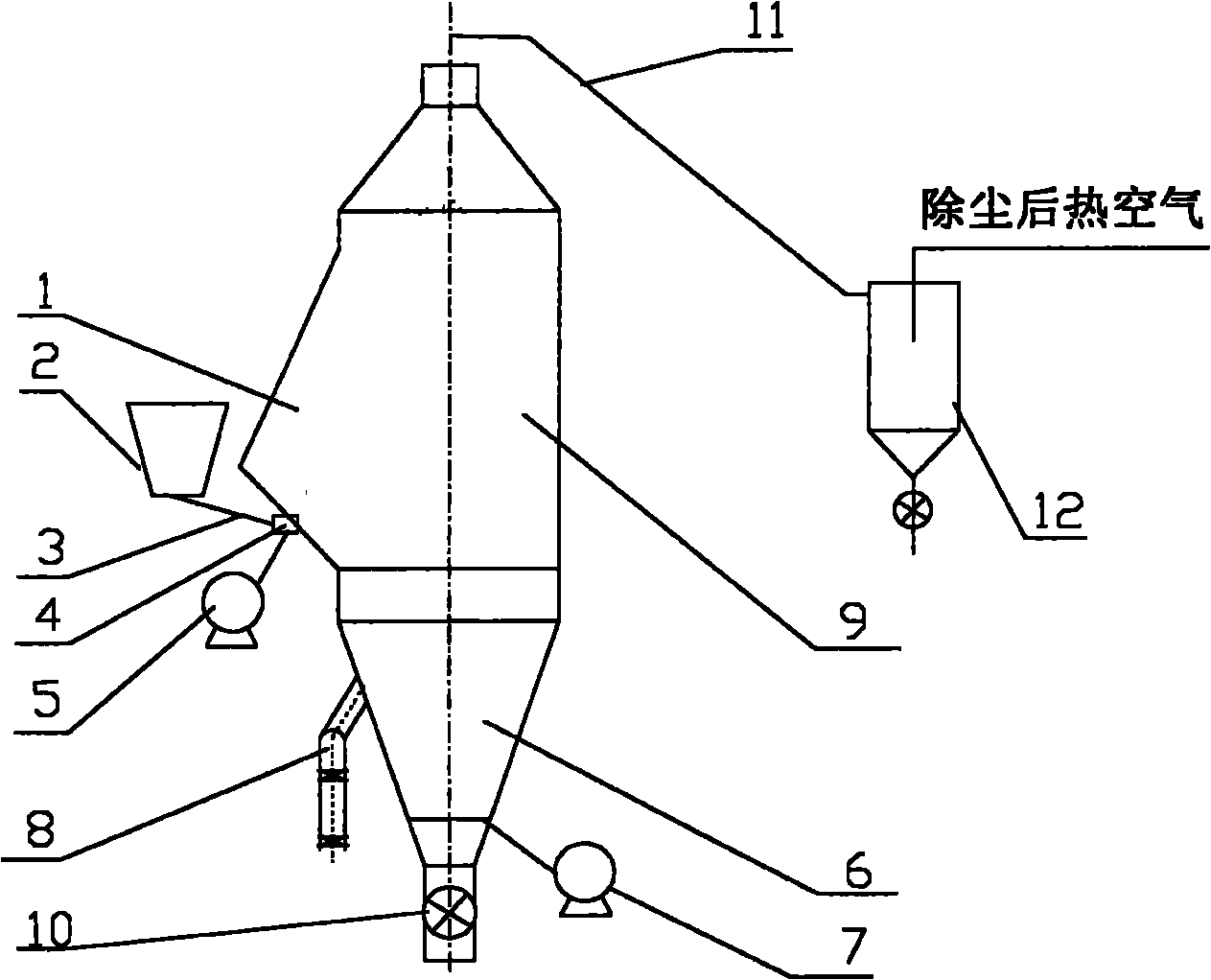

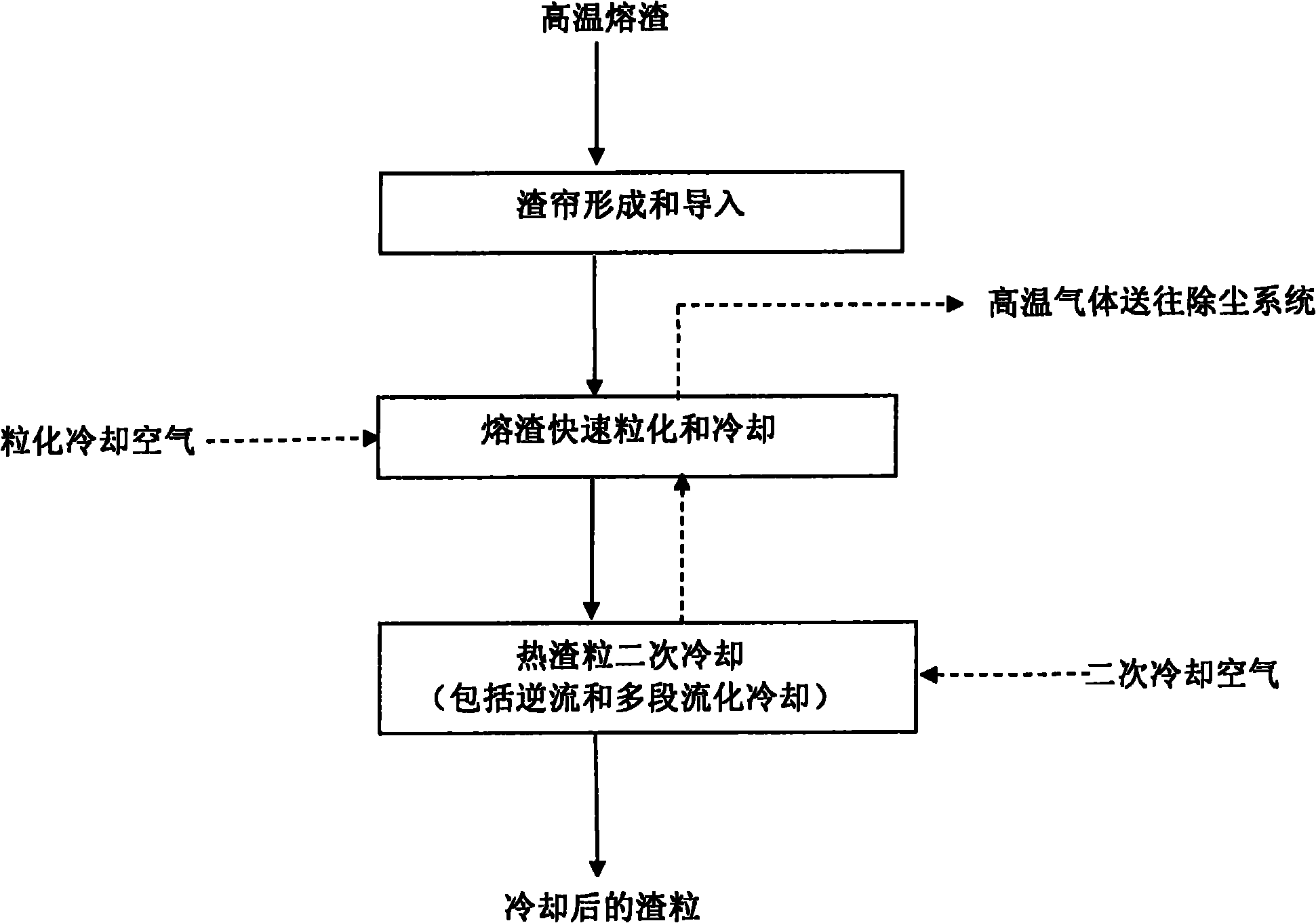

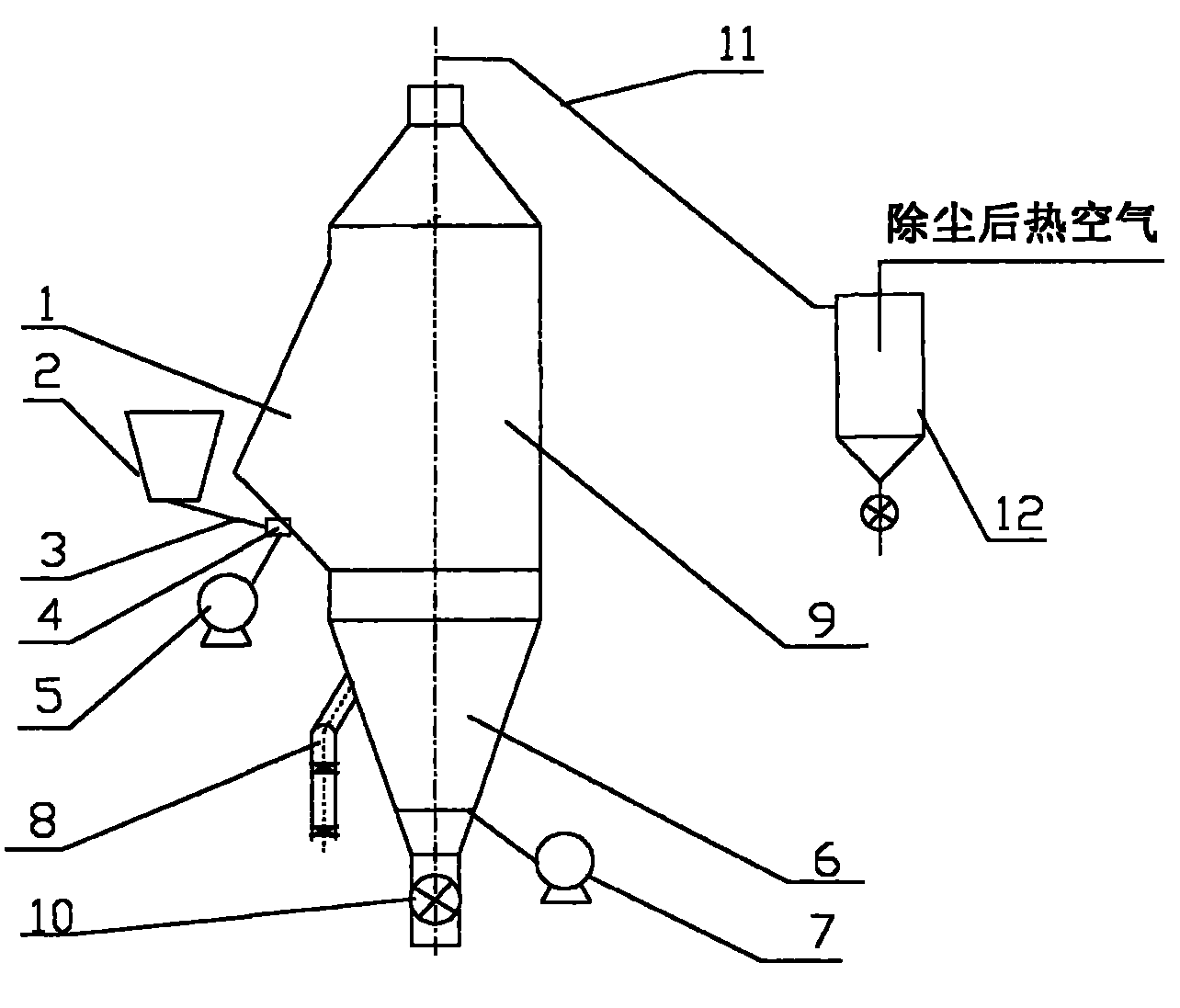

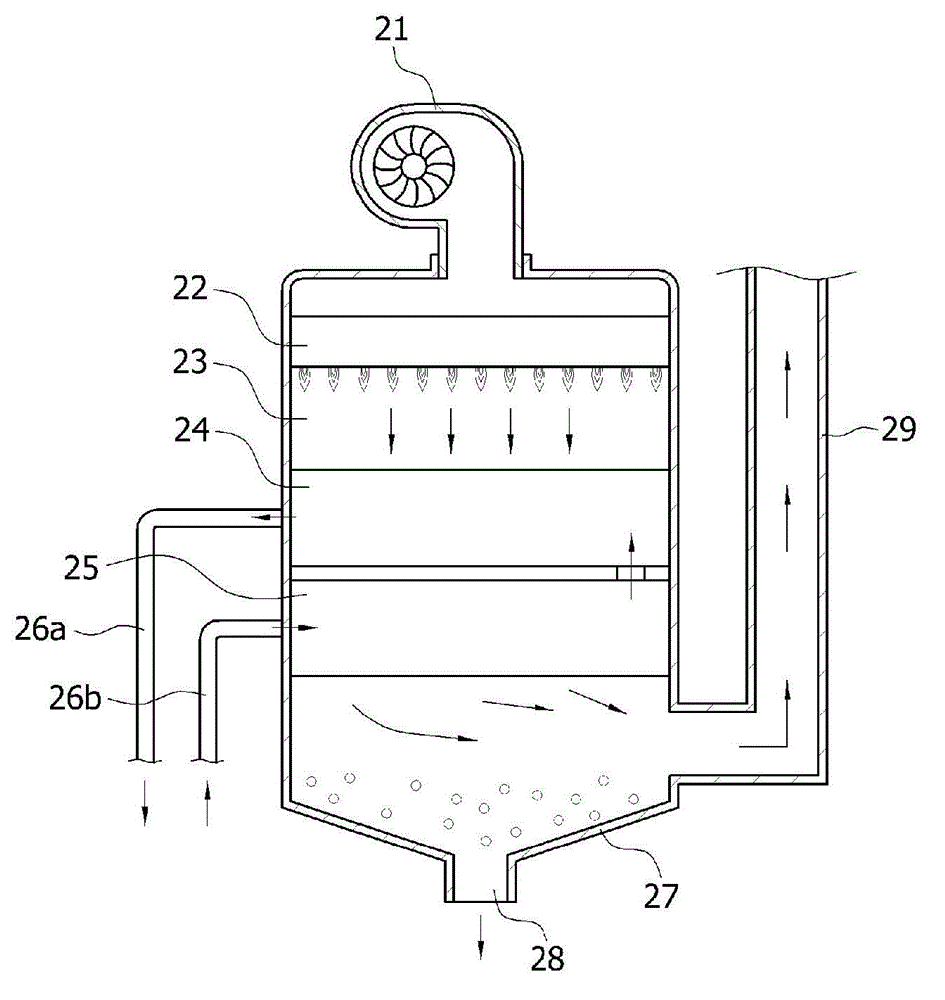

Metallurgical molten slag dry-type processing device and processing method thereof

InactiveCN101871025ARemarkable effectRapid secondary coolingRecycling and recovery technologiesProcess efficiency improvementFluidized bedMolten salt

The invention discloses a metallurgical molten slag dry-type processing device and a molten slag dry-type processing method. The processing device comprises a molten slag lead-in unit and a processing furnace, wherein the processing furnace comprises a granulating cooling nozzle, a multi-section fluidized bed device for secondarily cooling hot slag particles, a slag discharging pipe which is arranged nearby a multi-section fluidized bed top layer fluidized plate and is used for accidental maintenance and a rotary sealing valve which is arranged at a discharging outlet below the multi-section fluidized bed; in the processing furnace, the rapid granulating and cooling of the molten slag are completed inside a drum area on the upper part of the furnace body, the secondary cooling of the falling hot slag particles is completed through multi-section circular heat exchange with the ascending gas from the multi-section fluidized bed inside the multi-section fluidized bed, so the rapid granulating and the cooling of the molten slag as well as the secondary cooling of the hot slag particles can be continuously completed inside one processing furnace. The dry-type processing device reduces the heat loss of the system, improves the total recycling efficiency of the molten slag heat, and improves the installation feasibility near the main smelting device since the land occupation area is reduced.

Owner:北京睿德趋势量化咨询有限公司

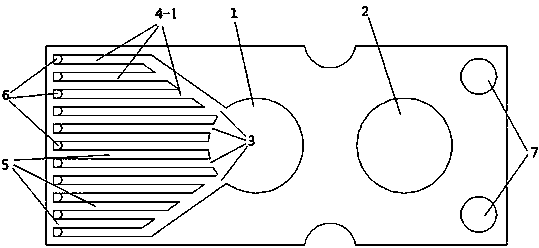

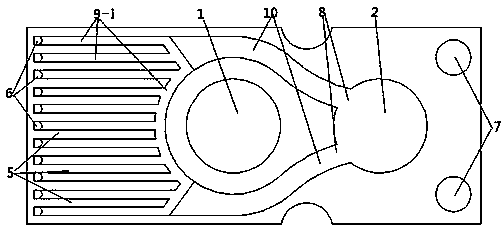

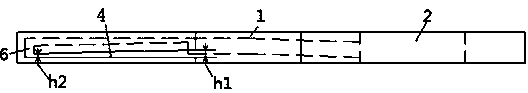

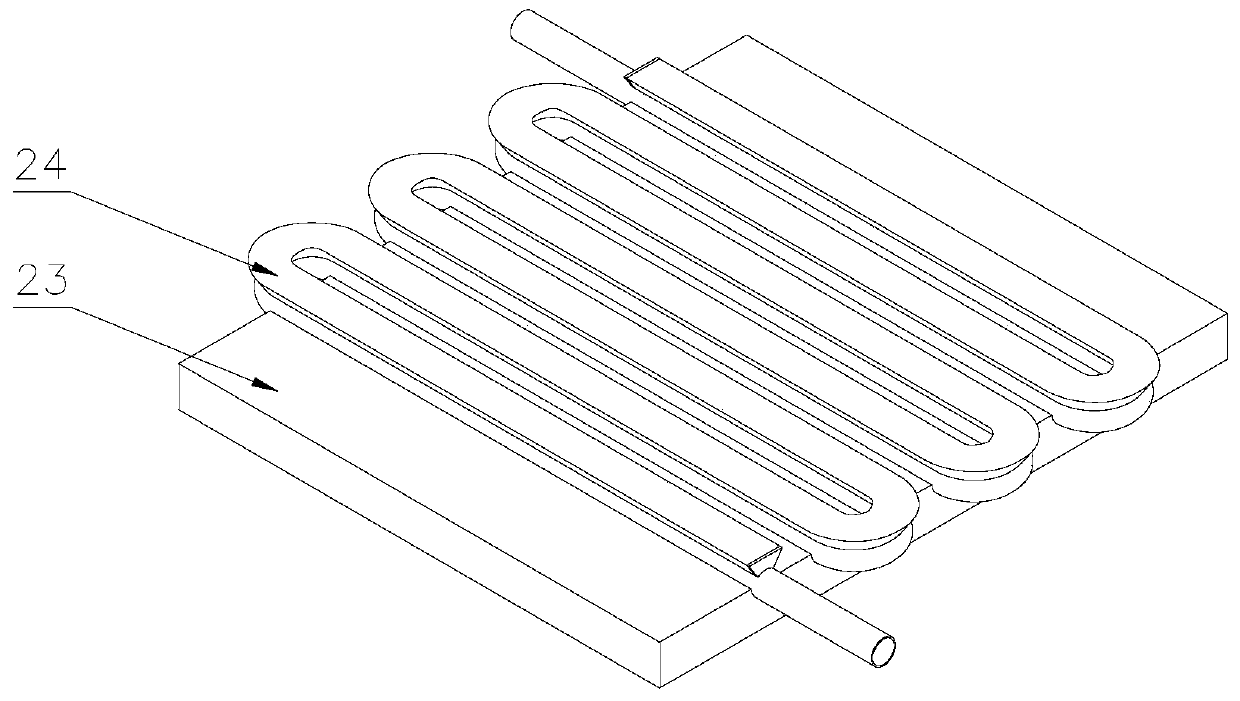

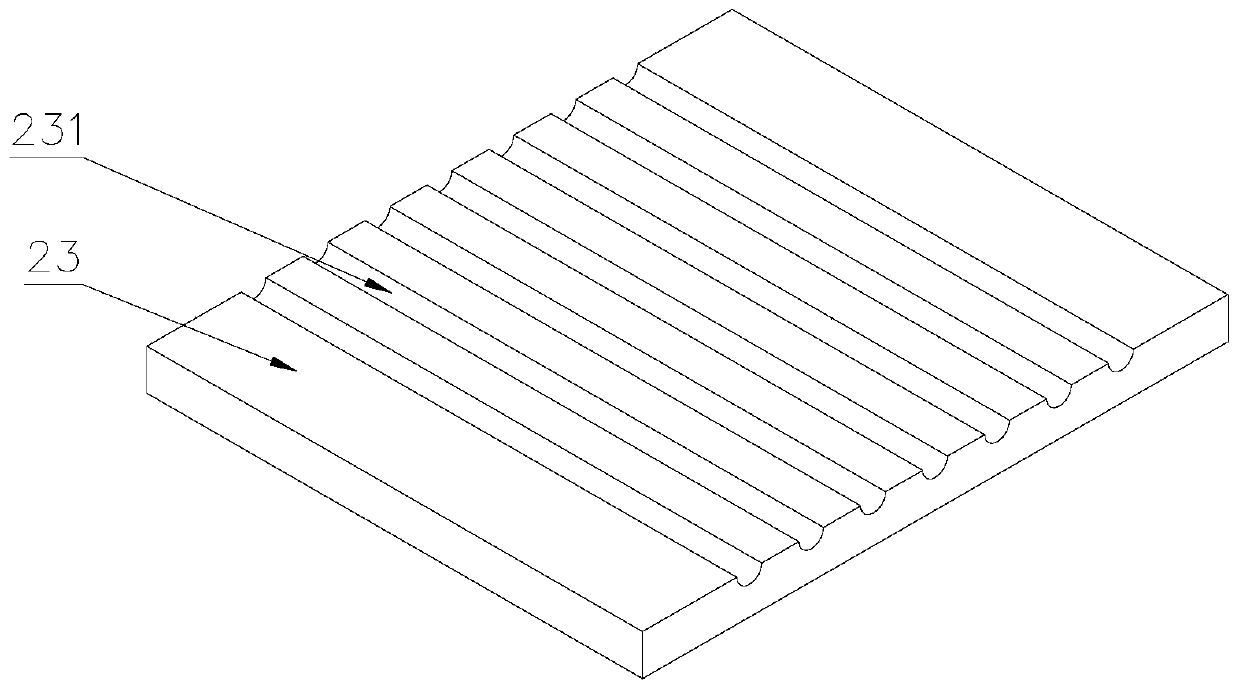

Internal micro-channel heat sink

ActiveCN104051952AHigh speedRaise the temperature differenceLaser detailsSemiconductor lasersInlet channelHeat resistance

The invention provides an internal micro-channel heat sink and relates to the field of heat dissipation structures of a semiconductor laser, an array device and a large-scale integrated circuit. The internal micro-channel heat sink mainly overcomes the defects that an existing heat sink is low in heat exchange efficiency and reduces heat resistance and pressure drop. The internal micro-channel heat sink comprises a water outlet layer, a water distribution layer and a water inlet layer which are arranged in sequence from top to bottom. A water inlet hole is formed in the water inlet layer and connected with water inlet channels. Return water holes are formed in the water distribution layer. A water outlet hole is formed in the water outlet layer and connected with water outlet channels. The water inlet channels are connected with the water outlet channels through the return water holes. The internal micro-channel heat sink is characterized in that the apertures of the water inlet channels decrease in the direction from the water inlet hole to the return water holes; the apertures of the water outlet channels decrease in the direction from the return water holes to the water outlet hole.

Owner:CHENGDU 3D CHANGE TECH

Tube heat exchange tube

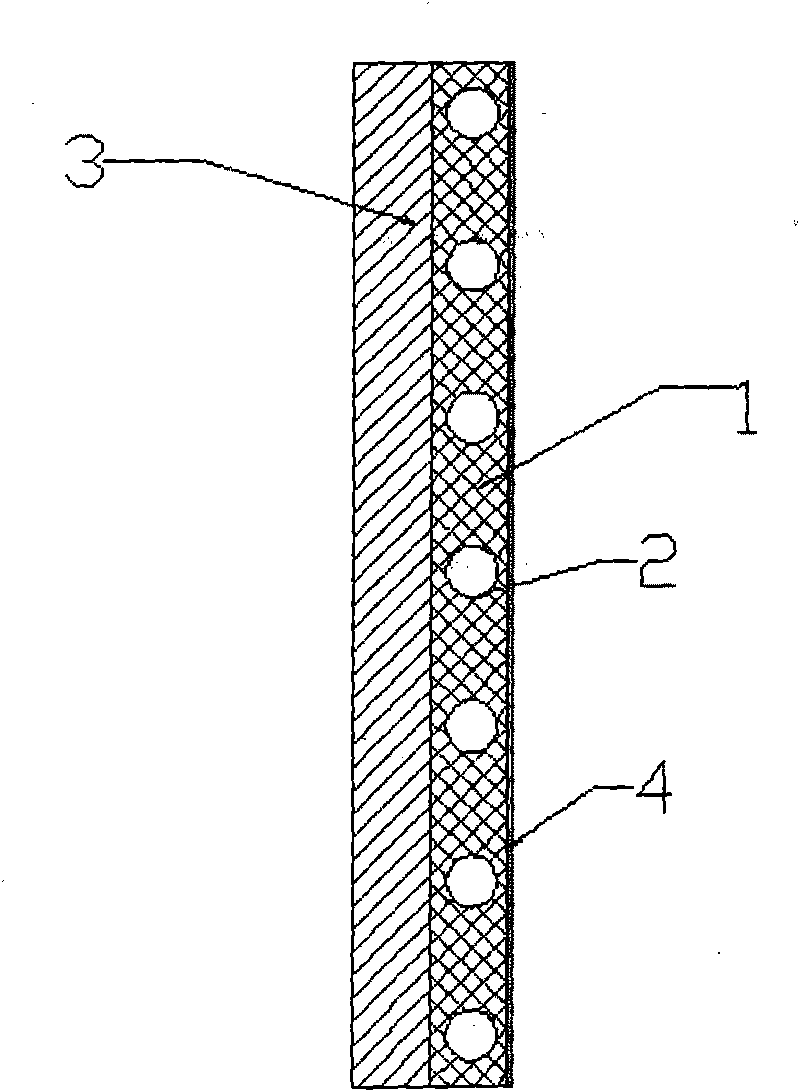

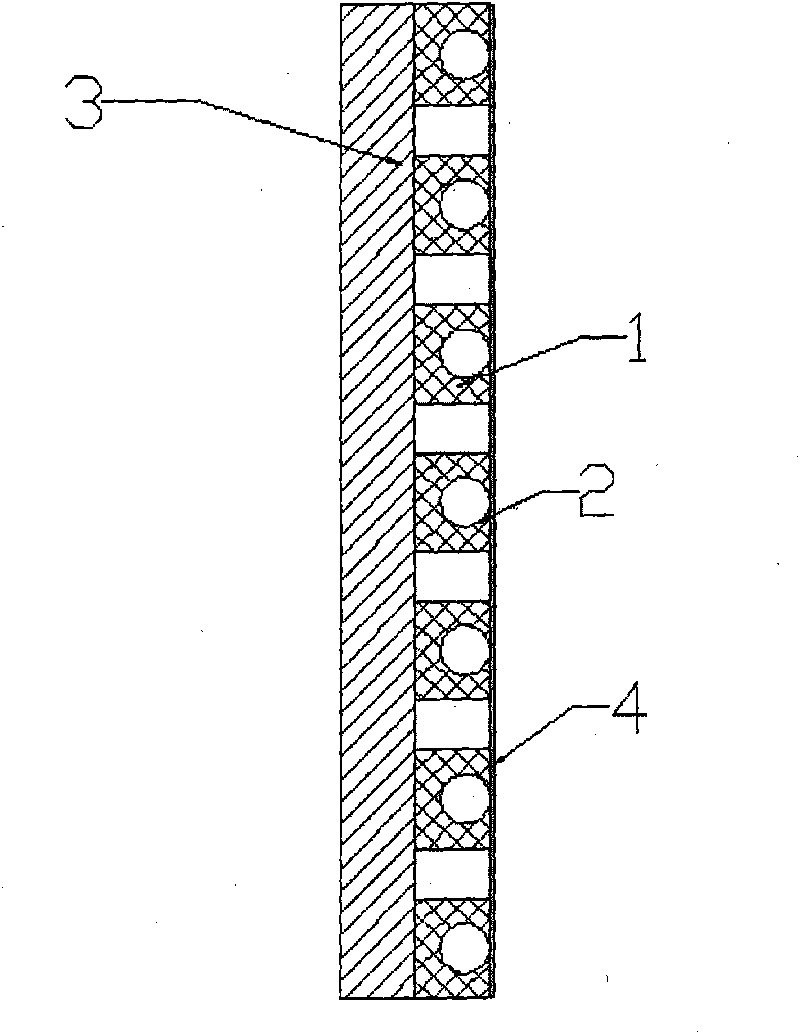

InactiveCN102278901AExtend heat exchange timeReduce flow rateStationary tubular conduit assembliesAir conditioning systemsEngineeringExchange time

The invention discloses a casing type heat exchange tube, which comprises an inner tube and an outer tube, the inner tube is located in the outer tube, the upper end of the outer tube is connected with the medium inlet, the lower end of the outer tube is sealed, the upper end of the inner tube is connected with the medium The outlet is connected, and the lower end of the inner pipe is open. The sleeve-type heat exchange tube has the following advantages: 1) It increases the contact area with the surrounding filler or soil; 2) The flow velocity of the heat exchange medium in the outer tube is reduced, which increases the heat exchange time of the heat exchange medium; The heat exchange medium conducts heat exchange downwards by its own weight, and the flow distance of the heat exchange medium in the tube is shortened.

Owner:谢学军

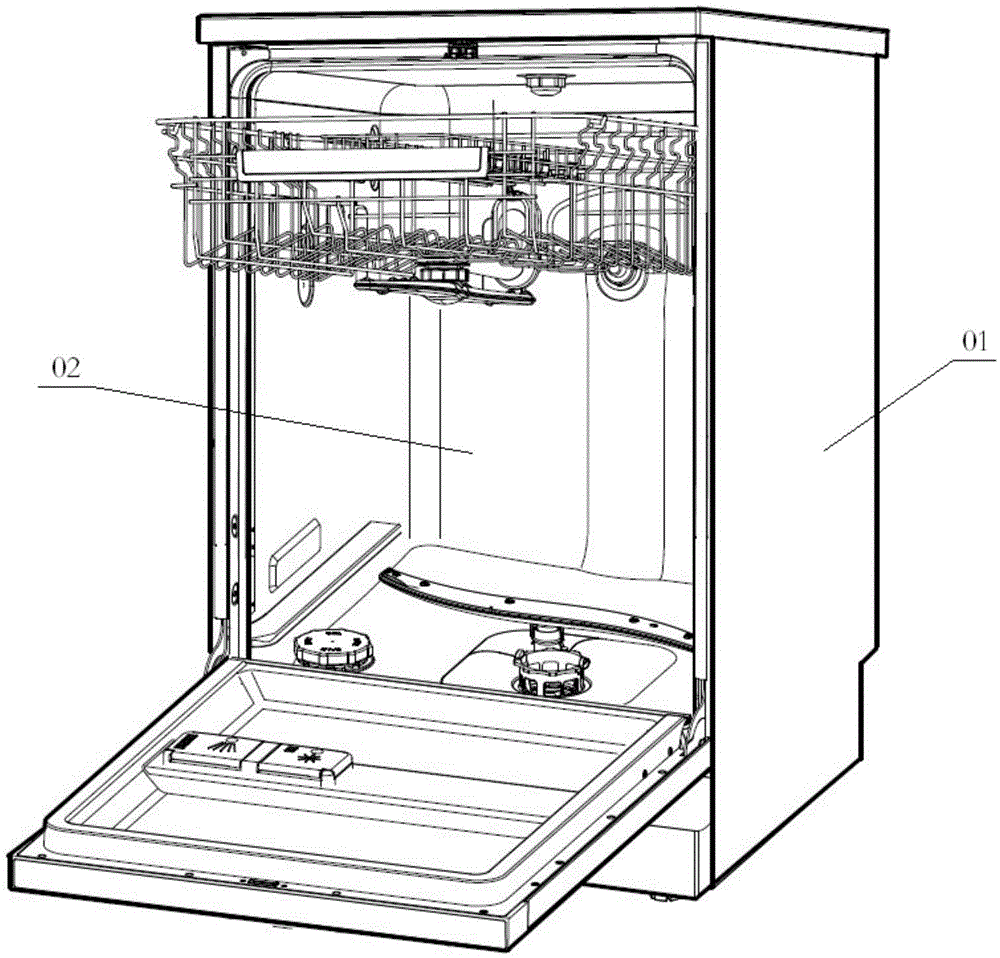

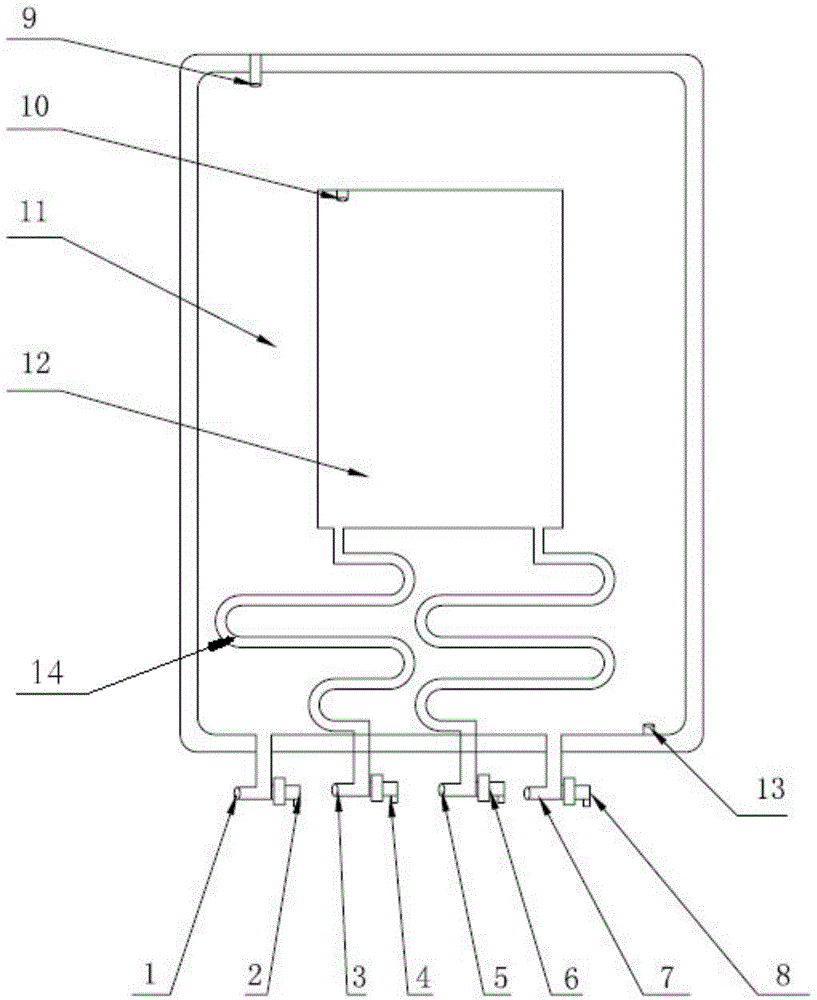

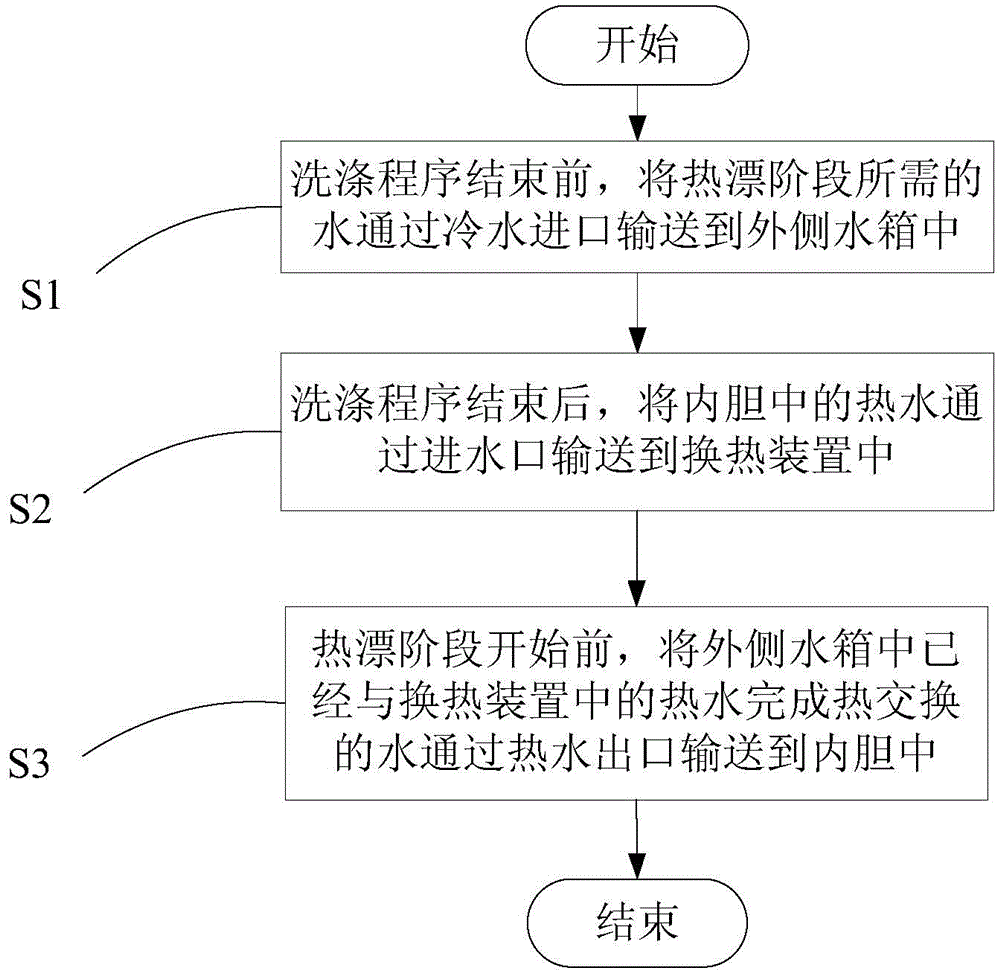

Dish-washing machine heat recovery device and method and dish-washing machine

InactiveCN106137080ASave time at workIncrease water temperatureTableware washing/rinsing machine detailsHome appliance efficiency improvementWater useWater discharge

The invention relates to the field of household appliances, in particular to a dish-washing machine heat recovery device and method and a dish-washing machine. The dish-washing machine heat recovery device comprises an outer-side water tank and a heat exchange device arranged in the outer-side water tank and used for performing heat exchange with water in the outer-side water tank, a cold water inlet and a hot water outlet are formed in the outer-side water tank, and the outer-side water tank is communicated with an outside water source through a cold water inlet and is communicated with a dish-washing machine inner container through a hot water outlet. A water inlet for feeding water into the heat exchange device and a water outlet for discharging water of the heat exchange device are further formed in the outer-side water tank, the heat exchange device is communicated with the dish-washing machine inner container through the water inlet and is communicated with a water discharging pipe through the water outlet. The heat recovery device can recover hot water at a recovery washing stage, improves the water temperature of water used at a hot-rinsing stage in a heat exchange mode, further reduces a heating temperature point of the water used at the hot-rinsing stage, reduces power consumption and does not produce power consumption in the hot water recovery process at a washing stage.

Owner:QINGDAO HAIER DISHWASHER

Process for recycling ammonium chloride waste water

InactiveCN102020389AReduce steam consumptionLow running costMultistage water/sewage treatmentAmmonium salt fertilisersTriple effectFertilizer

The invention provides a process for recycling ammonium chloride waste water, which comprises the steps of pre-heating ammonium chloride waste water and performing triple effect evaporation on feed liquid by using a plate type evaporator in turn. The process has the advantages that: triple effect downstream evaporation is adopted, pressure is kept between normal pressure and low vacuum, and evaporation temperature is lowered with the increase in the ammonium chloride concentration in waste water to reduce the corrosion of a medium by ammonium chloride, and the enough gas heat generated by steam-liquid separation at the previous effect evaporation is used as the heat source for later effect evaporation, so that the heating medium is fully utilized and steam consumption and operation cost are reduced; the first effect evaporation and second effect evaporation are falling film evaporation which has high evaporating capacity; the third effect evaporation is forced circulation evaporation; and the concentration of ammonium chloride solution after triple effect evaporation is controlled to be saturated, cooling and crystallizing can be performed subsequently, and the dried material can be used as a fertilizer directly and has a high commercial value.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Sludge treatment apparatus for water conservancy project

ActiveCN107381987AAvoid damageAvoid the impact of product qualitySludge treatment by de-watering/drying/thickeningHydraulic engineering apparatusExpanded clay aggregateHydraulic engineering

The invention relates to a sludge treatment apparatus for a water conservancy project. The sludge treatment apparatus comprises a transport apparatus, a stirring chamber, a transport pipeline part, a sludge filter chamber, a sludge mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber. By arranging various parts, the sludge treatment, the ceramsite preparation from sludge and the ceramsite forming can be continuously carried out, so that not only can the sludge containing heavy metal be removed and the secondary pollution of the sludge to a water body be avoided, but also heavy metal elements are secondarily utilized for the ceramsite, and the harmful sludge can be actually turned into benefit.

Owner:畅庆环保科技(太仓)有限公司

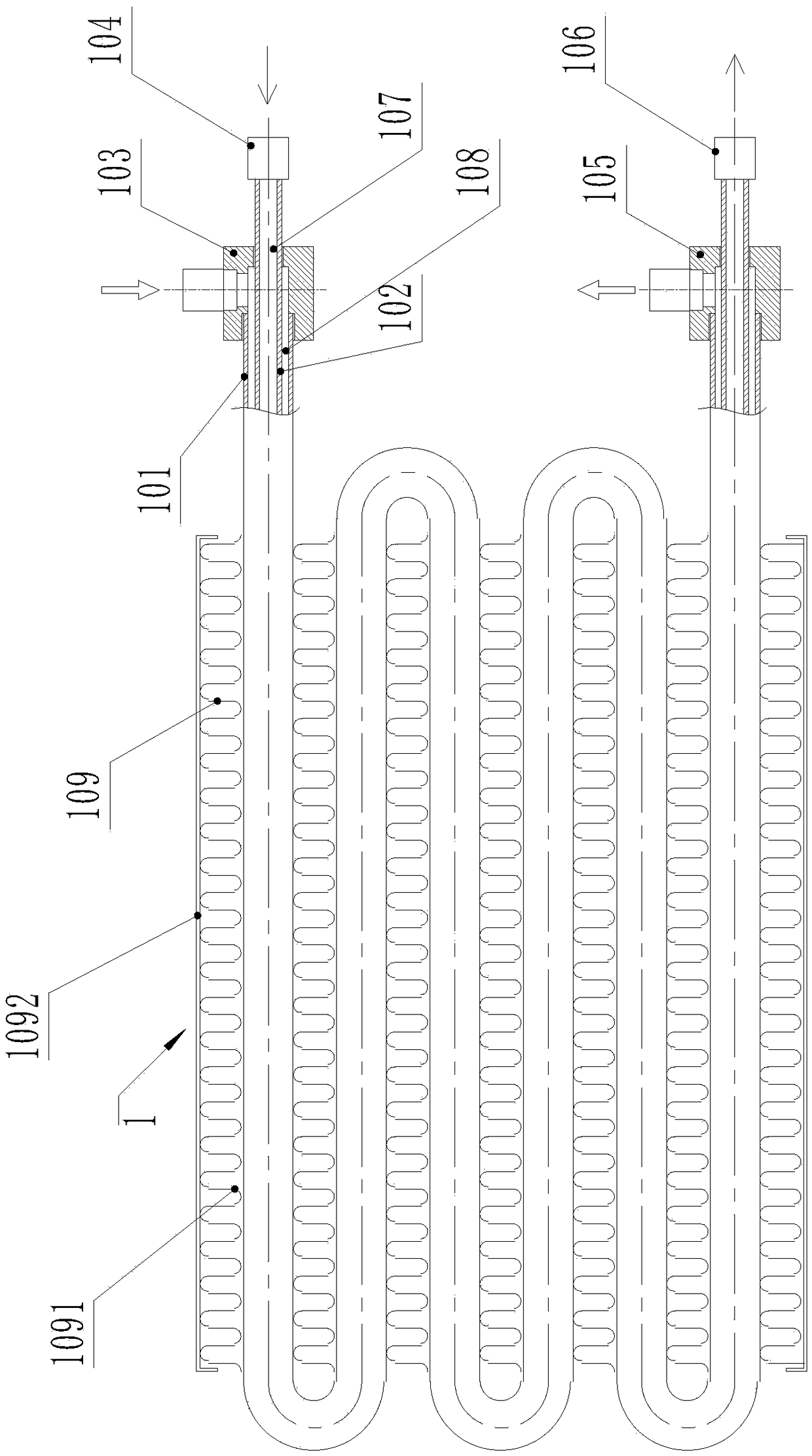

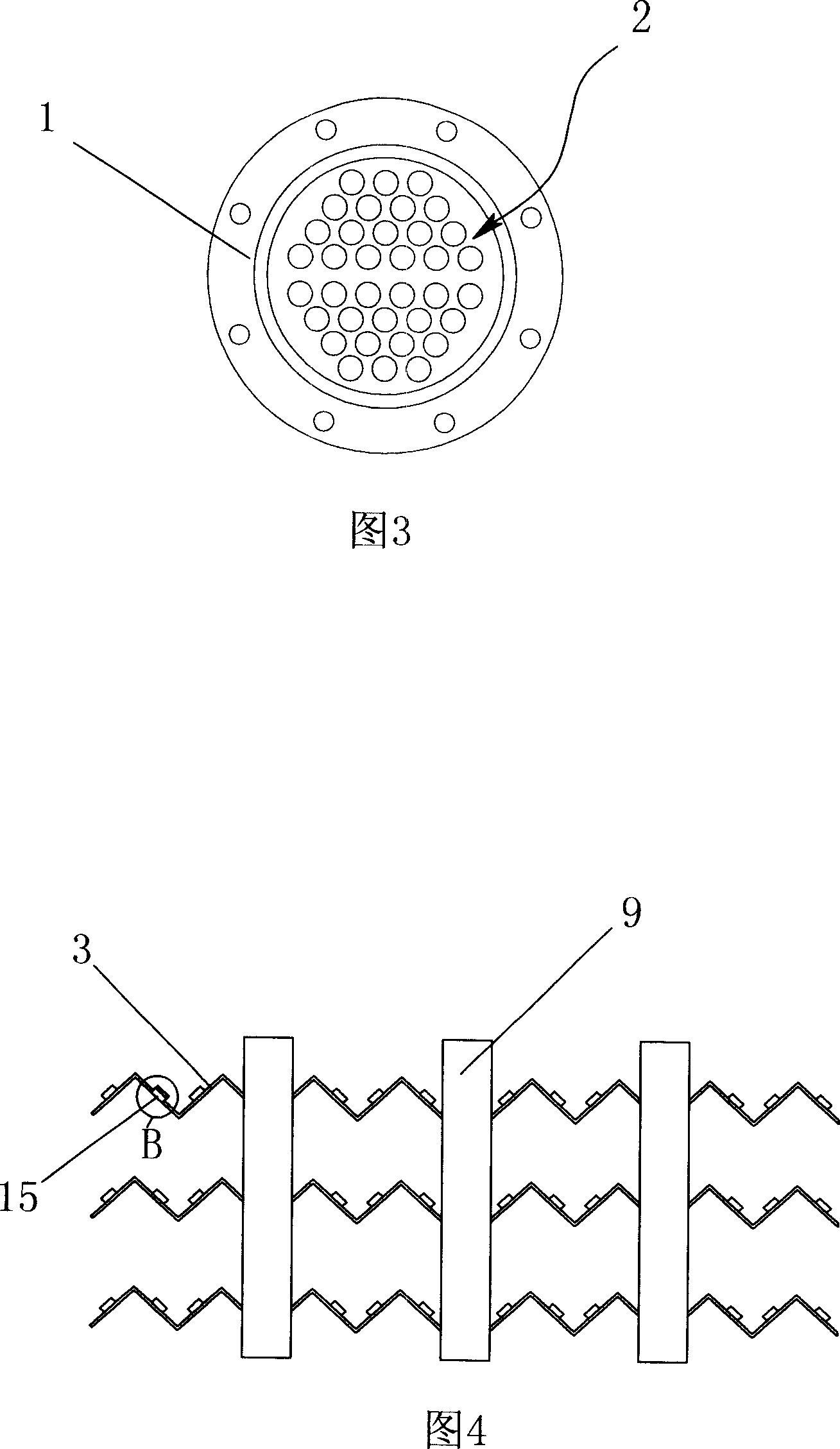

Header cold water pipe open communication heat absorption heat exchanger and manufacturing process thereof

ActiveCN102927604AReduce cloggingReduce heat lossLighting and heating apparatusSpace heating and ventilation detailsWater channelMetallic materials

The invention discloses a header cold water pipe open communication heat absorption heat exchanger and a manufacturing process of the header cold water pipe open communication heat absorption heat exchanger. The header cold water pipe open communication heat absorption heat exchanger at least comprises two heat supply pipes, wherein two ends of the heat supply heats are respectively welded with a header, at least one cold water channel is arranged inside a heat supply pipe cavity, ports at two ends of the cold water pipe channel are communicated in open cavity mode, and deposited scales in a cold water pipe can be conveniently cleaned by poured acid liquor. The cold water pipe stores water and absorbs heat, effective heat sources can be fully utilized, the heat is quickly absorbed through multiple dividing walls, the heat is transmitted in step mode, a heat absorption area is enlarged, and due to the fact that water is stored in the headers, the length of flow path of cold liquor is increased, the time of heat exchange is prolonged, heat loss is reduced, and heat exchange efficiency is improved. Longitudinal or transverse flexible installation is achieved by reasonable utilization of space, requirements of users can be met, materials are saved, and production cost is reduced. Product quality is stable and reliable, and service life is prolonged. The same kind of metal material is adopted, the weight is light, transportation is convenient, and logistics transportation cost is saved.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

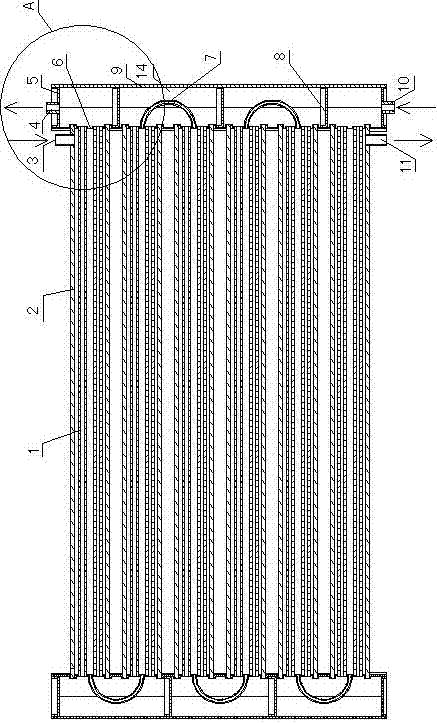

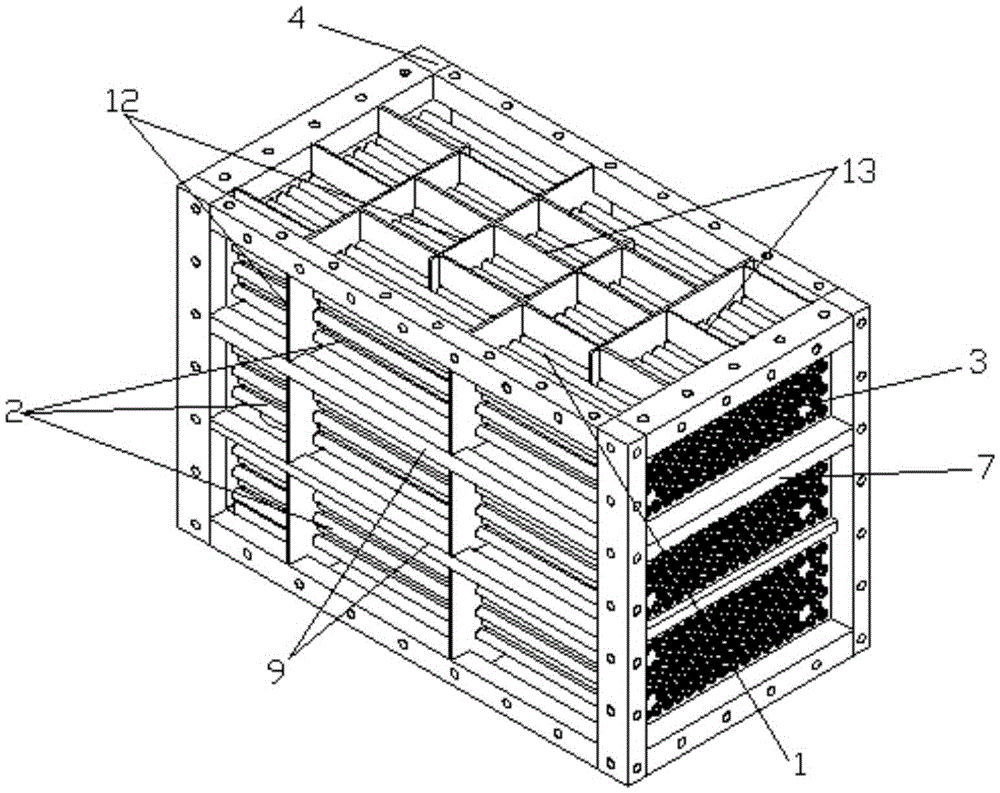

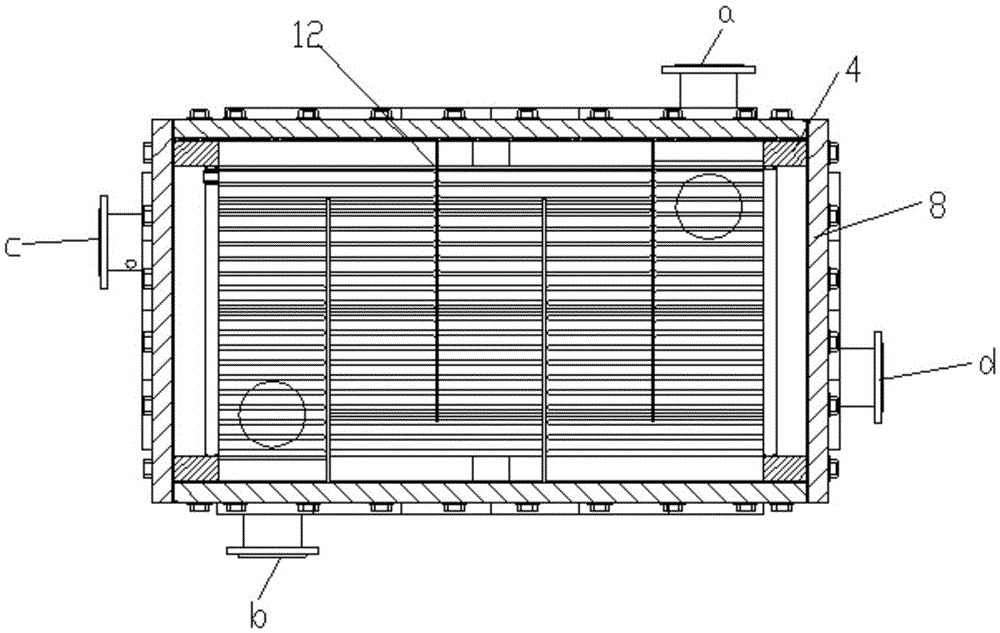

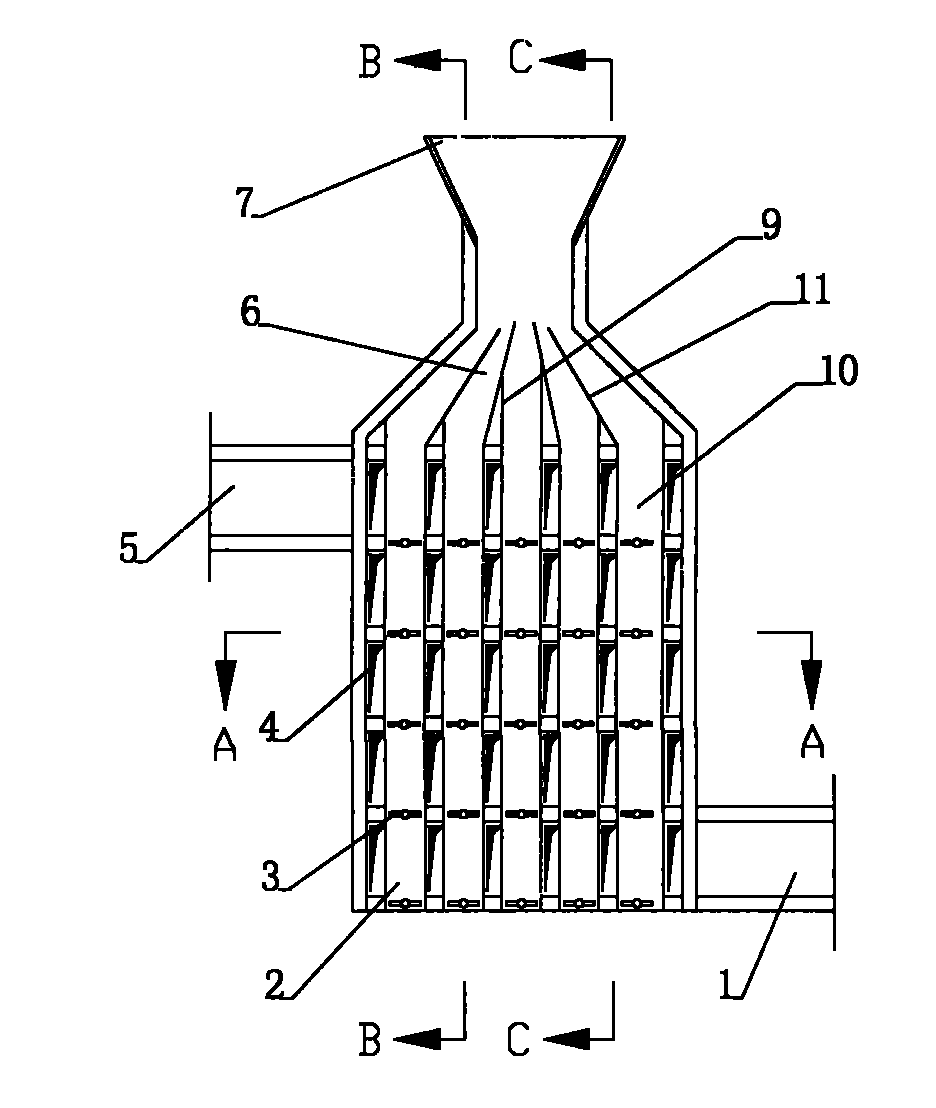

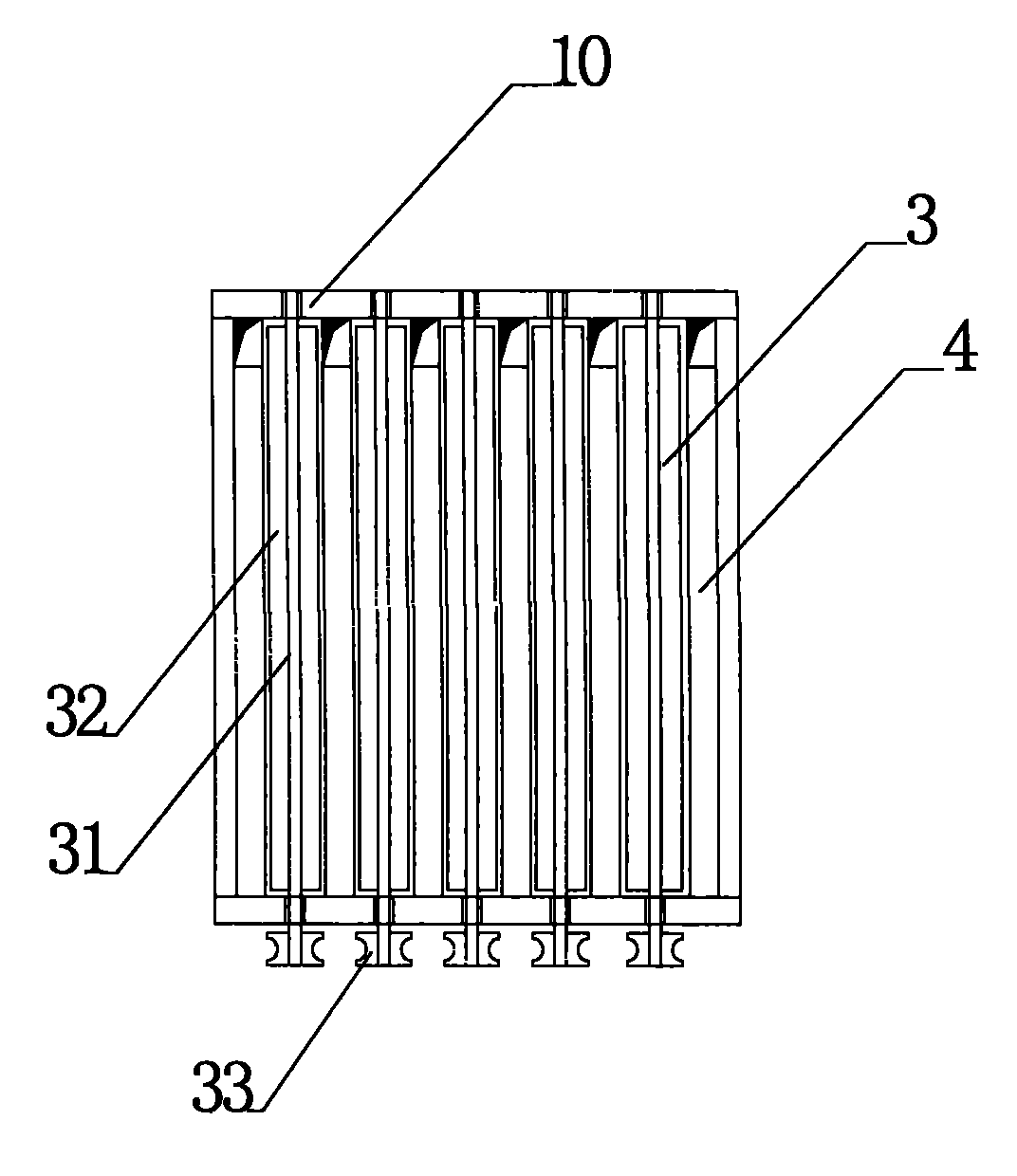

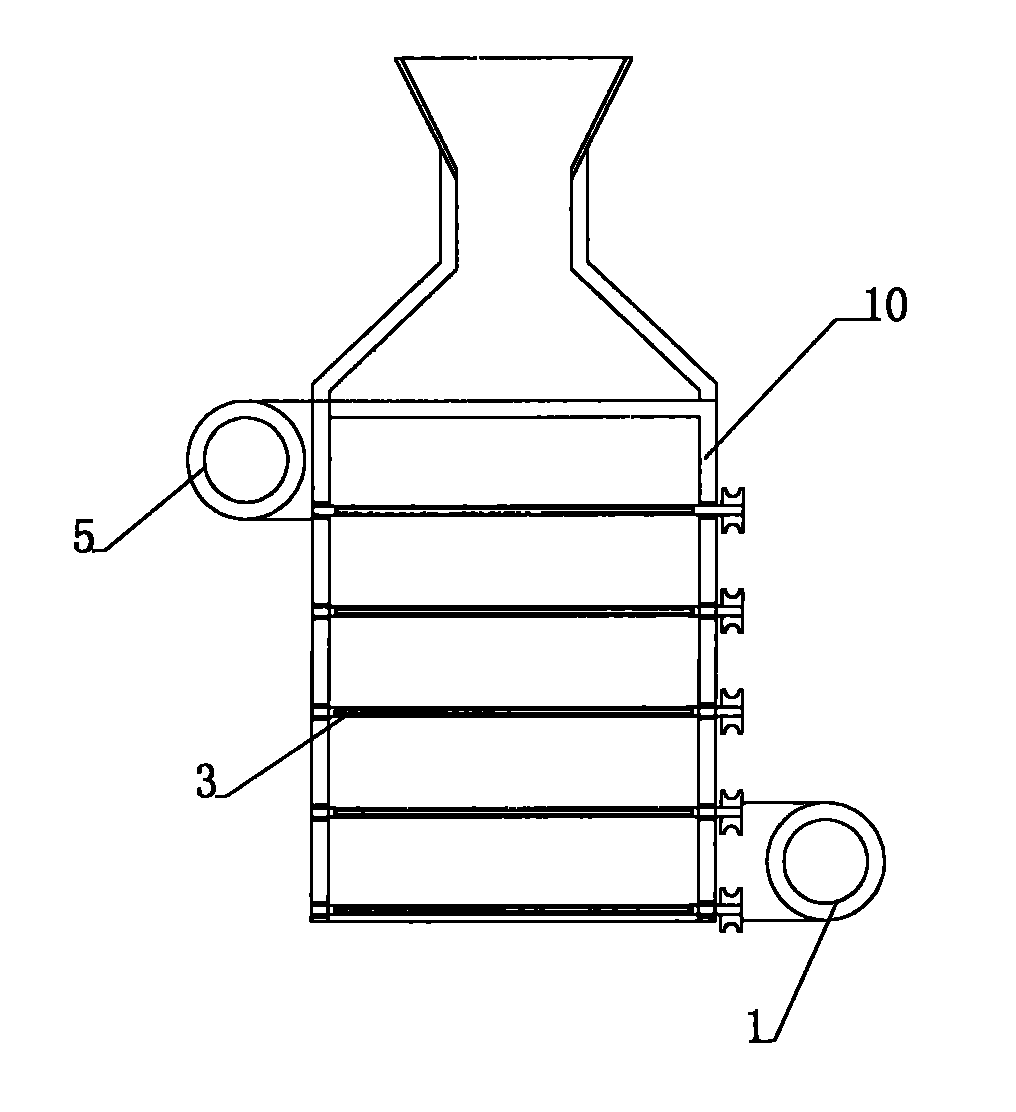

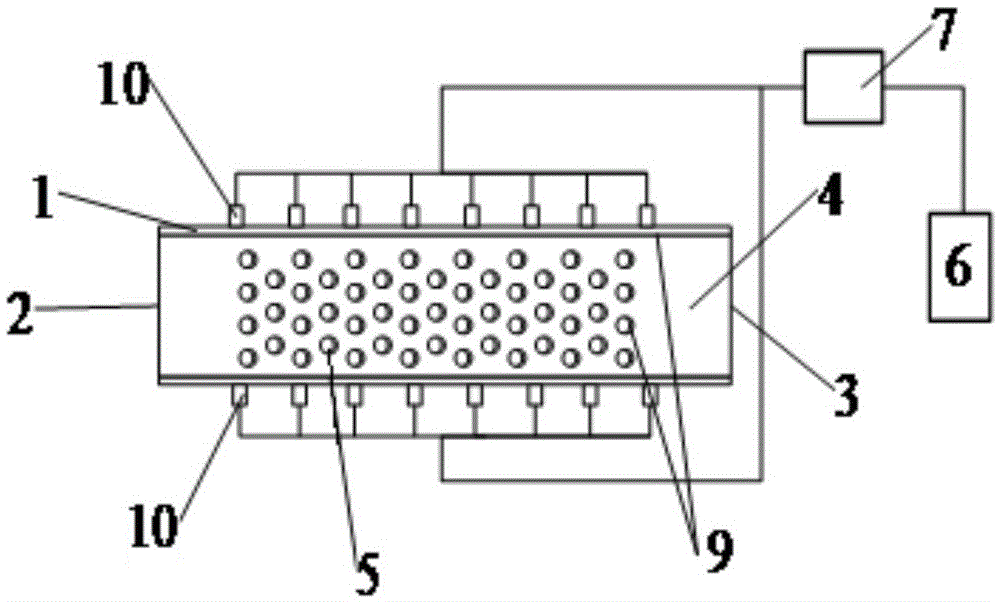

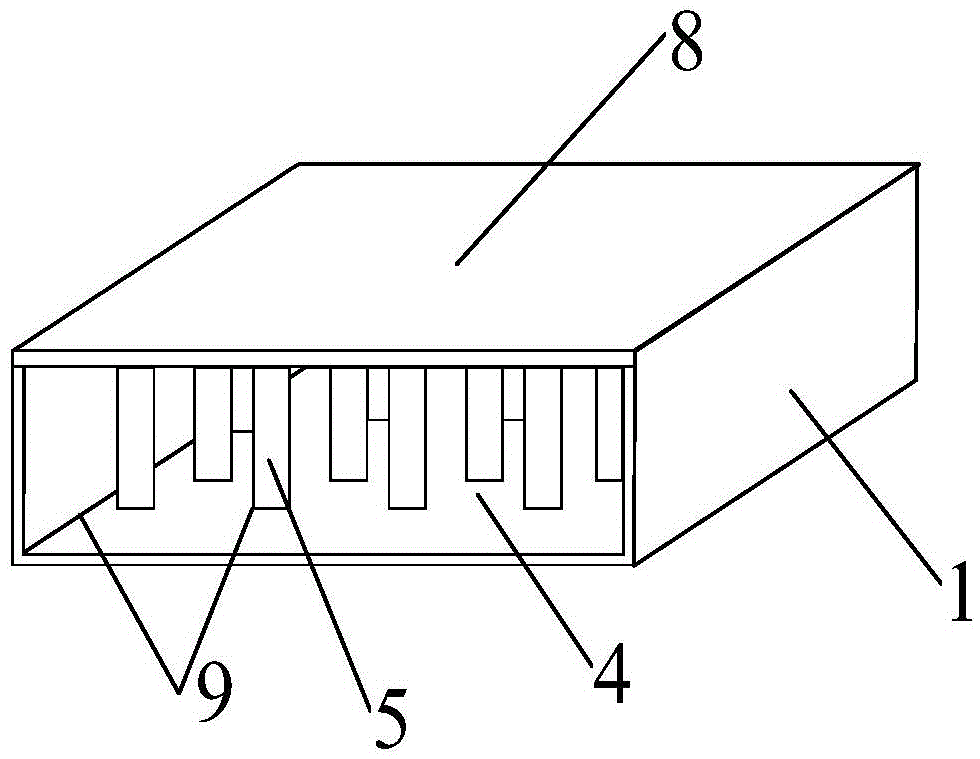

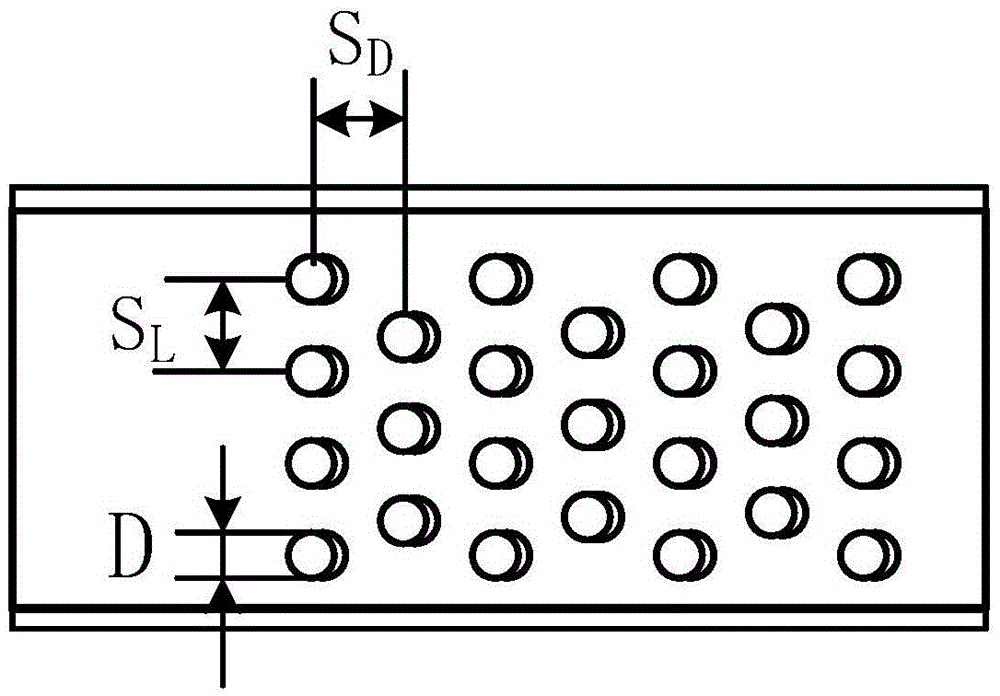

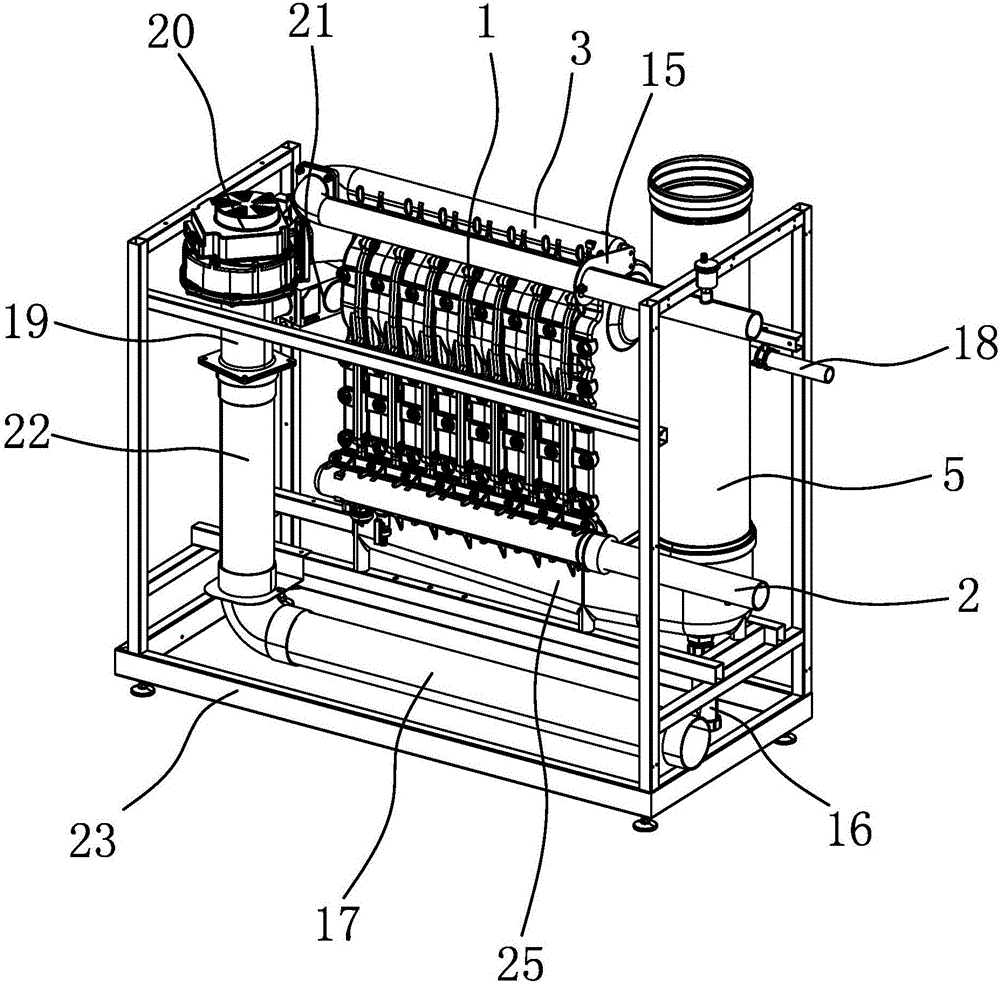

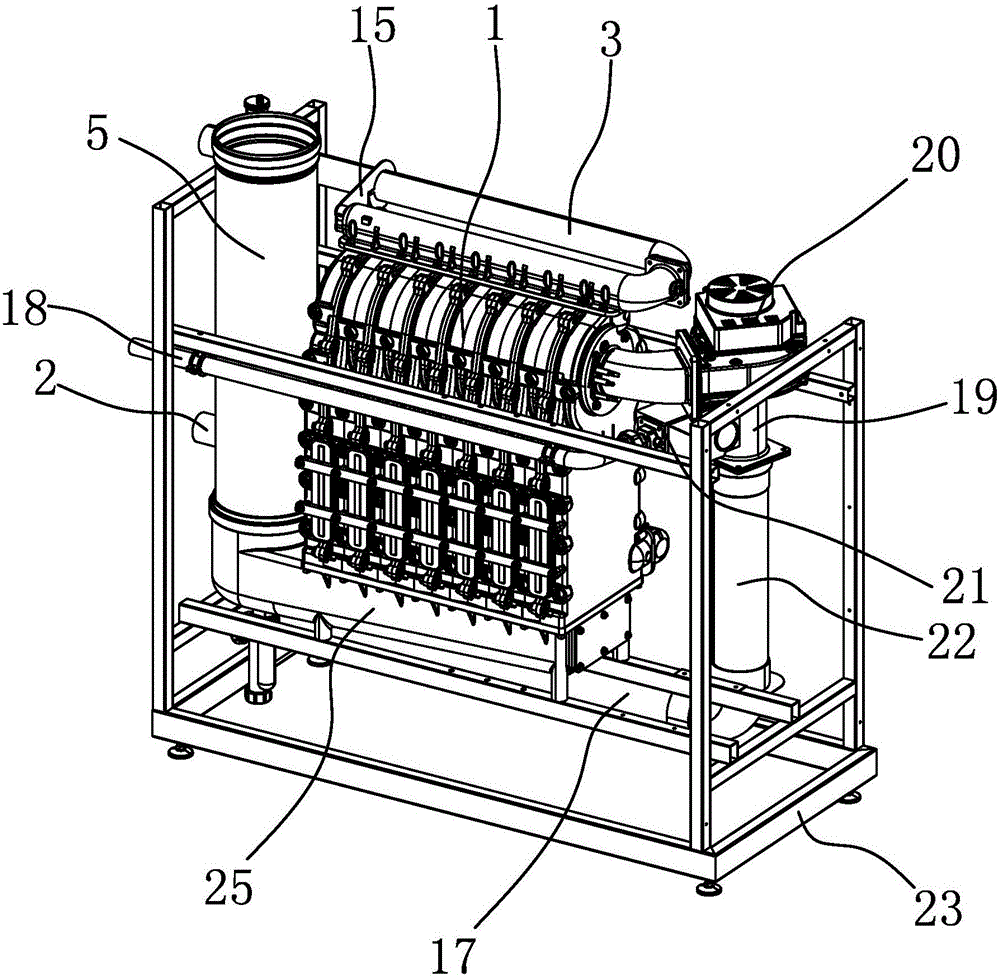

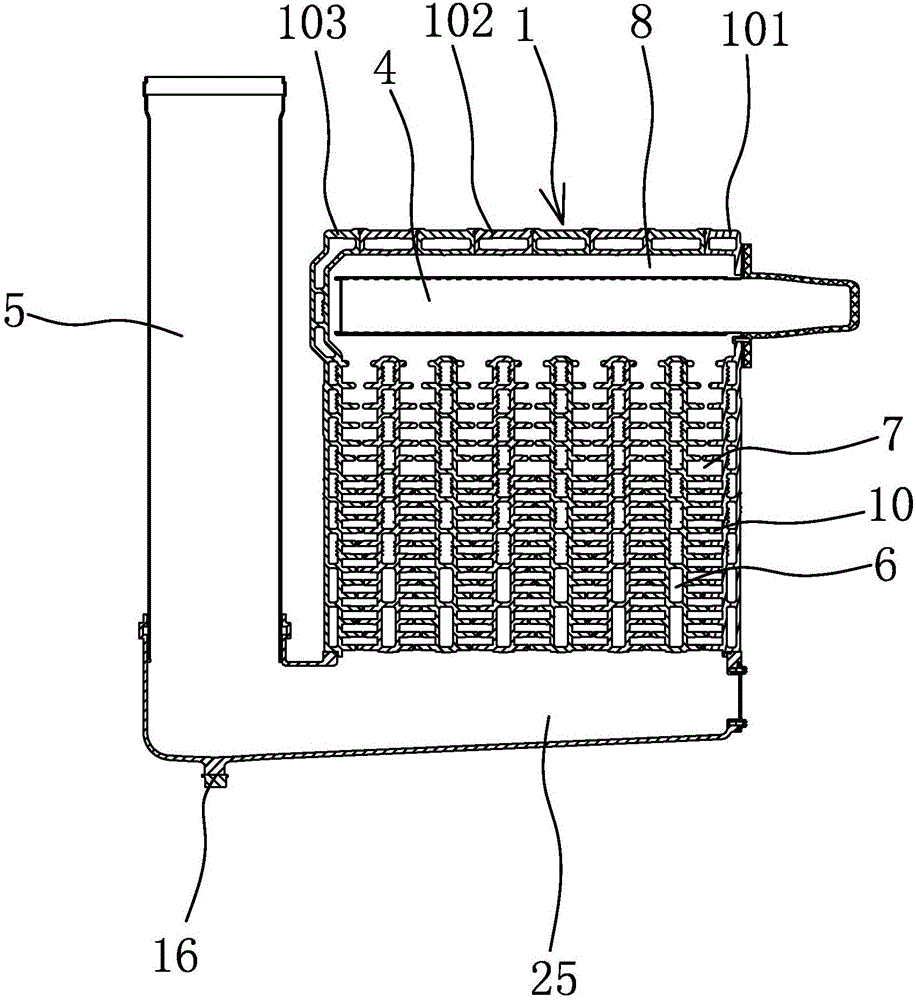

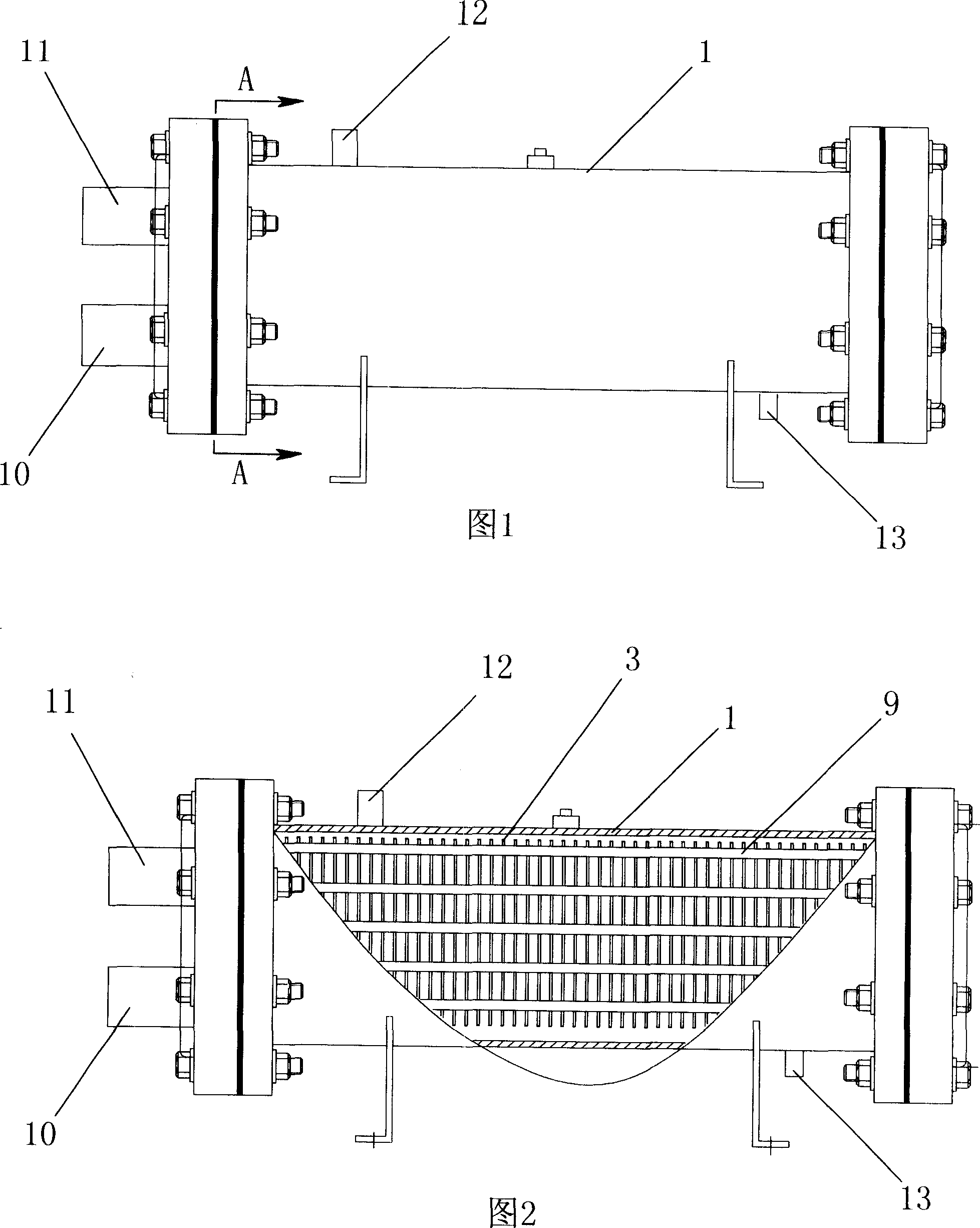

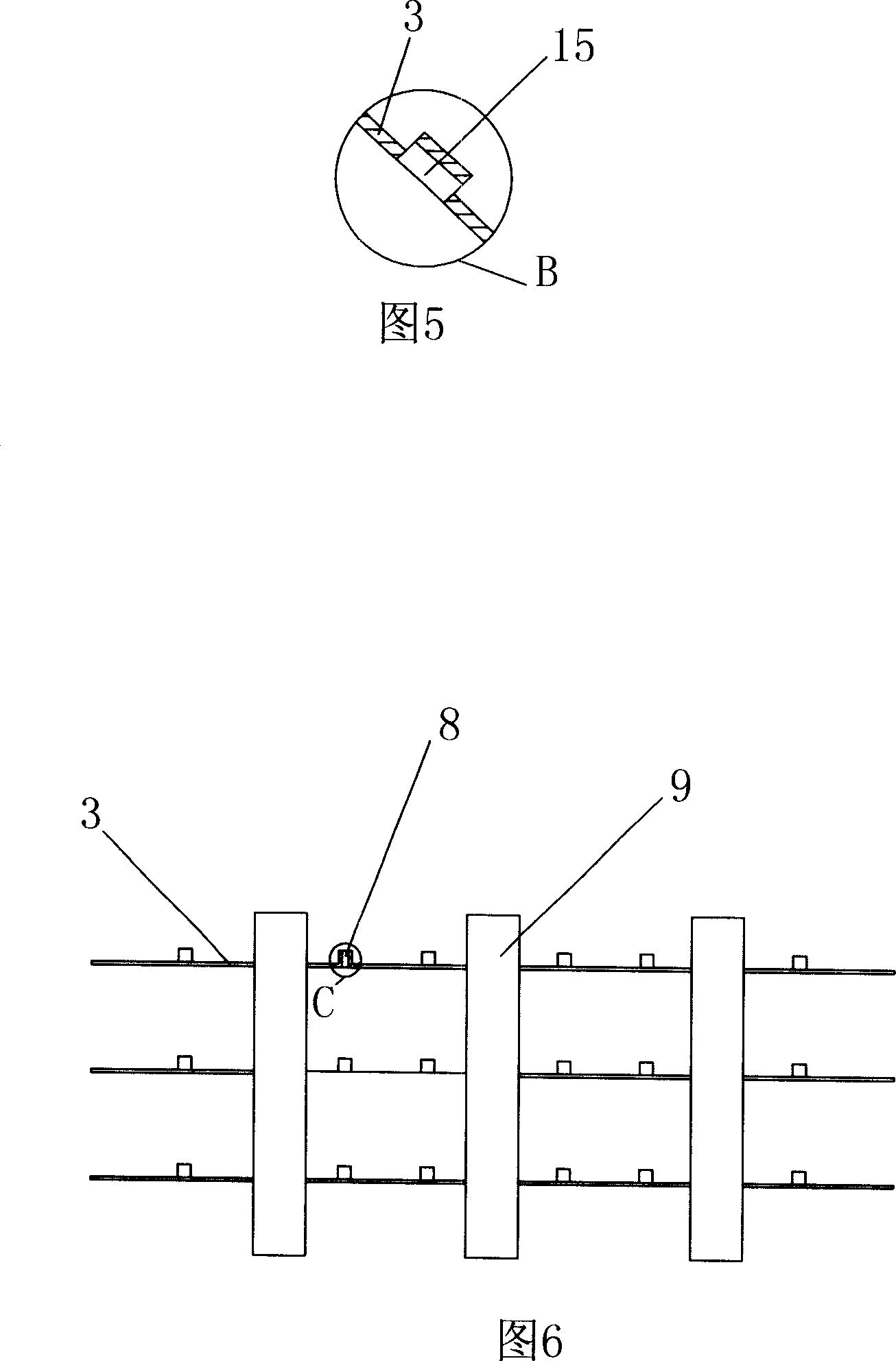

Efficient module type heat exchanger

ActiveCN105486124AExtend heat exchange timeIncrease the heat exchange areaChemical industryHeat exchanger casingsEngineeringHot Temperature

The invention discloses an efficient module type heat exchanger which comprises a heat exchange body. One or more layers of heat exchange units are arranged in the heat exchange body. A plurality of layers of heat exchange pipes are horizontally and evenly arranged in each layer of heat exchange unit. The heat exchange pipes in each layer of heat exchange unit are in the consistent left-right direction and used for allowing high-temperature fluid to pass. The heat exchange units are sequentially communicated from top to bottom end to end, and an S-shaped high-temperature fluid circulating channel is formed from top to bottom. Shell sides of the heat exchange pipes in each layer of heat exchange unit are used for allowing low-temperature fluid to pass. The direction of the low-temperature fluid is perpendicular to that of the high-temperature fluid. In the same heat exchange unit, the low-temperature fluid flows from one end to the other end in the horizontal plane in an S-shaped manner. The side ends of the heat exchange units are sequentially communicated from top to bottom end to end, and an S-shaped low-temperature fluid circulating channel is formed from top to bottom. The efficient module type heat exchanger is high in heat efficiency and can be conveniently and flexibly combined.

Owner:西安雷德热能技术工程有限公司

High thermal conductivity silica brick for coke oven and preparation method thereof

ActiveCN104119081ADense microstructureImprove thermal conductivitySilica particleCarboxymethyl cellulose

The invention relates to a high thermal conductivity silica brick for coke oven and a preparation method thereof. The high thermal conductivity silica brick for a coke oven comprises the following components by weight: 68.0%-82.0% of natural silica particles, 13.0%-26.0% of natural silica powder, 0.5%-2.0% of an additive containing dispersant, 1.5%-5.0% of siliceous non oxide, 1.0%-3.0% of a mineralization agent, and an additional binder in the weight 1.5%-3.0% of the total weight of the previous materials. The additive comprises a dispersant carboxymethyl cellulose (CMC) with granularity less than 0.088 mm and siliceous non-oxide Si with granularity less than 0.043 mm, wherein the content of Si is greater than 96 wt.%. The silica brick provided by the invention has high thermal conductivity and keeps other comprehensive excellent performances of silica brick, and can satisfy the demands of coke oven for longevity, energy saving and high efficient production.

Owner:BAOSHAN IRON & STEEL CO LTD +1

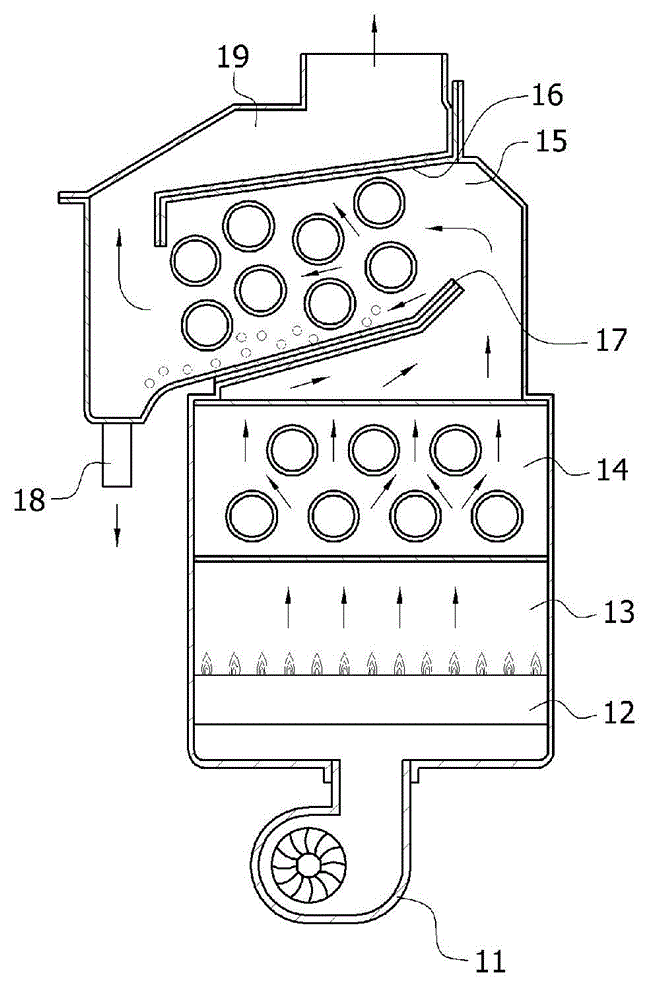

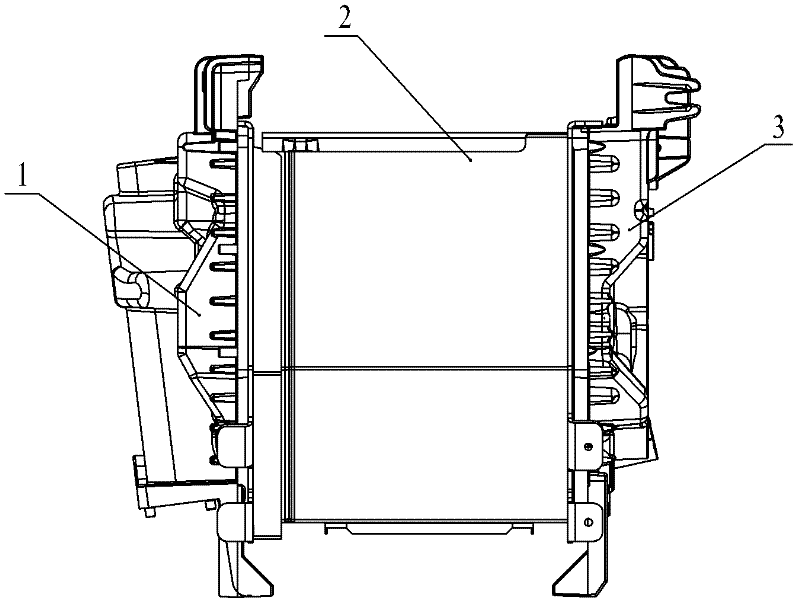

Latent heat exchanger in condensing boiler

InactiveCN103069225AReduced exhaust resistanceSmooth dischargeRecuperative heat exchangersEnergy efficient heating/coolingCombustorAcute angle

The present invention aims to provide a latent heat exchanger in a condensing boiler, which has no limit in the usage of a burner, comprises an upward combustion condensing boiler with a simple installation structure, reduces the exhaust resistance of a combustion product, and allows seamless discharging of condensed water generated from the latent heat exchanger so as to enhance the efficiency of latent heat recovery. To this end, the condensing boiler of the present invention comprises: a sensible heat exchanger for absorbing combusted sensible heat from the burner; the latent heat exchanger for absorbing the latent heat in water vapors in the combustion product that has been heat-exchanged in the sensible heat exchanger; an exhaust hood for discharging the combustion product that has passed through the latent heat exchanger; and a condensed water outlet port for discharging the condensed water generated from the latent heat exchanger, wherein the combustion product combusted in the burner is passed through the sensible heat exchanger, perpendicularly raised to the latent heat exchanger, descended in a slanted manner on the outer side, creating an acute angle with a horizontal surface, for heat-exchanging in the latent heat exchanger, and then perpendicularly raised and discharged from the exhaust hood.

Owner:KYUNGDONG NAVIEN

Wet type exhaust silencer

InactiveCN106089384AReduce noiseIncreased contact area and heat exchange timeExhaust apparatusSilencing apparatusSulfideDust particles

A wet type exhaust silencer comprises a silencer body and a silencer shell; the silencer body is wrapped by the silencer shell to form an annular jacket pipe cavity; a cooling water inlet joint is arranged on the silencer shell, and water spraying holes are formed in the position, located on the pipe wall of the annular jacket pipe cavity, of the silencer body; according to the wet type exhaust silencer, the diameter of a tail gas way of the silencer body is larger than that of an air inlet, and therefore tail gas is expanded, and the noise is effectively lowered. Meanwhile, the water spraying holes spray small water columns to the interior of the tail gas way of the silencer body, a water curtain is formed in the silencer body, the contact area between high-temperature gas and the water curtain is increased, the heat exchange time of the high-temperature gas and the water curtain is prolonged, the inherent frequency of exhausted gas of a diesel engine is changed, and the effects of cooling and silencing are achieved; dust particles, sulfide and the like contained in gas can be effectively removed, and emissions of harmful gas to the atmosphere are avoided. The wet type exhaust silencer is particularly suitable for silencing and purification of tail gas of large internal combustion machines of luxury yachts, passenger ships, public service ships, cargo / passenger ferries and the like.

Owner:GUANGDONG XINCHUAN HEAVY IND

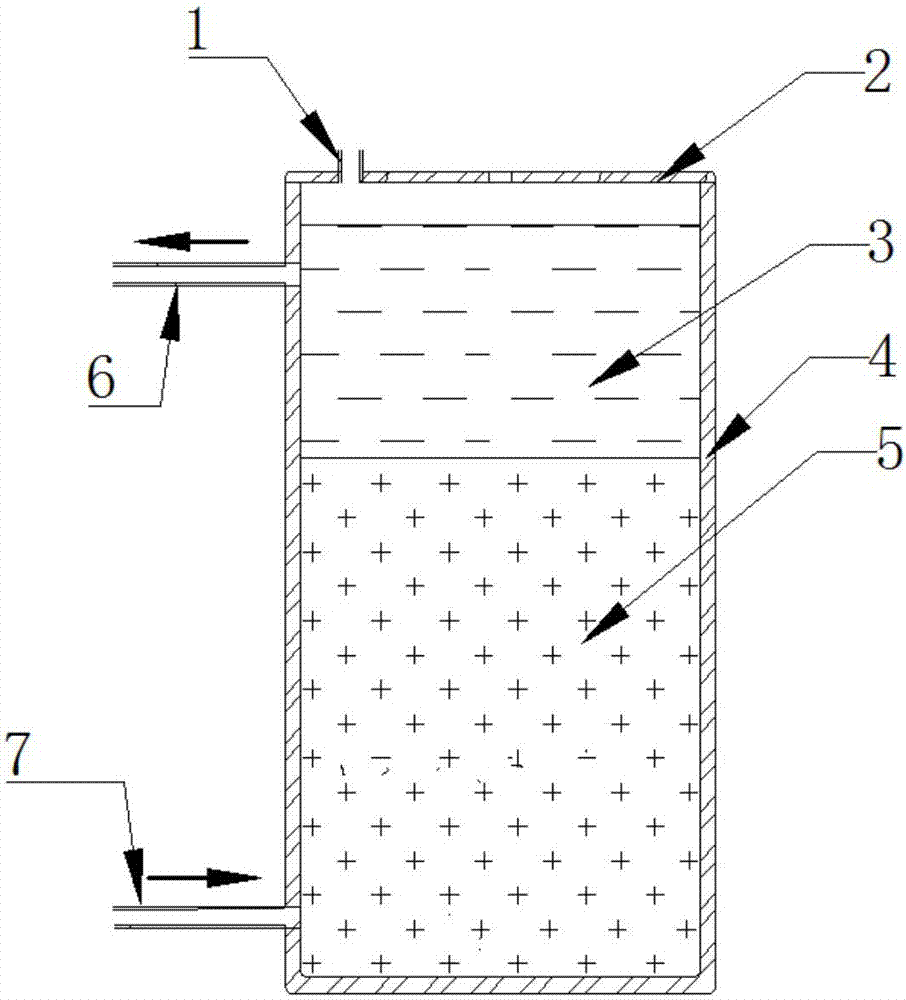

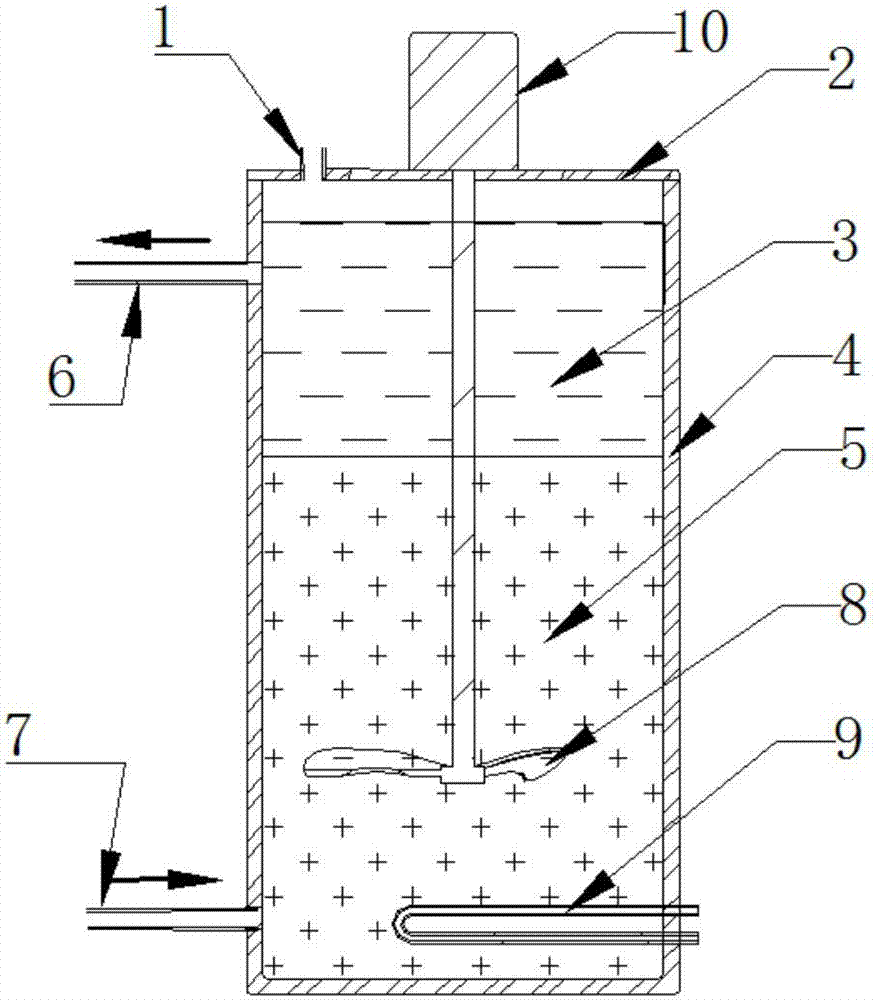

Novel phase change energy storage type device and method

PendingCN106885486AReduce subcoolingImprove heat transfer performanceHeat storage plantsHeat transfer modificationElectricityEngineering

The invention relates to a novel phase change energy storage type device. The device comprises a storage container (2), a phase change heat storage material (5) and a heat exchange medium (3) are arranged in the heat storage container (2), an inlet pipeline (7) and an outlet pipeline (6) allowing the heat exchange medium (3) to circulate are arranged on the side wall of the storage container (2), the phase change heat storage material (5) and the heat exchange medium (3) make direct contact and are not soluble, the density of the heat exchange medium (3) is smaller than that of the phase change heat storage material (5), the inlet pipeline (7) is located on the lower portion of the storage container (2), and the outlet pipeline (6) is located on the upper portion of the storage container (2). Compared with the prior art, the device is simple in structure, no heat exchange pipeline assemblies exist in the interior, the heat exchange efficiency is high, maintenance is convenient, the cost is low, meanwhile, the off-peak electricity can be used for heat storage, the running cost is low, and the device is suitable for large-scale batched production.

Owner:PIONEER ENERGY JIANGSU

Double-effect cooler

InactiveCN102759287AIncrease the heat exchange areaLow costStationary tubular conduit assembliesSample waterEngineering

The invention relates to cooling equipment, and discloses a double-effect cooler. The double-effect cooler comprises an outer barrel with a closed end and an open end, wherein an outer barrel flange is arranged on the outer rim of the open end; an end cover flange is fixed on the outer barrel flange through a bolt; a cooling water inlet is formed on the wall of the outer barrel; a cooling water outlet, a sample water outlet and a sample water inlet are formed on the end cover flange; the sample water outlet and the sample water inlet are respectively connected to the two ends of a dual-helix coil pipe; an inner barrel is arranged inside the outer barrel; the dual-helix coil pipe is divided into an outer coil pipe and an inner coil pipe; the inner coil pipe is inserted into the inner barrel; the outer coil pipe is sleeved on the outer side of the inner barrel; the inner coil pipe is connected with the sample water inlet at the end cover flange; the outer coil pipe is connected with the sample water outlet at the end cover flange; and the cooling water outlet is in the range of the inner barrel at the end cover flange. Compared with the conventional single-helix-coil-pipe cooler, the double-effect cooler has the advantages of increasing the heat exchange area, saving the material cost, prolonging the heat exchange time, improving the heat exchange efficiency and reducing the running cost.

Owner:HANGZHOU DACHAO PETROCHEM EQUIP

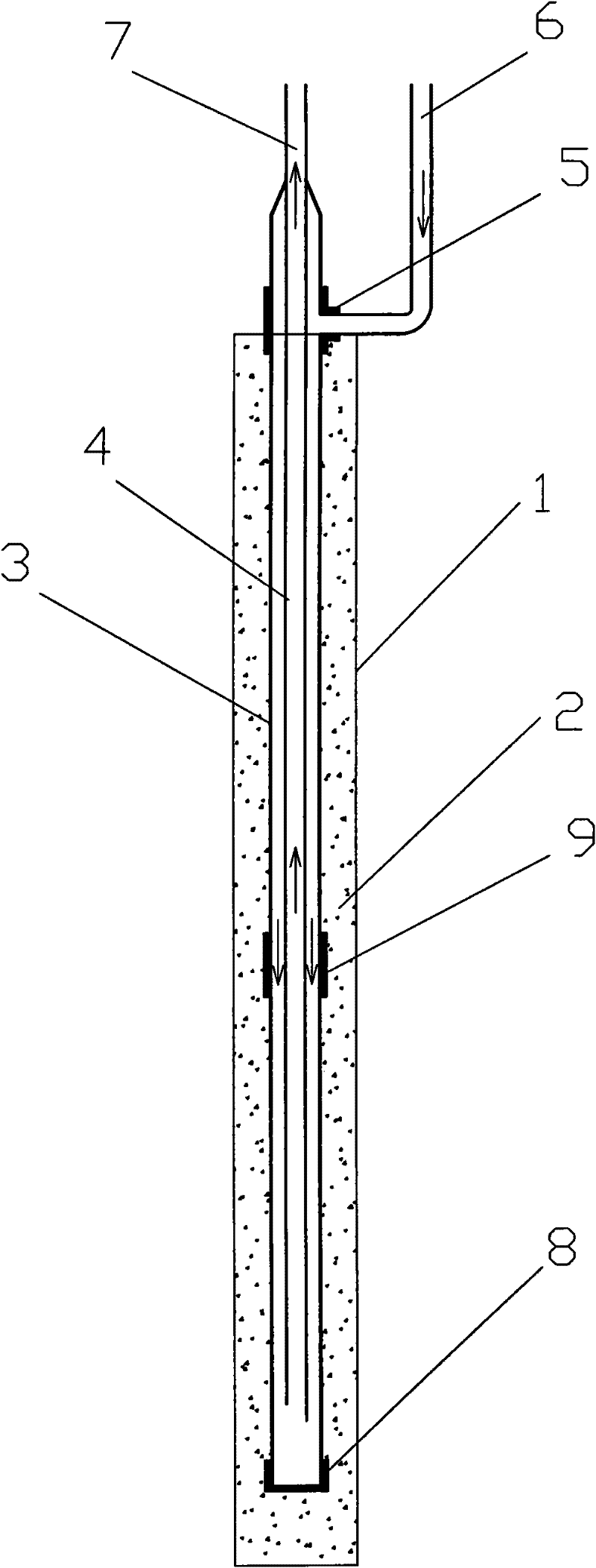

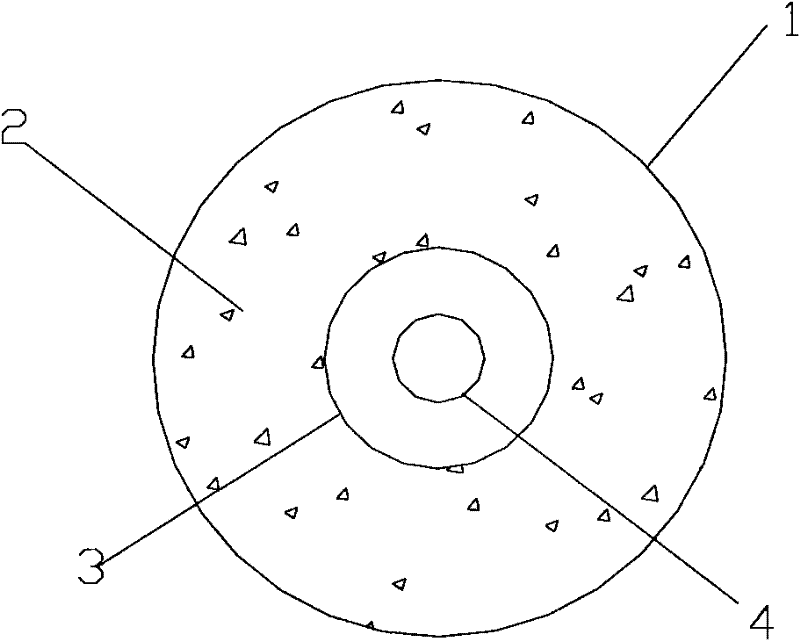

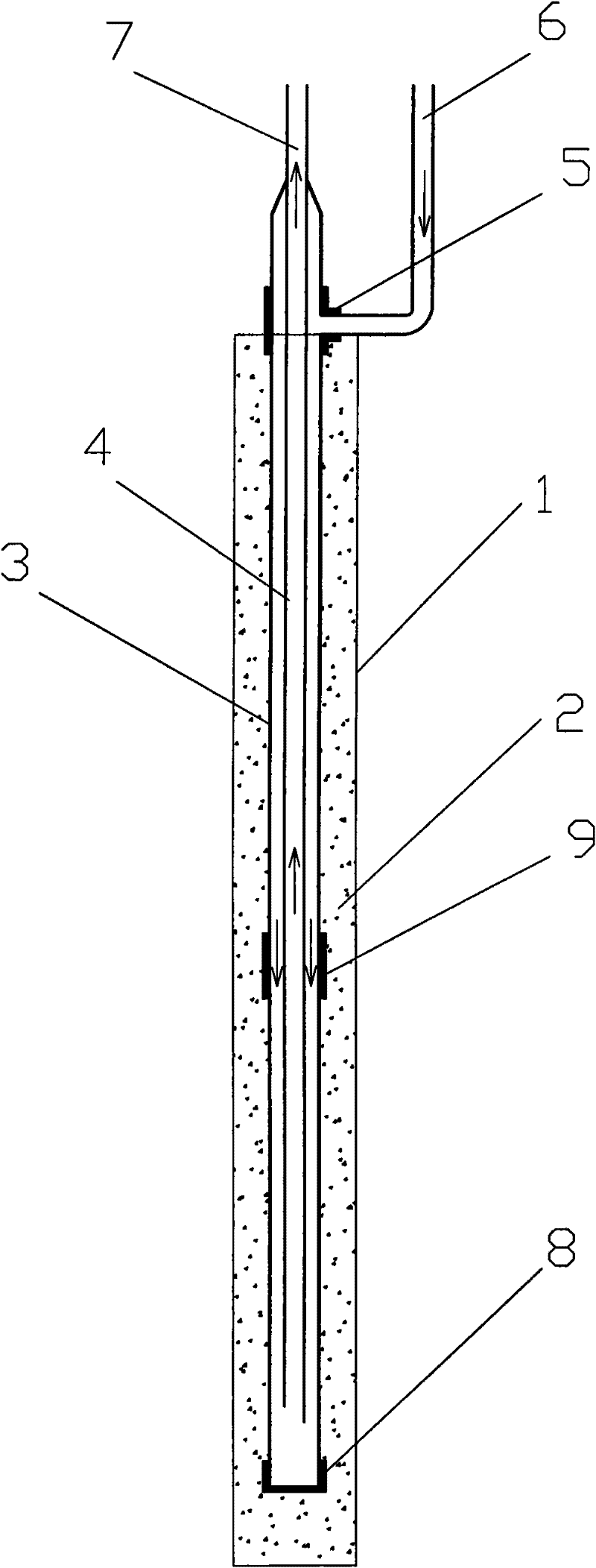

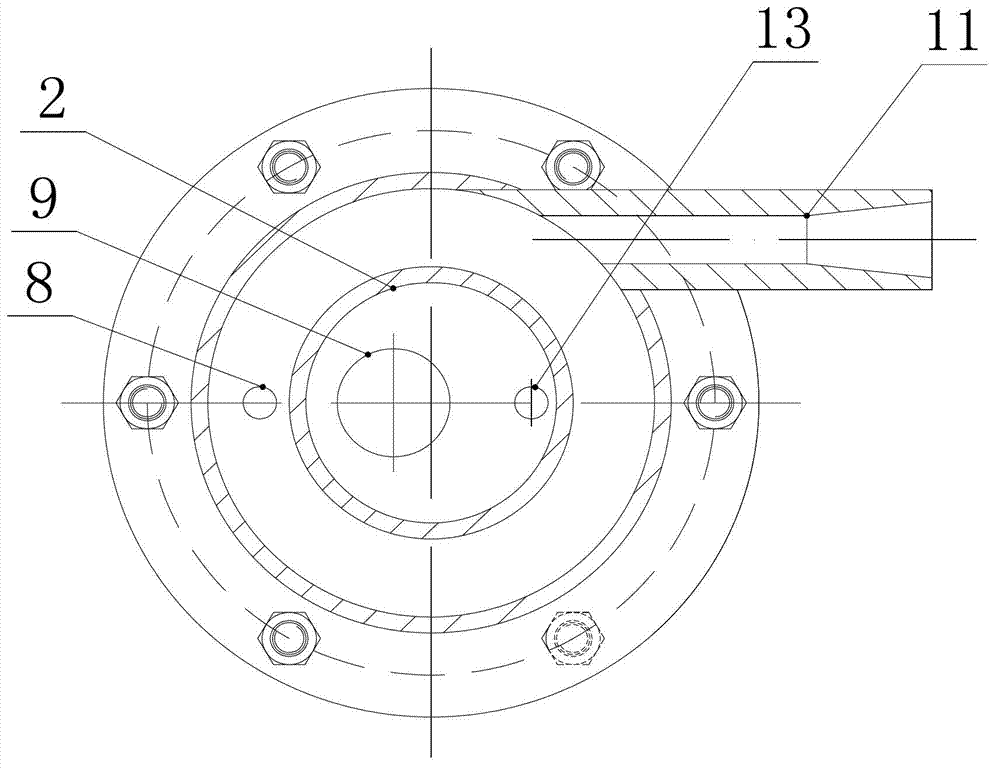

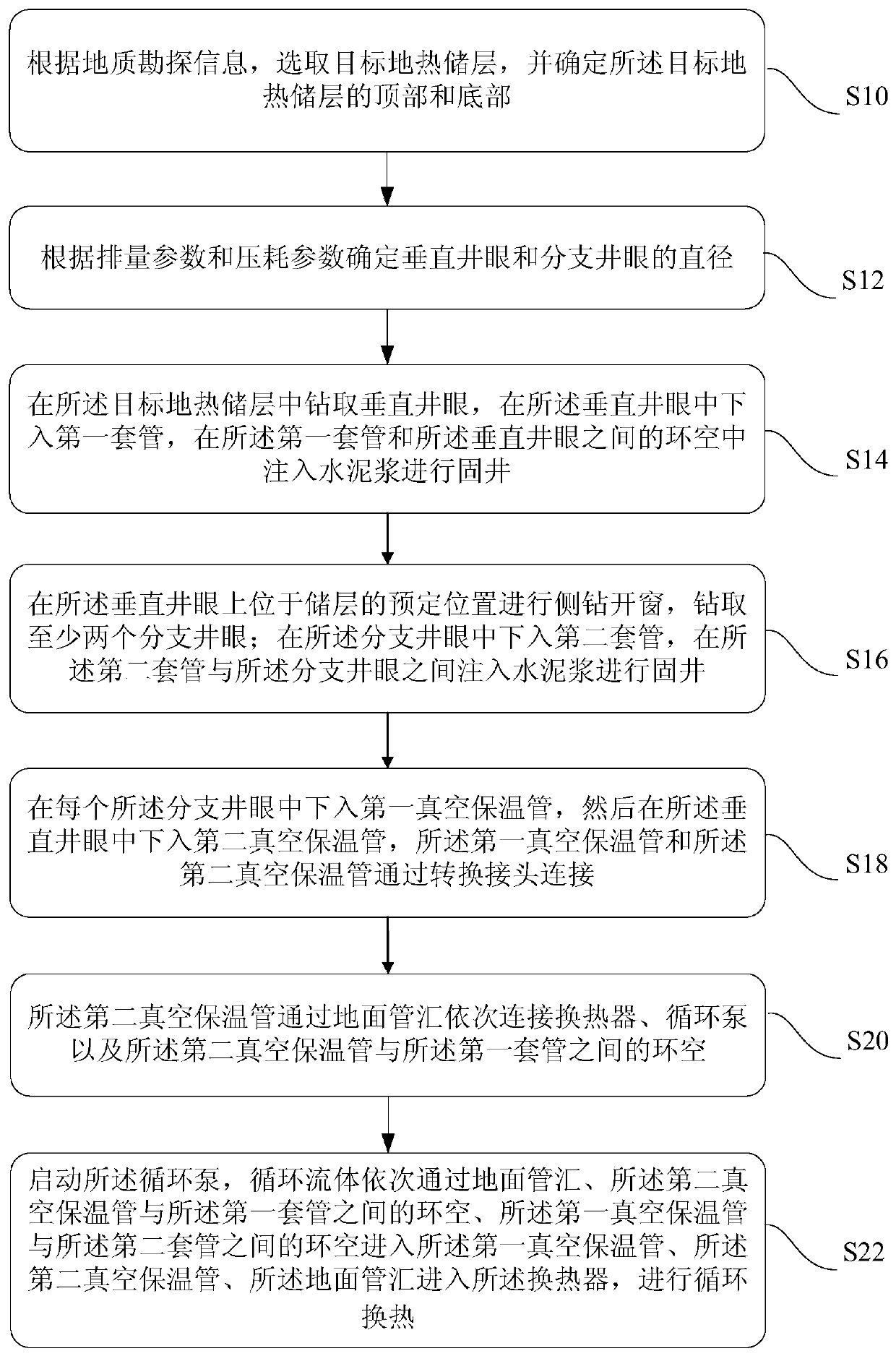

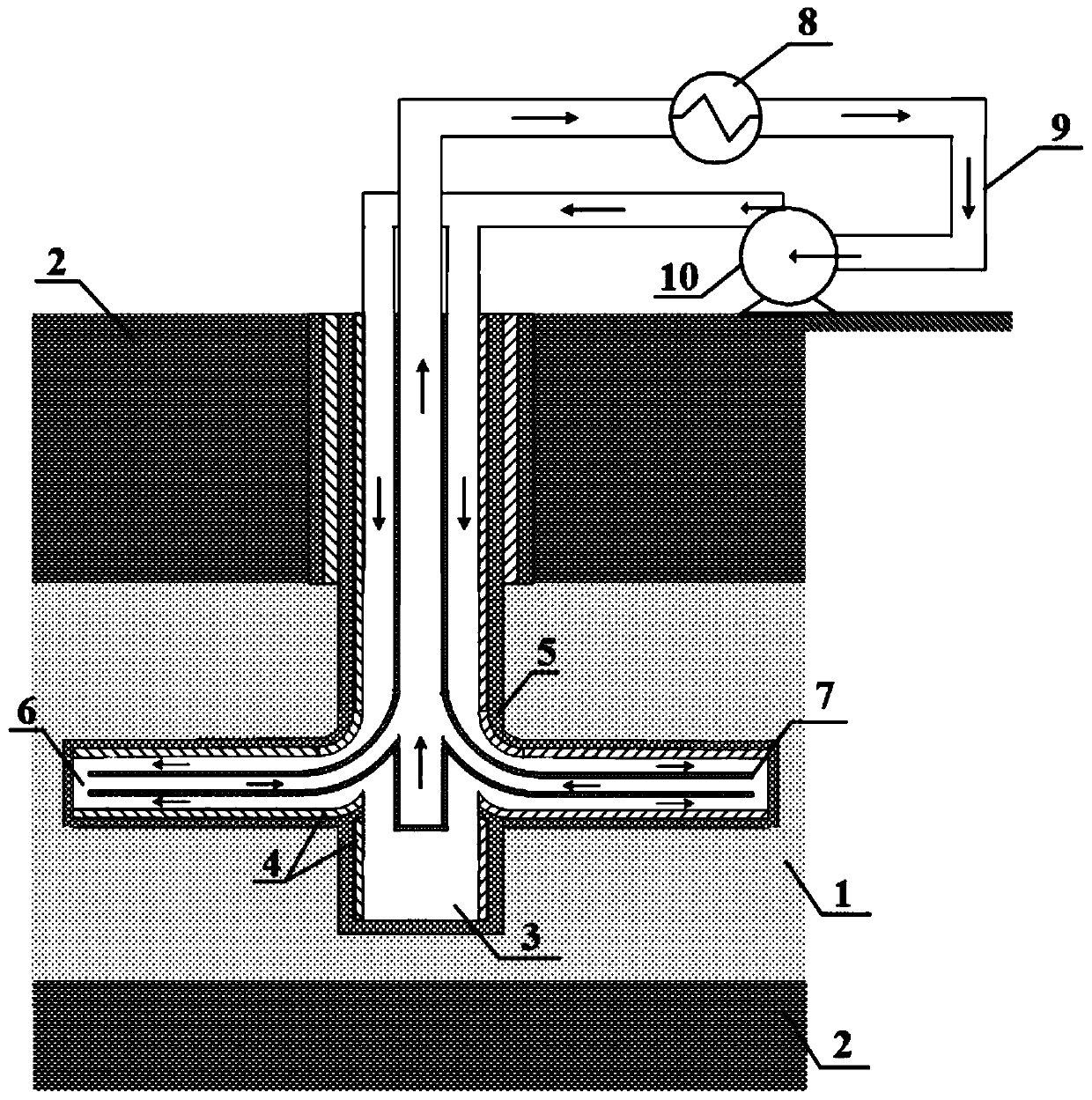

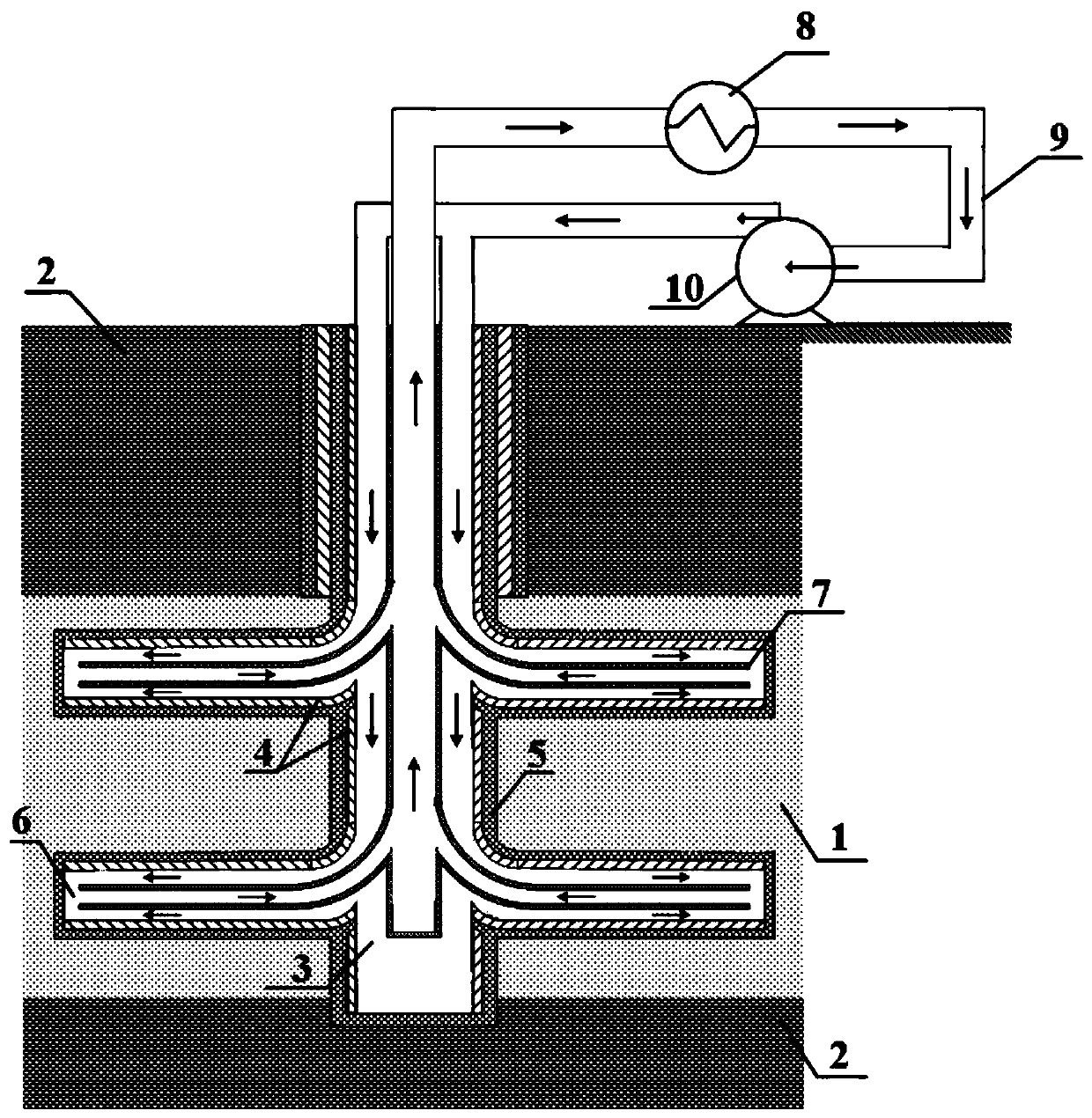

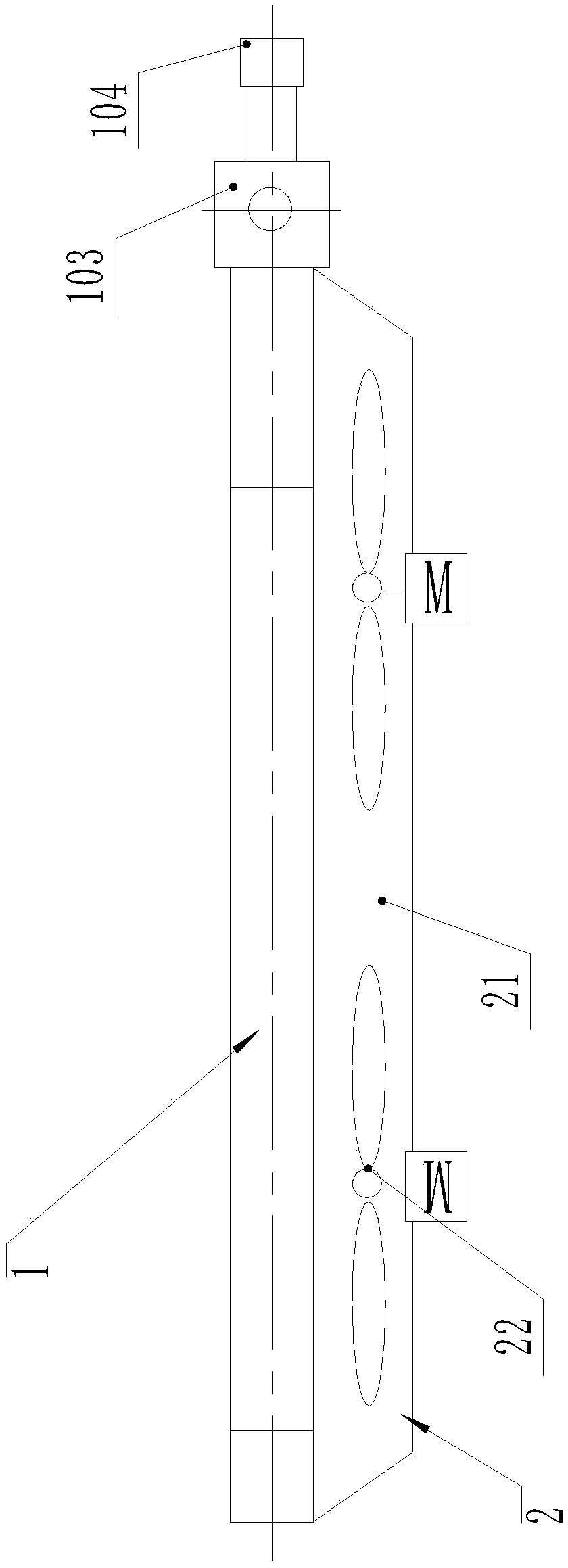

Closed circulation well and development method of dry hot rock

InactiveCN109798091AEfficient and sustainable miningReduce the number of wells drilledLighting and heating apparatusGeothermal energy generationThermal insulationCement paste

The invention discloses a closed circulation well and a development method of dry hot rock. The method comprises the following steps: choosing a target geothermal reservoir stratum, and determining the diameters of a vertical borehole and a branch borehole according to a discharge parameter and a pressure loss parameter; drilling the vertical borehole, and injecting cement paste to carry out wellcementation after enabling a first casing pipe to enter; drilling at least two branch boreholes; injecting the cement paste to carry out the well cementation after second casing pipes enter the branchboreholes; enabling a vacuum thermal insulation pipe to enter, wherein the vacuum thermal insulation pipe is successively connected with a heat exchanger, a circulating pump and a circular space between the vacuum thermal insulation pipe and the casing pipes through a ground pipe complex; and starting the circulating pump, wherein circulating fluid successively passes through the ground pipe complex, the circular space between the vacuum thermal insulation pipe and the casing pipes, the vacuum thermal insulation pipe and the ground pipe complex and then enters the heat exchanger to carry outcircular heat exchange. The method can realize the efficient and continuous exploitation of the dry hot rock at a relatively low cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

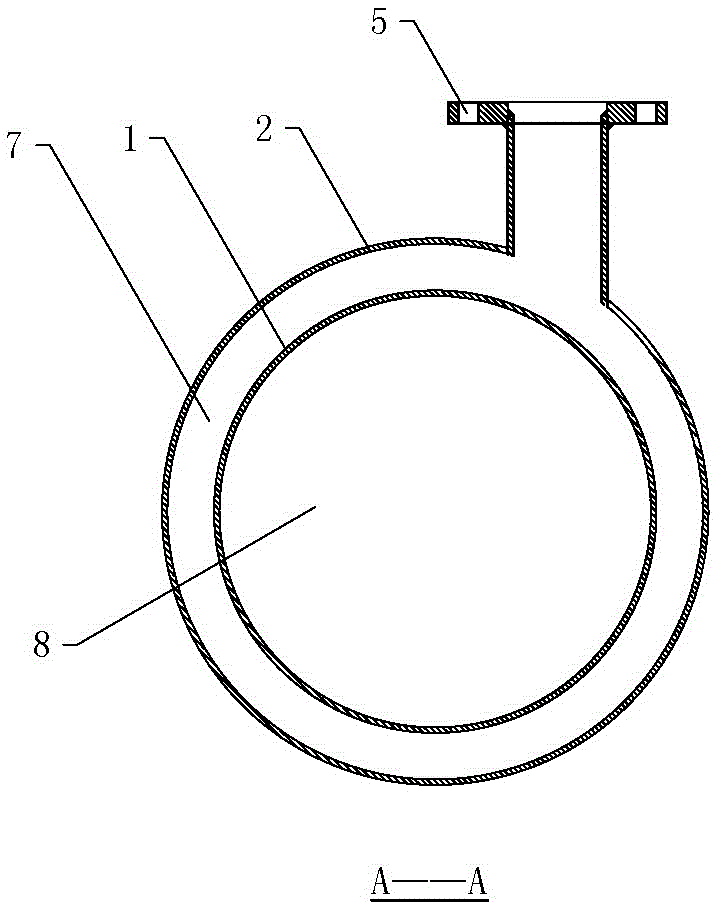

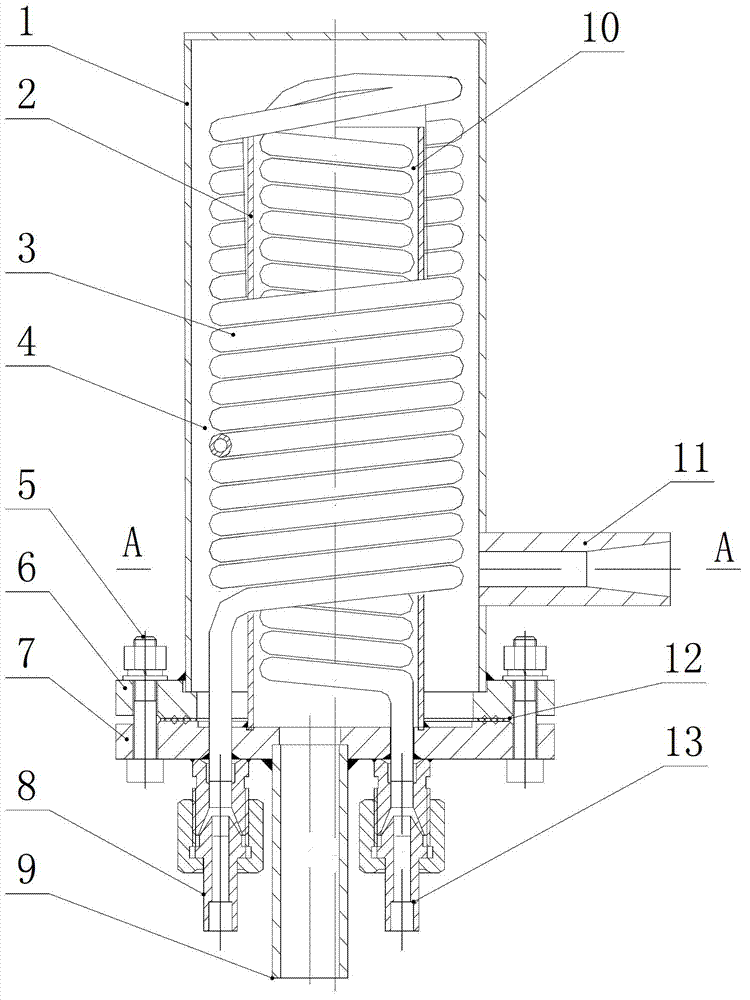

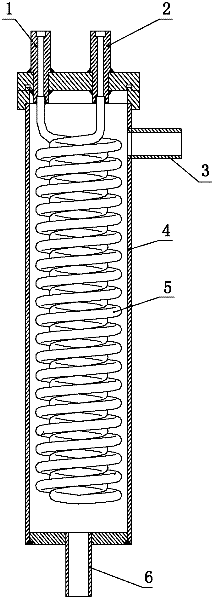

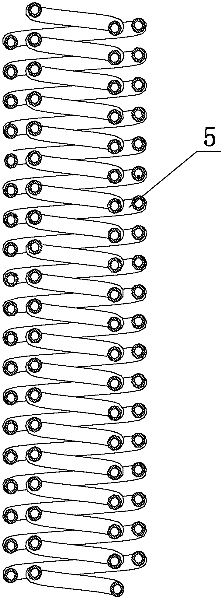

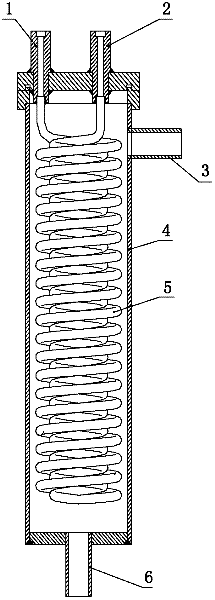

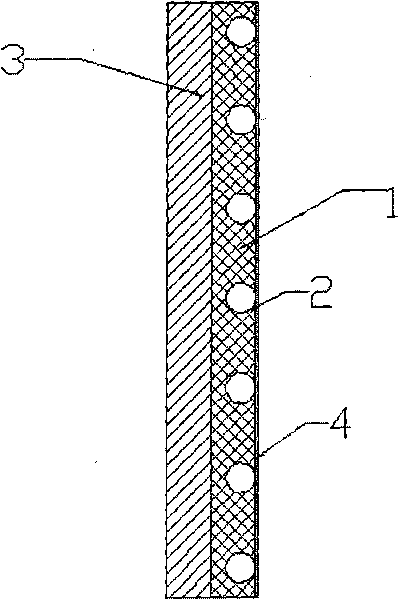

Double-layer coiled pipe cooler

InactiveCN102374800AIncreased circulation distanceExtend heat exchange timeStationary tubular conduit assembliesTubular elementsEngineeringLayer interface

The invention discloses a double-layer coiled pipe cooler, comprising a cooler cylinder body, and a cooling water inlet and a cooling water outlet arranged on the cooler cylinder body, wherein a double-layer coiled pipe is installed in the cooler cylinder body, the double-layer coiled pipe is of a structure with an inner layer and an outer layer formed by winding one pipe, the outer layer interface of the outer layer structure extends out of the cooler cylinder body to be connected with the cooling water inlet, and the inner layer extends out of the cooler cylinder body to be connected with the cooling water outlet; according to the double-layer coiled pipe cooler provided by the invention, the heat exchange performance of the cooler can be enhanced, the equipment space can be saved, and the material cost can be reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

Heat accumulation type condenser using shape-stabilized phase-change material

InactiveCN101718482AIncrease heat transfer areaExtend heat exchange timeEvaporators/condensersParaffin waxSolid-state

The invention relates to a heat accumulation type condenser using shape-stabilized phase-change material, comprising the shape-stabilized phase-change material, a condenser pipe, a refrigerator wall and refrigerator heat insulation material. The heat accumulation type condenser is characterized in that the condenser pipe is completely or partly surrounded by the shape-stabilized phase-change material, and is fixed between the refrigerator heat insulation material and the refrigerator wall by the shape-stabilized phase-change material. The phase-change material in the shape-stabilized phase-change material is paraffin wax substances, support material is high-density polyethylene, and expanded graphite can be taken as heat conduction reinforcing agent. In the invention, the shape-stabilized phase-change material can be used for reinforcing the heat transmission between the condenser pipe and the refrigerator wall, and is also used for accumulating heat to lead the condenser pipe to continuously emit heat outside, so that the condensation efficiency of the condenser can be improved; furthermore, in the process of heat accumulation, the shape-stabilized phase-change material is maintained to be a solid state and does not flow, so that the leakage problem is not caused, and the condenser is not needed to be encapsulated so as to have low production difficulty. The heat accumulation type condenser is applicable to refrigeration equipment such as a refrigerator, a low temperature box, a freezer, a cold drink machine, an ice cream machine, an intermittent minitype refrigerating machine, etc.

Owner:UNIV OF SCI & TECH OF CHINA

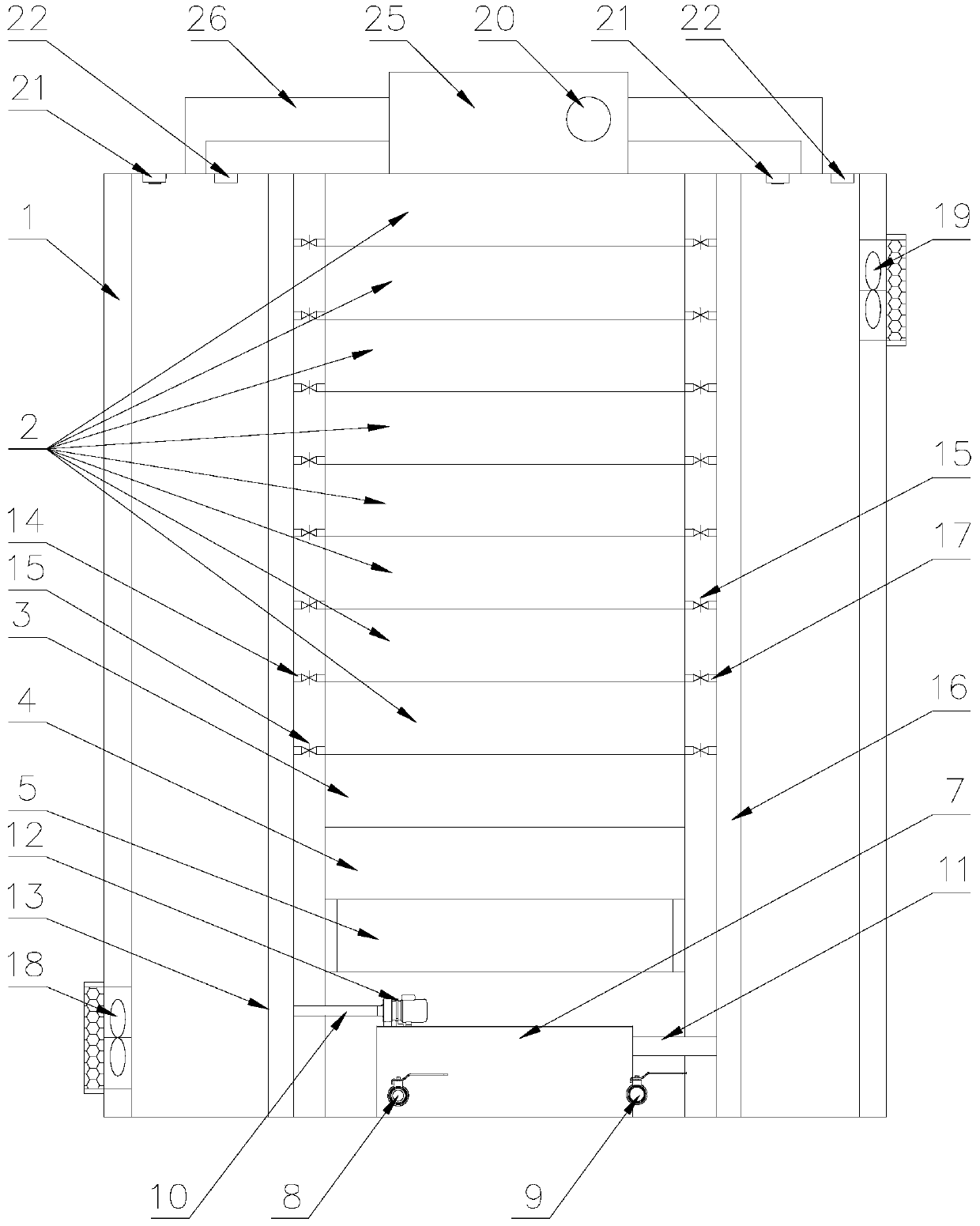

Method and device for preheating batch by using waste heat of fume from pure-oxygen combustion glass furnace

InactiveCN101830628AShorten melting timeRaise the preheat temperatureGlass productionCombustionGlass furnace

The invention relates to a method and a special device for preheating a batch by using the waste heat of fume from a pure-oxygen combustion glass furnace. The method comprises the following steps: granulating the glass batch; dehydrating and drying the grains; and preheating the grains by using a multilayer vertical turning plate preheating mode, wherein the glass batch and the hot fume are contacted indirectly, namely the fume radiates heat to the glass batch by convection, and the glass batch is preheated by a multilayer turning plate preheater to above 400 DEG C and then is delivered to the next process step. Multiple layers of turning plates and multiple flues are arranged in the preheating device, a fume inlet communicated with the flues is positioned on the outer side of the side water on the lower part of the preheater, a fume outlet communicated with the flues is positioned on the outer side of the other side wall on the upper part of the preheater, and the fume inlet and the fume outlet are arranged diagonally; the special preheating device is used to preheat the glass batch, the utilization rate of the waste heat of the high-temperature fume is high, no smoke dust pollution is produced; under self suction, the fume rises along the flues, so no power is consumed; the vertical structure occupies small floor area, so the replacement of space for time is realized; and the promotion and implementation of the device are easy.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

Liquid-cooled single cabinet data center

PendingCN110278690AImprove stabilityGuaranteed uptimeCooling/ventilation/heating modificationsData centerWarm water

The invention discloses a liquid-cooled single cabinet data center. A heat exchanger is installed at that bottom end inside the cabinet. A separating plate is arranged inside shell. A coolant is arranged on the upper side of the separating plate and circulating water is arranged on the lower side of the separating plate. The lower side of the separating plate is provided with a cold water inlet pipe. The other side of the lower part of the separating plate is provided with a warm water outlet pipe. One side of the water outlet pipe of a circulating water pump is connected with a cold water outlet pipe. One side of the cold water outlet pipe is connected with a water distribution pipe which is provided with multiple water inlet branch pipes. Multiple cold plates are arranged inside the cabinet. A cooling coil pipe is arranged in an installing groove. One end of the cooling coil pipe is connected with the water inlet branch pipes. A water collecting pipe is arranged on the server side. One end of the water collecting pipe is connected with the warm water inlet pipe. Multiple return water branch pipes are arranged on the water collecting pipe. The other end of the cooling coil pipe is connected with the return water branch pipes. The heat exchanger is arranged at the bottom of the cabinet, and the coolant flows into the cooling coil pipe of the upper part of the cold plate through the water distribution pipe and the water inlet branch pipes in turn to cool and dissipate heat for the server so as to improve the stability of the server operation.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Ultrasonic reinforced micro-channel heat exchanger

InactiveCN105609475AImprove heat transfer effectSlow down the flow of waterSemiconductor/solid-state device detailsSolid-state devicesUltrasonic cavitationPlate heat exchanger

The invention provides an ultrasonic reinforced micro-channel heat exchanger. The heat exchanger comprises a shell, a water-cooling system, micro pin fins, an ultrasonic generator and an ultrasonic transducer, wherein the water-cooling system comprises a cooling water channel, a water inlet and a water outlet; the cooling water channel is arranged in the shell; the water inlet and the water outlet are connected with the cooling water channel to form the water-cooling system; the shell comprises a channel main body and an upper sealing cover; the channel main body and the upper sealing cover are connected in a sealing manner; the micro pin fins and the cooling water channel are arranged in the channel main body; the micro pin fins are arranged along the axial direction of the channel main body; the cooling water channel is formed in the spaces among the micro pin fins, and the spaces between the micro pin fins and the inner wall of the channel main body; ultrasonic transducer oscillators are distributed on the two sides of the channel main body; and the ultrasonic generator is connected with the transducer through a wire. According to the ultrasonic reinforced micro-channel heat exchanger, the ultrasonic generator is adopted to give out high-frequency signals to enable the transducer to generate ultrasonic vibration; an ultrasonic cavitation effect generated by the cooling water is changed into an ultra-turbulent flow state, so that the cooling effect is reinforced; and in addition, dirt in the channel can be cleaned at any time, and the heat transfer resistance is lowered.

Water passage circulation structure for condensing heat exchanger

ActiveCN102364264AIncrease profitNot easy to deposit carbonFluid heatersPlate heat exchangerWater flow

The invention relates to a water passage circulation structure for a condensing heat exchanger. The water passage circulation structure comprises a shell, and a left cover plate and a right cover plate which are provided with cavities, wherein the left and right cover plates are arranged on the left and right side walls of the shell. The water passage circulation structure is characterized in that: the left cover plate is provided with a water inlet and a water outlet; the cavity of the left cover plate is divided into a plurality of independent left water circulating areas; one is communicated with the water inlet, and another independent left water circulating area is communicated with the water outlet; the cavity of the right cover plate is divided into a plurality of independent rightwater circulating areas; the plurality of left water circulating areas on the left cover plate and the plurality of right water circulating areas on the right cover plate are connected and matched through asymmetrical layer-staggered radiating straight pipes in the mode; and water spirally circulates in a W-shaped route among the left cover plate, the radiating straight pipes and the right cover plate and flows out of the water outlet on the left cover plate finally. The water passage circulation structure is novel; and the heat exchanger with the water passage circulation structure has a medium volume, longer service life, and higher thermal efficiency, and is energy-saving and durable.

Owner:WUXI XIZHOU MACHINERY

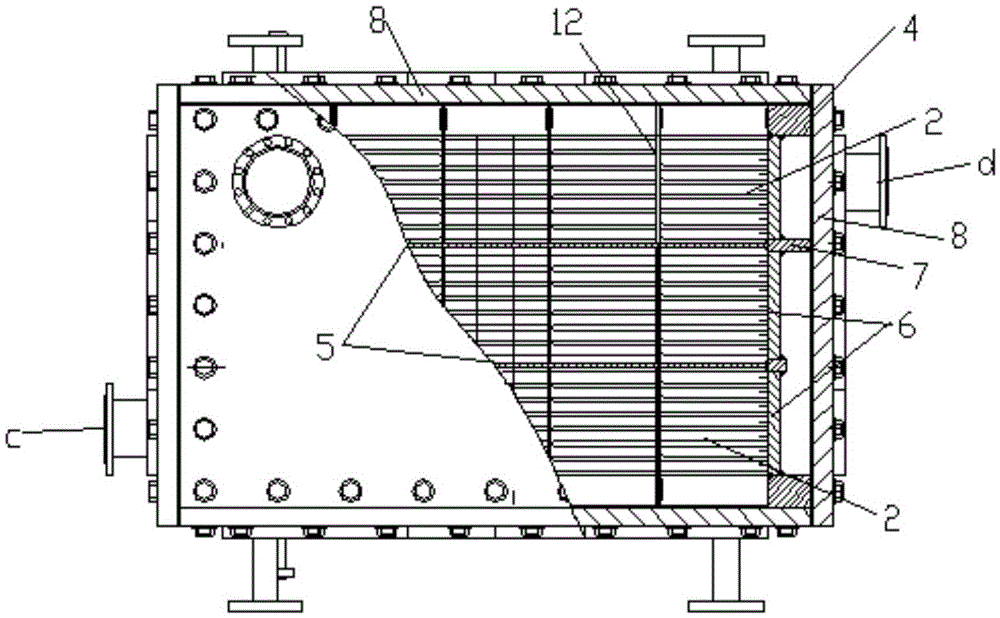

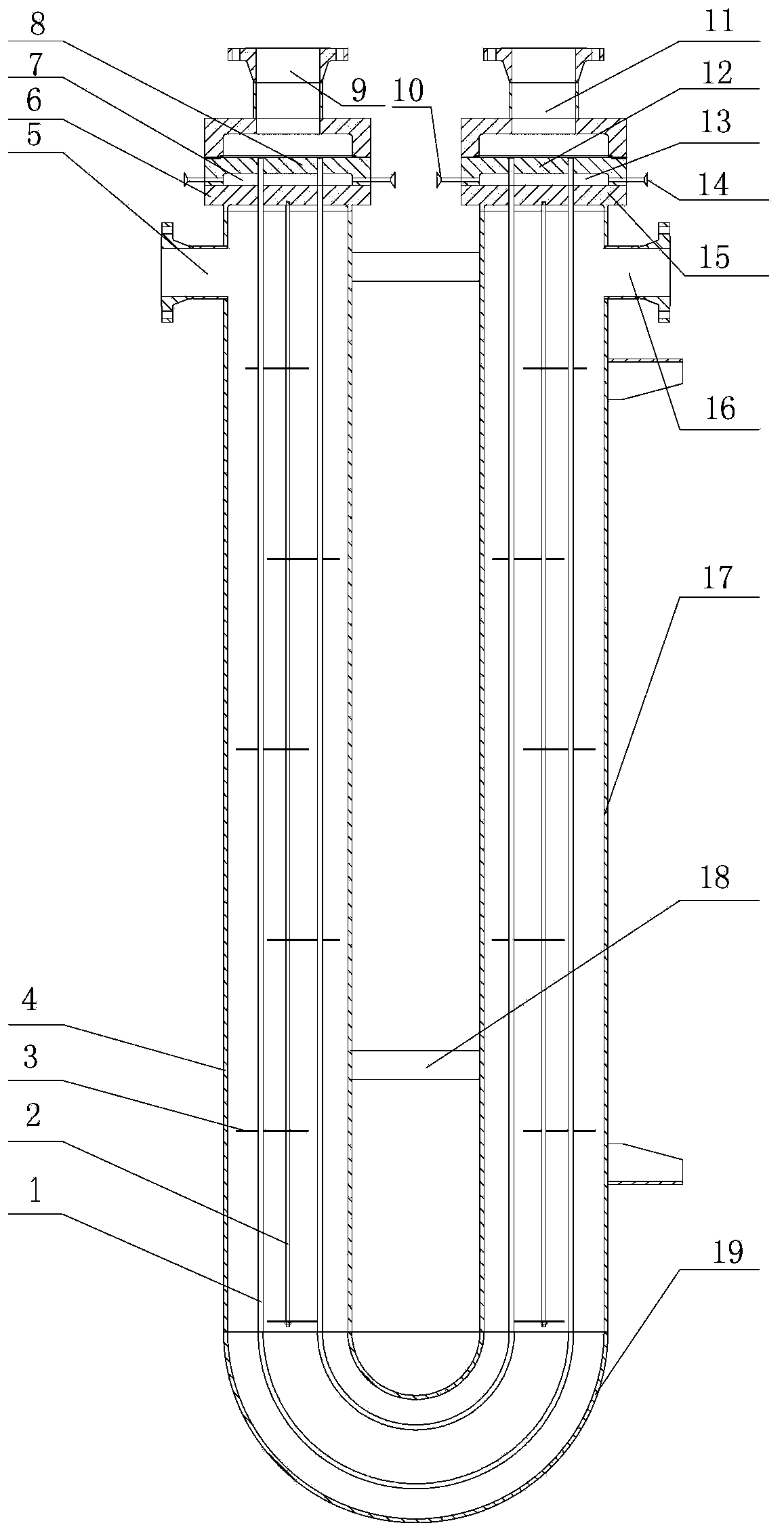

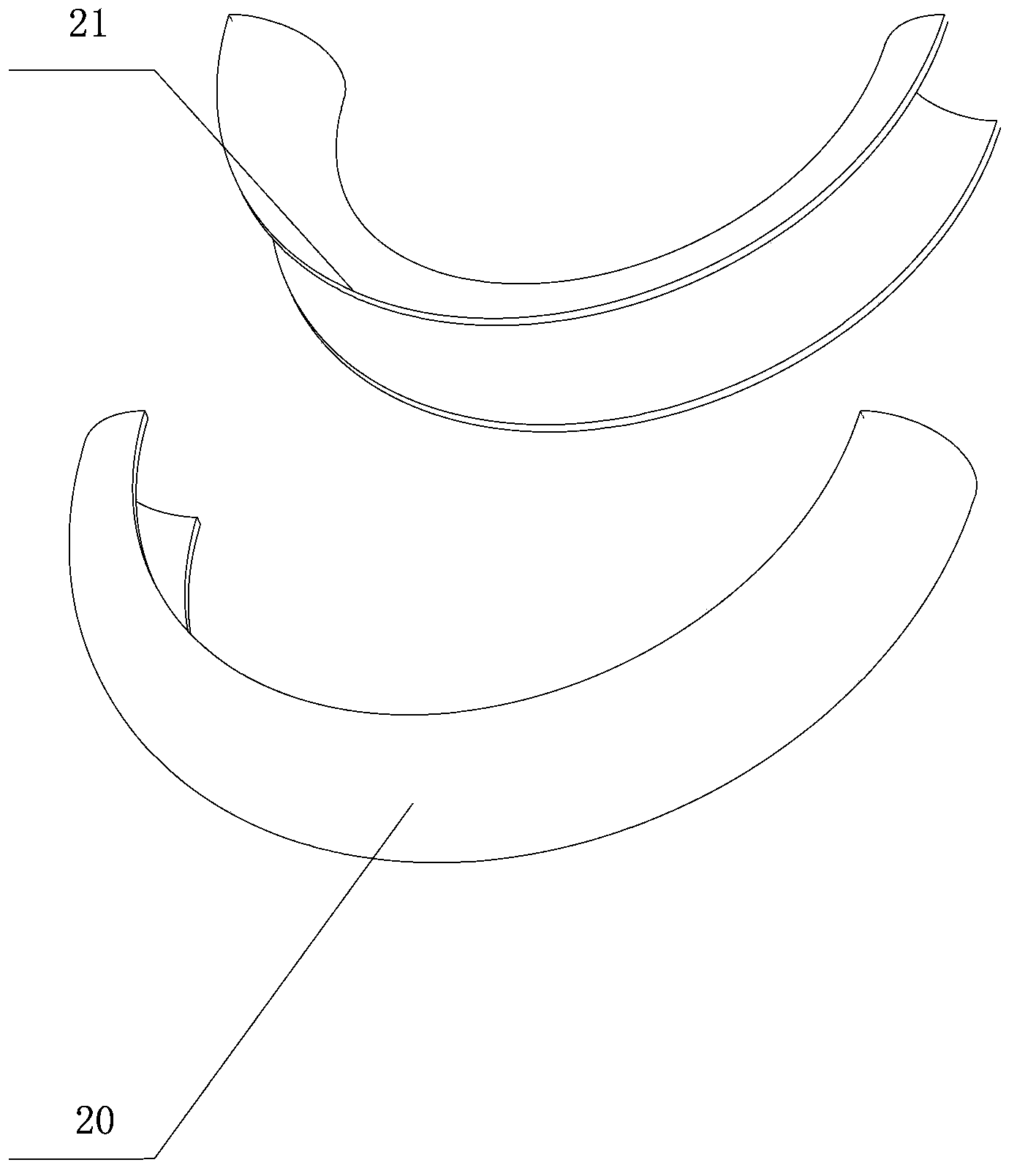

Hairpin type double-tube-plate heat exchanger and method for assembling heat exchanging tube and shell body thereof

ActiveCN103673681AIncrease the heat exchange areaAvoid pollutionStationary tubular conduit assembliesWelding apparatusDouble tubeEngineering

The invention relates to a hairpin type double-tube-plate heat exchanger and a method for assembling a heat exchanging tube and a shell body thereof. The hairpin type double-tube-plate heat exchanger comprises the U-shaped heat exchanging tube, the shell body and tube plates, wherein the shell body is U-shaped, the U-shaped shell body is composed of an A section, a B section and a C section, the A section and the B section constitute the two arms of the U-shaped shell body, and the C section constitutes the bent section in the middle of the U-shaped shell body; the tube plates include a first front tube plate, a first rear tube plate, a second front tube plate and a second rear tube plate, a first isolation cavity is arranged between the first front tube plate and the first rear tube plate, and a second isolation cavity is arranged between the second front tube plate and the second rear tube plate; the U-shaped heat exchanging tube is embedded in the U-shaped shell body, and the two arms of the U-shaped heat exchanging tube are positioned on the first front tube plate and the second front tube plate respectively. According to the heat exchanger obtained with the method for assembling the heat exchanging tube and the shell body, the heat exchanging area between pipe side media and shell side media is increased in limited equipment space, and leakage of exchanging media at the positions of the tube plates is avoided.

Owner:FUNKE HEAT EXCHANGER SYST CHANGZHOU

New energy automobile water-cooled condenser

PendingCN108709342AFast coolingLess power consumptionEvaporators/condensersTubular elementsThermal energyNew energy

The invention discloses a new energy automobile water-cooled condenser which comprises a condenser body and a draught fan assembly. The condenser body comprises an outer pipe and an inner pipe which are fixedly installed in a sleeve manner, a refrigerant flowing channel is formed in an inner cavity of the inner pipe, a water flowing channel is formed in a space between the inner pipe and the outerpipe, the two ends of the outer pipe are provided with a water inlet connector and a water outlet connector, the two ends of the inner pipe are provided with a refrigerant inlet connector and a refrigerant outlet connector, the water inlet connector and the water outlet connector both communicate with the water flowing channel, the refrigerant inlet connector and the refrigerant outlet connectorboth communicate with the refrigerant flowing channel, heat conduction fins are arranged outside the outer pipe, and the draught fan assembly is arranged on one side of the condenser body to be used for blowing air to or sucking air from the condenser body. By means of the water-cooled condenser, the inner pipe and the outer pipe which are installed in the sleeve manner are used for achieving heatexchange between medium water and a high temperature refrigerant, heat in the high temperature refrigerant is conveniently recovered, utilization of thermal energy in a new energy automobile is morereasonable, and the aim of energy saving is achieved.

Owner:苏州赛普瑞新能源科技有限公司

Condensation type gas heating water heater

The invention provides a condensation type gas heating water heater and belongs to the technical field of water heaters. The condensation type gas heating water heater solves the problem that an existing water heater is low in heat exchange efficiency. The condensation type gas heating water heater comprises a heat exchanger assembly, a water inlet pipe, a water outlet pipe, a combustor and a smoke exhausting pipe; a plurality of water way channels and a plurality of flue gas channels are arranged in the heat exchanger assembly; the water way channels and the flue gas channels are arranged at intervals and are not communicated with one another; the water inlet pipe is located at the bottom of the heat exchanger assembly; the water outlet pipe is located on the top of the heat exchanger assembly; the water inlet pipe is communicated with the water outlet pipe through the water way channels; a combustion chamber is arranged in the top of the heat exchanger assembly; the flue gas channels are located below the combustion chamber; the combustor is located in the combustion chamber; the smoke exhausting pipe is communicated with the bottom of the heat exchanger assembly; and the smoke exhausting pipe is communicated with the combustion chamber through the flue gas channels. The condensation type gas heating water heater has the beneficial effect that the heat exchange efficiency is high.

Owner:ZHEJIANG INOVISEN THERMAL ENERGY TECH CO LTD

High efficient large fin case tube heat exchanger

InactiveCN101000187AIncrease subcoolingIncrease the areaEvaporators/condensersStationary conduit assembliesEngineeringFlanging

The invention discloses a high efficiency big fin shell pipe heat exchanger, comprising shell pipe and small copper pipe beam arranged in the shell pipe along the shell pipe axis, where several big fins are arranged at intervals in the shell pipe and separately and in turn equipped with corresponding through holes to each small copper pipe of the small copper pipe beam, and each small copper pipe is separately inserted into the corresponding through holes on these big fins and fixed with them, the big fin is separated into flat and ripple plates, the big fin is equipped with punch seam, hole flanging, or shutter. And it increases heat exchange area, able to effectively raise heat exchange efficiency. The bottom of the shell pipe can be equipped with at least a row of several smooth copper pipes without big fins or outer screw threaded copper pipes so as to increase supercooling of refrigerant.

Owner:DONGGUAN GUANGDA REFRIGERATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com