Latent heat exchanger in condensing boiler

A heat exchanger, condensing technology, applied in the field of latent heat heat exchangers, can solve the problems of long flame length, complex combustion control, high price control system, etc. The effect of air resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the configuration and operation of preferred embodiments of the present invention will be described in detail with reference to the drawings. Here, the same symbols are used for components that have the same functions and perform the same functions as those in the prior art.

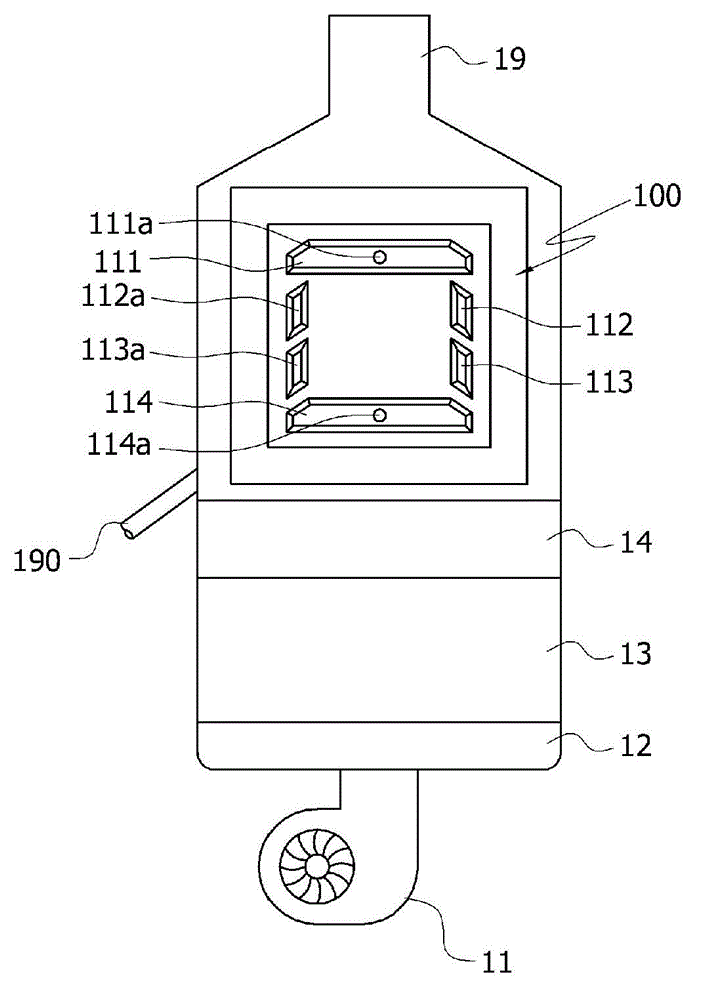

[0049] image 3 is a schematic diagram showing the structure of a condensing boiler to which the present invention is applied, Figure 4 Yes image 3 longitudinal section of the image 3 and Figure 4 It is a figure seen from the left side of a condensing boiler.

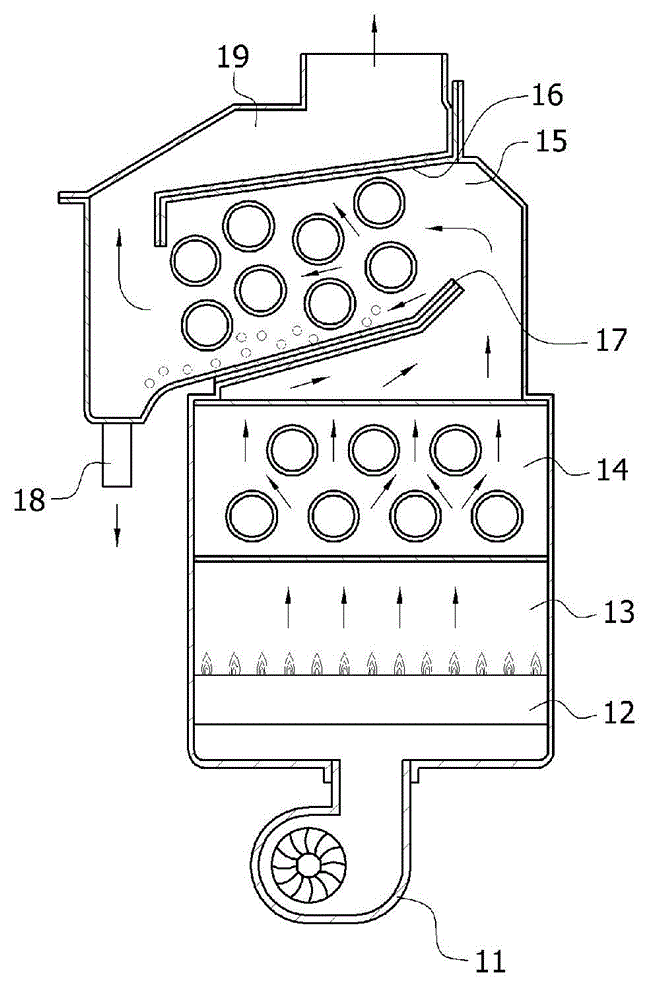

[0050] The condensing boiler provided by the present invention has an upward burning burner 12 and a combustion chamber 13 with an upwardly formed flame on the upper side of the exhaust fan 11, and a combustion chamber 13 for absorbing the combustion phenomenon generated in the burner 12 is provided on the upper side. Sensible heat exchanger 14, latent heat exchanger 100 for absorbing latent heat of water vapor contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com