High efficient large fin case tube heat exchanger

A shell-and-tube heat exchanger and fin technology is applied in the field of high-efficiency large-finned shell-and-tube heat exchangers, which can solve the problems of large number of copper tubes, short heat exchange time, low heat conduction efficiency, etc. The effect of improving heat conduction efficiency and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following best embodiments of the high-efficiency large-fin shell-and-tube heat exchanger described in the present invention do not limit the protection scope of the present invention.

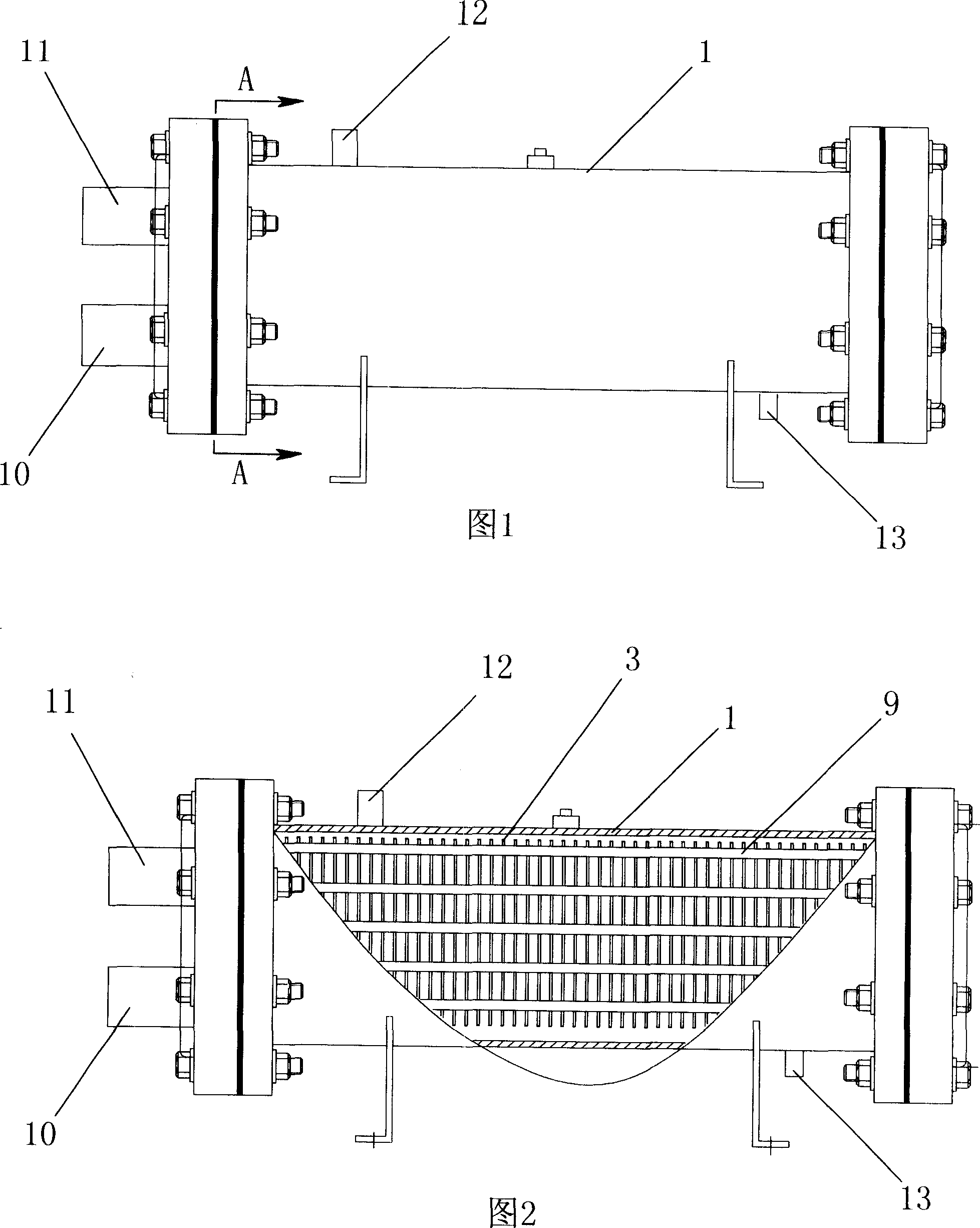

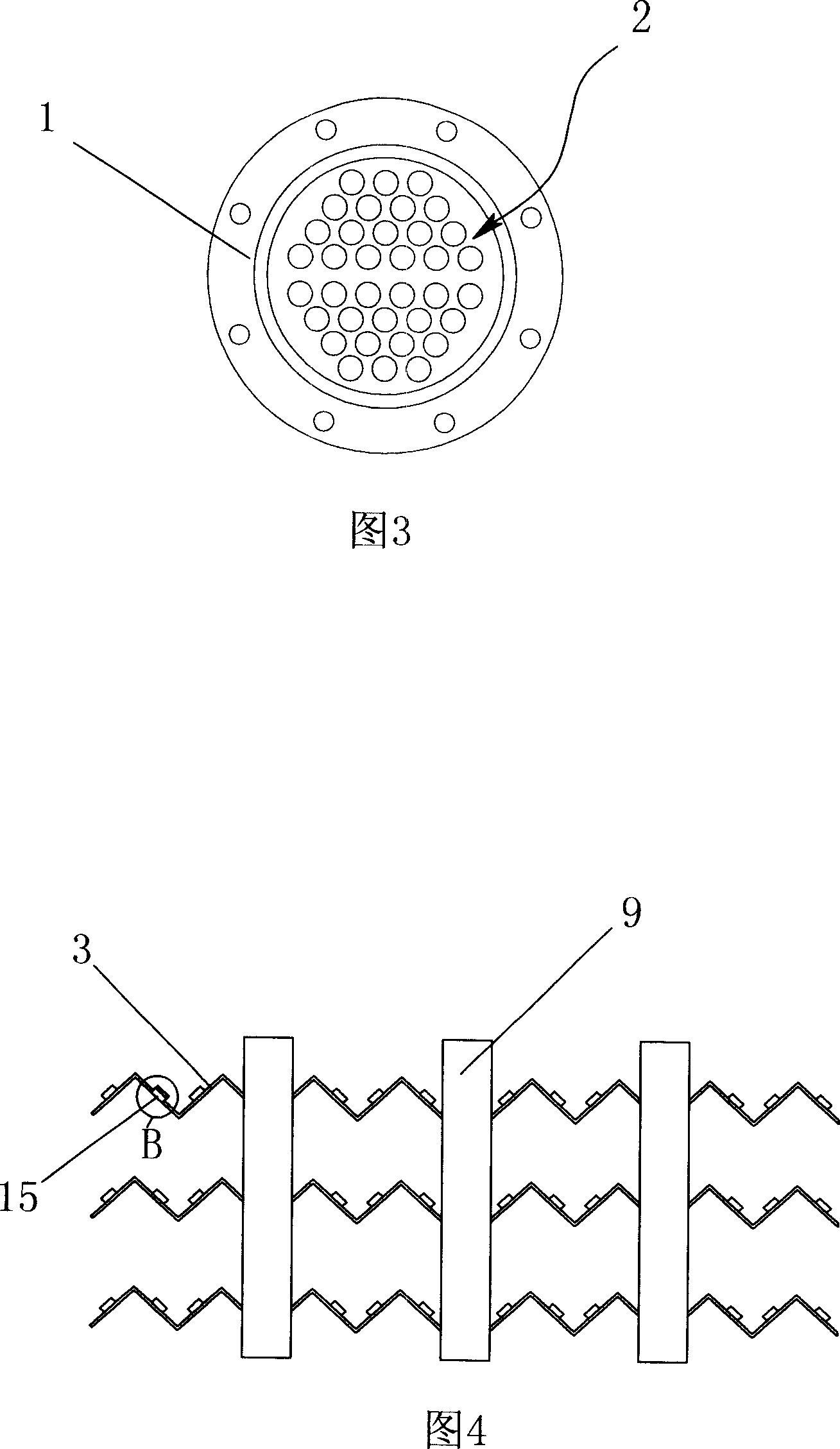

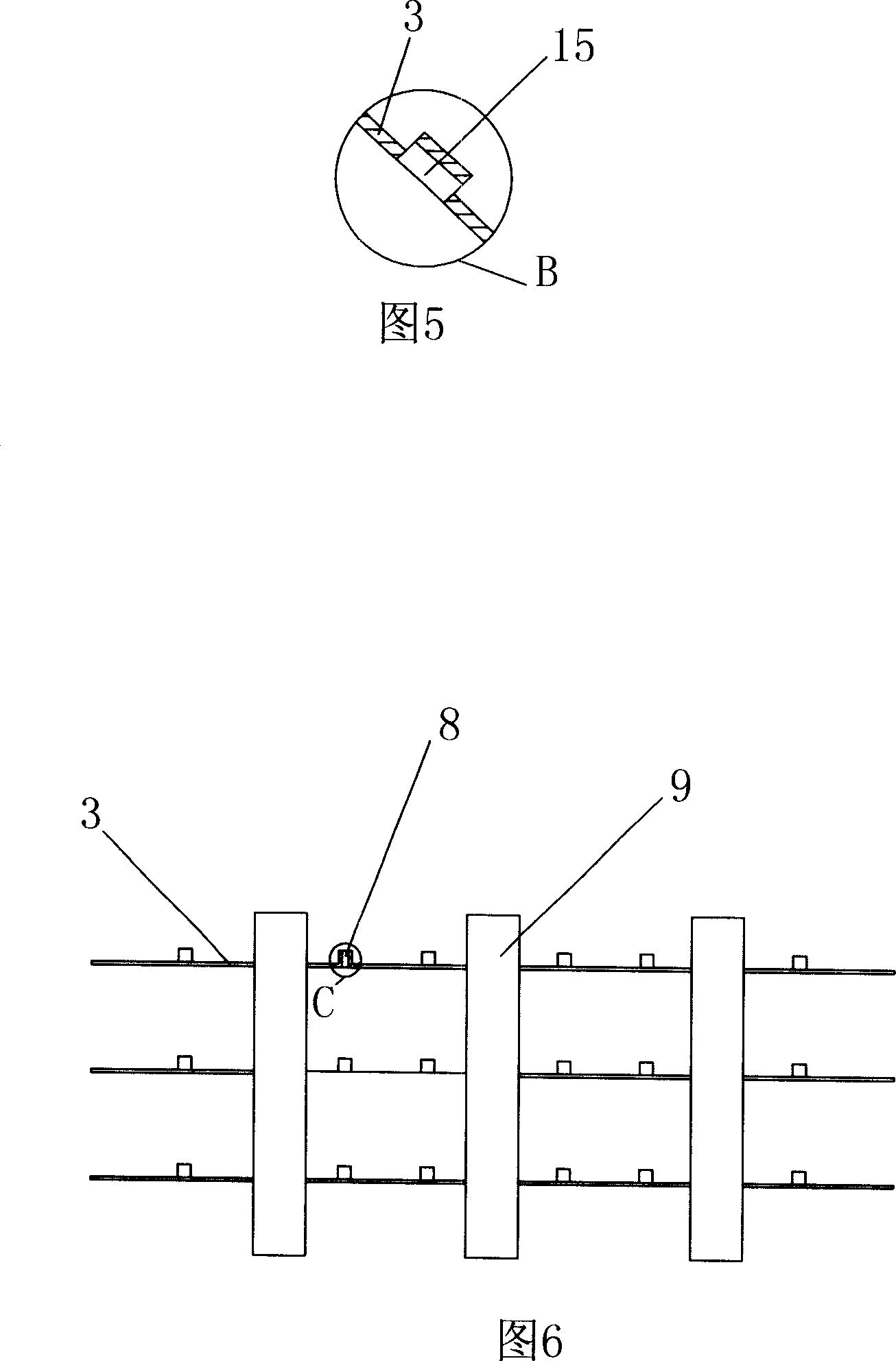

[0027] Referring to Fig. 1, Fig. 2 and Fig. 3, a high-efficiency large-finned shell-and-tube heat exchanger is provided, including a shell tube 1, a small copper tube bundle 2 arranged in the shell tube 1, and intervals are arranged in the shell tube 1 Several large fins 3 radially close to the inner wall of the shell tube 1, the edge shape of the large fins 3 is one of the following shapes: circular, circular, quadrilateral or polygonal, the several large fins 3 There are through holes corresponding to each small copper tube 9 of the small copper tube bundle 2 in sequence, and each small copper tube 9 is respectively pierced in the through holes on several large fins 3 corresponding to it. It is fixedly connected with the several large fins 3, and the large fins 3 are in the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com