Patents

Literature

124results about How to "Not easy to deposit carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

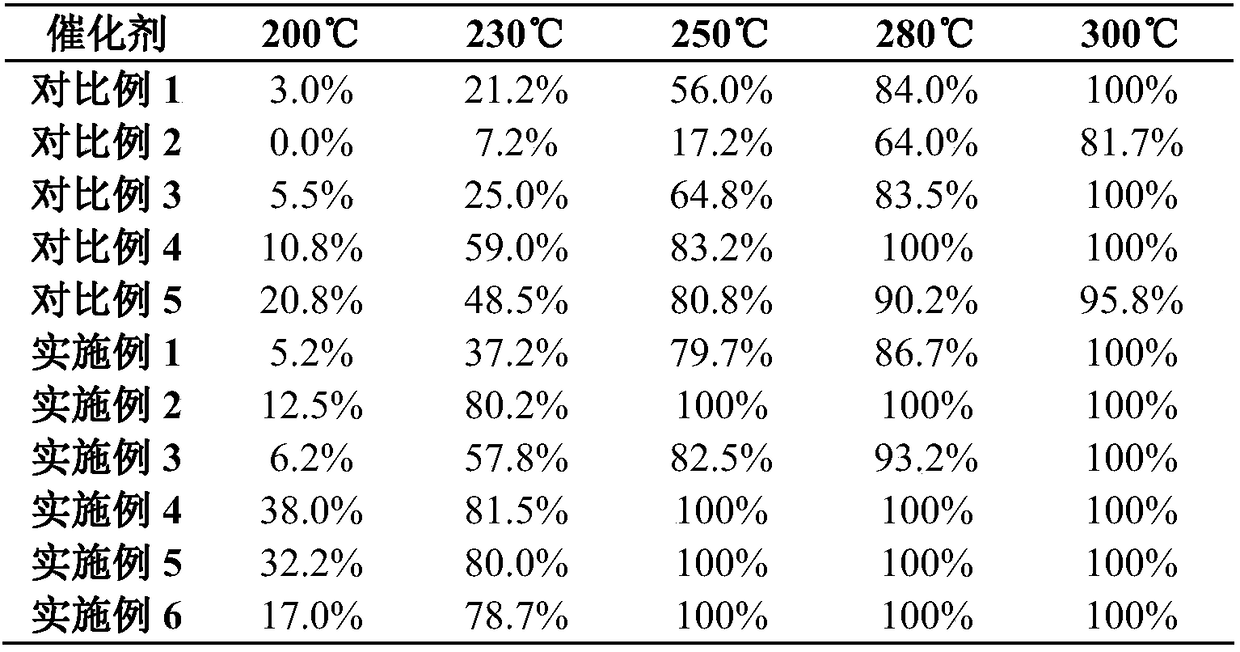

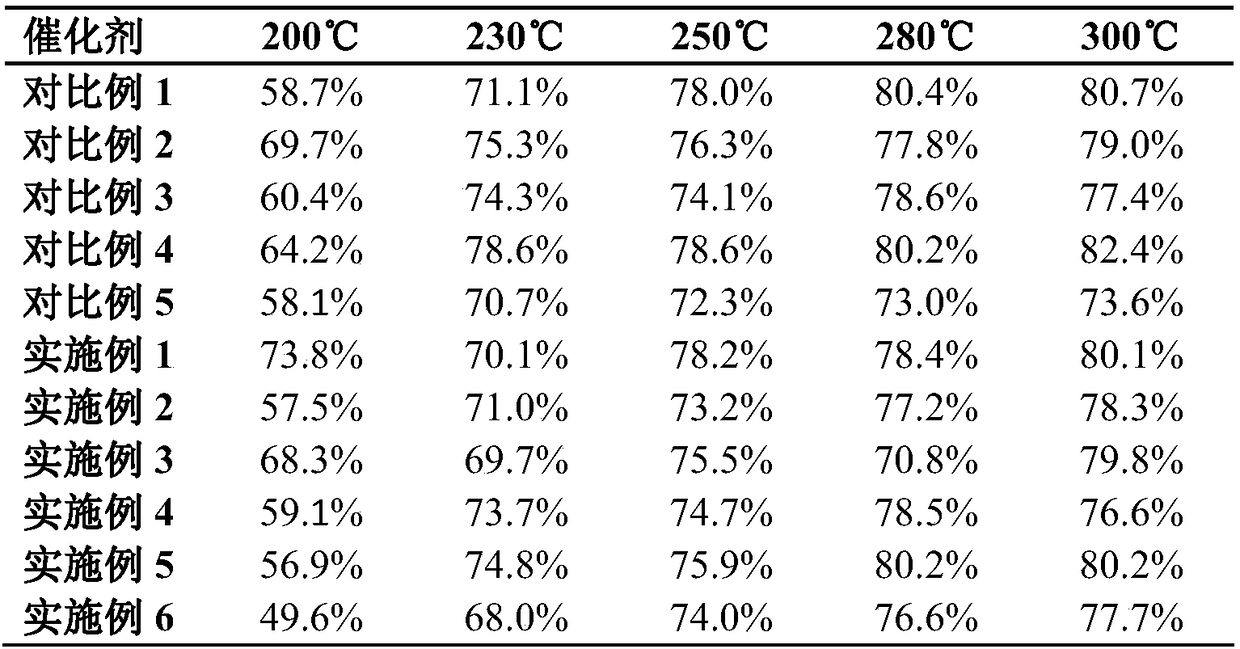

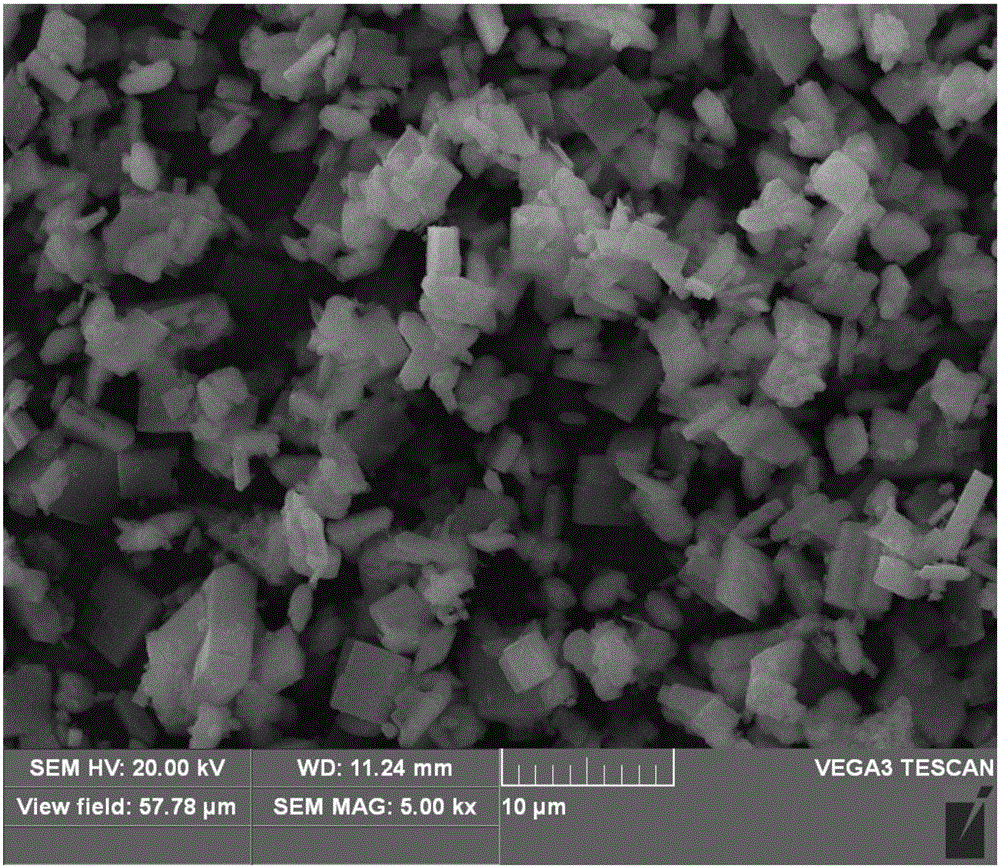

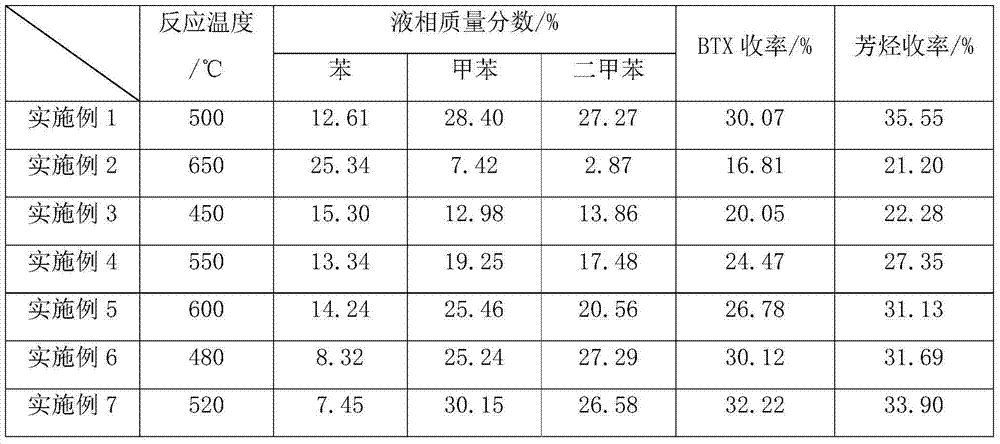

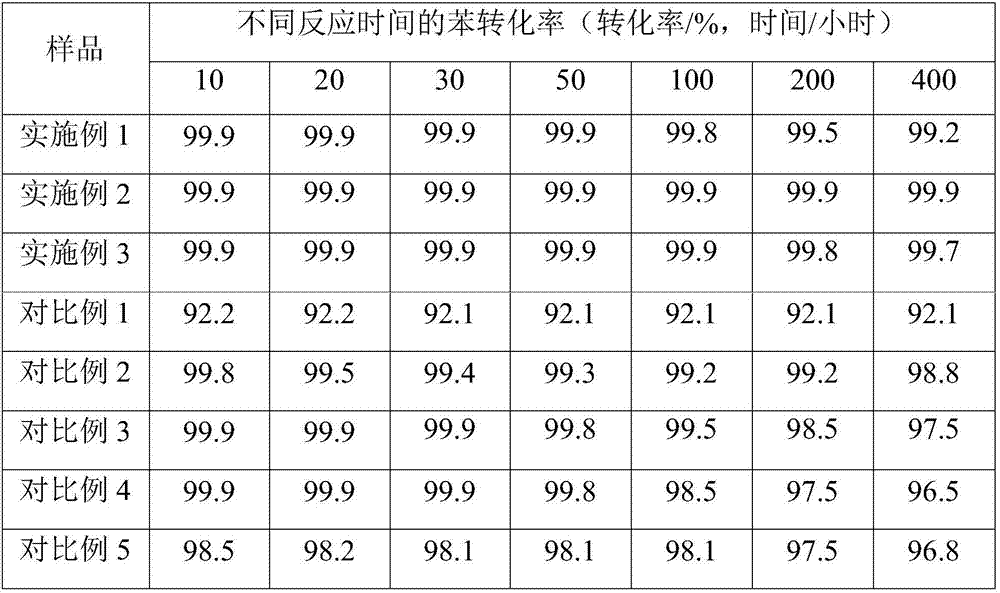

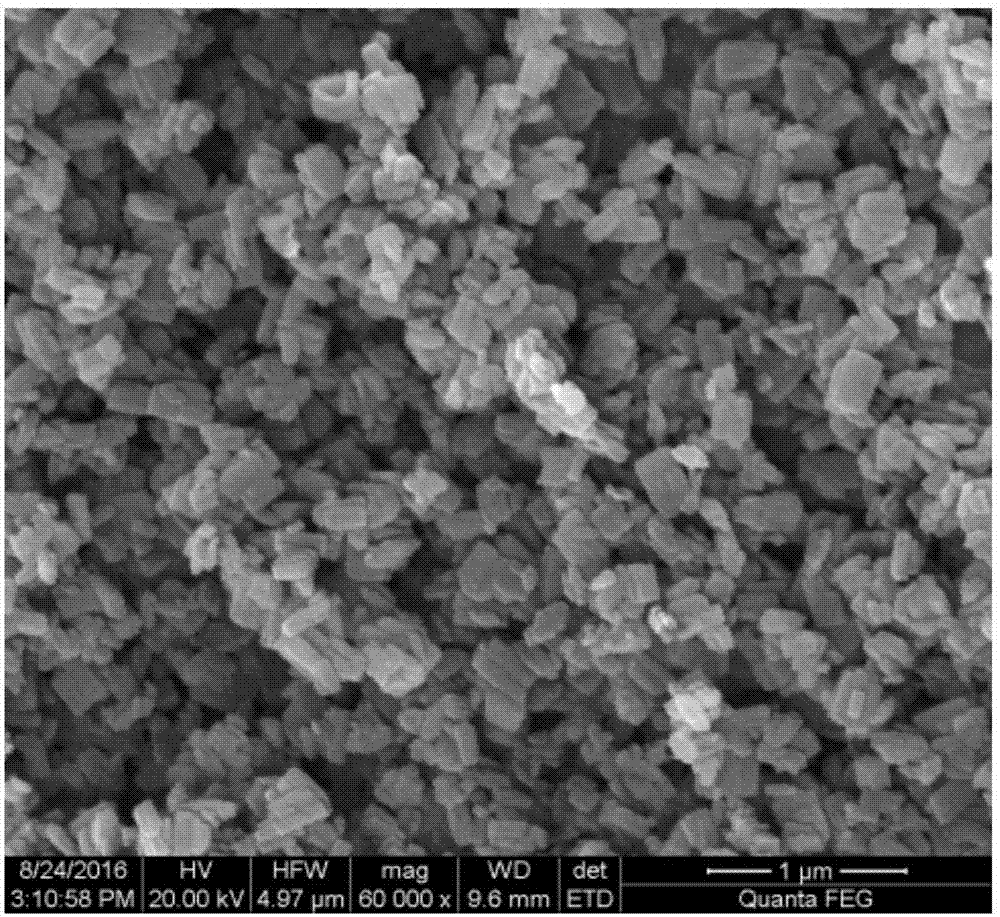

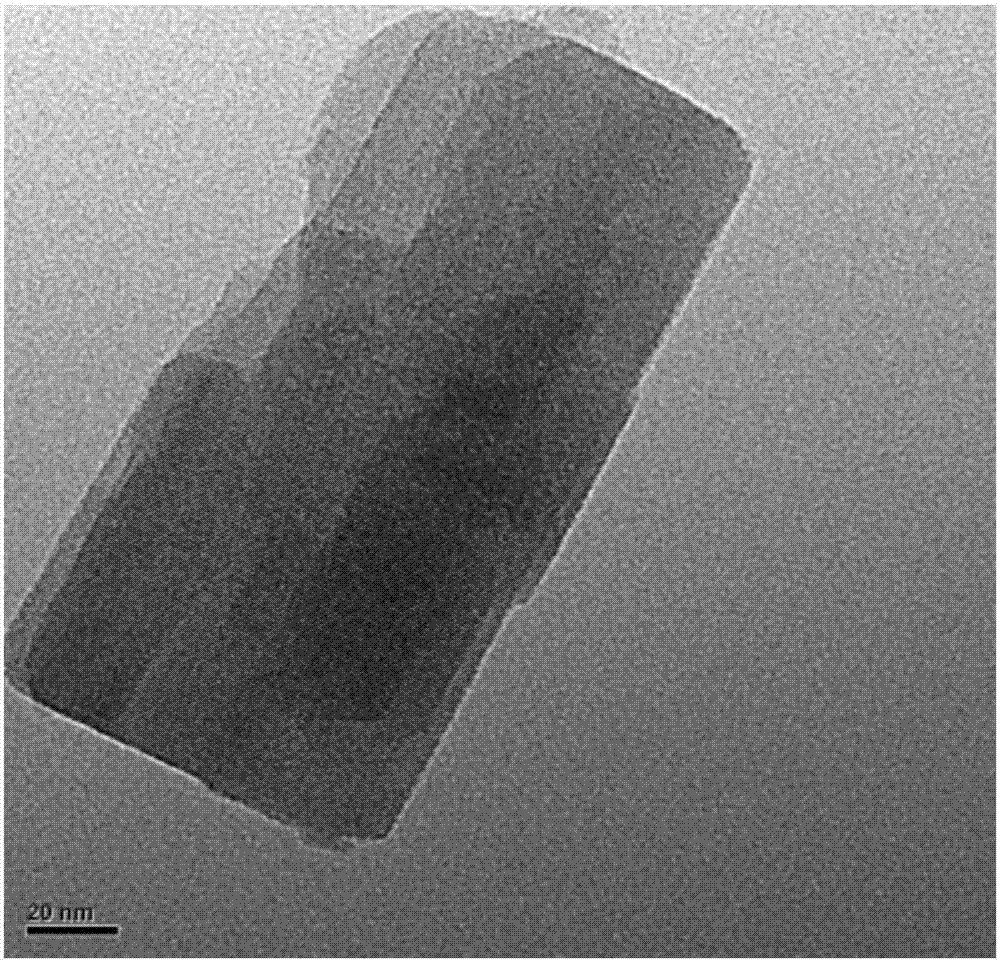

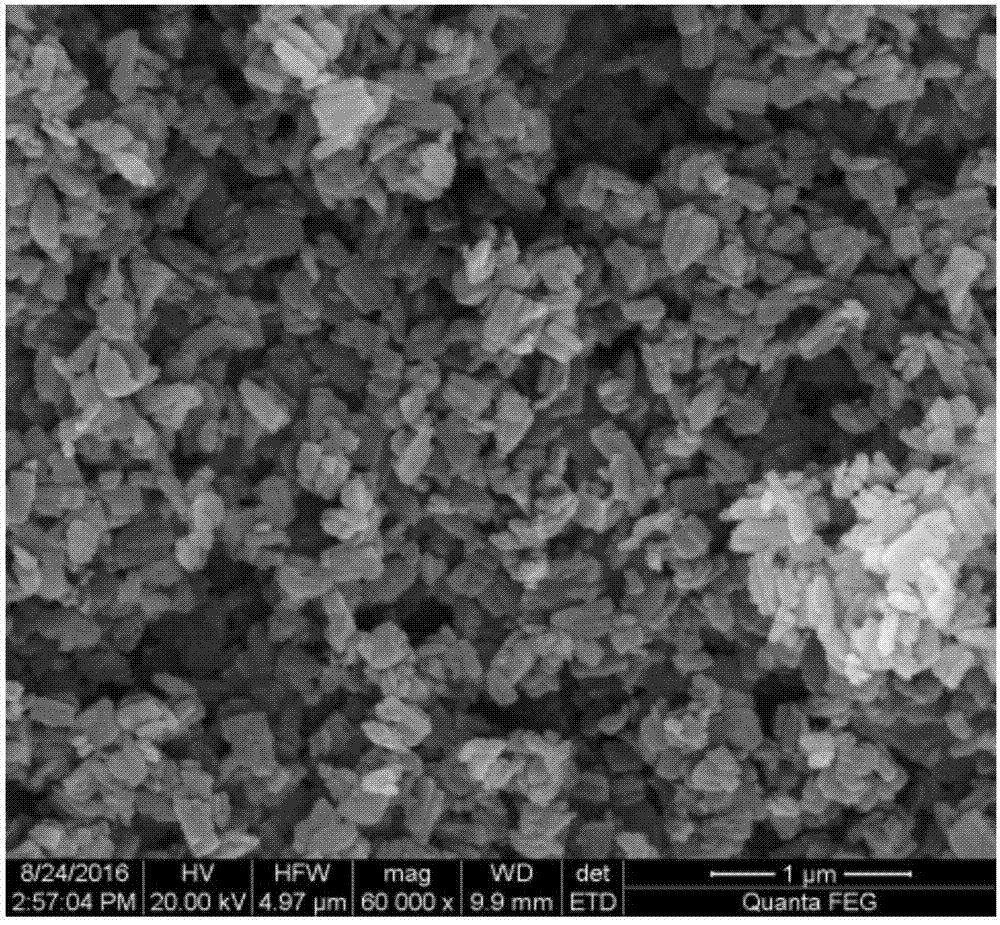

Nano ZSM-5 molecular sieve based catalyst and preparation and use methods

ActiveCN104941695AShorten the diffusion pathEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsStrong acidsZSM-5

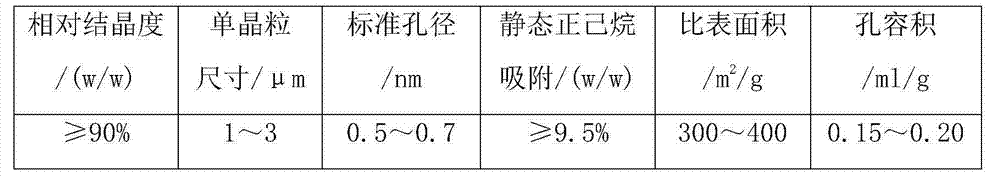

The invention discloses a nano ZSM-5 molecular sieve based catalyst and preparation and use methods. The molecular sieve catalyst consists of molecular sieves and metal components, wherein the molecular sieves are nano ZSM-5 molecular sieves with a short b-axis, a medium high silica-alumina ratio, less strong acid, high Lewis acid content, and resistance to hydrothermal deactivation. The preparation method is as follows: mixing a silicon source, an aluminum source, a template agent, a structure promoter, an additive and alkali with water, and stirring to prepare a precursor solution, then crystallizing, separating solid from liquid, and calcinating to obtain molecular sieve raw powder; mixing the molecular sieve raw powder with an ammonium salt solution, stirring, filtering, mixing with the ammonium salt solution for several times, stirring, filtering, and calcinating to obtain hydrogen-type ZSM-5 molecular sieves; mixing with the metal precursor solution, drying and calcinating to obtain the aromatization catalyst. The use method is as follows: transforming oxy-compound raw materials to aromatic hydrocarbon through the catalyst under the reaction conditions. The nano ZSM-5 molecular sieve based catalyst has the characteristics of being high in aromatics yield (reaching up to 99%) and long in service life (the catalyst is alive after 300 hours, and the aromatics selectivity reaches up to 70% after the catalyst is subjected to hydrothermal aging at 760 DEG C for 4 hours).

Owner:TSINGHUA UNIV

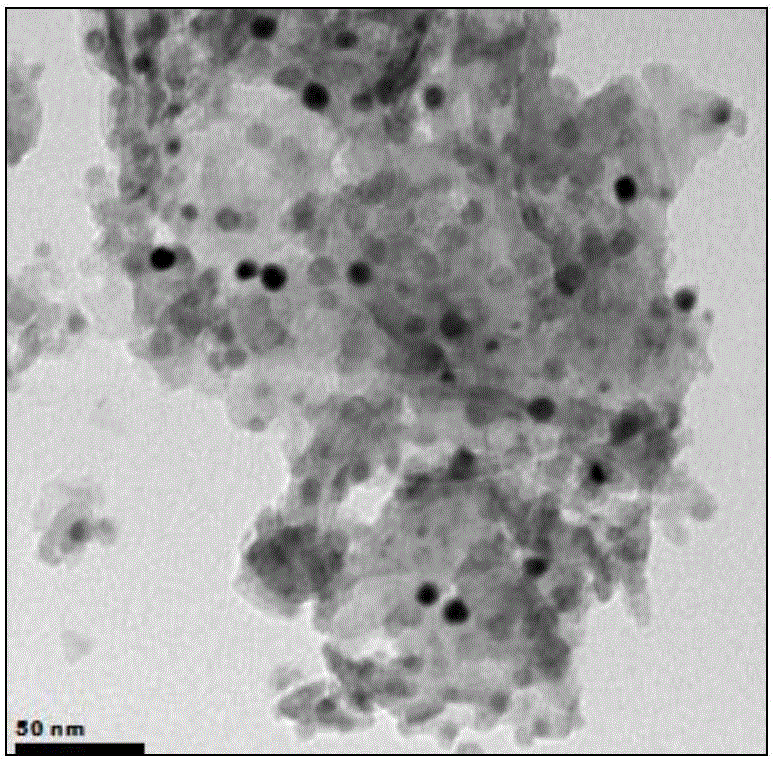

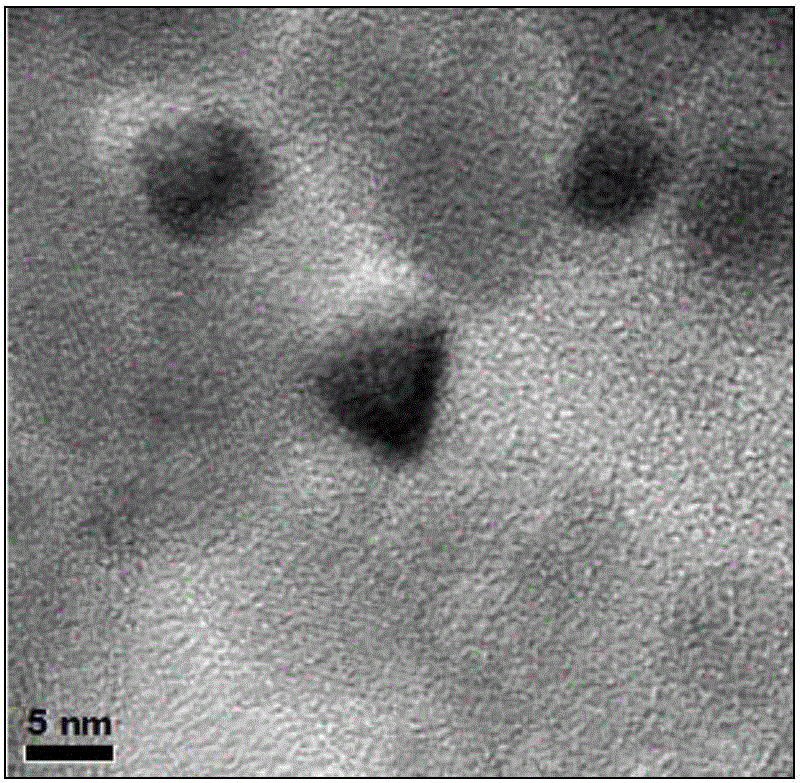

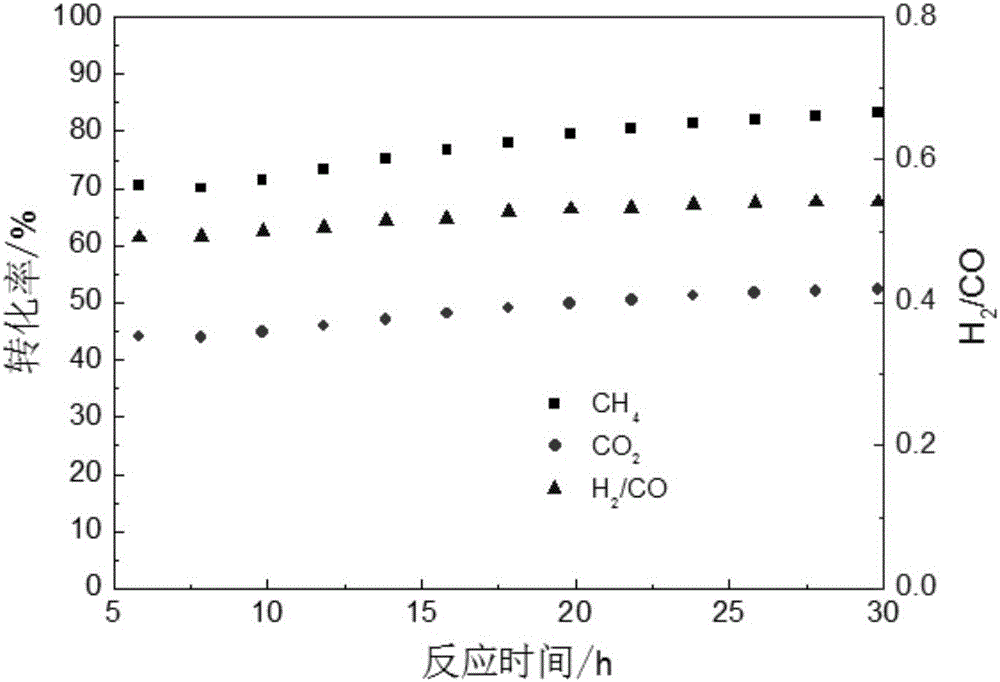

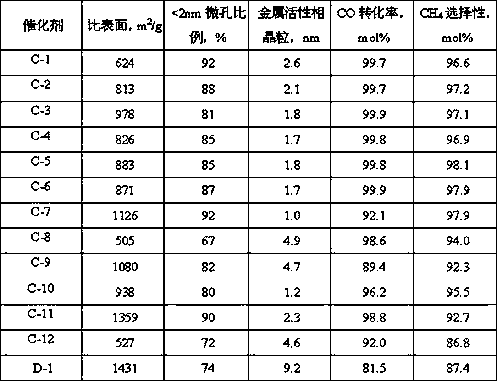

High-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming and application of high-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming

ActiveCN105688916AReduce operating costsHigh reforming catalytic activityHydrogenHydrogen/synthetic gas productionSteam reformingChemical industry

The invention belongs to the field of chemical industry, and relates to a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst and its application. The invention provides a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst, which comprises the following components in terms of mass percentage: active component 20-25%; synergistic component 1-30%; carrier 45-79% . The present invention further provides a preparation method of a high-dispersion, high-load and high-activity low-temperature methane reforming nickel-based catalyst and its use in low-temperature methane reforming reactions. The invention provides a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst and its application, which is suitable for high-pressure and low-temperature methane-carbon dioxide reforming reaction at a reaction temperature of 400-800°C, high-pressure and low-temperature methane-steam reforming, high-pressure and low-temperature reforming Methane reforming processes such as methane-carbon dioxide-steam mixed reforming have high catalytic activity and stability.

Owner:高潞空气化工产品(上海)能源科技有限公司

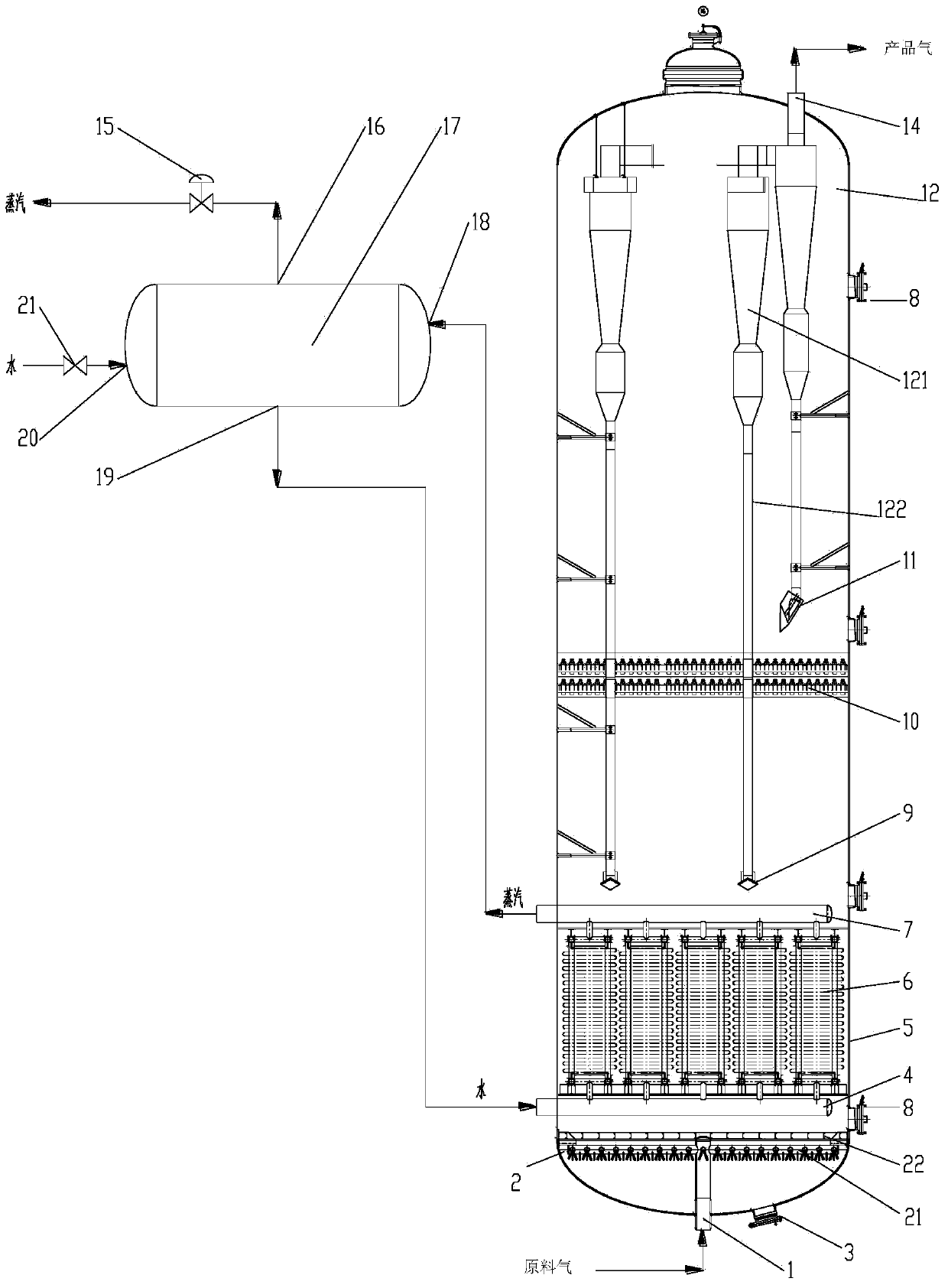

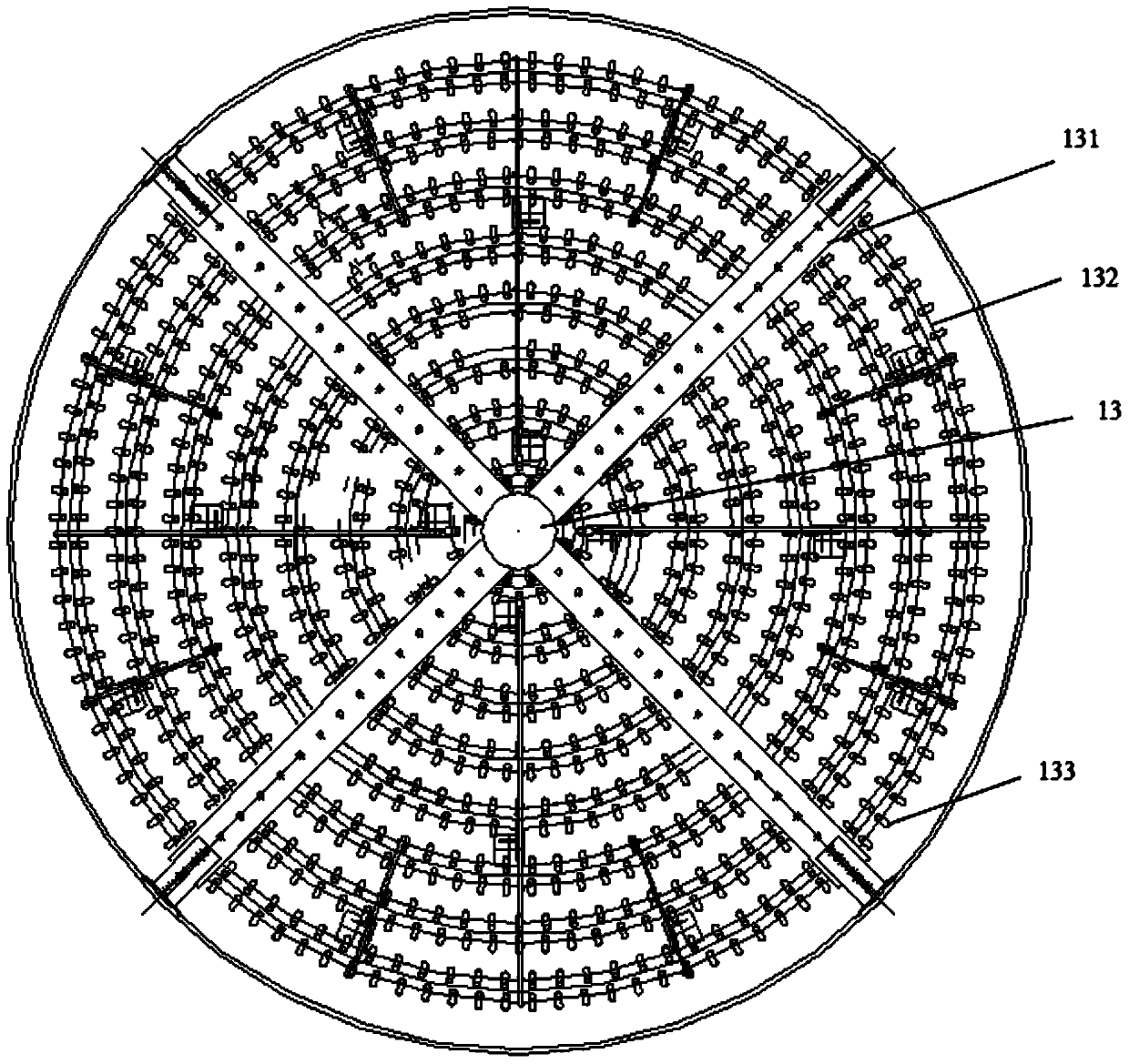

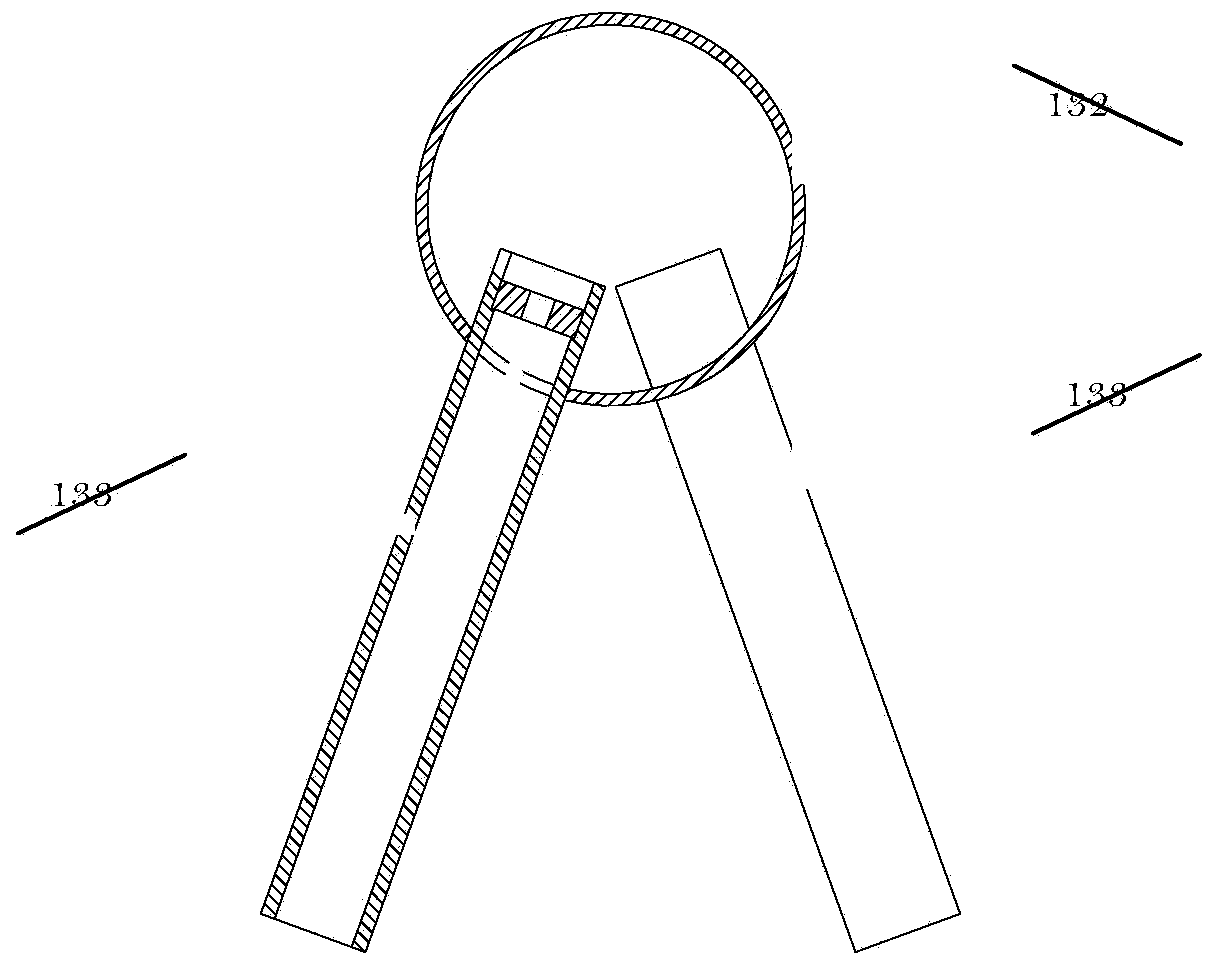

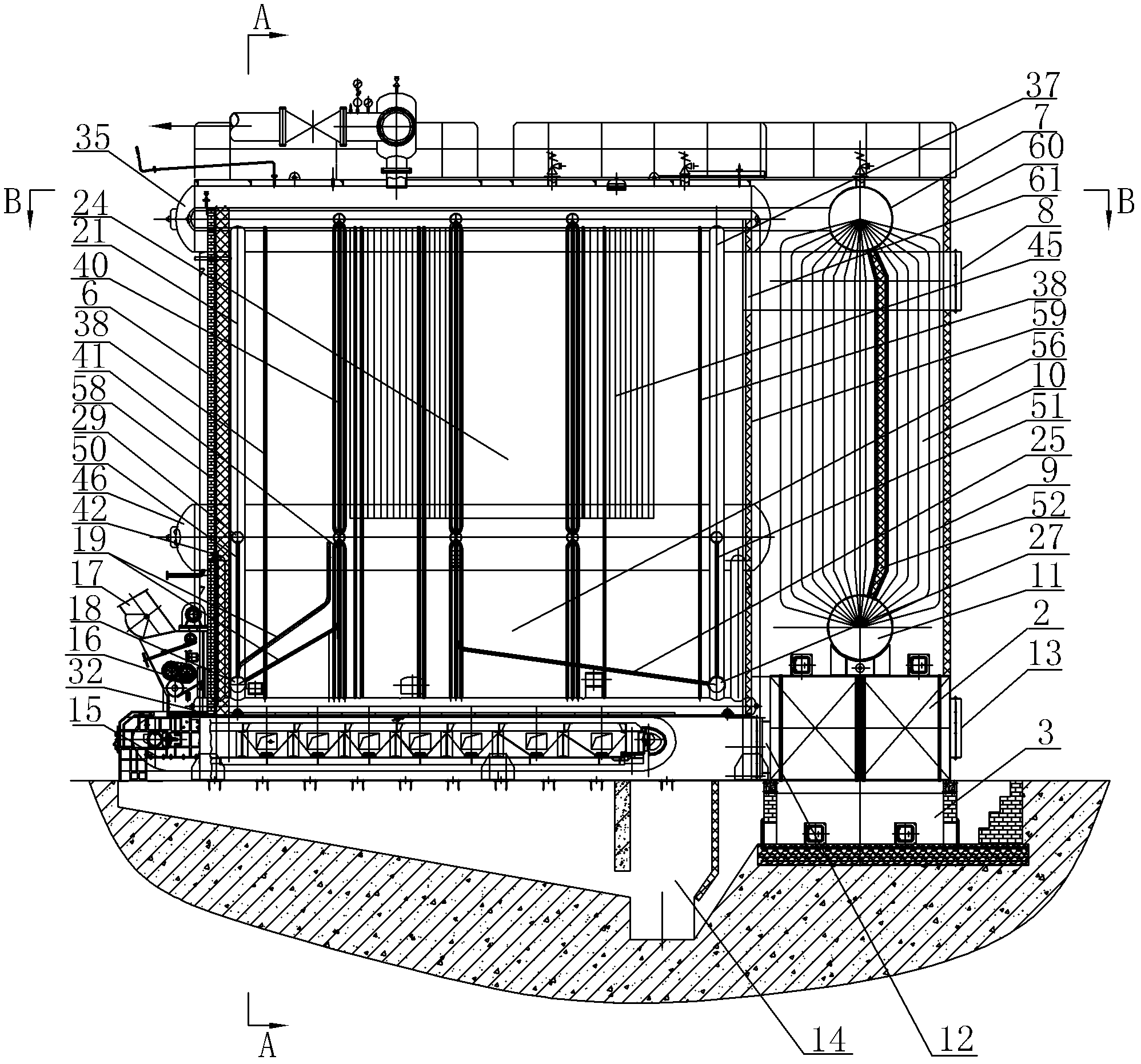

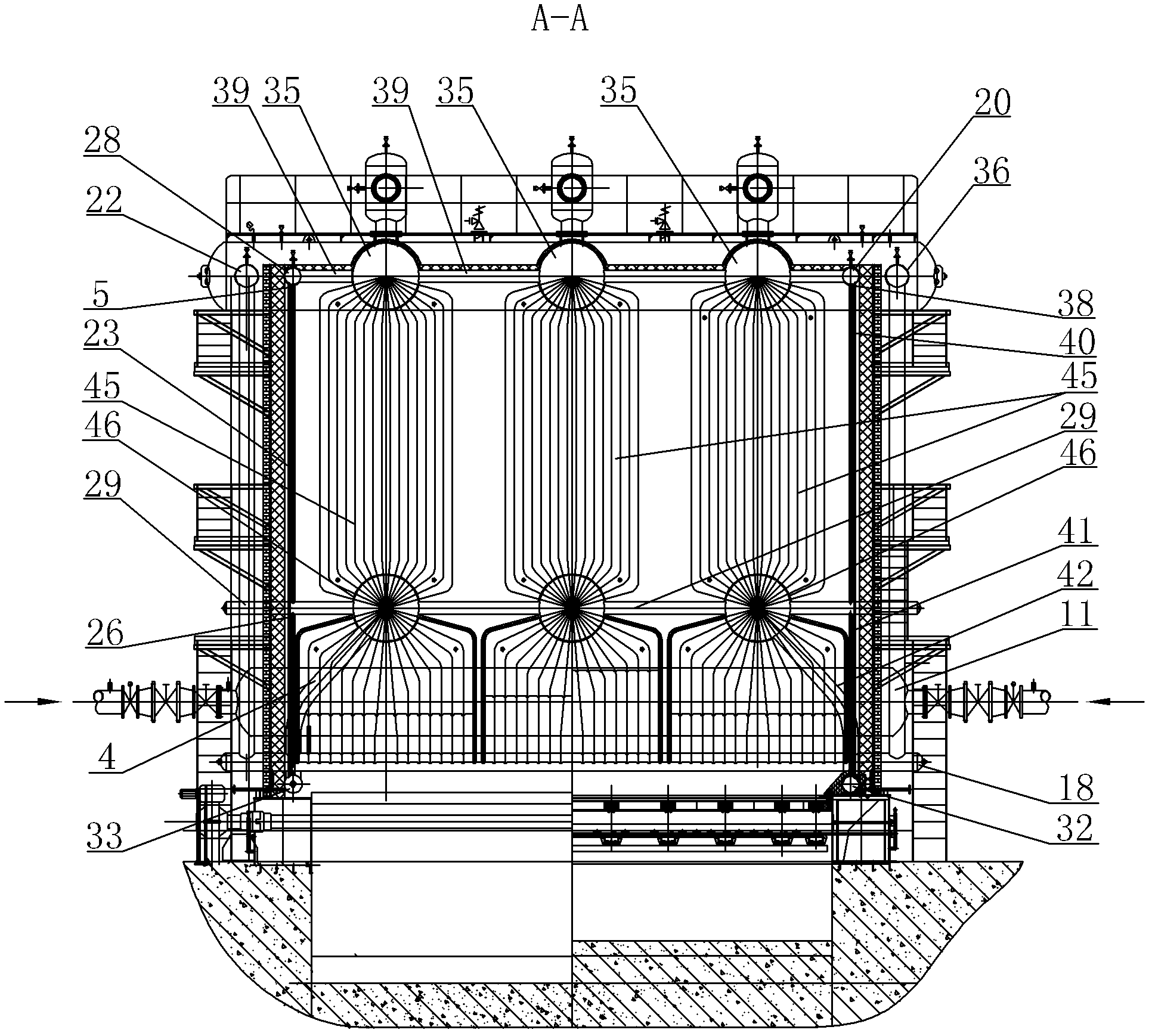

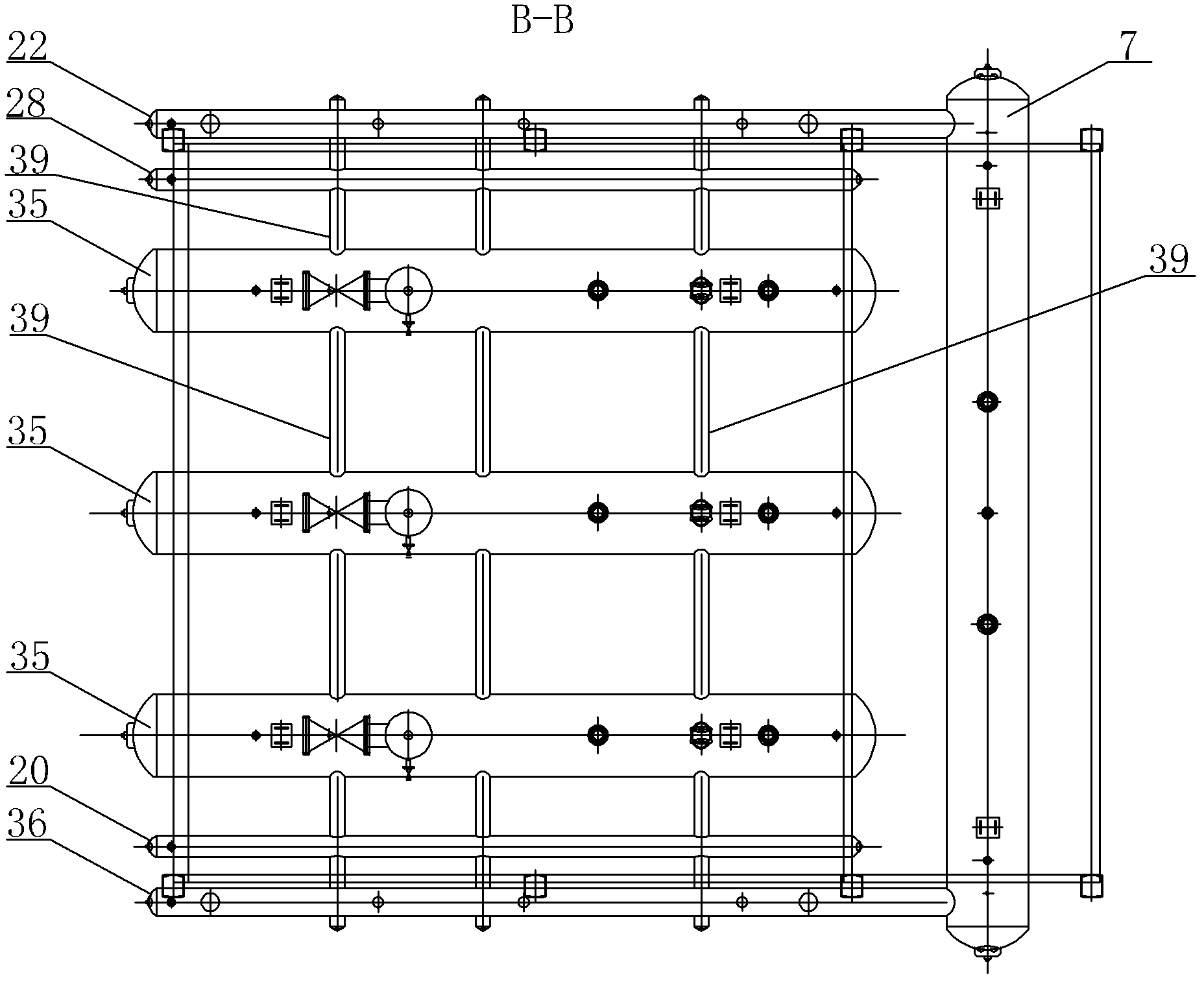

Methanation fluidized bed reactor

ActiveCN104001457AGuaranteed uptimeReduce consumptionGaseous fuelsChemical/physical processesFluidized bedMethanation

The invention provides a methanation fluidized bed reactor which is equipment for performing reaction on CO and H2 to generate methane and water and performing reaction on CO2 and H2 to generate methane and water at a certain constant low temperature. The methanation fluidized bed reactor comprises a cylindrical shell and inner parts, wherein a primary gas distributor and a secondary gas distributor are arranged at the bottom, and a catalyst is filled to form a catalyst bed; a heat exchange device consisting of a plurality of groups of heat exchange tubes is arranged in the catalyst bed; the lower ends of the heat exchange tubes in each group are communicated with a water inlet header pipe which is communicated with a water outlet of a steam drum, and the upper ends of the heat exchange tubes in each group are communicated with a steam outlet header pipe which is communicated with a steam inlet of the steam drum. According to the methanation fluidized bed reactor, heat continuously released during methanation reaction can be timely transferred through another medium, and the reaction can be performed at the constant low temperature.

Owner:尹明大

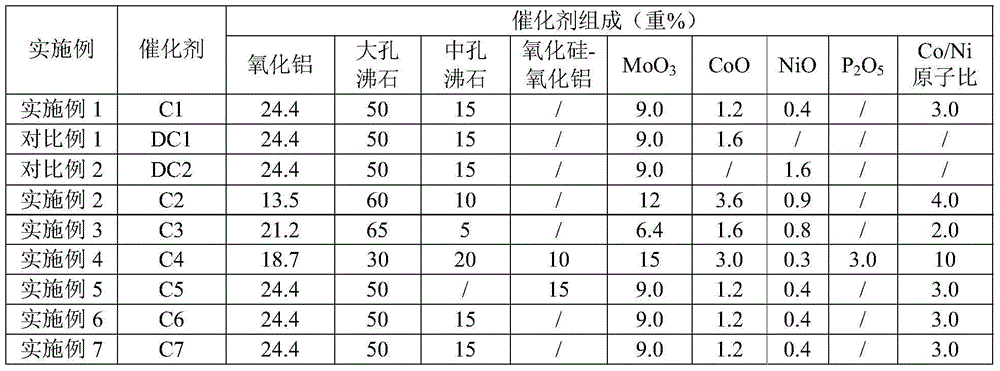

Hydrocracking catalyst and preparation method thereof, and hydrocracking reaction method

ActiveCN105413741AOvercome the defect of easy carbon deposition and deactivationEasy to deposit carbonMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveCobalt atom

The present invention provides a hydrocracking catalyst and a preparation method thereof, and a hydrocracking reaction method. The hydrocracking catalyst comprises a carrier and active components loaded on the carrier, wherein the active components comprise three components such as molybdenum, cobalt and nickel, the molybdenum content is 3-20 wt%, the cobalt content is 0.5-5 wt% and the nickel content is 0.1-1.5 wt% by adopting the total weight of the hydrocracking catalyst as the reference (calculated as the oxide), a molar ratio of cobalt atoms to nickel atoms in the active components is 1-10:1, the carrier contains a solid acid component and an inorganic heat-resistant oxide, and the solid acid component comprises at least two components selected from amorphous silicon-aluminum, a macroporous zeolite molecular sieve and a mesoporous zeolite molecular sieve. The hydrocracking catalyst of the present invention does not easily produce carbon deposition, can obtain the hydrocracking product having the high aromatic hydrocarbon content, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing ethylene by ethanol dehydration and preparation method thereof

InactiveCN101579638AOvercome and address costsOvercoming and addressing shortagesMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMorpholineSynthesis methods

The invention discloses a catalyst for preparing ethylene by ethanol dehydration and a preparation method thereof, belonging to the technical filed of biomass power source and catalyst preparation. The catalyst is SAPO-34 molecular sieve modified by metal Mn ions, namely Mn / SAPO-34; and the catalyst is prepared by using the Morpholine as template agent and then introducing the modified metal ions before the molecular sieve is crystallized by the direct synthesis method. The invention overcomes and solves the problems of high cost and shortage of petroleum fuel, so that the process energy consumption is reduced, and the problem that zymotic ethanol of biomass is low in concentration and difficult in post application is solved; the ethanol is high in transformation rate, high in selectivity and purity of ethylene, good in catalytic activity, uneasy in carbon accumulation and long in operating period; the obtained molecular sieve is big grain single crystals which can be directly used in the fluidized bed and have good wearing resistance and reduced pelleting step; the modified metal ions are introduced before the molecular sieve is crystallized by the direct synthesis method so that the activity stability is good and the modified ions are not easy to run off during the reaction process.

Owner:TSINGHUA UNIV +1

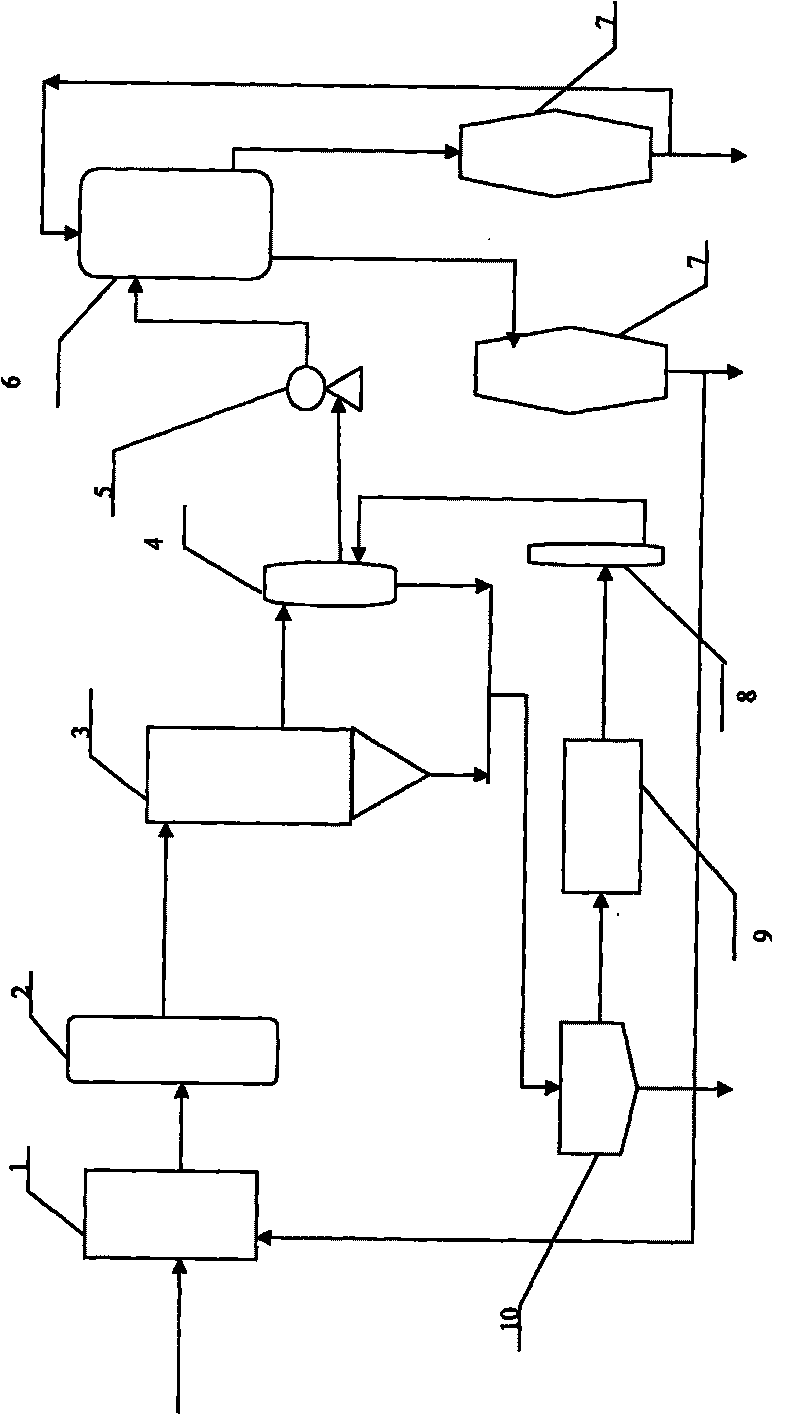

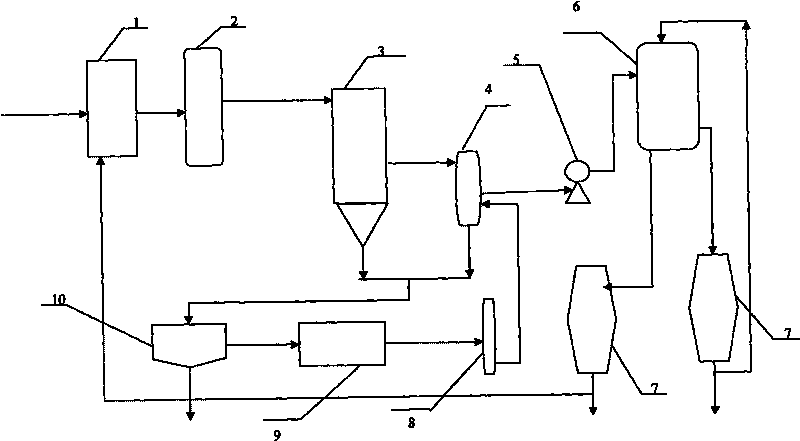

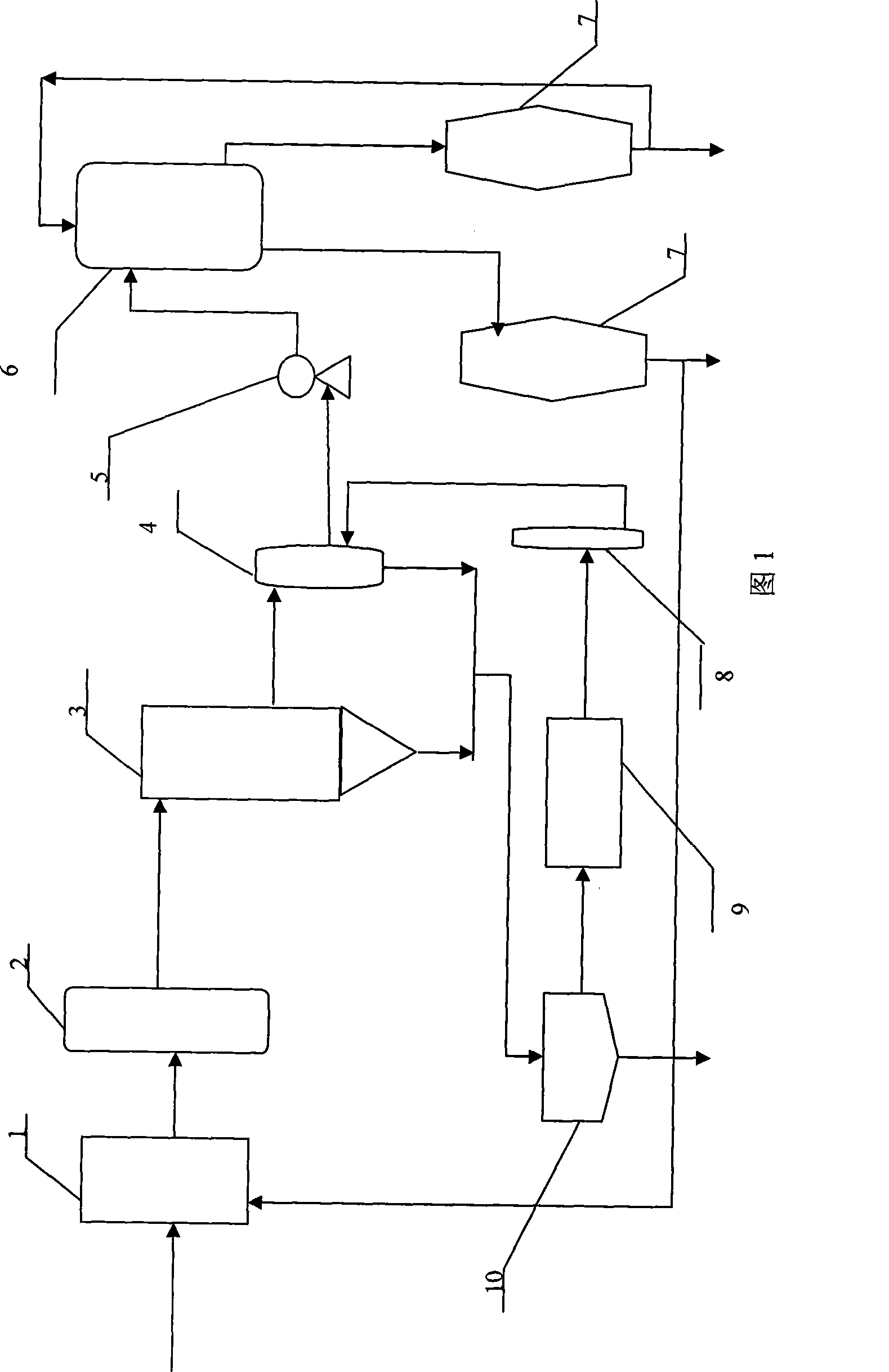

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

Methanation catalyst taking rutile type TiO2 as carrier and preparation method of methanation catalyst

ActiveCN108246300AHigh specific surface areaGood activity at low temperatureHydrocarbon from carbon oxidesCatalyst activation/preparationCooking & bakingNickel salt

The invention relates to a methanation catalyst taking rutile type TiO2 as a carrier and a preparation method of the methanation catalyst and relates to methanation catalysts. The methanation catalysttaking the rutile type TiO2 as the carrier is prepared from the ingredients in percentage by mass: 2% to 16% of nickel oxide, 75% to 90% of titanium dioxide, 2% to 10% of rare-earth metal oxide and the balance of aluminum oxide. The preparation method comprises the steps: putting pseudo-boehmite and diluted acid into a kneader to prepare an aluminum sol composite binder, then, adding the rutile type TiO2 powder, carrying out kneading to obtain plastic mass, then, carrying out strip extruding forming, carrying out standing, carrying out baking, and carrying out roasting, so as to obtain the rutile type TiO2 carrier; preparing a complexing solution from a soluble nickel salt, a rare-earth metal soluble salt, ammonia water and citric acid, dipping the formed TiO2 carrier; after dipping, carrying out room-temperature standing, and carrying out baking; carrying out heat treatment: subjecting the dipped catalyst to programmed heating roasting, subjecting the nickel salt and the rare-earth metal salt to pyrolysis to obtain oxidation states, thereby obtaining the methanation catalyst taking the rutile type TiO2 as the carrier.

Owner:XIAMEN UNIV

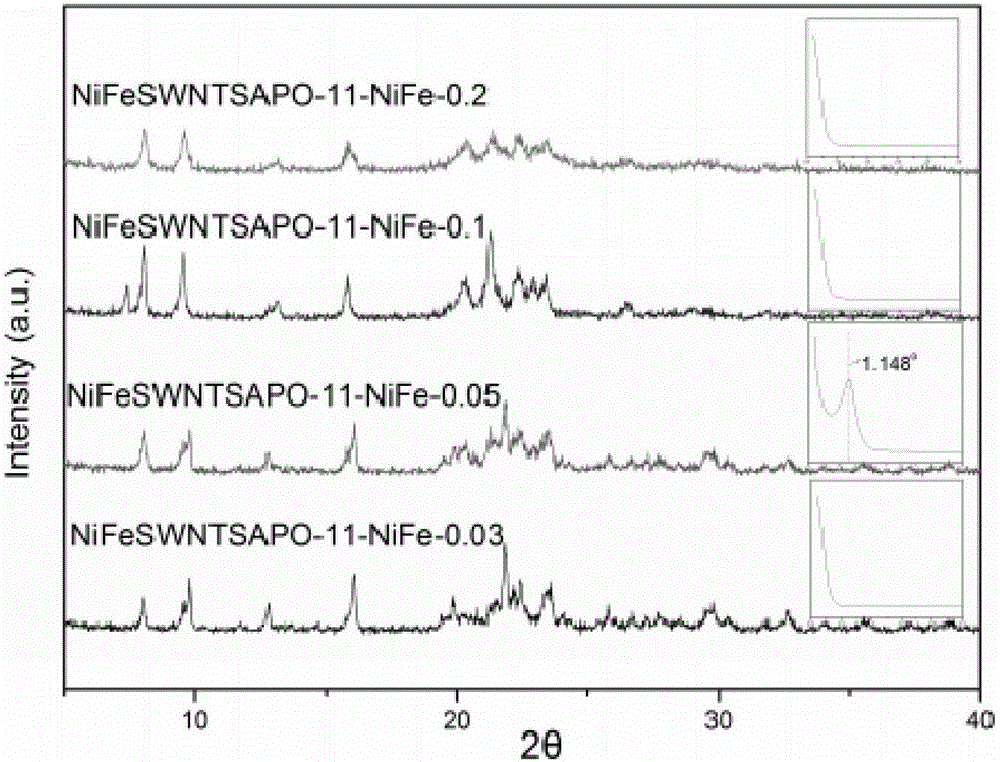

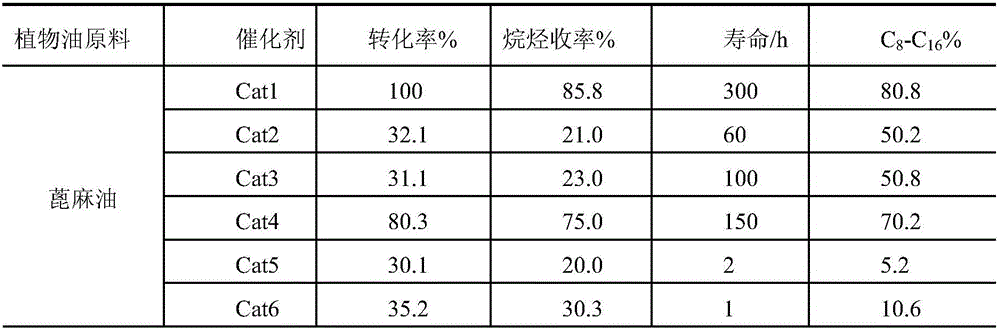

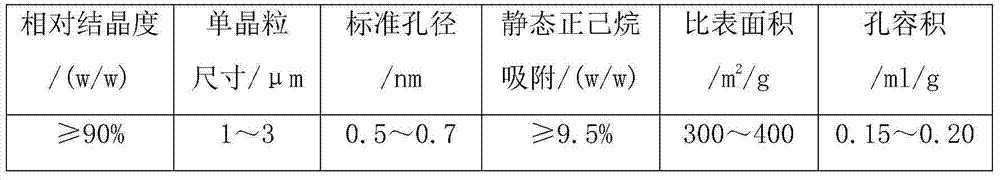

Preparation method of hydrodeoxidation isocatalyst, hydrodeoxidation isocatalyst and application thereof

ActiveCN105921168AImprove playbackLarge specific surface areaFatty acid hydrogenationFatty acid isomerisationVegetable oilKerosene

The invention belongs to the technical field of preparation of aviation kerosene, and particularly relates to a preparation method of a hydrodeoxidation isocatalyst, a hydrodeoxidation isocatalyst and application thereof. Carbon nanotubes are modified by nickel phthalocyanine so as to introduce Ni and N elements into the carbon nanotubes, iron phthalocyanine is added to cooperate with the nickel phthalocyanine, and the modified carbon nanotubes are added into a SAPO-11 synthetic gel in the form of a gel component, so that the synthesized SAPO-11 has more abundant pores and higher acid strength; and by introducing the Ni, Fe and N, the synthesized molecular sieve has the hydrodeoxidation activity, so that the synthesized NiFeCNTSAPO-11 can be directly used as a biological aviation kerosene catalyst for hydrogenating vegetable oil, thereby omitting the step of impregnating active components into the support and simplifying the preparation procedure. Besides, the hydrodeoxidation isocatalyst has high catalytic efficiency and high biological aviation kerosene yield (up to 78-85%).

Owner:NANKAI UNIV +2

High-activity oxygen carrier and preparation method and application thereof

ActiveCN103785389AHigh activityNot easy to deposit carbonHydrogenFuel additivesChemistryInteraction forces

The invention discloses an oxygen carrier, which employs SiO2 as a carrier, NiO as an active component and CaO as an additive. The oxygen carrier comprises, by weight, 1-30% preferably 5-20% of the active component NiO, 1-20% preferably 1-10% of the additive CaO, and the balance of the carrier SiO2. A preparation method of the oxygen carrier is by successively loading CaO and NiO with SiO2 as the carrier by an impregnation method. The preparation method of the oxygen carrier is simple, the active component has small particle size, uniform dispersion and weak interaction force with the carrier, and the oxygen carrier has the advantages of high activity stability under high temperature and / or long period operation in chemical chain hydrogen production or combustion reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid fuel and preparation thereof

InactiveCN101475857AReduce volatilityImprove performanceLiquid carbonaceous fuelsThermal energyHexamethylenetetramine

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is mainly prepared from the following raw materials in portion by mass: 150 to 300 portions of water, 650 to 850 portions of methanol, 5 to 20 portions of butyl acetate, 5 to 20 portions of sodium hydroxide, 2 to 10 portions of hexamethylenetetramine, 10 to 30 portions of hydrogen peroxide with a mass concentration of 30 percent, and 50 to 150 portions of ethanol. The liquid fuel has low volatility and steady performance, is safe during the transportation and storage when being distributed to users due to the high temperature resistance, is difficult to ignite if no open flame exists, does not splash liquids and fumigate eyes during the use, can completely burn, is difficult to generate harmful gas such as formaldehyde and the like, has no smoke, no toxicity, no carbon deposition, no pot blackening, violent fire, high heat energy, no pressure, and no explosion danger, has a combustion calorie more than 9,500kcal / kg, can be extinguished by water during the fire extinguishing, and has the characteristics of cleanliness, environment protection, safety, simple and convenient production, and low production cost. The liquid fuel can substitute diesel oil and liquefied gas, and is suitable to be used by diesel furnaces, liquefied gas furnaces, boilers and the like.

Owner:廖新明 +1

Catalyst for aromatization of low-carbon mixed hydrocarbons in Fischer-Tropsch synthesis tail gas and its preparation method and use

ActiveCN103752346AOmit the dehydrogenation stepMultiple reactive sitesOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrocarbon condensationAlkanePtru catalyst

The invention discloses a catalyst for aromatization of low-carbon mixed hydrocarbons in Fischer-Tropsch synthesis tail gas and its preparation method and use. The catalyst comprises a Pt-loading inorganic refractory oxide and a transition metal- and heteropoly acid-modified ZSM-5 molecular sieve according to a weight ratio of 0.3-3.0: 1. The Pt-loading inorganic refractory oxide comprises 0.2-5wt% of Pt2O and the balance an inorganic refractory oxide. The transition metal- and heteropoly acid-modified ZSM-5 molecular sieve comprises 0.5-10wt% of a transition metal oxide, 1.0-15wt% of heteropoly acid and the balance a ZSM-5 molecular sieve. The catalyst can be directly used for an aromatization reaction of mixed low-carbon alkanes and mixed low-carbon olefins separated from Fischer-Tropsch synthesis tail gas, can avoid a raw material dehydrogenation step, and has the advantages of high activity, good selectivity, carbon formation difficulty and good stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

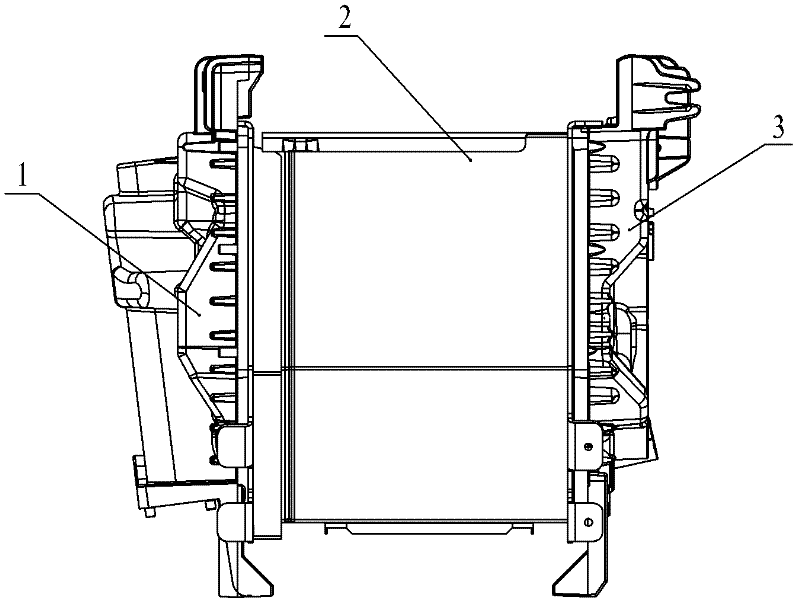

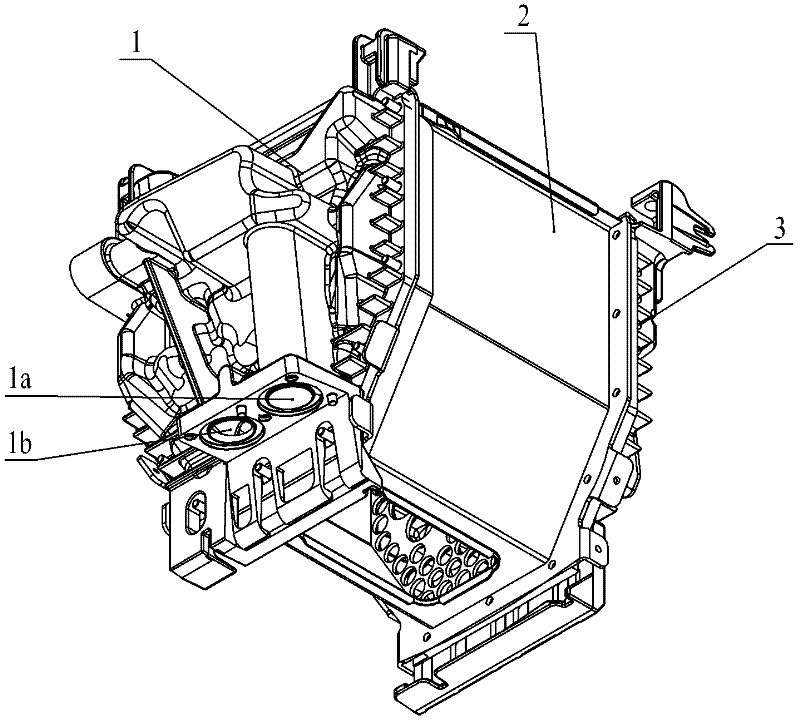

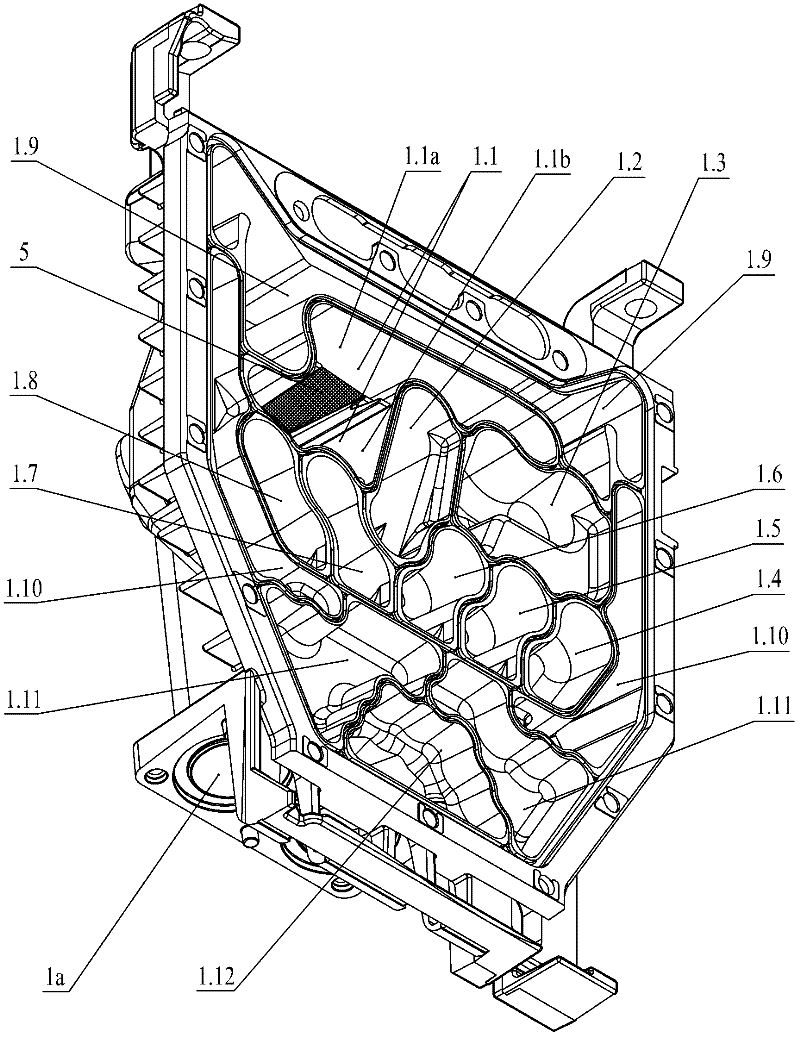

Water passage circulation structure for condensing heat exchanger

ActiveCN102364264AIncrease profitNot easy to deposit carbonFluid heatersPlate heat exchangerWater flow

The invention relates to a water passage circulation structure for a condensing heat exchanger. The water passage circulation structure comprises a shell, and a left cover plate and a right cover plate which are provided with cavities, wherein the left and right cover plates are arranged on the left and right side walls of the shell. The water passage circulation structure is characterized in that: the left cover plate is provided with a water inlet and a water outlet; the cavity of the left cover plate is divided into a plurality of independent left water circulating areas; one is communicated with the water inlet, and another independent left water circulating area is communicated with the water outlet; the cavity of the right cover plate is divided into a plurality of independent rightwater circulating areas; the plurality of left water circulating areas on the left cover plate and the plurality of right water circulating areas on the right cover plate are connected and matched through asymmetrical layer-staggered radiating straight pipes in the mode; and water spirally circulates in a W-shaped route among the left cover plate, the radiating straight pipes and the right cover plate and flows out of the water outlet on the left cover plate finally. The water passage circulation structure is novel; and the heat exchanger with the water passage circulation structure has a medium volume, longer service life, and higher thermal efficiency, and is energy-saving and durable.

Owner:WUXI XIZHOU MACHINERY

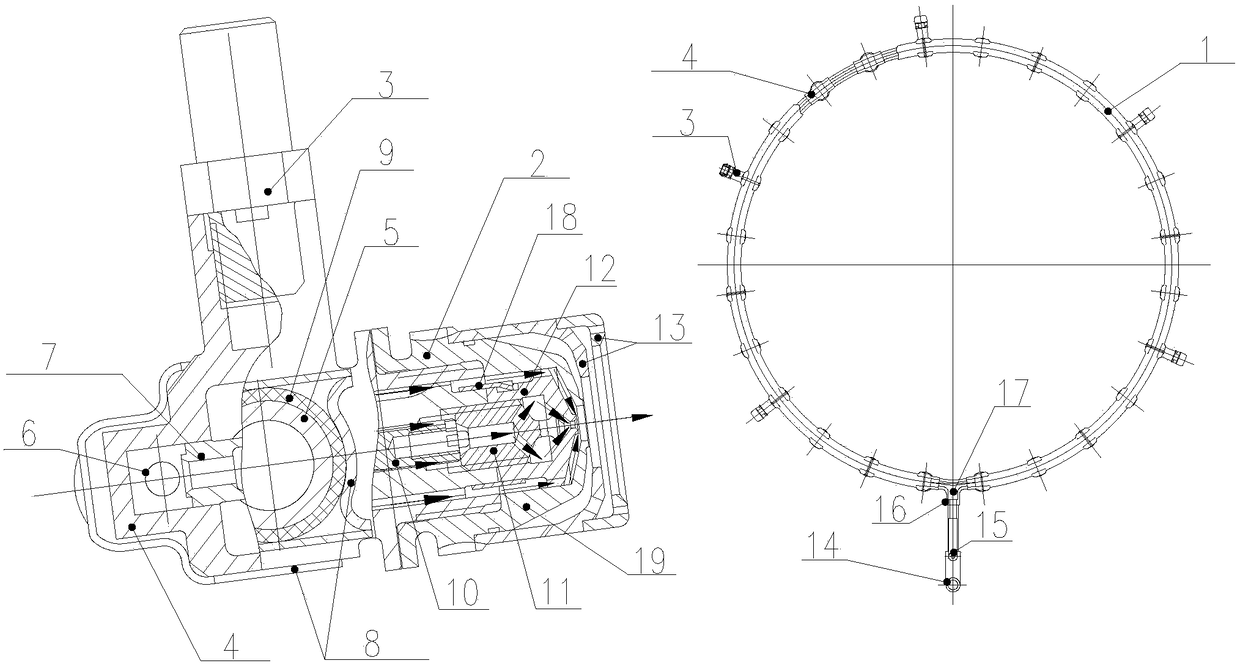

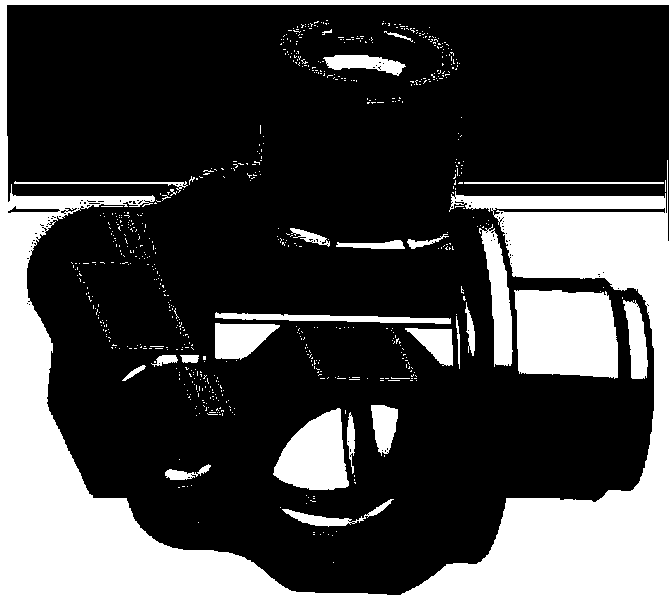

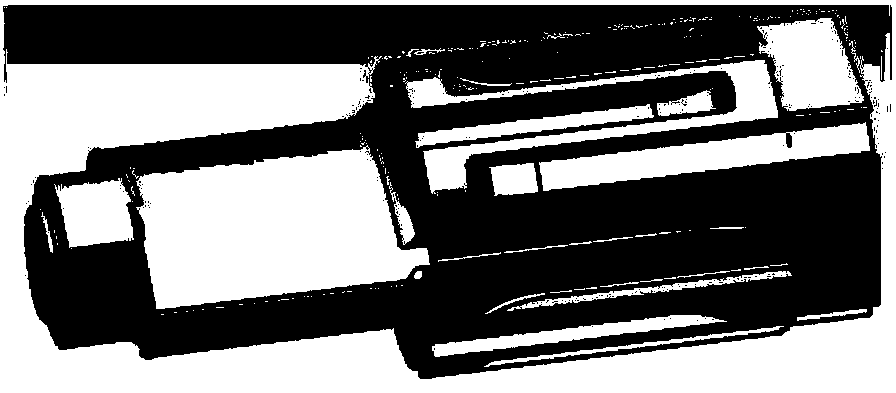

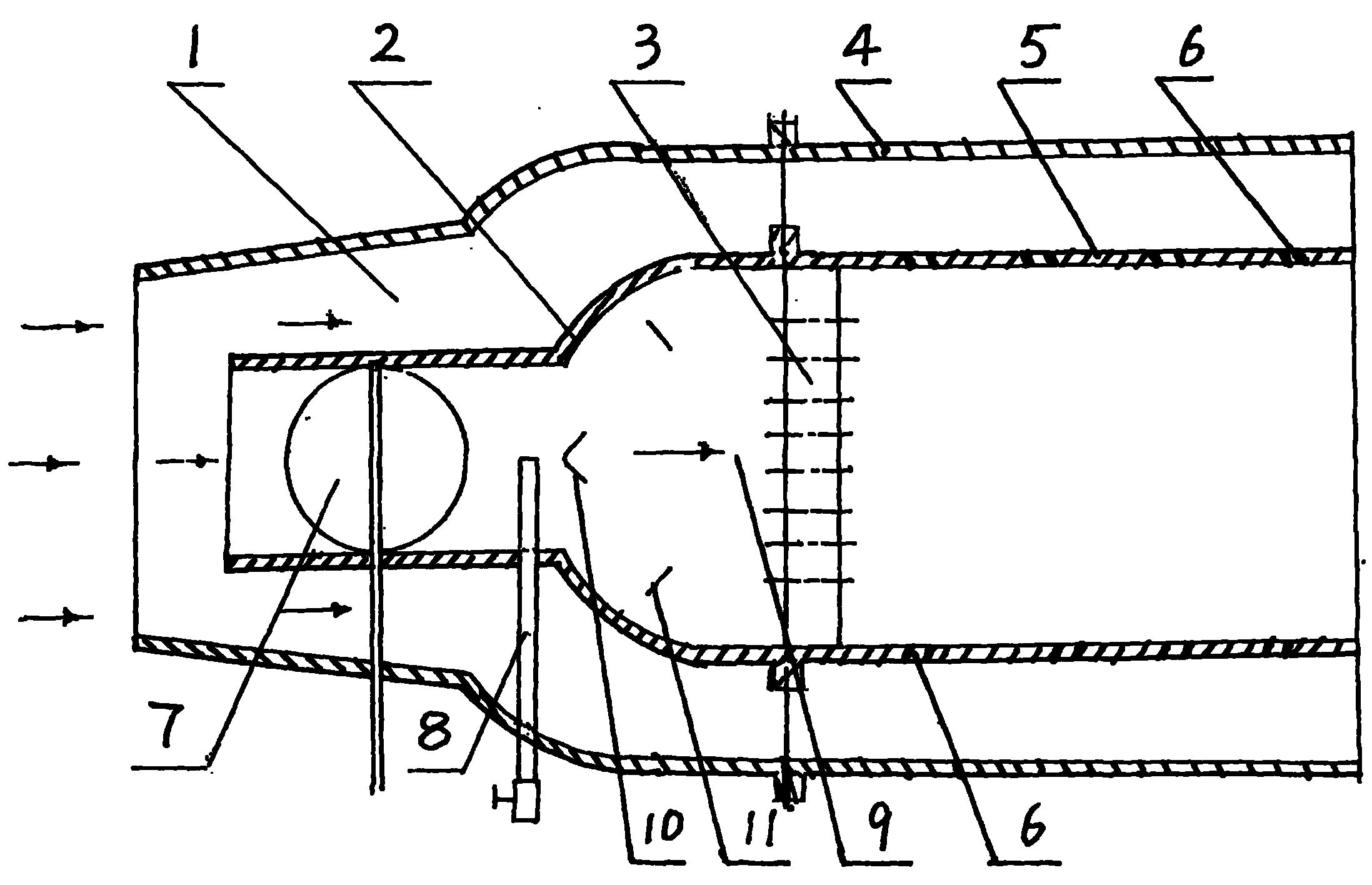

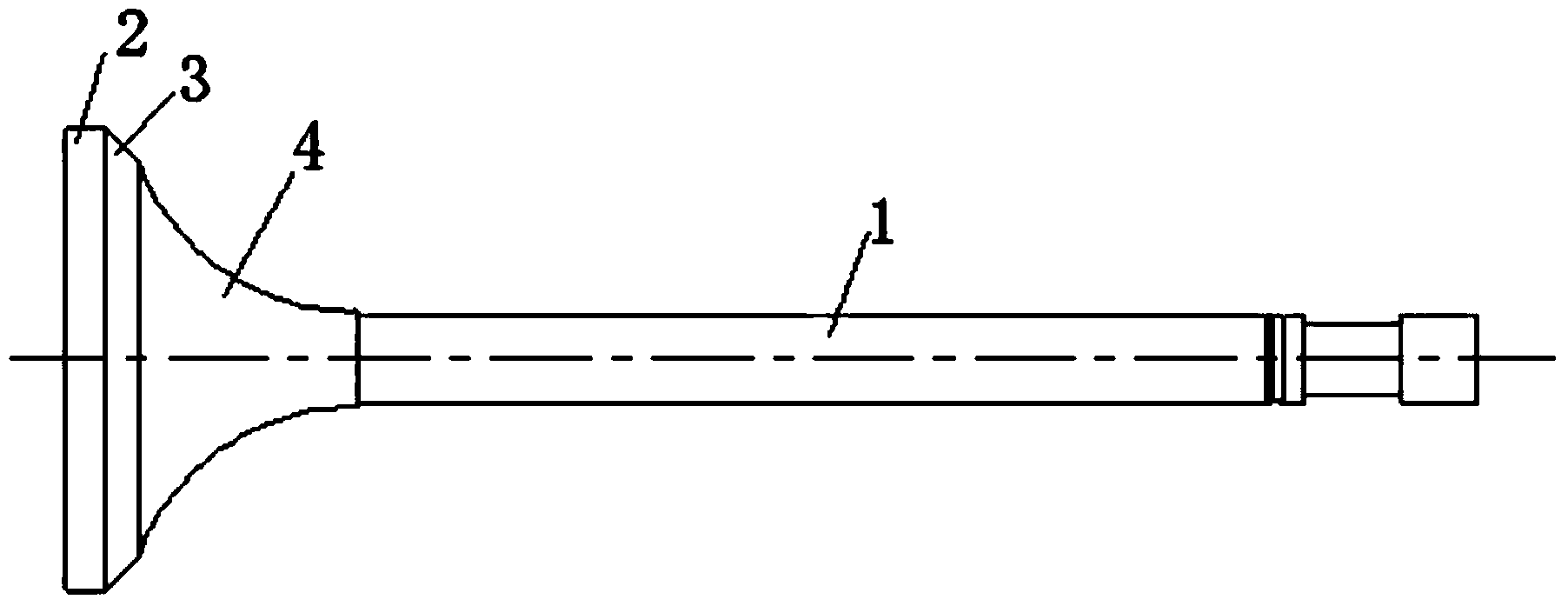

Internal fuel main pipe for double-way fuel conveying and atomization

ActiveCN109140502ACompact structureLittle effect of gravityContinuous combustion chamberCycloneCombustion chamber

The invention discloses an internal fuel main pipe for double-way fuel conveying and atomization. The internal fuel main pipe consists of a main pipe (1) and a nozzle (2); the fuel main pipe is fixedthrough a support column (3) with a ball; a main-way fuel supply pipe (5) and a secondary-way fuel supply pipe (6) are connected through a nozzle shell (4); the heat protection of the pipe is realizedthrough a cover (7) and a thermal insulation layer (8); through a bushing (9) with a thread fuel filter and a thread surface on the surface of a secondary fuel filter (10), the filtration and the stable flowing of fuel are realized; the centrifugal atomization of the fuel is realized through cyclone grooves on a cyclone (11) and a nozzle cyclone (12); and accumulated carbons on the nozzle are reduced through inclined intake holes on a gas cover (13). The fuel main pipe can meet the demands of different fuel supply characteristics of double fuel ways, has the advantages of good atomization effect, compact structure, low mass, low influence on the fuel gravity, difficult accumulation of carbons on the end surface of the nozzle and difficult influence from instable fuel flowing, and is suitable for an aero-engine and a gas turbine combustion chamber.

Owner:中国航发贵阳发动机设计研究所

Method for preparing styrene through oxidative dehydrogenation of ethylbenzene

ActiveCN107285979AMild oxidation capacityPromote activationCatalystsHydrocarbon preparation catalystsDehydrogenationNitrous oxide

The invention relates to a method for preparing styrene through oxidative dehydrogenation of ethylbenzene and aims at solving the problem that the selectivity is poor when styrene is prepared through oxidative dehydrogenation of the ethylbenzene at an oxygen gas atmosphere in the prior art. According to the technical scheme, the method for preparing the styrene through oxidative dehydrogenation of the ethylbenzene comprises the following step: by taking a carbon nonmaterial as a catalyst, nitrous oxide as an oxidant and gas which is inert to reaction as a diluent, preparing the styrene through oxidative dehydrogenation of the ethylbenzene, so that the method relatively well solves the technical problems and can be used for industrial production of the styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

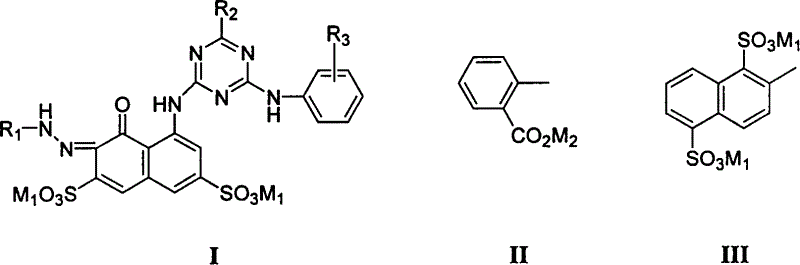

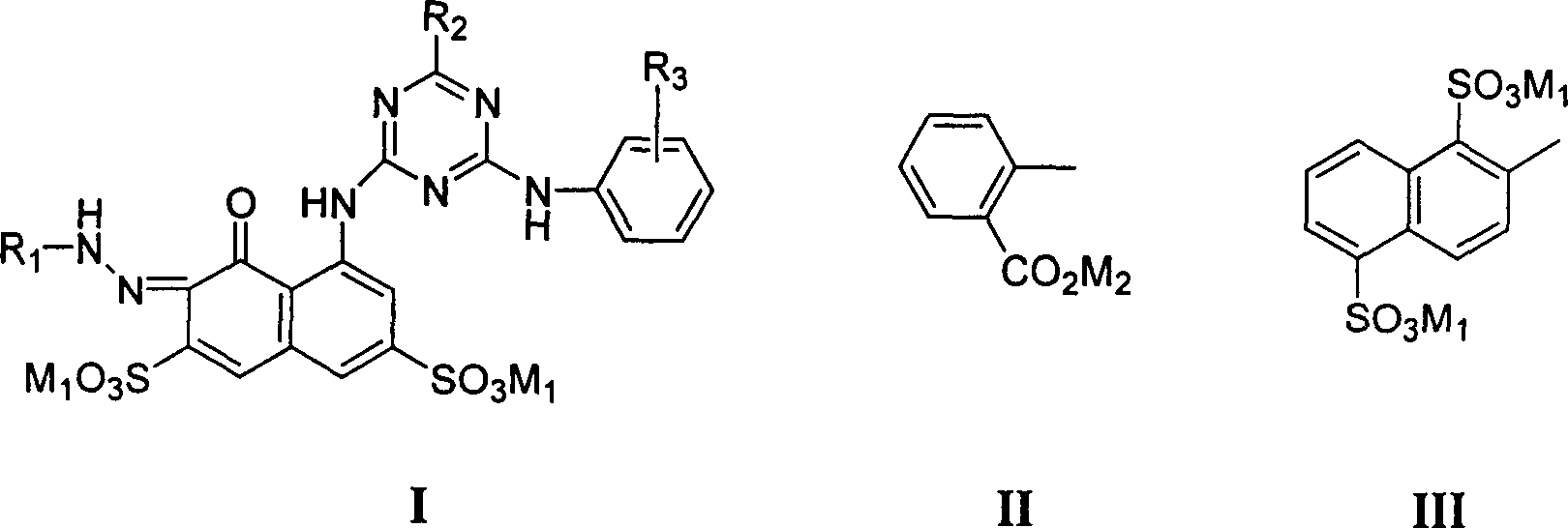

Ink jet dye capable of improving the service life of nozzle

InactiveCN1664015ANot easy to deposit carbonEliminate risk factorsMonoazo dyesInksInjectorDigital ink

The invention relates to a mew type of ink-ejecting dye which can be used in computer ink-ejecting print, chromatic colour print and textile digital ink-ejecting screen printing. Said dye mixes with lower boiling alcohol, humectant, higher boiling organic solvent to get the ink-ejecting ink, and the dye don't accumulates on injector for its special structure and avoids accumulating carbon for the heating effect, and as a result reduces the danger of injector destruction and increases its length of life.

Owner:DALIAN UNIV OF TECH

Catalyst using Al modified active carbon as carrier, and preparation method thereof

ActiveCN109908931ALarge specific surface areaHigh reactivityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMethanation

The invention provides a catalyst using Al modified active carbon as a carrier, and a preparation method thereof, wherein the catalyst comprises an active component, an auxiliary agent and a carrier,the active component is selected from Ni and Co, the auxiliary agent is one or a plurality of materials selected from rare earth elements, and the carrier is petroleum coke-based active carbon. The preparation method comprises: uniformly mixing petroleum coke, metaaluminate and an activator, activating, washing, separating to obtain a solid sample, introducing an active metal and an auxiliary agent into the obtained sample, washing, and drying to obtain a syngas methanation catalyst. According to the present invention, the obtained catalyst has advantages of good dispersion of the active component, high activity, less carbon deposition and the like, and further can solve the problem of high temperature aggregation of the active metal of the active carbon supported catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

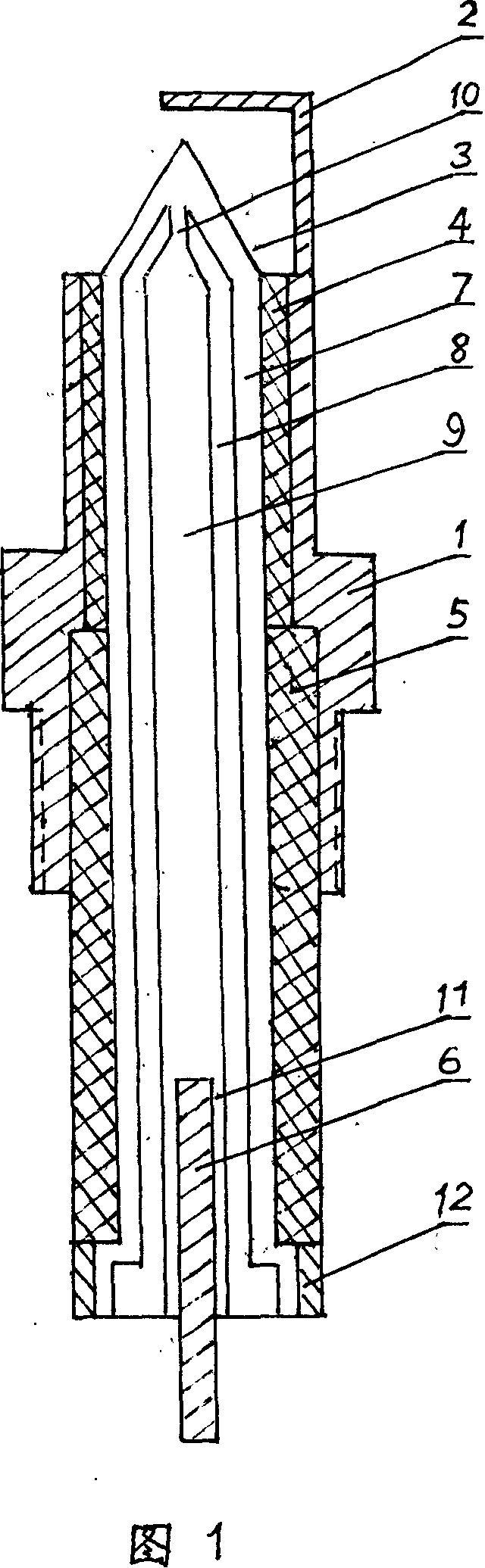

Sparking plug with full-ceramic electrically-heated body as center electrode

ActiveCN101132121ANot easy to deposit carbonStable combustionSparking plugsElectrical resistance and conductanceInsulation layer

This invention relates to an ignition plug by using all-ceramic electrically heating unit as the central electrode. It is composed of: the shell of the ignition plug (SIP), a side electrode (SE), a central electrode (CE), an upper insulation tube (UIT), a lower insulation tube (LIT) and a conducting electrode (CDE). The SIP, connecting SE, is equipped on the engine. The CE is equipped in the upper part of the inner hole of SIP, between its upper end and the SE is clearance. The CE comprises an external resistance layer (ERL), insulation layer (IL) and inner conducting layer (ICL). An interlinkage hole is at the upper end of IL, the partial material of ERL and partial material of ICL are inter linked through said hole. A receptacle of the CDE is at the lower end of ICL, the CED is in the receptacle. The UIT is at the upper part of the inner hole of SIP, as the LIT at the lower part. This invention ensures the stable burning of gas.

Owner:CHONGQING LE MARK CERAMIC TECH CO LTD

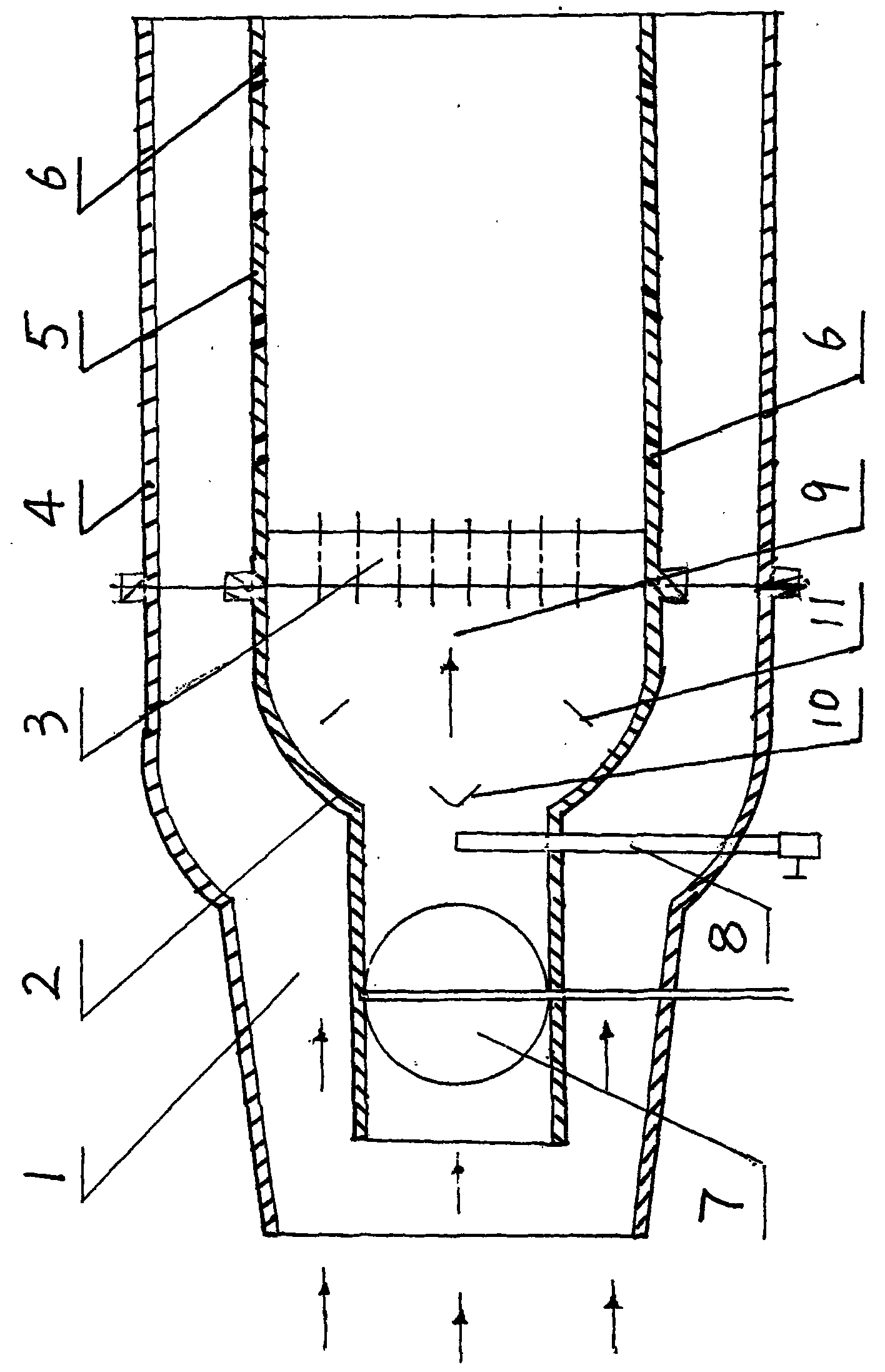

Double control fuel mixing chamber and separation flame plate

InactiveCN101922735AStable combustionIncrease temperatureContinuous combustion chamberAviationAir velocity

The invention is named a turbine engine fuel mixing chamber with a separation flame plate, belongs to the technical field of turbine engines, and mainly solves the problems that air velocity cannot be controlled and a fixed-point fire source cannot be realized better in the conventional engine. The double control fuel mixing chamber is mainly characterized by comprising the mixing chamber and the separation flame plate which is connected with an outlet end of the mixing chamber; an inlet end of the mixing chamber is provided with a valve which can adjust compressed air flow; a wall of the mixing chamber is provided with a fuel pipe which passes through the wall, and a pipe head of the fuel pipe is positioned on a main air flow channel behind the valve; a gas separation tray which guides the air flow to the periphery is arranged on a central axis position of the mixing chamber; and a gas collecting tray which guides the air flow to the center is arranged around the inner wall of the mixing chamber. The double control fuel mixing chamber and the separation flame plate have the characteristics that: air is mixed with fuel oil at a low temperature, then the mixture is heated and finally combusted at a fixed point in the mixing chamber, and are mainly used for the turbine engines of aviation, navigation, electricity generation, land transportation and the like.

Owner:叶民主

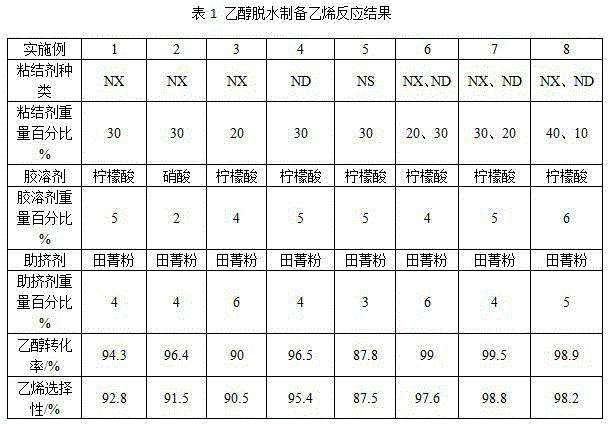

ZSM-5 molecular sieve based catalyst used for preparing ethylene through ethanol dehydration and preparation method thereof

InactiveCN102614906AHigh ethylene selectivityImprove thermal stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAdhesiveHeat stability

The invention belongs to the technical field of catalyst used in preparation of ethylene through ethanol dehydration and provides a catalyst and a preparation method thereof. The catalyst is high in ethylene selectivity, high in heat stability and not prone to carbon deposition in the catalyst process. The technical scheme is that the ZSM-5 molecular sieve based catalyst used for preparing ethylene through ethanol dehydration comprises the following components: a. a ZSM-5 molecular sieve with silicon / aluminum molar ratio as 25 and occupying 40% to 80% of the weight of the catalyst, and b. an adhesive occupying 20% to 50% of the weight of the catalyst. The adhesive is at least one of pseudo-boehmite, aluminum sol and silica sol. The catalyst prepared by the method has the advantages of being high in ethylene selectivity and heat stability if used in preparation of ethylene through ethanol dehydration.

Owner:TAIYUAN UNIV OF TECH

Drum vertical chain grate hot water boiler

ActiveCN102297509AImprove thermal efficiencyHigh thermal efficiencyWater heatersEngineeringEconomizer

The invention discloses a boiler drum longitudinally arranged chain grate hot water boiler, and relates to a hot water boiler to solve the problems that the conventional boiler has low thermal efficiency and high coal consumption, pipes are easy to block, and smoke discharging temperature is high. The boiler drum longitudinally arranged chain grate hot water boiler comprises a left longitudinal upper header, a right longitudinal upper header, a left longitudinal water tank, two first vertical water distributing pipes, two second vertical water distributing pipes, a plurality of upper transverse headers, a plurality of lower transverse headers, a front transverse header, a rear transverse header, a plurality of first water cooling wall pipes, a plurality of second water cooling wall pipes,a plurality of groups of third water cooling wall pipes, a plurality of groups of fourth water cooling wall pipes, a plurality of groups of fifth water cooling wall pipes, a plurality of groups of sixth water cooling wall pipes, a plurality of groups of upper convection banks, a plurality of groups of front convection banks, a plurality of groups of rear convection banks, and at least one convection economizer, wherein the front transverse header and the rear transverse header are communicated with a left coking prevention ark and a right coking prevention ark; adjacent upper boiler drums in a plurality of upper boiler drums, and the left longitudinal upper header and the right longitudinal upper header and the respectively adjacent upper boiler drums are communicated thorough the plurality of upper transverse headers. The boiler drum longitudinally arranged chain grate hot water boiler is used for central heating.

Owner:HARBIN TIANDIKUAN ENERGY SAVING TECH

Syngas preparation catalyst and preparation method thereof

ActiveCN109908906AHigh reactivityAnti-sinteringHydrogenMetal/metal-oxides/metal-hydroxide catalystsAluminateAlkaline earth metal

The invention provides a syngas preparation catalyst and a preparation method thereof, wherein the catalyst comprises an active component and a composite carrier, the active component is selected fromNi and Co, and the carrier is a composite material of an alkaline earth metal aluminate and petroleum coke-based active carbon. The preparation method comprises: uniformly mixing petroleum coke, an alkaline earth metal aluminate and an activator, and activating; washing the obtained sample, and drying; and introducing an active component, drying, and calcining to obtain the catalyst for preparingsyngas through methane carbon dioxide reforming. According to the present invention, the prepared catalyst has advantages of good active metal dispersion, high reaction activity, sintering resistance, less carbon deposition and the like; and the preparation method is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

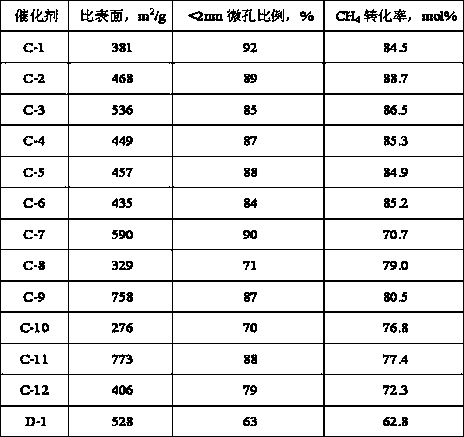

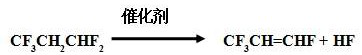

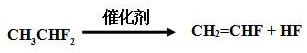

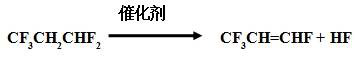

Sub-nano AlF3 catalyst as well as preparation method and application thereof

ActiveCN112675882AHigh catalytic activityImprove catalytic stabilityPreparation by hydrogen halide split-offCatalyst activation/preparationNano catalystAlkane

The invention discloses a sub-nano AlF3 catalyst and a preparation method and application thereof.The preparation method comprises the steps that MIL-53-Al serves as a precursor to prepare the sub-nano AlF3 catalyst, and the specific preparation process comprises the steps that a proper amount of Al (NO3) 3 . 9 H2O and an organic ligand are put into a polytetrafluoroethylene lining to be stirred for 30 min, then put into a hydrothermal kettle and subjected to a hydrothermal reaction at 160-220 DEG C for 0.5-3 d, and naturally cooled to room temperature; and respectively washing with DMF (Dimethyl Formamide) and ethanol in a water bath at 60-80 DEG C for 2-4.5 hours, and drying at 60-120 DEG C for 10-24 hours to obtain white powder MIL-53-Al for later use, and under the action of a fluorine source, fluorinating the white powder (MIL-53-Al) to obtain the sub-nano AlF3 catalyst. The catalyst prepared by the method disclosed by the invention shows extremely high activity and stability in the reaction of preparing fluorine-containing olefin by removing HF from fluorine-containing alkane in a gas phase. The catalyst provided by the invention has the characteristics of simple preparation, high conversion rate, good selectivity, high stability and difficulty in carbon deposition.

Owner:ZHEJIANG UNIV OF TECH

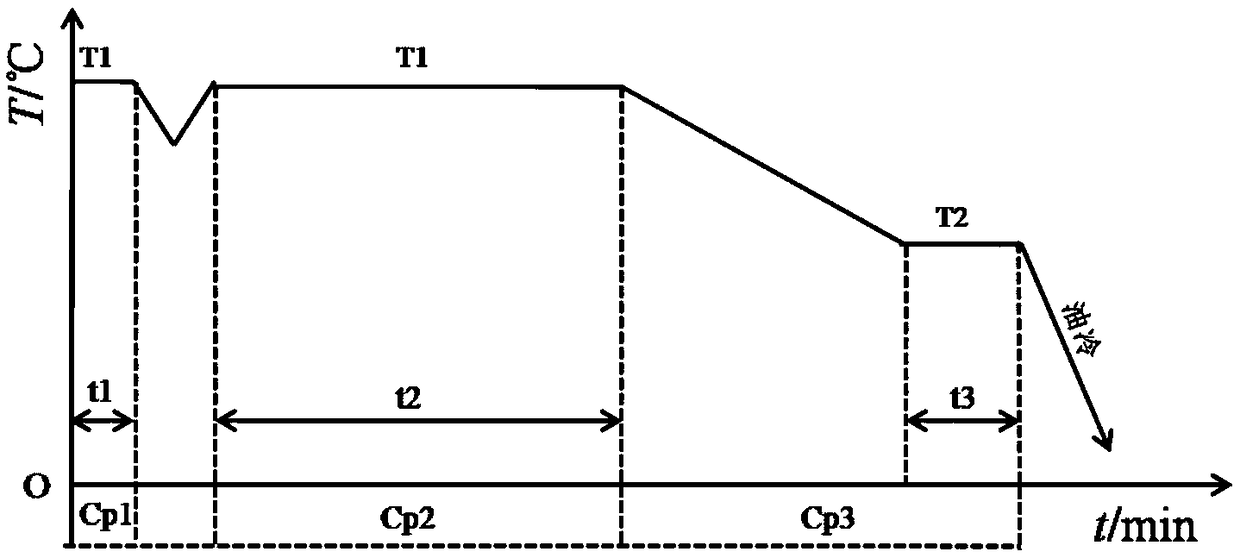

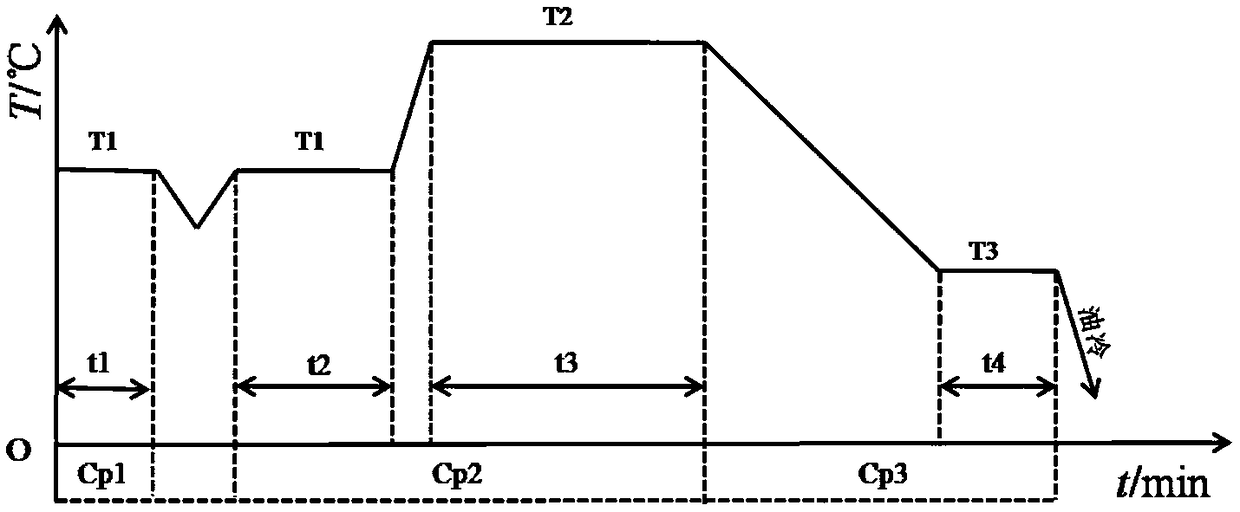

Method for preparing high-stability methanation catalyst carrier

ActiveCN105727920AGood hydrothermal stabilityImprove heat stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationMagnesium salt

The invention belongs to the technical field of catalysis, relates to a method for preparing a high-stability methanation catalyst carrier and particularly relates to a method for preparing a high-stability magnesia-alumina spinel catalyst carrier by adopting a hydrothermal synthesis method. The carrier can be applied to the preparation of a catalyst by a dipping method and is especially suitable for serving as a carrier of a methanation catalyst. The methanation catalyst carrier is prepared through adding water and a dispersant which are in a certain ratio into a soluble magnesium salt or a magnesium oxide and a soluble aluminum salt or an aluminum oxide, then, putting the mixture into a high-pressure reactor, carrying out hydrothermal treatment for certain time under the conditions of certain pressure and temperature, carrying out cooling and depressurizing, opening the high-pressure reactor, taking out the material from the reactor, subjecting the material to washing, carrying out filtering, drying, roasting, pelleting and tabletting forming, and then, carrying out roasting. The carrier has good hydrothermal stability; and the methanation catalyst prepared by adopting the carrier has the characteristics that the heat-resisting stability is good, the applicable temperature zone is wide, carbon deposition is not easy under the condition of high CO content, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodechlorination catalyst and preparation method and application thereof

ActiveCN112547093ANot easy to deposit carbonReduced carbon deposition active centersPreparation by dehalogenationCatalyst activation/preparationActivated carbonPtru catalyst

The invention relates to a hydrodechlorination catalyst and a preparation method and application thereof. The catalyst takes activated carbon as a carrier, active metal components comprise Pd and Cu,auxiliaries comprise Zn, and on the basis of the total weight of the catalyst, the catalyst comprises 0.5-3% by mass of the active metal components, 0.2-2% by mass of the auxiliaries, 800-1500m < 2 > / g of the specific surface area of the catalyst and 0.2-1.5 mmol / g of the total acid content of the catalyst. By modulating the acid property, pore structure and the like of the catalyst, the carbon deposition active center of the catalyst is reduced, the catalyst is not easy to deposit carbon, the side reaction is inhibited, and the service life of the catalyst is prolonged.

Owner:SINOCHEM LANTIAN +2

Carbon nanotube catalyst for preparation of acetaldehyde by selective oxidation of ethanol and application thereof

InactiveCN106311203AImprove performanceHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationAlcoholGas phase

The invention discloses a carbon nanotube catalyst for preparation of acetaldehyde by selective oxidation of ethanol and an application thereof, and belongs to the technical field of applications of catalysts to selective oxidation of gas phase alcohol. A carbon nanotube material which is treated by high temperature is used as the catalyst for a reaction for preparing acetaldehyde by selective oxidation of ethanol, ethanol is converted into acetaldehyde with catalysis in a condition with oxygen, and the usage temperature of the catalyst is 200-350 DEG C; the conditions of the catalytic reaction are as follows: air speed is 10000-50000ml / g.h, the volume concentration of ethanol is 0.1-2%, and volume ratio of ethanol to oxygen is 0.1-10; the catalyst has stable performance, carbon deposition is not easy to happen in a reaction process, the treatment conditions of the catalyst are simple, and industrial application is easy to realize.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing cyclohexane through benzene hydrogenation

ActiveCN107973681AAchieve stabilityHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationBenzeneHydrogen

The invention provides a method for preparing cyclohexane through benzene hydrogenation. The method comprises two-stage hydrogenation procedures. In the primary hydrogenation procedure, a high polymermaterial-supported Raney nickel catalyst, benzene and hydrogen contact with each other for a reaction so as to obtain a first material flow; in the secondary hydrogenation procedure, a compound hydrogenation catalyst contacts with the first material flow for a reaction; the high polymer material-supported Raney nickel catalyst comprises a high polymer material used as a carrier and Raney alloy particles loaded on the surface of the high polymer material, wherein the Raney alloy particles are loaded on the surface of the high polymer material in the form of partial embedding into the high polymer material; and the compound hydrogenation catalyst comprises continuous-phase carbon and dispersion-phase Raney alloy particles. The method makes full use of the respective advantages of two catalysts in the two-stage hydrogenation procedures to realize complete hydrogenation of benzene for production of cyclohexane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995BThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustDust control

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

Mesoporous selective molecular sieve and preparation method thereof

InactiveCN107324356AImprove fluidization stateNot easy to deposit carbonCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a mesoporous selective molecular sieve and a preparation method thereof. The mesoporous selective molecular sieve is obtained by performing alkali treatment on IM-5 zeolite with the silica-alumina ratio being 10 to 14. The preparation method comprises the following steps that the IM-5 zeolite is added into an alkali treatment solution for alkali treatment; after filtering, washing and drying, the mesoporous selective molecular sieve is obtained, wherein the alkali treatment solution comprises one or a combination of several of a NaOH solution, a KOH solution, a TPAOH solution and a TBAOH solution. The mesoporous IM-5 molecular sieve can be applied to cracking reaction; the mesoporous IM-5 molecular sieve has rich mesopores, so that in the reaction process, the catalyst fluidizing state is better; heavy oil macromolecules can easily approach to the active center; cracked products can be easily diffused; the yield of ethylene and propylene is relatively high; catalysts cannot generate carbon deposition, so that the catalysts have good catalytic activity and long service life.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

12Cr2Ni4A material gas carburizing and quenching method

InactiveCN109385596ANot easy to deposit carbonExtended service lifeSolid state diffusion coatingFurnace typesPre treatmentControllability

The invention discloses a 12Cr2Ni4A material gas carburizing and quenching method. The 12Cr2Ni4A material gas carburizing and quenching method successively comprises the following steps: atmosphere construction, feeding of workpieces into a furnace, pretreatment, conventional carburization, quenching, cryothermal treatment and low tempering, wherein during pretreatment, a part is insulated for a certain time at the temperature which is higher than a carburizing steel critical temperature (20-40 DEG C) and under the carbon potential of austenite saturated carbon concentration, thus, the surfaceof carburizing steel sufficiently absorbs carbon and carbide nucleuses, and the carburizing steel grows up to a certain size. The carbon potential in the furnace is monitored by an oxygen probe, thepretreatment is added before the conventional carburization, the process is simple, the repeatability is good, automatic production is easy to implement, controllability is good, and the efficiency ishigh; the used carbon potential is not high, the oxygen probe does not have carbon deposit easily, and the service life is long; and carbides formed by the pretreatment stops high-temperature austenite from growing up, a preheating effect is achieved, deformation of workpieces is relieved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

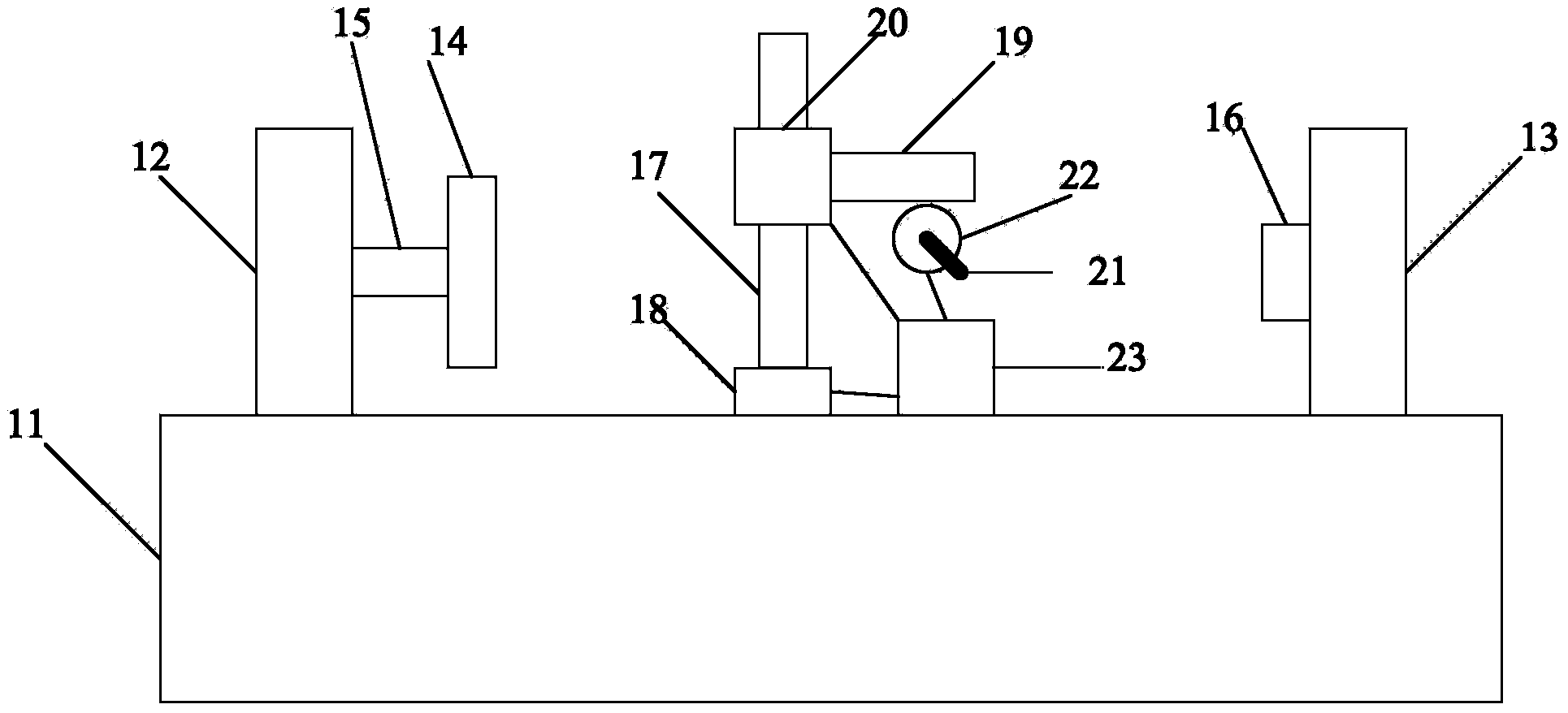

Air valve machining device with angle-adjustable cutters

InactiveCN103506890AExtended service lifeIncrease powerAutomatic control devicesInternal combustion piston enginesEngineeringMachining

The invention discloses an air valve machining device with angle-adjustable cutters. A first motor, a second motor and a rotating motor are installed on a cutter support, wherein the first motor is used for adjusting the vertical positions of the cutters, and the second motor is used for adjusting the positions of the cutters in the direction of an air valve shaft. The cutters can be directly installed by rotating the motors, the machining angles of the cutters can be adjusted and radian machining of arc surfaces can be achieved. The air valve machining device with the angle-adjustable cutters eliminates protruding edges probably generated between the two cutters, ensures that carbon is not easily accumulated when the air valve arc surfaces work, prolongs the service life of an air valve and accordingly increases the power of an engine and prolongs the service life of the engine.

Owner:ANHUI WODE VALVE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com