High-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming and application of high-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming

A nickel-based catalyst and dispersant technology, applied in the chemical industry, can solve problems such as poor stability, high equipment material requirements, harsh operating conditions, etc., achieve broad industrial utilization prospects and value, reduce enterprise operating costs, and realize resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

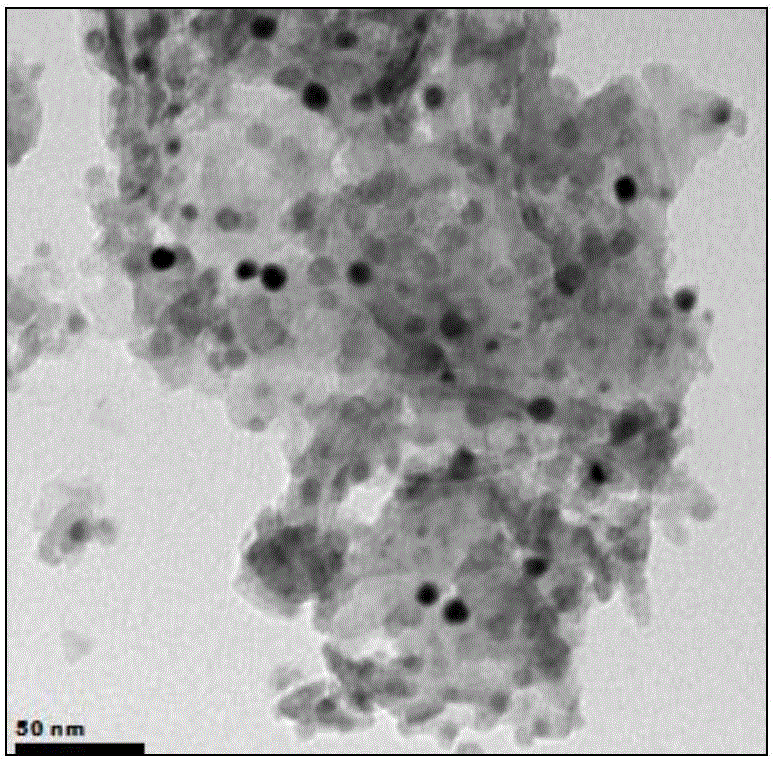

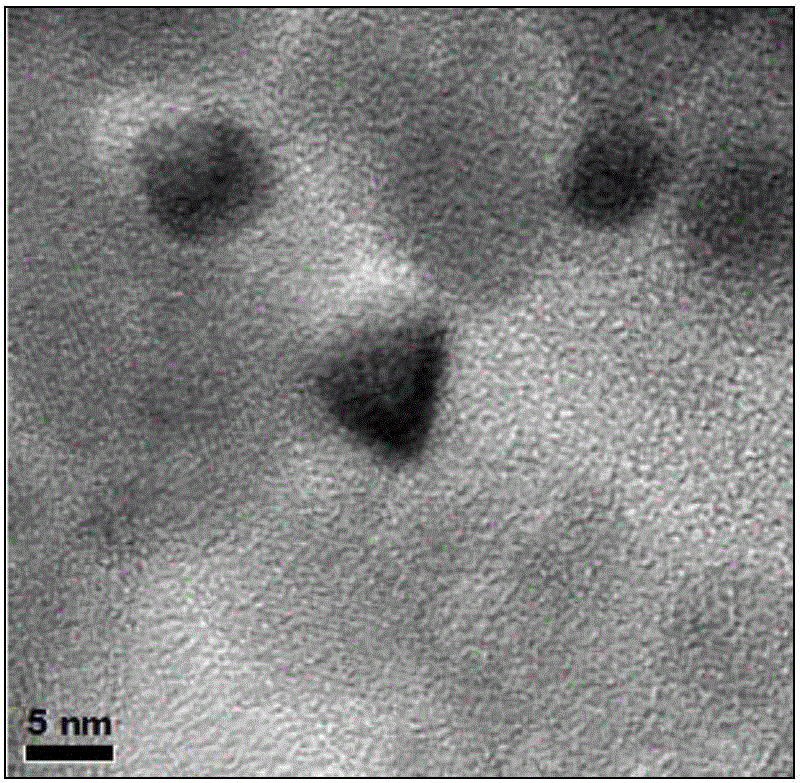

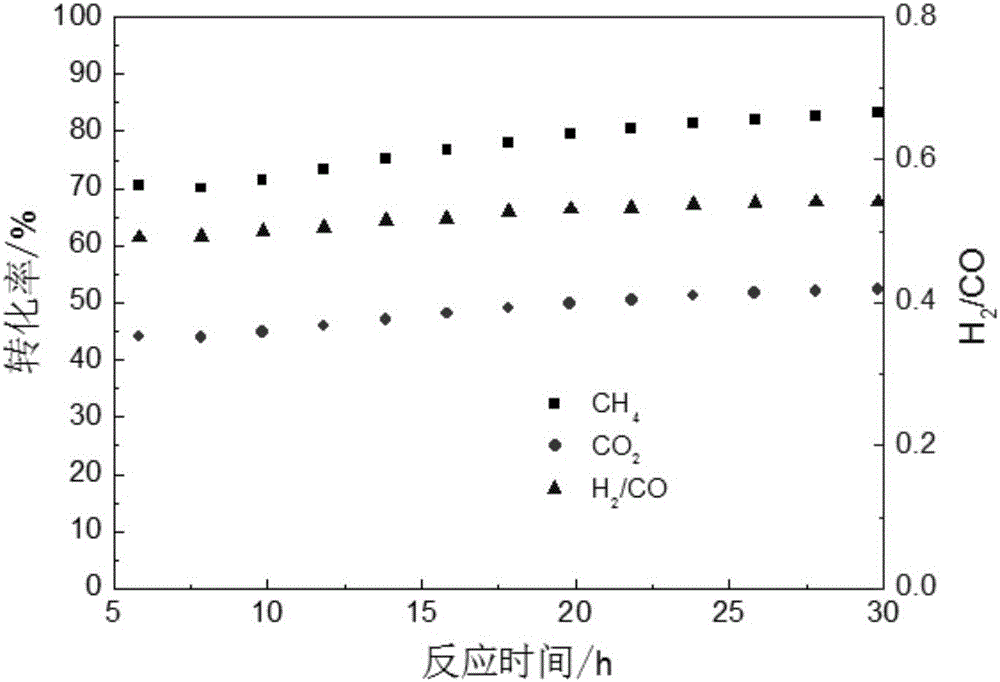

[0070] By Ni-Ca / Al 2 O 35g of carrier alumina with a mass percentage of 75% in the finished catalyst product is used as the calculation basis, and the mass percentage of the active component Ni element is 20%, and the mass percentage of the synergistic component Ca element is 5%. The ratio of 1:1 is calculated to obtain the desired preparation of Ni-Ca / Al 2 O 3 The mass of the reactants in the finished catalyst product was 5.000 g of α-alumina, 6.606 g of nickel nitrate, and 1.964 g of calcium nitrate. And according to the formula V=n / C, the nickel element concentration in the reaction solution is 0.13mol / L to calculate the consumption of deionized water and n-butanol mixed solvent (the volume ratio of deionized water and n-butanol is 1:1) 175ml. And calculate the consumption of sodium dodecylbenzenesulfonate according to 1% of solvent quality.

[0071] Add α-alumina, nickel nitrate, calcium nitrate and sodium dodecylbenzene sulfonate to a mixed solvent composed of deioni...

Embodiment 2

[0075] By Ni-Ca-La / Al 2 O 3 In the finished catalyst, 5 g of carrier alumina with a mass percentage of 75% is used as the calculation basis, and the mass percentage of the active component Ni element is 20%, the mass percentage of the synergistic component Ca element is 3%, and the mass percentage of the synergistic component La element Calculated as 2%, and calculated according to the molar ratio between the corresponding elements of 1:1, to obtain the desired preparation of Ni-Ca-La / Al 2 O 3 The mass of reactants in the finished catalyst, in which β-Al(OH) 3 7.650 g, 5.653 g of nickel acetate, 0.879 g of calcium acetate, and 0.312 g of lanthanum nitrate. And according to the formula V=n / C and the nickel element concentration in the reaction solution is 0.2mol / L, the amount of absolute ethanol needed as a solvent is calculated as 113.6ml. And the amount of polyethylene glycol is calculated according to 1% of the solvent mass.

[0076] Use 113.6ml of absolute ethanol as s...

Embodiment 3

[0080] By Ni-Ce-Zr-Y / Al 2 O 3 5g of carrier alumina with a mass percentage of 74.8% in the finished catalyst product is used as the calculation basis, and the mass percentage of the active component Ni element is 20%, the mass percentage of the synergistic component Ce element is 3%, and the mass percentage of the synergistic component Zr element 2%, the mass percentage of the synergistic component Y element is 0.2%, and the molar ratio between the corresponding elements is 1:1 to obtain the desired preparation of Ni-Ce-Zr-Y / Al 2 O 3 The mass of reactants in the finished catalyst, in which γ-Al 2 O 3 5.000 g, 6.624 g of nickel nitrate, 0.621 g of cerium nitrate, 0.629 g of zirconium nitrate, and 0.058 g of yttrium nitrate. And according to the formula V=n / C and the nickel element concentration in the reaction solution is 0.2mol / L, the amount of deionized water needed as a solvent is calculated as 113.9ml. And the amount of polyethylene glycol is calculated according to 1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com