Patents

Literature

256 results about "Zr element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium (Zr), chemical element, metal of Group 4 (IVb) of the periodic table, used as a structural material for nuclear reactors.

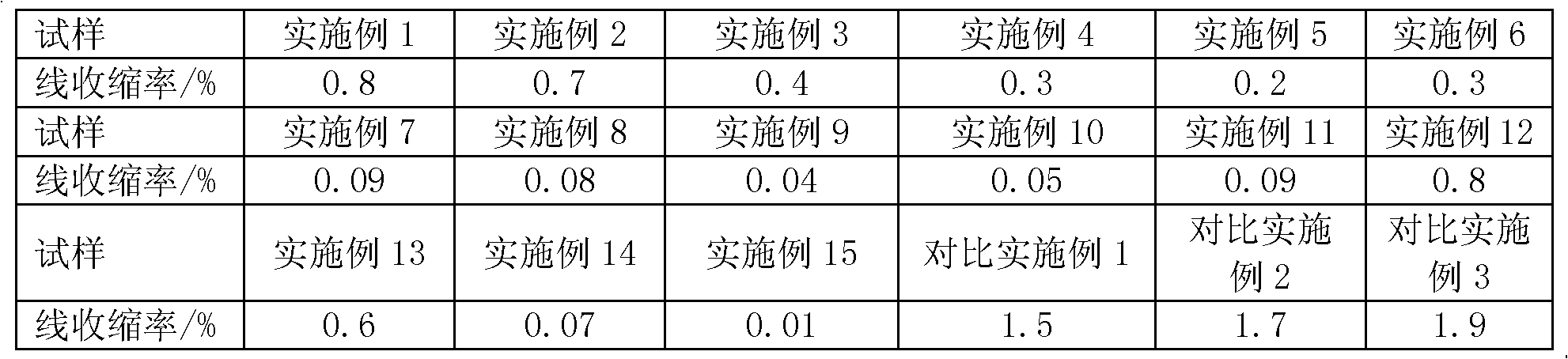

Cast magnesium alloy of low linear shrinkage

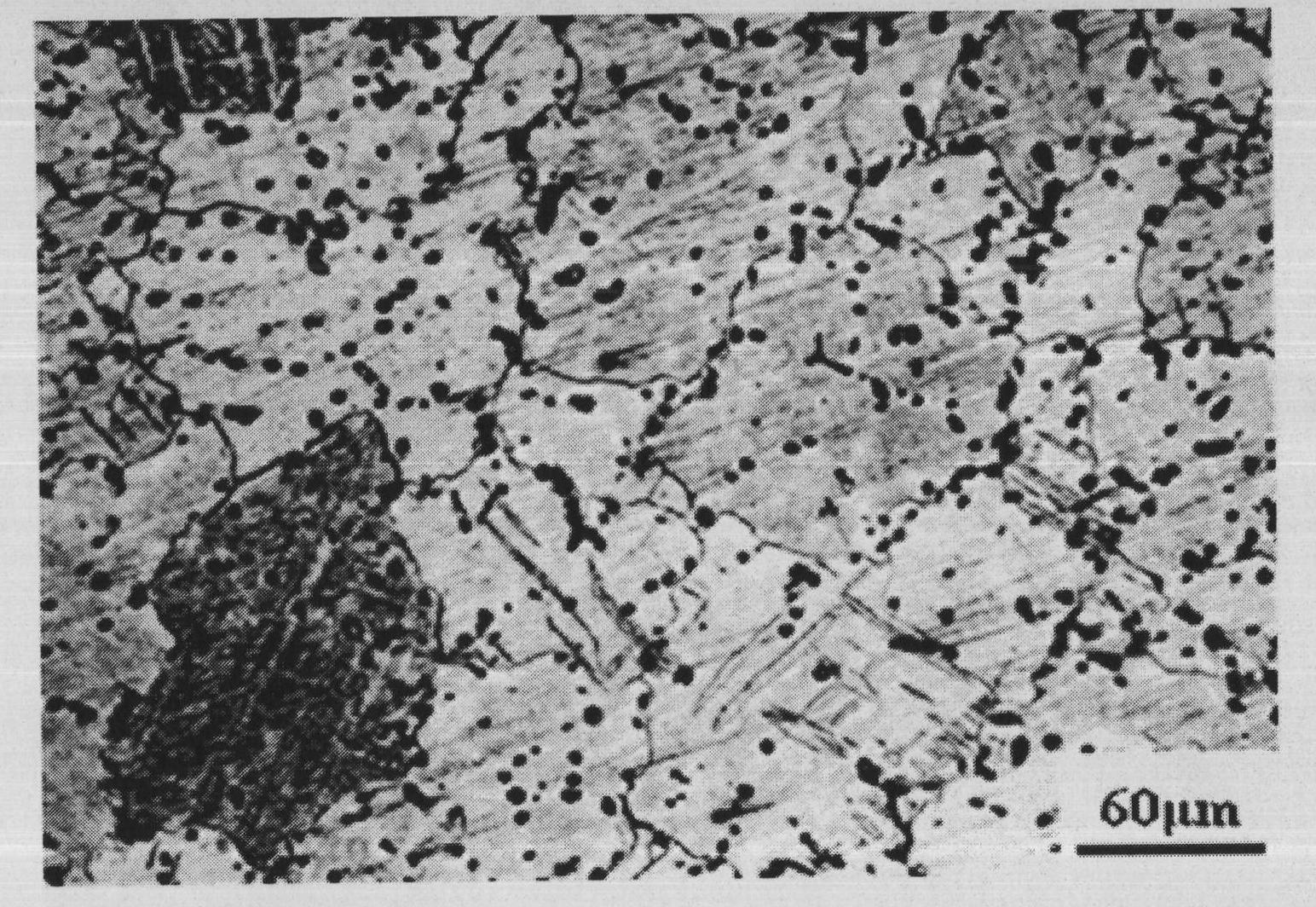

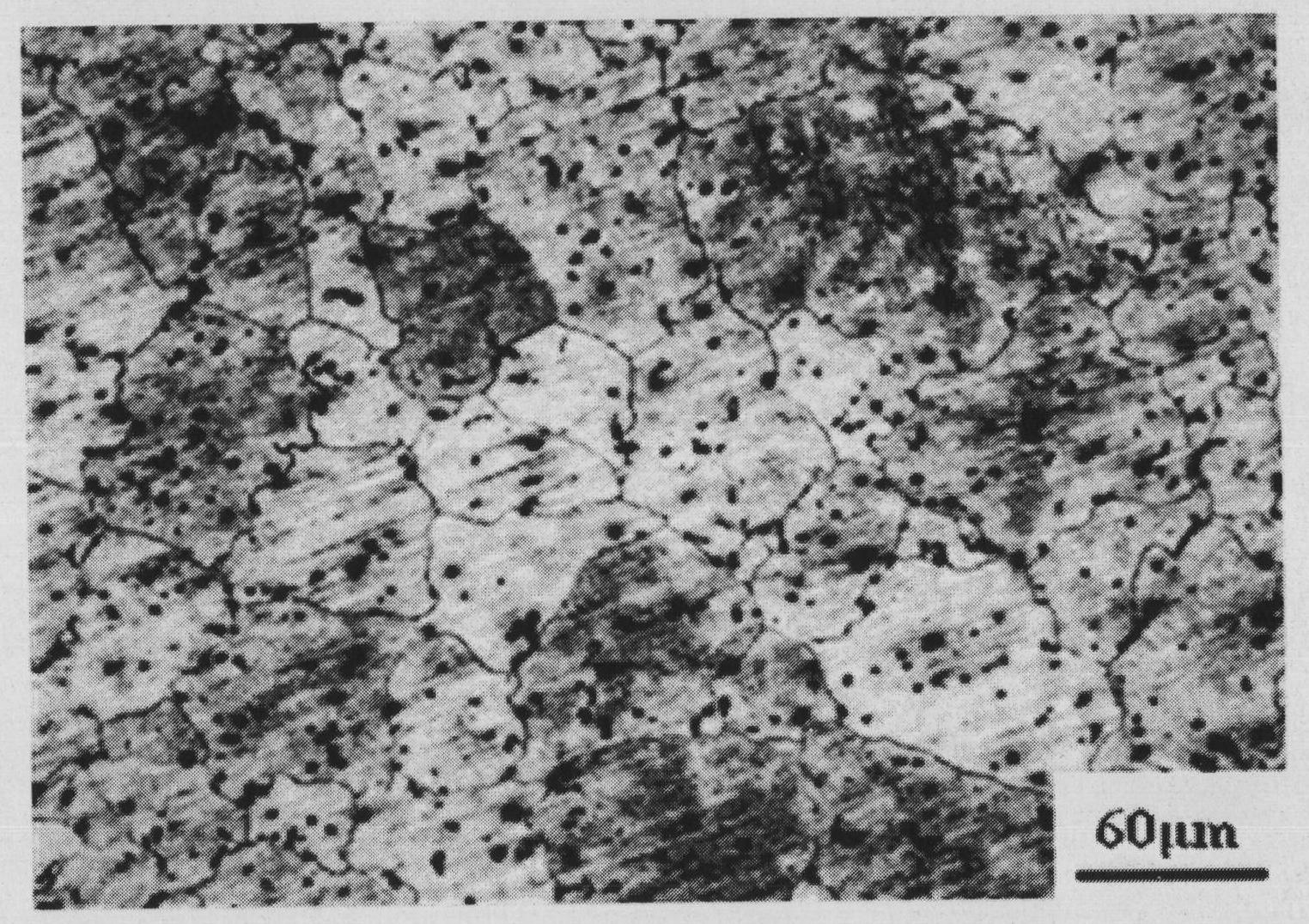

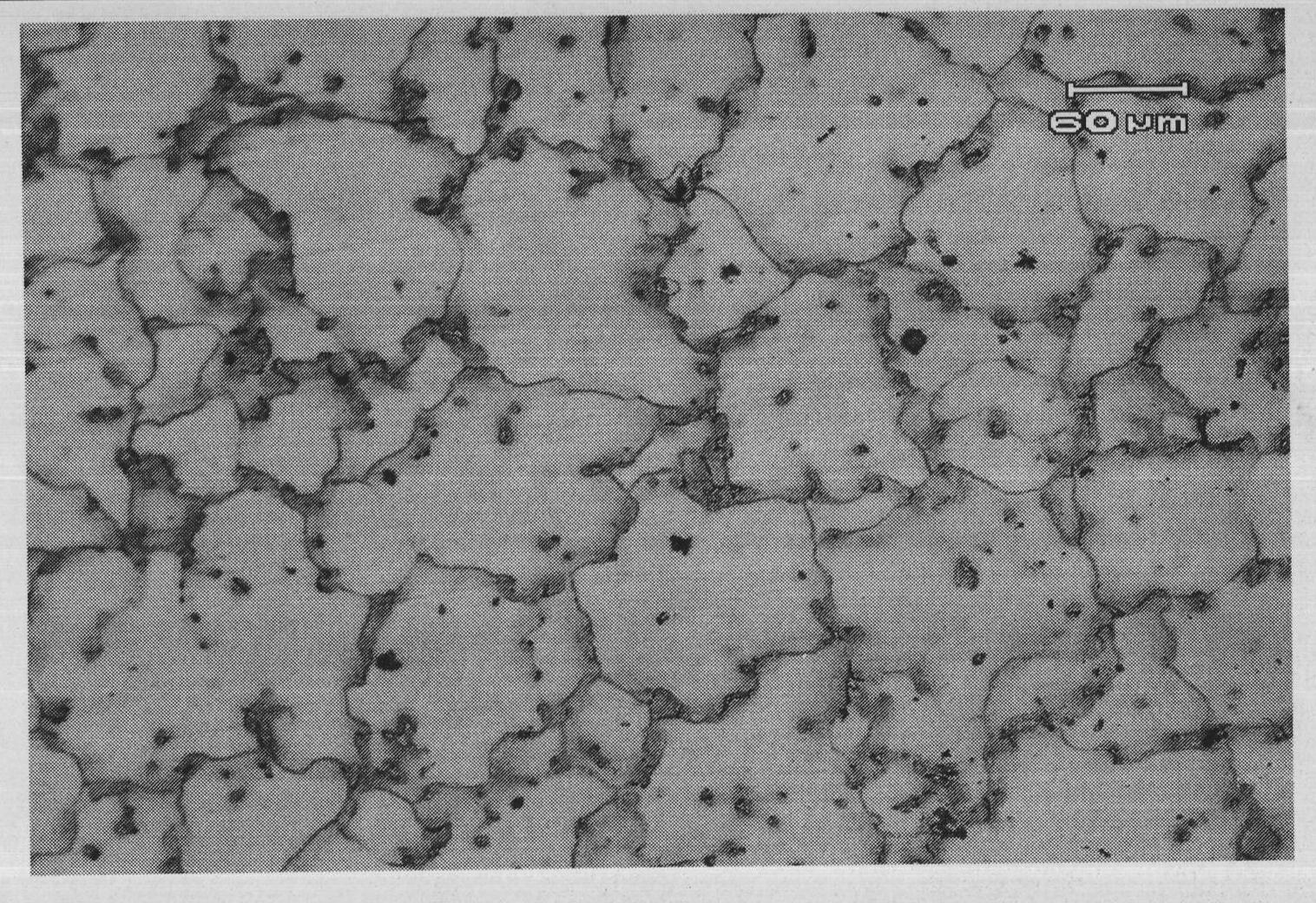

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method has high temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

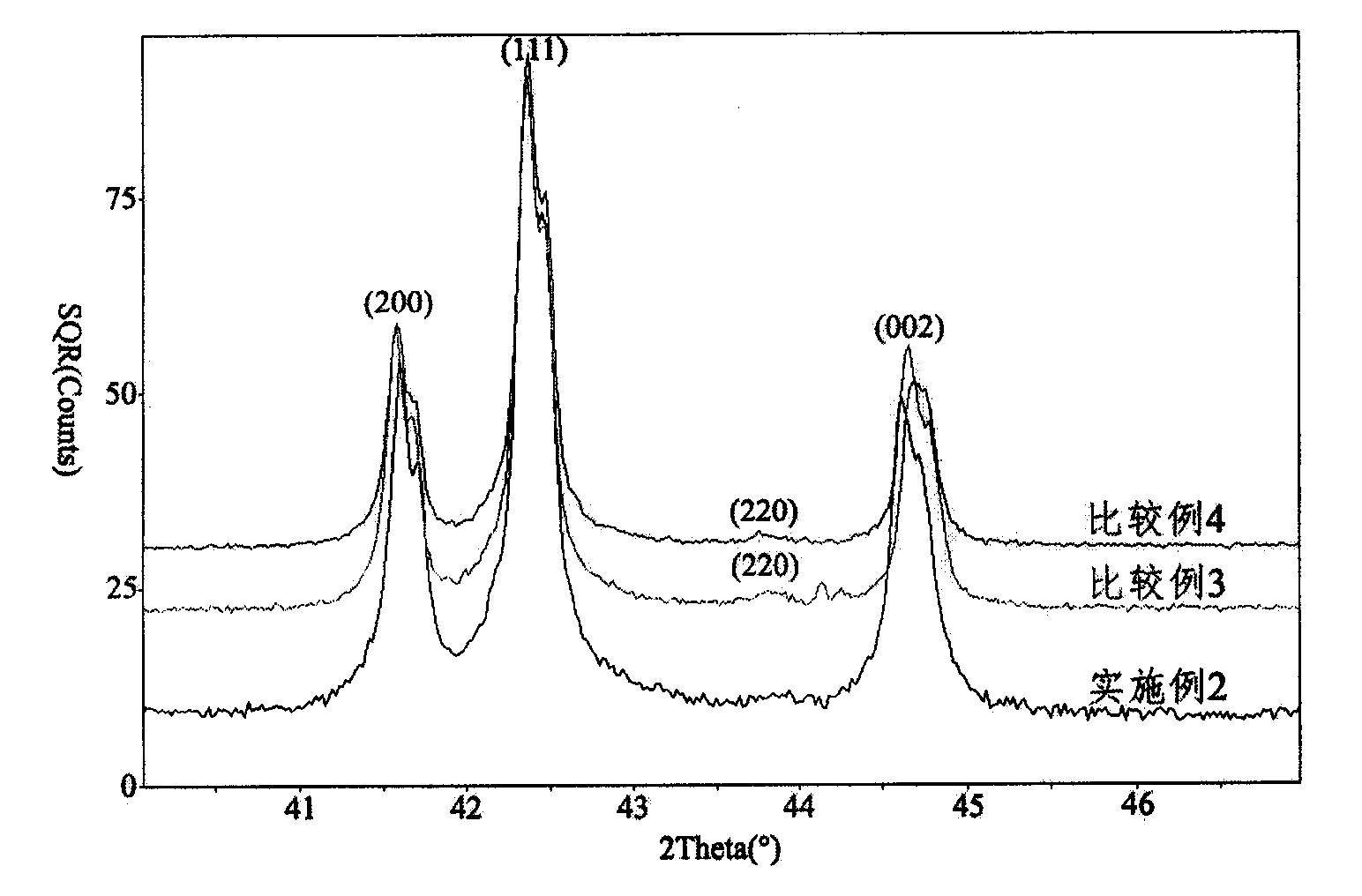

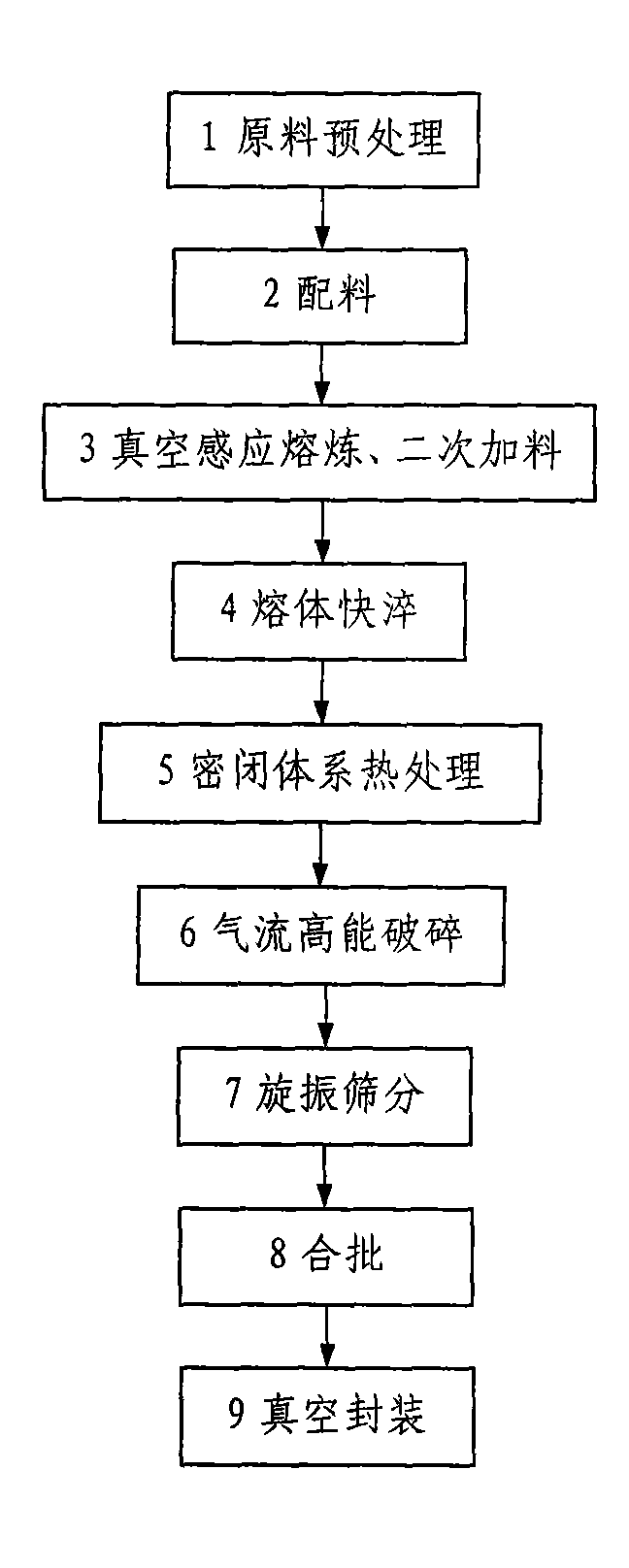

Low-cost high-performance rare-earth-based AB5-type hydrogen storage alloy and preparation method thereof

ActiveCN101629255AIncrease capacitySolution to short lifeFurnace typesHeat treatment furnacesRecovery performanceRare earth

The invention relates to a low-cost high-performance rare-earth-based AB5-type hydrogen storage alloy and a preparation method thereof. The alloy has a general formula: Ml(Ni(1-x-y-w)CoxMnyAlzMw)mMgn, wherein x, y, z, w, m and n present a mol ratio; x is larger than zero and smaller than or equal to 0.1; y is larger than zero and smaller than or equal to 0.2; z is larger than zero and smaller than or equal to 0.2; w is larger than or equal to zero and smaller than or equal to 0.06; m is larger than or equal to 4.8 and smaller than or equal to 5.5; n is larger than zero and smaller than or equal to 0.1; the Ml comprises La and at least one element selected from Ce, Pr, Nd, Sm, Gd, Dy, Y, Ca, Ti and Zr; the content of the La in the Ml is 40-80 percent by weight; accordingly, the content of the La in the alloy is 10-26 percent by weight; and the M comprises at least one element of Cu, Fe, Si, Ge, Sn, Cr, Zn, B, V, W, Mo Ta and Nb. The alloy has high content, long service life, low Co content, low cost and good recovery performance.

Owner:XIAMEN TUNGSTEN +1

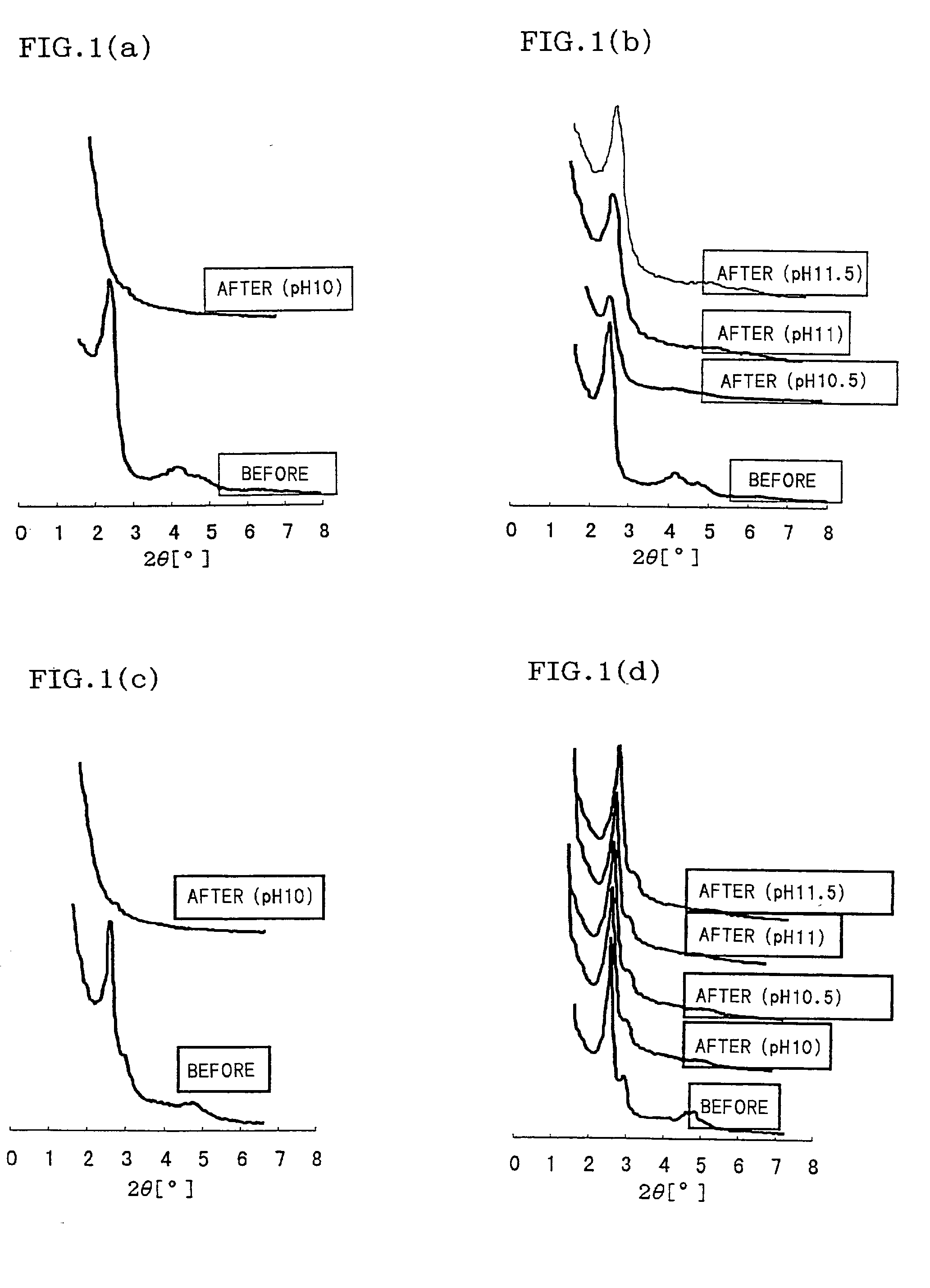

Mesoporous silica, mesoporous silica composite material, and processes for production thereof

A mesoporous silica has uniform mesopores and a periodic structure, which contains a Zr element in the form of a Si-O-Zr bond and wherein the Zr content in the Si-O-Zr bond, represented by [Zr / (Si+Zr)] is 0.05 to 20 mole %. The mesoporous silica is superior in alkali resistance and is suitably used particularly as a separation membrane (e.g. a ceramic membrane) and a catalytic support for solid-liquid system, in which an alkaline liquid may be used.

Owner:NGK INSULATORS LTD +1

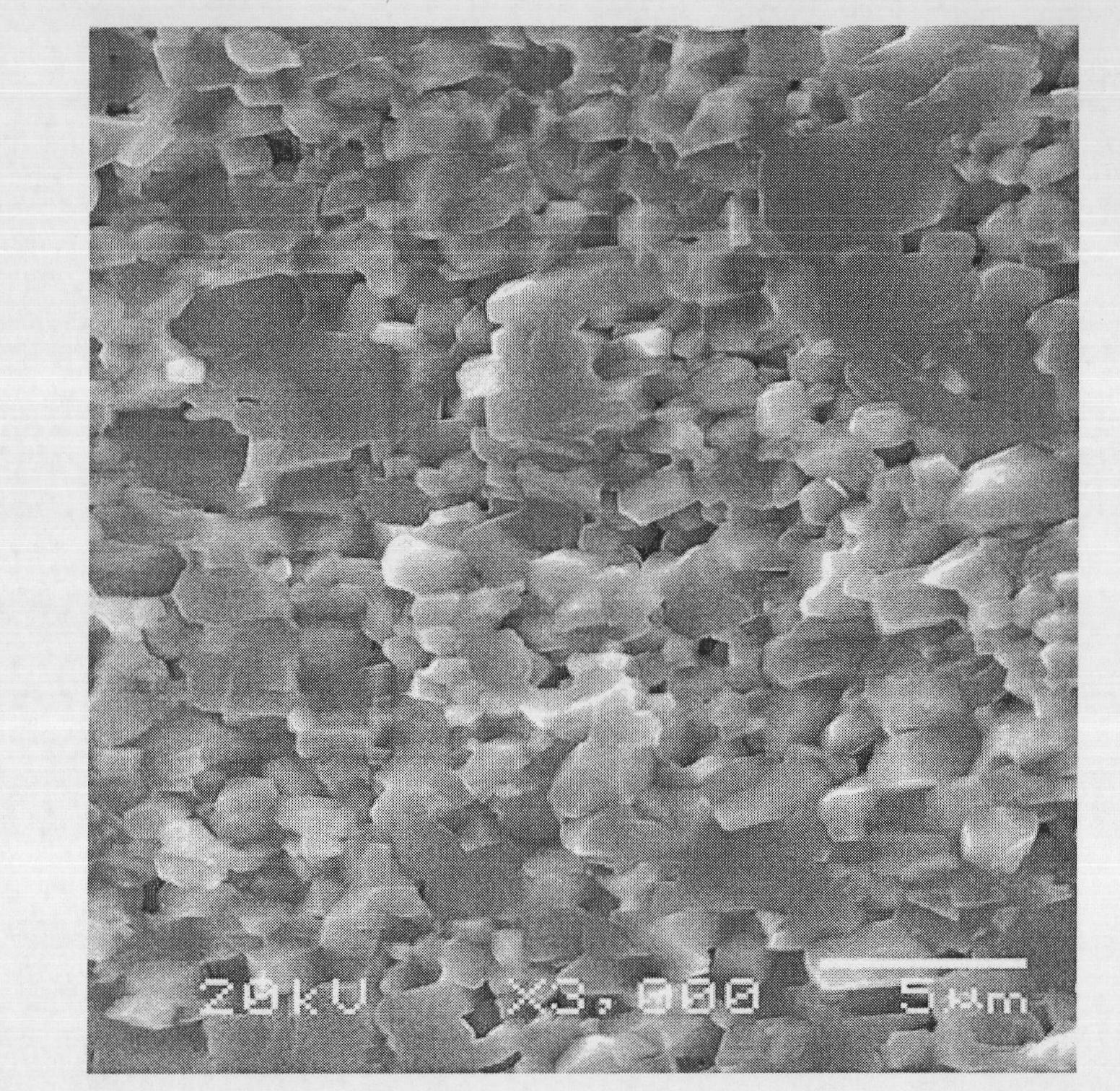

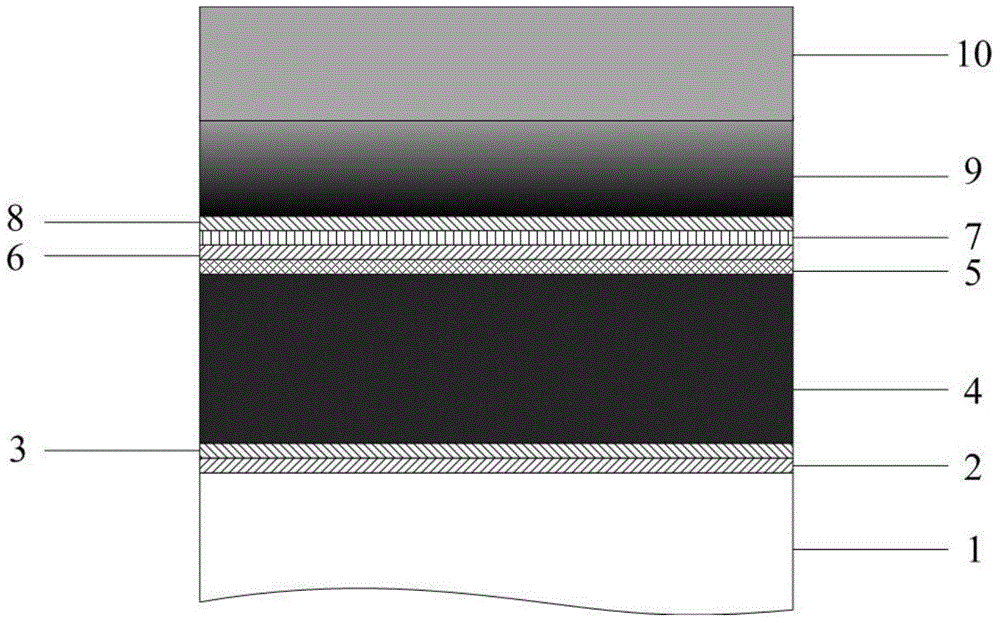

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

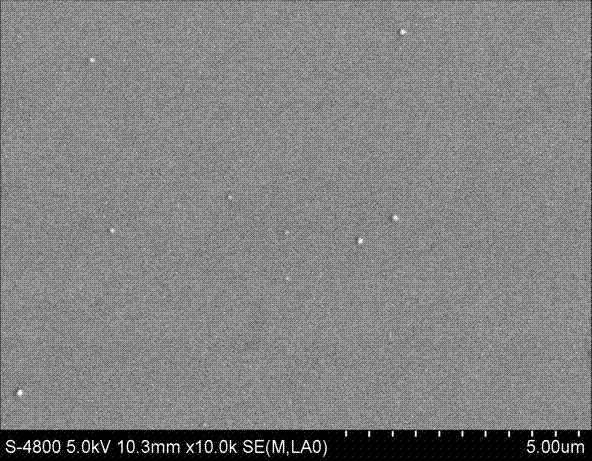

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

Ceramic particle reinforced aluminium-based composite material and powder metallurgical process to prepare the material

The present invention belongs to the field of composite material preparation technology. The composite material has the chemical expression of: AlaMgbBcMd, Where a is 50-96, b 1-7, c3-30 and d 0-13; M is one or several of Si, Cu, Ni, Ti, Fe, Cr, La, Mn, Ce, Zn, V and Zr. The preparation process is one combined powder metallurgy and in-situ reaction process and includes mixing material powder, cold pressing the mixture for forming, heating the formed mixture and hot pressing for the material powder to produce chemical reaction at temperature over 950 deg.c. Inside the aluminum alloy base, A1MgB14 ceramic phase particle as reinforcing phase is formed to prepare the composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material has light weight and high strength, integrated functions, and may be used widely in transport industry and national defence industry.

Owner:SHANGHAI JIAO TONG UNIV

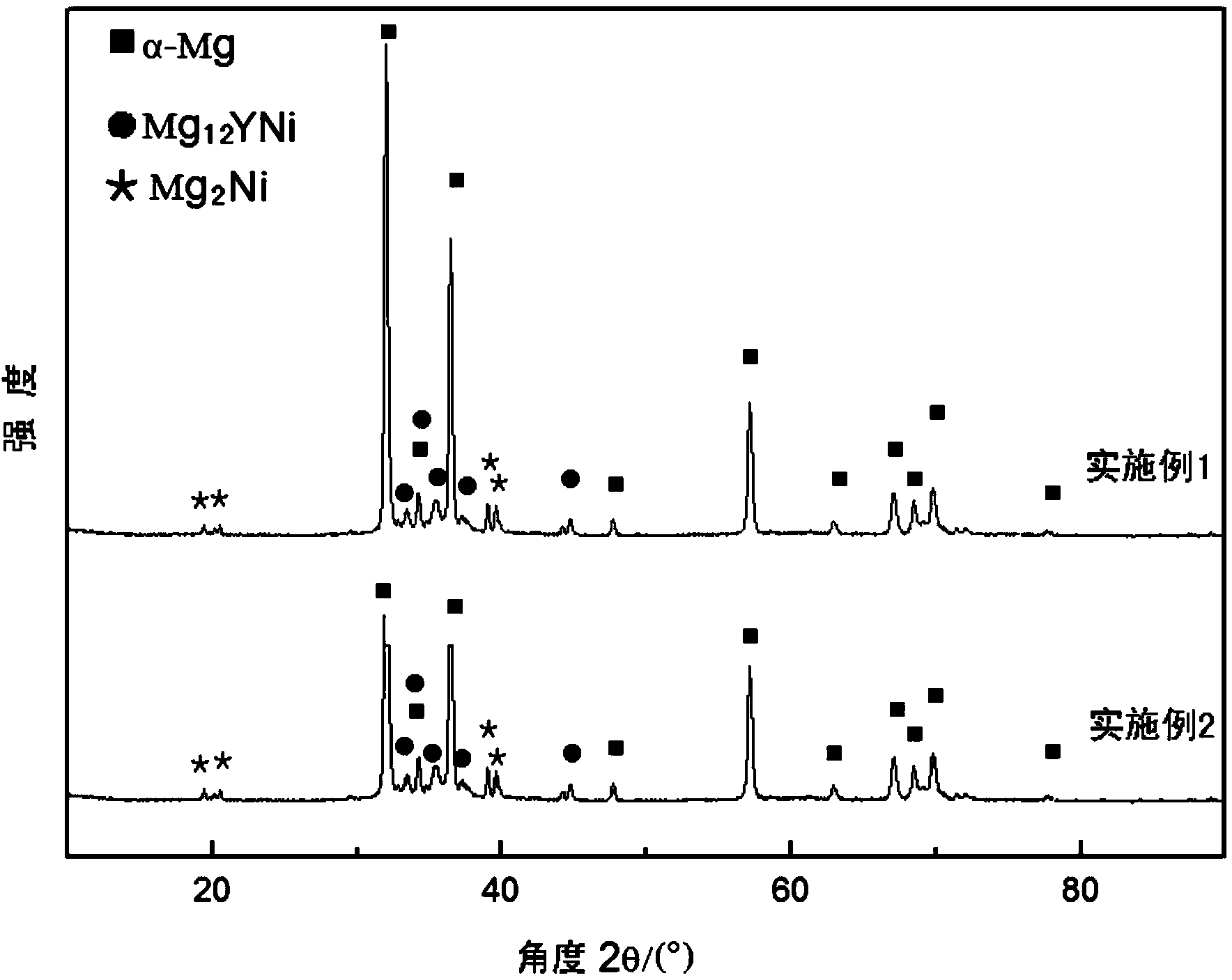

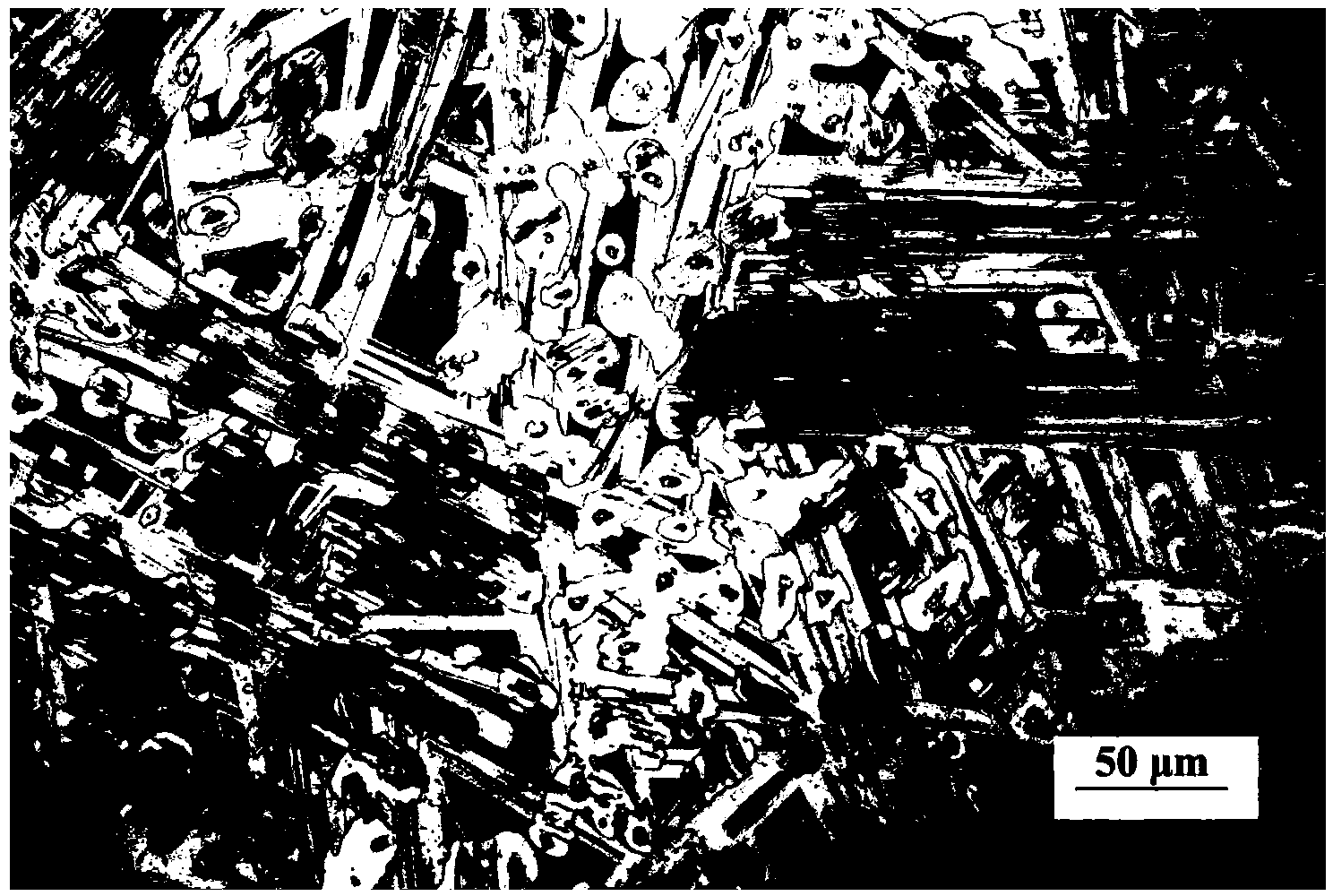

High-strength and high-plasticity magnesium alloy

The invention discloses a high-strength and high-plasticity magnesium alloy. The high-strength and high-plasticity magnesium alloy comprises the following components in percentage by mass: 3.0-4.5% of Ni, 4.0-5.0% of Y, 0.01-0.1% of Zr, not more than 0.15% of inevitable impurities and the balance of magnesium. According to the high-strength and high-plasticity magnesium alloy disclosed by the invention, Y and Ni elements are simultaneously added into a magnesium matrix, and in the smelting and molding process of the alloy, Y and Ni form Mg2Ni and Mg12YNi phases with the magnesium matrix, wherein the Mg12YNi phase is a long-period stacking ordered structure (LPSO), so that the strength of the alloy can be improved, and the plasticity of the alloy can also be improved; and Mg2Ni can improve the strength of the alloy by a strengthening mechanism of the second phase. According to the high-strength and high-plasticity magnesium alloy disclosed by the invention, an appropriate amount of Zr element is further added into the alloy, and zirconium can be dispersed and distributed in the matrix in an elemental form by controlling the smelting and molding process to play a role in refining grains.

Owner:CHONGQING ACADEMY OF SCI & TECH

Magnetoplumbate-type permanent magnetic ferrite and manufacturing method thereof

InactiveCN101844914AImprove powder propertiesUniform powder propertiesCrystal structureProcess design

The invention relates to a magnetoplumbate-type permanent magnetic ferrite and a manufacturing method thereof, which relate to the field of the permanent magnet. Main component of the magnetoplumbate-type permanent magnetic ferrite is expressed by the following formula: (1-x-y)Ca0.xSrO.(y / 2)R2O3.(n-z / 2-m / 2)Fe2O3.zMO.MzrO2, wherein R is of at least one element of La, Nd and Pr and contains La, M is selected from at least one element of Co, Zn, Ni, Mn and Cu and contains Co, and x, y, z, m and n respectively indicating the addition ratio of each main metal element calculated at mol. By adopting optimized formula and process design and adding less Zr element, the Zr element is introduced into ferrite lattice during the pre-burning process so as to inhibit the growth of abnormal crystal particle and to reduce the pores; moreover, N(CH2CH2OH)3 dispersing agent is particularly added, the appearance of the powder particles is effectively controlled, so the obtained crystal particles are moreuniform, the arrangement of the crystal structure is more compact, and the permanent magnetic ferrite material is obtained under the condition that substitute of the Co element is not high.

Owner:杨宗维

TiSiN-WS2/Zr-WS2 coated cutting tool and preparation process thereof

InactiveCN104060222AImprove the lubrication effectReduce wearVacuum evaporation coatingSputtering coatingIntermediate frequencyCombined method

The invention relates to a TiSiN-WS2 / Zr-WS2 coated cutting tool and a preparation process thereof. The matrix material of the TiSiN-WS2 / Zr-WS2 coated cutting tool is a hard alloy, and the cutting tool is prepared by adopting a multi-arc ion plating and intermediate-frequency magnetron sputtering combined method; and a coating is of a multilayer structure and sequentially comprises a Ti+TiN transition layer, a TiSiN layer, a TiN+Ti+Ti / Zr+Zr transition layer, a WS2 / Zr layer and a WS2 layer from the matrix to the surface coating of the tool, wherein the content of Zr element in the WS2 / Zr layer is gradually reduced from inside to outside. Due to the gradient change of Zr element in the WS2 / Zr layer, the hardness and the bearing capability of a lubricating layer are increased, a better transition between the TiSiN layer and the WS2 layer is achieved, and thus the lubricating effect is enhanced. The high hardness and high wear resistance of the TiSiN layer and the lubricating property of the WS2 coating are well combined, thereby preventing adhering, reducing a cutting force and a cutting temperature, reducing the abrasion of the tool, and prolonging the service life of the tool. The cutting tool can be widely applied to dry cutting and cutting of a difficult-to-machine material.

Owner:SHANDONG UNIV

Low-cost magnesium alloy with high room-temperature plastic deformation and preparation process thereof

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Crystal grain refining agent for aluminum or aluminum alloy

Owner:BEIJING UNIV OF TECH

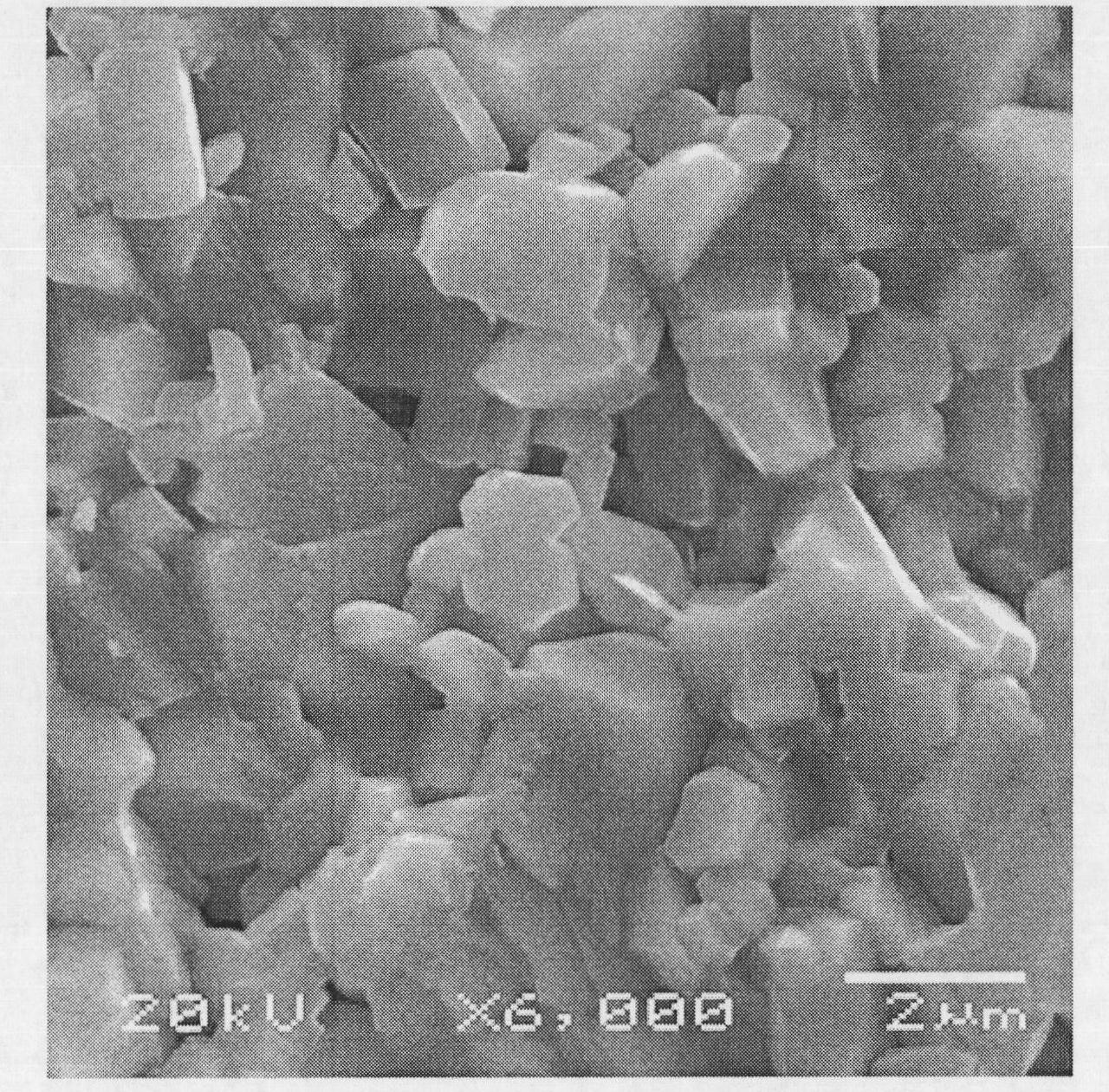

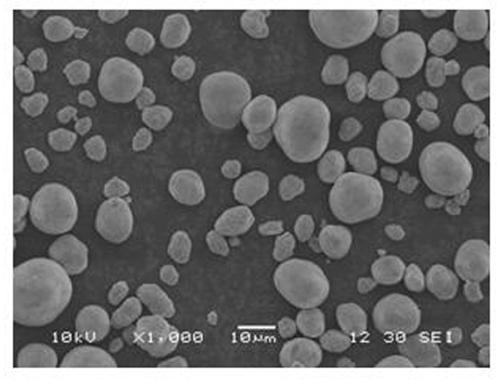

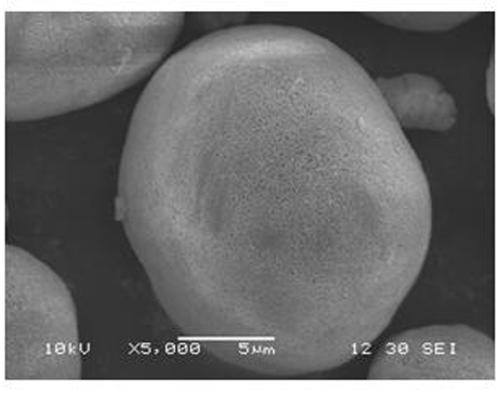

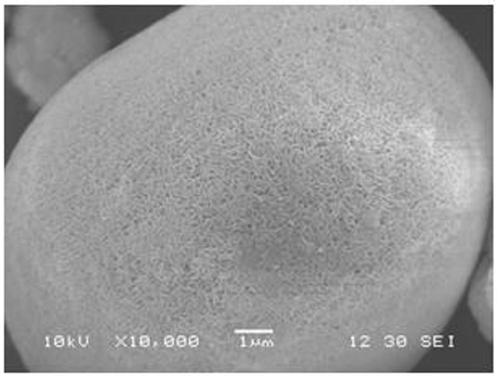

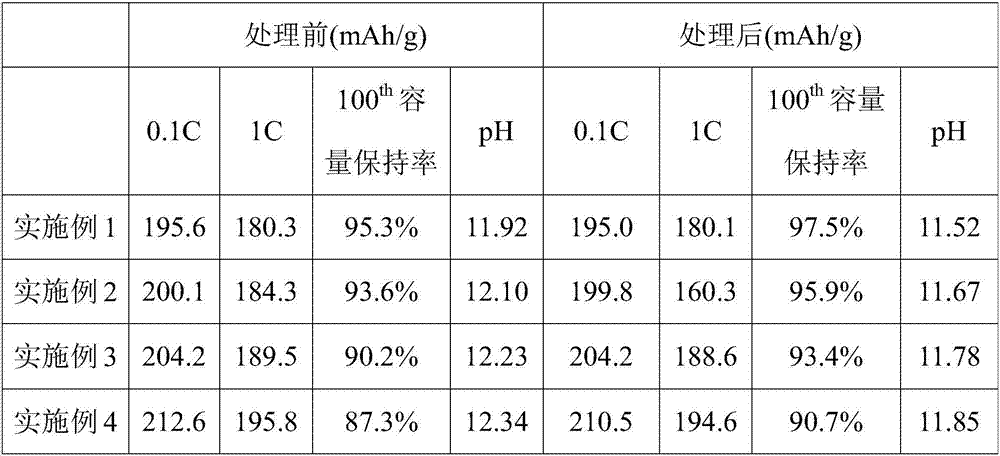

Wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and preparation method thereof

ActiveCN110127777AIncrease capacityImprove cycle stabilityNickel compoundsConcentration gradientCobalt

The invention discloses a wet-method zirconium-doped concentration-gradient nickel-cobalt-aluminum ternary precursor and a preparation method thereof. The nickel-cobalt-aluminum ternary precursor hasa chemical general formula of NixCoyAlz(OH)2, wherein x+y+z=1, 0.3<=x<=0.9, 0.01<=y<=0.4, and 0.01<=z<=0.4; the Zr element accounts for 0.001%-3% of the total mass of the nickel-cobalt hydroxide precursor, the ternary precursor consists of three layers, and the inner layer is a zirconium-doped nickel-cobalt binary precursor with a molecular formula of NixCoy(OH)2; and the outer layer is a zirconium-doped nickel-cobalt-aluminum ternary precursor with a molecular formula of NixCoyAlz(OH)2, and the intermediate layer is a concentration-gradient precursor between the zirconium-doped nickel-cobaltbinary precursor and the zirconium-doped nickel-cobalt-aluminum ternary precursor. The invention also includes the method for preparing the nickel-cobalt-aluminum ternary precursor. The zirconium-doped nickel-cobalt-aluminum ternary precursor has a narrow particle size distribution and good particle morphology, the doped element is distributed uniformly through complex controlled crystallizing co-precipitation, and a positive-electrode precursor prepared from the zirconium-doped nickel-cobalt-aluminum ternary precursor has high specific capacity, good cycling stability, good processability andstable performance.

Owner:ZHUJI PAWA NEW ENERGY

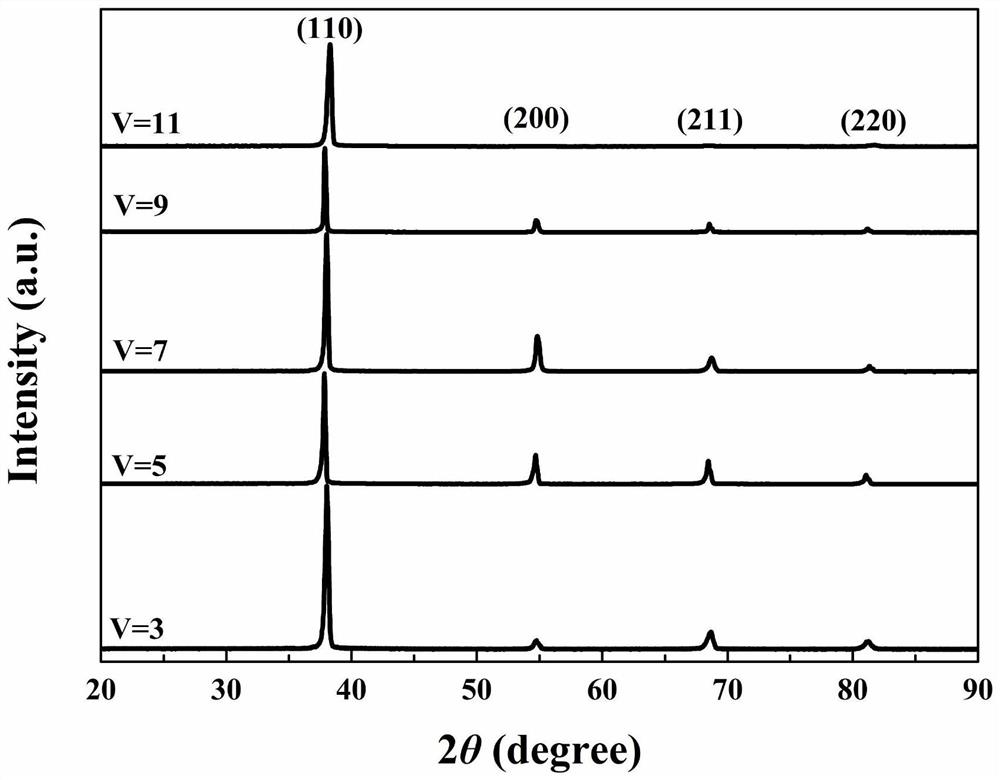

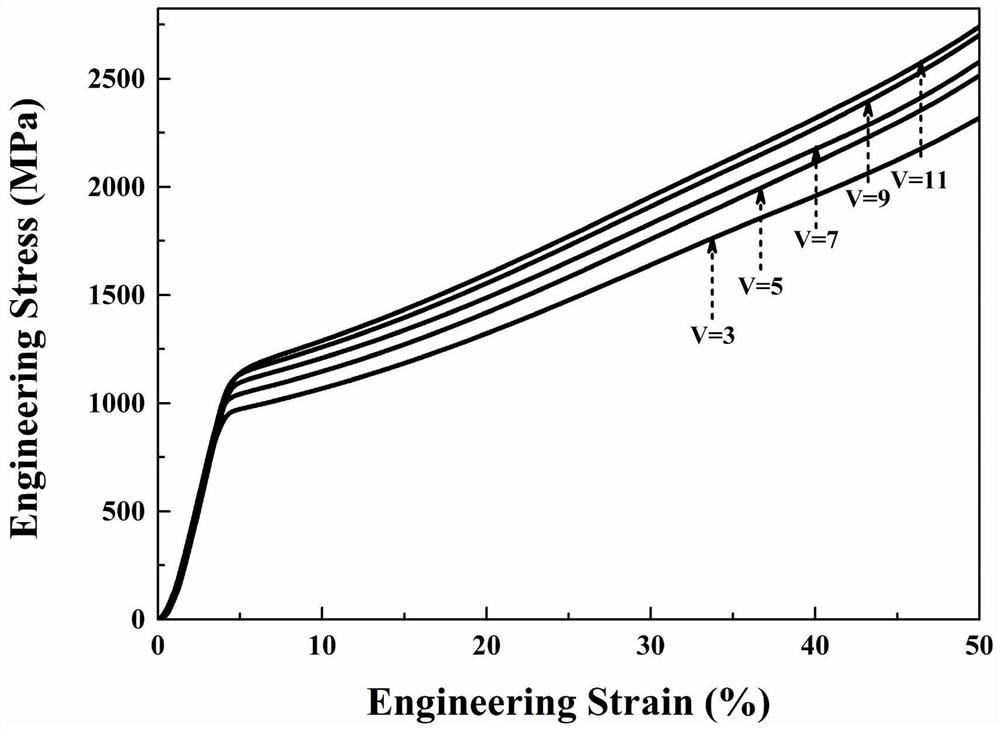

Refractory high-entropy alloy material with high plasticity and low neutron absorption section and preparation method thereof

InactiveCN112708817AHigh melting pointExcellent high temperature mechanical propertiesOptical rangefindersNuclear energy generationHigh entropy alloysUltimate tensile strength

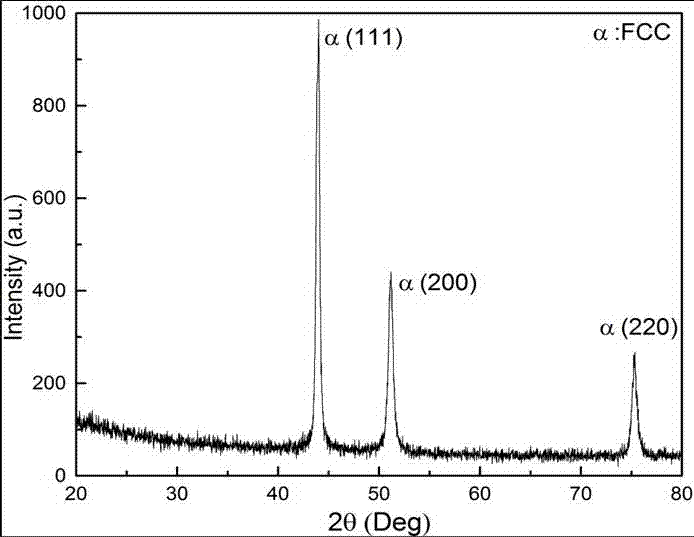

The invention relates to a refractory high-entropy alloy material with high plasticity and low neutron absorption cross section and a preparation method thereof, and belongs to the technical field of high-entropy alloys. The high-entropy alloy material is AlVTiNbZr high-entropy alloy, wherein the atomic percent of an aluminum element is 5%-10%, the atomic percent of a V element is 3%-15%, the atomic percent of a Ti element is 20%-40%, the atomic percent of an Nb element is 25%-35%, and the atomic percent of a Zr element is 20%-35%. The AlVTiNbZr high-entropy alloy is of a single-phase BCC structure. The AlVTiNbZr high-entropy alloy is obtained in a vacuum arc melting mode, has a high theoretical melting point, low alloy density, high room-temperature yield strength and deformation plasticity, can resist deformation failure in the service process, and brings sufficient safety margin in the service process.

Owner:CHONGQING UNIV

Layered positive electrode material for lithium-ion battery and preparation method of layered positive electrode material

ActiveCN107994212AStable crystal structureReduce surface residual alkali contentSecondary cellsPositive electrodesManganeseCobalt

The invention discloses a layered positive electrode material for a lithium-ion battery. The layered positive electrode material comprises a body and a B2O3 coating layer, wherein a chemical formula of the body is Li<x>(NiCoMn<c>)<1-y>M<y>O<2>, wherein x is smaller than or equal to 1.04 and greater than or equal to 0.96, y is smaller than or equal to 0.06 and greater than or equal to 0.01, ais smaller than or equal to 0.9 and greater than or equal to 0.8, a+b+c is equal to 1, and M is selected from at least one of an Al element, a Mg element, a Ti element and a Zr element. The inventionfurther discloses a preparation method of the layered positive electrode material for the lithium-ion battery. The method comprises the following steps of mixing a nickel-cobalt manganese hydroxide,a lithium source and a nano oxide additive evenly and carrying out first sintering to obtain unmodified powder; stirring the unmodified powder and water, carrying out centrifugal separation to obtaina solid material, drying and crushing to obtain washing powder; adding LIBOB to an organic solvent for dissolving, adding the washing powder for mixing, stirring, evaporating and carrying out second sintering to obtain the layered positive electrode material for the lithium-ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method of infiltrating metal infiltrating agent to cerium-containing neodymium iron boron magnetic material

InactiveCN103757586AImprove coercive forceReduce dosageInorganic material magnetismSolid state diffusion coatingCeriumDysprosium

Owner:赣州诚正稀土新材料股份有限公司 +1

Heat-resisting magnesium alloy

The invention discloses heat-resisting magnesium alloy and belongs to the field of magnesium alloy. The heat-resisting magnesium alloy comprises the following elements in percent by weight: 1.5 to 25% of Al (aluminium), 0.1 to 2% of Mn (manganese), 0.0002 to 16% of rare earth, 0.0002 to 4% of Nb (niobium), 0.001 to 2% of Zr (zirconium), and Mg (magnesium) in balancing amount. The beta-phase structure is changed by adding the rare earth element and the Nb element in the magnesium alloy, and the grain refinement and the alloy liquid purification are achieved by adding the Zr element, so as to improve the high temperature resistance of the magnesium alloy, and obtain the heat-resisting magnesium alloy which has an excellent mechanical property, machinability, flowability and good die-casting performance and is suitable for casting, particularly die-casting.

Owner:嘉兴佳斯贝特新材料有限公司

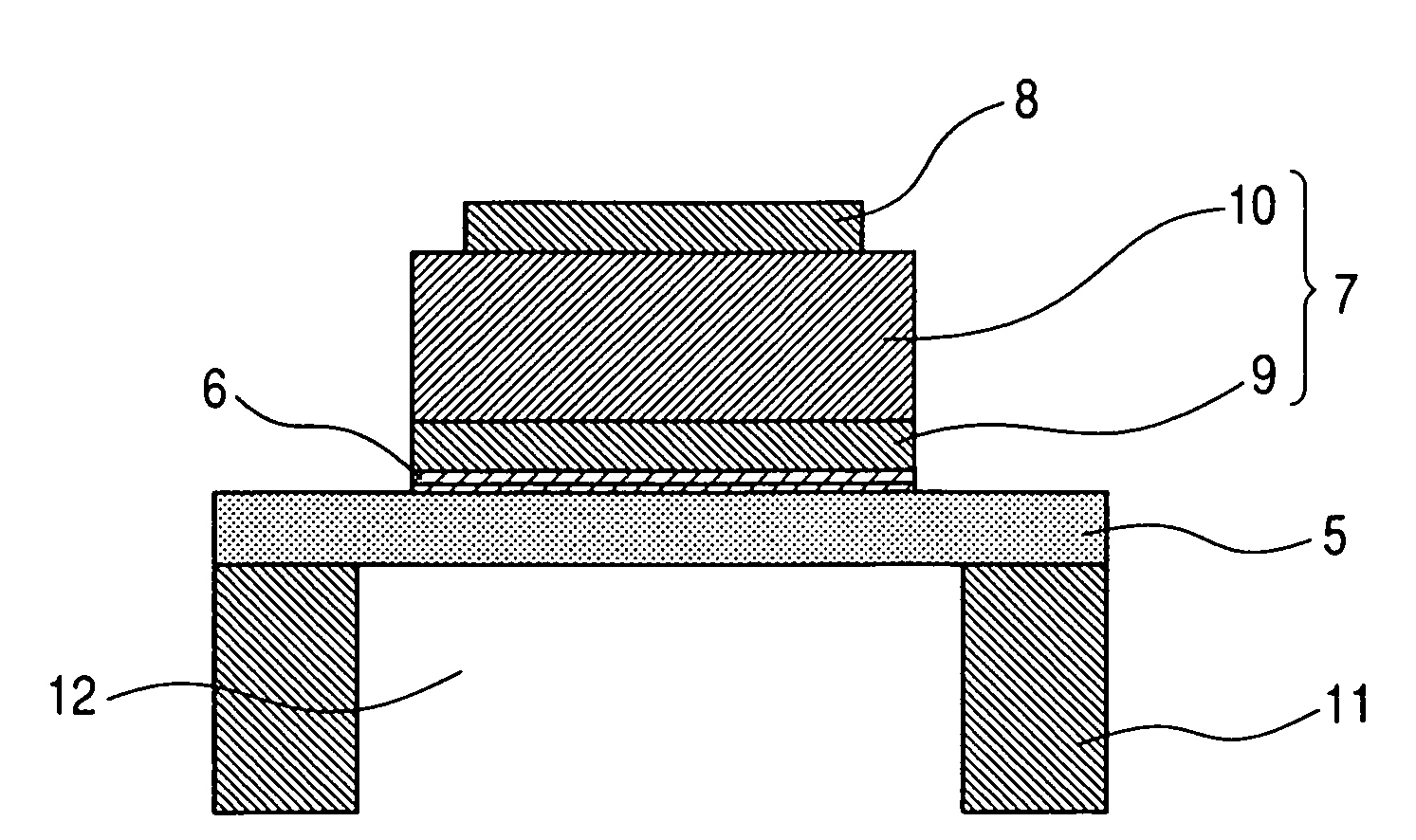

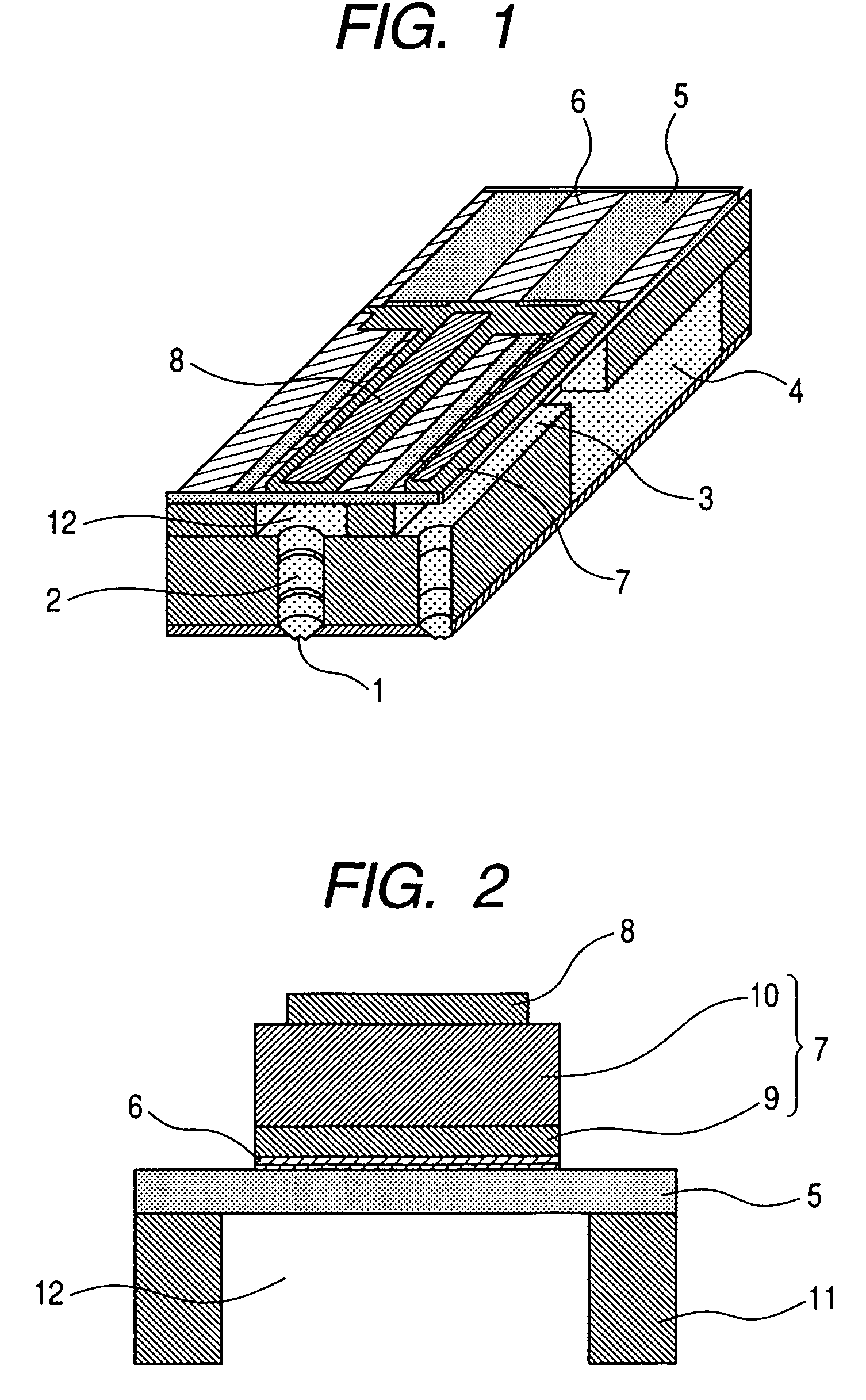

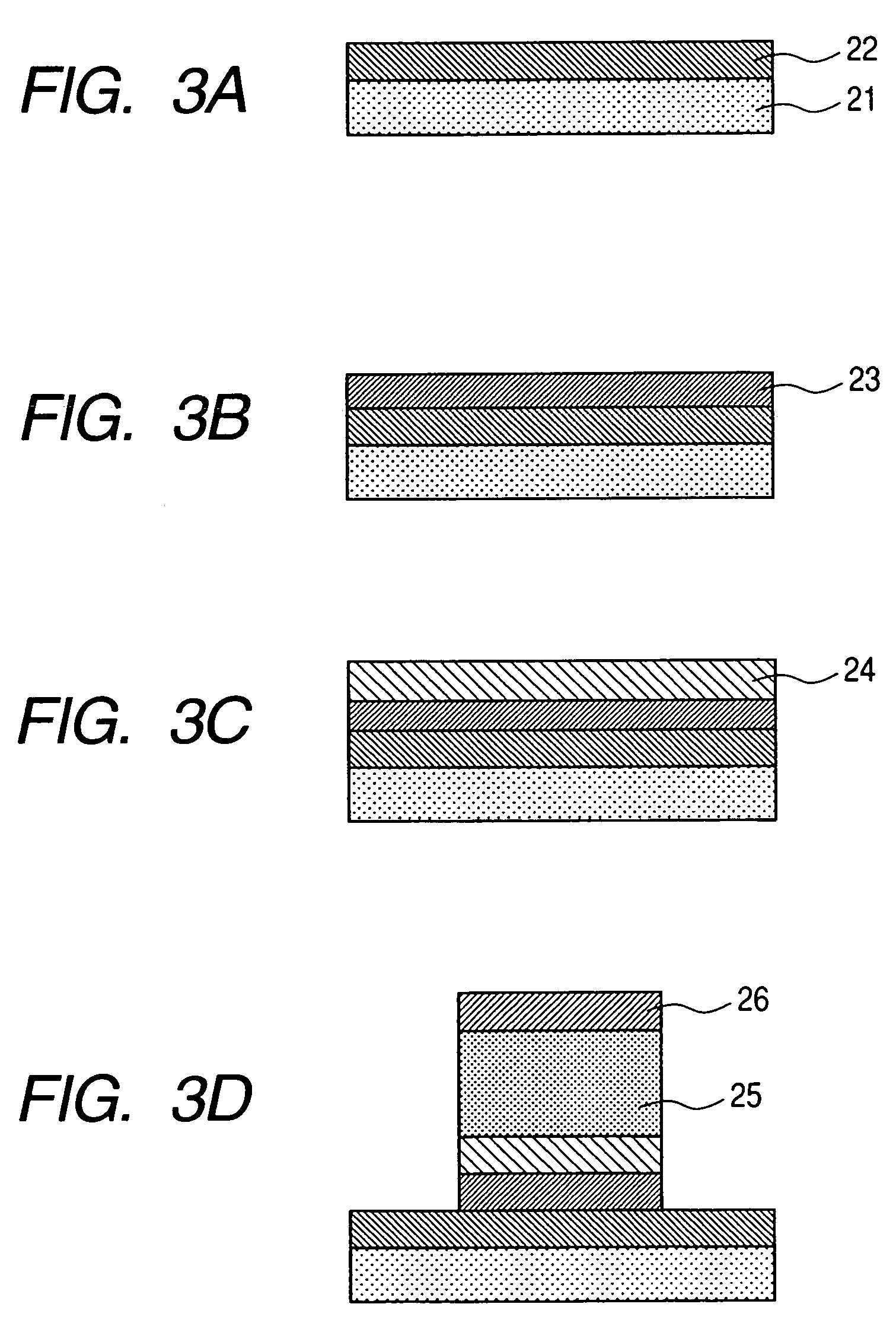

Dielectric element, piezoelectric element, ink jet head and ink jet recording apparatus and manufacturing method of same

ActiveUS7453188B2Improve featuresLow-voltage drivingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric layerMetal

A dielectric element includes a lower electrode layer provided on a substrate, a dielectric layer provided on the lower electrode layer and an upper electrode layer provided on the dielectric layer. The dielectric layer has a first dielectric layer provided on a side of the lower electrode layer, and a second dielectric layer provided on a side of the upper electrode layer. The second dielectric layer is a layer comprised mainly of an oxide including four or more kinds of metal element components, and the first dielectric layer does not substantially include at least one component selected from metal elements included in the oxide layer of the second dielectric layer and is comprised mainly of an oxide including at least three components selected from the remaining metal elements without substantially including Ti and Zr elements.

Owner:CANON KK +1

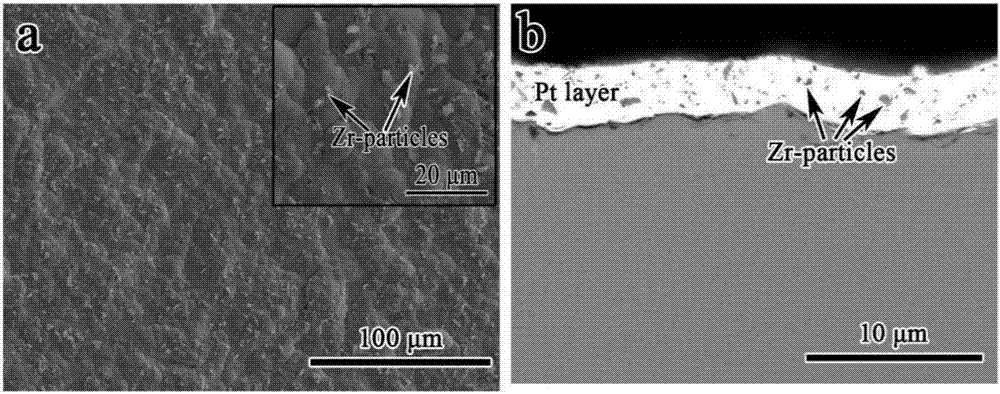

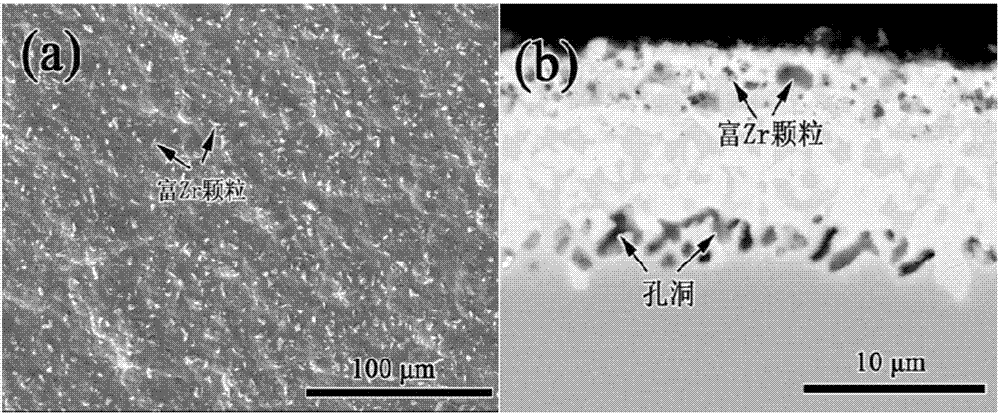

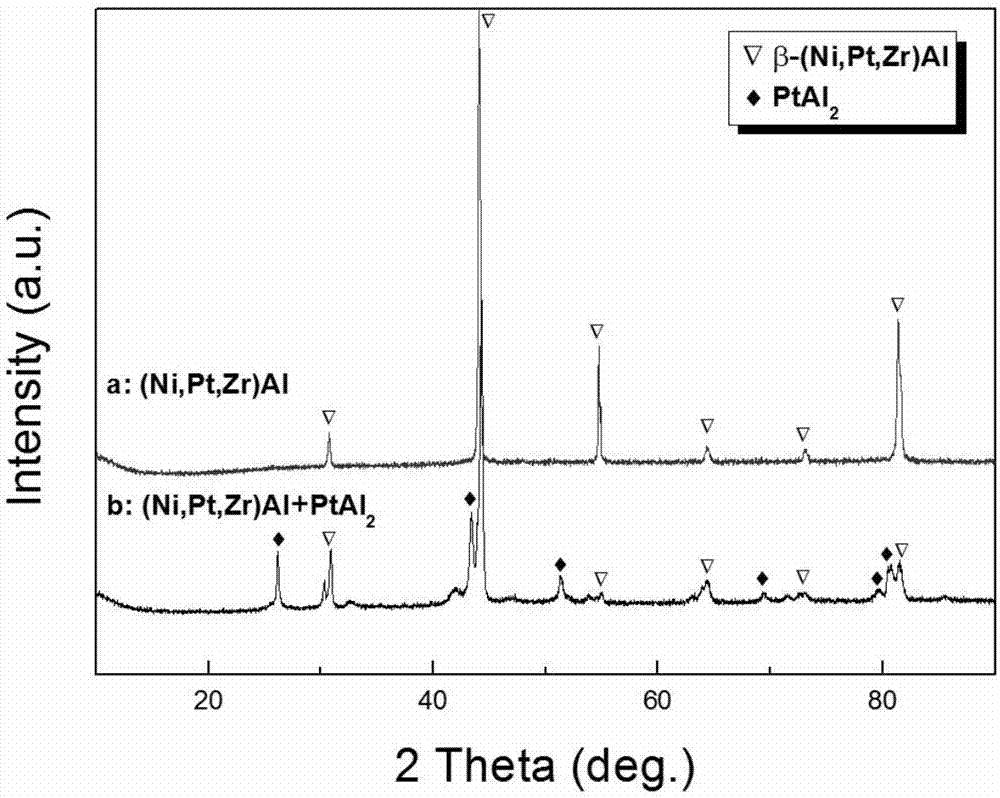

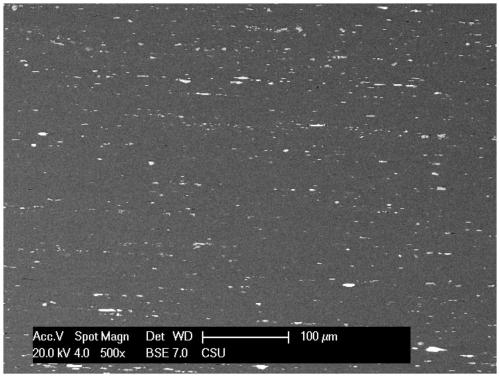

Preparation method for Pt-Zr modified aluminide coating

InactiveCN107268044AShape and size are not requiredLow costElectrolytic coatingsSolid state diffusion coatingPlatinumSlurry

The invention relates to a preparation method for a Pt-Zr modified aluminide coating. The preparation method comprises the following steps that surface treatment is carried out, pure Zr particles with the grain size ranging from 0.1 micron to 10 microns are added into conventional platinum plating bath, and a magnetic stirring instrument is used for stirring a mixed solution until even suspension is formed; the electroplating condition is set, wherein a Pt-Zr composite Pt-Zr method is adopted, in the process that an Zr element is led into the coating, except for basic electroplating equipment, the magnetic stirring instrument is led in to stir the solution, and the solution keeps to stay in the suspension state; electroplating solution maintenance is carried out, wherein Zr fine grains are added, a target platinum plating solution is supplemented, and the pH value is adjusted; a composite platinum plating is obtained after electroplating and is subject to annealing in a vacuum annealing furnace; and embedding, slurry and CVD chemical vapor deposition alumetizing are adopted, and the Pt-Zr modified high temperature protection aluminide coating is obtained. The preparation method has the beneficial effects that the method is easy, convenient and quick, and saves cost; meanwhile, the contents of the Pt and Zr contents are controllable, and distribution is even; and requirements for workpiece shape and size are avoided, and the service life of an engine blade component is obviously prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength aluminum alloy bar and preparing method thereof

InactiveCN109722579AFine grainThe effect of natural placement is obviousUltimate tensile strengthAluminium alloy

The invention provides a high-strength aluminum alloy bar and a preparing method thereof. An aluminum alloy comprises the following elements including, by mass percent, 0.70%-0.90% of Mg, 0.55%-0.65%of Si, 0.70%-0.80% of Mn, 3.7%-4.3% of Cu, smaller than or equal to 0.50% of Fe, smaller than or equal to 0.10% of Cr, smaller than or equal to 0.10% of Zn, 0.02%-0.06% of Zr, 0.02%-0.06% of Ti and the balance Al and inevitable impurity elements, wherein the content of the single impurity element is smaller than or equal to 0.05%, and the total amount of the impurity elements is smaller than or equal to 0.15%. By means of the high-strength aluminum alloy bar and the preparing thereof, the content of Cu and Mg is adjusted and the minor Zr elements are added so that grains of the extruded aluminum alloy bar can be fine, and after the aluminum alloy bar is naturally put for 96 H, the good texture performance that the strength is high, and high temperature resistance is achieved are obtained.

Owner:广东精美特种型材有限公司

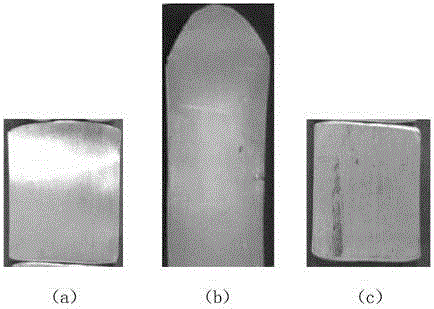

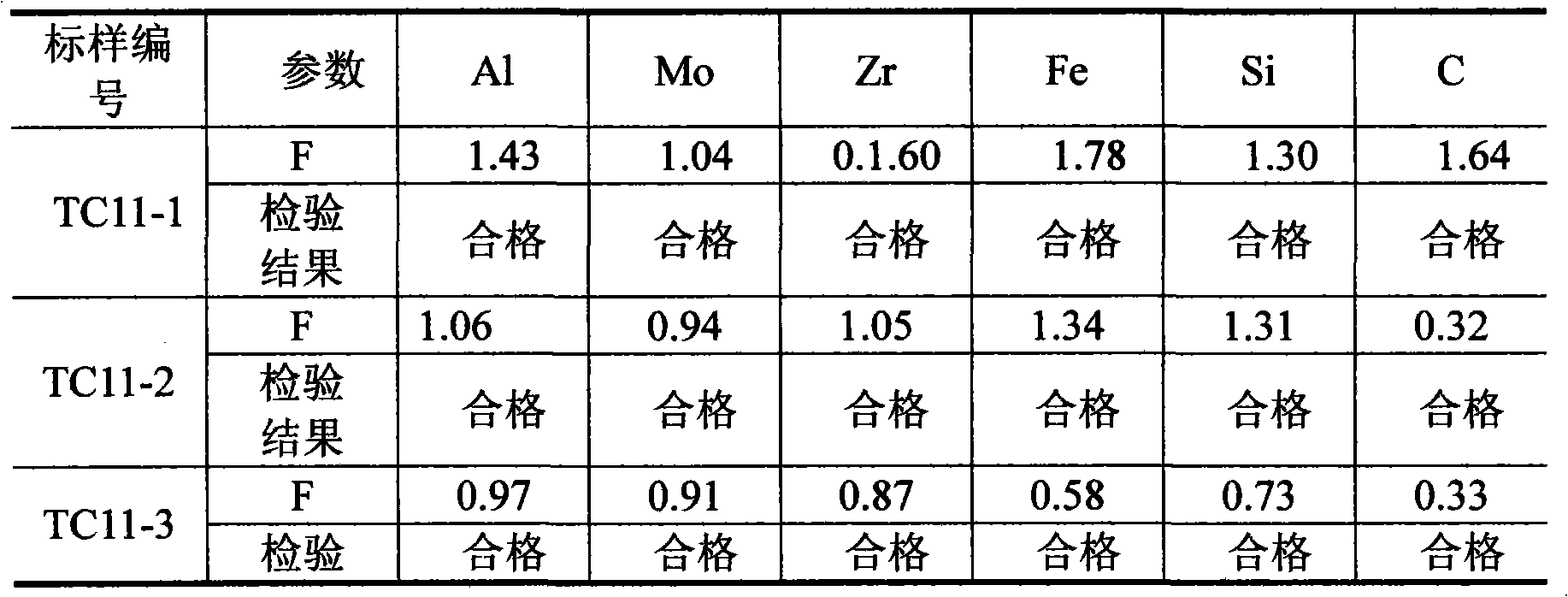

Standard substance for TC11 titanium alloy photoelectric spectral analysis and preparation method thereof

ActiveCN101975750AGood composition uniformityLarge coverageColor/spectral properties measurementsElectric arc furnaceHydrogen

The invention discloses a standard substance for TC11 titanium alloy photoelectric spectral analysis, which comprises the following components in percentage by weight: 4.53% to 7.51% of Al, 2.2% to 4.65% of Mo, 0.59% to 2.41% of Zr, 0.15% to 0.46% of Si, 0.15% to 0.35% of Fe, 0.021% to 0.12% of C and the balance of titanium, wherein the weight percentage sum of the components is 100%. The preparation method of the standard substance comprises the following steps: dosing; suppressing electrodes by utilizing a vertical lateral pressure machine; welding the electrodes in a vacuum argon charging tank; smelting primary cast ingots by utilizing a vacuum consumable electrode arc furnace; casting secondary cast ingots by utilizing a vacuum consumable electrode arc skull furnace; smelting tertiarycast ingots by utilizing the vacuum consumable electrode arc furnace; homogenizing and carrying out transform processing; and carrying out hot hydrogen processing to prepare the standard substance for the titanium alloy photoelectric spectral analysis. The standard substance and the preparation method of the invention have the advantages that the homogenization of the components is good; the problem that alloy elements cannot be effectively detected because the Zr element has no effective distribution point in the content section of 0.6 to 2.6% and the Mo element has no effective distributionpoint in the content section of 2.2 to 4.6% in the existing standard substance is solved.

Owner:CSIC NO 12 RES INST

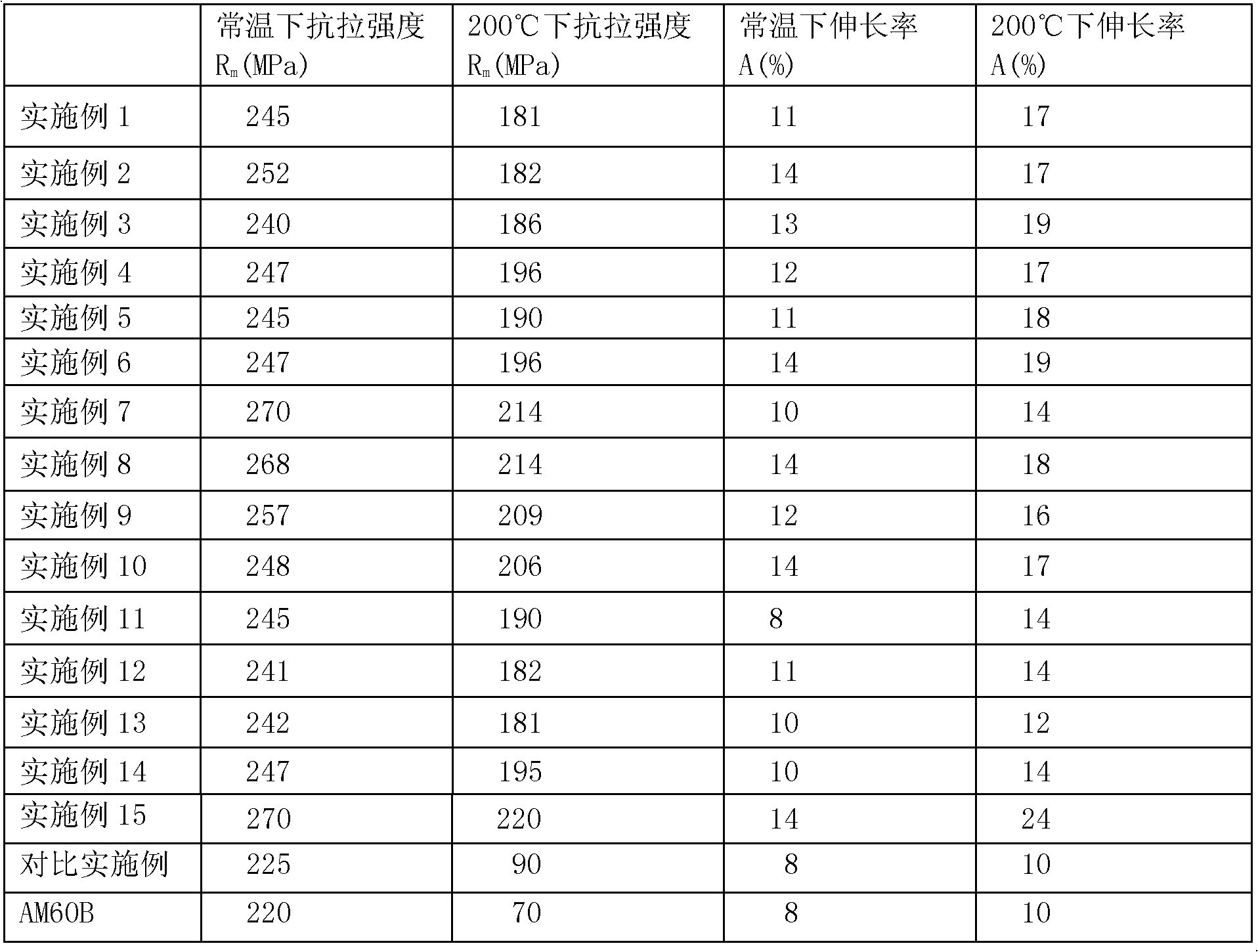

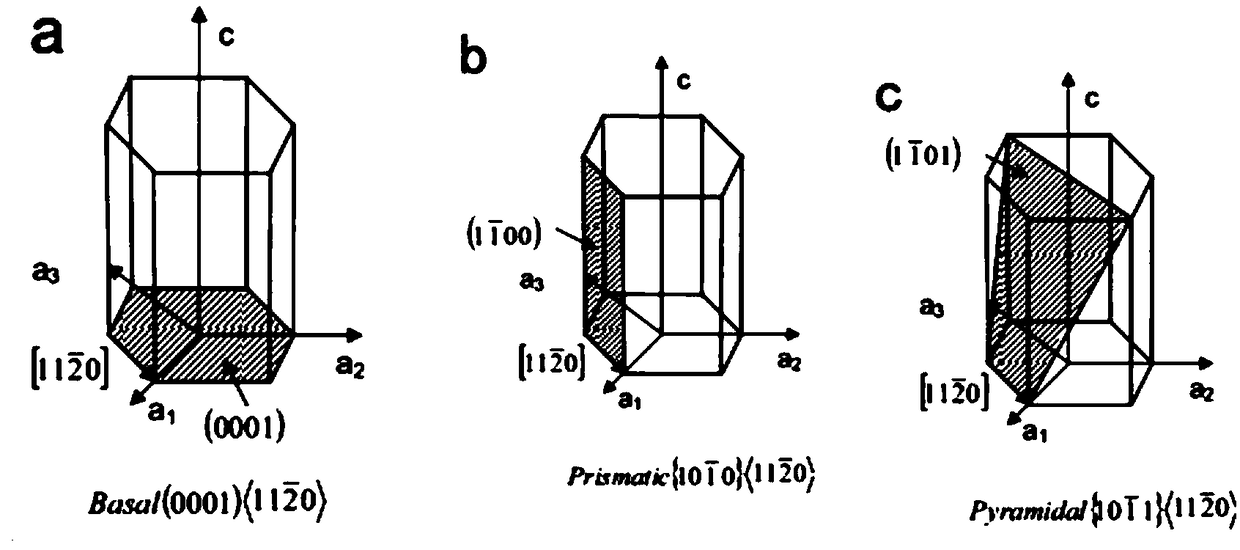

High-strength heat-resistant rare earth magnesium alloy and preparation method thereof

The invention provides a high-strength heat-resistant rare earth magnesium alloy. The high-strength heat-resistant rare earth magnesium alloy comprises 2-6 wt% of Sm, 0-3 wt% of Nd, 2-5 wt% of heavy rare earth elements, 0.5-4 wt% of Zn, 0.2-3 wt% of Zr, and the balance Mg and inevitable impurities. According to the high-strength heat-resistant rare earth magnesium alloy, the influence of elementssuch as Sm and the heavy rare earth on an electron migration state of the Zr element is utilized, so that Zr in a Zr-rich ring is separated out on a pyramidal surface of a magnesium alloy matrix in aZn-Zr heat-resistant compound form in a heat treatment process. In a high-temperature condition, a Zn-Zr phase can effectively inhibit a non-basal plane slip, a Mg-RE precipitated phase is formed through the heat treatment on the basis, and meanwhile, the magnesium alloy matrix is reinforced. The two phases in the magnesium alloy provided by the invention can effectively inhibit a high-temperatureprismatic slip, a pyramidal slip and a basal slip, and the high-temperature strength of the magnesium alloy is improved. The invention further provides a preparation method of the high-strength heat-resistant rare earth magnesium alloy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Heat resistant magnesium alloy

The invention discloses a heat resistant magnesium alloy and belongs to the magnesium alloy field. The magnesium alloy is composed of Mg, Al, Zn, Mn, rare earths, Nb and Zr, and comprises, by weight, 1.5 to 25 percents of Al, 0.1 to 3.5 percents of Zn, 0.1 to 2.2 percents of Mn, 0.0002 to 16 percents of rear earths, 0.0002 to 4 percents of Nb, 0.001 to 2 percents of Zr, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; and grains are refined and the alloy liquid is purified by adding the Zr element, so that the heat resistant performance of the magnesium alloy is improved, and the heat resistant magnesium alloy which has good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting in particular to die-casting is obtained.

Owner:JIANGHAN UNIVERSITY

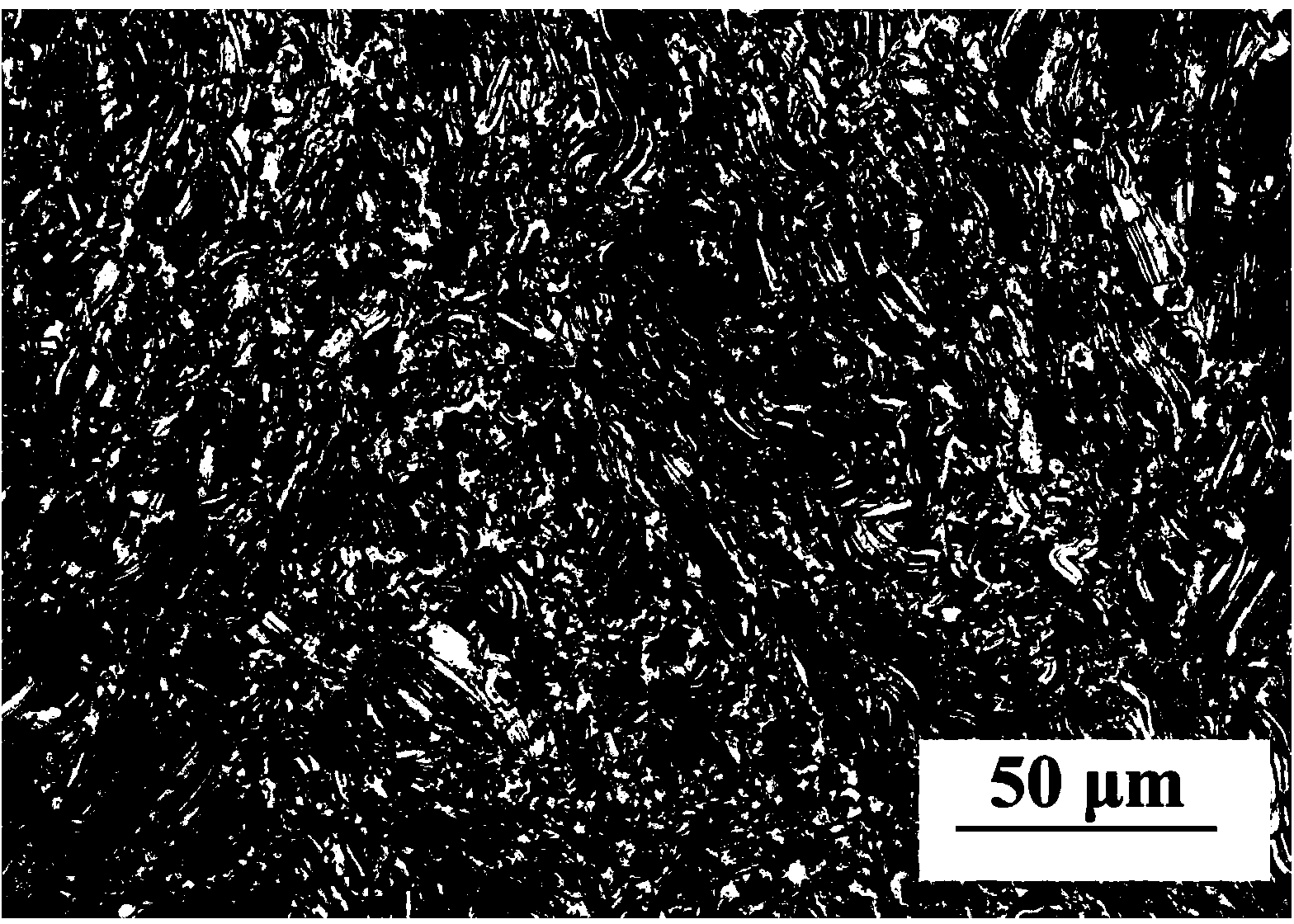

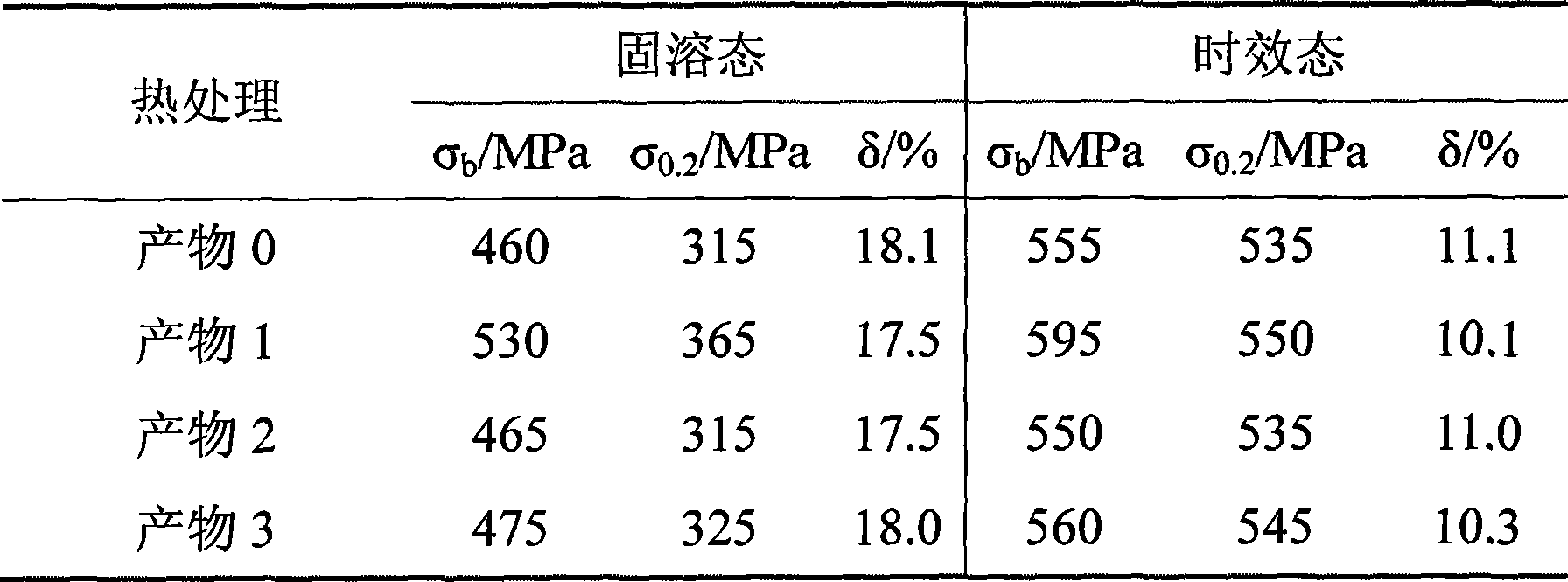

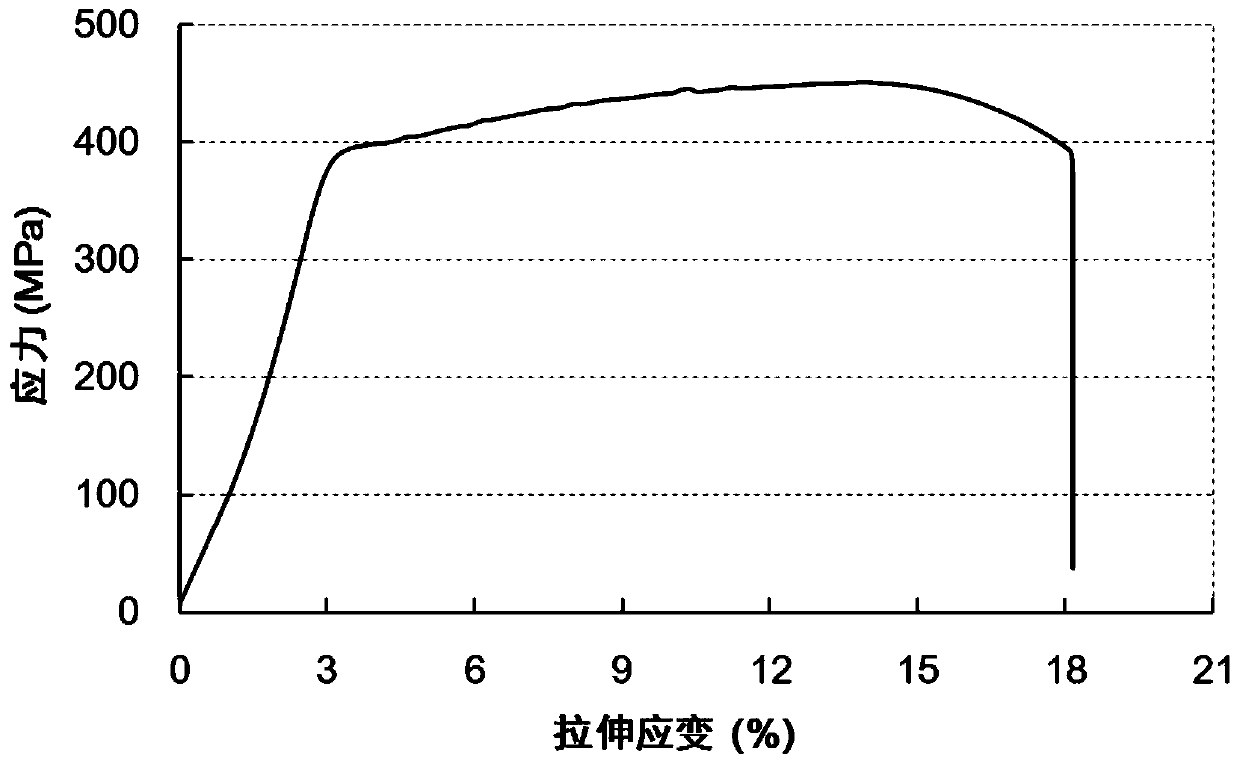

Thermal treatment method for Al-Zn-Mg-Sc-Zr alloy

A heat treatment method of Al-Zn-Mg-Sc-Zr alloy comprises such five steps as hot rolling, first solution, cold rolling, second solution and aging. During the first solution, a second-phase is dissolved in a base to obtain supersaturated solution, thus effectively improving the alloying effects of Sc and Zr and at the same time softening the alloy to provide fully softened organism for later cold rolling with comparatively large deformation; the later cold rolling can smash the undissolved coarse phase, thus is beneficial for the coarse phase to be dissolved in the matrix during the second solution, improves the supersaturation level of the base, lowers the probability of the occurrence of cracks during the alloy deformation, and at the same time lays a foundation for aging to precipitate more strengthening phases. Compared with the conventional heat treatable alloy, when the cold rolling deflection of the alloy treated by the method of the invention is 50.0%, the tensile strength and yield strength of the alloy in solution state are respectively improved by 70MPa and 50MPa and the tensile strength and yield strength of the alloy in aging state are respectively improved by 40MPa and 35MPa. The method of the invention is simple in technique and convenient in operation, is applicable to industrial application and provides a new processing method for the improvement of the property of aerospace materials.

Owner:CENT SOUTH UNIV

Photocatalyst-containing silicone resin composition, and coated article having cured coating film therefrom

The composition allows the formation of a coating film exhibiting high photocatalytic activity, good durability and high transparency by the firing at a relatively low temperature (for example, ca. 100 DEG C).A photocatalyst-containing silicon resin composition which contains TiO2, a compound containing a Zr element, a hydrolyzable silicone resin and a Si element containing compound containing SiO2 particles, wherein the content of the compound containing a Zr element in terms of an oxide is 0.005 to 0.1 parts by weight relative to 1 part by weight of TiO2, the content of the Si element containing compound in terms of an oxide is 0.5 to 6.0 parts by weight relative to 1 part by weight of TiO2, and the content of SiO2 particles is 0.1 to 3 parts by weight relative to 1 part by weight in terms of an oxide of the hydrolyzable silicone resin.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Aluminum alloy containing scandium, titanium and zirconium elements for 3D printing

The invention discloses an aluminum alloy containing scandium, titanium and zirconium elements for 3D printing. The aluminum alloy comprises the following components in percentage by weight: 1.5%-4.5%of Mg, 1%-3.5% of Mn, 0.2%-1.5% of Sc, 0.2-1% of Ti and Zr in total, 0.0001-0.15% of O, impurities, and the balance Al. Compared with an existing aluminum alloy for 3D printing, the aluminum alloy has the advantages that the Ti element in the alloy can replace the strengthening effect of the Sc element to a certain extent so as to improve the economical efficiency, the Ti element in the alloy canreplace the strengthening effect of the Zr element to a certain extent so as to reduce the preparation difficulty of the alloy, and the alloy has excellent mechanical properties and good forming characteristics.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

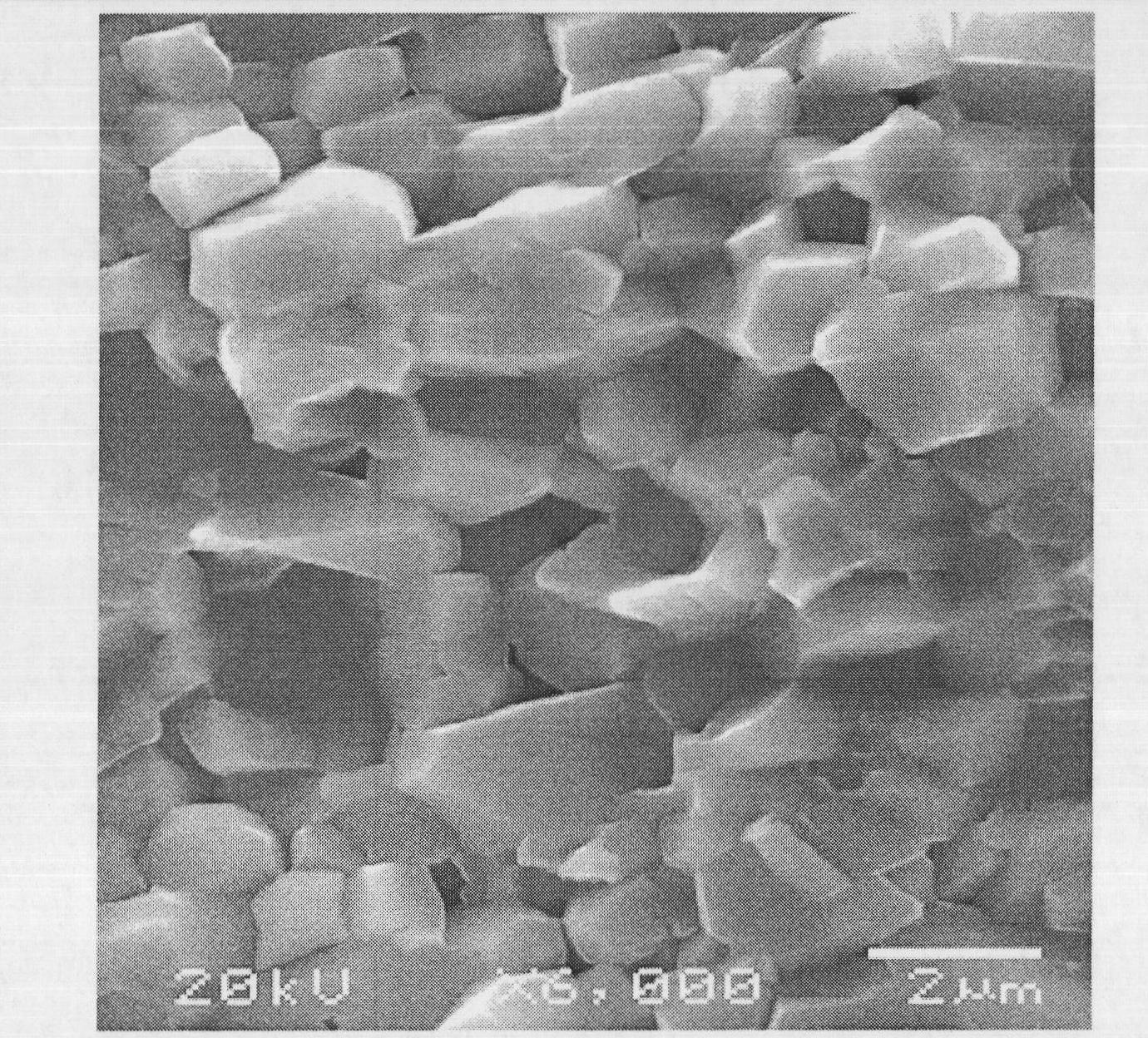

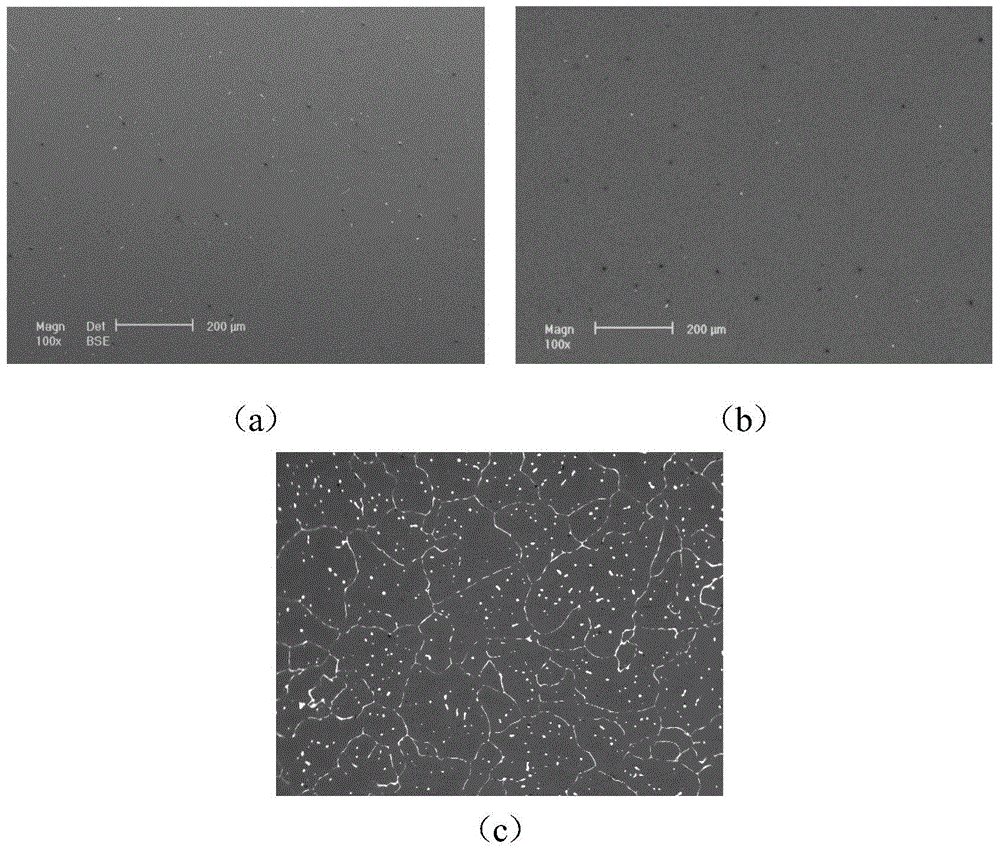

Al-30Si aluminum alloy containing Sr, B, Ti and Zr and preparation process thereof

The invention discloses a Al-30Si aluminum alloy containing Sr, B, Ti and Zr and a preparation process thereof. The high-silicon aluminum alloy is prepared by pouring an aluminum alloy molten mass at 750 DEG C into a metal mold with 200 DEG C in an atmospheric environment. The Al-30Si mother alloy is prepared by the following steps: smelting industrial pure aluminum with the purity of higher than 99.8 Wt% and silicon metal with the purity of higher than 99.5 Wt% in a graphite crucible by using a well-type resistance furnace, keeping the temperature at 850 DEG C for 4 hours, carrying out refining and degassing on the alloy liquid with hexachloroethane at 750 DEG C, and keeping the temperature for 30 minutes. The elements Sr, B, Ti and Zr are alloyed by respectively adding Al-10Sr, Al-5Ti-1B, Al-10Zr and other alloys at 720 DEG C and keeping the temperature for 30 minutes. The aluminum-silicon alloy comprises the following chemical components: 0.03-0.09 Wt% of Sr, 0.01-0.05 Wt% of B, 0.05-0.25 Wt% of Ti, 0.03-0.09 Wt% of Zr, 30 Wt% Si and the balance of Al. The tensile strength of the alloy is 149.4-245.4 MPa, the hardness is 37.5-82.1 HBW, and the resistivity is 0.107-0.127 ohm m.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

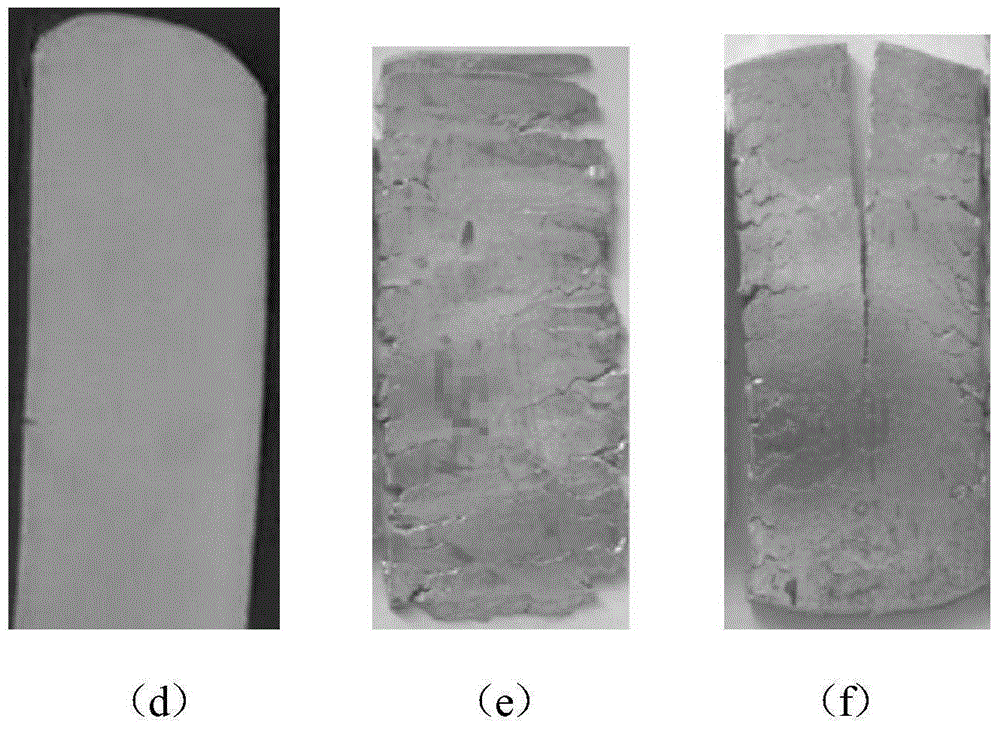

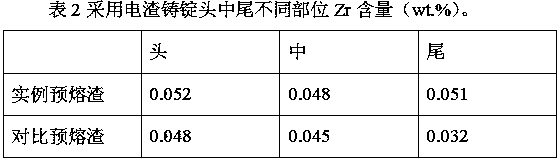

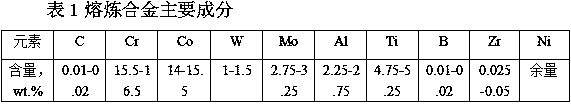

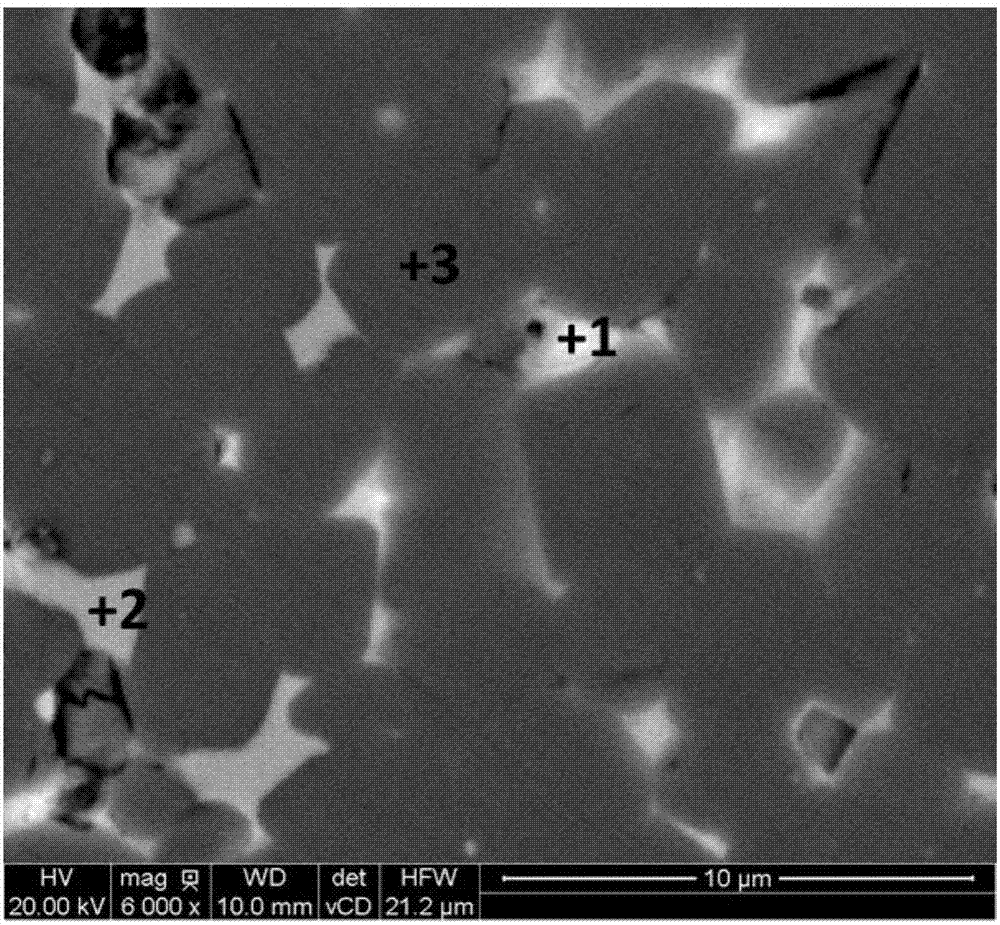

Pre-melting slag for high-temperature alloy electroslag remelting

The invention discloses pre-melting slag for high-temperature alloy electroslag remelting. The pre-melting slag for high-temperature alloy electroslag remelting comprises the following components of,by weight, 50%-60% of CaF2, 15%-25% of Al2O3, 10%-20% of CaO, 1%-5% of MgO, 1%-5% of TiO2, and 2%-10% of ZrO2. The pre-melting slag is used for improving the uniformity of the components of a high-temperature alloy cast ingot, and the problems that the Zr element content in electroslag remelting is difficult to control and segregation is caused are solved; and the characteristics that the surfacequality of the electroslag ingot is improved, and the effect of removing included impurities is not affected are achieved.

Owner:西安聚能高温合金材料科技有限公司

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Zn, rare earths, Nb, Al and Li, and comprises, by weight, 0.2 to 9 percents of Zn, 0.0002 to 2 percents of Zr, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.001 to 1.49 percents of Al, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li and Zr elements; and the crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Rare earth permanent magnetic material and preparation method thereof

ActiveCN107958760AImprove liquidityEutectic reaction melting temperatureInorganic material magnetismRare earthMagnetic powder

The invention relates to a preparation method of a rare earth permanent magnetic material. The method comprises the following steps that 1, main alloy magnetic powder and auxiliary alloy powder are provided separately, wherein the chemical formula of the main alloy magnetic powder is [(PrrNd1-r)xMM1-x)]aTmbBcFe1-a-b-c, MM is at least one of high-abundance rare earth La and Ce, Tm is one or more ofFe, Ga, Co, Cu, Nb, Al and Zr, the chemical formula of the auxiliary alloy powder is Cey(FedM1-d)1-y, y and d are the mass percentages of corresponding elements, and M is one or more of Cu, Al, Ga, Co and Ni; 2, the main alloy magnetic powder and the auxiliary alloy powder are uniformly mixed to obtain mixed magnetic powder, wherein the mass percentage of the auxiliary alloy powder in the mixed magnetic powder is 1-5%; 3, the mixed magnetic powder is sequentially subjected to orientation forming, sintering and tempering, and the rare earth permanent magnetic material is obtained. The invention further provides the rare earth permanent magnetic material obtained by means of the preparation method.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

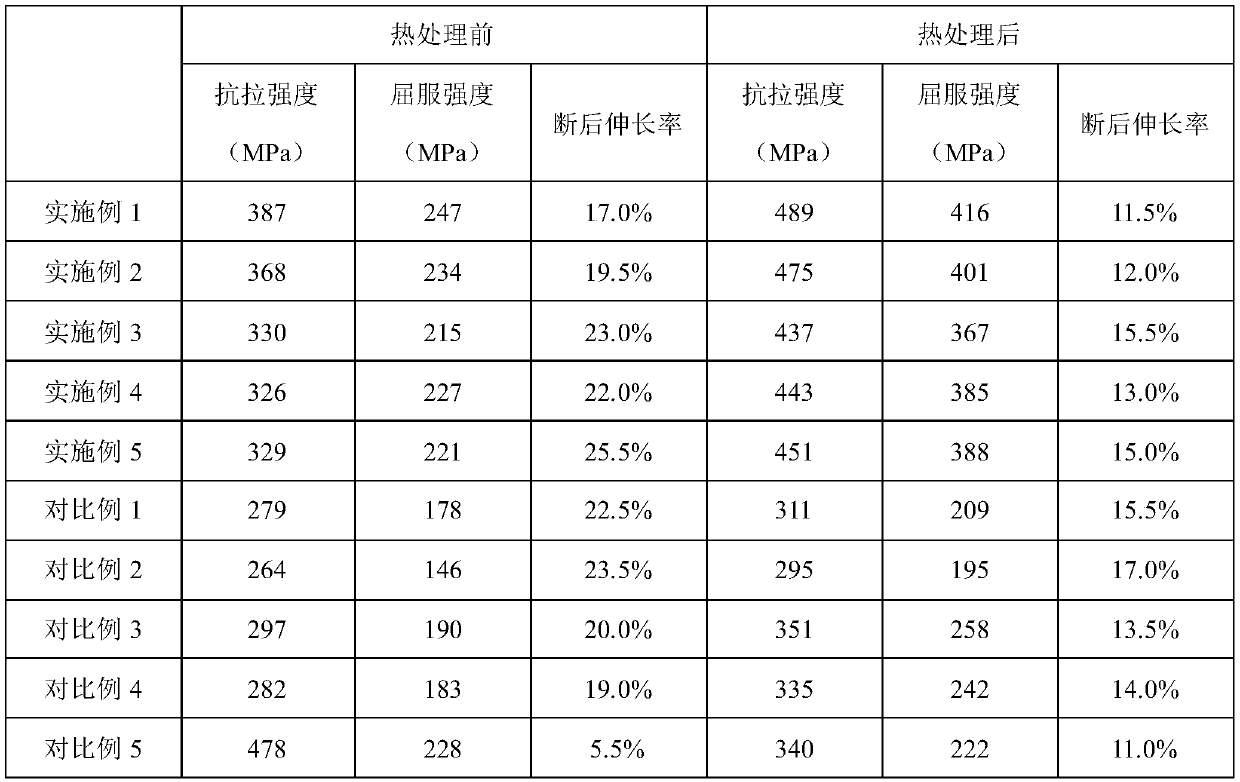

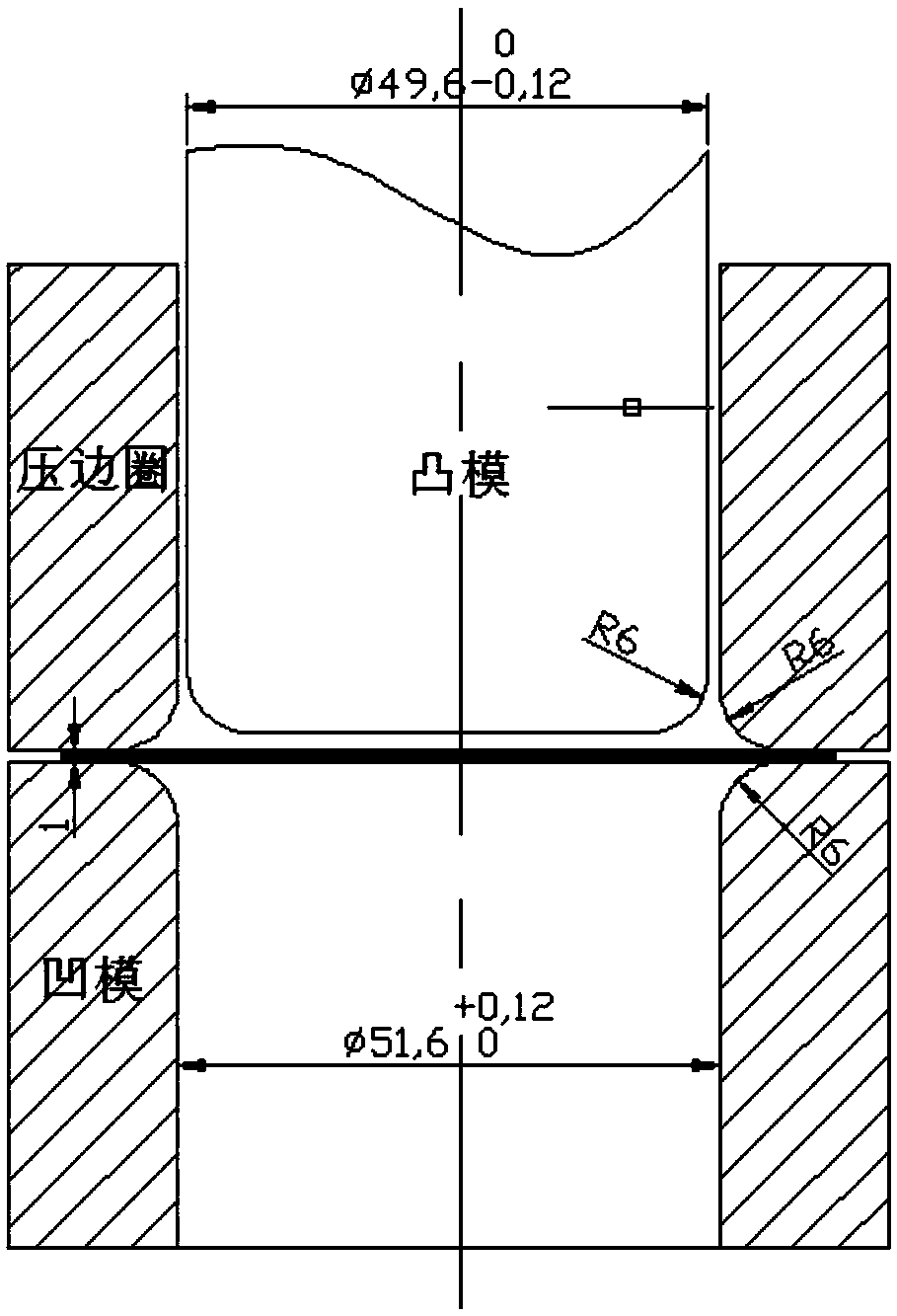

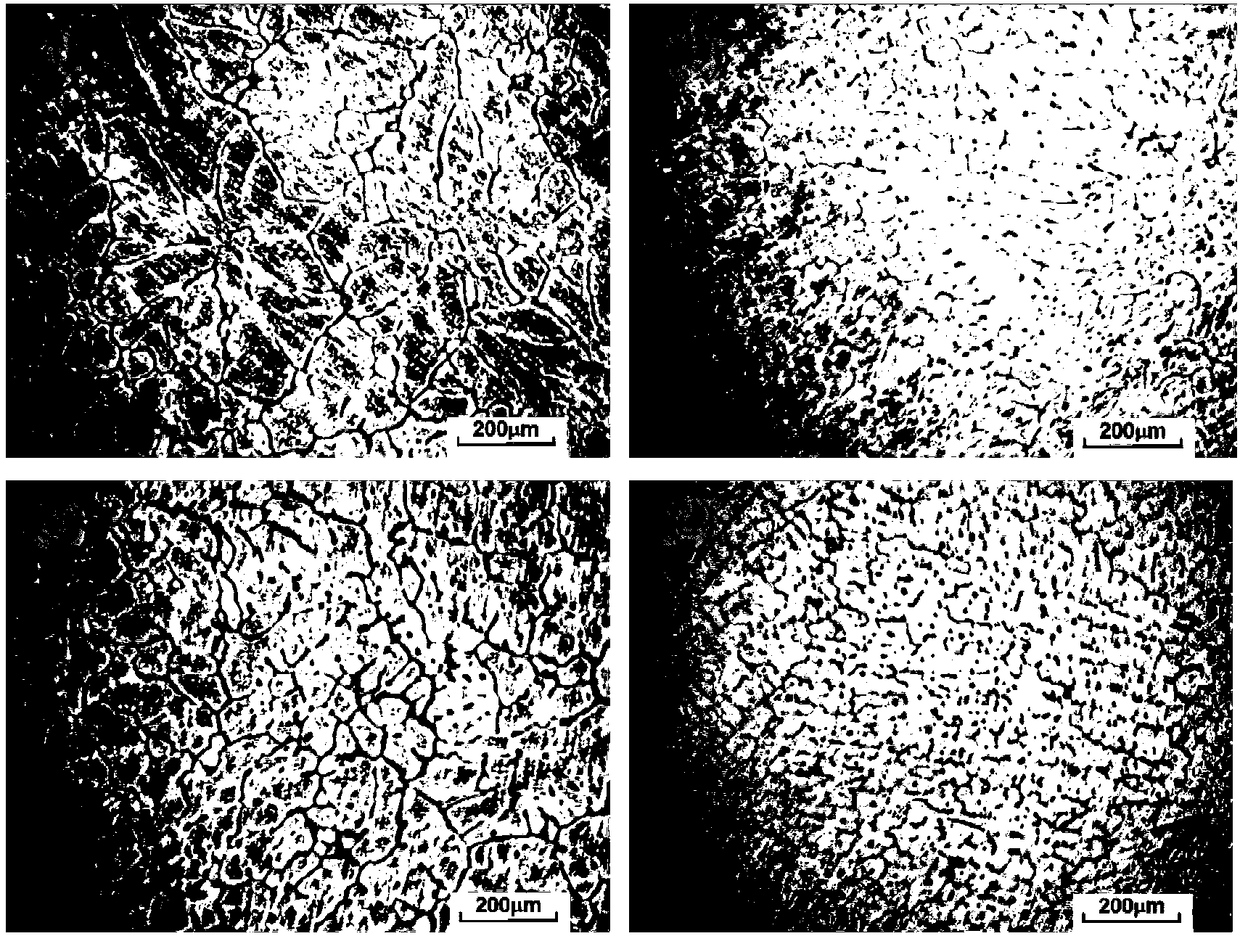

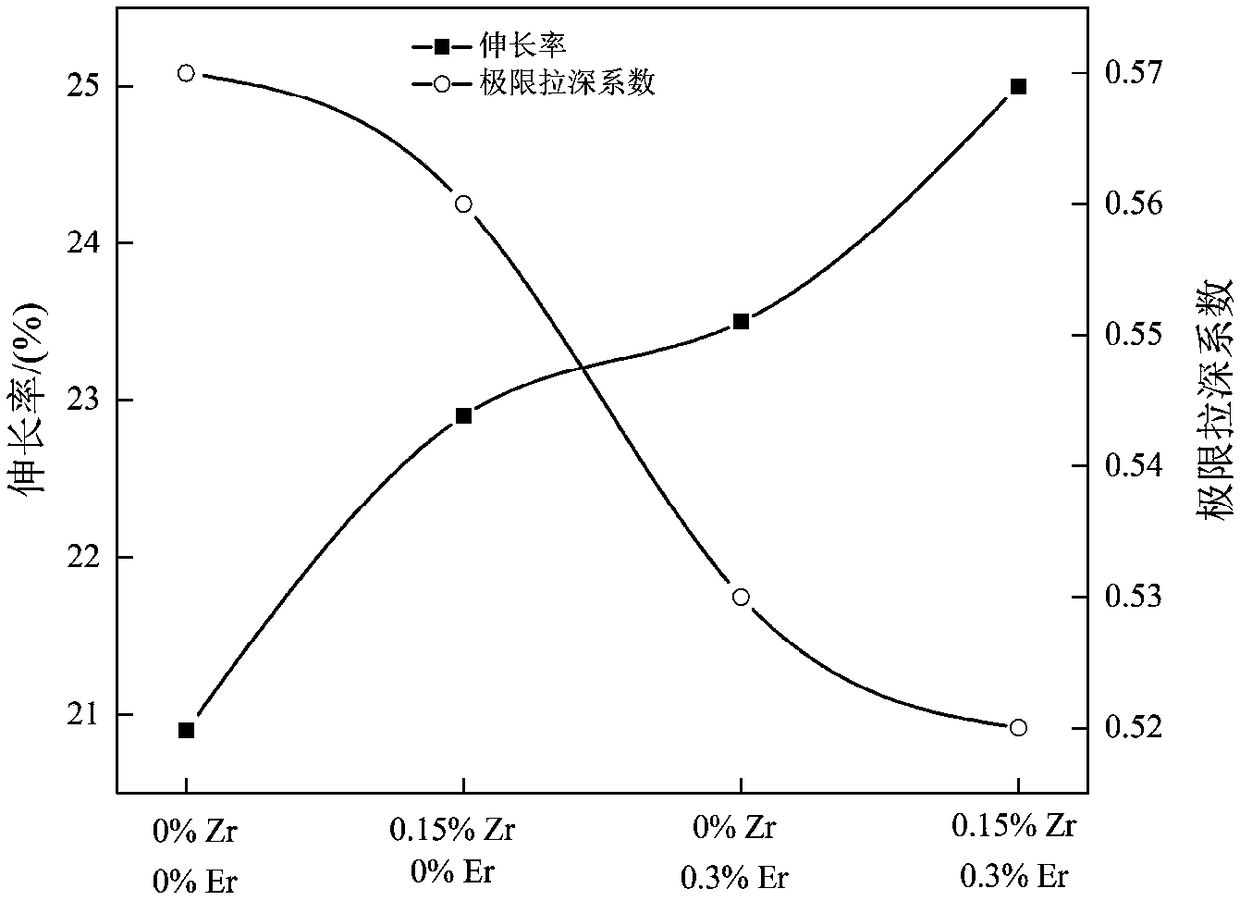

Al-Mg-Si-Cu-Zr-Er alloy having excellent stamping formation performance and preparation method thereof

The invention discloses an Al-Mg-Si-Cu-Zr-Er alloy having excellent stamping formation performance. The Al-Mg-Si-Cu-Zr-Er alloy having the excellent stamping formation performance comprises, by mass,0.14%-0.18% of transitional element Zr and 0.28%-0.32% of rare earth element Er. The Zr element and the Er element are added to an Al-Mg-Si-Cu alloy for compounding, the contents of other alloy elements are reasonably designed, a reasonable smelting technology and a rapid solidification technology are adopted, repeated rolling and appropriate heat treatment are conducted, and then the Al-Mg-Si-Cu-Zr-Er alloy material uniform in microscopic structure and fine in crystal particle is prepared. The obtained alloy material has good formation performance, the ductility delta of the alloy material islarger than or equal to 24%, and the limiting drawing coefficient of the alloy material is smaller than or equal to 0.53. The technology process is simple, the cost is low, and the comprehensive performance is excellent.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com