High-strength and high-plasticity magnesium alloy

A magnesium alloy, high-strength technology, applied in the field of non-ferrous metals, can solve problems such as inability, low elongation, complex alloy preparation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

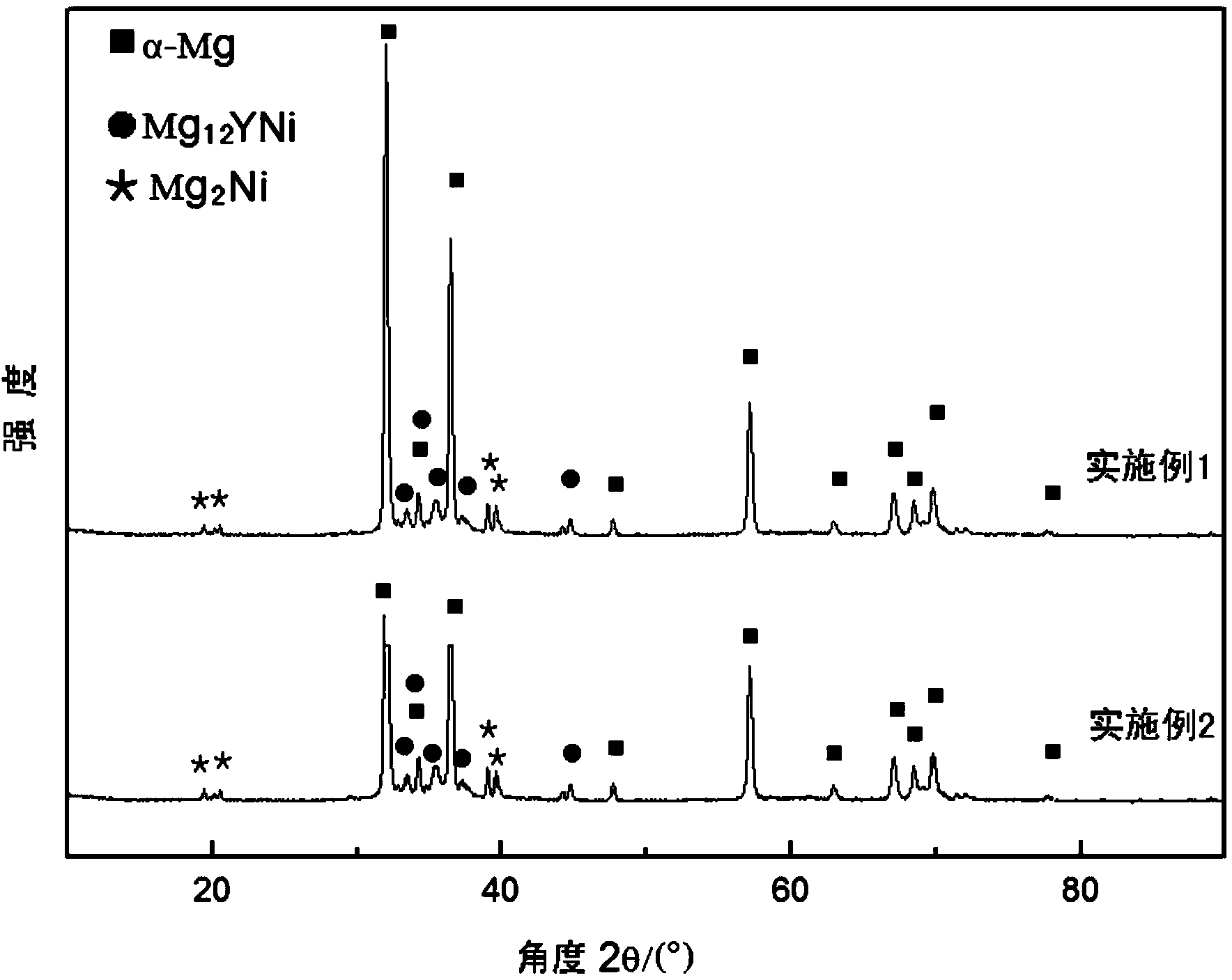

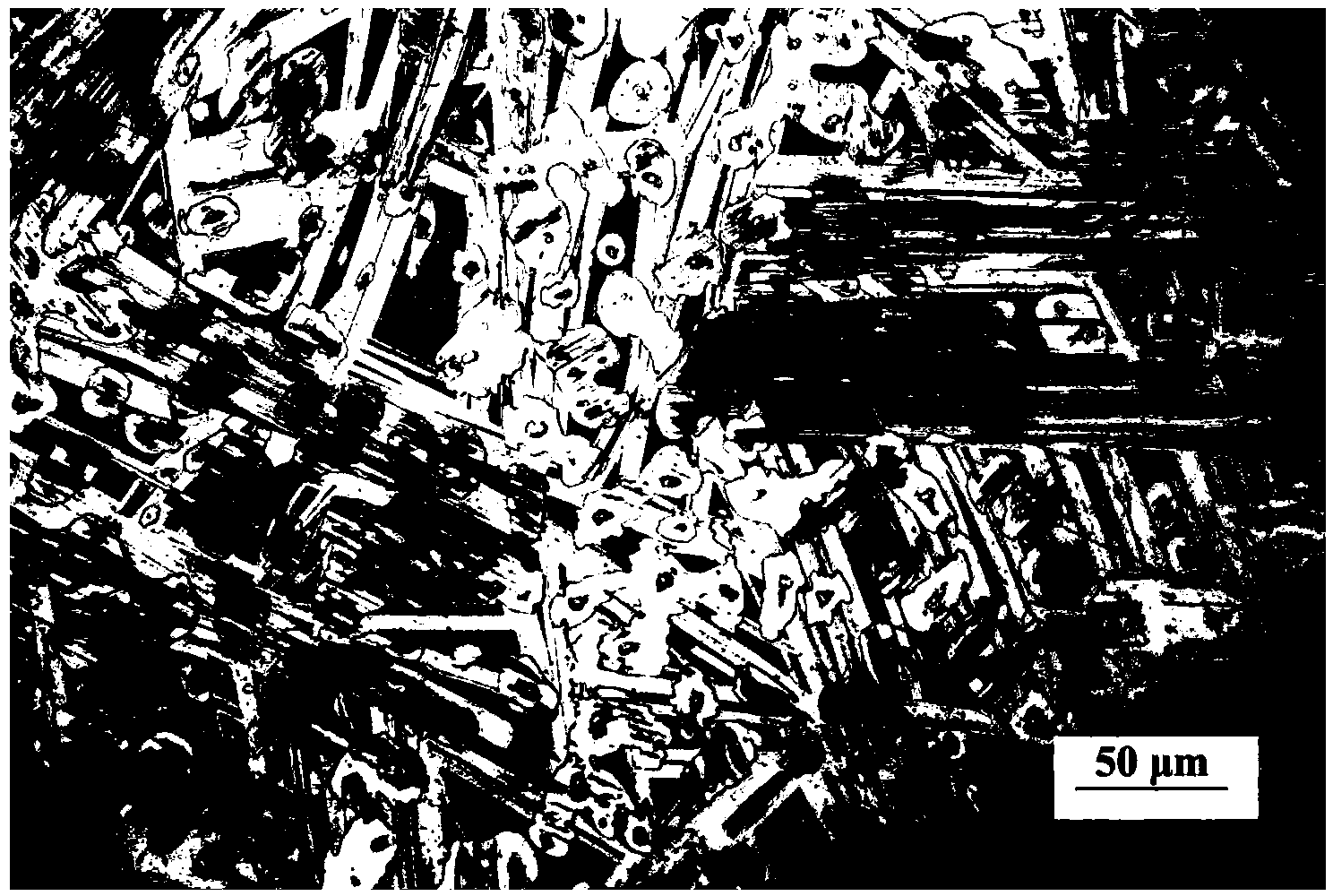

Embodiment 1

[0023] In this embodiment, the magnesium alloy is composed of the following components by mass: Ni: 4.03%; Y: 4.74%; Zr: 0.03%; unavoidable impurities are about 0.15%, of which Al 0.02%, Si 0.02%, Cu 0.01%, Fe 0.02%.

[0024] The method for preparing a high-strength and high-plasticity magnesium alloy in this embodiment comprises the following steps:

[0025] 1), material selection: select raw materials according to the above mass ratio, the selected raw materials for this implementation are industrial pure magnesium ingots, industrial pure zirconium, Mg-40%Y master alloy and Mg-30%Ni master alloy;

[0026] 2) Smelting: First, heat industrial pure magnesium to 700°C in a resistance crucible boiler, and after the masterbatch is completely melted, heat up to 750°C for slag removal; then add zirconium ingots and Mg-40%Y master alloy into the crucible and Mg-30%Ni intermediate alloy, stir for 2 to 5 minutes after they are completely melted, and keep the temperature for 15 minutes...

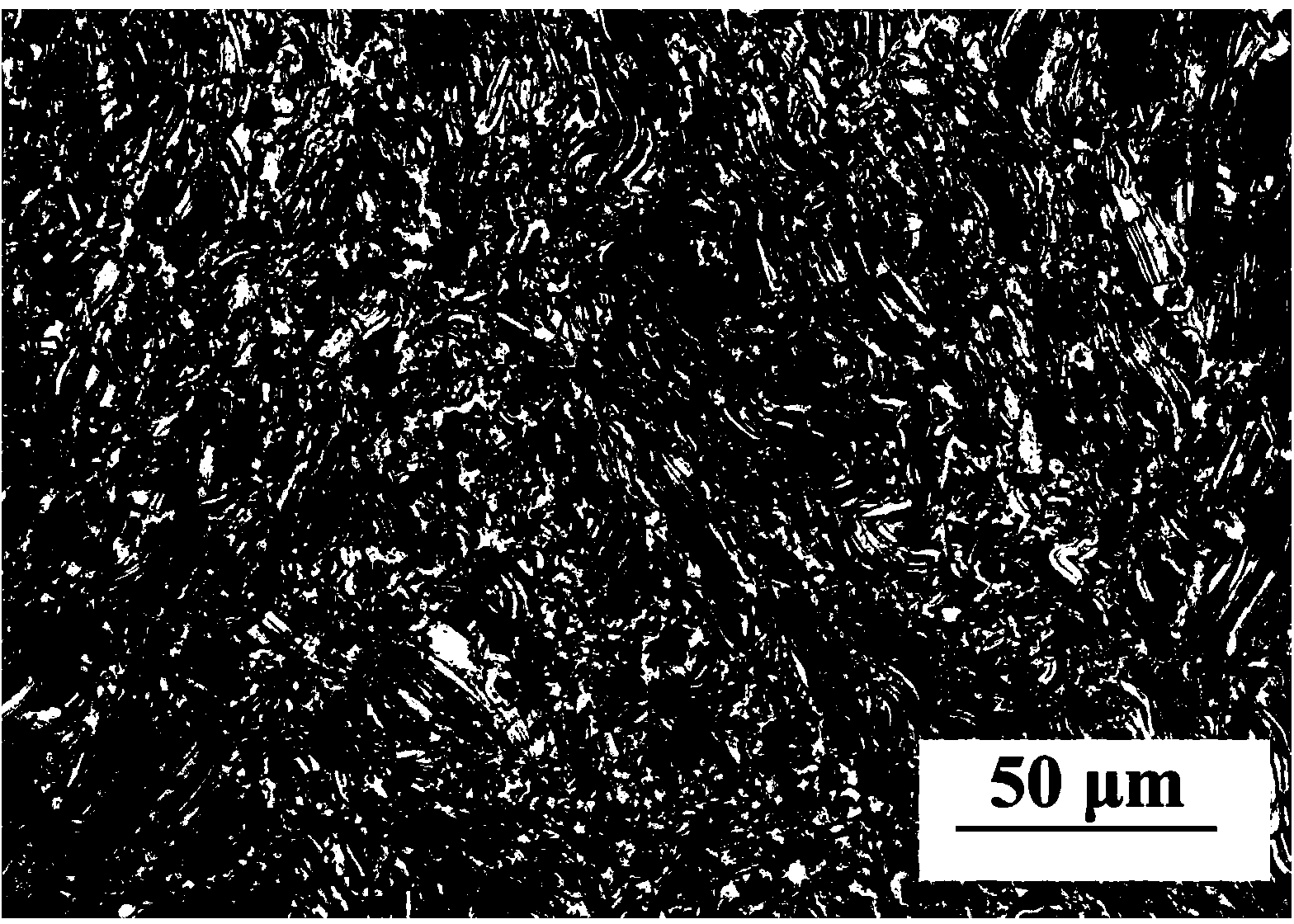

Embodiment 2

[0032] In this embodiment, the magnesium alloy is composed of the following components by mass: Ni: 3.54%; Y: 5.08%; Zr: 0.01%; unavoidable impurities 0.15%, the rest is magnesium, of which Al 0.01%, Si 0.03 %, Cu 0.02%, Fe 0.02%.

[0033] The method for preparing a high-strength and high-plasticity magnesium alloy in this embodiment comprises the following steps:

[0034] 1), material selection: select raw materials according to the above mass ratio, the selected raw materials for this implementation are industrial pure magnesium ingots, industrial pure zirconium, Mg-40%Y master alloy and Mg-30%Ni master alloy;

[0035] 2) Smelting: First, heat industrial pure magnesium to 700°C in a resistance crucible boiler, and after the masterbatch is completely melted, heat up to 750°C for slag removal; then add zirconium ingots and Mg-40%Y master alloy into the crucible and Mg-30%Ni intermediate alloy, stir for 2 to 5 minutes after they are completely melted, and keep the temperature ...

Embodiment 3

[0041] The following examples will disclose a high-strength and high-plasticity magnesium alloy, which is composed of the following components by mass: Ni: 3.0%; Y: 5.0%; Zr: 0.01%; unavoidable impurities 0.12%; the rest is magnesium; Al 0.02%, Si 0.02%, Cu 0.02%, Fe 0.03%.

[0042] The method for preparing a high-strength and high-plasticity magnesium alloy in this embodiment comprises the following steps:

[0043] 1), material selection: select raw materials according to the above mass ratio, the selected raw materials for this implementation are industrial pure magnesium ingots, industrial pure zirconium, Mg-40%Y master alloy and Mg-30%Ni master alloy;

[0044]2) Smelting: First, heat industrial pure magnesium to 700°C in a resistance crucible boiler, and after the masterbatch is completely melted, heat up to 750°C for slag removal; then add zirconium ingots and Mg-40%Y master alloy into the crucible and Mg-30%Ni intermediate alloy, stir for 2 to 5 minutes after they are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com