Magnesium alloy refiner and preparation method thereof

A refiner and magnesium alloy technology, applied in the field of grain refiner and its preparation, can solve the problems of high temperature of carbon-containing material treatment method, reduced corrosion resistance of magnesium alloy, serious magnesium oxidation burning loss, etc., to avoid Effects of oxidative burn loss, improved tensile strength, and no segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

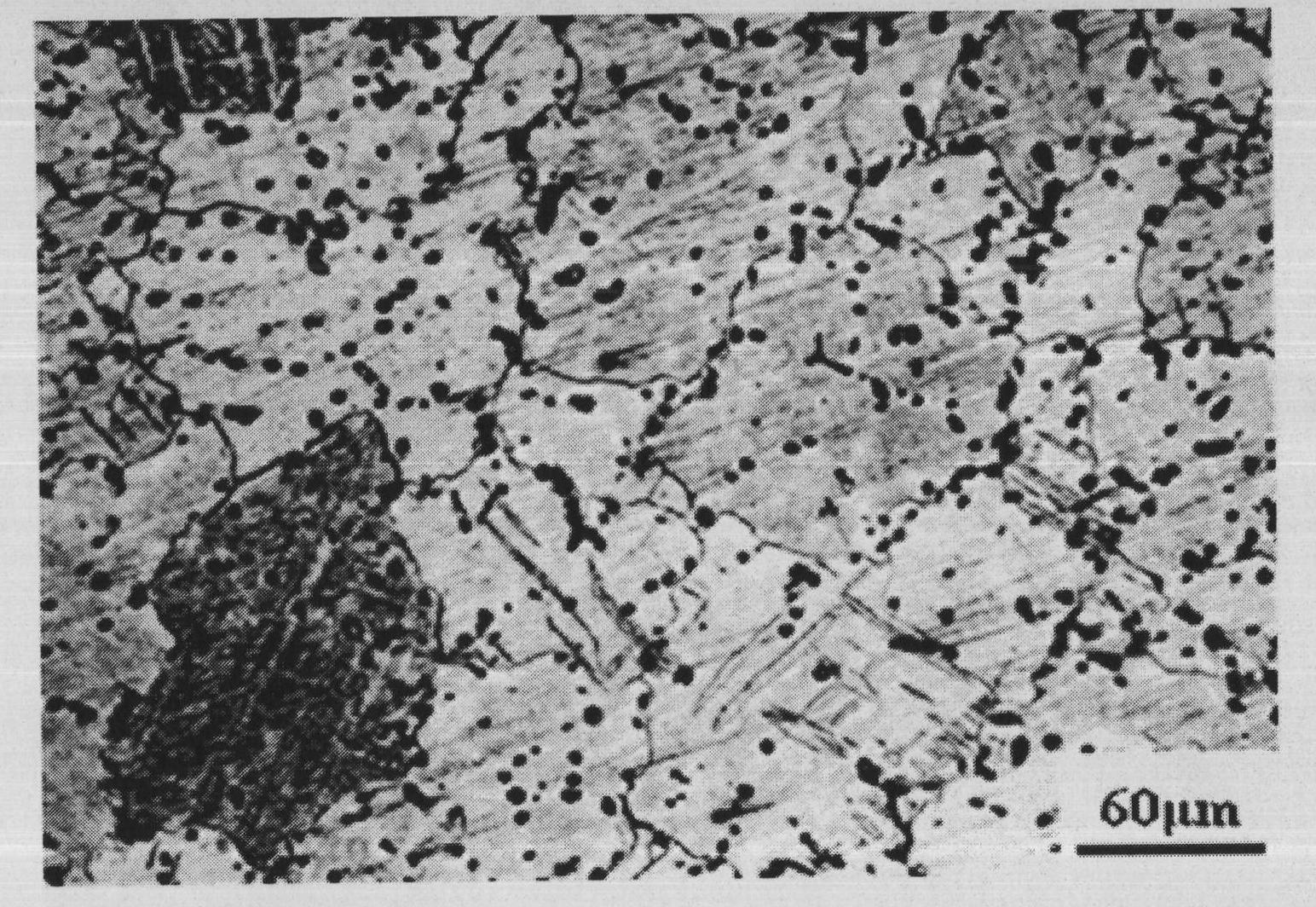

[0012] Embodiment 1: A magnesium alloy refining agent in this embodiment is made of 1%-30% calcium metal and 70%-99% primary magnesium ingots by mass percentage.

[0013] The addition temperature of the magnesium alloy refining agent in this embodiment is consistent with the smelting temperature of conventional magnesium alloys, and no overheating treatment is required, which avoids the oxidation and burning loss of magnesium. During use, the elements in the magnesium alloy refiner are completely dissolved into the magnesium alloy melt, and no impurities or gases are generated; the calcium element is used to refine the structure of the magnesium alloy, which has no effect on the corrosion resistance of the magnesium alloy , the raw materials in the magnesium alloy refiner are metal calcium and primary magnesium ingots, compared with the alloy method, the raw material cost of metal calcium is greatly reduced than that of cerium, so that the cost of the present invention is relat...

specific Embodiment approach 2

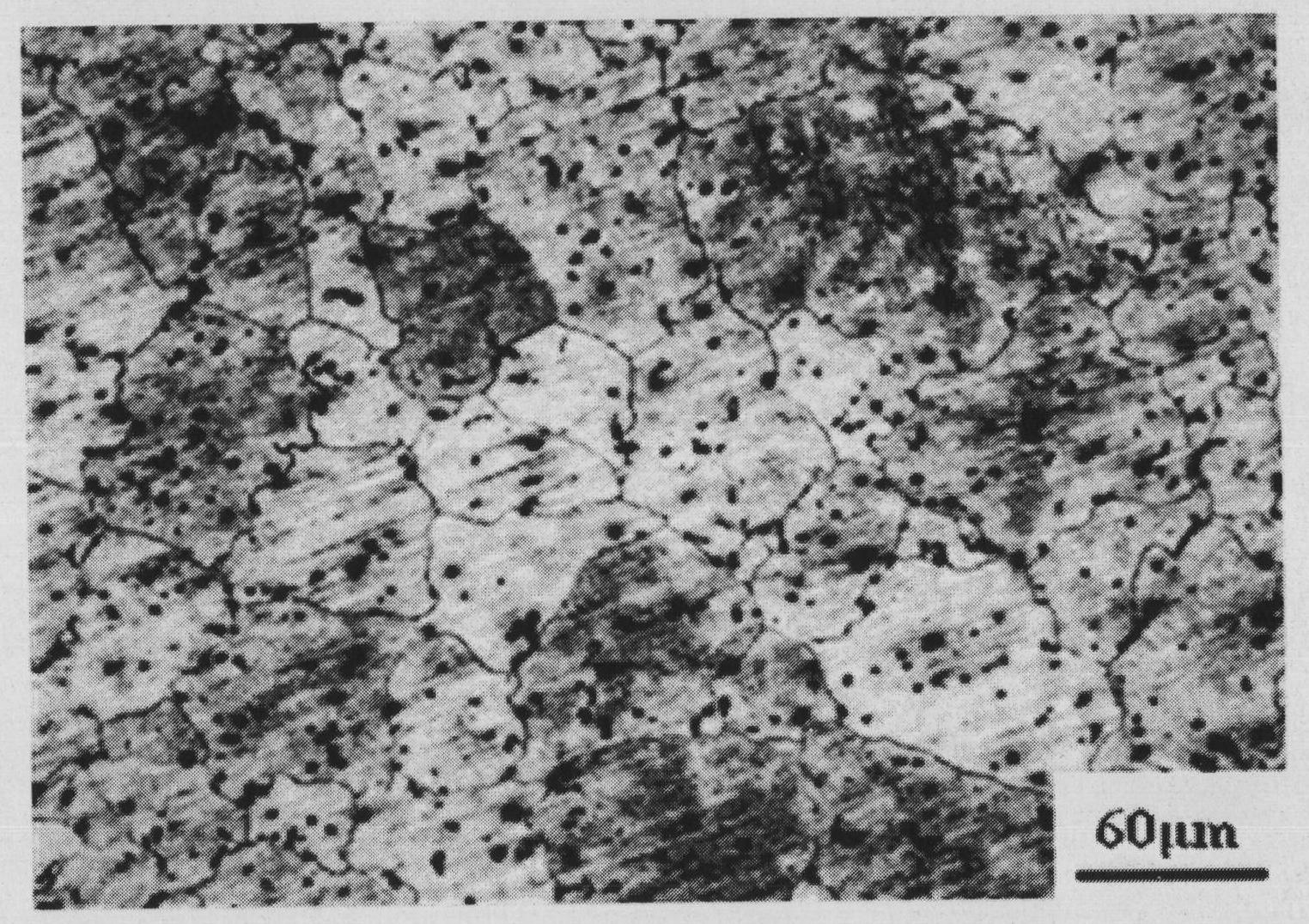

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: a magnesium alloy refiner is made of 5% to 25% calcium metal and 75% to 95% primary magnesium ingots by mass percentage.

specific Embodiment approach 3

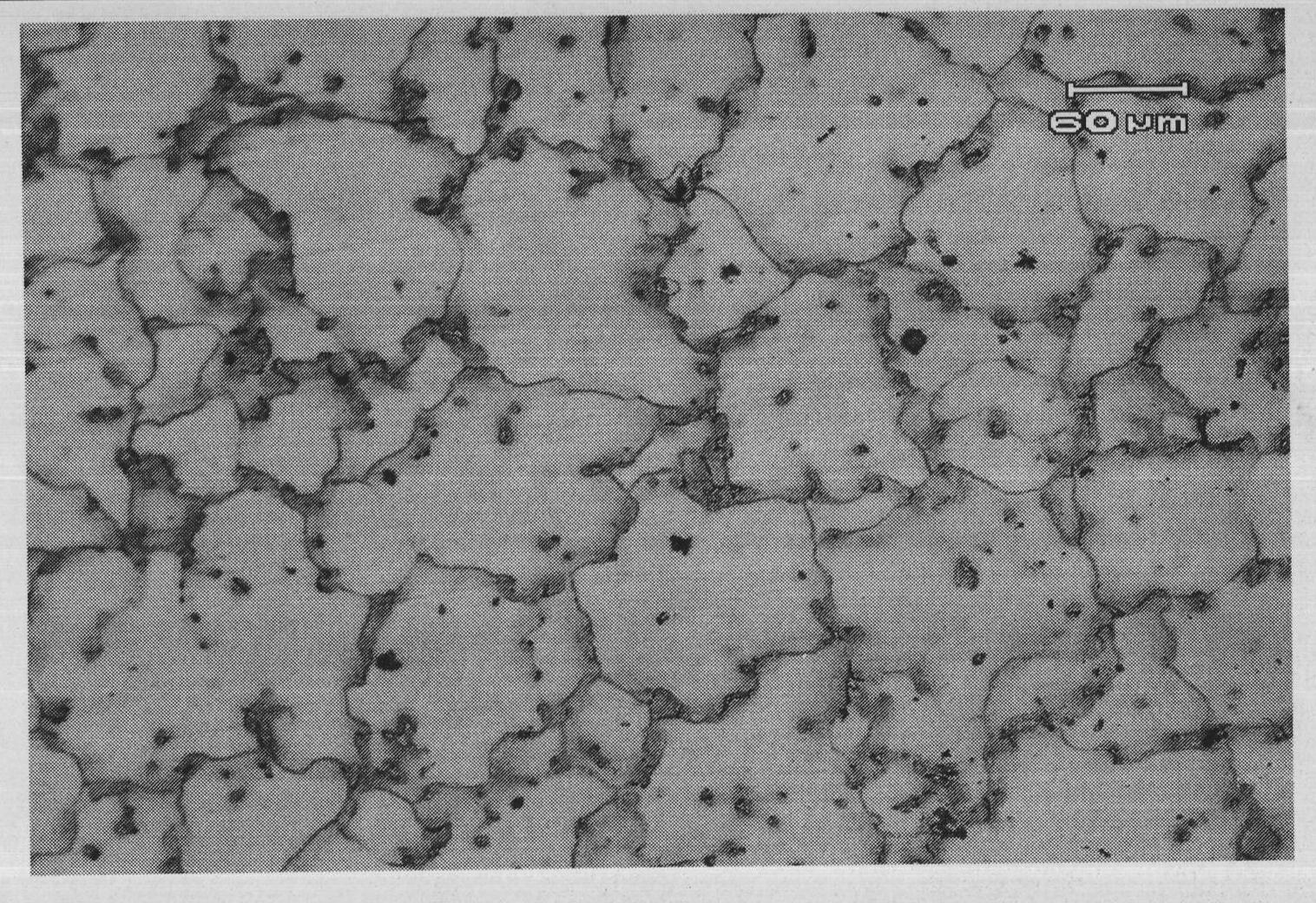

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: a magnesium alloy refiner is made of 15% calcium metal and 85% primary magnesium ingots by mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com