Patents

Literature

42results about How to "Play a role in refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

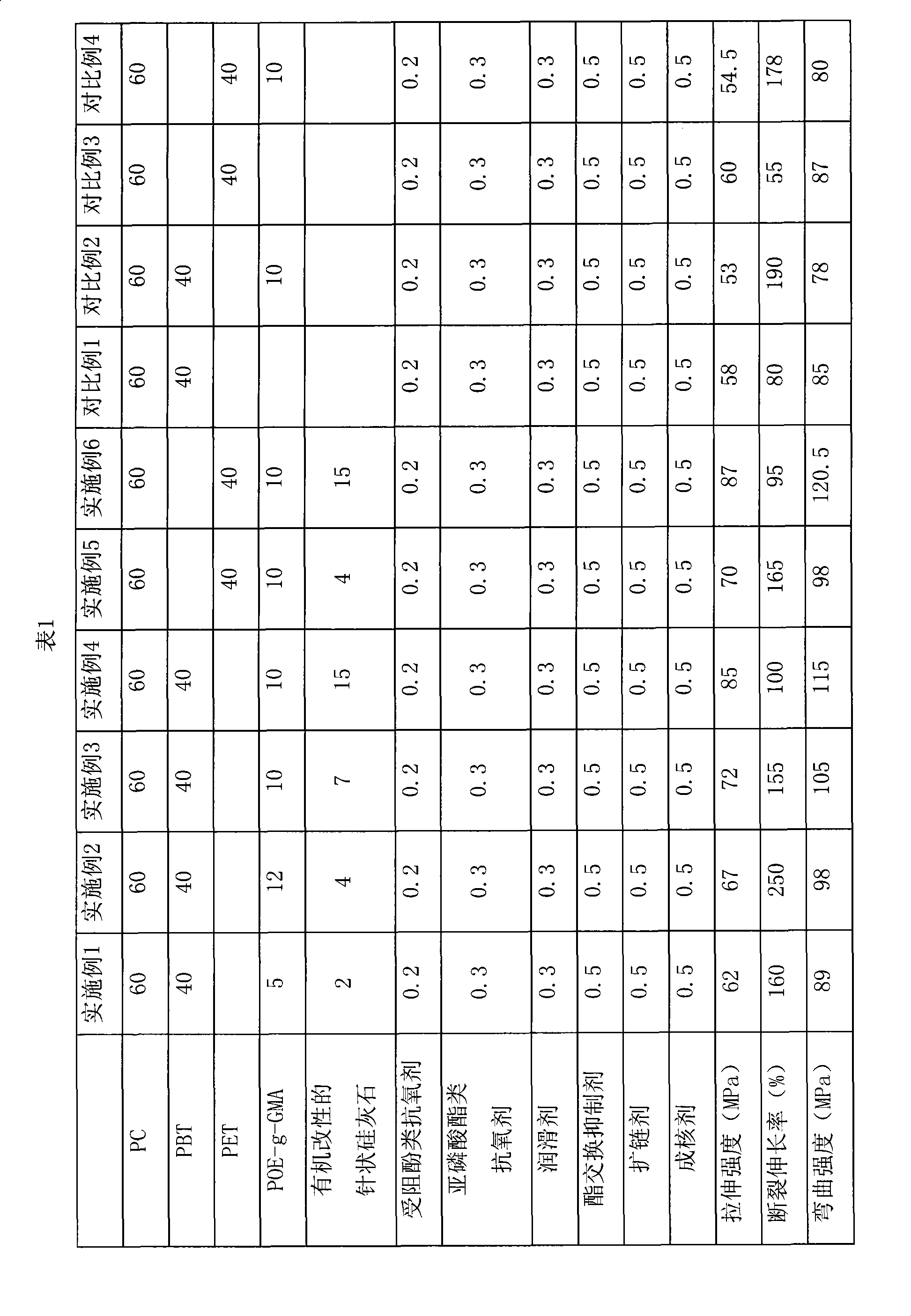

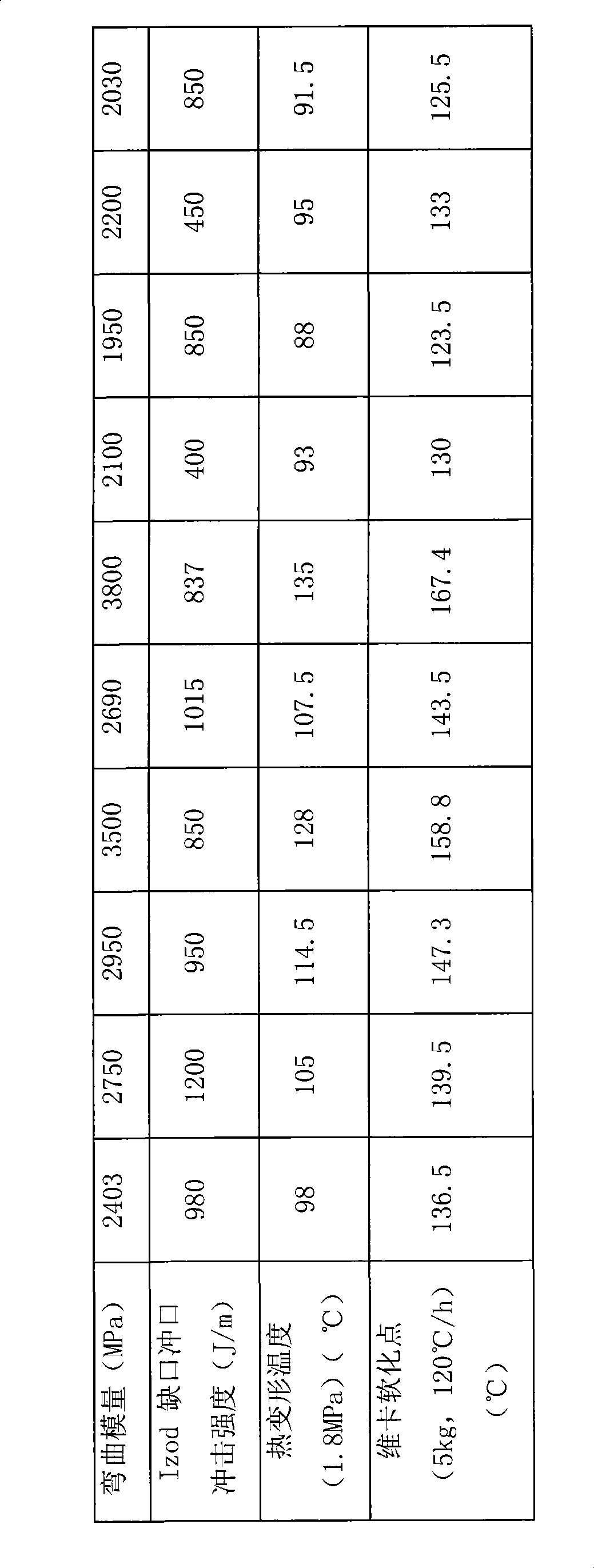

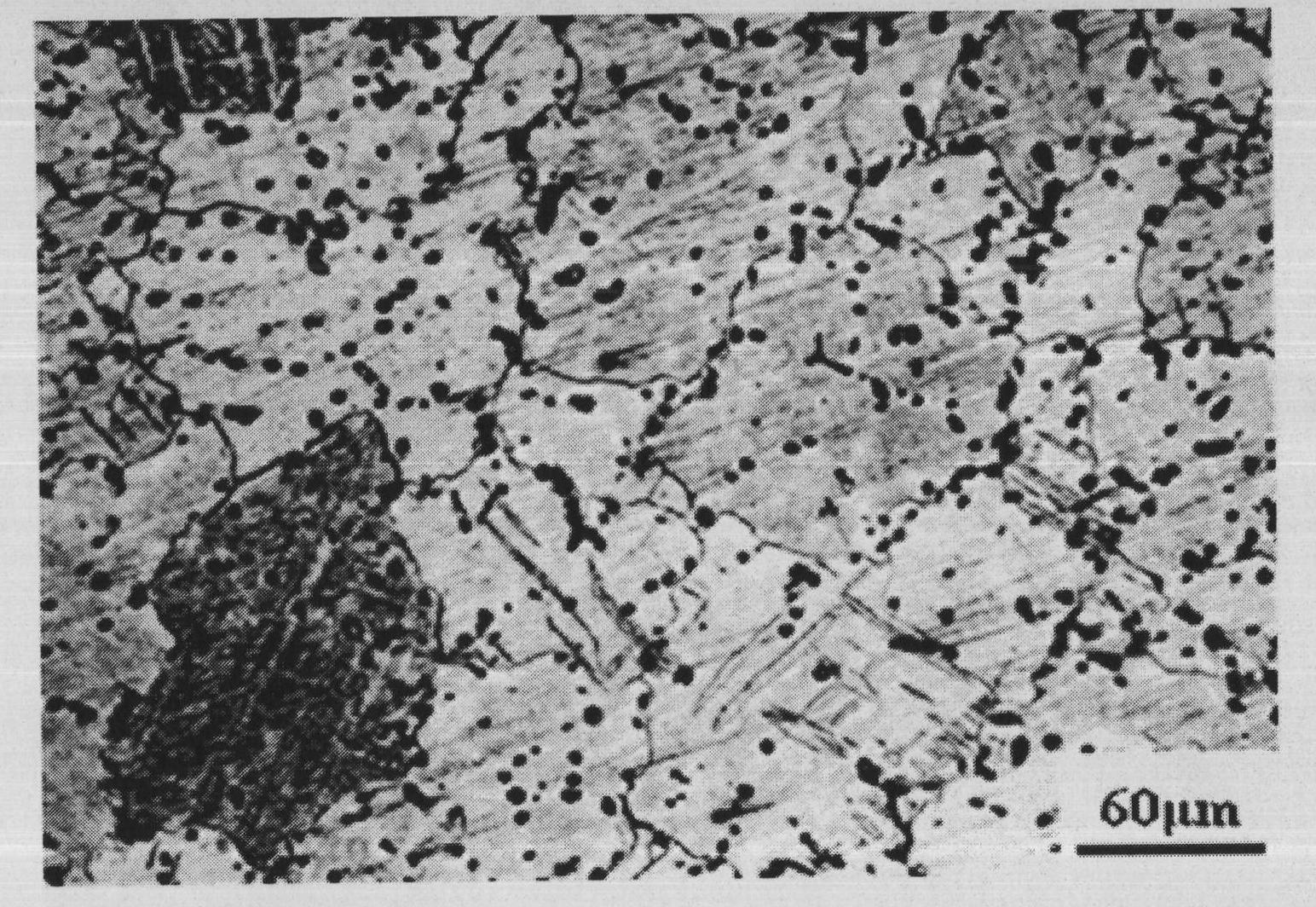

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method has high temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

High-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and preparation method thereof

The invention discloses high-plasticity two-phase yttrium-containing magnesium-lithium-aluminum alloy and a preparation method thereof. The alloy comprises the following specific components in percentage by weight: 9.50-10.80% of Li, 3.00-5.00% of Al, 0.50-0.70% of Y, 0.10-0.30% of Zr and the balance of Mg; the alloy has the structural characteristics that an alpha phase, a beta phase and a precipitated phase exist at the same time, wherein the alpha phase is a Mg-based solid solution and is in a close-packed hexagonal structure, the beta phase is a Li-based solid solution and is in a body-centered cubic structure, and the precipitated phase is a rare earth compound Al2Y; and the alloy has the characteristics of low density, high plasticity and higher strength. The preparation method disclosed by the invention is a normal-temperature plastic deformation method which combines casting with equal channel angular extrusion or traditional extrusion deformation process; and compared with the traditional high-temperature deformation process, the preparation method has good practicality and is simpler and more convenient to operate, and can be used for effectively lowering the production cost, thus the preparation method has good industrial production prospects.

Owner:SOUTH CHINA UNIV OF TECH

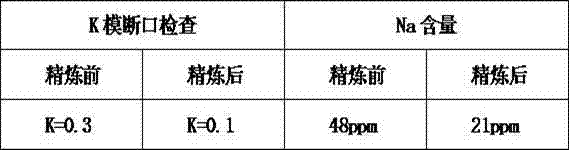

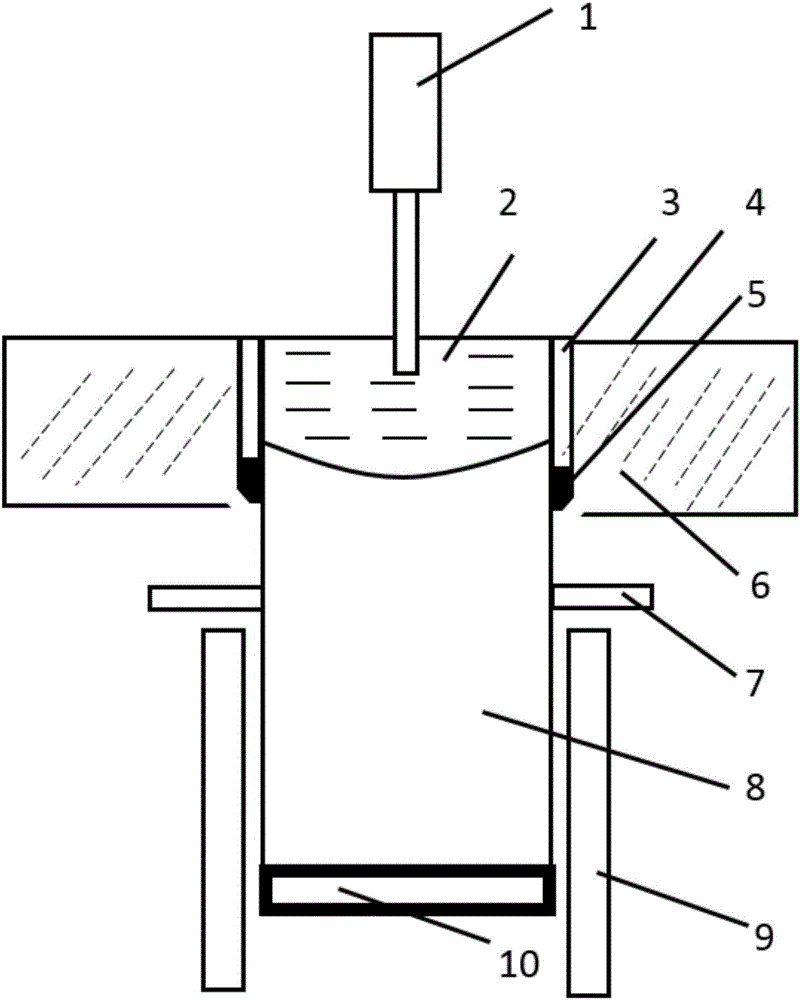

Flux for aluminum and aluminum alloy melt refining and preparation method of flux

The invention discloses flux for aluminum and aluminum alloy melt refining. The flux consists of the following components in percentage by mass: 5-40% of Na3AlF6 and K3AlF6, 20-50% of MgCl2 and / or AlF3, 10-40% of KCl, 3-8% of K2TiF6 and 0.1-3% of graphite powder, and the flux is prepared by virtue of a hybrid melting method. Na3AlF6 and K3AlF6 in the flux have effects of adsorbing and dissolving impurities of aluminum oxide, and Na3AlF6 and K3AlF6 can be matched for use to achieve relatively good effects. The flux is prepared by adopting a hybrid melting method, so that the water in the components can be completely removed, and the flux is uniform in component and stable in quality.

Owner:SHANDONG NANSHAN ALUMINUM

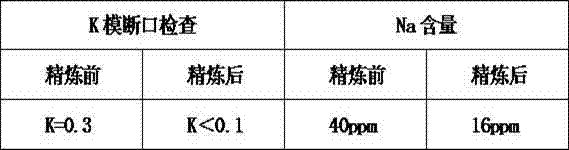

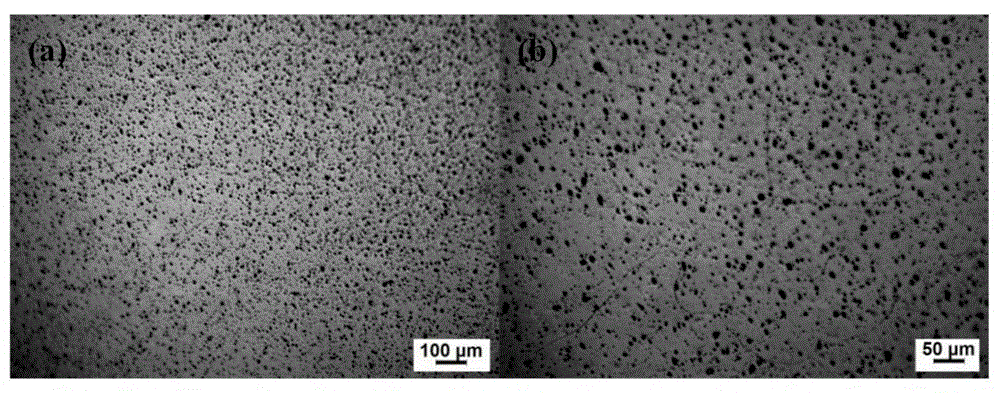

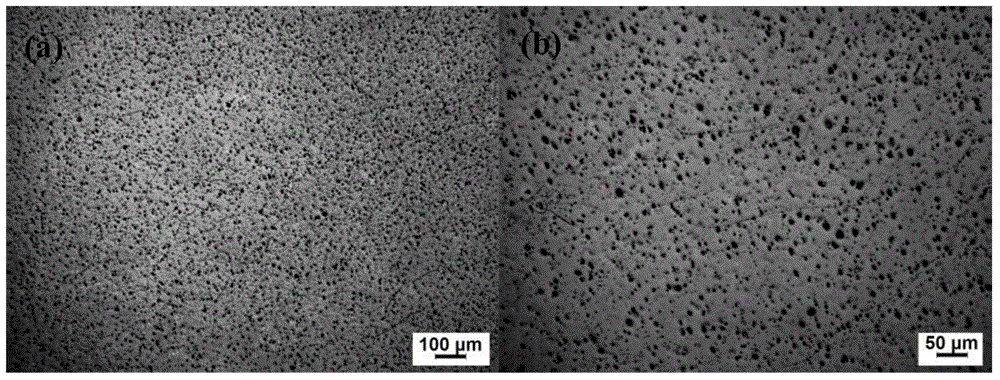

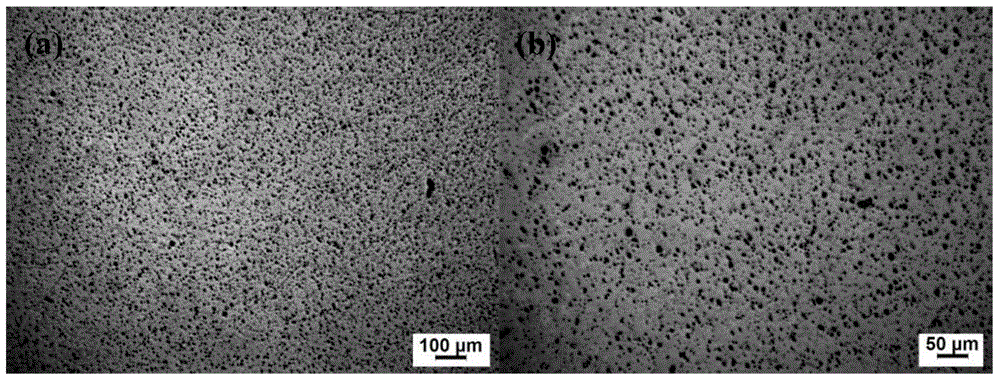

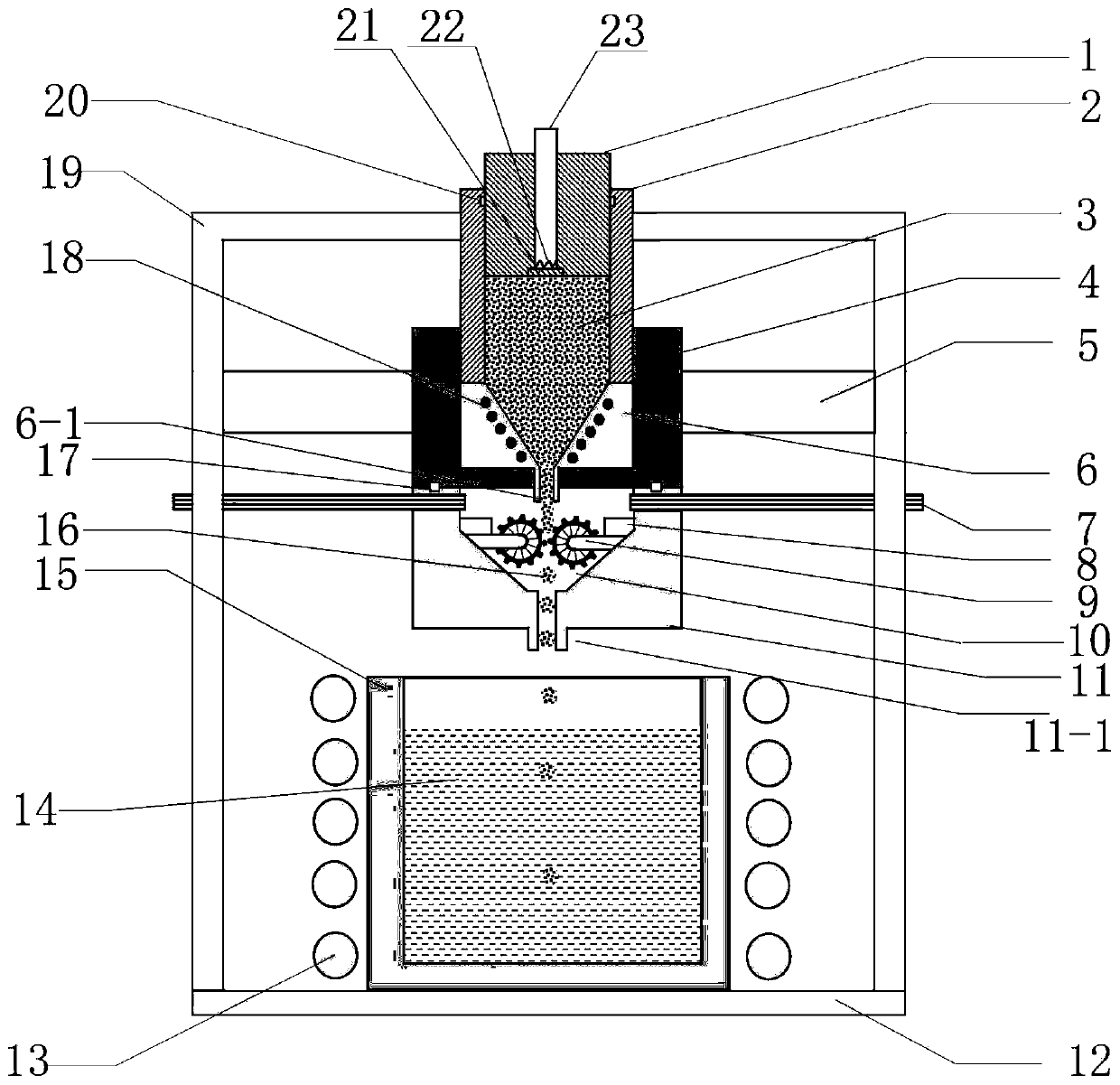

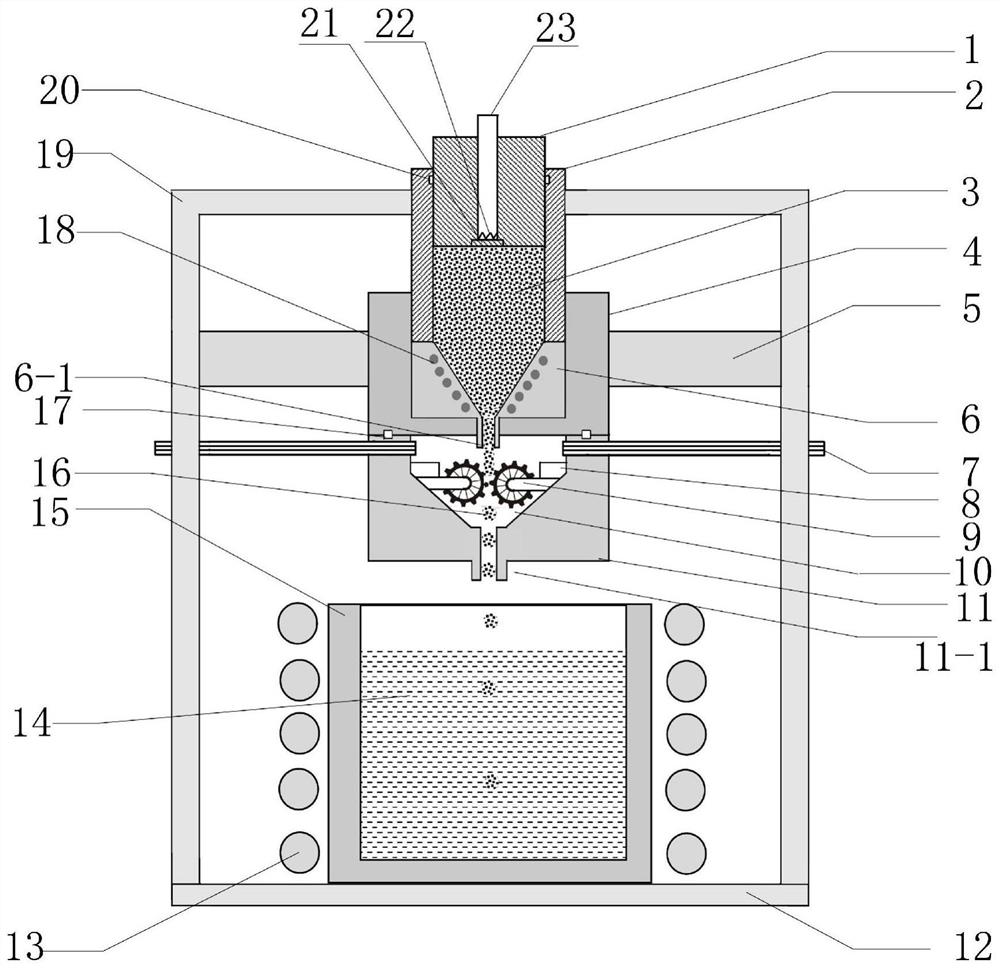

Semi-continuous casting method for in-situ particle reinforced aluminum-based composite

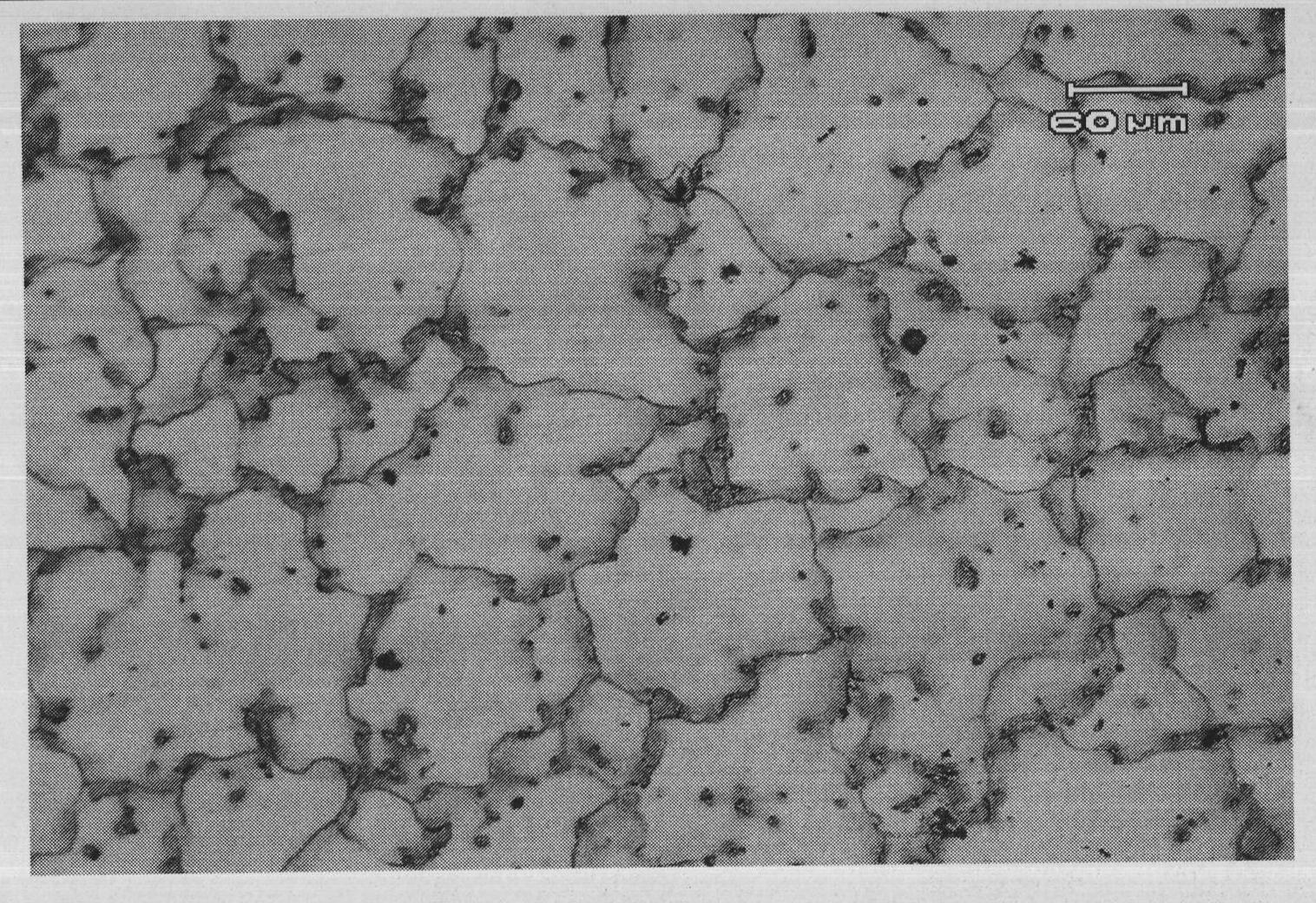

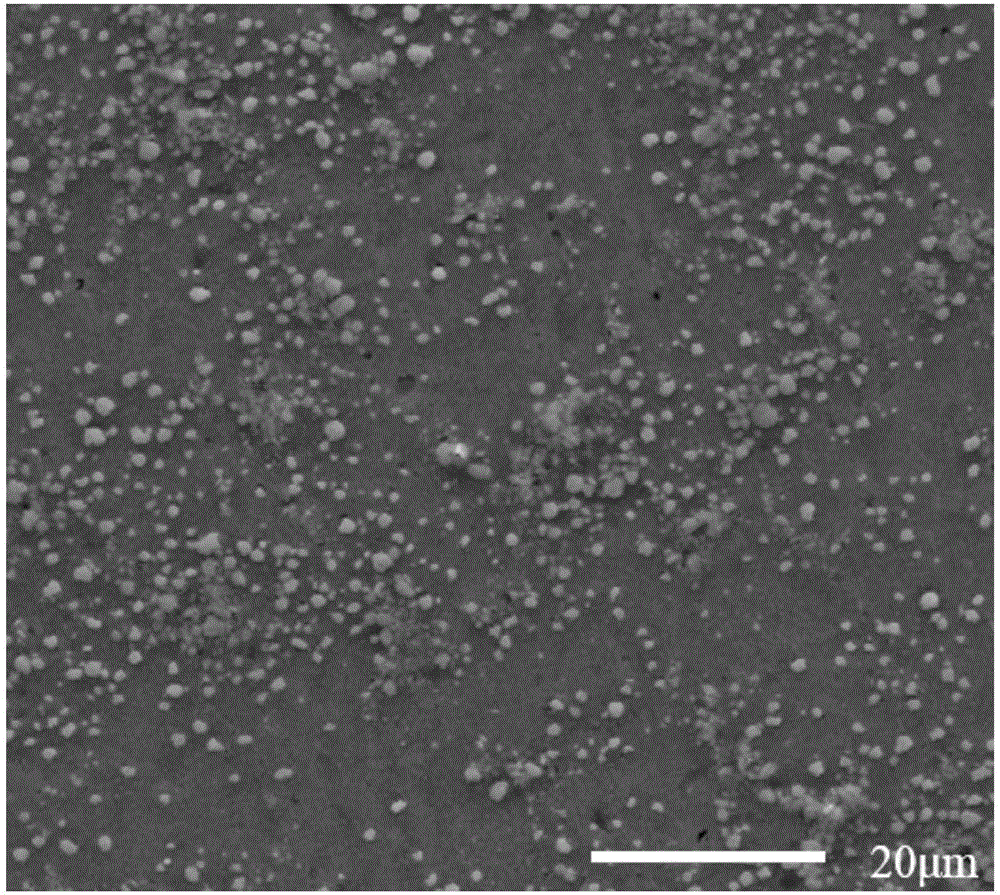

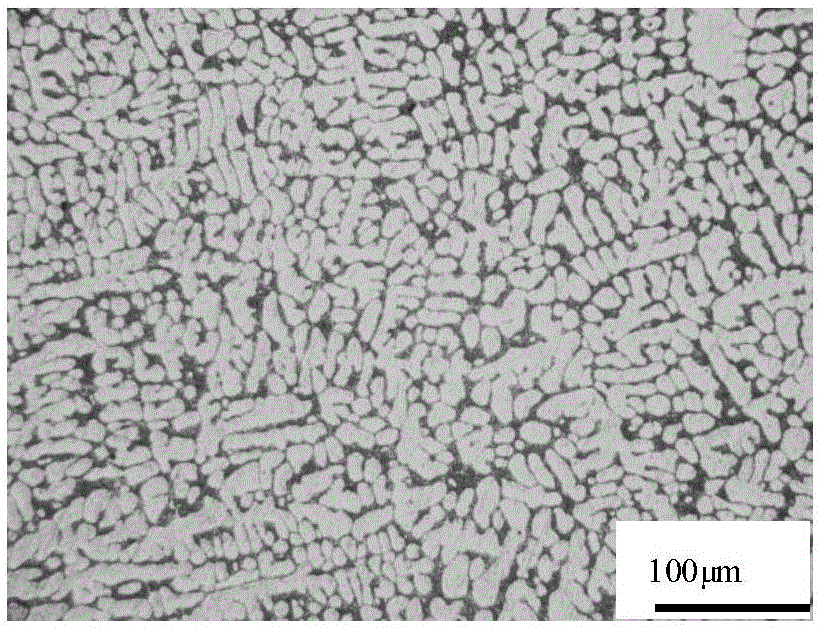

The invention relates to a semi-continuous casting method for an in-situ particle reinforced aluminum-based composite and belongs to the technical field of composite forming. The method includes the following steps that an in-situ ceramic particle reinforced aluminum-based composite is taken, melted and subjected to heat preservation to obtain composite melt; the composite melt is injected into a crystallizer, and meanwhile ultrasonic treatment is carried out; when the melt is solidified at the position of a graphite annulus, a dummy bar head descends, and meanwhile cooling water is started to cool a cast rod; when the dummy bar head descends to the position of a scraper blade, the scraper blade starts to make contact with the surface of the cast rod, and the cooling water is scraped away from the surface of the cast rod; along with descending of the dummy bar head, the cast rod slowly enters a heating furnace to be annealed; and the cast rod is hoisted after casting is completed, and an aluminum-based composite semi-continuous cast rod is obtained. The method is simple in device, easy and convenient to operate and suitable for large-scale industrial production of the aluminum-based composite, and has good practical application value, and large-size in-situ particle reinforced aluminum-based composite cast ingots with fine crystal particles and evenly-distributed particles can be prepared.

Owner:ALUMICS MATERIALS INSTIUTUTE ANHUI CO LTD

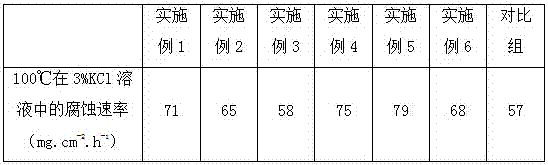

High-strength rapid-corrosion magnesium alloy and preparation method thereof

The invention discloses high-strength rapid-corrosion magnesium alloy and a preparation method thereof. The high-strength rapid-corrosion magnesium alloy comprises the chemical components including, by weight, 2-7% of Al, 1-2% of Zn, 0.2-0.6% of Zr, 0.1-0.3% of Si, 0.1-0.5% of Mn, 0.1-0.3% of Ca, 1-1.5% of Fe, 0.05-5% of Cu and the balance magnesium and inevitable impurities, wherein the Si and the Mn are added as intermediate alloy. The magnesium alloy has the more excellent strength, ductility, hardness and mechanical performance such as creep resistance compared with those of traditional commercial magnesium alloy and the advantage of rapid dissolution.

Owner:田哿

Aluminum alloy sodium-free refining agent containing rare earth

The invention discloses an aluminum alloy sodium-free refining agent containing rare earth. The aluminum alloy sodium-free refining agent comprises, by weight, 50-60 parts of KCl, 30-35 parts of K2CO3, 10-15 parts of LiCl, 30-35 parts of AlF3, 10-12 parts of potassium fluoroaluminate, 5-10 parts of CaF2, 5-10 parts of carbon powder, 15-25 parts of light calcium carbonate, 2-8 parts of CaO, 2-5 parts of fluorite and 5-10 parts of rare earth. By means of the refining agent, no impurity sodium is introduced into the aluminum alloy refining process, rare earth metal is added, and therefore the mechanical performance of alloy can be effectively improved.

Owner:广西平果铝合金精密铸件有限公司

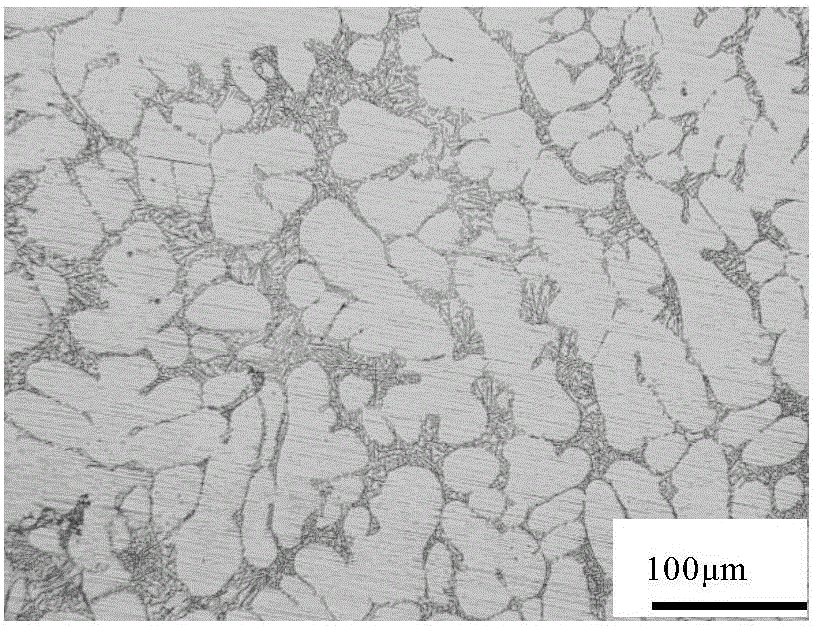

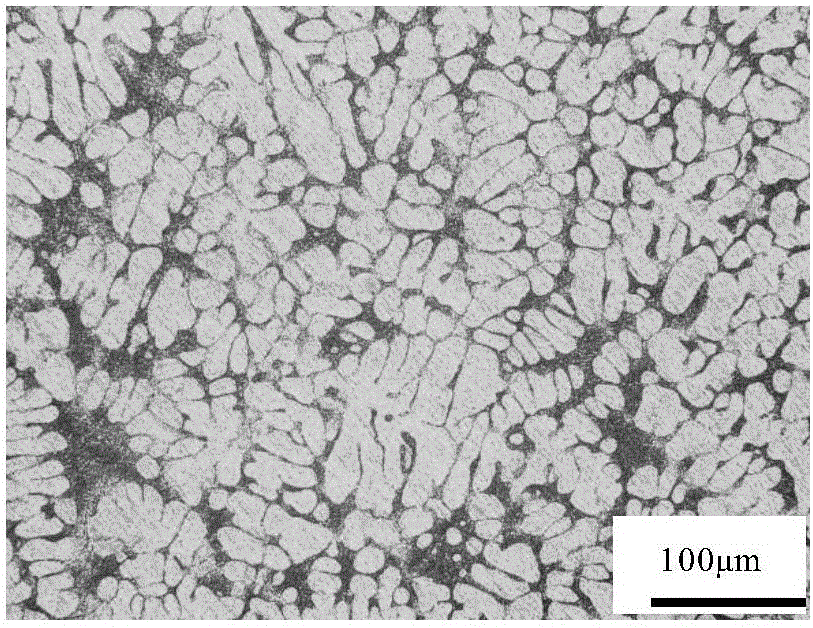

Modification treatment method of aluminium alloy

The invention belongs to the technical field of aluminium alloys, and relates to a modification treatment method of an aluminium alloy. The modification treatment method is characterized in that Al-10Zr and Al-12Er intermediate alloys are adopted as an alterant, an A356 aluminium alloy is adopted as a modification object; 0.20% of Zr and 0.40% of Er are added, and the microstructure and performance of the A356 aluminium alloy are remarkably improved through the technological processes like batching, smelting and modification treatment; and tensile strength of the A356 aluminium alloy subjected to modification treatment of the Al-10Zr intermediate alloy and the Al-12Er intermediate alloy is 225 MPa, elongation is 6.4%, and tensile strength and elongation are respectively improved by 52.8% and 36.2% compared with tensile strength and elongation of the A356 aluminium alloy which is not subjected to modification treatment.

Owner:JIANGSU UNIV OF TECH

Special aluminum alloy ingot for wheel hub and preparation method of aluminum alloy ingot

InactiveCN105506411AThe average grain size is smallEvenly distributedMechanical property6111 aluminium alloy

The invention discloses a special aluminum alloy ingot for a wheel hub. The aluminum alloy ingot comprises the components by mass percent: 1.2-2.0% of Si, 0.05-0.2% of Mn, 0.05-0.1% of Cr, 2.0-2.8% of Mg, 0.1-0.3% of Cu, 0.1-0.3% of Zn, 0.3-0.8% of Ti, 0.09-0.25% of Sn, 0.1-0.2% of Zr, 0.1-0.2% of Er, 0.1-0.2% of Sr, less than or equal to 0.5% of gross other metallic and nonmetallic impurity elements, and the balance Al. A preparation method of the aluminum alloy ingot comprises the steps of melting, refining, standing and casting. According to the aluminum alloy ingot, the elements such as Ti, Zr, Er and Sr are added, so that metamorphism and refining functions can be exerted on the structure of an aluminium alloy, so that the mechanical property of the aluminium alloy is improved, and a guarantee is provided for improving the mechanical property of the aluminium alloy wheel hub.

Owner:BAISE UNIV

Sodium-free refining agent for smelting aluminum alloy and preparation method thereof

InactiveCN107779637ARefining purpose of removing slag and degassingPlay a role in refinementSlagSodium salt

The invention discloses a sodium-free refining agent for aluminum alloy smelting and a preparation method thereof. The refining agent is prepared from the following raw materials in parts by weight: 15-20 parts of potassium fluorosilicate, 8-12 parts of potassium chloride, 10‑16 parts of aluminum fluoride, 8‑14 parts of magnesium chloride, 12‑18 parts of calcium fluoride, 18‑24 parts of potassium fluotitanate, 10‑14 parts of potassium fluoborate, 6‑10 parts of titanium dioxide, 4‑10 parts of potassium nitrate parts, 3‑5 parts of toner. The preparation method is as follows: (1) fully mix and stir each component of the formula amount, carry out crushing treatment, and pass through a sieve of 80-100 mesh, (2) put the mixture obtained in step (1) into a crucible, heat and melt to remove crystal water , the heating temperature is 80-100°C, the heating time is 2-2.5 hours, and then kept for 50-60 minutes, (3) the product obtained in step (2) is cooled to 40-45°C, and the obtained granular mixture It is the refining agent, and (4) is packed in a waterproof plastic bag. The refining agent of the invention can serve the refining purpose of removing slag and degassing, does not contain sodium salt components, and has good refining effect.

Owner:徐州轩辕铝业有限公司

Aluminum alloy refining agent containing La, Er and Zr

The invention discloses an aluminum alloy refining agent containing La, Er and Zr. The aluminum alloy refining agent comprises a material A and a material B, wherein the material A comprises, by weight, 70-80 parts of NaCl, 50-56 parts of KCl, 12-18 parts of LiCl, 30-36 parts of NaF, 10-12 parts of AlF3, 10-12 parts of sodium fluoroaluminate, 12-18 parts of carbon powder, 20-28 parts of light calcium carbonate and 5-10 parts of CaO; the material B is composed of C2Cl6, TiO2 and metal with the weight ratio of 5: 1.5-2: 1-1.5, and the metal is mixed metal containing Mg, La, Er and Zr; the material A and the material B are matched for use and the weight ratio is 2-4: 1. In the process of refining aluminum alloy through the refining agent, dehydrogenation and oxide inclusion removal can be achieved, and the refining agent has the modification and refining function on an aluminum alloy structure.

Owner:广西平果铝合金精密铸件有限公司

Aluminum alloy cast rod for casting hub and preparing method of aluminum alloy cast rod

The invention discloses an aluminum alloy cast rod for casting a hub. The cast rod is made of raw materials including, by mass percentage, 0.4% of Si, 0.12% of Mn, 0.08% of Cr, 1.7% of Mg, 0.2% of Cu, 0.6% of Ti, 0.05% of B, 0.11% of Sb, 0.16% of Zr, 0.04% of Gd, not larger than 0.5% of other metal and nonmetallic impurity elements and the balance Al. The preparing method of the aluminum alloy cast rod comprises the steps of smelting, refining, standing and casting. According to the aluminum alloy cast rod, elements of Sb, Zr, Gd and the like are added to achieve the modification and refining effects on an aluminum alloy structure, the cast rod is used for producing the aluminum alloy hub, the tensile strength, the yield strength and the ductility of the aluminum alloy hub can be greatly improved, and the excellent impact toughness and corrosion resistance are achieved.

Owner:BAISE UNIV

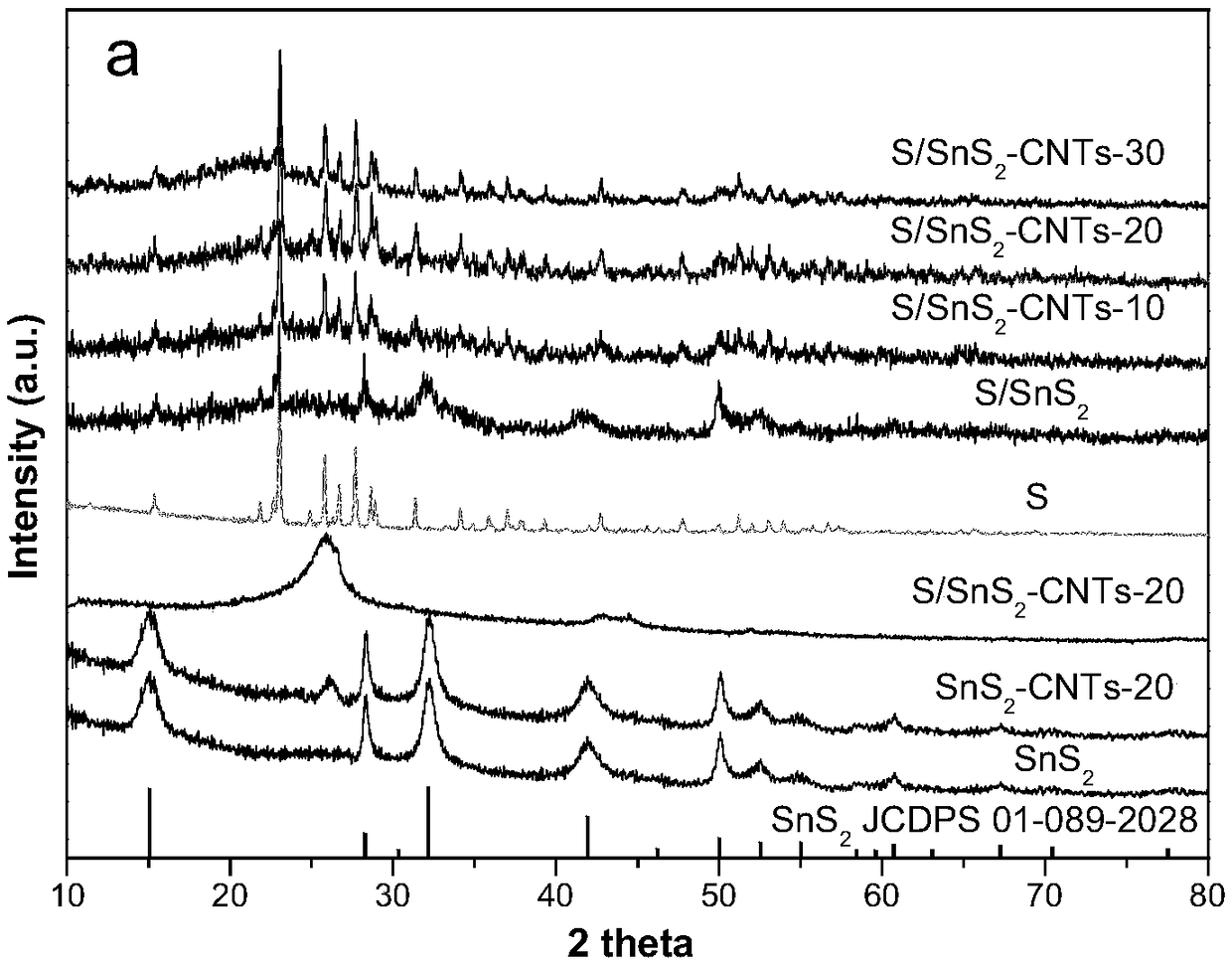

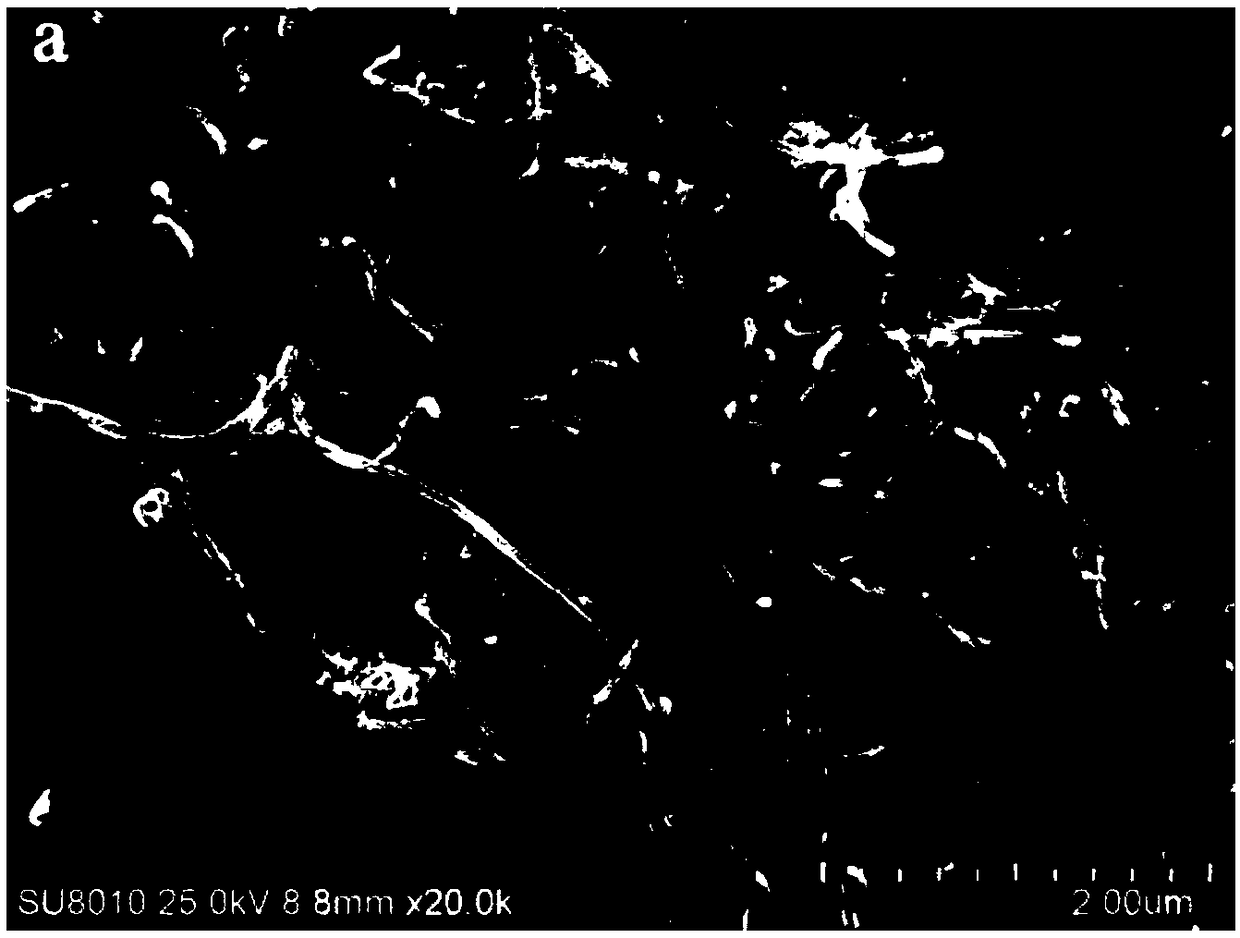

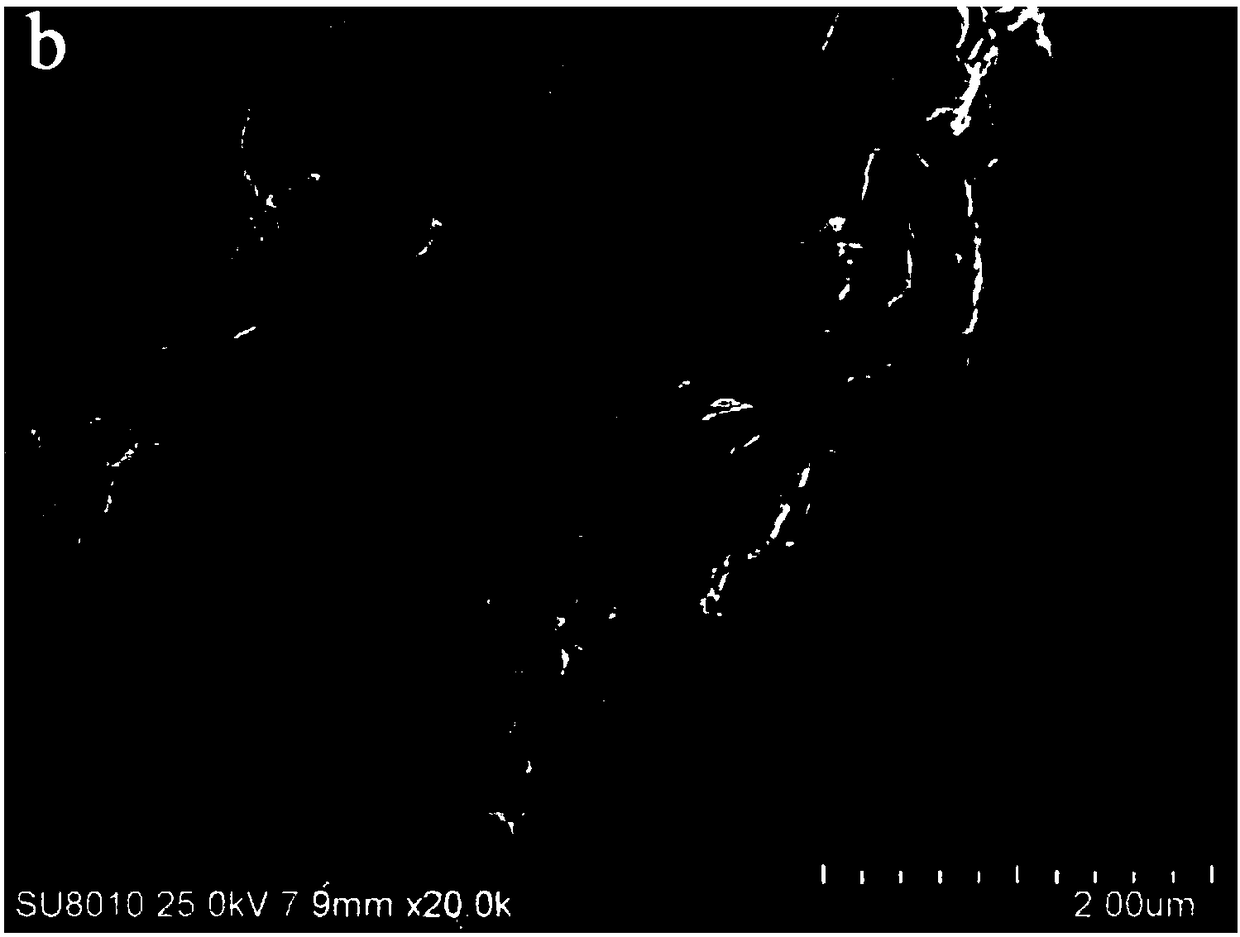

SnS2-CNTs composite material and preparation method thereof, as well as preparation method of composite anode material

InactiveCN108878885AImprove electrochemical performanceImprove conductivityCell electrodesLi-accumulatorsSulfurChemical adsorption

The invention relates to the field of materials, in particular to a SnS2-CNTs composite material and a preparation method thereof, as well as a preparation method of a composite anode material. preparation method of the SnS2-CNTs composite material comprises the steps that tin chloride pentahydrate is added to a uniformly dispersed CNTs dispersion solution, and after uniform stirring is completed,a first solution is obtained; a sulfur source solution is added to the first solution, after uniform stirring is completed, reaction is carried out for 20-25 hours at 175-185 DEG C, and after coolingis carried out until the room temperature is reached, the SnS2-CNTs composite material is obtained. The preparation method of the composite anode material comprises the step that the SnS2-CNTs composite material and sulfur are subjected to thermal melting treatment, and a SnS2-CNTs composite anode material is obtained. Tin disulfide has high chemical adsorption performance, carbon nano tubes havegood electrical conductivity, SnS2 and CNTs have a synergistic effect, and the electrochemical properties of sulfur anodes are improved effectively.

Owner:SOUTHWEST JIAOTONG UNIV

High-strength cast magnesium alloy and preparation method thereof

ActiveCN105112751AGood aging precipitation strengthening effectImprove mechanical propertiesUltimate tensile strengthAluminium element

The invention relates to a high-strength cast magnesium alloy. The high-strength cast magnesium alloy is an Mg-Bi-Al-Zn-Sr alloy and comprises components in percentage by weight as follows: 3wt%-8.0wt% of Bi, 0.5wt%-4.0wt% of Al, 0.1wt%-1.0wt% of Zn, 0.05wt%-0.15wt% of Sr and the balance of Mg. The Bi element is used as a main alloy element, a large quantity of Mg3Bi2 phases are formed through simple alloying means, a small quantity of aluminum and zinc elements are used for improving the strength of the alloy, so that the high-strength cast magnesium alloy is developed from the alloy series, and the alloy has the tensile strength of 276-296 MPa, the yield strength of 155-170 MPa and the elongation of 5.3%-7.3% and has mechanical properties comparable with those of rear earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

Aluminum alloy casting rod for automobile hub and preparation method for aluminum alloy casting rod

The invention discloses an aluminum alloy casting rod for an automobile hub. The aluminum alloy casting rod consists of the following components in percentage by mass: 0.8-1.3% of Si, 0.03-0.09% of Mn, 0.9-1.6% of Mg, 0.3-0.8% of B, 0.15-0.28% of Cr, 0.03-0.08% of Fe, 0.03-0.08% of Nd, 0.09-0.16% of La, 0.04-0.08% of Yb, less than or equal to 0.5% of other metal and non-metal impurity elements, and the balance of Al. A preparation method for the aluminum alloy casting method comprises the steps of melting, refining, stewing and casting. The casting rod disclosed by the invention is utilized to produce the aluminum alloy hub, so that the obtained aluminum alloy hub is beautiful in outlook, is light in weight and is high in strength, has relatively high corrosion resistance and relatively high fatigue resistance, and has a long service life.

Owner:BAISE UNIV

Aluminium alloy casting preparing method

The invention discloses an aluminium alloy casting preparing method, and relates to the technical field of aluminum alloy preparing methods. According to the method, pure aluminum powder, pure titanium powder and borohydride titanium powder are mixed evenly to serve as a refiner, the refiner mixed powder is subjected to high-temperature preheating to enable borohydride titanium to be decomposed, through high-temperature, the self-propagating reaction in the refiner mixed powder forms fine TiAl3 and TiB2 particles, through high-temperature extrusion, a filamentous refiner containing hydrogen holes is formed, and then is cut into fine blocky refiners, finally, through the high-pressure spraying method, the fine blocky refiners are sprayed to aluminum alloy melt, after the melt is solidified,the refining effect is achieved, and residual hydrogen in the aluminum alloy melt is subjected to vacuum pumping so as to be removed. The method is simple in process, the prepared aluminum alloy is good in refining effect, and the aluminum alloy casting strength is improved.

Owner:刘燕岭

1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel and preparation method thereof

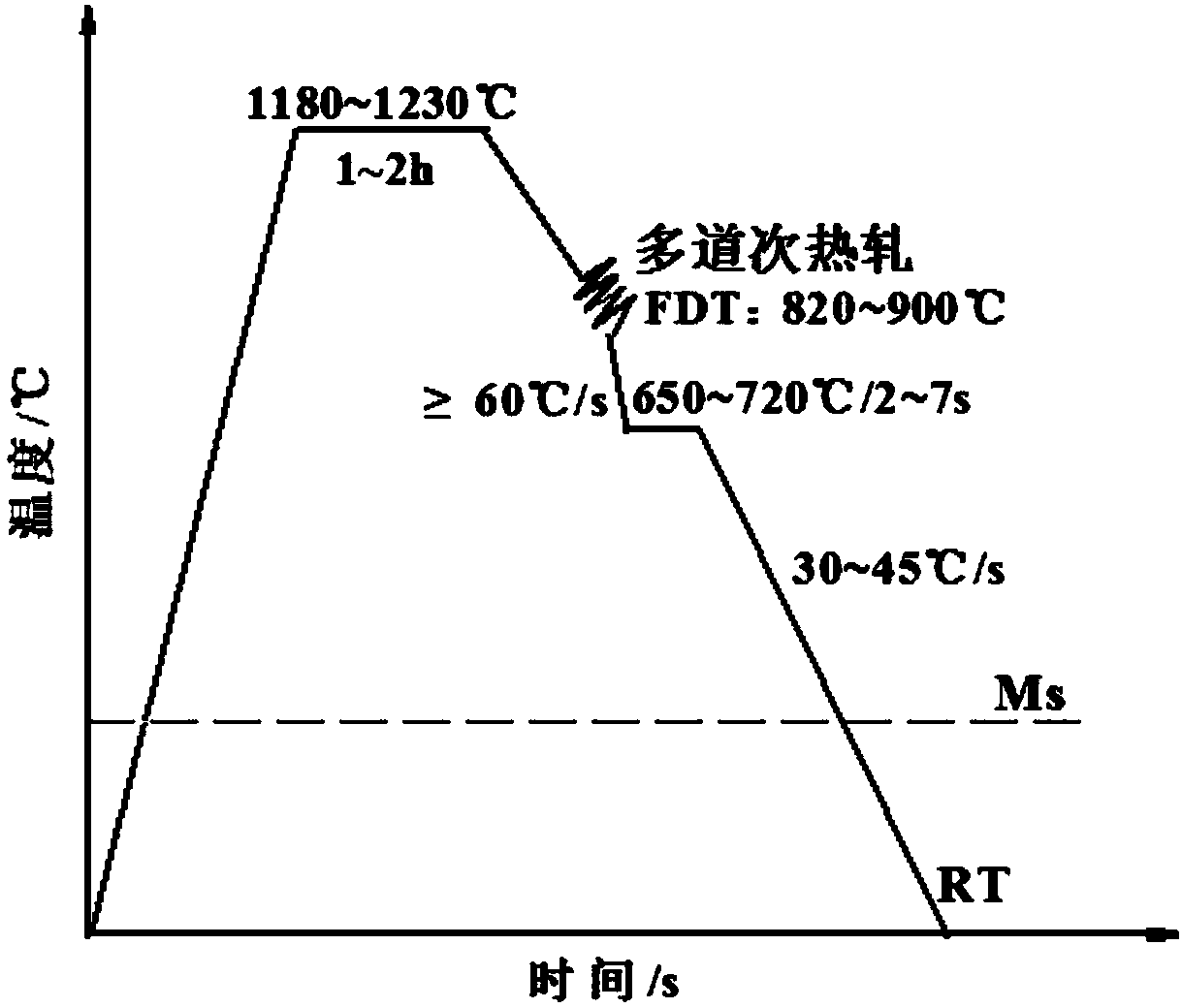

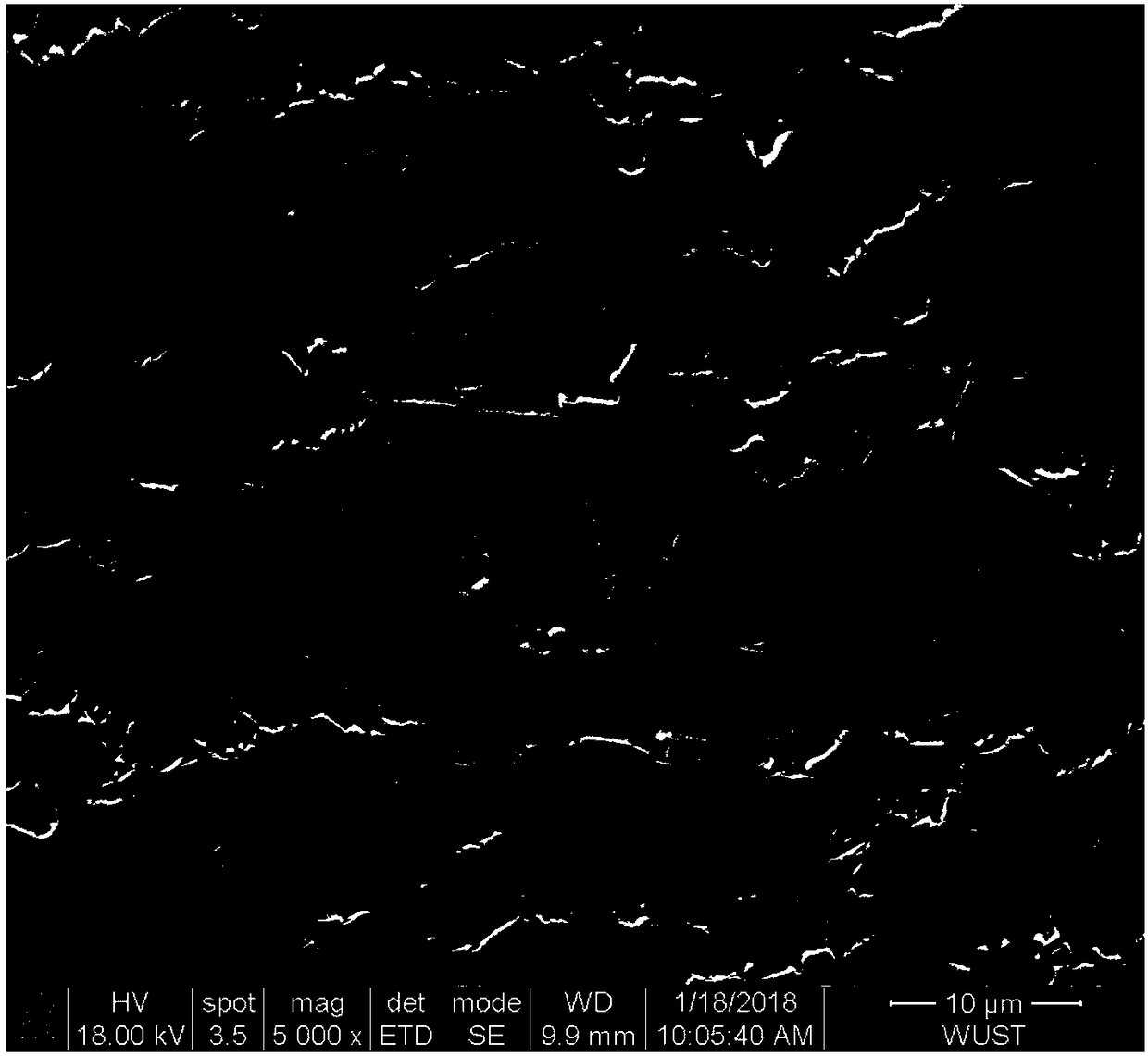

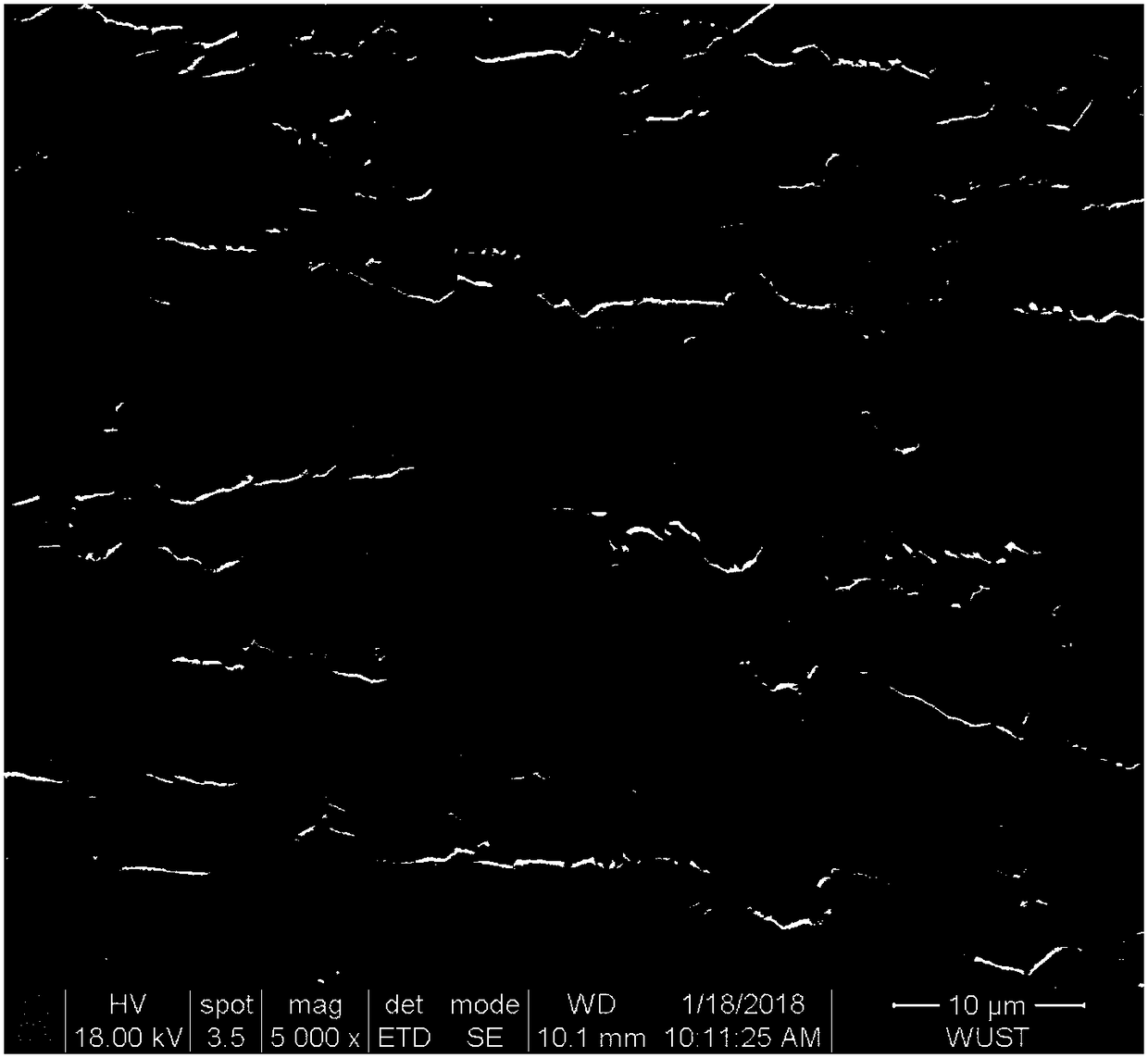

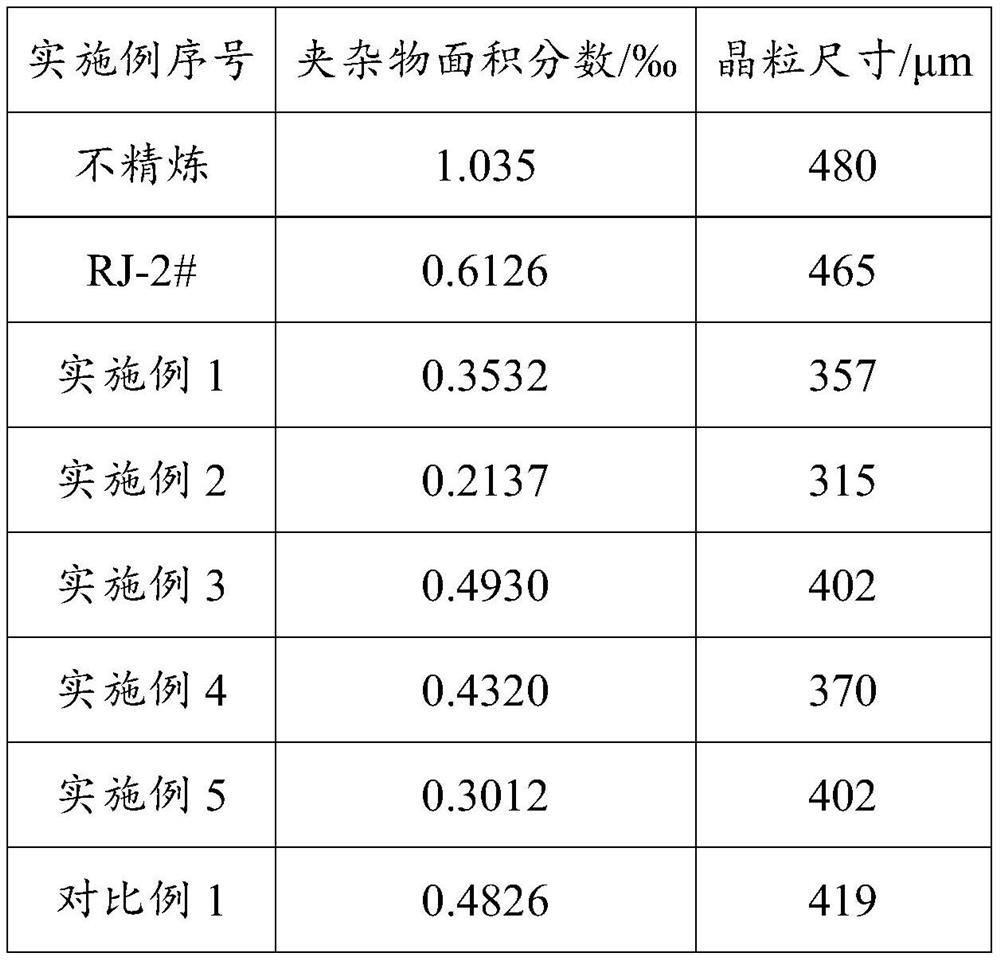

The invention relates to 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel and a preparation method of the 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel. According to the technical scheme, the low-carbon hot-rolled dual-phase steel comprises the chemical components of 0.17-0.22 wt% of C, 0.2-0.8 wt% of Si, 1.4-2.0 wt% of Mn, 0.03-0.06 wt% of Al, 0.03-0.06wt% of Nb, 0.001-0.004 wt% of B, not larger than 0.020 wt% of P, not larger than 0.005 wt% of S and the balance Fe and inevitable impurities. According to the preparation method, the chemical components are smelted, refining and blank casting are conducted, the blank is placed in a heating furnace, the charging temperature is 700-850 DEG C, and the temperature is kept at 1180-1230 DEG C for 1-2 h;large reduction is adopted during the first three passes, the reduction rate is 40%-60%, and the finish rolling temperature is 820-900 DEG C; after finish rolling, the rolled blank is rapidly cooledto 650-720 DEG C, air cooling relaxation is conducted for 2-7 s so as to separate out ferrite, then the obtained steel is water cooled to the indoor temperature, and therefore the 1400MPa-grade B micro-alloyed low-carbon hot-rolled dual-phase steel is obtained. The technology is simple, the production cost is low, the strength, plasticity and tenacity of the obtained product match well, and the formation performance is excellent.

Owner:WUHAN UNIV OF SCI & TECH

Composite flux suitable for magnesium-aluminum-series magnesium alloy, preparation method thereof and application thereof

The invention discloses composite flux suitable for magnesium-aluminum-series magnesium alloy, a preparation method of the composite flux and application of the composite flux. The composite flux comprises, by mass, 30-40 parts of magnesium chloride, 20-30 parts of potassium chloride, 4-8 parts of sodium chloride, 6-12 parts of barium chloride, 3-6 parts of calcium chloride, 6-12 parts of calcium fluoride, 0.5-3 parts of carbon powder, 1-5 parts of titanium powder and 1-30 parts of mixed rare earth oxide. The mixed rare earth oxide is a mixture of cerium oxide, yttrium oxide and scandium oxide. The preparation method of the composite flux comprises the steps of uniformly mixing the magnesium chloride, the potassium chloride, the sodium chloride, the calcium chloride, the barium chloride and the calcium fluoride, crushing the materials to form powder, then adding the carbon powder and the titanium powder to conduct mixing so as to obtain the composite flux suitable for the magnesium-aluminum-series magnesium alloy. The provided composite flux has the remarkable purifying and refining effects.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method hashigh temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

High conductivity copper clad aluminum magnesium alloy wire

InactiveCN106952672AImprove conductivityImprove mechanical propertiesSingle bars/rods/wires/strips conductorsConductive materialRare-earth elementManganese

The invention relates to a high conductivity copper clad aluminum magnesium alloy wire. The surface of the aluminum magnesium alloy core of the alloy wire is concentrically coated with a copper layer, and the aluminum magnesium alloy core comprises the following ingredients calculated by weight percentage: aluminum 94-96.6%, magnesium 2.1-3.9%, silicon 0.1-0.3%, manganese 0.1-0.3%, titanium 0.1-0.2%, iron 0.1-0.2%, molybdenum 0.2-0.4%, tungsten 0.4-0.6% and rare earth elements 0.1-0.3%. The volume ratio of the copper layer of the high conductivity copper clad aluminum magnesium alloy wire is 5-10%. The high conductivity copper clad aluminum magnesium alloy wire has good conductivity and good mechanical properties; the proportion of pure copper is decreased, therefore, the production costs are reduced; the rare earth elements are added, therefore, the influence of harmful impurities are eliminated; and the refined grain strengthens the function of the matrix, therefore, tthe mechanical strength, corrosion resistance and processability of the material are improved, and the conductivity is guaranteed.

Owner:浙江恒久电讯设备制造有限公司

Aluminum alloy casting rod for car hub and preparing method of rod

The invention discloses an aluminum alloy casting rod for a car hub and a preparing method of the rod. The aluminum alloy casting rod comprises, by mass percent, 0.3 to 1.5% of Si, 0.06 to 0.1% of Mn,0.8 to 1.5% of Mg, 0.2 to 0.5% of Zn, 0.3 to 0.6% of Ti, 0.04 to 0.06% of Be, 0.03 to 0.1% of Zr, 0.03 to 0.1% of Er, 0.01 to 0.05% of Ce, 0.2 to 0.6% of B, 0.08 to 0.1% of Cr, 0.02 to 0.06% of Nd and the balance Al and inevitable metal and non-metal impurity elements. According to the aluminum alloy bar, through adding of Er, Zr, Ce and the like, the metamorphic and refining effect on an aluminum alloy structure can be achieved, the casting rod is used for producing the aluminum alloy hub, the tensile strength, the yield and the ductility of the aluminum alloy hub can be greatly improved, and excellent impact toughness and corrosion resistance are achieved.

Owner:益阳仪纬科技有限公司

Aluminum alloy ingot used for hub and preparation method of aluminum alloy ingot

The invention discloses an aluminum alloy ingot used for a hub. The aluminum alloy ingot comprises, by mass, 0.8-1.5% of Si, 1.0-1.8% of Mg, 0.12-0.22% of Ni, 0.1-0.3% of Zn, 0.30-0.42% of Ti, 0.09-0.21% of Sr, 0.06-0.12% of Y, 0.08-0.14% of Er, 0.02-0.04% of Ga, 0-0.5% of other metal impurity elements and non-metal impurity elements, and the balance Al. A preparation method of the aluminum alloy ingot comprises the steps of melting, refining, standing and casting. According to the aluminum alloy ingot, the elements such as Ti, Y, Er and Ga are added so that aluminum alloy structures can be modified and refined, the mechanical properties of aluminum alloy are improved, and the effect that the mechanical performance of the aluminum alloy hub is improved is guaranteed.

Owner:广西平果铝合金精密铸件有限公司

Sodium-free refining agent used for smelting aluminum alloy

The invention discloses a sodium-free refining agent used for smelting an aluminum alloy. The refining agent is prepared from the following raw materials including, by weight, 10-16 parts of calcium fluoride, 10-14 parts of potassium fluorosilicate, 10-14 parts of potassium fluotitanate, 8-12 parts of potassium chloride, 8-14 parts of lithium chloride, 8-14 parts of magnesium chloride, 6-10 partsof titanium dioxide and 3-5 parts of carbon powder. According to the refining agent, in the refining process, the hydrogen removing effect is remarkable, oxide impurities in melt can be removed fully,hot slag is recovered more conveniently, and the recovery rate is higher. Due to containing of titanium, a certain effect of refining the alloy is achieved. The refining agent does not contain sodiumsalt ingredients and has a good refining effect.

Owner:徐州轩辕铝业有限公司

Die casting aluminum alloy

The invention discloses a die casting aluminum alloy. The die casting aluminum alloy comprises following components including, by weight percent, 8.5% to 10.5% of Si, 2.2% to 4.2% of Cu, 0.15% to 0.25% of Mg, 0.5% to 0.8% of Zn, 0.2% to 0.8% of Fe, 0.1% to 0.3% of Mn, 0.1% to 0.3% of Ni, 0.1% to 0.2% of Sn, 1.5% to 2.5% of Sr, 0.05% to 0.08% of Ti, and the balance Al. Al-Si eutecticum formed by Si and Al in the die casting aluminum alloy has the good plasticity, added Mg and Mn can improve alloy mechanical strength, in addition, through the synergistic effect of Sr, Ti and the other elements, an aluminum alloy structure can be refined, the average size of grains of the all portions of the aluminum alloy structure can be small, distribution is uniform, and toughness and ductility are greatly improved.

Owner:王婷

Aluminum alloy casting preparation method

The invention discloses an aluminium alloy casting preparing method, and relates to the technical field of aluminum alloy preparing methods. According to the method, pure aluminum powder, pure titanium powder and borohydride titanium powder are mixed evenly to serve as a refiner, the refiner mixed powder is subjected to high-temperature preheating to enable borohydride titanium to be decomposed, through high-temperature, the self-propagating reaction in the refiner mixed powder forms fine TiAl3 and TiB2 particles, through high-temperature extrusion, a filamentous refiner containing hydrogen holes is formed, and then is cut into fine blocky refiners, finally, through the high-pressure spraying method, the fine blocky refiners are sprayed to aluminum alloy melt, after the melt is solidified,the refining effect is achieved, and residual hydrogen in the aluminum alloy melt is subjected to vacuum pumping so as to be removed. The method is simple in process, the prepared aluminum alloy is good in refining effect, and the aluminum alloy casting strength is improved.

Owner:刘燕岭

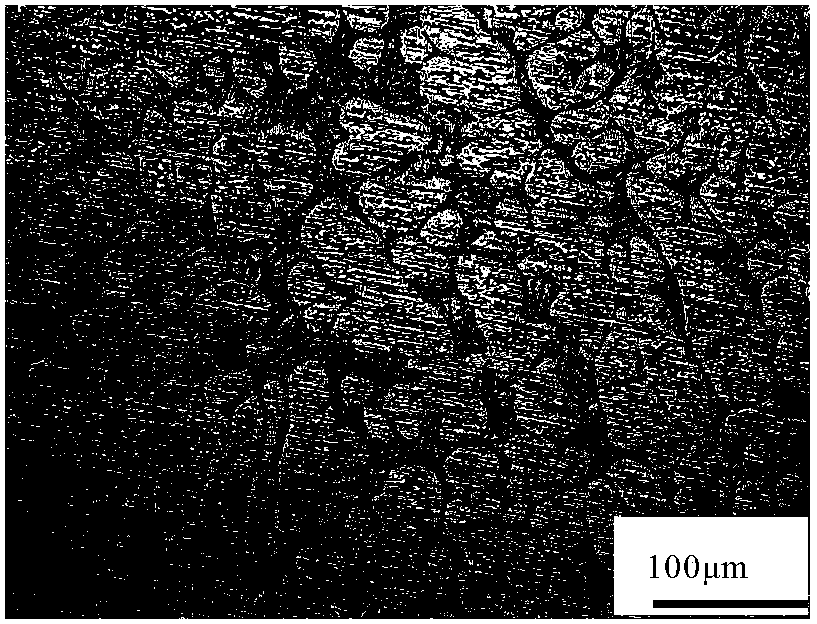

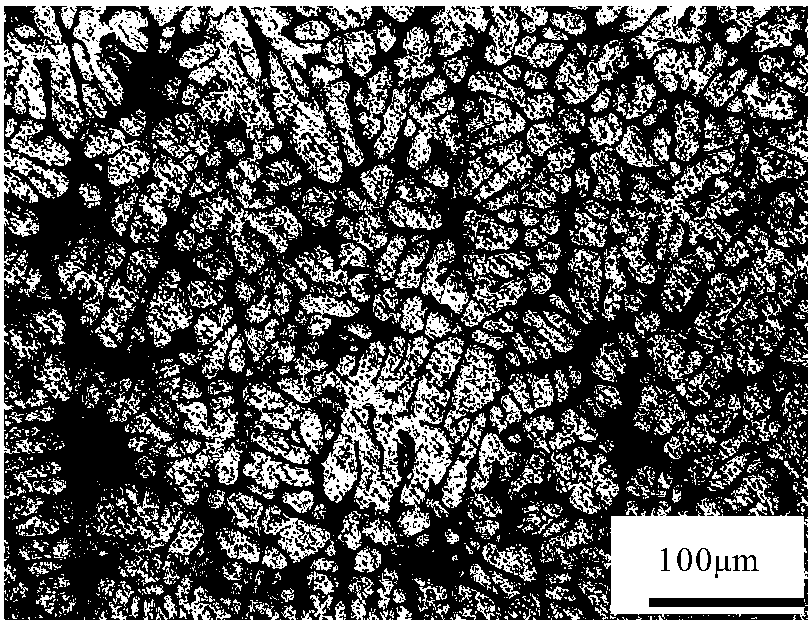

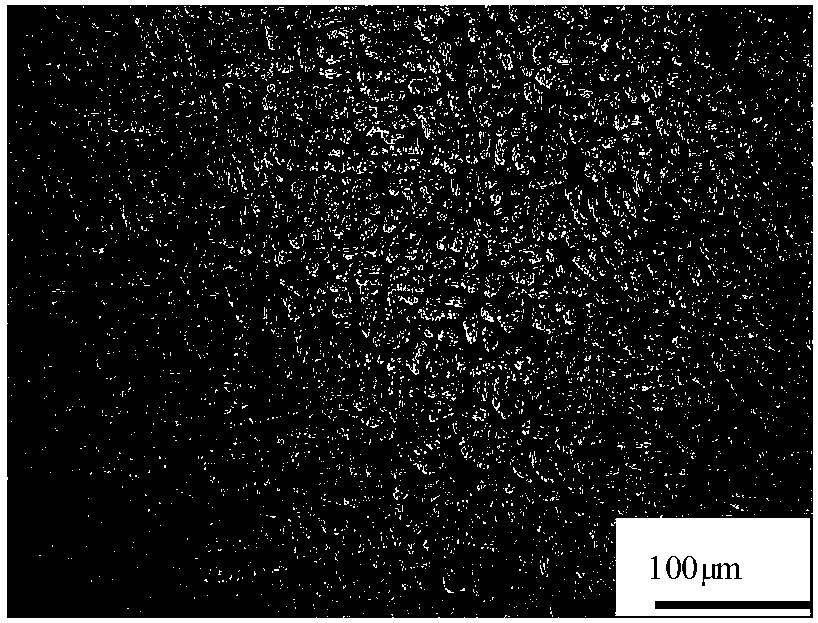

A kind of modification treatment method of aluminum alloy

The invention belongs to the technical field of aluminum alloys, and relates to a modification treatment method for aluminum alloys. In the present invention, Al-10Zr and Al-12Er master alloys are used as modifying agents, and A356 aluminum alloy is used as the object of modification; 0.20% Zr and 0.40% Er are added, and the A356 aluminum alloy is significantly improved through processes such as batching, smelting, and modification treatment. The microstructure and performance of Al-10Zr master alloy and Al-12Er master alloy modified A356 aluminum alloy have a tensile strength of 225MPa and an elongation of 6.4%, which is higher than that of the unmodified A356 aluminum alloy. , elongation were increased by 52.8%, 36.2%.

Owner:JIANGSU UNIV OF TECH

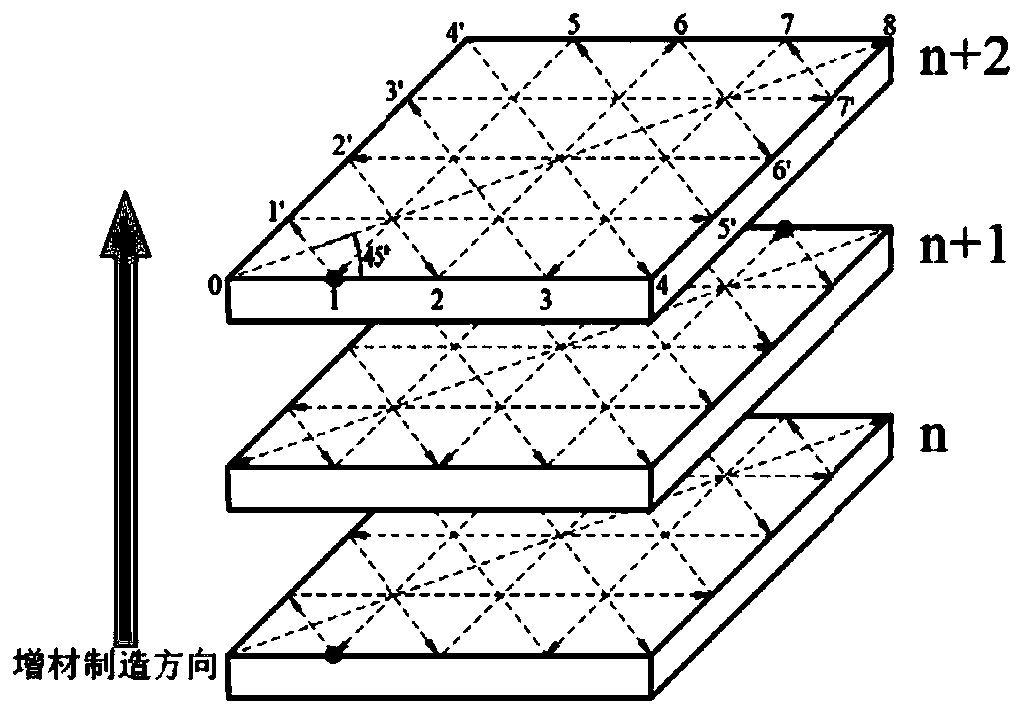

A method of manufacturing medical dense titanium alloy parts with high mechanical properties

ActiveCN109722563BHigh densityThin diameterAdditive manufacturing apparatusNitrogen gasTitanium alloy

The invention discloses a manufacturing method for medical compact titanium alloy parts with higher mechanical performances. Mixed powder of palladium, aluminum, nickel, titanium and inevitable impurities is prepared as blanks by adopting an AM250 system through a 3D printing mode. The AM250 system adopts a pulse optical fiber laser with single mode power of 125-200 W; protective gas is nitrogen and oxygen; and the oxygen content is maintained within 0.5-1.5%. A scanning system is an optical scanning system for scanning by adopting a cross scanning mode. Finally, the blanks are put in a vacuumheat treatment furnace of 200-400 DEG C for heat oxidation by 3-6 hours. The metal powder can be fully heated through laser by the scanning mode for melting, and is combined after cooling, so that the product compactness can reach 99.8% to the greatest extent.

Owner:南通致远机械铸造有限公司

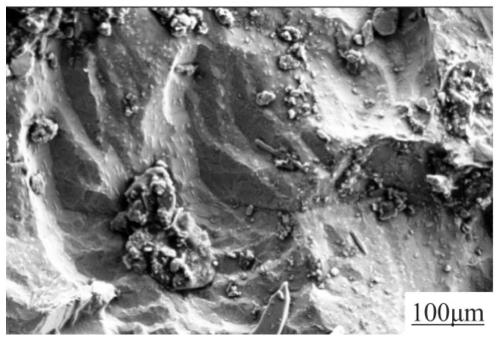

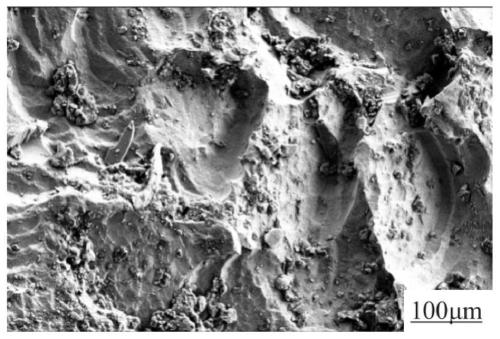

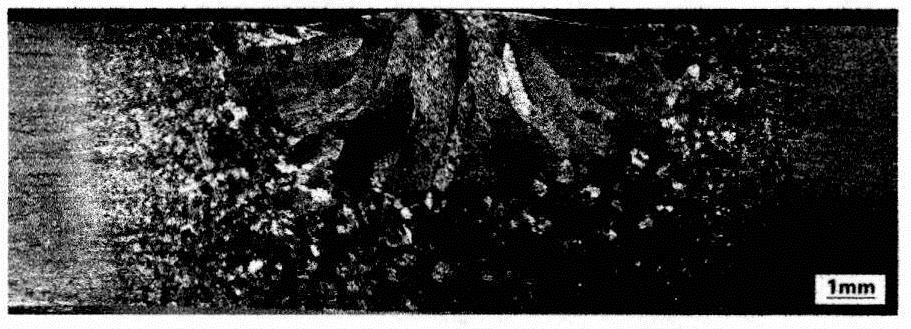

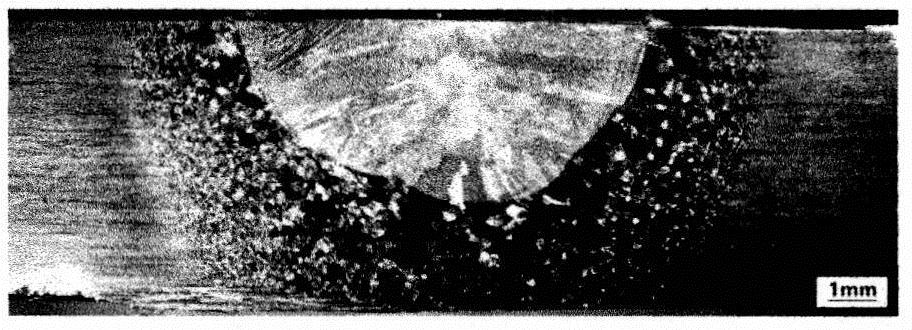

A highly efficient active agent for a-tig welding of titanium alloys

ActiveCN109807495BLight weightLow priceArc welding apparatusWelding/cutting media/materialsActive agentWeld seam

The invention discloses an efficient active agent for titanium alloy A-TIG welding, which belongs to the technical field of active agent welding. The grade of titanium alloy is TC4, and the active agent formula is MgF 2 , La 2 o 3 , BaCl 2 and AlCl 3 Composition, its mass content is MgF 2 : 20%~30%; La 2 o 3 : 20% ~ 30%; BaCl 2 : 20% ~ 25%; AlCl 3 margin. After mixing the above ingredients according to the ratio, evenly apply it on the surface of the titanium alloy test plate, dry it and wait for welding. The proportion of toxic fluoride in the active agent is small. Using this invention to carry out A-TIG welding, compared with the traditional TIG welding with the same parameters, can make 6mm thick TC4 titanium alloy without opening the groove for one-time penetration, and obtain a weld with a weld shape coefficient of less than 1.30 (depth-width ratio greater than 0.77) At the same time, the grain size of the weld zone can be refined. Suitable for efficient welding of titanium alloys.

Owner:INNER MONGOLIA UNIV OF TECH

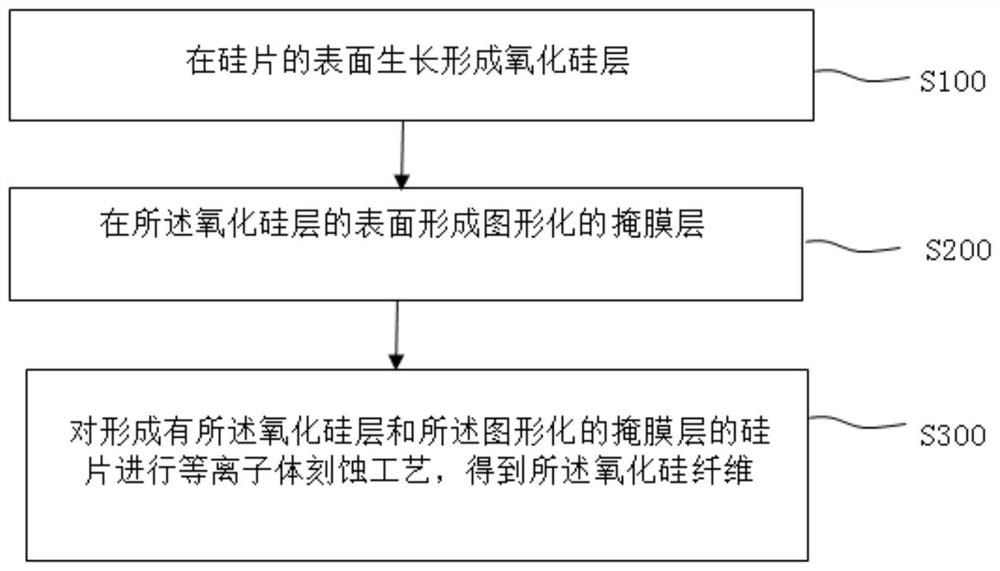

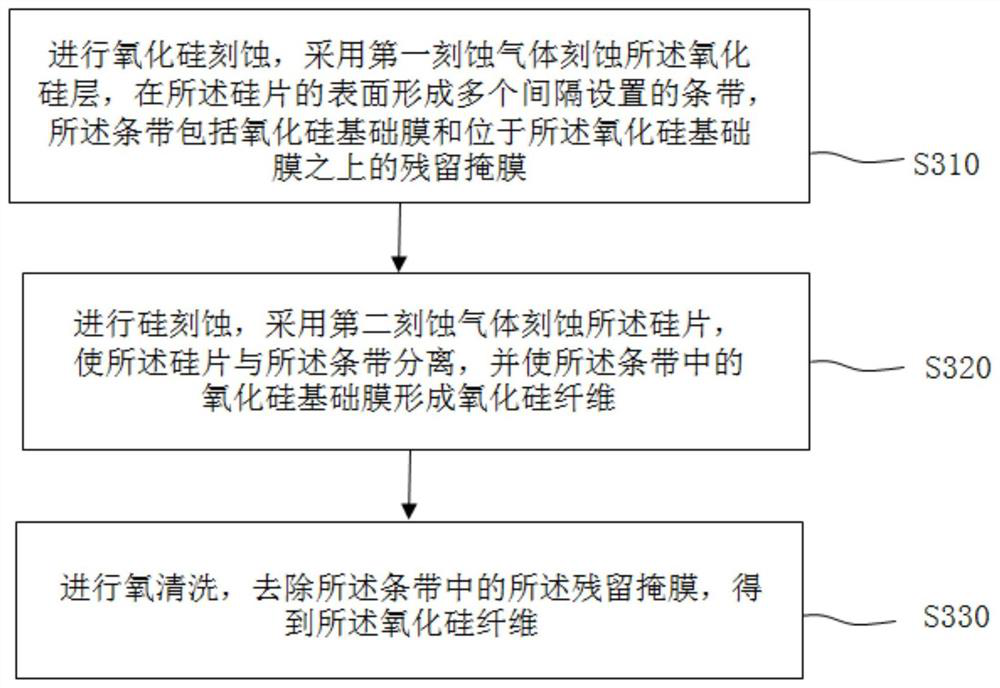

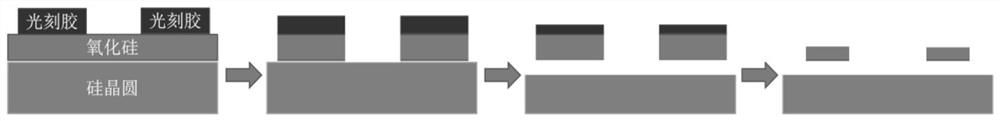

Preparation method of silicon oxide fiber, and silicon oxide fiber

PendingCN113097053AGood size controlDensity controllableSemiconductor/solid-state device manufacturingFiberPhysical chemistry

The invention discloses a preparation method of a silicon oxide fiber, and the silicon oxide fiber. The preparation method of the silicon oxide fiber comprises the following steps: allowing a silicon oxide layer to grow on the surface of a silicon wafer; forming a patterned mask layer on the surface of the silicon oxide layer; and performing a plasma etching process on the silicon wafer on which the silicon oxide layer and the patterned mask layer are formed to obtain the silicon oxide fiber. By adopting the preparation method of the silicon oxide fiber, the silicon oxide fiber with a uniform size can be prepared, and the prepared silicon oxide fiber is controllable in size, controllable in density and good in uniformity. Therefore, the problems that the scale and the density are difficult to accurately control, and the scale uniformity between batches is poor during industrial production in an existing method for preparing the silicon oxide fibers can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

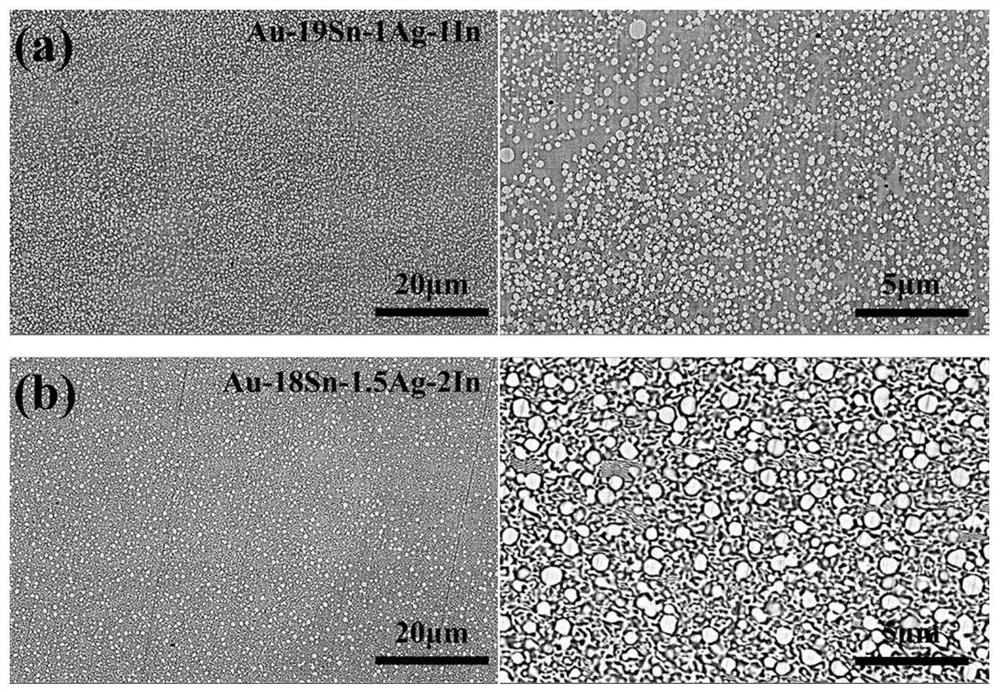

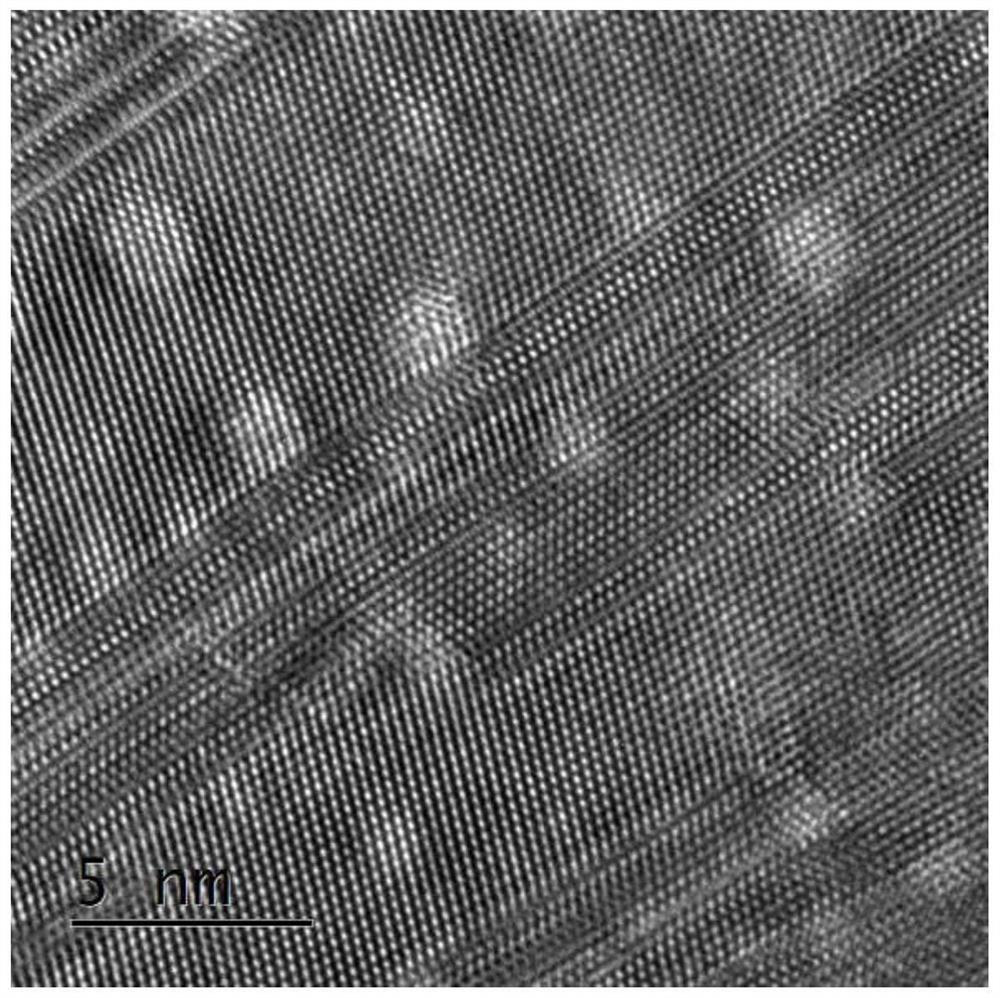

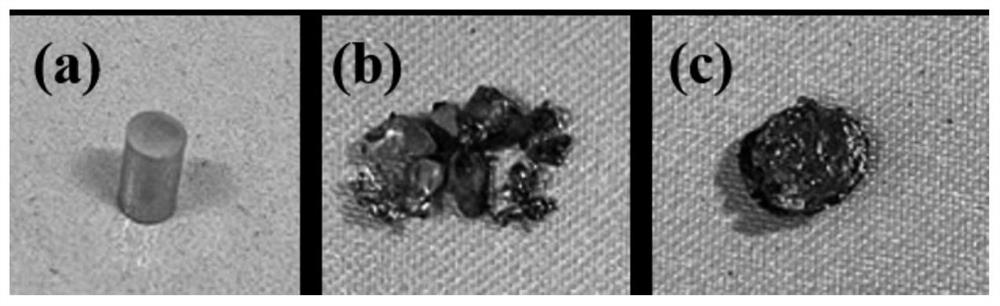

Gold-tin-series lead-free solder and preparation method thereof

ActiveCN113146098AGood solder wettabilityGood weld structureWelding/cutting media/materialsSoldering mediaIngotMachinability

The invention relates to a gold-tin-series lead-free solder and a preparation method thereof. The gold-tin-series lead-free solder comprises the following components in percentage by mass: 17.9%-19.9% of Sn, 0.8%-1.9% of Ag, 0.8%-2.7% of In, and the balance of gold. The preparation method comprises the following steps: Au and Sn are smelted together to obtain an Au-Sn intermediate alloy, and Ag and In are smelted together to obtain an Ag-In intermediate alloy; then, the Au-Sn intermediate alloy and the Ag-In intermediate alloy are smelted together to obtain a gold-tin-series cast ingot; the obtained solder is high in reliability, uniform and fine in structure, high in strength, high in machinability, and capable of being widely popularized and applied to low-temperature packaging occasions and multi-stage packaging occasions of electronic products.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com