High-strength rapid-corrosion magnesium alloy and preparation method thereof

A rapid corrosion, magnesium alloy technology, applied in the field of magnesium alloy and its preparation, can solve the problems of poor creep resistance, low high temperature strength, slow application development and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

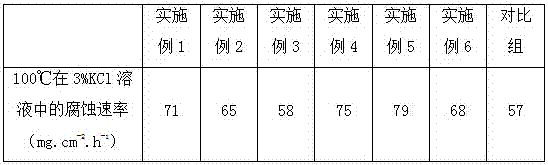

Examples

Embodiment 1

[0017] A high-strength rapid corrosion magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy matrix: 2% Al, 1% Zn, 0.2% Zr, 0.1% Si, 0.1% Mn, 0.3% Ca, 1% Fe, 0.05% Cu, the balance being magnesium and unavoidable impurities.

[0018] The preparation steps are as follows,

[0019] (1) Preheat the pretreated pure magnesium, Al, Zn, Zr, intermediate alloys Si-Mn, Ca, Fe, and Cu to 100-180°C respectively, and then place the pure magnesium, Al, and Zn in Heat up to 700-750°C in a furnace protected by a mixed gas of CO2 and SF6 to melt it;

[0020] (2) After melting, keep it at 700-750°C for 25-45 minutes, then raise the temperature to 750-850°C, then add Zr, Si-Mn master alloy, Ca, Fe, Cu in sequence, and stir under the protection of CO2 and SF6 Evenly, to obtain a melt, continue to heat up to 770-800 ° C for 30-50 minutes;

[0021] (3) Cool the molten material to 650-700°C, let it stand for 10-20 minutes, and then cast it. The steel mold for c...

Embodiment 2

[0024] A high-strength rapid corrosion magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy matrix: 7% Al, 2% Zn, 0.6% Zr, 0.3% Si, 0.5% Mn, 0.3% Ca, 1.5% Fe, 5% Cu, the balance is magnesium and unavoidable impurities.

[0025] The preparation steps are as in Example 1.

[0026] The tensile strength of the prepared magnesium alloy is 354MPa and the elongation is 19%.

Embodiment 3

[0028] A high-strength rapid corrosion magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy matrix: 2% Al, 1% Zn, 0.2% Zr, 0.1% Si, 0.5% Mn, 0.1% Ca, 1.2% Fe, 1% Cu, the balance is magnesium and unavoidable impurities.

[0029] The preparation steps are as in Example 1.

[0030] The tensile strength of the prepared magnesium alloy is 385 MPa and the elongation is 21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com