A method of manufacturing medical dense titanium alloy parts with high mechanical properties

A technology of mechanical properties and manufacturing methods, applied in the field of manufacturing of medical dense titanium alloy parts, can solve problems such as mechanical properties being difficult to meet requirements, and achieve the effects of small thermal stress, increased strength, and reduced Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Provided by Runcorn, UK LPW Technology Co., Ltd., 1% of palladium, 2% of aluminum, 3% of nickel are prepared by atomization powder making method, and the rest is composed of titanium and unavoidable impurities. The average particle size distribution of the powder is 25μm . YSH-double-helix conical mixer mixed for 1 hour, and the powder was fully stirred evenly.

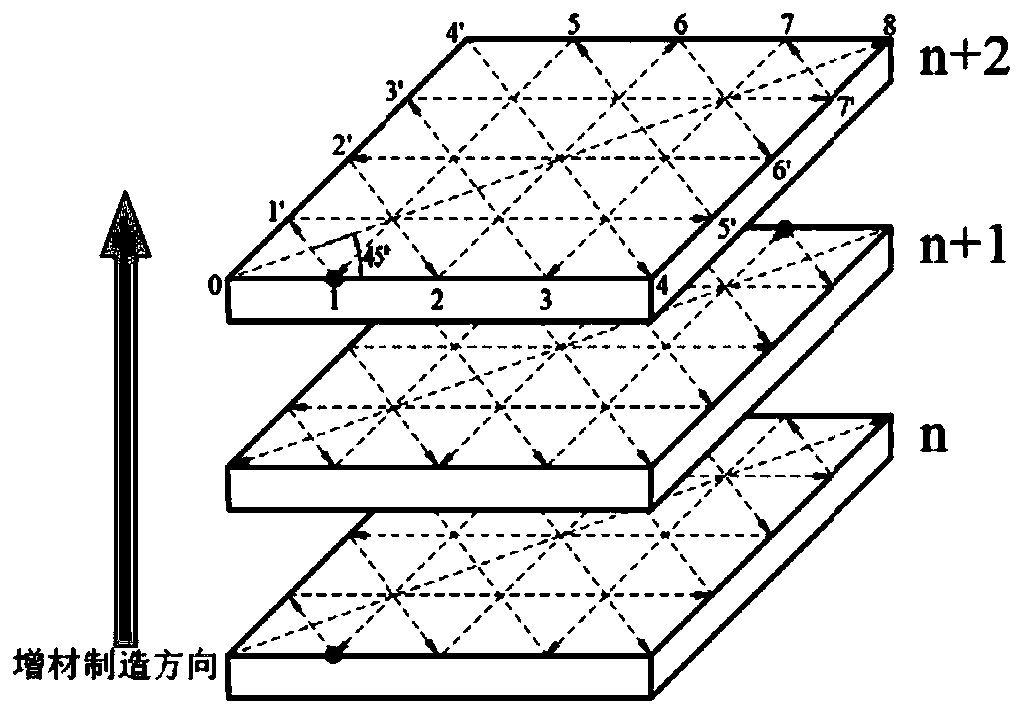

[0036] 2, 3D printer adopts AM250 system (Wotton-under-Edge, Britain), adopts the present invention as figure 1 The laser scanning method shown. A pulsed fiber laser with a single-mode power of 125W is used, and the protective gas is nitrogen and oxygen, and the oxygen content is kept at 0.5% by volume. The powder spreading method is scraper powder spreading, the thickness of each powder layer is 0.03mm; the distance between powder layers is 0.06mm. The scanning system is an optical scanning system with a spot size of 0.15mm, the scanning galvanometer is SCANLAB, and the scanning speed of the laser melting...

Embodiment 2

[0039] 1. Firstly, provided by Runcorn of British LPW Technology Co., Ltd., 2% palladium, 2% aluminum, 4% nickel are prepared by atomization powder making method, and the rest is composed of titanium and unavoidable impurities. The average particle size distribution of the powder is 26μm . YSH-double-helix conical mixer mixed for 1.5 hours, and the powder was fully stirred evenly.

[0040] 2, 3D printer adopts AM250 system (Wotton-under-Edge, Britain), adopts the present invention as figure 1 The laser scanning method shown. A pulsed fiber laser with a single-mode power of 150W is used, and the protective gas is nitrogen and oxygen, wherein the oxygen content is kept at 1.0% by volume. The powder spreading method is scraper powder spreading, the thickness of each powder layer is 0.04mm; the distance between powder layers is 0.07mm. The scanning system is an optical scanning system, its spot size is 0.18mm, the scanning galvanometer is SCANLAB, and the scanning speed of las...

Embodiment 3

[0043] 1. Provided by Runcorn, a British LPW Technology Co., Ltd., 3% of palladium, 5% of aluminum, and 6% of nickel are prepared by atomization powder making method, and the rest is composed of titanium and unavoidable impurities. The average particle size distribution of the powder is 28μm . YSH-double-helix conical mixer mixed for 2 hours, and the powder was fully stirred evenly.

[0044] 2, 3D printer adopts AM250 system (Wotton-under-Edge, Britain), adopts the present invention as figure 1 The laser scanning method shown. A pulsed fiber laser with a single-mode power of 200W is used, and the protective gas is nitrogen and oxygen, wherein the oxygen content is kept at 1.5% by volume. The powder spreading method is scraper powder spreading, the thickness of each powder layer is 0.06mm; the distance between powder layers is 0.09mm. The scanning system is an optical scanning system, its spot size is 0.20mm, the scanning galvanometer is SCANLAB, and the scanning speed of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com