Patents

Literature

190results about How to "Solid solution strengthening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

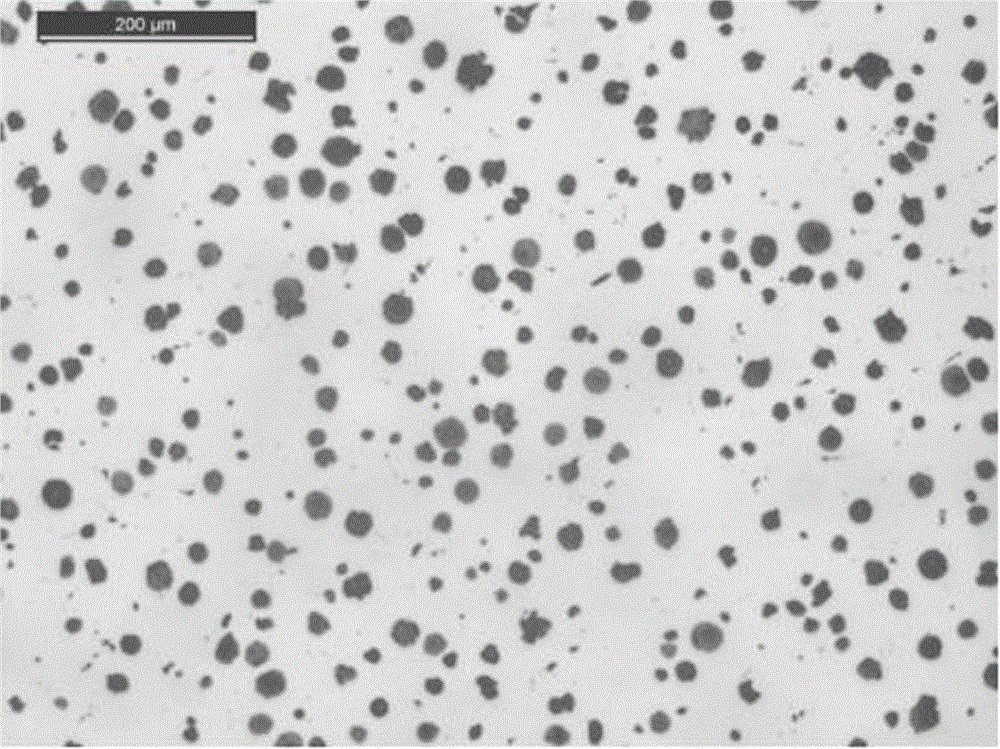

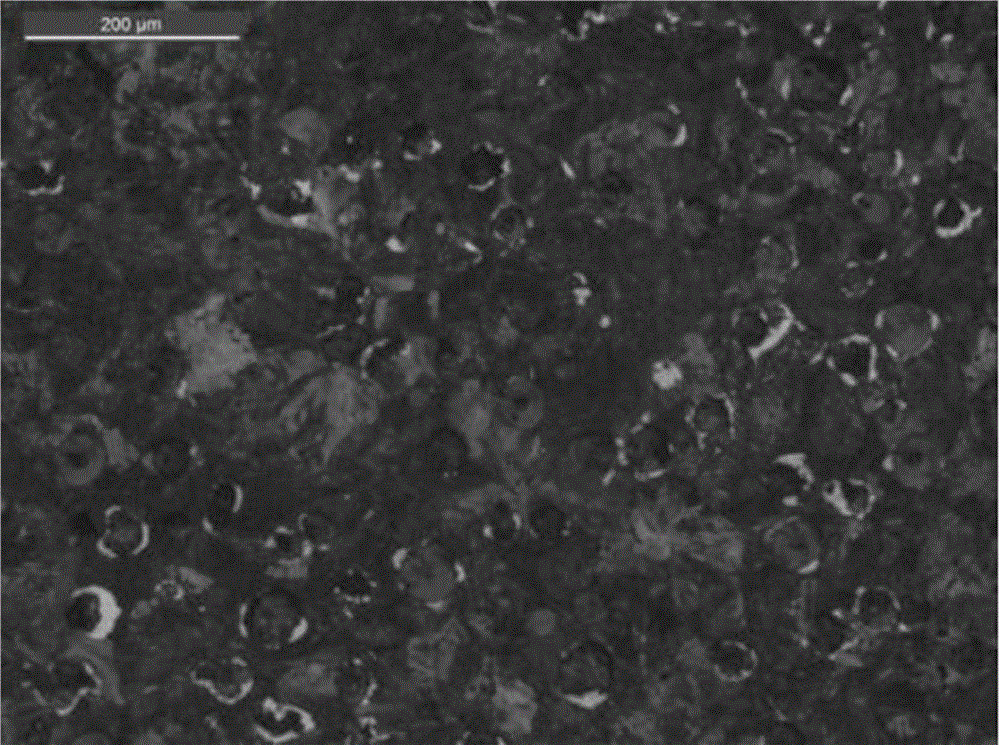

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing LNG storage tank

ActiveCN107052618AAvoid organizationAvoid performance changesArc welding apparatusWelding/cutting media/materialsUltimate tensile strengthToughness

The invention discloses a full-automatic submerged-arc welding solid-core welding wire for high-manganese steel for preparing an LNG storage tank. According to the technical scheme, the full-automatic submerged-arc welding solid-core welding wire comprises 0.25-0.45wt% of C, 23-26wt% of Mn, 6-8wt% of Ni, 3-5wt% of W, 0.02-0.04wt% of N, less than or equal to 0.02wt% of P, less than or equal to 0.001wt% of S and the balance of Fe and inevitable impurities. The full-automatic submerged-arc welding solid-core welding wire has the advantages that the price of adopted alloy elements is low, and an alloy component system is simple; and the low-temperature toughness of weld metal formed by the prepared full-automatic submerged-arc welding solid-core welding wire is excellent, the strength of the full-automatic submerged-arc welding solid-core welding wire is matched with the strength of the ultralow-temperature high-manganese steel for preparing the LNG storage tank, and the technical requirements for the strength and the ultralow-temperature toughness of the welded LNG storage tank can be met.

Owner:WUHAN UNIV OF SCI & TECH +1

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

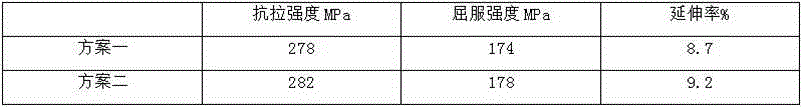

Ca and heavy rare earth Gd-containing die-casting heat resisting magnesium alloy and preparation thereof

The invention relates to a die-casting heat resistant magnesium alloy containing Ca and heavy rare earth element Gd and a preparation method thereof, pertaining to the metal material technical field. The components and weight percentage thereof of the alloy are: 3.0 to 8.0 percent of Al, 0.1 to 3.0 percent of Ca, 0.1 to 3.0 percent of Gd, 0 to 0.5 percent of Mn, lower than 0.02 percent of impurity elements and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and 0.2 percent of SF6; after Mg is wholly melted, industrial pure Al, industrial pure Ca and Al-Mn interalloy are added at the temperature of 650 to 680 DEG C, Mg-Gd interalloy is added at the temperature of 660 to 680 DEG C, the temperature is increased to 740 to 760 DEG C, and when the Mg liquid is cooled to 670 to 690 DEG C, the mixture carries out die casting. The preparation method of the invention has the advantages of low cost and high production efficiency, obviously increases the tensile strength, the yield strength, the elongation percentage and the creep resistance of the alloy at room temperature, and has excellent die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

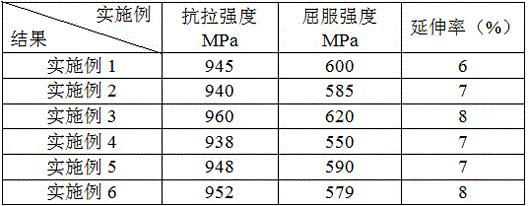

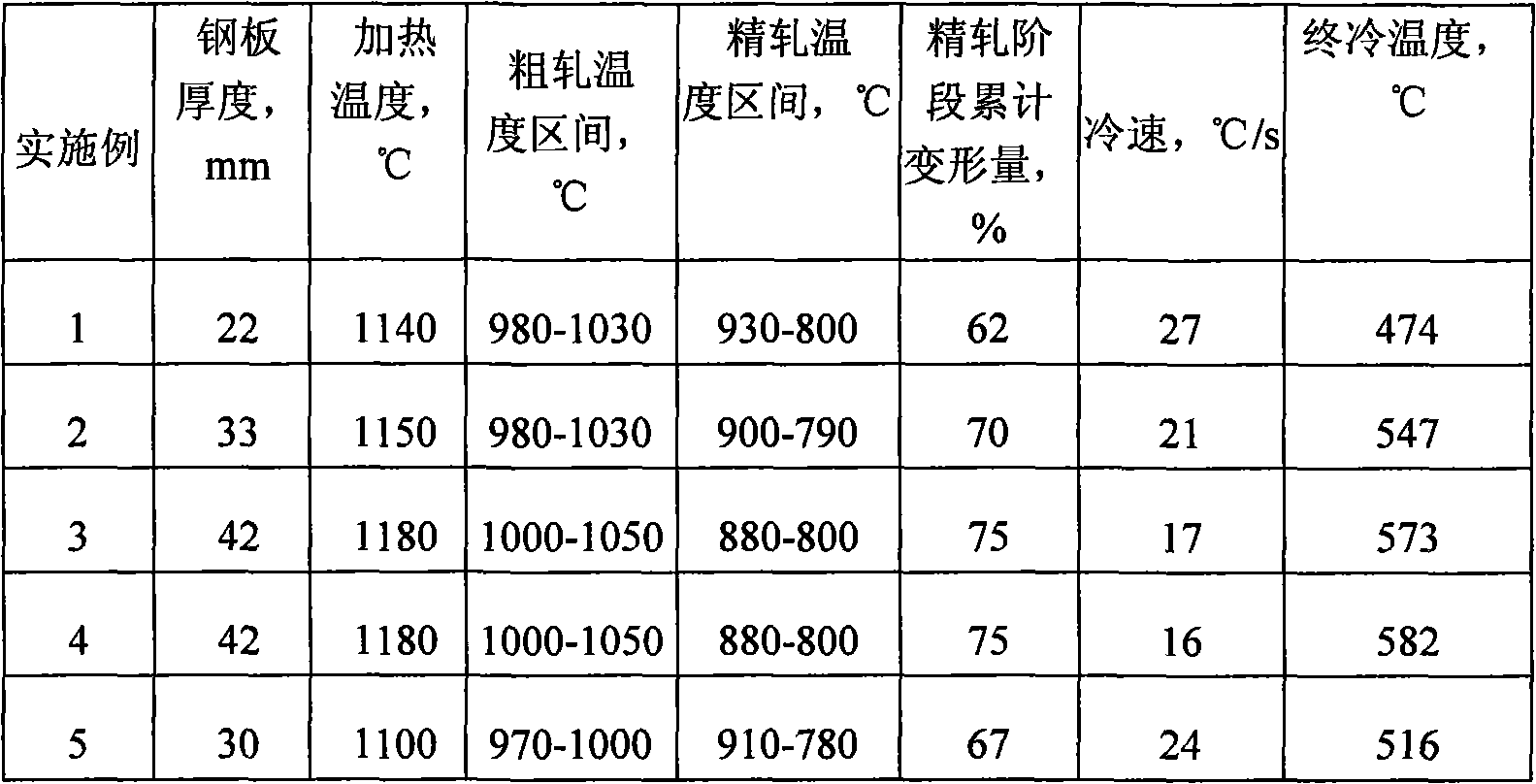

High-intensity pipe steel and production method thereof

ActiveCN101994067AMeet technical requirementsHigh strengthTemperature control deviceChemical compositionMetallurgy

The invention discloses a high-intensity pipe steel and a production method thereof. The pipe steel comprises the following chemical compositions in percentage by weight: 0.07 to 0.15 percent of C, 0.15 to 0.35 percent of Si, 1.55 to 1.85 percent of Mn, 0.04 to 0.10 percent of Nb, 0.01 to 0.025 percent of Ti, 0.10 to 0.40 percent of Cu, 0.01 to 0.045 percent of Als, 0 to 0.35 percent of Ni, 0 to 0.05 percent of V, 0 to 0.35 percent of Cr, 0 to 0.30 percent of Mo and the balance of iron and inevitable impurities. The yield strength of the pipe steel is more than or equal to 690 MPa, the tensile strength is more than or equal to 760 MPa, and the impact toughness at the temperature of 30 DEG C below zero is more than or equal to 90 J; and the pipe steel fully meets the technical requirements of X100 level pipe steel and can be taken as a raw material which is suitable for manufacturing an oil gas conveying X100 pipe.

Owner:ANGANG STEEL CO LTD

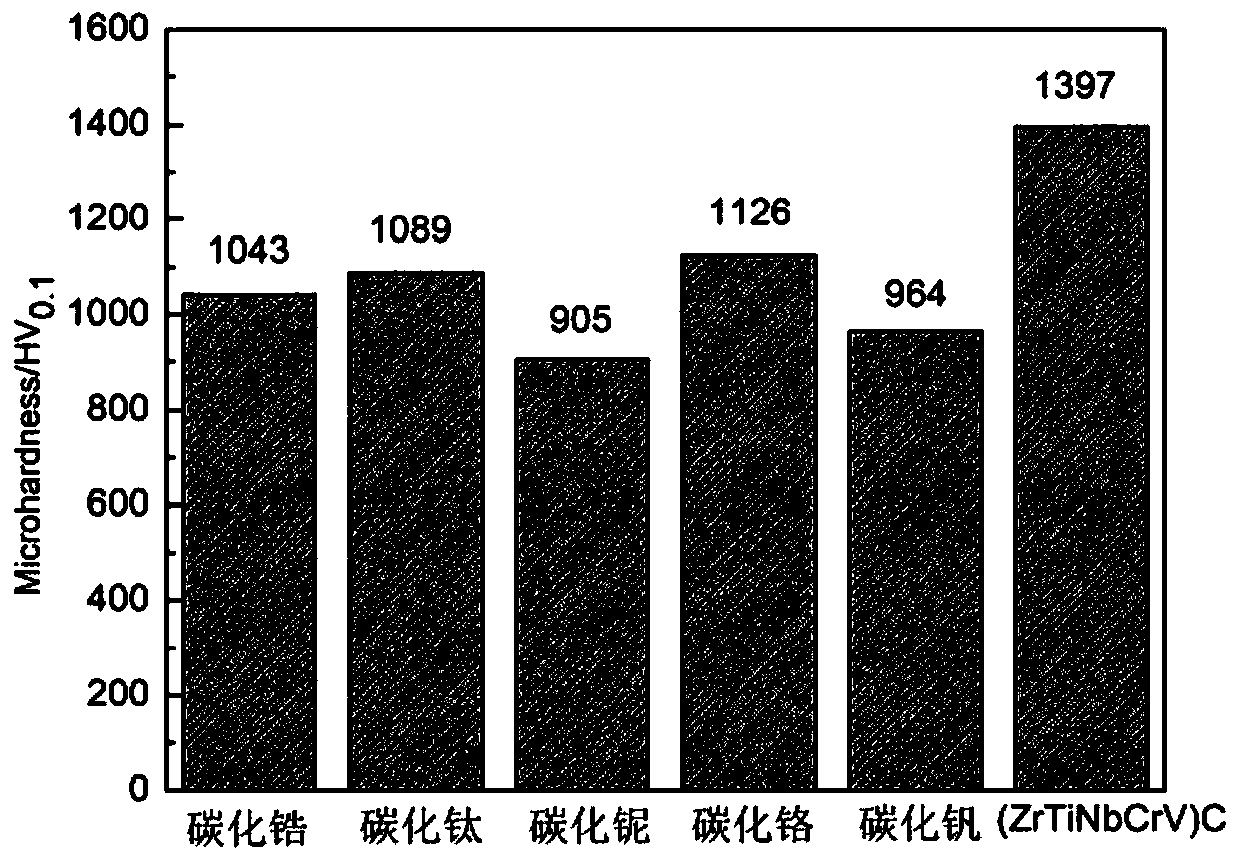

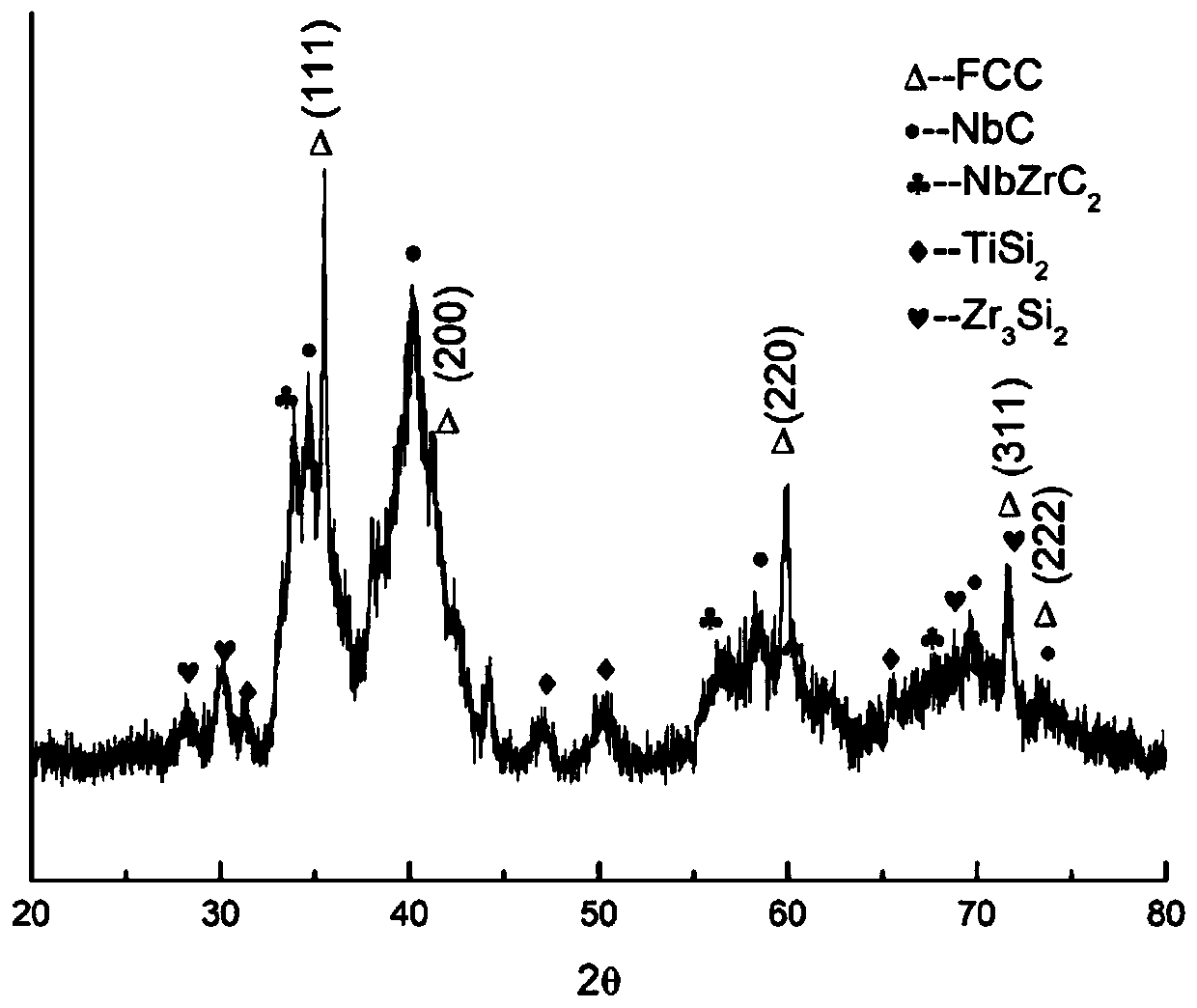

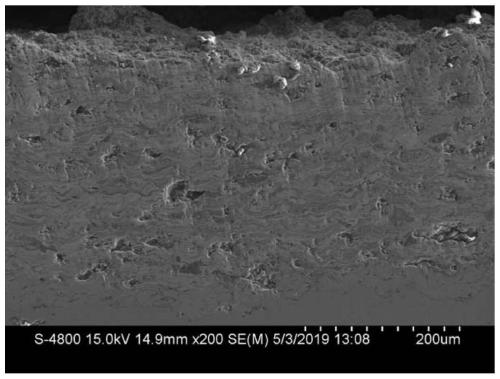

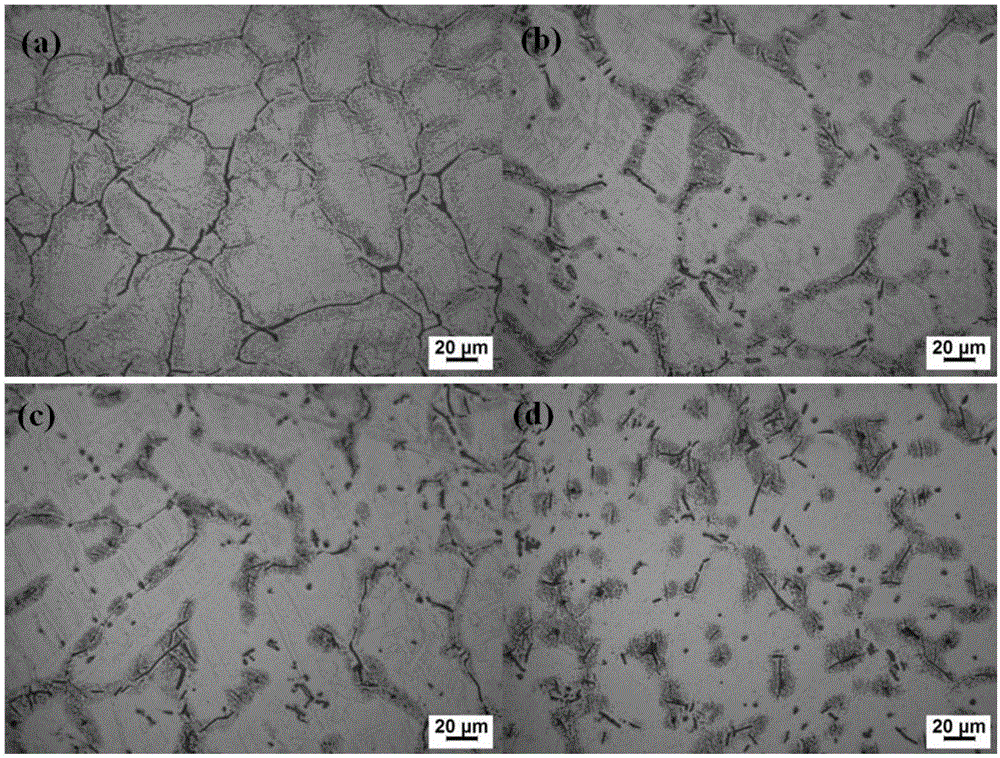

Preparation method of high-entropy ceramic coating

The invention discloses a preparation method of a high-entropy ceramic coating. The method comprises the following steps: firstly, mixing a plurality of single-element compound raw material powder toobtain composite powder, and then mixing a binder into the composite powder to prepare multi-element composite powder for thermal spraying, wherein the single-element compound is carbide, nitride or diboride, and the multiple elements are any five or more of zirconium, titanium, hafnium, tantalum, niobium, vanadium, chromium, molybdenum or tungsten; secondly, pretreating the surface of a substrateof the required coating; and thirdly, spraying the multi-component composite powder on the surface of the substrate by adopting a thermal spraying method so as to form the high-entropy ceramic coating through in-situ synthesis. The high-entropy ceramic coating prepared by the invention has high compactness, hardness, wear resistance, corrosion resistance, high-temperature resistance and oxidationresistance.

Owner:HEBEI UNIV OF TECH

Preparation method of high-entropy ceramic composite coating

ActiveCN111254376AHighlight substantive featuresSimple preparation processMolten spray coatingCeramic compositeThermal spraying

The invention provides a preparation method of a high-entropy ceramic composite coating. The preparation method of the high-entropy ceramic composite coating comprises the following steps that step one, metal simple-substance powder, silicon carbide powder and a binder are prepared into metal simple-substance / silicon carbide composite powder, and the metal simple-substance powder is any five or more than five of zirconium, titanium, hafnium, tantalum, niobium, vanadium, chromium, molybdenum, tungsten, manganese or cobalt; step two, the surfaces of base materials needing coating are pretreated;and step three, a method of thermal spraying is adopted to spray the metal simple-substance / silicon carbide composite powder on the surfaces of the base materials, so that the high-entropy ceramic composite coating is synthesized through an in-situ reaction. The obtained coating has excellent performance, and the disadvantage that high-entropy ceramic composite powder is required to be prepared in the process of preparing the high-entropy ceramic composite coating in the prior art is further overcome.

Owner:HEBEI UNIV OF TECH

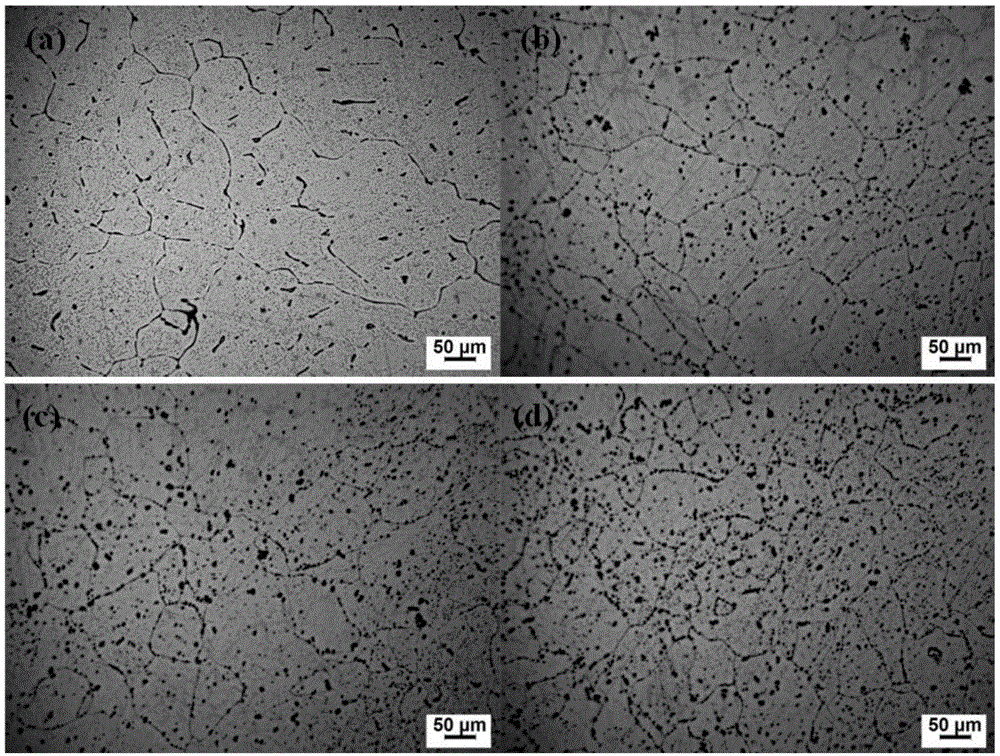

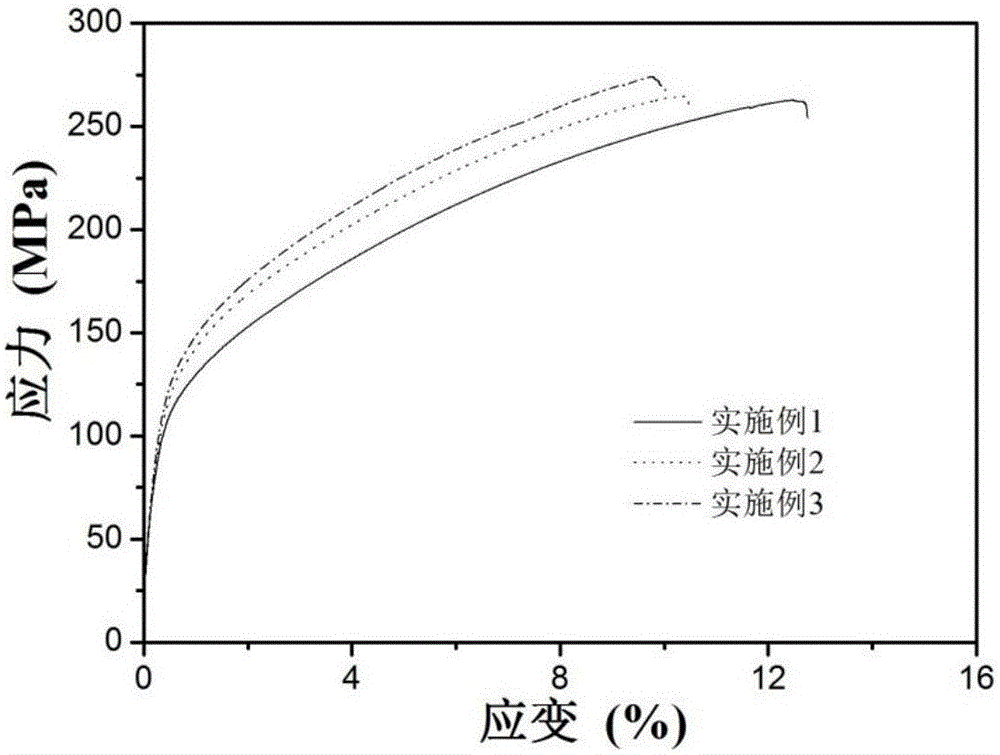

High-strength and high-toughness cast magnesium alloy and preparation method thereof

The invention discloses high-strength and high-toughness cast magnesium alloy. The high-strength and high-toughness cast magnesium alloy is Mg-Bi-Ca-Zn alloy and composed of, by weight, 3.0-8.0% of Bi, 0.1-1.2% of Ca, 0.1-2.0% of Zn and the balance Mg. According to the invention, Bi serves as the main alloy element, lots of Mg3Bi2 phases are formed through the simple alloying way, few Ca elements and Zn elements are adopted for improving the strength of the alloy, the Ca elements effectively improve the morphology and distribution of the Mg3Bi2 phases so as to improve the plasticity of the alloy, and therefore the high-strength and high-toughness cast magnesium alloy can be developed for the Mg-Bi alloy series. The cast magnesium alloy is high in strength and plasticity, the tensile strength of the alloy with the components optimized reaches about 270 MPa, the yield strength of the alloy reaches about 145 MPa, and the ductility of the alloy reaches about 10%. Thus, the strength can be as high as that of rare earth magnesium alloy, and the ductility is high.

Owner:山东汇达蠕墨装备有限公司

Narrow-hardenability pinion steel and preparation method thereof

ActiveCN102400052AImprove hardenabilityHardenability improved and stabilizedManufacturing convertersProcess efficiency improvementTemperature resistanceWear resistance

The invention provides a narrow-hardenability pinion steel which comprises the following components in percentage by weight: 0.18%-0.22% of C, 0.20%-0.30% of Si, 0.90%-1.15% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.35% of Cr, 0.04%-0.08% of Ti, 0.004%-0.005% of B, 0.025%-0.038% of W, less than or equal to 11.5*10<-6> of [O], less than or equal to 1.5*10<-6> of [H], 35*10<-6>-45*10<-6> of [N] and the balance of Fe and inevitable impurities. The invention provides a preparation method of the narrow-hardenability pinion steel. The preparation method comprises the following steps: 1) primary smelting based on a top-bottom blowing converter; 2) ladle deoxidizing and alloying; 3) LF (ladle furnace) refining; 4) RH refining; and 5) continuous casting. Compared with the prior art, the narrow-hardenability pinion steel provided by the invention has the characteristics of better wear resistance and high temperature resistance, higher hardenability andnarrower jominy hardenability.

Owner:WANGUAN SMELTING MOLD CASTING

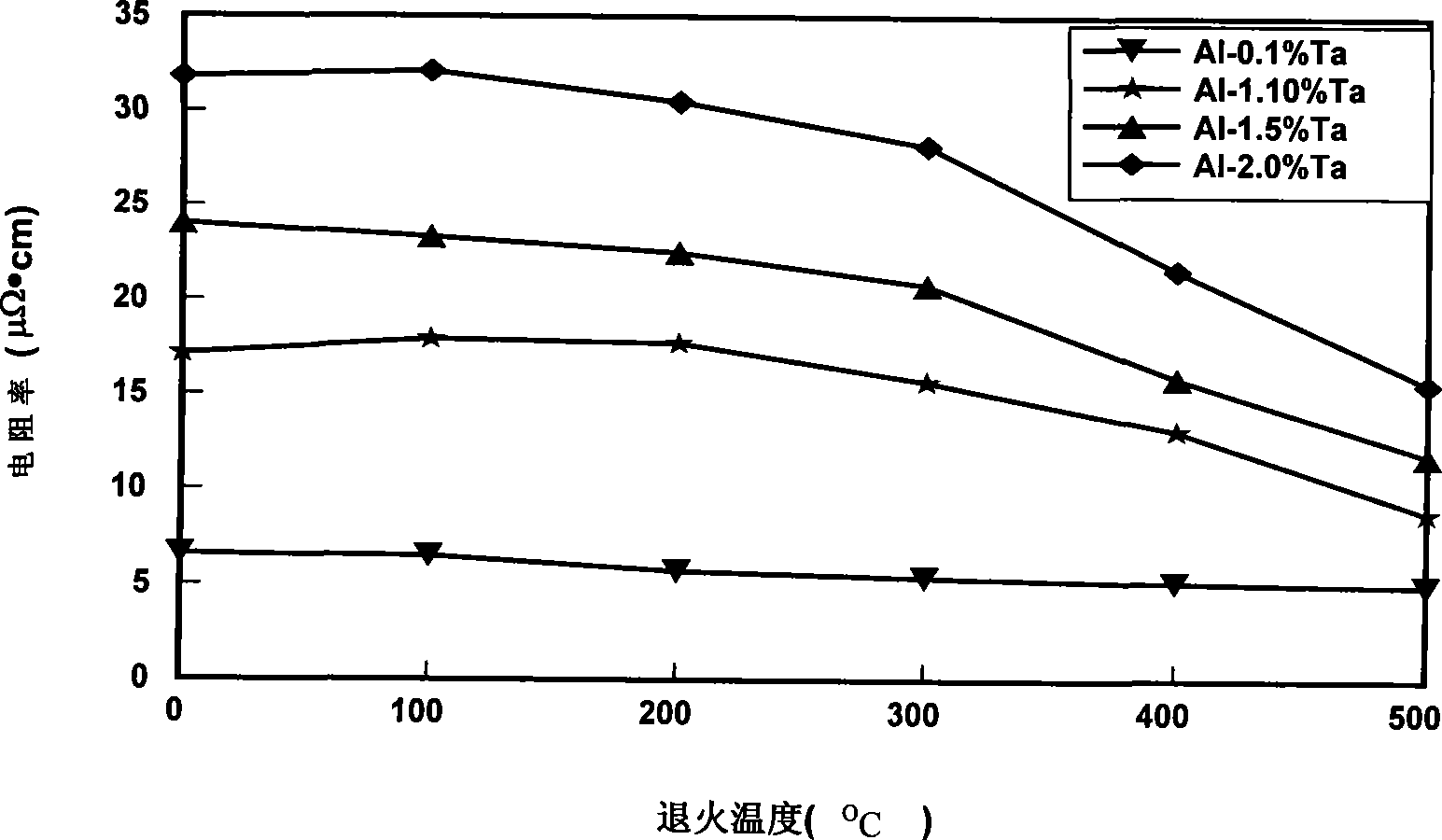

Target material for preparing TFT LCD electrode film and target material and electrode film preparation method

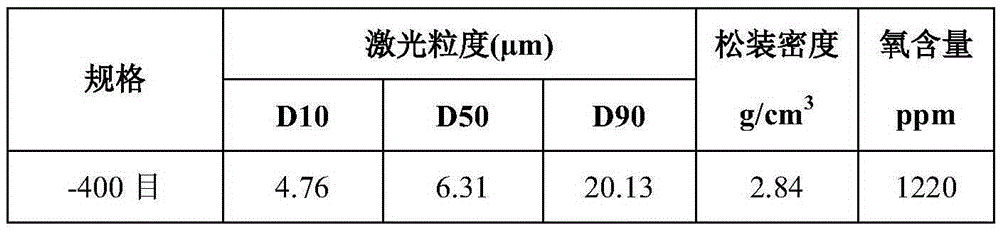

InactiveCN101386974AReduce manufacturing costSolid solution strengtheningVacuum evaporation coatingSputtering coatingActive matrixVolumetric Mass Density

The invention provides a target for preparing a TFT LCD active matrix electrode membrane, wherein the target is Al-Ta alloy, Al-Ti alloy or Al-Fe alloy; the content of alloying element of the target is 1at percent to 3at percent. The invention also discloses a method for preparing the target, which comprises the steps of: heating and completely melting the fully mixed Al-Ti, Al-Fe or Al-Ta alloy powder, atomizing the molten alloy frog into droplets by spraying working gas from an atomizing nozzle and rapidly driving the droplets towards a cooled and rotating substrate by airflow at a certain speed and obtaining a blank with certain density on the substrate surface; or heating and completely melting the fully mixed Al-Fe, Al-Ti or Al-Ta alloy powder, and pouring the uniformly stirred alloy liquid into a cavity preheated to a certain temperature to condense and form the alloy liquid. The manufacturing cost of the target and the electrode membrane can be reduced by using resourceful Fe, Ti or Ta to replace the scarce Nd with high price.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

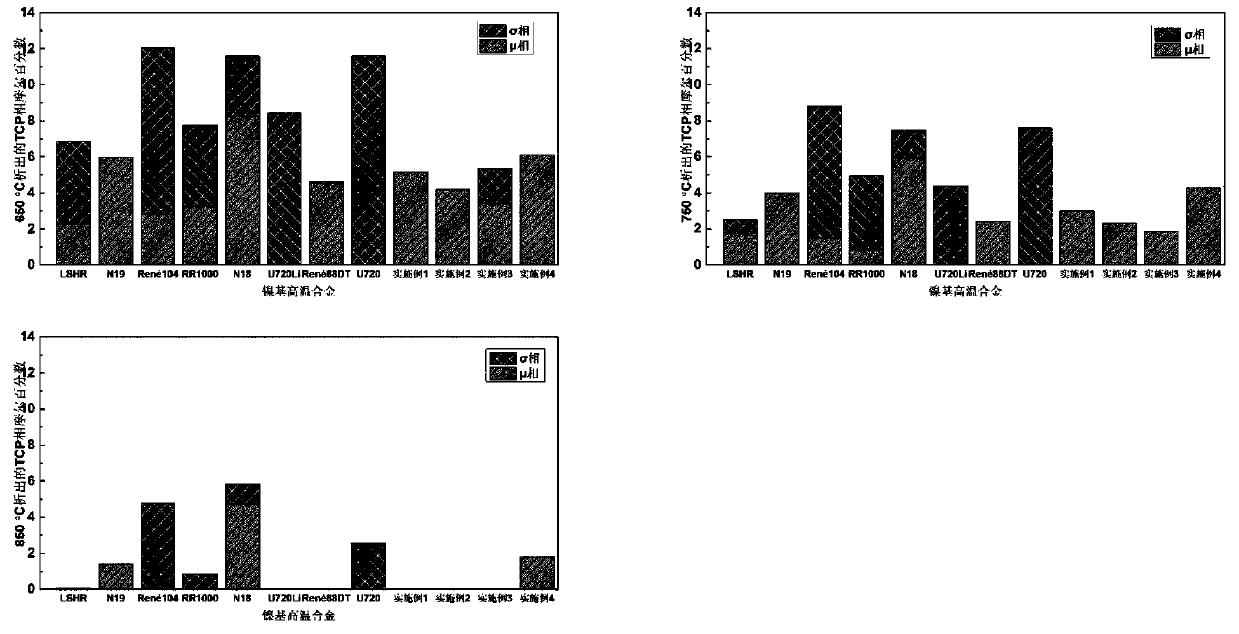

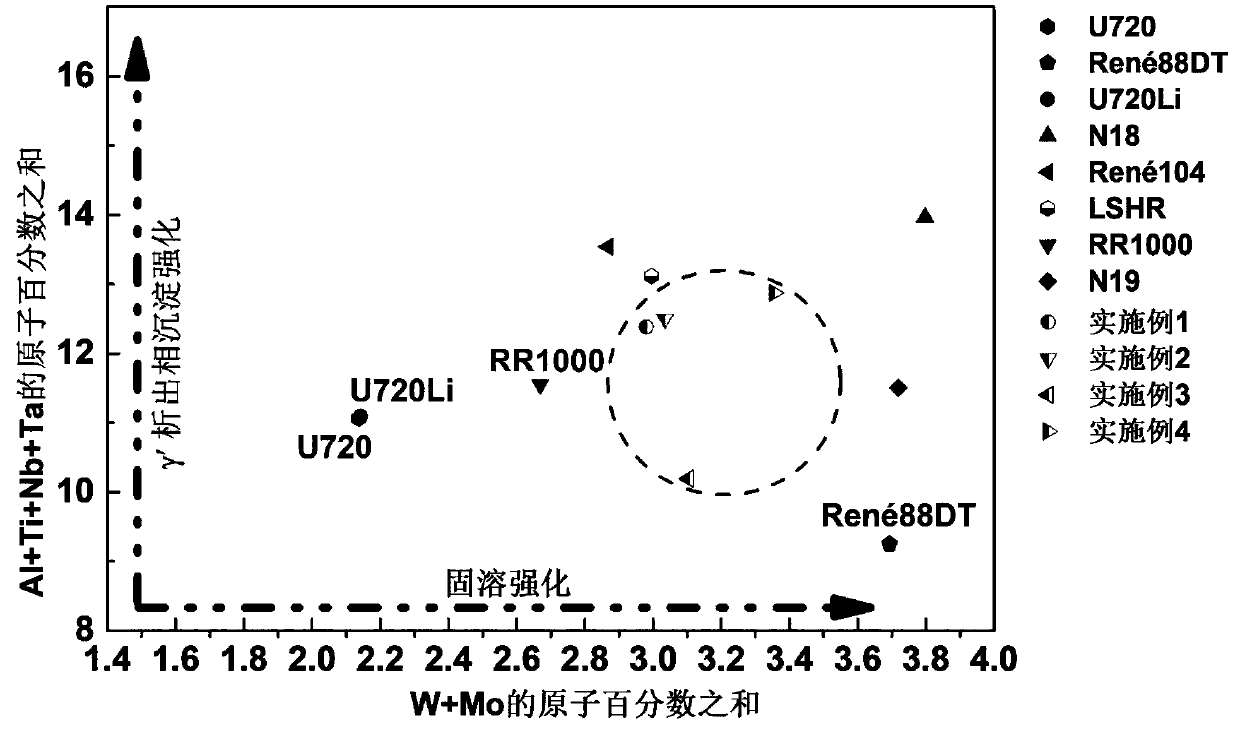

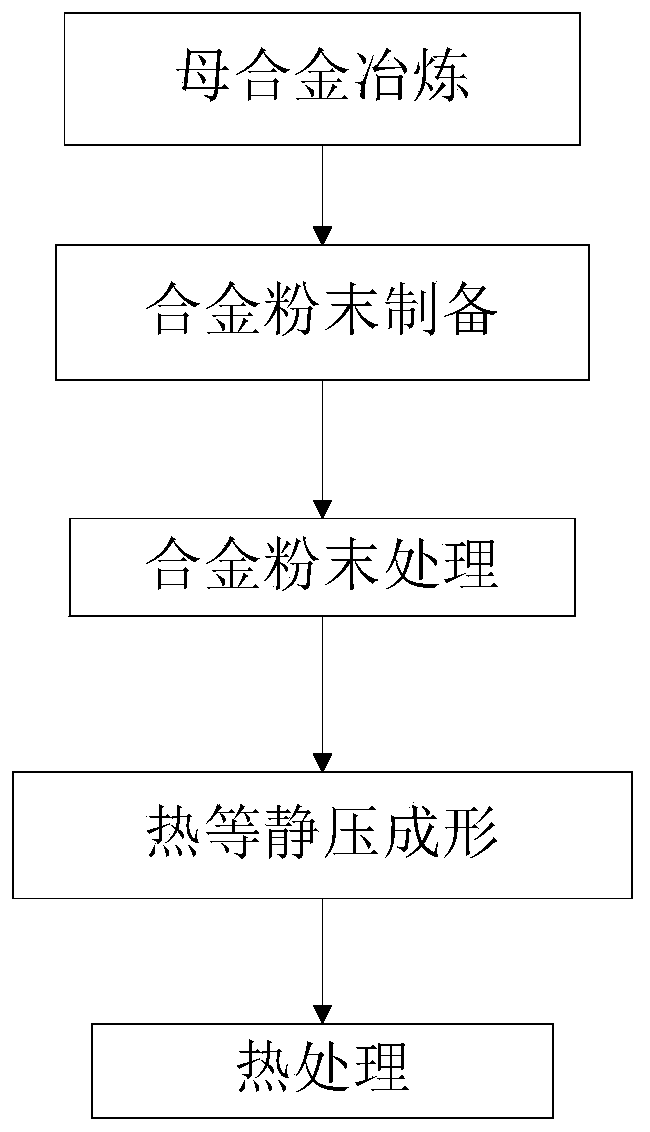

Nickel-based alloy, preparation method of nickel-based alloy and manufacturing product

The invention provides a nickel-based alloy. The nickel-based alloy comprises the following components including, by weight, 18.0%-23.5% of cobalt, 10%-15% of chromium, 2.5%-3.5% of aluminum, 2.0%-4.0% of titanium, 0.1%-2.0% of niobium, 1.0%-3.0% of tantalum, 0%-2.5% of tungsten, 4%-5.5% of molybdenum, 0.03%-0.1% of zirconium, 0%-1.0% of hafnium, 0.01%-0.1% of carbon, 0.01%-0.1% of boron and the balance nickel. According to the nickel-based alloy, the content of alloy elements in the high-temperature alloy is adjusted systematically, so that it is ensured that the alloy has good mechanical properties, and the alloy has good tissue stability at high temperature.

Owner:CENT SOUTH UNIV

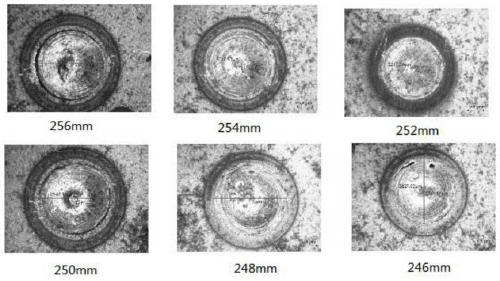

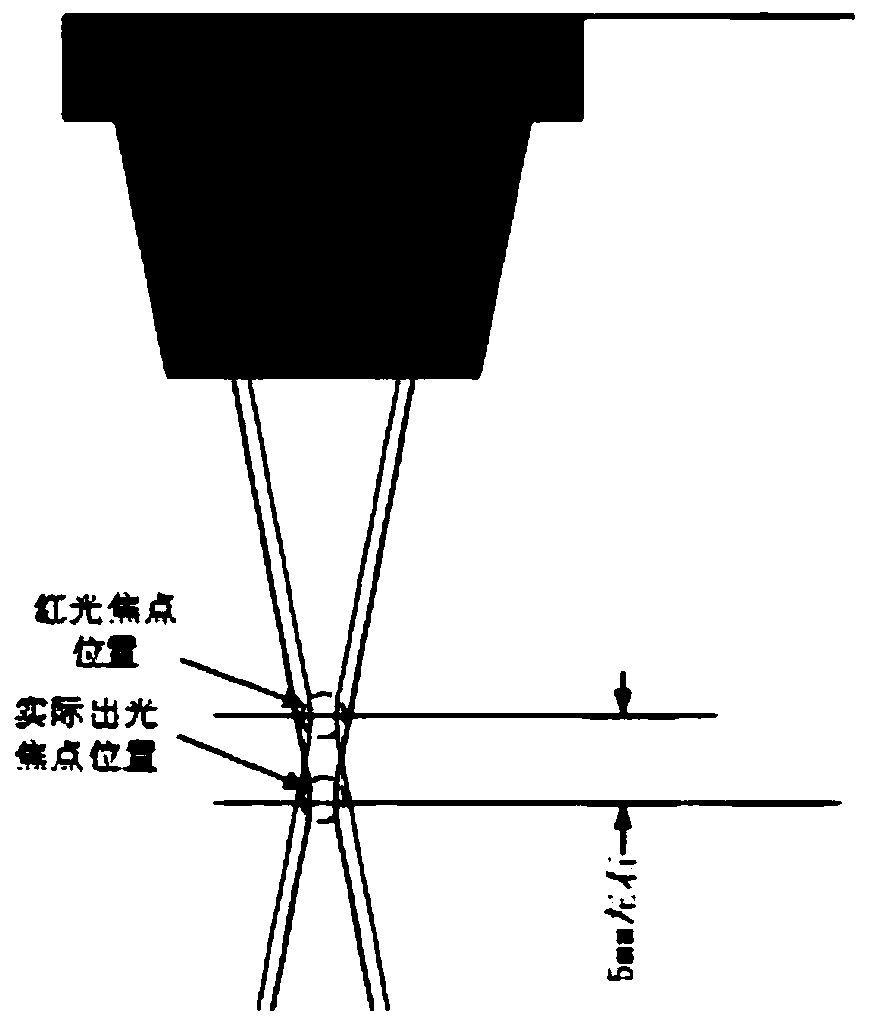

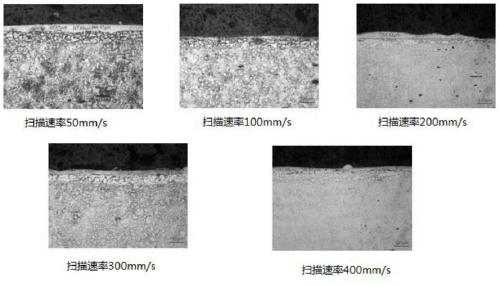

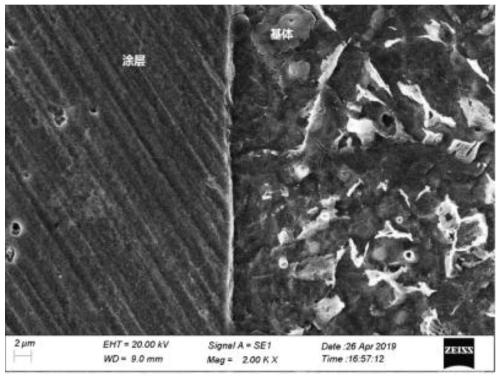

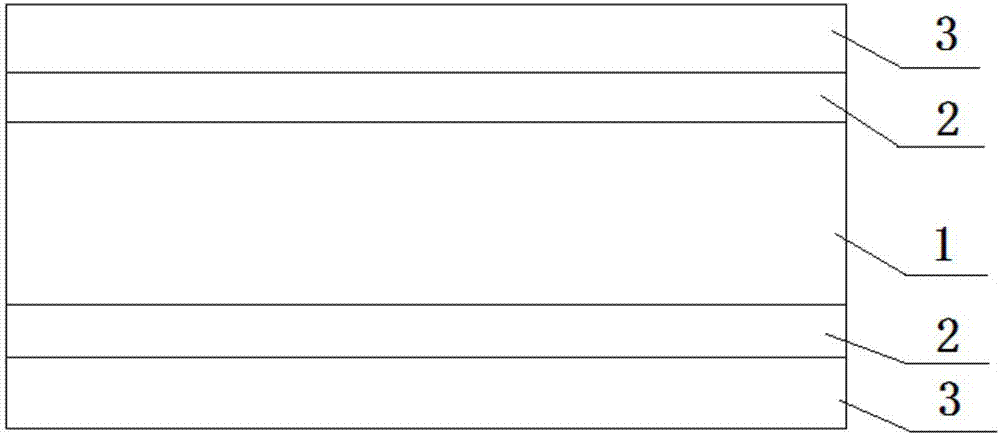

Process for preparing cladding layer on surface of copper base body by utilizing high-speed laser cladding technology

The invention discloses a process for preparing a cladding layer on the surface of a copper base body by utilizing a high-speed laser cladding technology. The process is characterized in that a lasercoaxial powder feeder is used for feeding a cladding alloy material to the surface of the copper base body, meanwhile, layer-by-layer high-speed laser cladding is performed by using an optical fiber laser or an optical fiber coupling semiconductor laser, wherein the process parameters of the laser in the cladding operation process are as follows, the focal length of a focusing lens is 250-300 mm,the cladding power is 2000-8000 W, the diameter of a light spot is 0.3-1.2 mm, the cladding scanning speed is 100-400 mm / s, and the lap joint rate is 65%. According to the preparation process of the obtained cladding layer, by utilizing the laser with the high scanning speed and adopting the specific cladding alloy powder for cooperation, the process parameters of the high-speed laser are determined, on the premise that subsequent other treatment is not needed, the cladding layer with the compact structure, without cracks and air holes and with extremely low dilution rate can be formed the surface of the copper base body, good metallurgical bonding between the cladding layer and the surface of the copper base body can be formed.

Owner:唐山中科量子激光科技有限公司

Precipitation-hardening martensitic stainless steel for surgical operation and heat treatment process thereof

ActiveCN103866198AImprove antibacterial propertiesImprove mechanical propertiesSurgical operationChemical composition

The invention discloses precipitation-hardening martensitic stainless steel for a surgical operation and a heat treatment process thereof, and belongs to the technical field of stainless steel material. The stainless steel comprises the following chemical composition: not more than 0.07 wt% of C, not more than 1.00 wt% of Si, not more than 1.00 wt% of Mn, not more than 0.040 wt% of P, not more than 0.030 wt% of S, 3.00-5.00 wt% of Ni, 15.0-17.5 wt% of Cr, 3.5-5.5 wt% of Cu, 0.05-0.15 wt% of N, 0.15-0.45 wt% of Nb, and the balance Fe. After the stainless steel is subjected to special heat treatment, a copper-rich phase can be precipitated evenly and dispersedly in a stainless steel matrix, and thus the stainless steel is endowed with an antibacterial function. The stainless steel solves the problem of bacterial infection caused by the use of stainless steel tools in a conventional surgical operation, is widely applied in various stainless steel appliances such as scalpels, surgical scissors, surgical forceps, intestinal forceps and curettes used in the surgical operation in the medical clinical field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

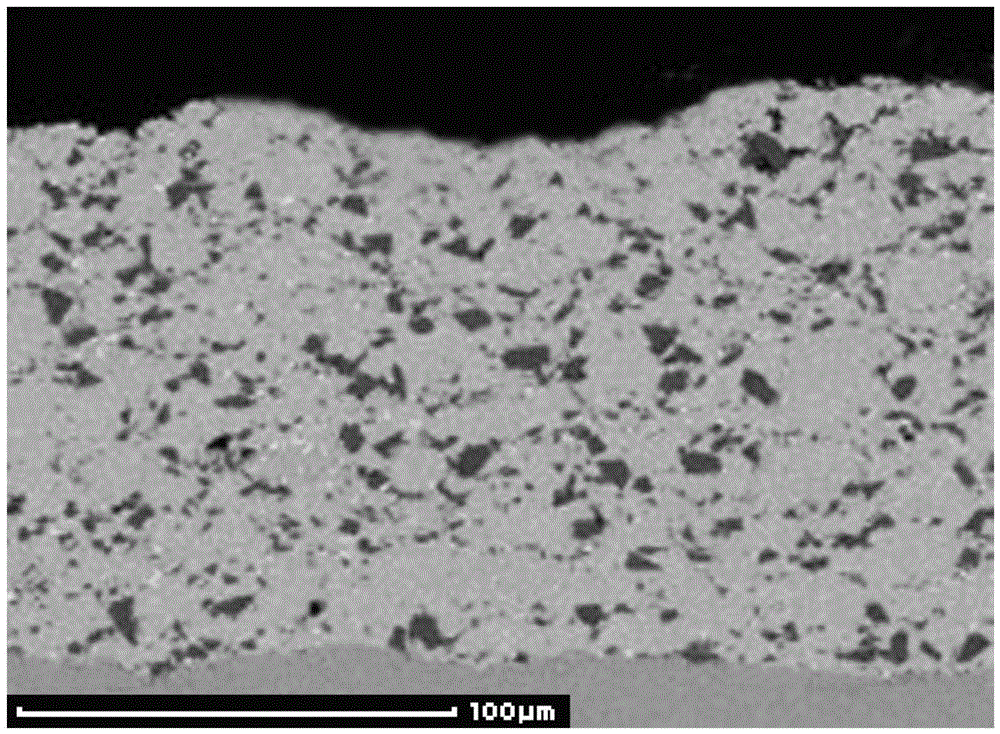

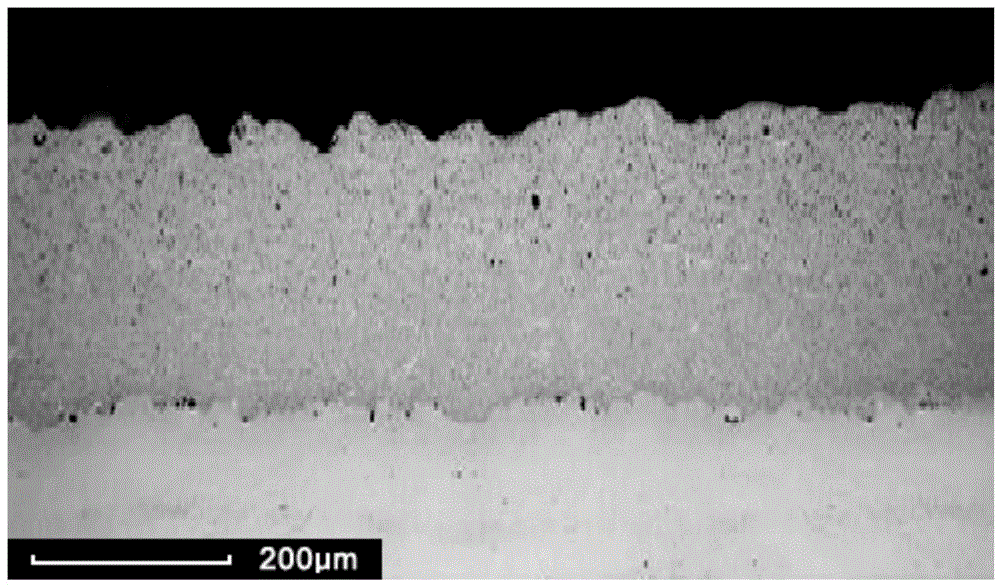

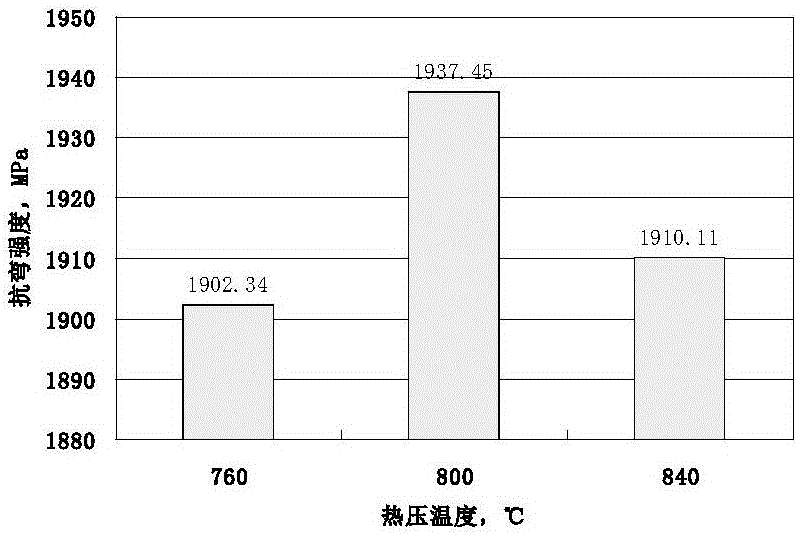

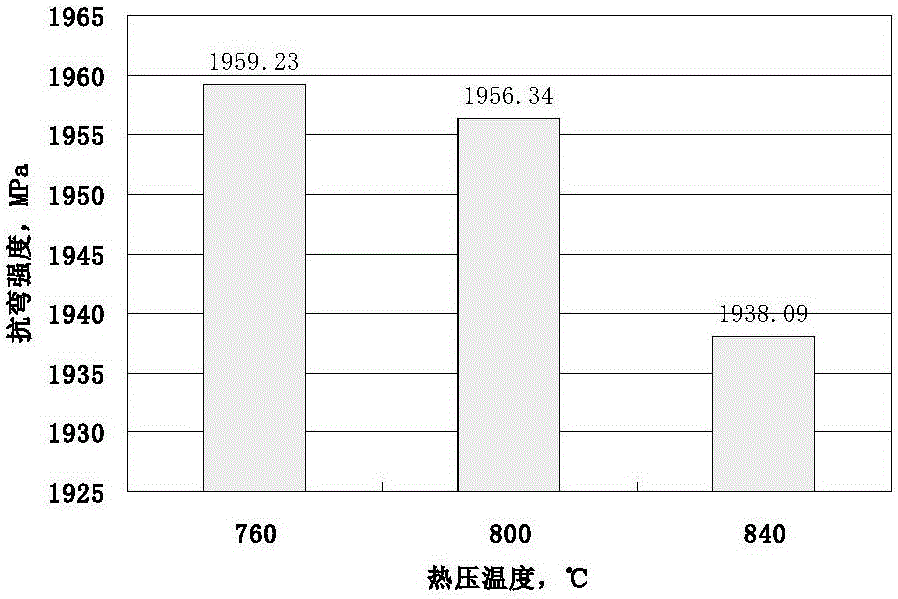

Ultrafine high-bending resistance alloy powder used for diamond tool and preparation method for ultrafine high-bending resistance alloy powder

The invention discloses ultrafine high-bending resistance alloy powder used for a diamond tool and a preparation method for the ultrafine high-bending resistance alloy powder. The ultrafine high-bending resistance alloy powder comprises the following components in percentage by weight: 5-75% of Cu, 1-15% of Ni, 1-15% of Sn, 1-5% of Si, 1-15% of Al, 1-10% of Cr, 0.1-3% of B, 0.1-3% of V, 0.1-2% of Nb, 0.1-4% of Zr, 0.1-7% of La and the balance of Fe. According to the preparation method, the prepared metal raw materials are subjected to the following steps of operation: (1), smelting; (2), water atomizing; (3), filter pressing and dewatering; (4), vacuum drying; and (5), restoring. According to the invention, the single power particle component uniformity is improved, and meanwhile, extremely high sintering activity is realized. Especially, micro liquid phase sintering is promoted due to the added low-melting point elements, so that higher density is obtained by a diamond tool bit sintering mould, and the holding force on diamond is enhanced. By adding the metal-structure intensifying alloy elements and rare earth elements, the bending resistance is improved to 1900 Mpa, so that the holding force of the mould on the diamond is finally improved, and the diamond tool bit tool with high cutting performance is obtained.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

345MPa-grade low-yield-ratio weather-resistant steel and preparation method thereof

The invention discloses 345MPa-grade low-yield-ratio weather-resistant steel. The 345MPa-grade low-yield-ratio weather-resistant steel comprises the following components in percentage by mass: 0.04 to0.12 percent of C, 0.50 to 0.75 percent of Si, 0.43 to 0.50 percent of Mn, 0.06 to 0.09 percent of P, 0.010 to 0.020 percent of Ti, less than or equal to 0.004 percent of S, 0.25 to 0.40 percent of Cu, 0.15 to 0.35 percent of Ni, 0.30 to 0.60 percent of Cr, 0.02 to 0.04 percent of Al and the balance of Fe and unavoidable impurities. The preparation method of the weather-resistant steel comprisesthe following steps: (1) smelting: performing smelting, refining, alloying and calcium treatment on raw materials to obtain molten steel; (2) performing continuous casting: performing continuous casting on a molten steel upper plate blank; (3) soaking: performing soaking treatment on the casting blank; (4) performing steel rolling: performing steel rolling after removing phosphorus; (5) performingrelaxation: performing relaxation on a thin steel plate after finishing rolling; and (6) cooling. The preparation method of the weather-resistant steel has low yield ratio, high-temperature and low-temperature toughness, extensibility and high properties.

Owner:NANJING IRON & STEEL CO LTD

Nickel silver alloy and processing technique

This invention relates to a zincum-white copper alloy and its processing technique. It comprises of 67~69wt% of Cu, 14~16wt% of Ni and 15~19wt% of zincum. Due to the creativity in weight percentage of the Cu-Ni-Zn ternary alloy in this invention, the alloy shows a considerably silvery color, an outstanding strength, wear resistance, corrosion resistance and discoloration resisting properties. This invention stressed a raw materials cost as low as possible, meanwhile assures excellent founding properties, corrosion resisting properties and coin processing properties.

Owner:CHINA BANKNOTE PRINTING & MINTING

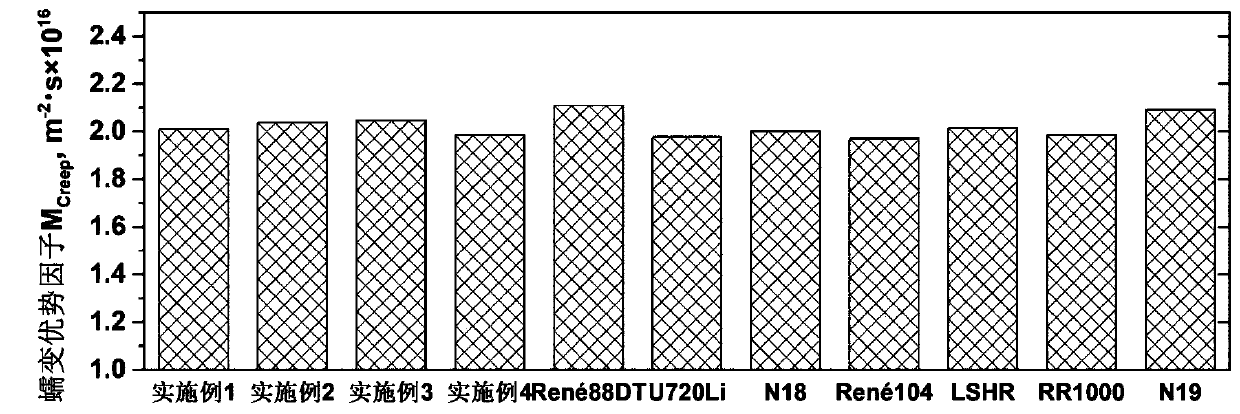

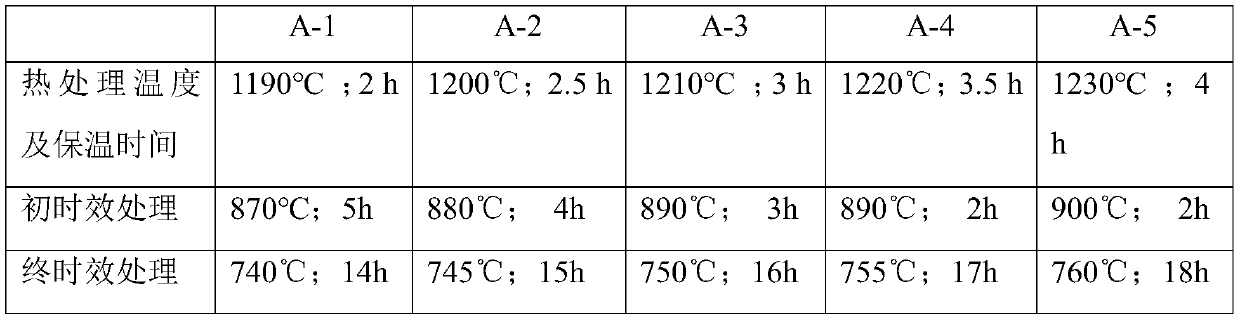

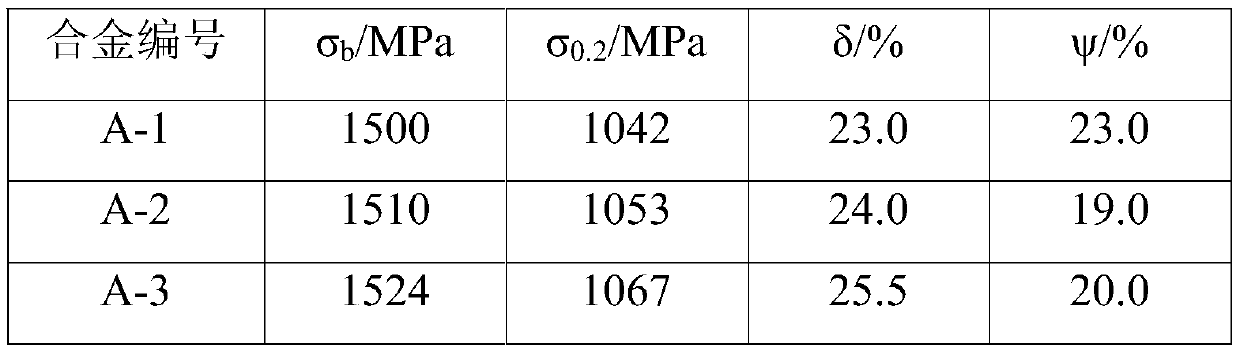

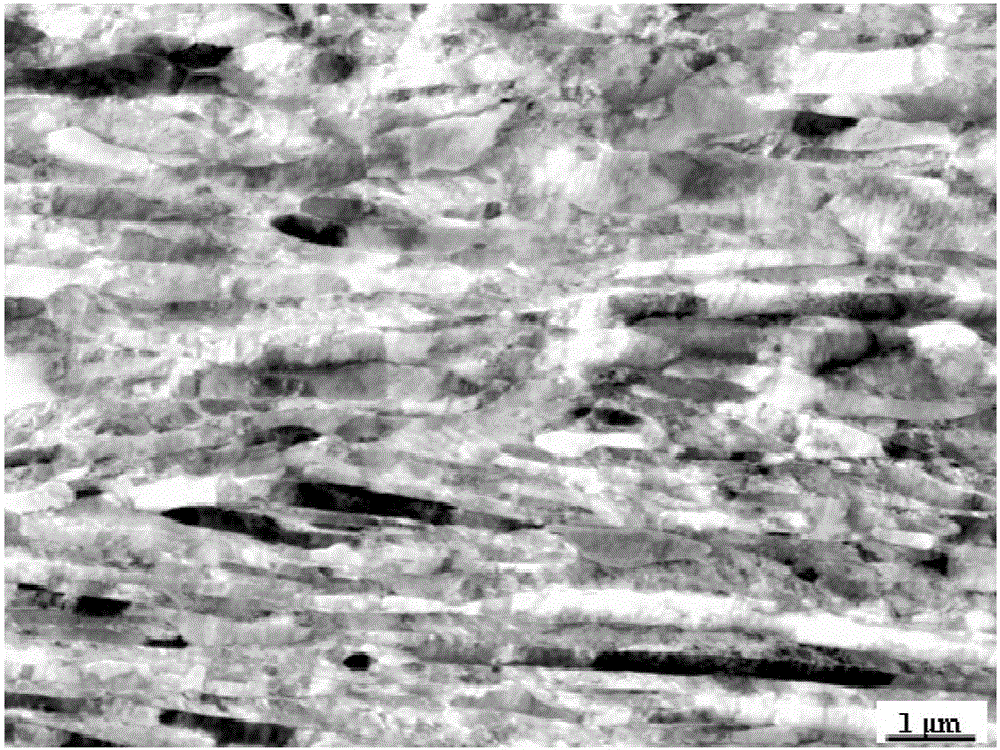

Nickel base powder high-temperature alloy with high tensile strength and preparation method thereof

ActiveCN110205523AImprove high temperature durabilityImprove acceleration performanceUltimate tensile strengthTurbine

The invention relates to a nickel base powder high-temperature alloy with high tensile strength and a preparation method thereof, belongs to the technical field of high-temperature alloys, and solvesthe technical problems of strict requirements on high-temperature alloy materials by such hot end parts as turbine discs in traditional engines and incapability of meeting the performance requirementsby traditional high-temperature alloy materials. The powder high-temperature alloy comprises the following chemical components in percentage by mass: 0.04-0.08 of C, 17.0-19.0 of Co, 11.0-13.0 of Cr,6.0-6.7 of W, 4.3-5.0 of Mo, 4.9-5.4 of Al, 1.5-1.9 of Ti, 2.5-2.9 of Nb, 0.2-0.5 of Hf, B less than 0.03, Zr less than 0.03, Mg less than 0.005, Ce less than 0.002, and the balance of Ni and other inevitable impurities. The powder high-temperature alloy achieves high tensile strength and excellent high-temperature creep resistance and high-temperature endurance, and is mainly used for preparingsuch hot end parts as aeroengine turbine discs.

Owner:BEIJING CISRI GAONA TECH

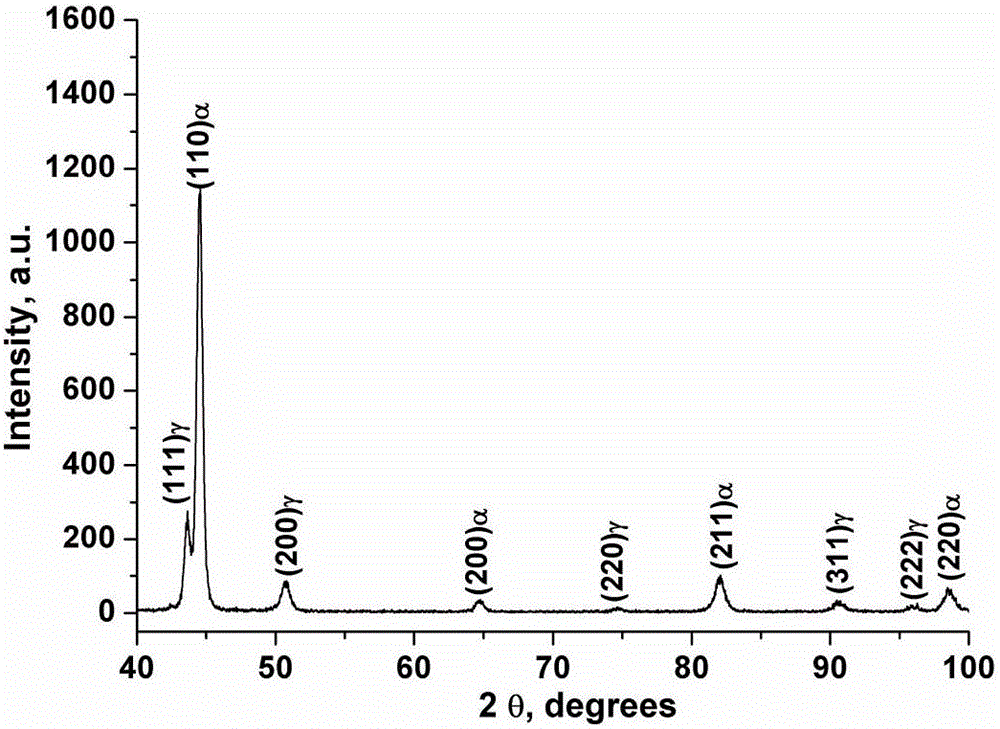

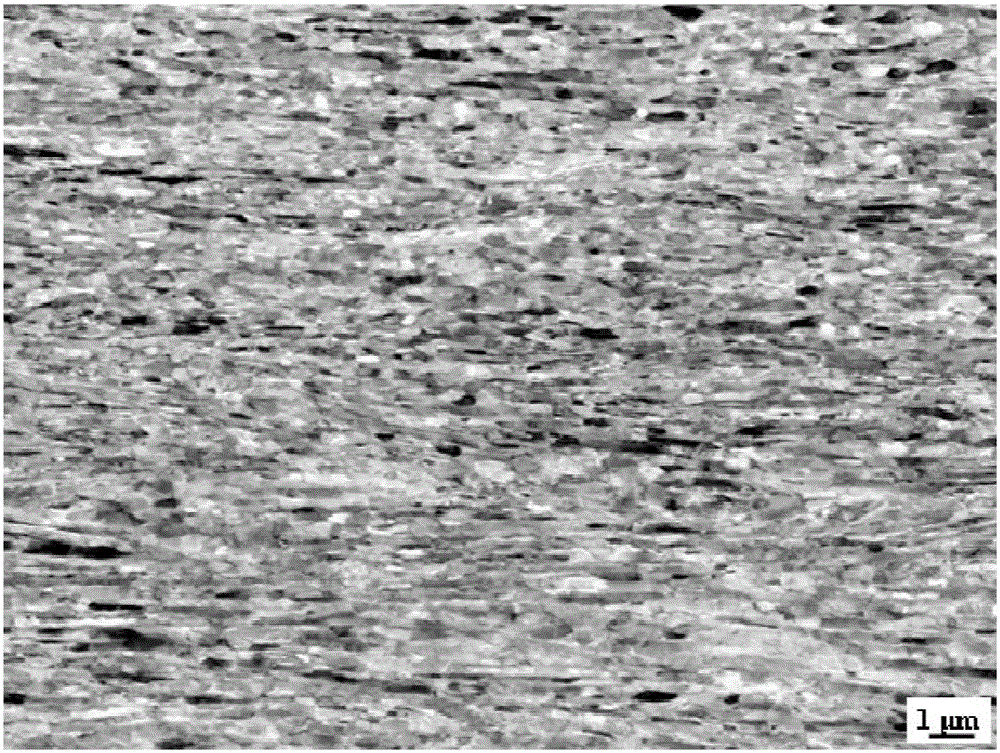

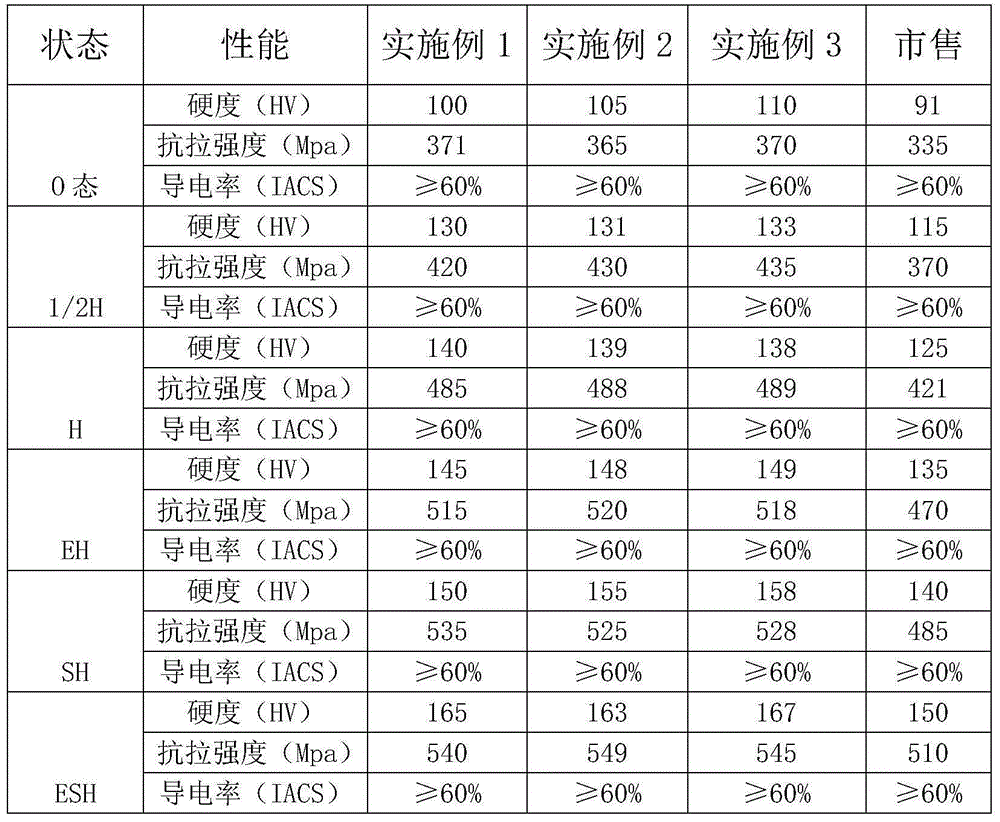

Nano/superfine medium-manganese TRIP (transformation induced plasticity) steel plate and warm-rolling preparation method thereof

The invention relates to a nano / superfine medium-manganese TRIP (transformation induced plasticity) steel plate and a warm-rolling preparation method thereof, belonging to the technical field of ultrahigh-strength steel. The nano / superfine medium-manganese TRIP steel plate comprises the following chemical components in percentage by weight: 0.17-0.25wt.% of C, 0.00-0.50wt.% of Si, 5.00-7.00wt.% of Mn, 1.00-1.50wt.% of Al, 0.014-0.03wt.% of N, 0.00-0.06wt.% of Nb, 0.00-0.25wt.% of Mo, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, forging, carrying out hot rolling, and carrying out warm rolling to obtain the nano / superfine medium-manganese TRIP steel plate; and carrying out heat treatment on the steel plate to obtain the nano / superfine medium-manganese TRIP heat-treated steel plate. By using the warm-rolling technique instead of the typical technique for producing manganese steel, the method provided by the invention has the advantages of simple technique, short production cycle and controllable plate shape. The prepared steel plate has a nano / superfine structure, has the advantages of high strength and favorable properties, and satisfies the target requirements of resource saving, energy consumption reduction, light weight and crash safety enhancement for automobile industry.

Owner:NORTHEASTERN UNIV

High-strength copper-iron-phosphorus alloy and production method thereof

InactiveCN105220007AHigh hardnessSolid solution strengtheningShort range orderSolid solution strengthening

The invention discloses a high-strength copper-iron-phosphorus alloy and a production method thereof. The formula of the copper-iron-phosphorus alloy comprises the following elements in percentage: 2.1-2.6% of Fe, 0.015-0.15% of P, 0.05-0.20% of Zn, Pb of which the percentage is smaller than or equal to 0.03%, 0.01-0.1% of Ni, 0.01-0.1% of Sn, and the balance being Cu. Compared with the prior art, according to the copper-iron-phosphorus alloy disclosed by the invention, trace amounts of Sn elements and Ni elements, which play a solution strengthening role in the alloy, are added in the raw material formula, so that the hardness of the materials under various states can be improved by nearly 5-10%. During the production of the copper-iron-phosphorus alloy disclosed by the invention, the condition of low-temperature annealing is adopted, so that on one hand, atoms of solution strengthening elements Sn and Ni are clustered at the periphery of a dislocation generated after being processed and hardened so as to perform dislocation pinning, and the strength of the alloy is improved; on the other hand, through low-temperature annealing, a short-range ordered structure formed in an organization and the dislocation perform interaction, so that the alloy is hardened.

Owner:安徽鑫科铜业有限公司

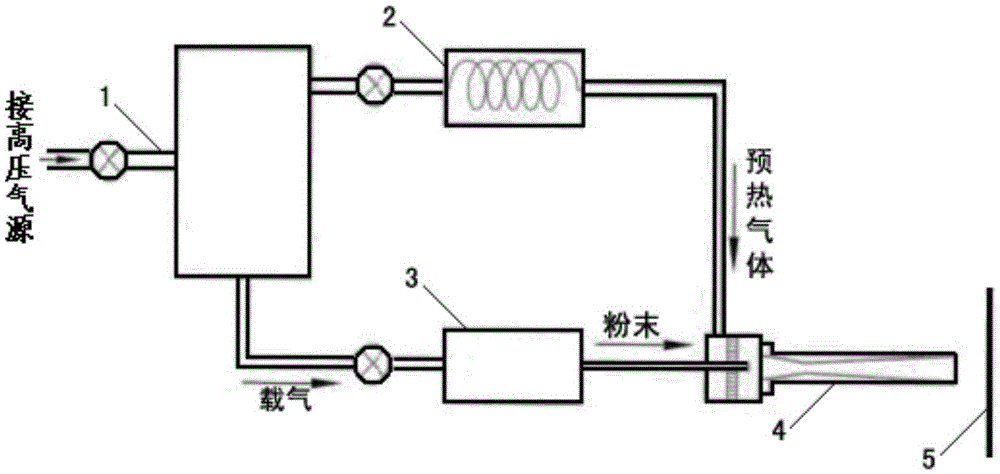

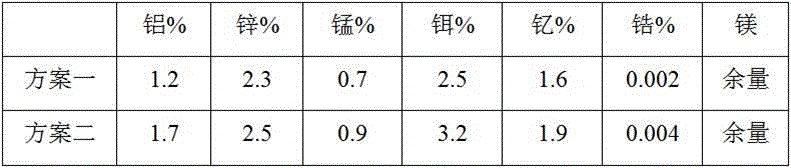

Steel structure part surface protective coating and preparation method thereof

ActiveCN105624665AIncreasing the thicknessSolve the Potential Reversal ProblemPressure inorganic powder coatingAlloyZinc

The invention relates to a steel structure part surface protective coating and a preparation method thereof. The preparation method comprises the following steps that Zn / Al / Mg alloy powder is directly sprayed on the surface of a steel structure part through high-speed airflow, so that the Zn / Al / Mg alloy powder is deposited on the surface to form the protective coating. The Zn / Al / Mg alloy powder is formed by mixing 5 wt%-15 wt% of aluminum powder, 0.01 wt%-0.02 wt% of magnesium powder and the balance zinc powder. The spraying technological parameters are as follows, the spraying distance is 25-50 mm, the air pressure is 3.5-5.0 MPa, the air temperature is 580-800 DEG C, and the air flow is 35-50 g / s. According to the preparation method, the uniformly distributed Zn / Al / Mg coating with the ideal thickness can be prepared on the surface of the steel structure part, the corrosion resistance of the steel structure part in the marine environment is remarkably improved, and the service life is prolonged.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Preparing method for superfine and high-bending-strength alloy powder used for diamond tool

The invention discloses a preparing method for superfine and high-bending-strength alloy powder used for a diamond tool. The preparing method includes the steps that metal raw materials are prepared and include, by weight percentage, 5%-85% of Cu, 1%-25% of Ni, 1%-20% of Sn, 0%-8% of Si, 1%-15% of Al, 5%-15% of Cr, 0.1%-5% of B, 0.1%-6% of V, 0.1%-5% of Nb, 0.1%-5% of Zr, 0.1%-10% of La and the balance Fe; and the steps of smelting, water atomization, filter pressing dewatering, vacuum drying and reduction are sequentially conducted, and the superfine and high-bending-strength water atomization alloy powder is prepared. Component uniformity of single-particle powder is improved due to the ultrafine granularity of the superfine alloy powder, and meanwhile extremely-high sintering activity is achieved; especially, the added low-melting-point elements promote sintering of a micro liquid phase, a diamond tool bit sintering matrix has higher density, and the holding force on diamond is improved. Due to the fact that the metal structure strengthening alloy elements and the rare earth elements are added, the bending strength is improved to 1900 MPa, finally, the holding force of the matrix on the diamond is improved, and the diamond tool bit tool high in cutting performance is obtained.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

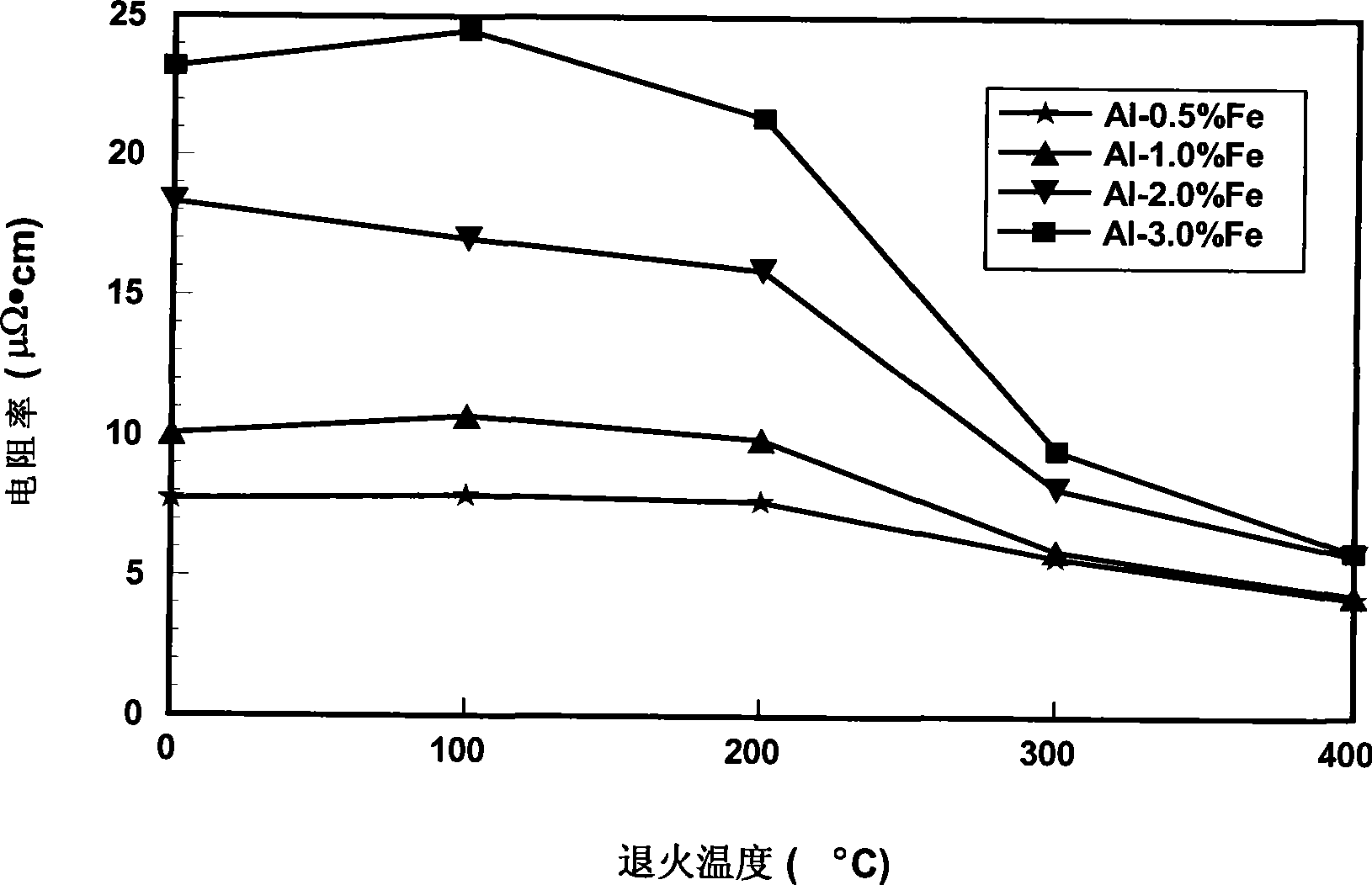

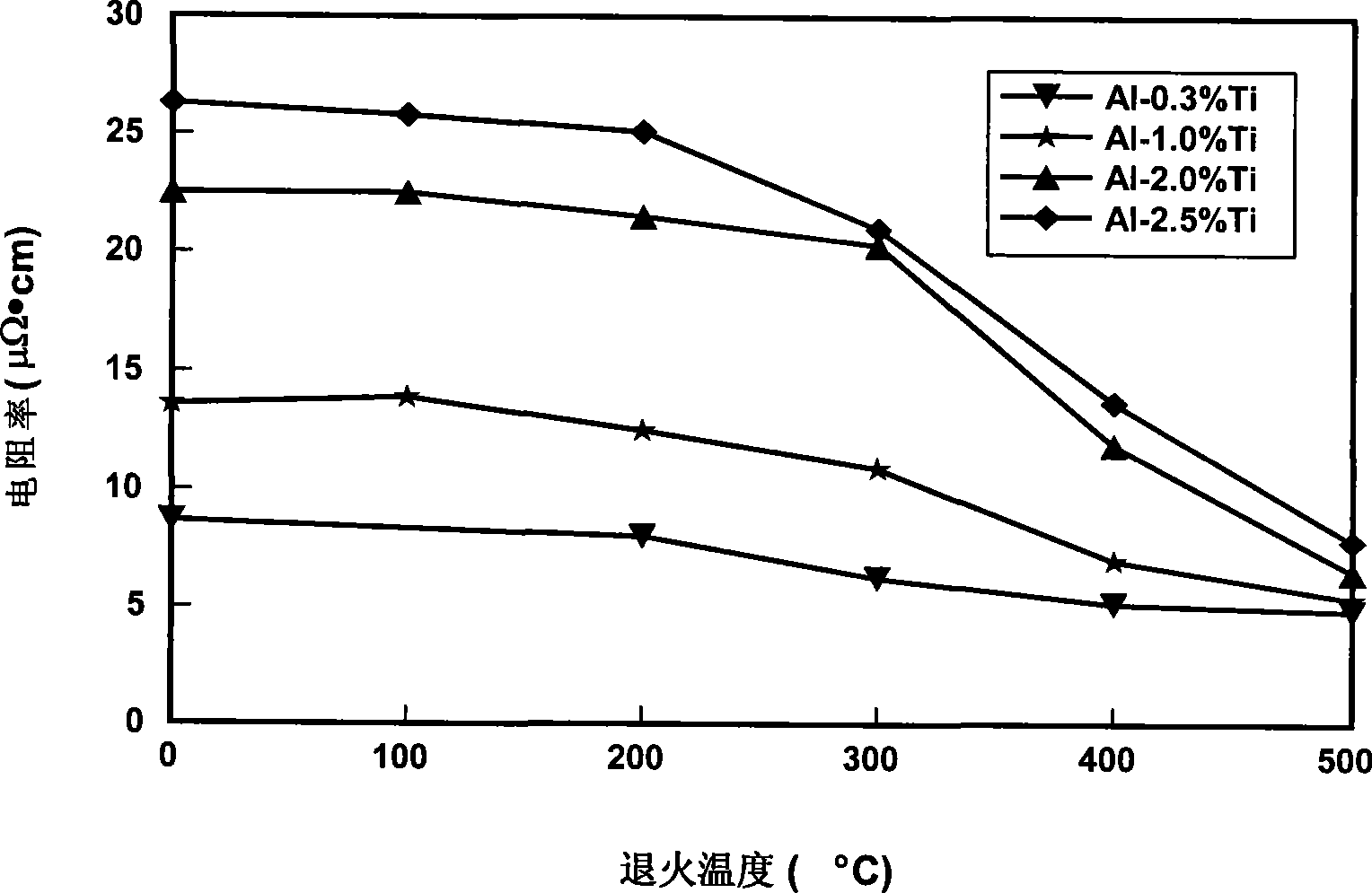

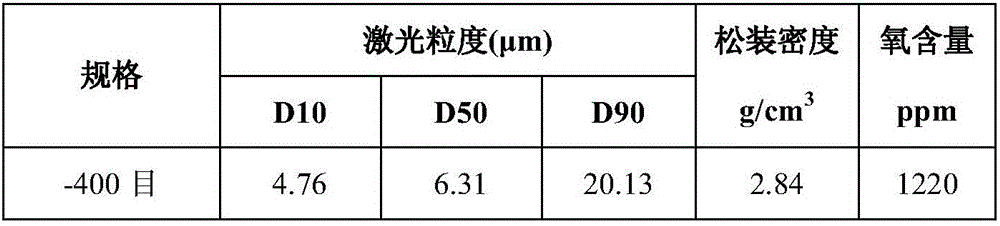

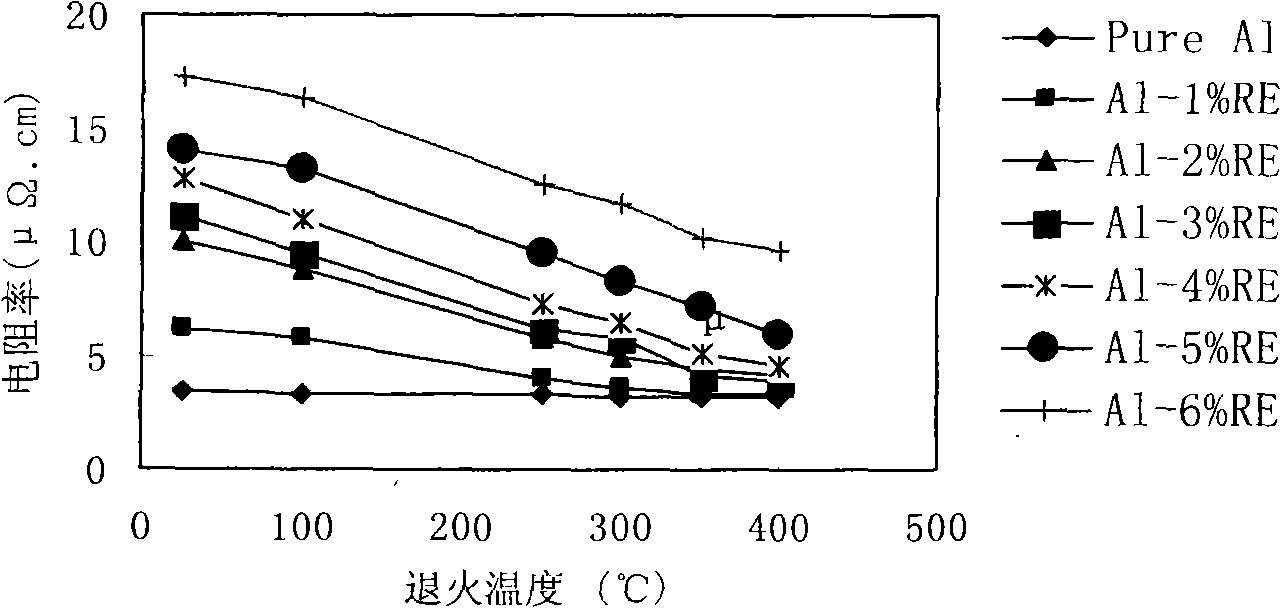

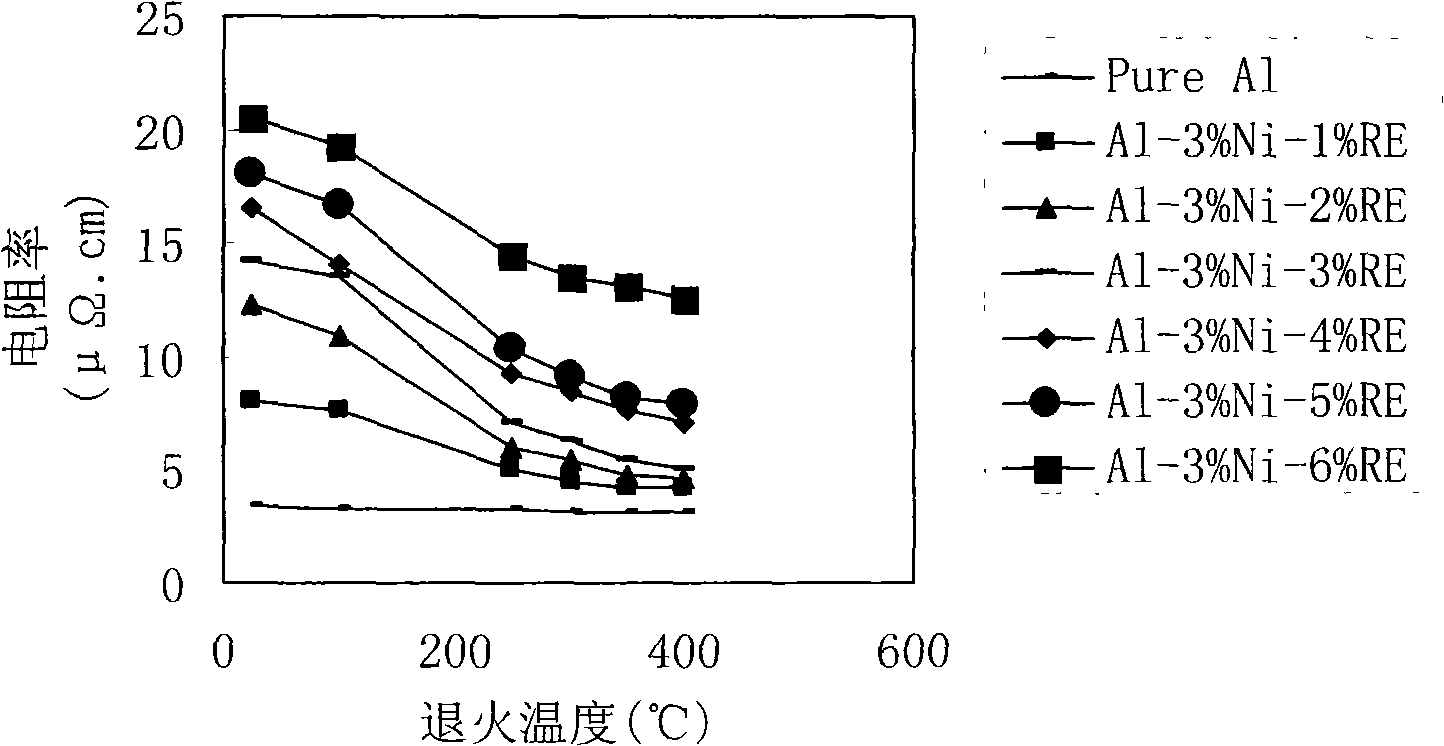

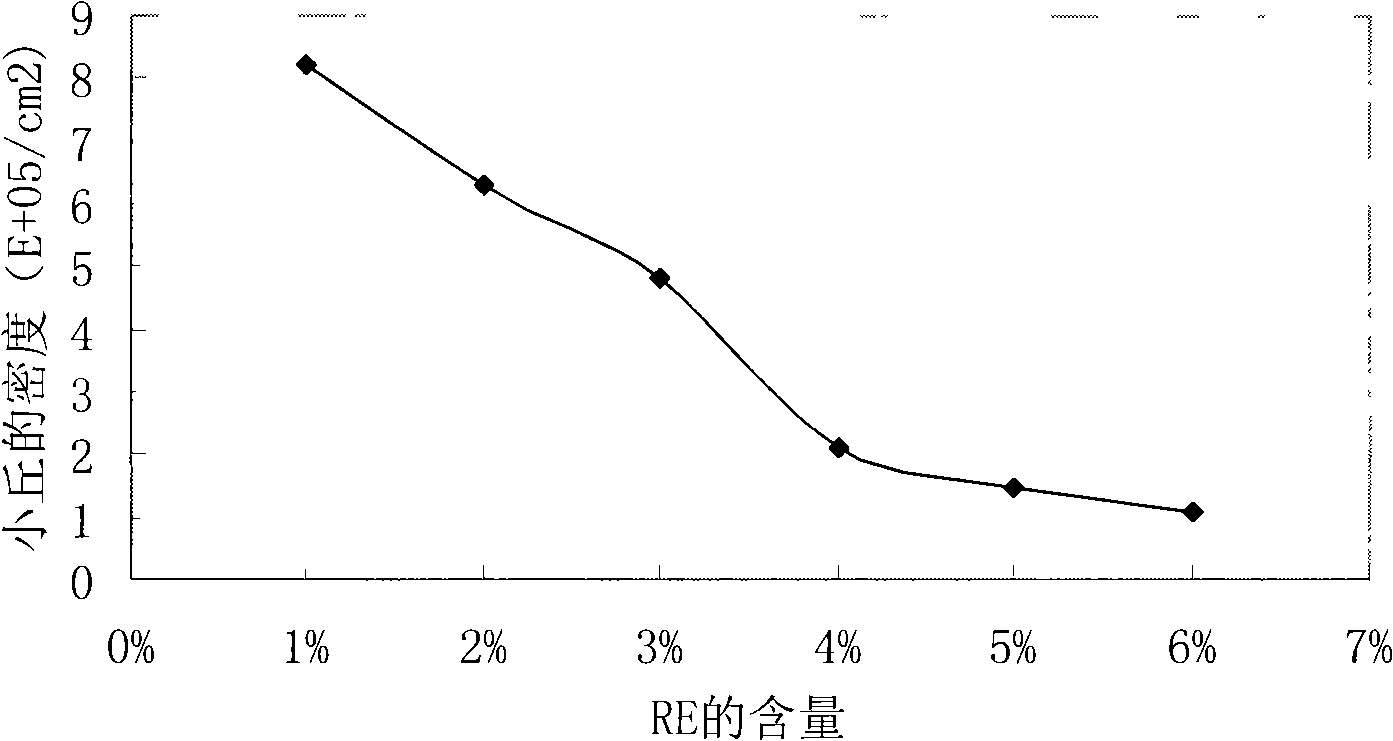

Target material for preparing TFT LCD electrode film and method for preparing target material and electrode

InactiveCN101285165AReduce manufacturing costSolid solution strengtheningMolten spray coatingVacuum evaporation coatingBinary alloyActive matrix

The invention discloses a target for manufacturing TFT LCD active matrix electrode film, wherein the target is Al-RE alloy, Al-Ni alloy or Al-Ni-Re alloy, and the content of the alloy element in the target is between 1 at percent and 10 at percent. The invention also discloses a manufacture method of the target for manufacturing the TFT LCD active matrix electrode film and a manufacture method for the TFT LCD active matrix electrode film. The invention manufactures a binary alloy target through replacing Nd which is scarce and expensive by Ni and Re which are abundant. The invention can reduce the cost of the target and the electrode film. The manufacture method for the electrode film enables the alloy elements to be solid dissolved therein by a magnetron sputtering method, and the thermal stability of the Al alloy film can be improved. In the manufacture method for the electrode film, during the annealing process, all or partial alloy elements in solid solution state are deposited, in the form of intermetallic compound, between grains, thereby reducing the resistivity and improving the thermal stability of the alloy film.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Full-automatic submerged-arc welding solid welding wire for nickel-saving high-manganese low-temperature steel

InactiveCN112171109AReduce manufacturing costImprove stabilityArc welding apparatusWelding/cutting media/materialsArc weldingWeld bead

The invention relates to a full-automatic submerged-arc welding solid welding wire for nickel-saving high-manganese low-temperature steel. According to the technical scheme, the full-automatic submerged-arc welding solid welding wire is prepared from the following chemical components in percentage by weight: 0.20-0.45% of C, 0.03-0.10% of Si, 26-31% of Mn, less than or equal to 1.2% of Ni, 2-6% ofCr, less than or equal to 1% of Mo, 0.02-0.08% of N, less than or equal to 0.002% of P, less than or equal to 0.001% of S, and the balance of Fe and inevitable impurities. The production cost is low;formed weld metal has high elongation and stable mechanical properties, and the strength and low-temperature toughness of the weld metal are matched with those of the high-manganese low-temperature steel; and a welded joint has high strength and excellent ultralow-temperature toughness mechanical properties, and can meet the technical requirements on the room-temperature and low-temperature properties of LNG storage tanks prepared by welding.

Owner:WUHAN UNIV OF SCI & TECH +1

Vacuum electronic tube-sealed low-silver multi-component alloy material and preparation method thereof

The invention provides a vacuum electronic tube-sealed low-silver multi-component alloy material and a preparation method thereof. The vacuum electronic tube-sealed low-silver multi-component alloy material comprises the following components by mass percentage: 35-45% of Ag, 45-55% of Cu, 5-8% of Si, 0.6-0.8% of Ni, 0.4-0.6% of B, 0.3-0.5% of Ge, 0.3-0.5% of Nd, 0.2-0.3% of Ce, and 0.2-0.3% of Co. The preparation method comprises the following steps: melting, casting, solid saluting, ageing, turning, cold rolling, tempering, annealing and fine processing. The sealing material has the advantages of high cleanliness, good flowability, corrosion resistance, good antioxidation performance, low sealing temperature, and low cost.

Owner:WUXI RIYUE ALLOY MATERIALS

Micro-nanoparticle reinforced high-indium copper-based active solder and preparation method thereof

ActiveCN110640351ALower melting temperatureDiffusion strengtheningWelding/cutting media/materialsSoldering mediaMicro nanoIndium

The invention relates to a micro-nanoparticle reinforced high-indium copper-based active solder. The active solder comprises the following raw materials of, in parts by weight, 85 - 95 parts of base component, 2.5 - 9 parts of active component, 0.1 - 1 part of micro-component and 2 - 5 parts of micro-nano reinforced particles. A preparation method of the micro-nanoparticle reinforced high-indium copper-based active solder comprises the following steps of weighing and preparing the materials, high-frequency induction melting an intermediate alloy, vacuum smelting a solder, and conventional processing the solder into a filamentous or ribbon-shaped active solder. According to the micro-nanoparticle reinforced high-indium copper-based active solder, the formula is reasonable in design and highin cost performance; the basic component comprises the following components of, in parts by weight, 5 - 15 parts of indium, 3 - 8 parts of tin, 1 - 3 parts of manganese, 1 - 5 parts of phosphorus, 0.5 - 3 parts of antimony, 0.5 - 5 parts of silicon, 0.5 - 5 parts of germanium and the balance copper, through a method of replacing the tin with the indium and the phosphorus compositely, not only isthe melting temperature of the copper-based active solder reduced, but also the plasticity of the solder is improved and the processability of the solder is improved; and by adding the micro-nanoparticles, the strength of the solder and a soldered joint is improved.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

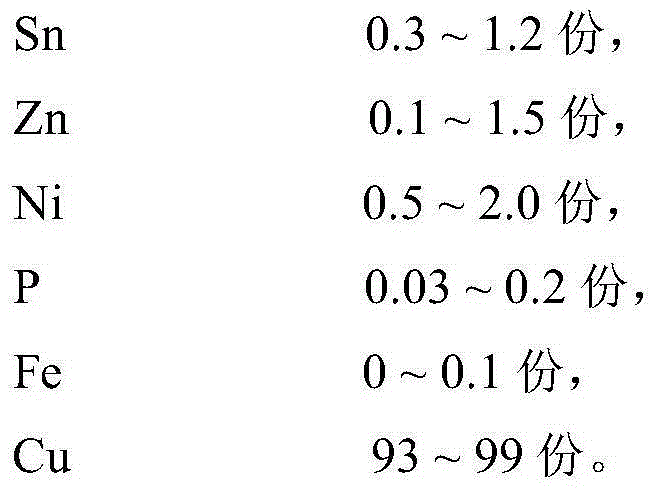

Low-alloying copper belt and preparation method thereof

The invention relates to a low-alloying copper belt and further relates to a preparation method of the low-alloying copper belt. The low-alloying copper belt is characterized by including the following components of, by weight, 0.3-1.2 parts of Sn, 0.1-1.5 parts of Zn, 0.5-2.0 parts of Ni, 0.03-0.2 part of Po, 0-0.1 part of Fe and 93-99 parts of Cu. In the low-alloying copper belt, the Sn, Ni, Zn and P of low contents are subjected to solid solution treatment and exist in a matrix in a solid solution mode, and meanwhile part of the Ni and P form second-phase phosphide, that is, nickel phosphide, so that strength and the stress relaxation resistant performance of materials are improved, and the materials have high elasticity and conductivity; besides, the proportional relation between contents of the Sn, Ni and Zn is good for improvement of intensity and elasticity of the materials, the strengthening effect is not apparent when the contents of the Sn, Ni and Zn are too low, and the material conductivity is reduced seriously when the contents of the Sn, Ni and Zn are too high; compound hard particles separate out from the Ni and P in the low-alloying copper belt, so that the material elasticity is improved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

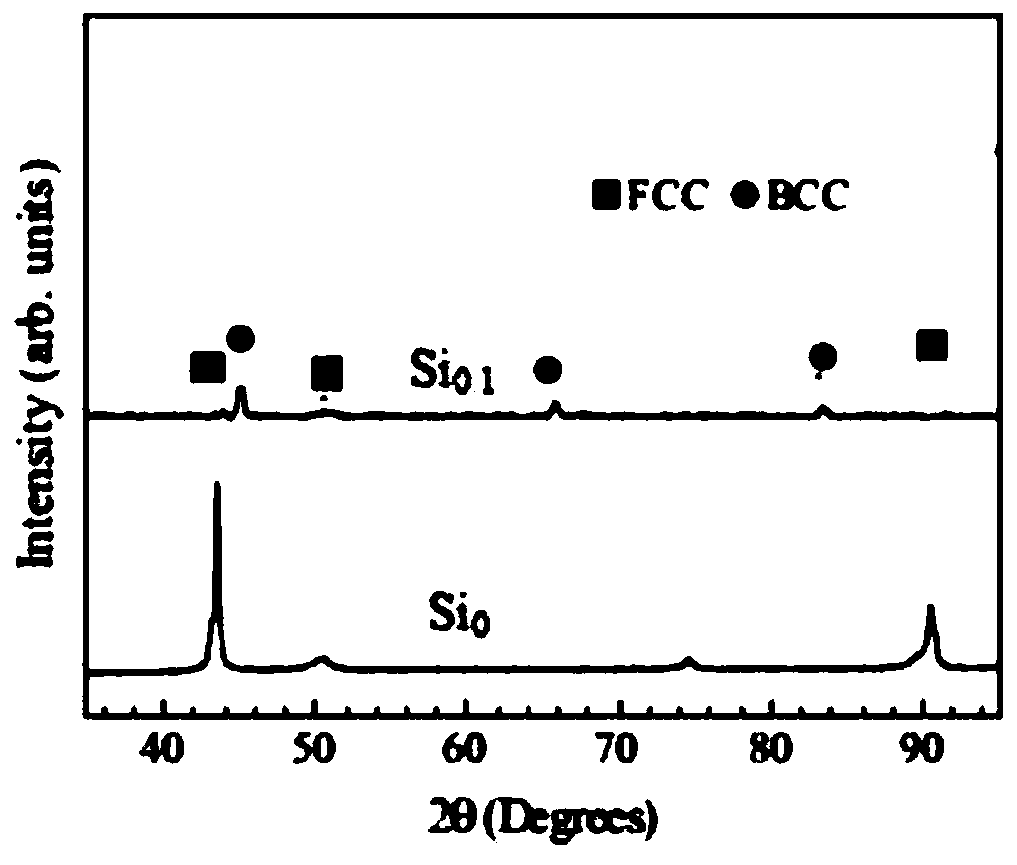

Silicon-containing high-entropy alloy coating and preparation method thereof

InactiveCN110306186ALarge lattice distortionHigh hardnessMetallic material coating processesCoated surfaceHigh entropy alloys

The invention provides a silicon-containing high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. According to the silicon-containing high-entropy alloy coating and the preparation method thereof, a silicon element is used as a secondary element and also is a gap element to be added into CoCrCuFeMn high-entropy alloy so that the quite good high-temperature softening resistance can be achieved through a gap effect of non-metal elements, then the lattice distortion of the high-entropy alloy of the kind can be increased, a solid solution strengthening effect can be achieved, the silicon element and the main element can also form a silicide to be dispersed in the alloy structure, a dispersion strengthening effect is generated, so that the hardness and the wear resistance of the high-entropy alloy of the kind are improved; the self-fluxing element Si is added so that the fluidity of the alloy in the liquid state can be improved, and then the macroscopic morphology of the surface of the coating is improved; and part of the Si can replace Cr with the large atom radius, so that the lattice distortion effect of the alloy is intensified, then the peak value of the FCC phase in the high-entropy alloy structure is changed, through the addition of the Si, the BCC phase can be converted to the FCC phase in the high-entropy alloy, so that thevolume fraction of the FCC phase is promoted to be increased.

Owner:NANCHANG UNIV +1

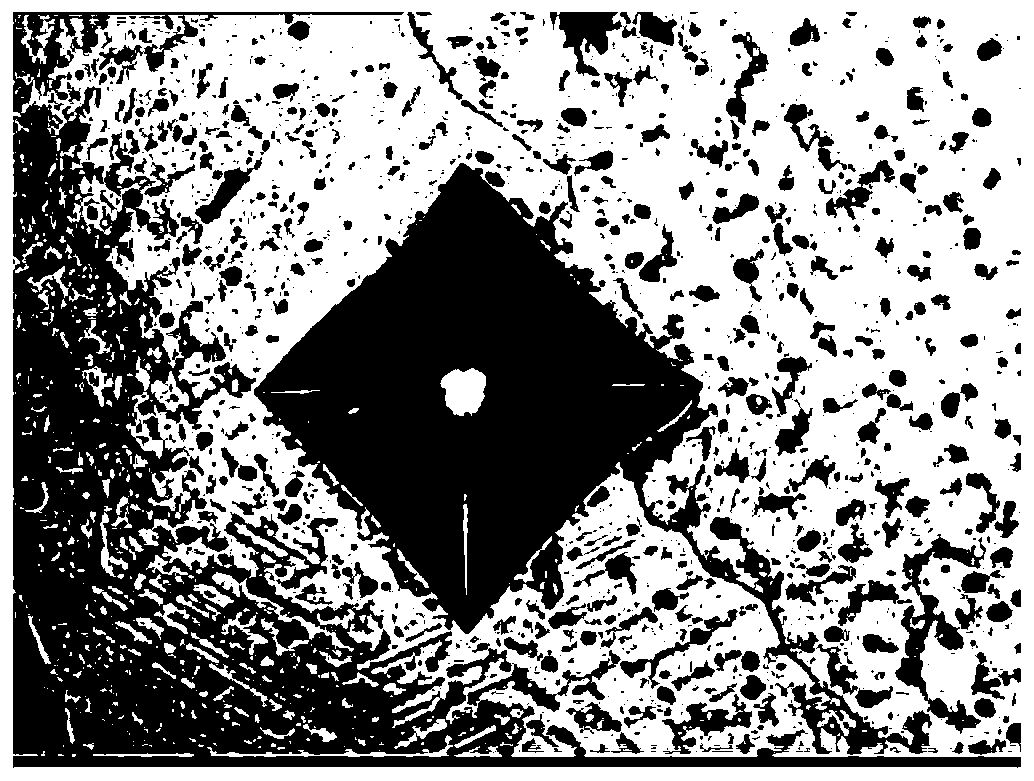

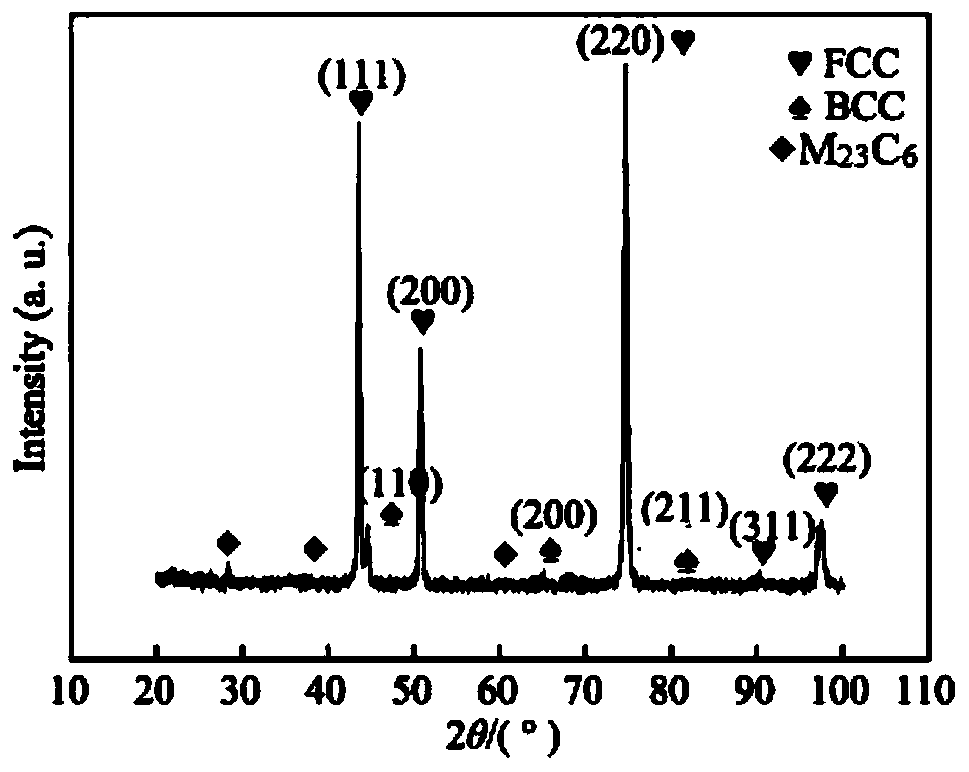

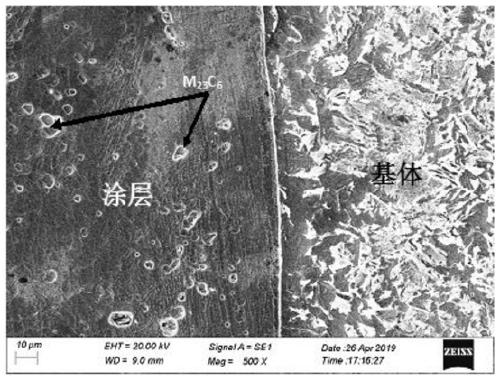

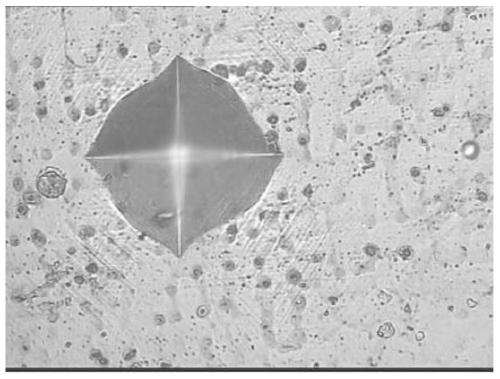

Carbonic high-entropy alloy coating and preparation method thereof

ActiveCN110241354ALarge lattice distortionHigh hardnessMetallic material coating processesHigh entropy alloysCarbide

The invention provides a carbonic high-entropy alloy coating and a preparation method thereof, and belongs to the field of alloy coatings. Co, Cr, Cu, Fe and Mn are adopted as main elements, a carbon element (C) is adopted as a secondary element, C is an interval element and is added into the CoCrCuFeMn high-entropy alloy, the stacking fault energy of the alloy can be improved through the interval effect of the non-metal element, lattice distortion of the high-entropy alloy is improved, the solid solution strengthening effect is achieved, the carbon element can form a carbide with the main elements, for example, Fe-C, Cr-C M23C6 or M7C3 carbides are formed and dispersed into alloy tissue, the dispersion reinforcing effect is generated, and the high-entropy alloy hardness and abrasion resistance are improved; meanwhile, the high-entropy alloy structure formed by the main elements is BCC+FCC, a dual-phase solid solution is formed, after the C element is added, and the phase structure type cannot change; due to the dual-phase solid solution, the high-entropy alloy has the higher strength, and the hardness of the carbonic high-entropy alloy coating is improved.

Owner:NANCHANG UNIV

High-strength and high-temperature-resistant magnesium alloy

The invention discloses a high-strength and high-temperature-resistant magnesium alloy, and belongs to the field of metallic materials. The magnesium alloy mainly comprises elements of magnesium, aluminum, zinc, manganese, erbium, yttrium, zirconium and the like, the magnesium alloy is composed, by weight percentage, of 1-2% of the aluminum, 2-3% of the zinc, 0.5-1% of the manganese, 2-3.5% of the erbium, 1.5-2% of the yttrium, 0.02-0.05% of the zirconium, less than 0.02% of silicon, less than 0.002% of copper, less than 0.002% of iron, less than 0.005% of other impurities and the balance magnesium. According to high-strength and high-temperature-resistant magnesium alloy, the elements such as the magnesium, the aluminum, the zinc, the manganese, the erbium, the yttrium and the zirconium are added into the magnesium alloy, room-temperature strength and corrosion resistance of materials are improved, tensile strength, elongation and high-temperature strength of the magnesium alloy are greatly improved, and the magnesium alloy can work under the temperature ranging from 200 DEG C to 300 EDG C for a long time.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

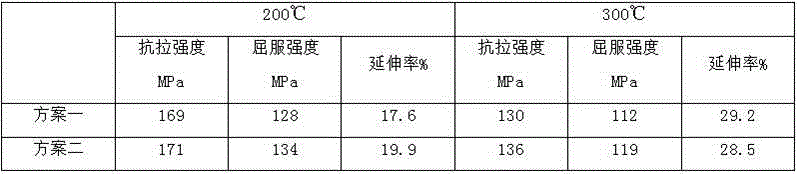

Five-layer aluminum alloy composite board and composite method

InactiveCN107881370AHigh strengthHigh hardnessLamination ancillary operationsLaminationAlloy compositeImpurity

The invention relates to a five-layer aluminum alloy composite board and a composite method. The structure of the composite board is 4xxx / 3003mod1 / 3003mod2 / 3003mod1 / 4xxx, wherein the 3003mod2 comprises the components of not greater than 0.15% of Si, not greater than 3.0% of Fe, 0.5%-0.8% of Cu, 1.3-1.85% of Mn, 0.05-0.15% of Ti, and the balance Al and inevitable impurities of which the total amount is less than 0.15%, and the 3003mod1 comprises the components of 0.45-0.8% of Si, 0.1-0.6% of Fe, 1.3-1.8% of Mn, 2.0-3.0% of Zn, 0.05-0.15% of Zr, and the balance Al and inevitable impurities of which the total amount is less than 0.15%. According to the five-layer aluminum alloy composite board and the composite method, the components and the structure are improved, and therefore the purpose of protecting a core material can be achieved, the strength of an alloy can be improved, meanwhile, the post-weld strength of the material can be improved, in addition, the composite method is simple and easy to realize, and the obtained five-layer aluminum alloy composite board is low in cost.

Owner:YINBANG CLAD MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com