Target material for preparing TFT LCD electrode film and target material and electrode film preparation method

An electrode film and target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of difficult purification and high price of AlNd, and meet the requirements of low resistivity and high thermal stability, thermal stability The effect of improving the performance and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The method for preparing the electrode film provided by the present invention is to deposit the electrode film on a substrate or other medium by a DC magnetron sputtering Al-Fe, Al-Ti or Al-Ta alloy target material.

[0038] The method for preparing the electrode film provided by the present invention can also be modified according to the requirements of the electrode film. Firstly, deposit a layer of refractory metal on a substrate or other medium, and then use DC magnetron sputtering Al-Fe, Al-Ti or Al-Ta The alloy target deposits a layer of Al-Fe, Al-Ti or Al-Ta alloy as a conductive layer to form a two-layer structure electrode film; or alternatively, first deposit a layer of refractory metal on the substrate or other medium, and then use direct current Magnetron sputtering Al-Fe, Al-Ti or Al-Ta alloy target deposits a layer of Al-Fe, Al-Ti or Al-Ta alloy as a conductive layer, and then deposits a layer of refractory metal on the conductive layer film layer , The format...

specific Embodiment 1

[0045] After fully mixing Al, Te (or Ti, Ta) alloy powder with a purity of 99.99wt%, heat the alloy with an induction or resistance furnace to completely melt it, and spray the working gas (usually Ar or N2) through atomization The nozzle atomizes the molten alloy into small droplets and moves quickly to the cooled and rotating substrate at a certain speed under the drive of the airflow, and obtains a body with a certain density on the surface of the substrate (generally the density is about 95% of the theoretical density) . The green body is preliminarily shaped, and then subjected to hot isostatic pressing to densify, and then forged and mechanically processed into the final alloy target shape.

specific Embodiment 2

[0047] The fully mixed Al, Te (or Ti, Ta) alloy powder with a purity of 99.99wt% is used to heat the alloy with an induction or resistance furnace to completely melt it. After stirring and homogenization, the alloy liquid is heated to a certain temperature After condensing it to room temperature, take it out of the cavity, with or without forging, and then mechanically process the alloy target to the final size.

[0048] Specific Example 1 of Preparation Method of Electrode Film

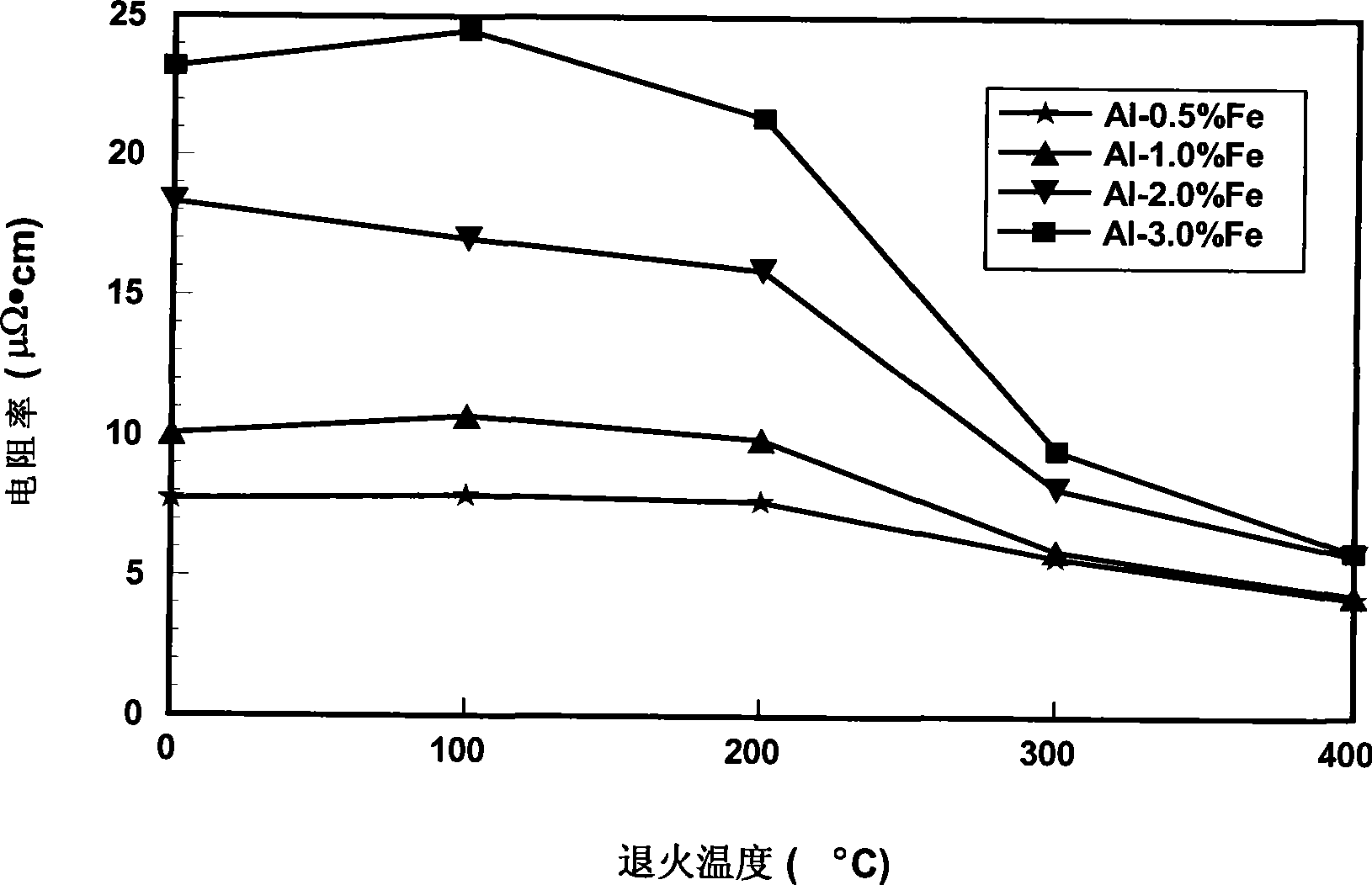

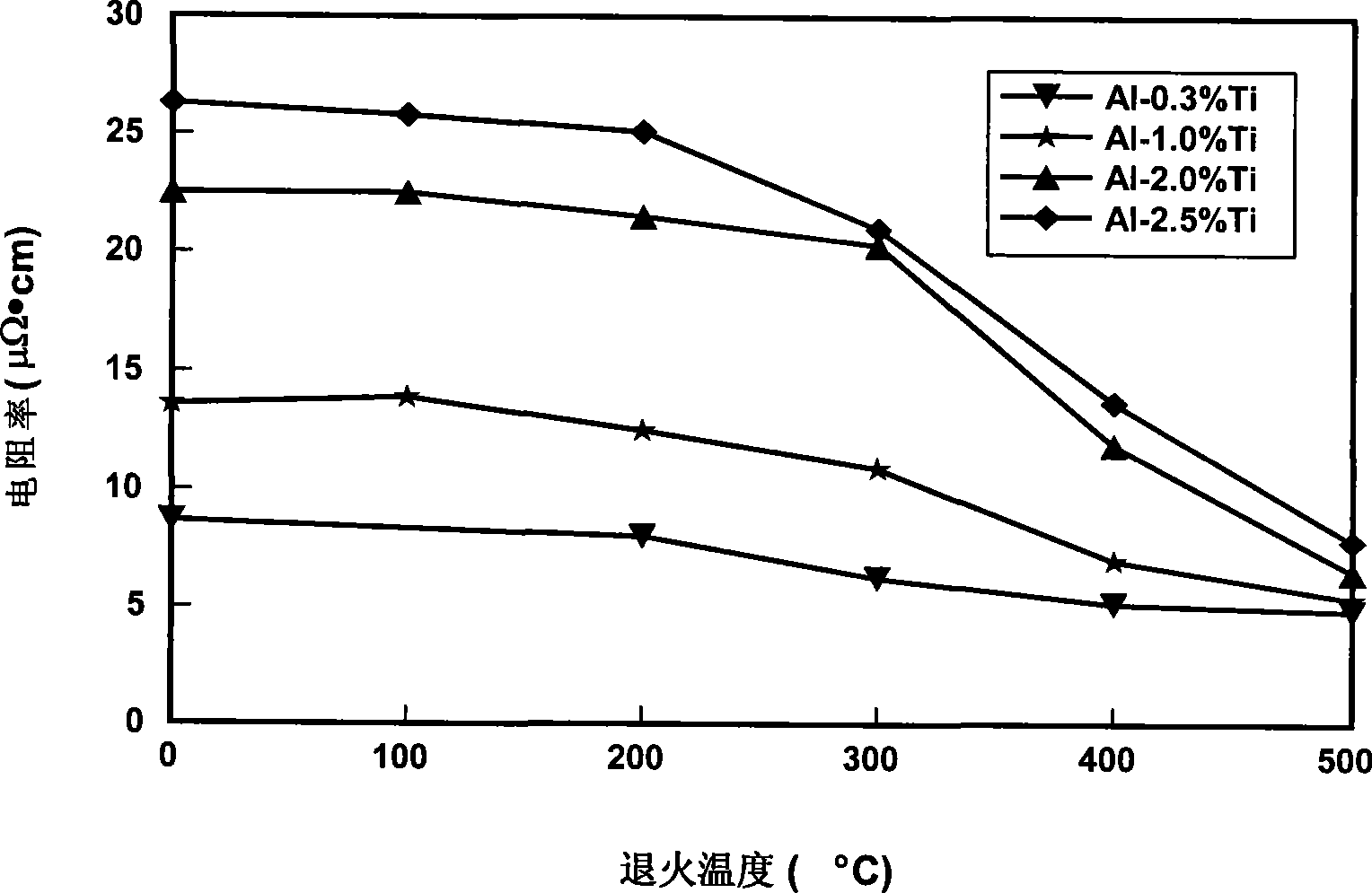

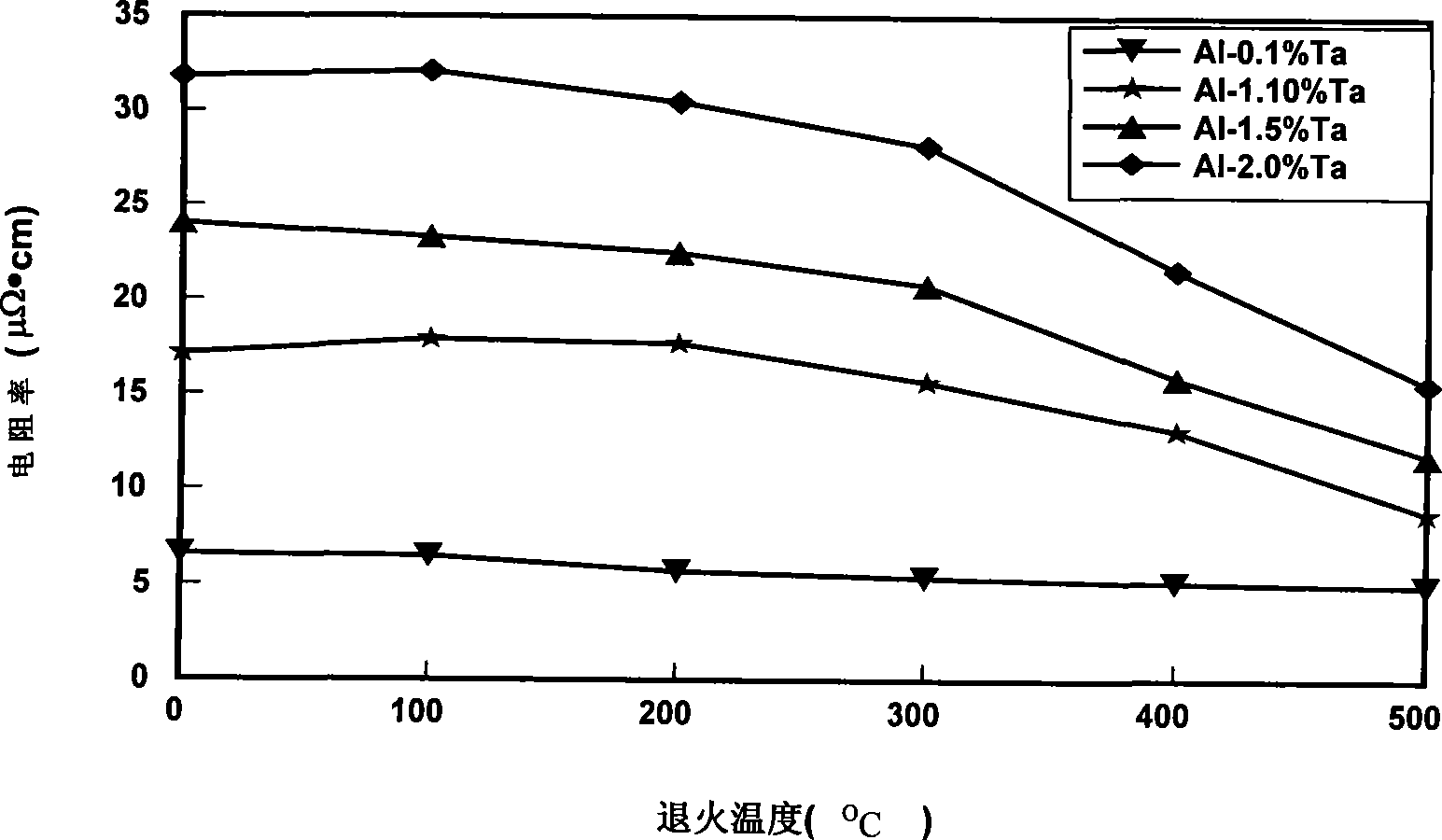

[0049] On 0.5mm thick glass, a 400nm thick Al alloy film was deposited by DC magnetron sputtering AlFe (or AlTi, AlFeTa) binary composite target. During the preparation process of the composite target, the content of alloying elements is controlled to be 0.5at%-3at%. The prepared film was annealed at 100°C, 200°C, 300°C, and 400°C and then cooled to room temperature, and its resistivity was measured by the 4-point method. Then measure its hillock density. Use the ICP method to measure the composition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com