Five-layer aluminum alloy composite board and composite method

A technology of composite sheet and aluminum alloy, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of limited application scope, increased cost, poor corrosion resistance, etc., to improve post-weld strength and prevent cracking , the effect of refining the as-cast structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the five-layer aluminum alloy brazing material comprises:

[0041] Melting and casting: smelting according to a certain element ratio, through melting, electromagnetic stirring, slag removal, degassing, refining, and semi-continuous casting, respectively to obtain 4343 ingots, 3003mod1 ingots, and 3003mod2 ingots. The thickness of the ingots is about 450mm.

[0042] Face milling of the ingot: according to the specifications, the ingot is face milled, and the amount of face milling is 5-15mm.

[0043] Hot rolling of the brazing layer and the middle layer: respectively hot rolling the 4343 ingot and the 3003mod1 ingot in the above steps to a thickness of 60mm.

[0044] Heating: 3003mod2 ingot and hot-rolled 4343 brazing layer and 3003mod1 intermediate layer are attached figure 1 Combine heating in the sequence shown.

[0045] Hot rolling: hot rolling the five-layer composite material in the previous step to a thickness of 5-8mm and coiling.

...

Embodiment 1

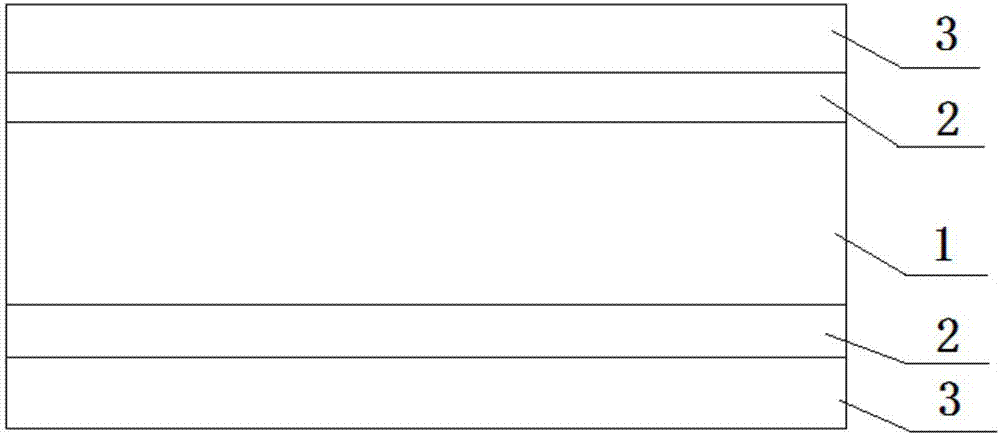

[0052] This embodiment is a five-layer aluminum alloy brazing material, hereinafter referred to as the five-layer material, and its structure is 4343 / 3003mod1 / 3003mod2 / 3003mod1 / 4343, as shown in the attached schematic diagram figure 1 shown. The brazing layer 3 is 4343 aluminum alloy, the middle layer 2 is 3003mod1 aluminum alloy, and the core material 1 is 3003mod2 aluminum alloy. The chemical composition of 3003mod1 is 0.8% Si, 0.1% Fe, 1.8% Mn, 3.0% Zn, 0.05% Zr, the rest is Al and the unavoidable impurities less than 0.15% in total. The chemical composition of 3003mod2 is 0.05% Si, 0.3% Fe, 0.8% Cu, 1.3% Mn, 0.15% Ti, the rest is Al and the unavoidable impurities whose total amount is less than 0.15%.

[0053] The preparation method of the five-layer aluminum alloy composite material in this embodiment is carried out according to the following steps:

[0054] Alloy melting and casting: according to the set ratio of alloys, through raw material melting, electromagnetic st...

Embodiment 2

[0065] This embodiment is a five-layer aluminum alloy brazing material, hereinafter referred to as the five-layer material, and its structure is 4343 / 3003mod1 / 3003mod2 / 3003mod1 / 4343, as shown in the attached schematic diagram figure 1 shown. The brazing layer 3 is 4343 aluminum alloy, the middle layer 2 is 3003mod1 aluminum alloy, and the core material 1 is 3003mod2 aluminum alloy. The chemical composition of 3003mod1 is 0.45% Si, 0.6% Fe, 1.3% Mn, 2.0% Zn, 0.15% Zr, the rest is Al and the unavoidable impurities less than 0.15% in total. The chemical composition of 3003mod2 is 0.1% Si, 0.15% Fe, 0.5% Cu, 1.85% Mn, 0.05% Ti, the rest is Al and the unavoidable impurities whose total amount is less than 0.15%.

[0066] The preparation method of the five-layer aluminum alloy composite material in this embodiment is carried out according to the following steps:

[0067] Alloy melting and casting: according to the set ratio of alloys, through raw material melting, electromagnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com