Patents

Literature

162results about How to "Increase potential difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength aluminium alloy brazing sheet

InactiveUS20050064226A1Good brazing propertyGood formability characteristicFurnace typesHigh frequency current welding apparatusSiluminHigh intensity

Disclosed is a high strength aluminium alloy brazing sheet, including an Al—Cu core layer and at least one clad layer, the core layer having the following composition (in weight percent): Cu: 1.2-4.0, Mn: 0.06-1.5, Mg: 0.06-1.5, Si: up to 0.5, Zn: <0.4, Zr: ≦0.25, Fe: ≦0.5, Ti: ≦0.25, Cr: ≦0.25; V≦0.25; the balance substantially aluminium and impurities, the clad layer including an Al—Si based filler alloy and being applied on at least one side of the core layer. Also disclosed is a brazed assembly including the brazing sheet and the use of the brazing sheet for a brazing application such as a heat exchanger.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

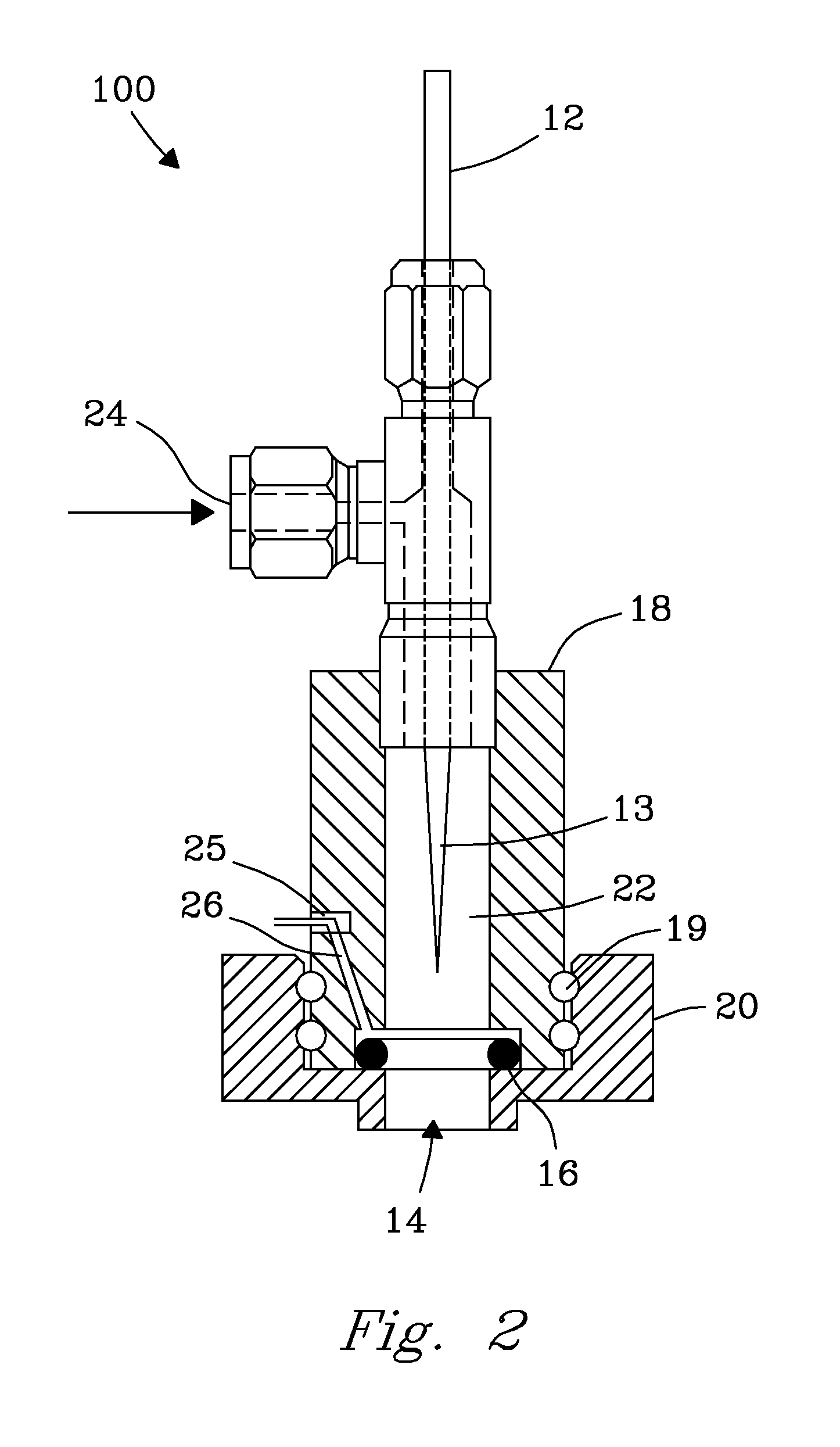

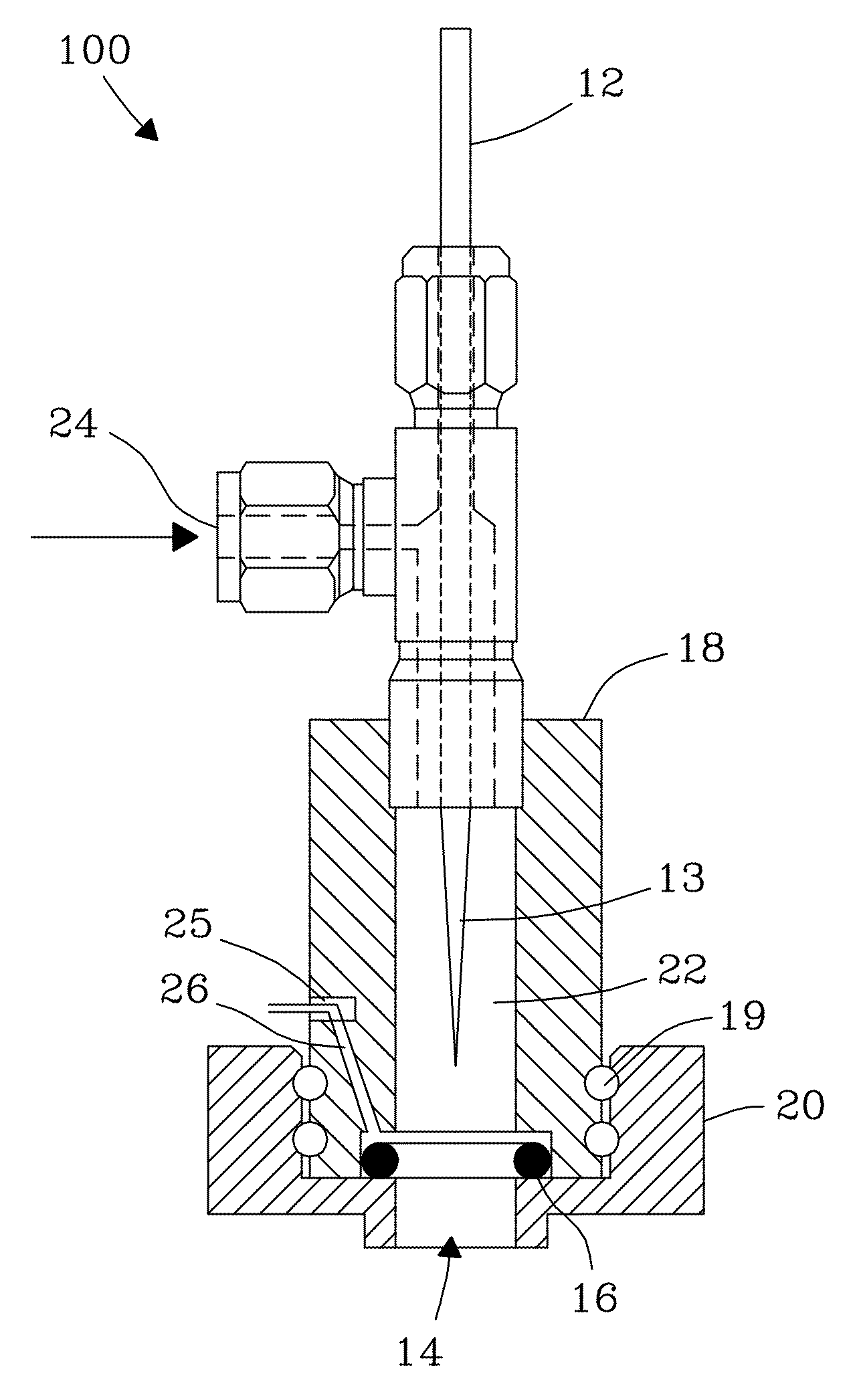

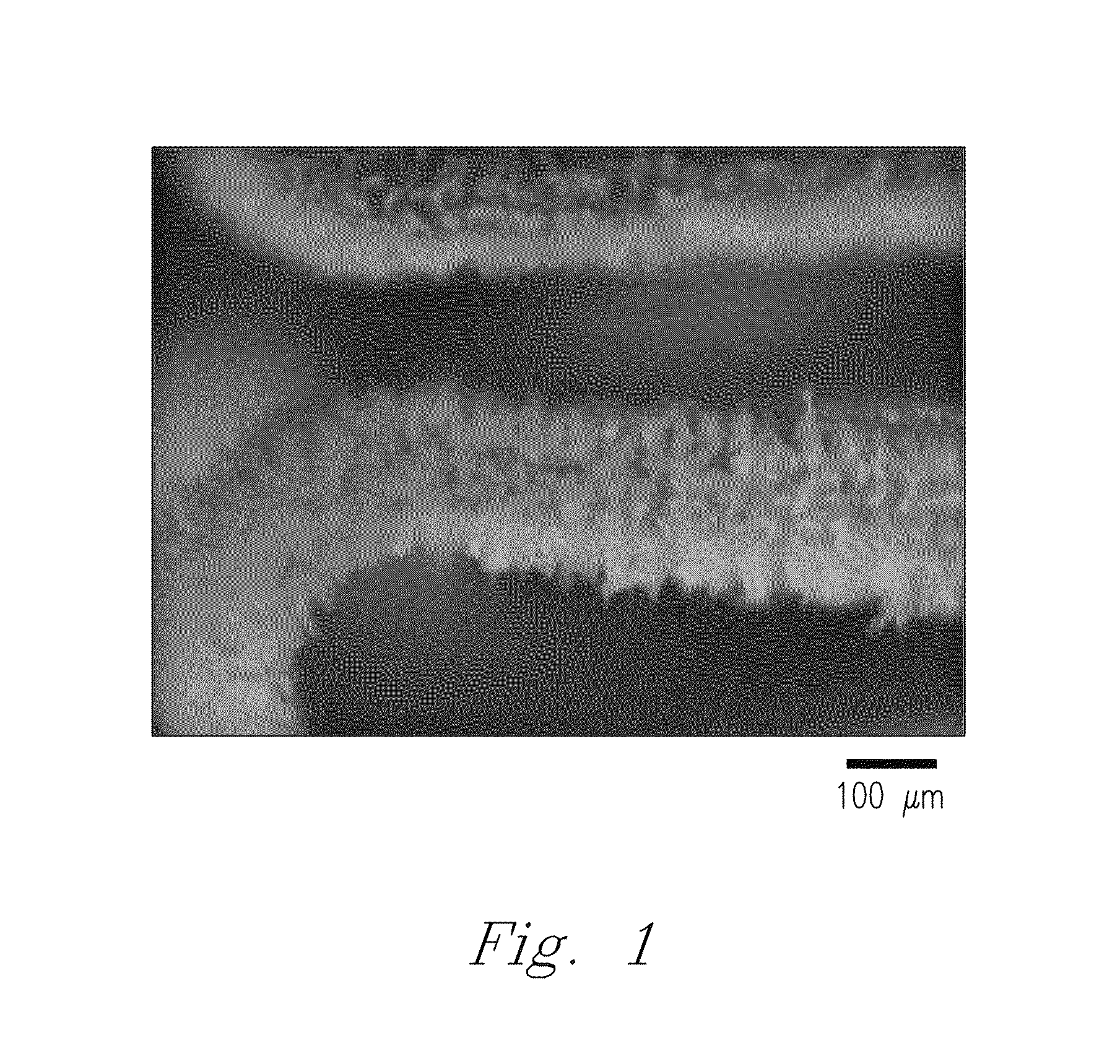

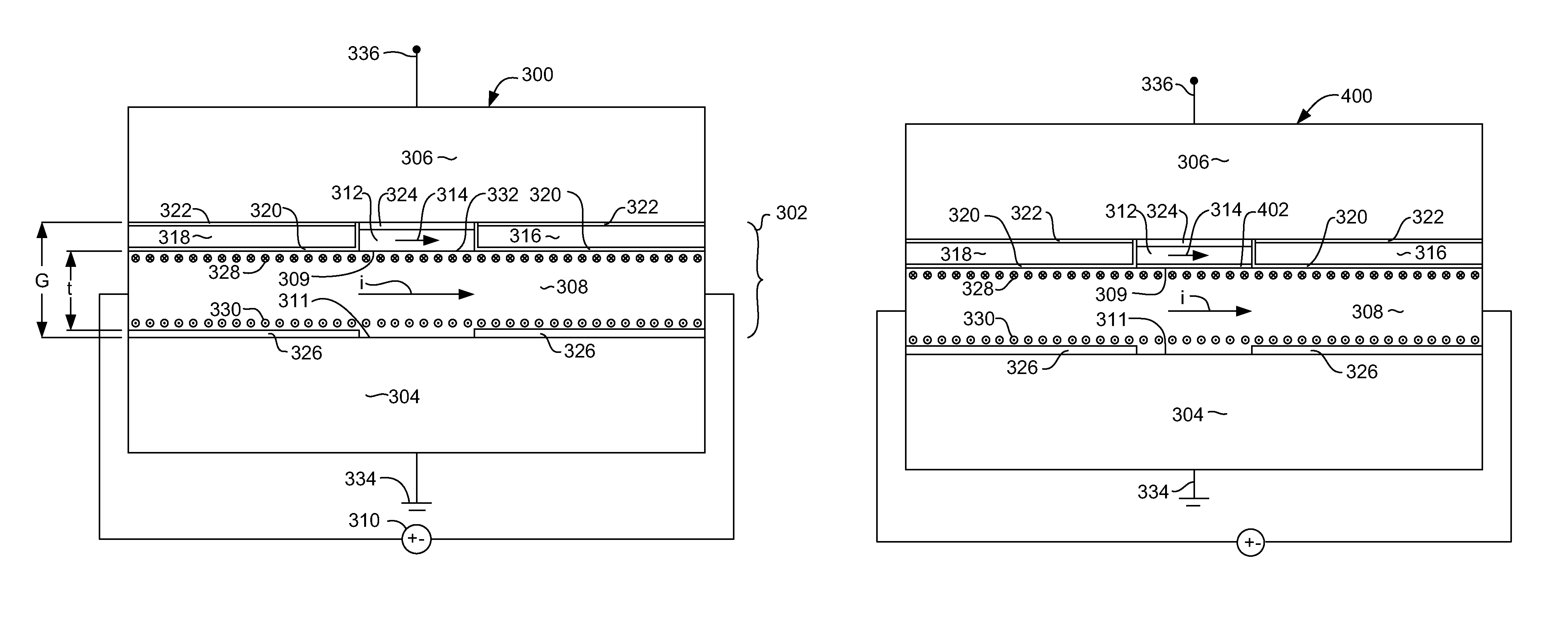

System and method for enhanced electrostatic deposition and surface coatings

ActiveUS20110238161A1Enhance charge differentialEasy to chargePretreated surfacesAdhesive dressingsSurface chargesSurface coating

This disclosure describes the application of a supplemental corona source to provide surface charge on submicrometer particles to enhance collection efficiency and micro-structural density during electrostatic collection.

Owner:BATTELLE MEMORIAL INST

System and method for enhanced electrostatic deposition and surface coatings

ActiveUS8795762B2Easy to chargeIncrease potential differencePretreated surfacesAdhesive dressingsSurface chargesSurface coating

This disclosure describes the application of a supplemental corona source to provide surface charge on submicrometer particles to enhance collection efficiency and micro-structural density during electrostatic collection.

Owner:MICELL MEDTECH INC +1

Metal surface multilayer nickel plating process with excellent corrosion resistance

The invention relates to a metal surface multilayer nickel plating process with excellent corrosion resistance. The manufacture process comprises the following steps of: plating a semi-bright layer firstly, plating a high-sulfur layer secondly, plating a bright layer thirdly and plating a nickel sealing layer fourthly from inside to outside. By adopting the technical scheme, the invention has the advantages of improving plating covering effect of a low current area, increasing the potential difference among nickel layers, protecting a matrix, slowing down the corrosion and greatly strengthening the corrosion resistance of the matrix by adopting the low concentration multilayer nickel (semi-bright nickel, high-sulfur nickel, bright nickel and nickel sealing) plus chrome plating process in an electroplating process, and by adopting the semi-bright nickel plating at the bottom layer, excellent leveling capability and scalability can be obtained, a plating solution is easy to control, harmful products cannot be produced after long-time operation, and the plating contains no sulfur and has higher corrosion resistance.

Owner:JIANGSU ZHENYU AUTOMOBILE PARTS

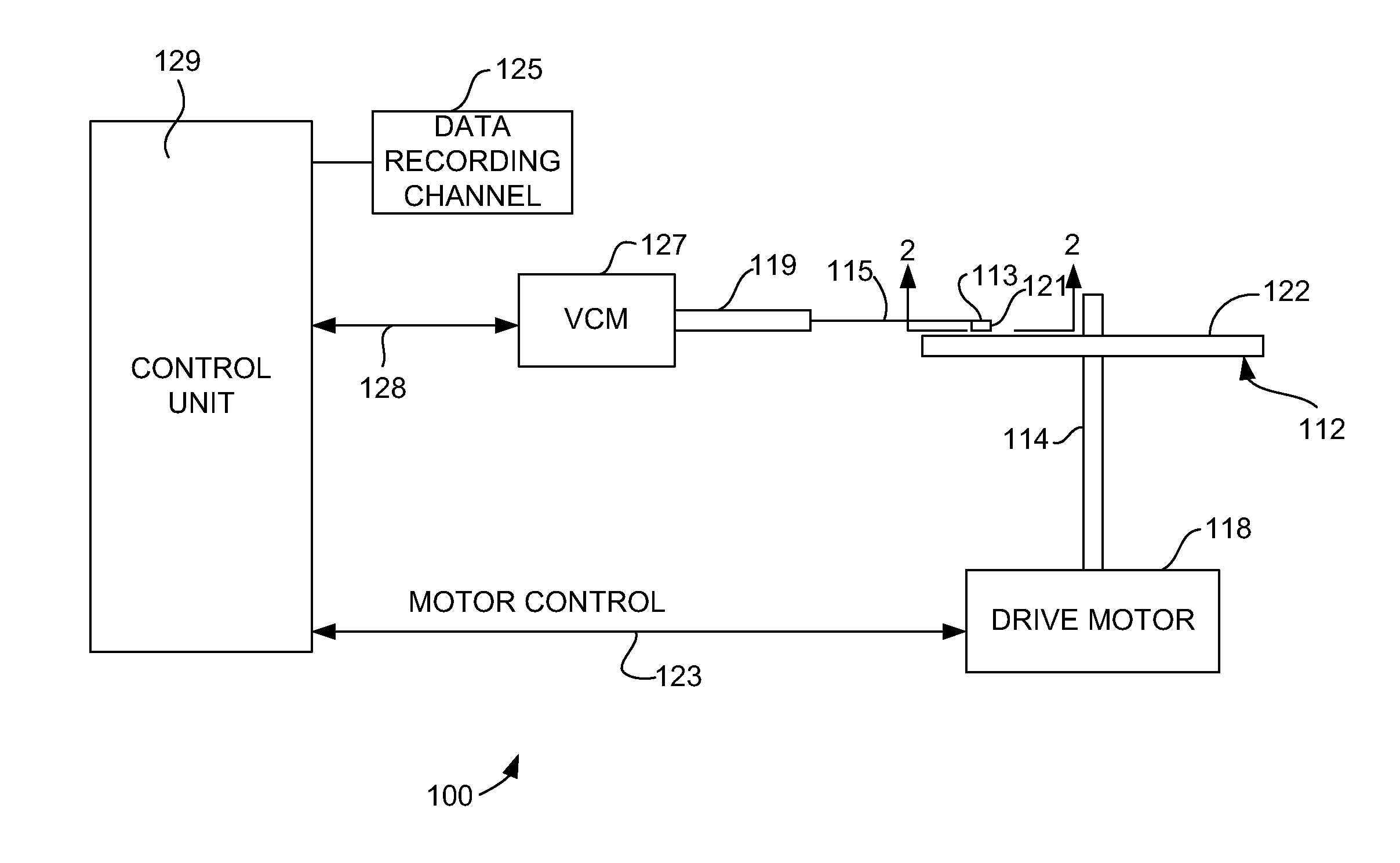

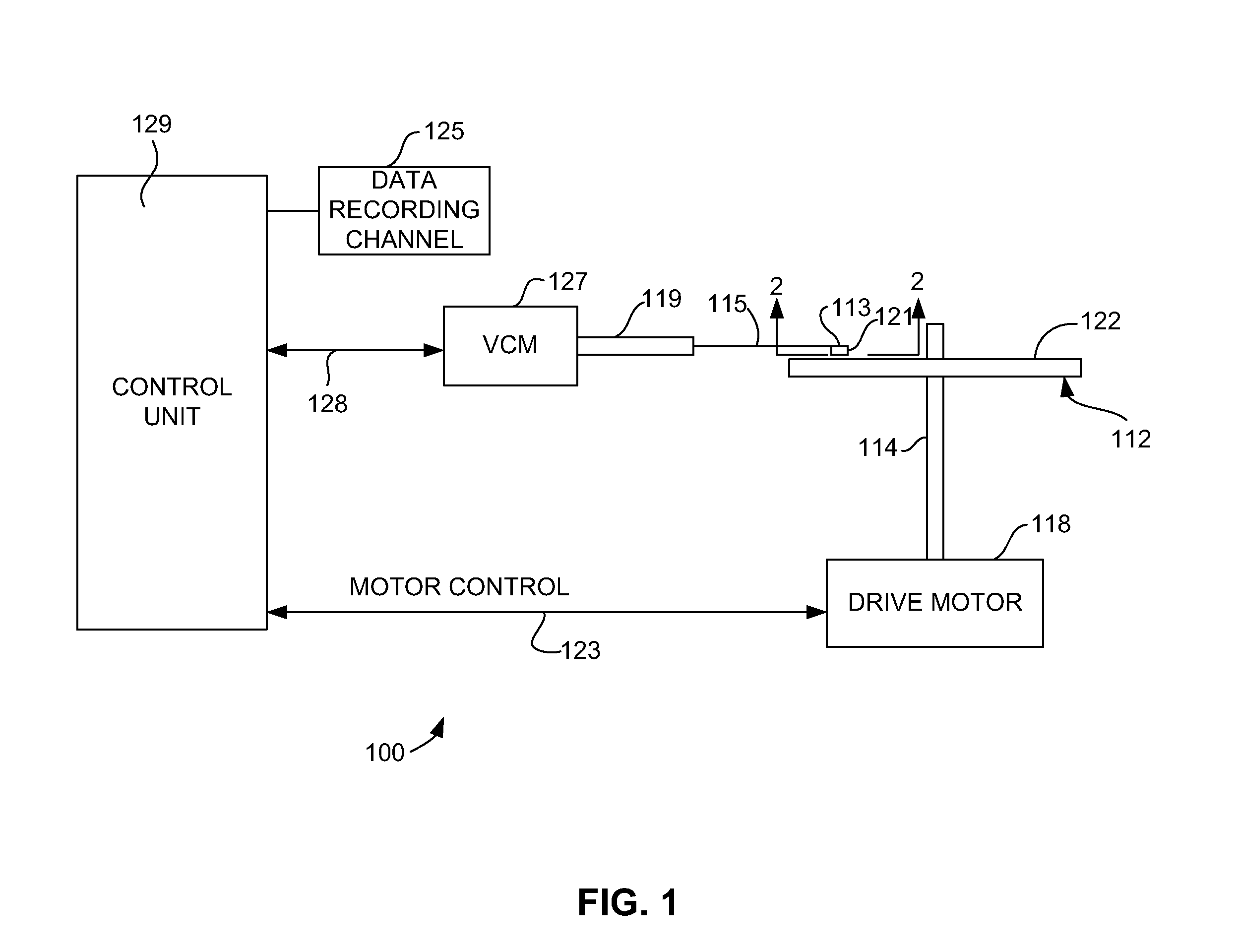

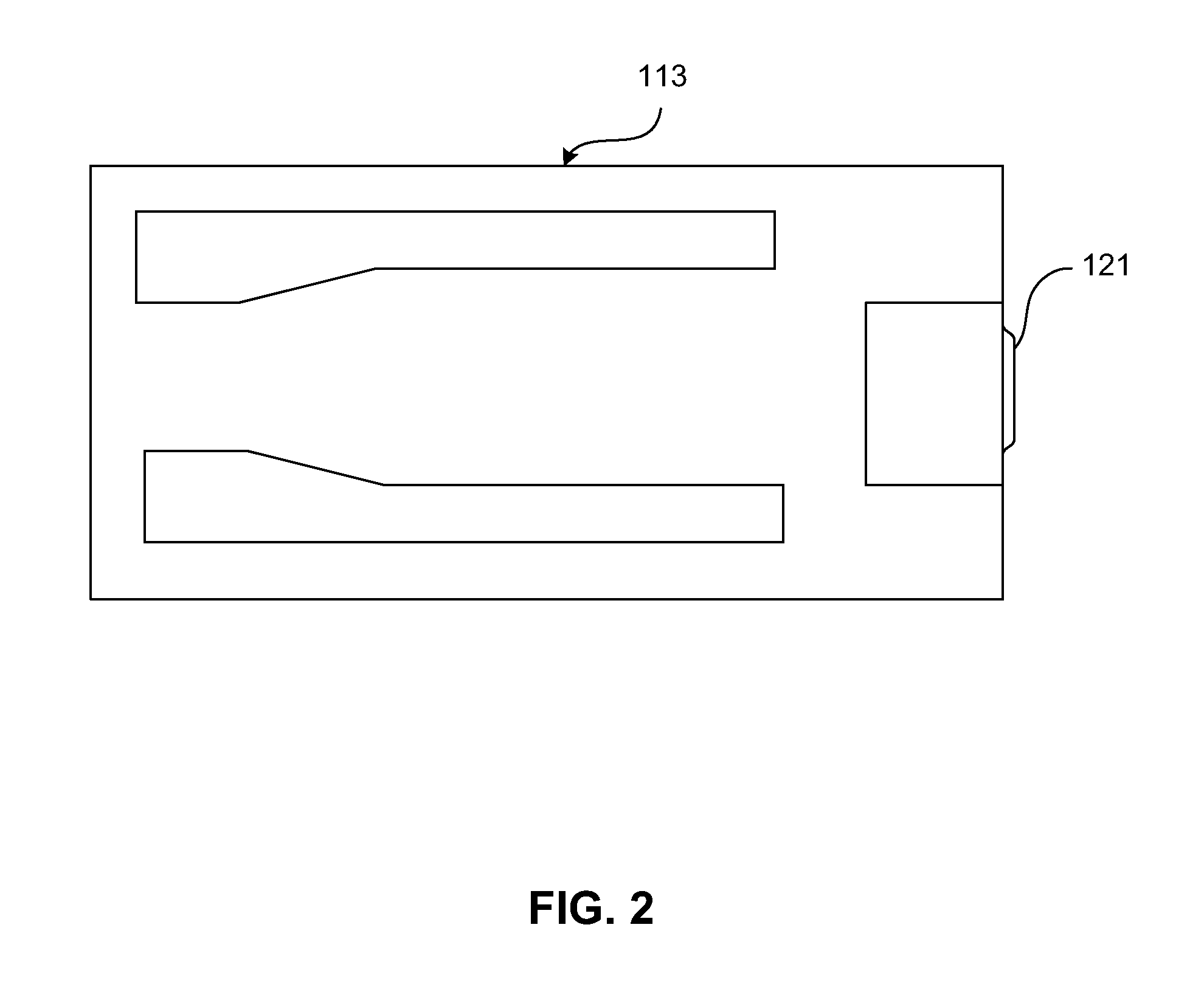

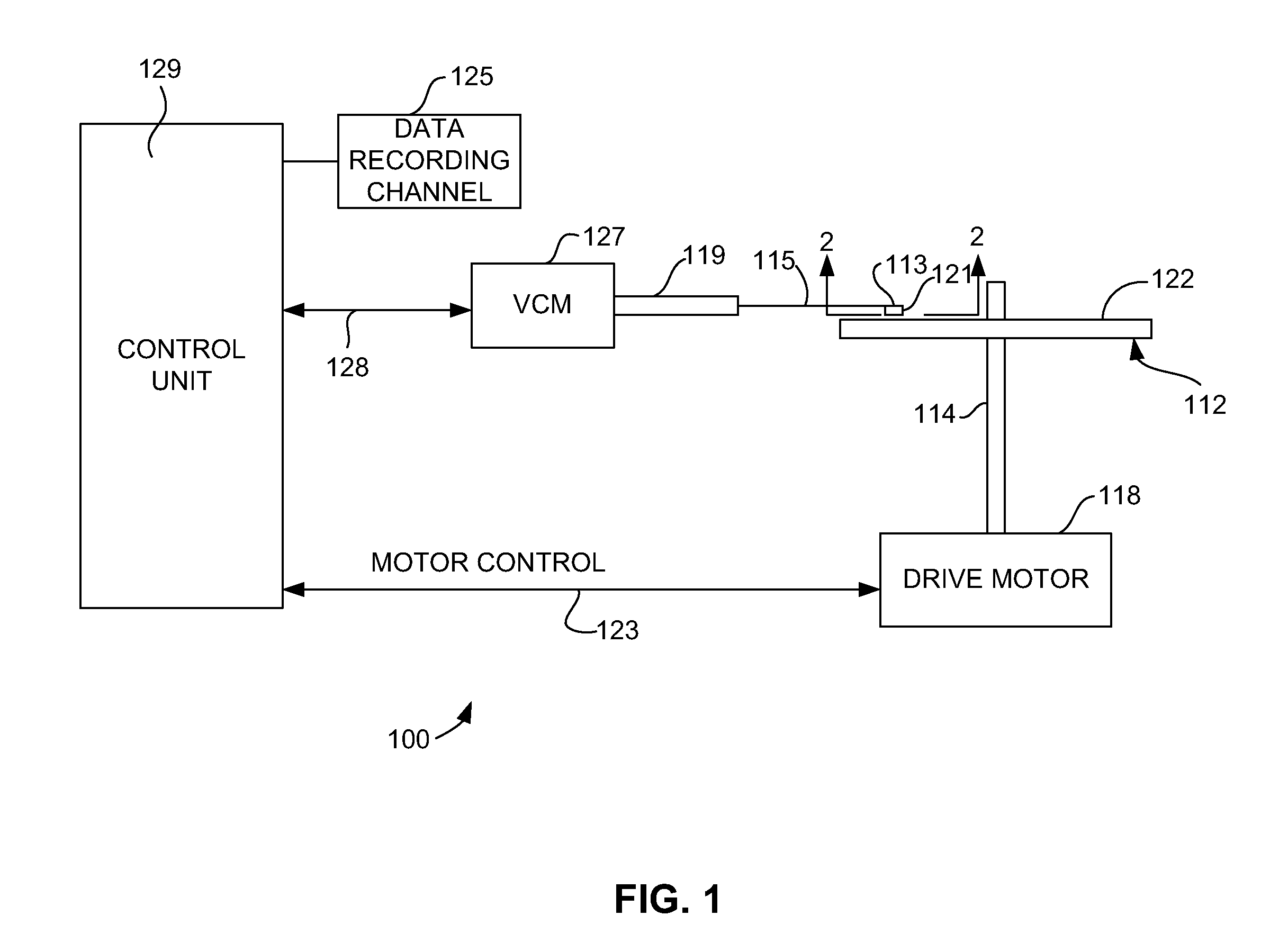

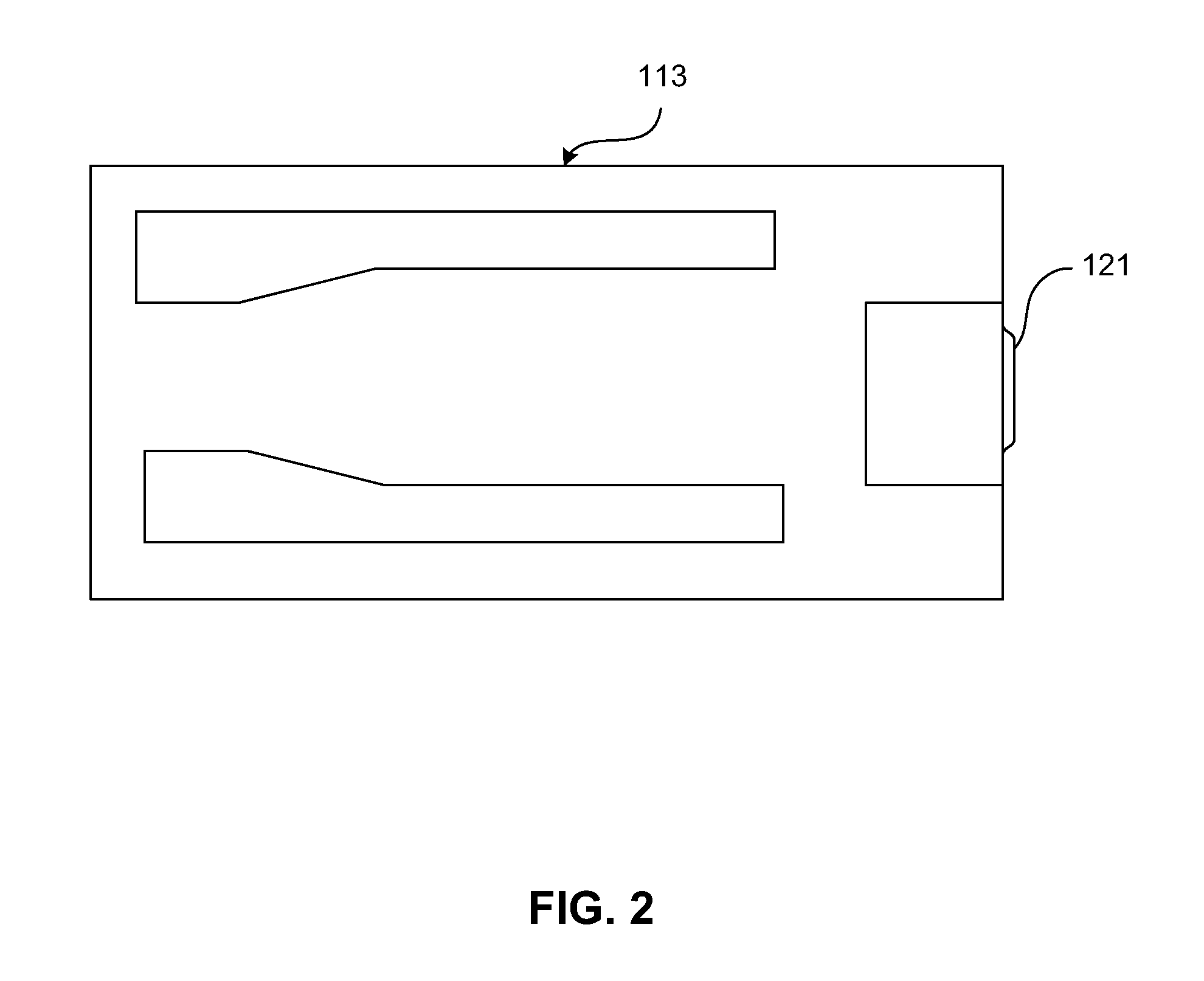

Magnetic read sensor using spin hall effect

ActiveUS20140226239A1Increase potential differenceOutput signalMagnetic measurementsRecord information storageSpin Hall effectMagnetization

A magnetic sensor utilizing the spin Hall effect to polarize electrons for use in measuring a magnetic field. The sensor eliminates the need for a pinned layer structure or antiferromagnetic layer (AFM layer), thereby reducing gap thickness for increased data density. The sensor includes a non-magnetic, electrically conductive layer that is configured to accumulate electrons predominantly of one spin at a side thereof when a current flows there-through. A magnetic free layer is located adjacent to the side of the non-magnetic, electrically conductive layer. A change in the direction of magnetization in the free layer relative to the orientation of the spin polarized electrons causes a change in voltage output of the sensor.

Owner:WESTERN DIGITAL TECH INC

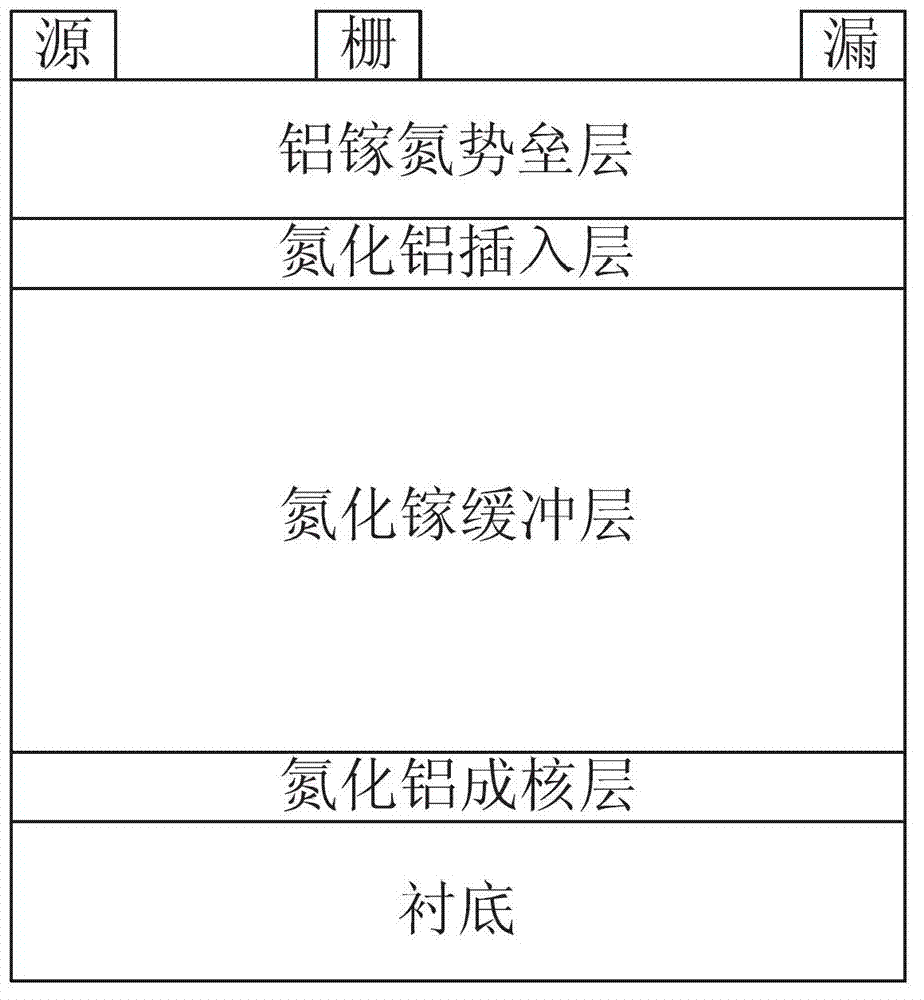

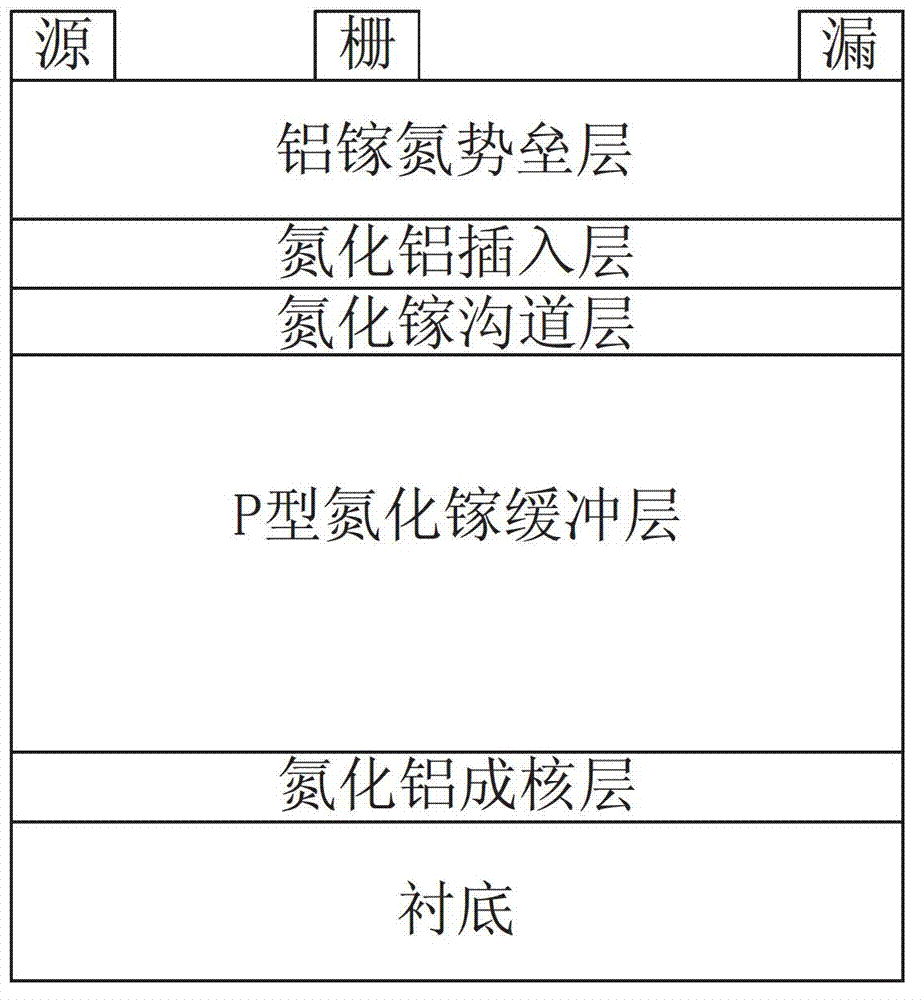

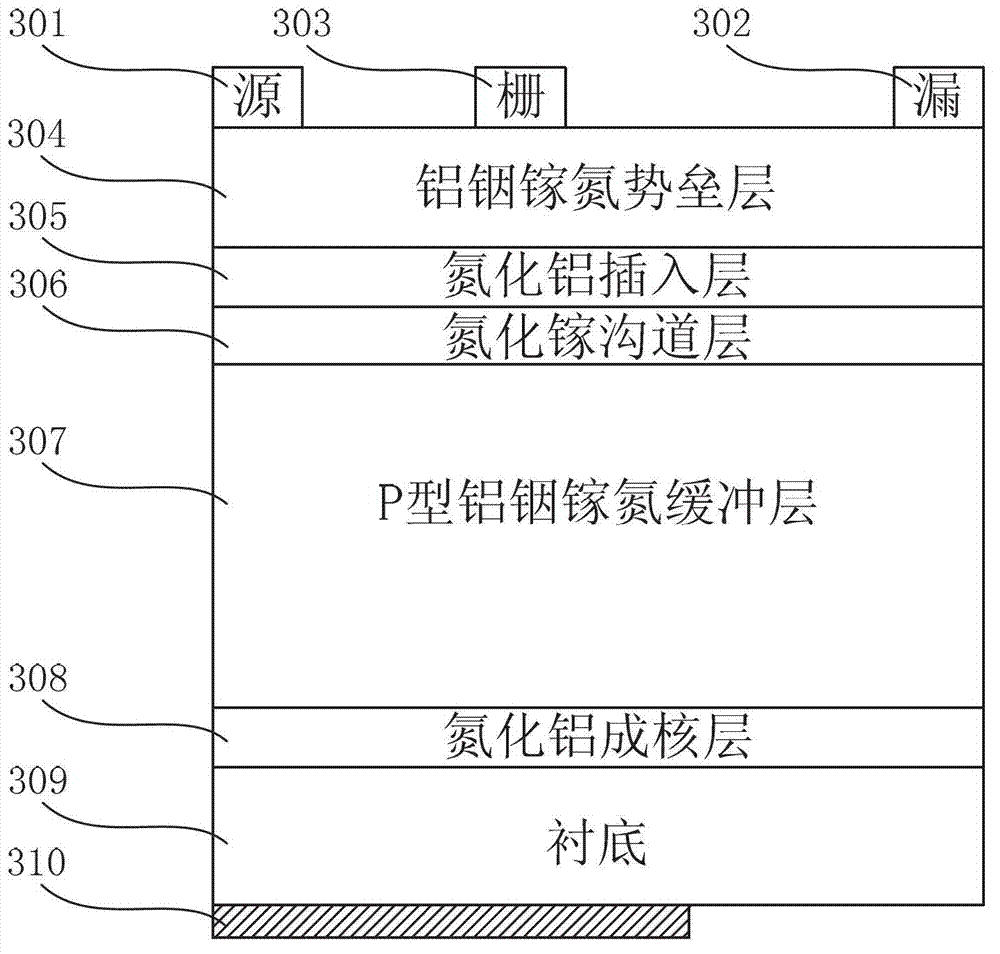

Gallium nitride-based hetero-junction field effect transistor with back electrode structure

ActiveCN102820325AImprove breakdown voltageSuppress leakage currentSemiconductor devicesIndiumOhmic contact

The invention discloses a gallium nitride-based hetero-junction field effect transistor with a back electrode structure. The gallium nitride-based hetero-junction field effect transistor mainly consists of a substrate, an aluminum nitride nucleating layer, a P-type aluminum-indium-gallium-nitrogen buffering layer, a gallium nitride channel layer, an aluminum nitride inserting layer and an aluminum-indium-gallium-nitrogen barrier layer in sequence from bottom to top; a source electrode, a drain electrode and a gate electrode are formed on the barrier layer; the source electrode and the drain electrode form ohmic contact with the barrier layer; the gate electrode and the barrier layer are in Schottky contact; and the gallium nitride-based hetero-junction field effect transistor further comprises the back electrode in contact with the substrate. The back electrode in the gallium nitride-based hetero-junction field effect transistor provided by the invention modulates potential distribution of a device buffering layer, so as to increase potential difference between the two-dimensional electron gas channel and the P-type aluminum-indium-gallium-nitrogen buffering layer. Therefore, two-dimensional electron gas in the channel and the P-type impurities in the buffering layer are entirely consumed, so that the electric field distribution of the device channel is more uniform, and the breakdown voltage of the device is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

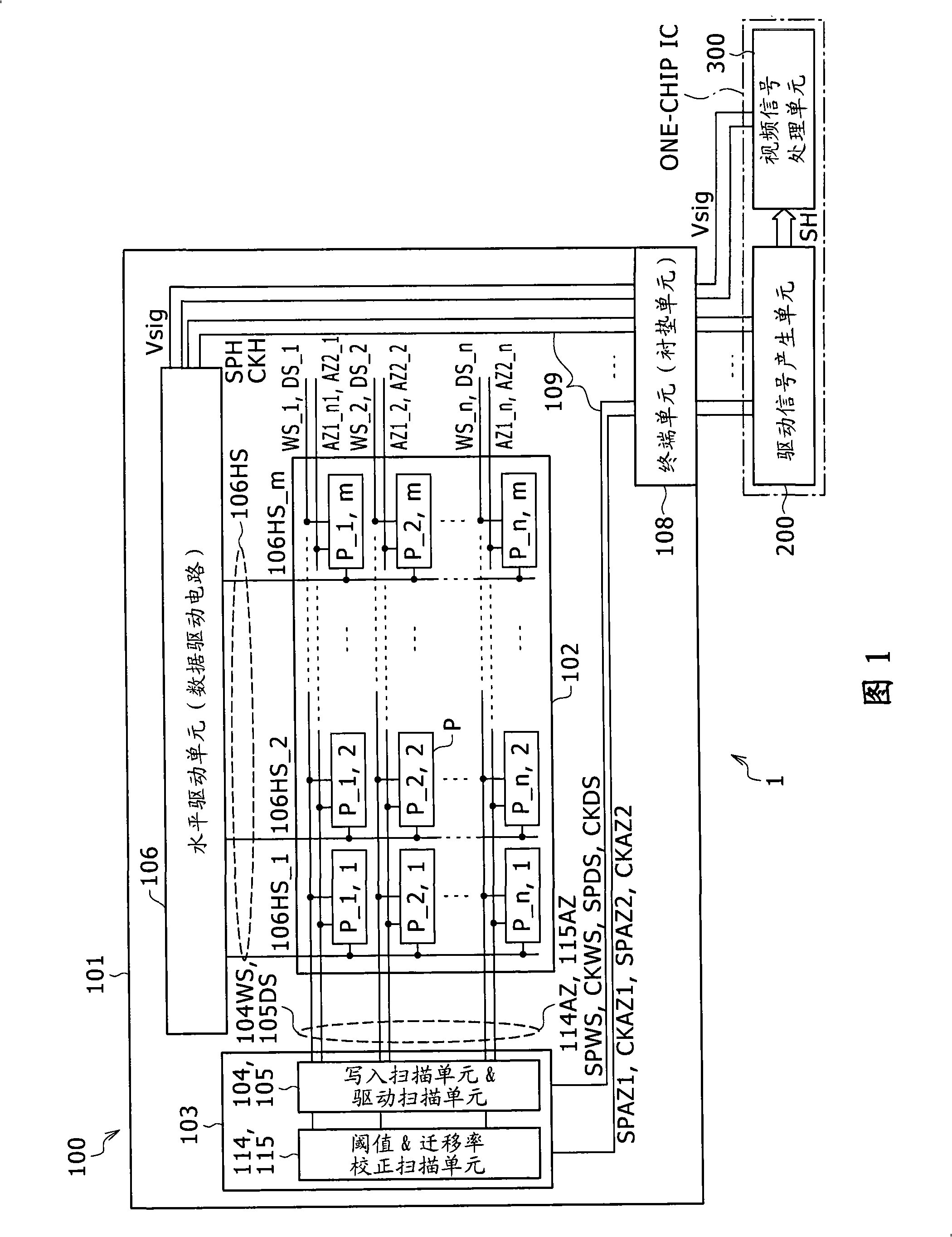

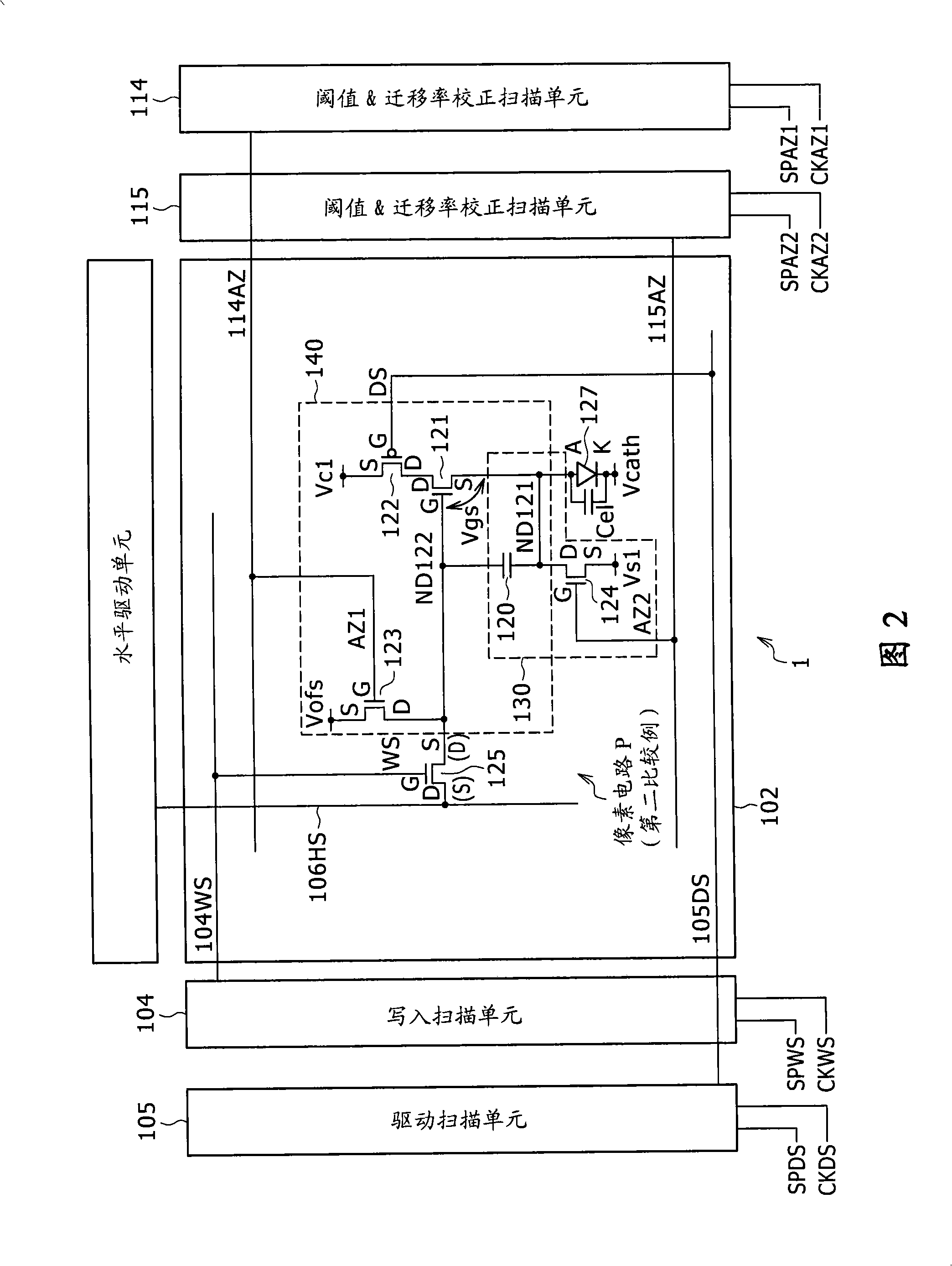

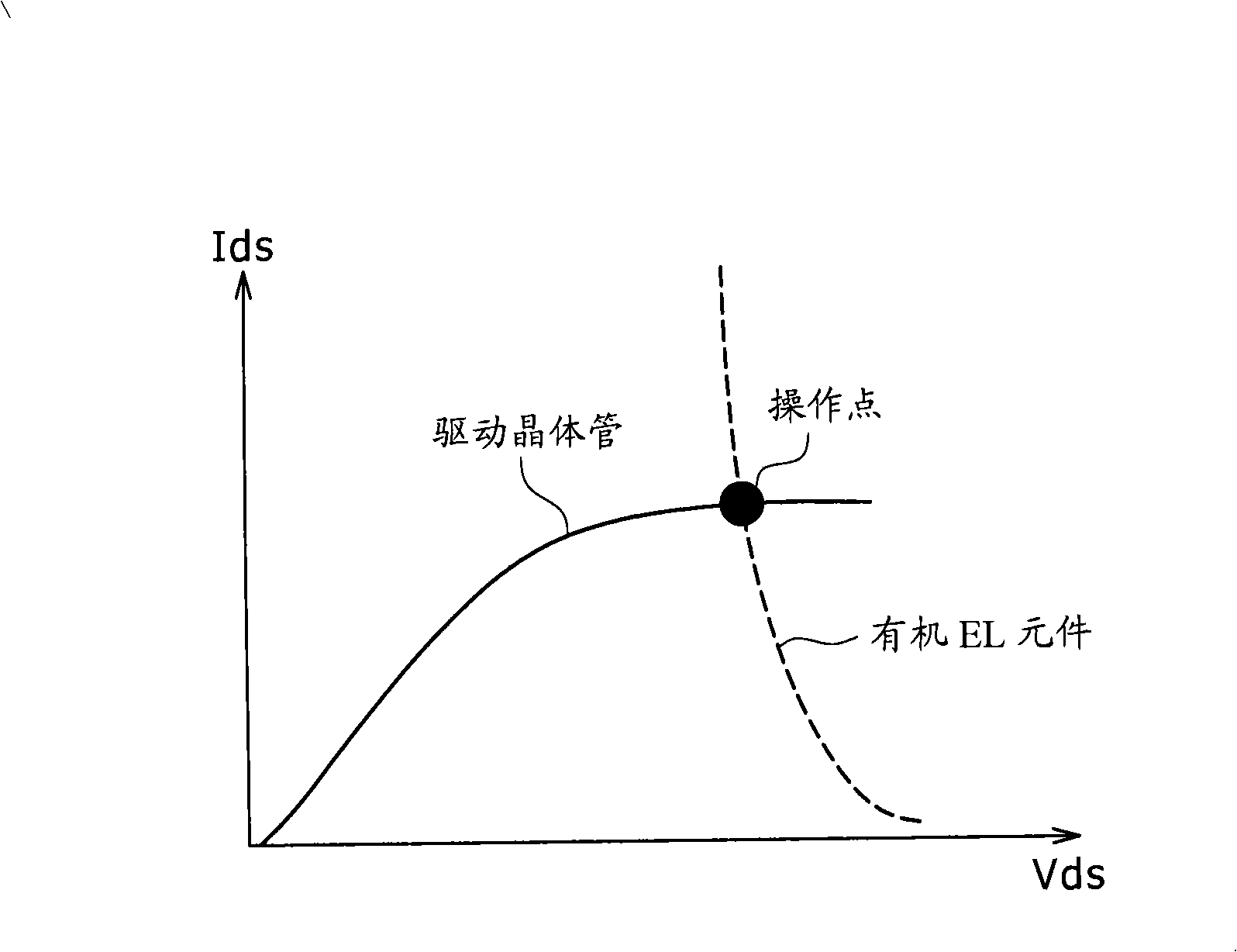

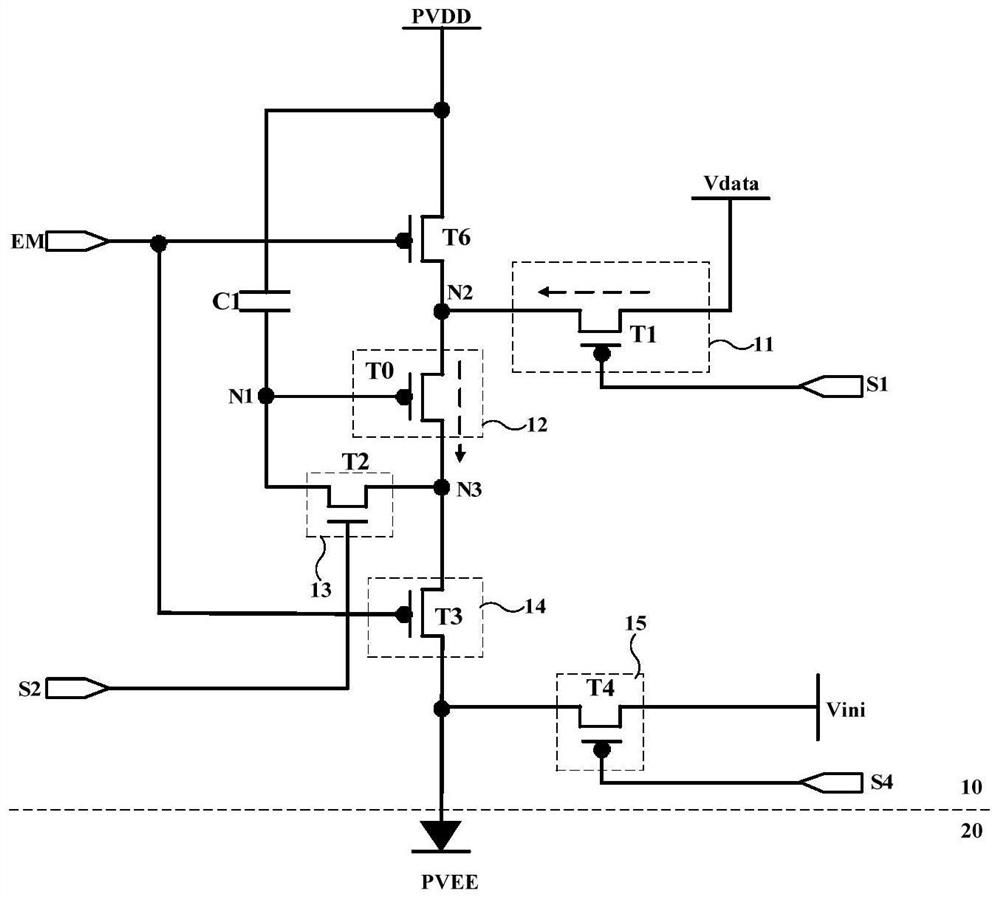

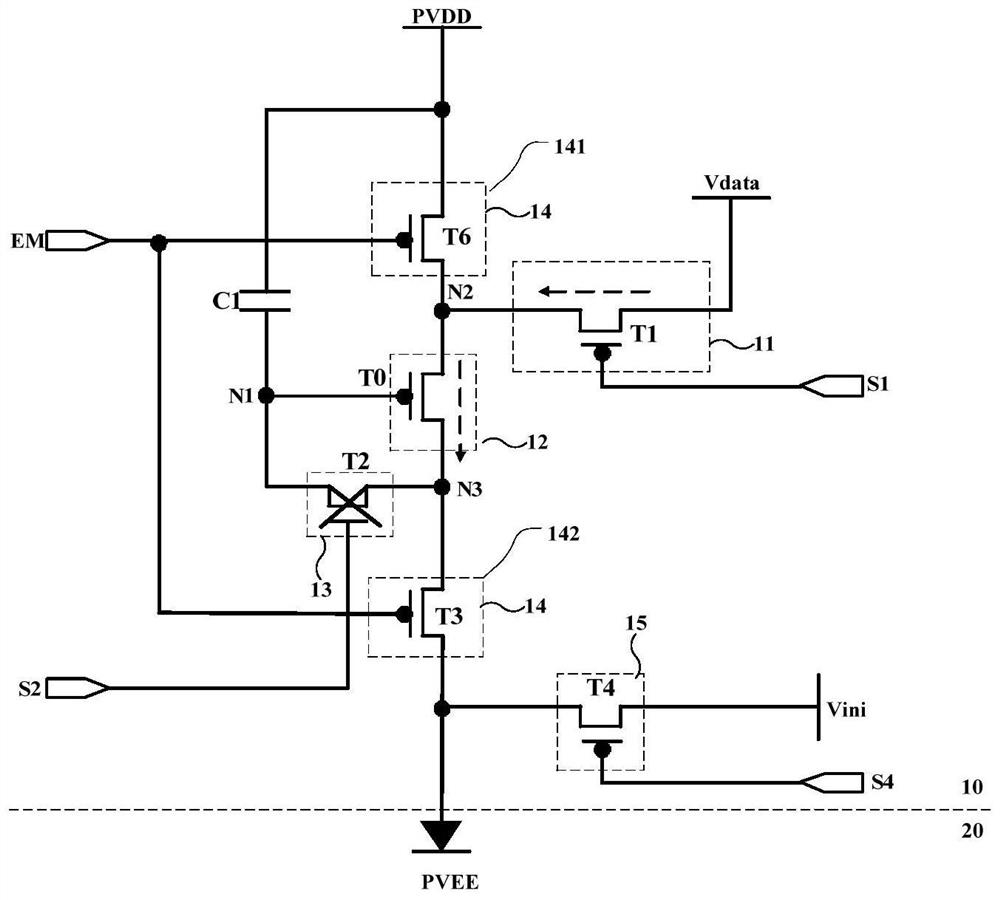

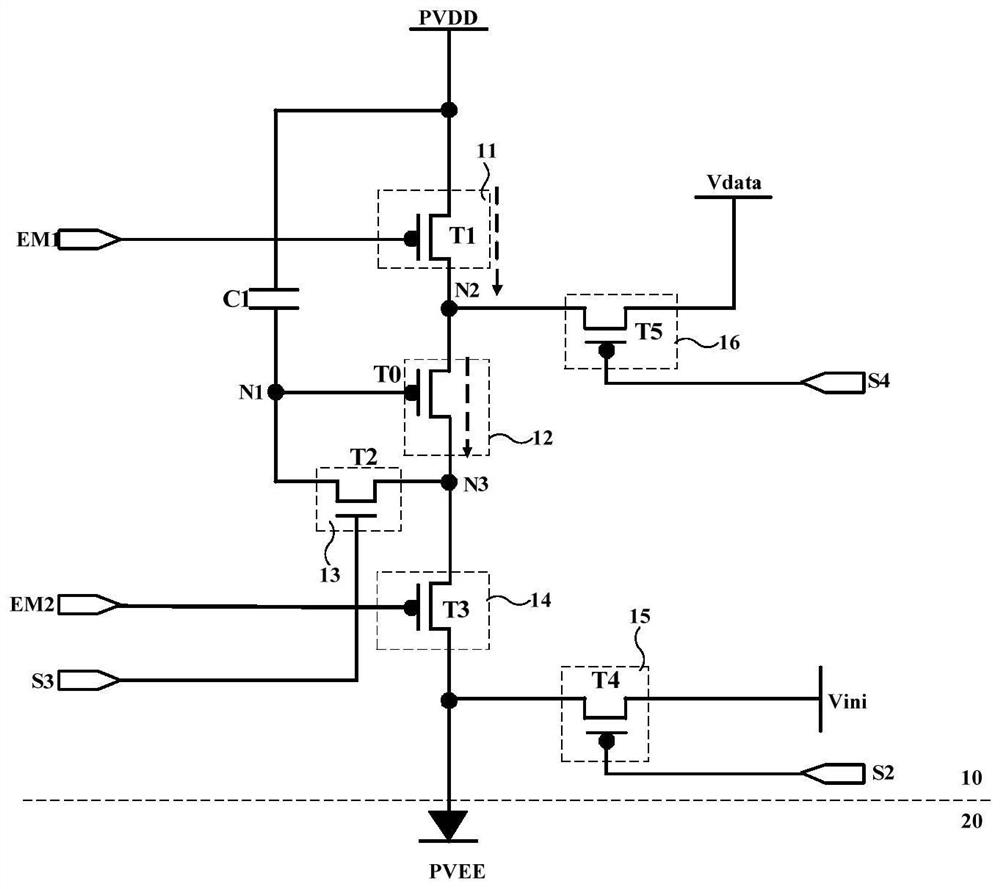

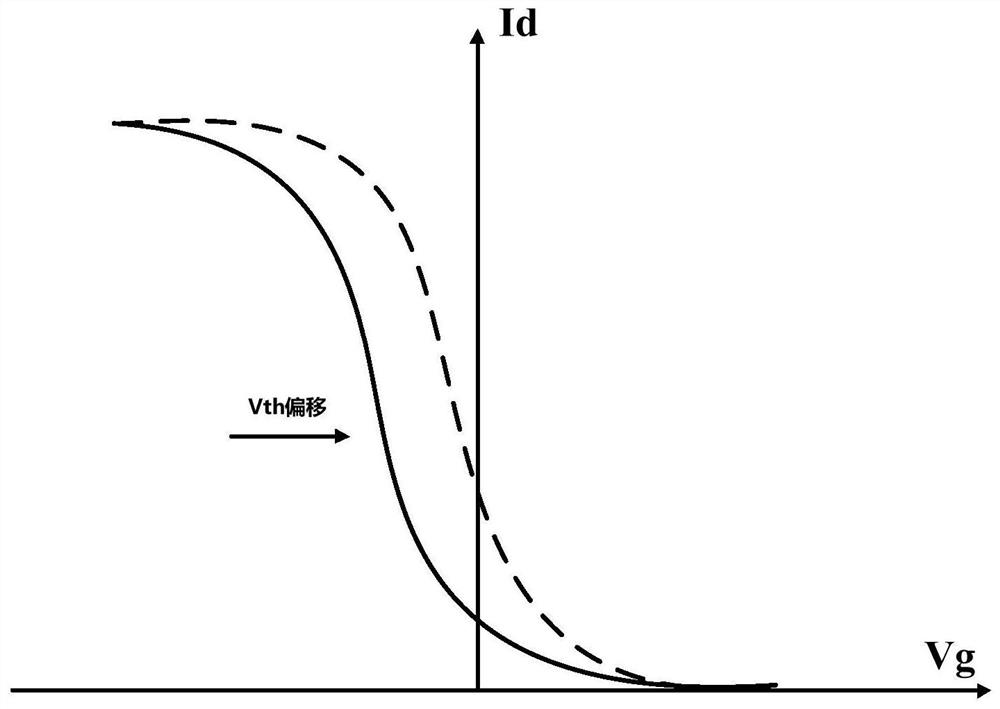

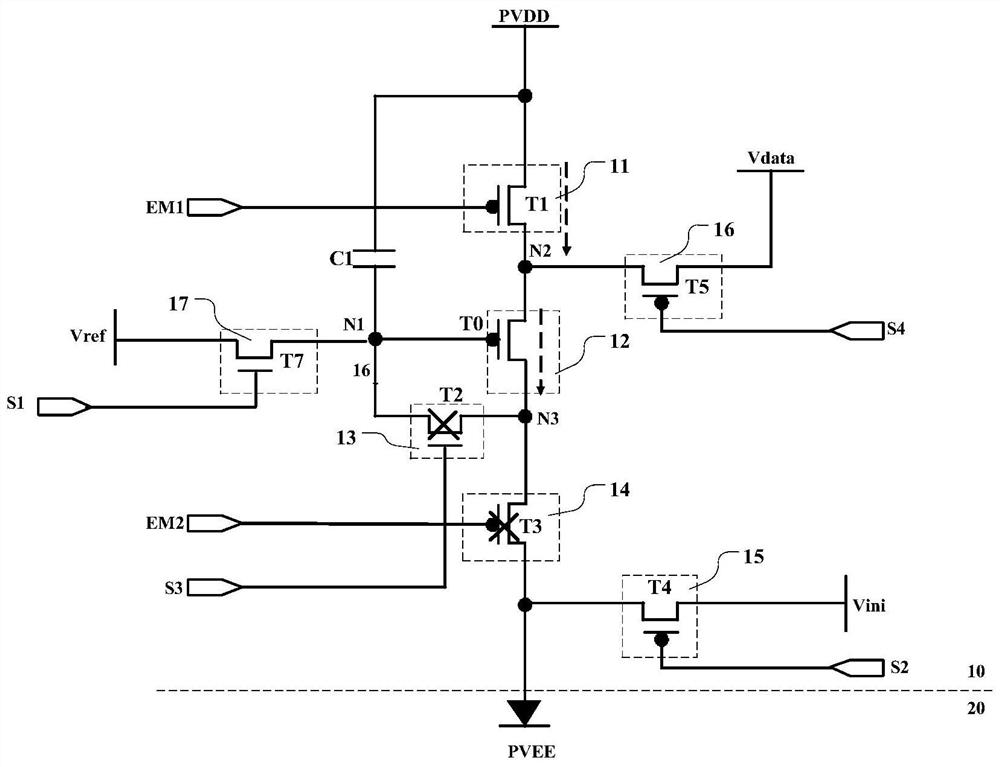

Pixel circuit, display device, and driving method thereof

InactiveCN101266755AIncrease potential differenceReduce potential differenceStatic indicating devicesElectroluminescent light sourcesDisplay deviceBrightness perception

The invention discloses a pixel circuit, a display device including the pixel circuit and a method for driving the pixel circuit. The display device includes a pixel array unit and a control unit. According with the invention, brightness decrease caused by mobility correction can be avoided, and video signal size needs not increased.

Owner:SONY CORP

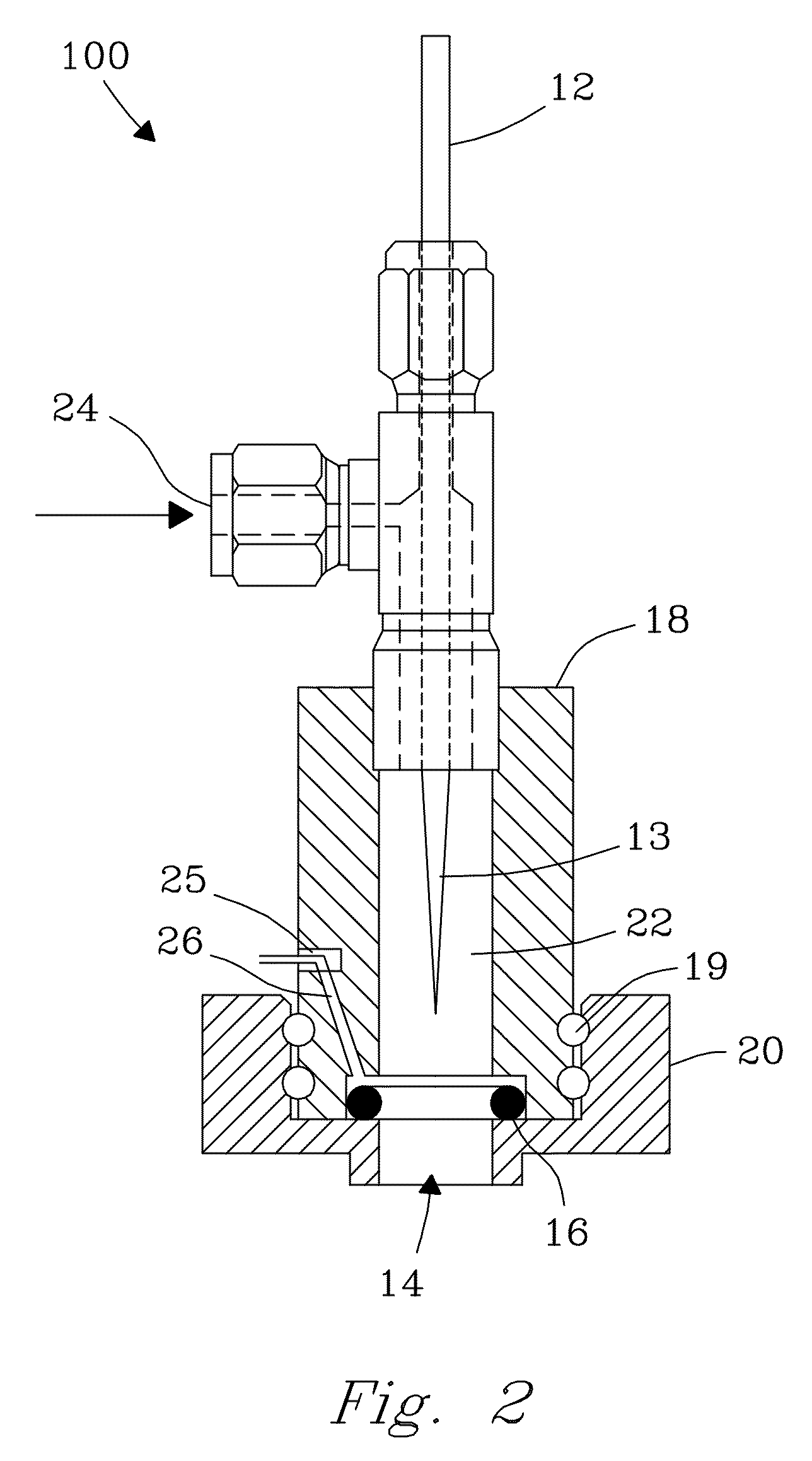

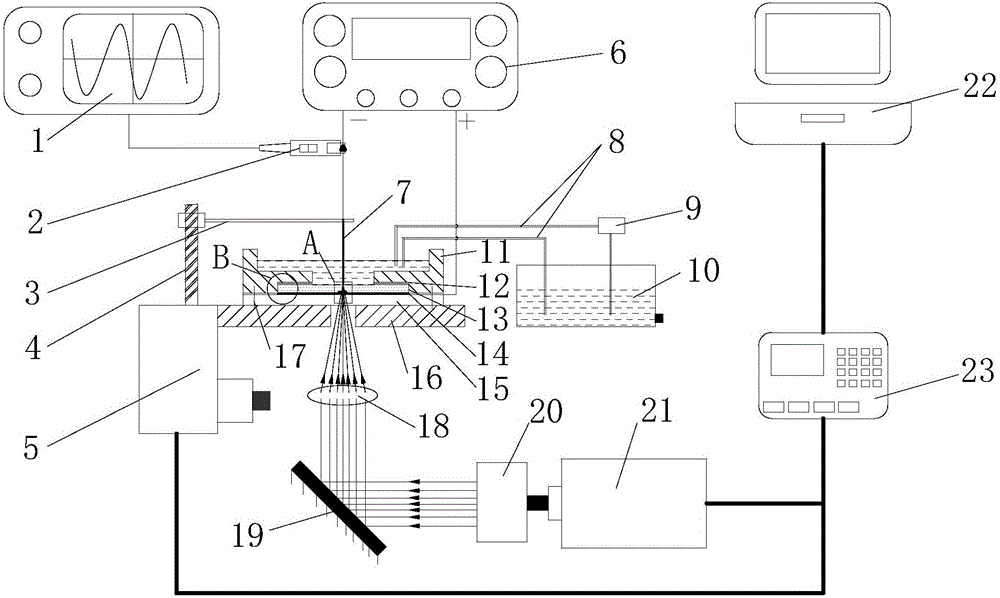

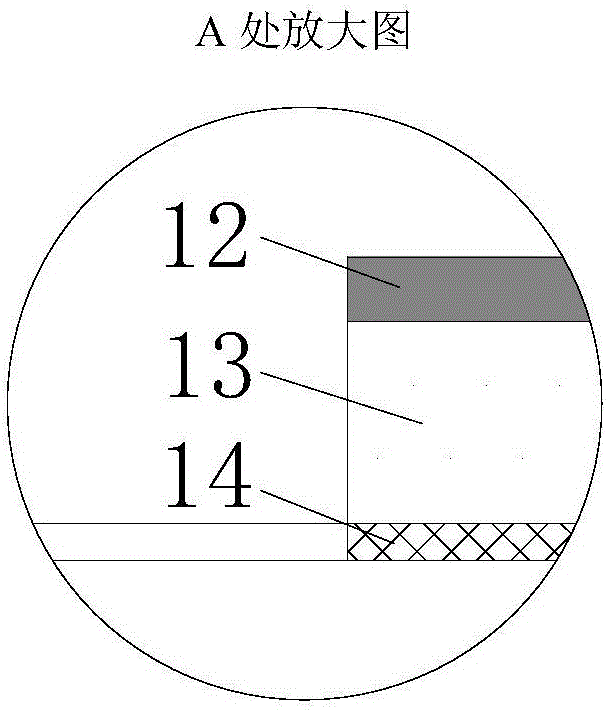

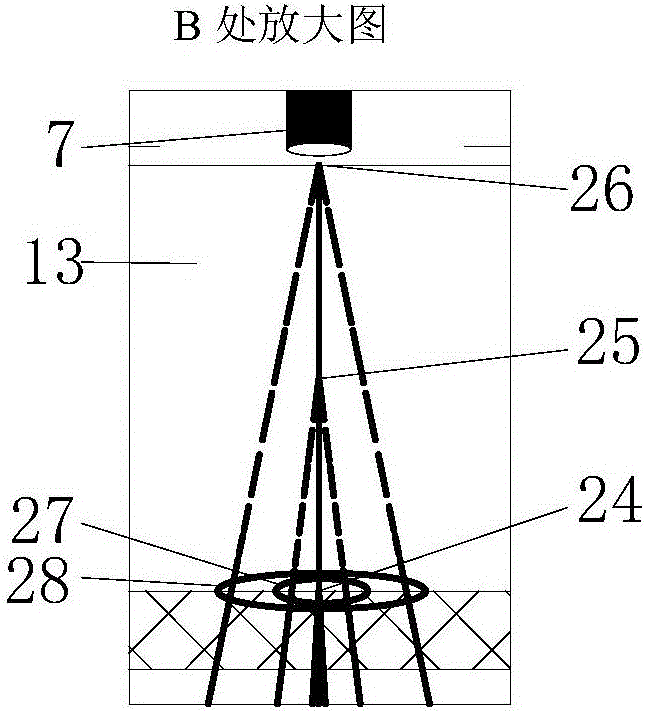

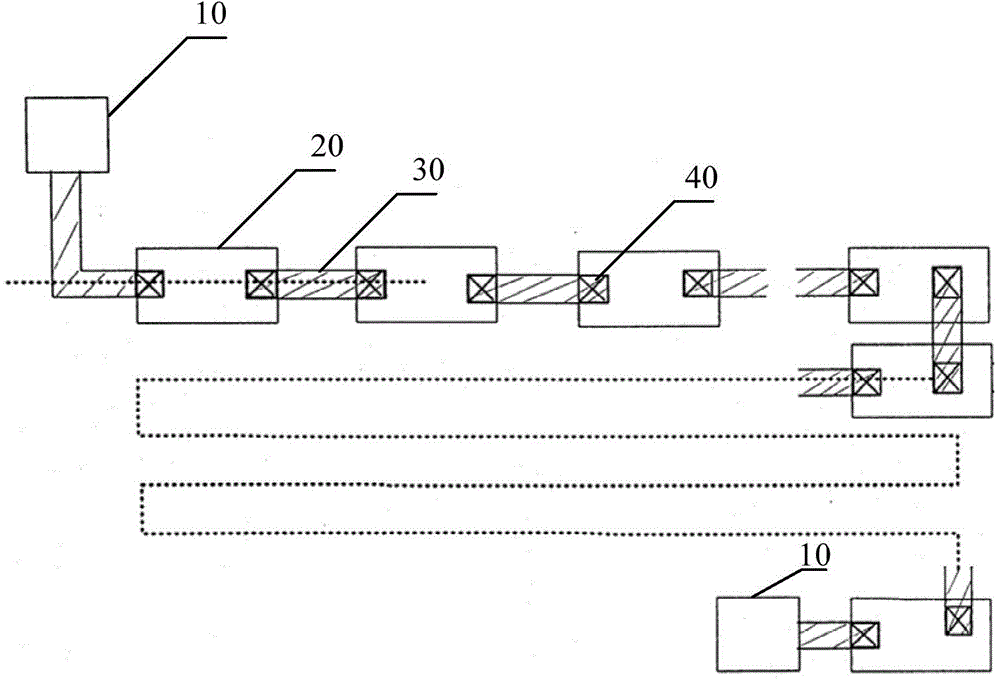

Device and method for processing semiconductor material through backward multifocal lasers and electrochemistry in combined manner

InactiveCN106735866APromotes electrochemical reactionsIncrease potential differenceOther manufacturing equipments/toolsLaser beam welding apparatusElectrochemical responseCorrosion

The invention provides a device and method for processing a semiconductor material through backward multifocal lasers and electrochemistry in a combined manner. The energy, frequency and wavelength of the lasers are regulated, and a multifocal laser beam acts on the back face of a semiconductor sample; on one hand, when the lasers radiate the back face of the semiconductor sample, a large amount of light can be stimulated in the semiconductor sample to generate holes, the holes move to the position of the surface of the polished semiconductor sample to participate in the electrochemistry reaction, and material corrosion removal is achieved; and on the other hand, on the back face of the semiconductor sample, the multifocal lasers gradually conduct processing inwards. A work electrode is a cathode, the semiconductor sample is used as an anode, and when the potential between the two electrodes is high, spark discharge processing is conducted; and when the potential is low, electrochemistry erosion removal is conducted. The multifocal lasers and electrochemistry act on the semiconductor sample in the combined manner, the corrosion efficiency is improved, and the surface quality of through holes is improved. When the high-precision micro-through-holes are processed in the semiconductor material, the combination effect is good in action effect, and the device and the method are suitable for precise processing.

Owner:JIANGSU UNIV

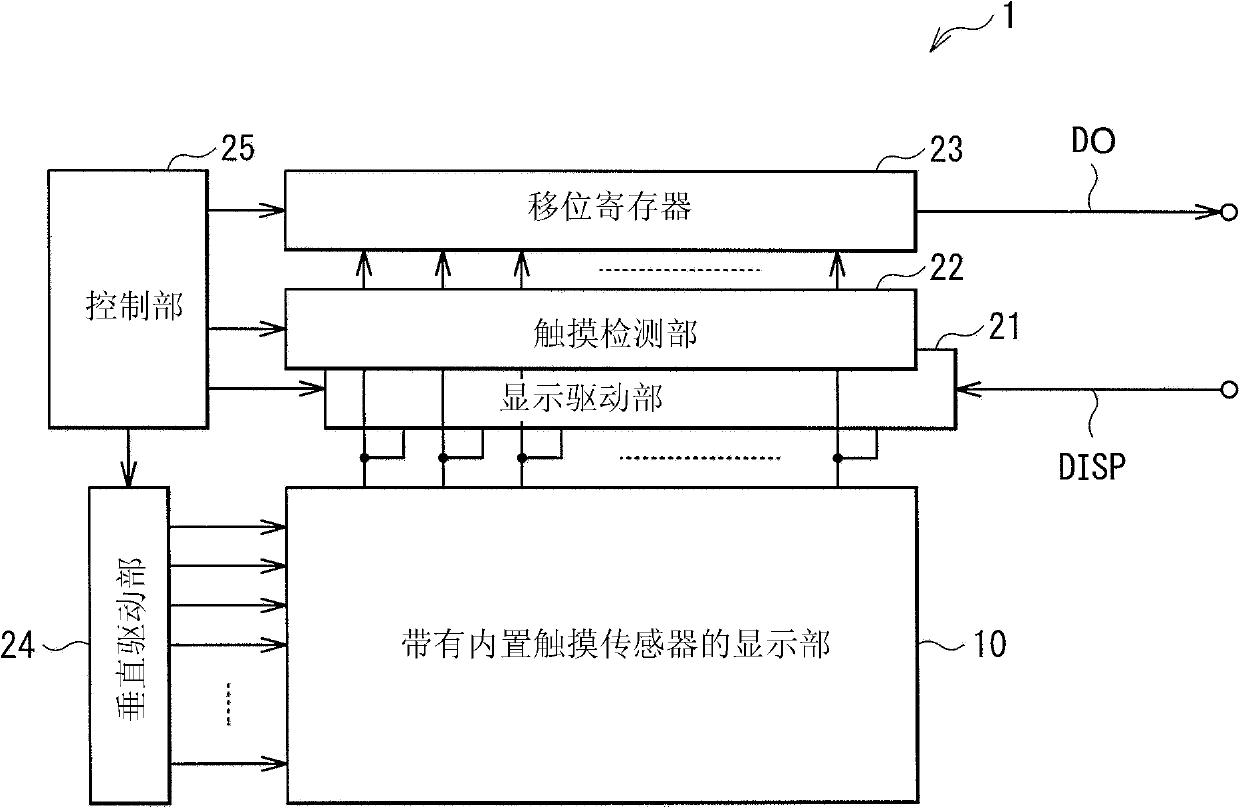

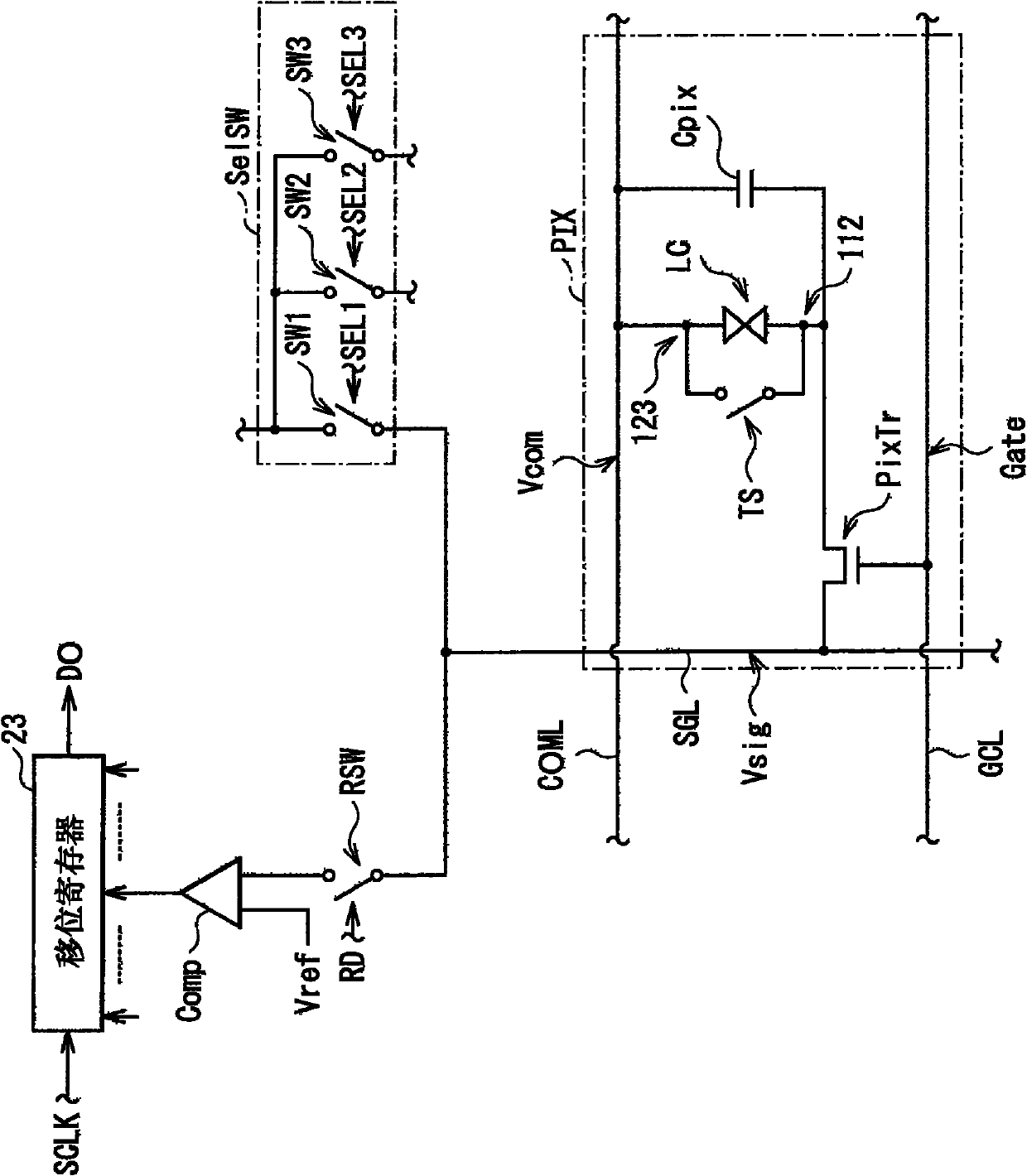

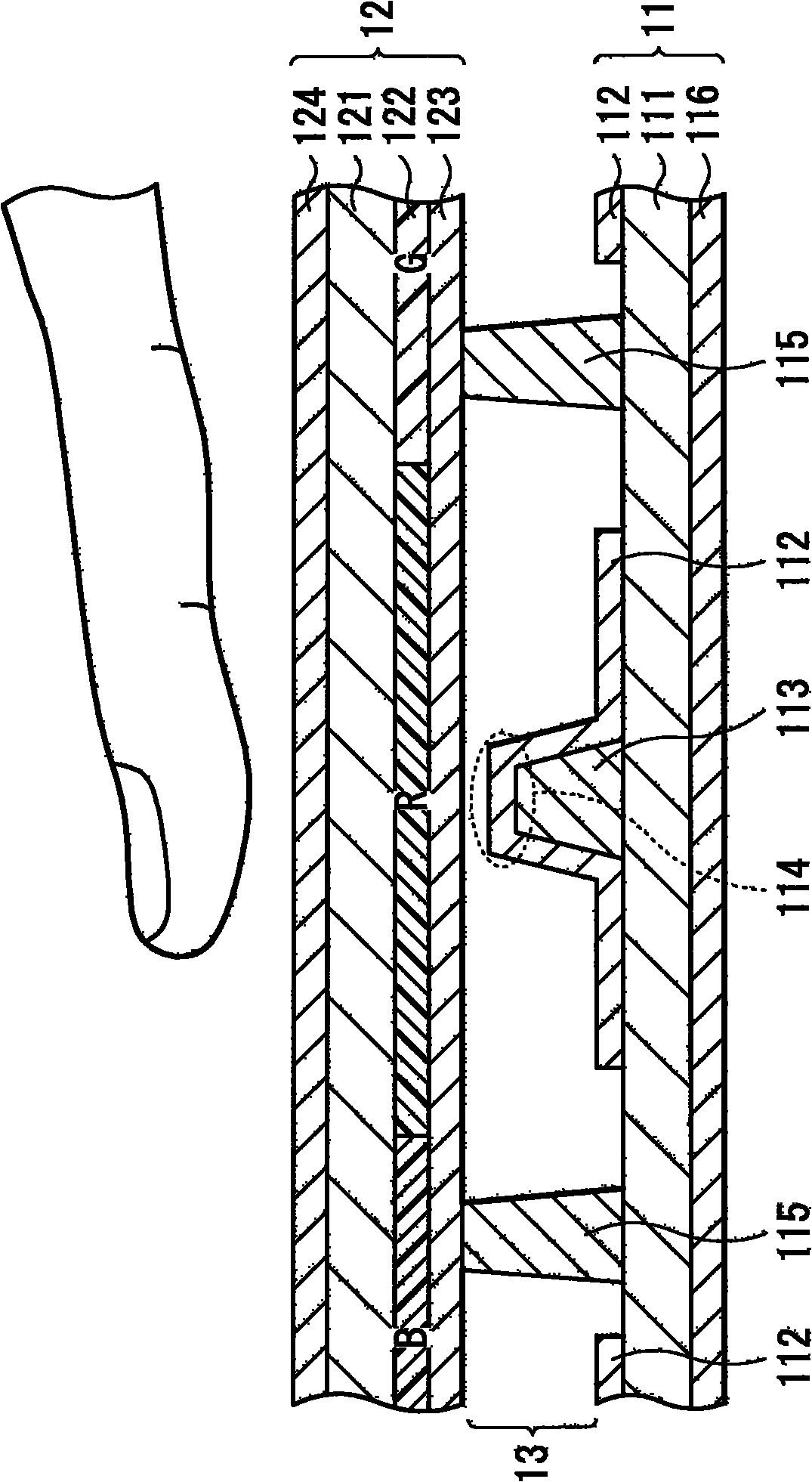

Touch panel and its display device, method of driving touch panel, and electronic device

InactiveCN102169248AHigh sensitivityNo increase in quantityStatic indicating devicesInput/output processes for data processingTouch panelSignal lines

The invention provides a touch panel and its display device, a method of driving touch panel and an electronic device. In one example embodiment, a display device includes a drive control section operatively coupled to a signal line and a display section. The signal line has a first voltage. In one example embodiment, the display section includes: (a) a touch detection element which outputs a touch voltage; and (b) an electrode which has a second voltage. In one example embodiment, the drive control section increases a potential difference between the first voltage and the second voltage before the touch detection element outputs the touch voltage.

Owner:JAPAN DISPLAY INC

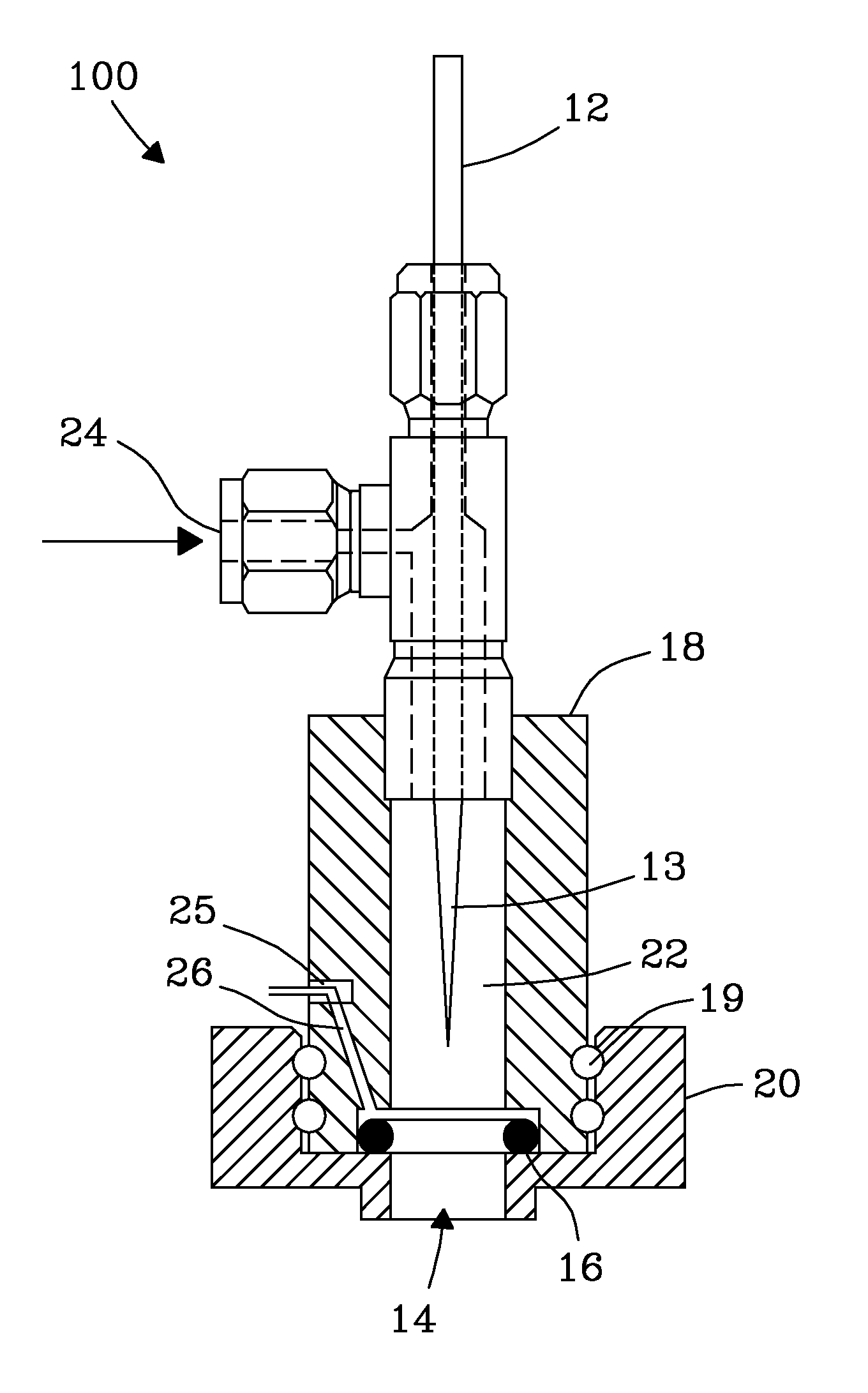

Sensor isolation plane for planer elements

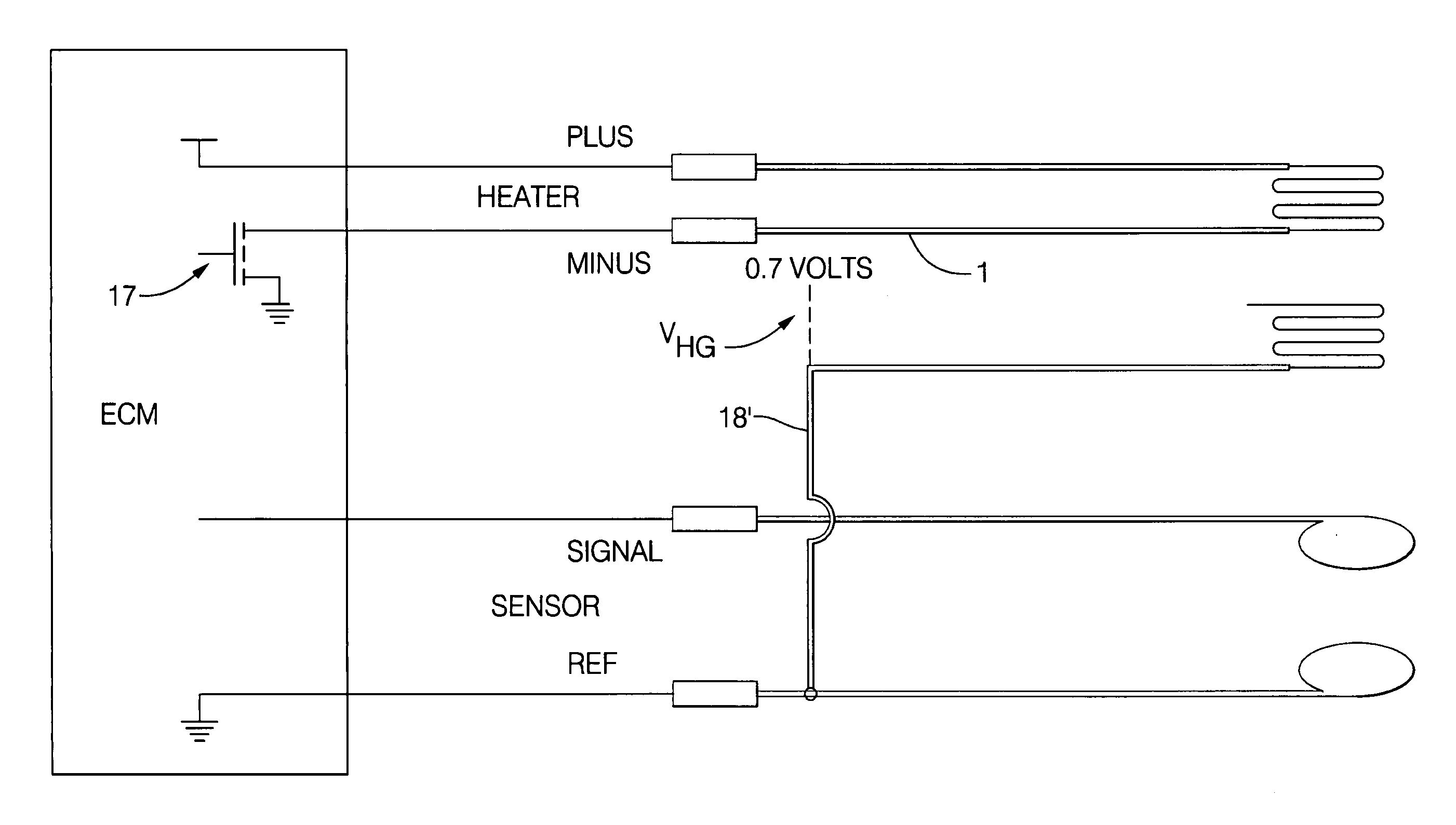

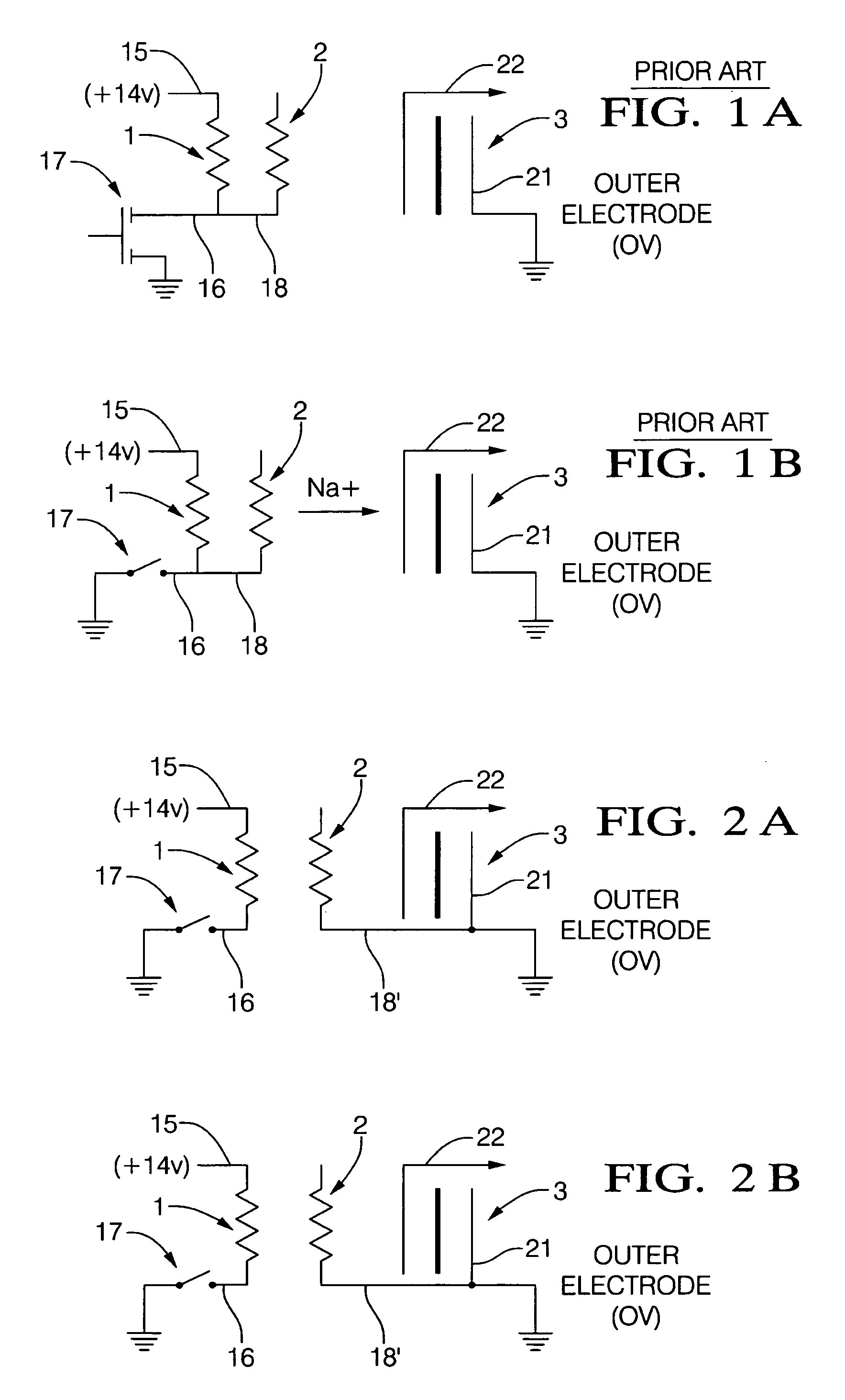

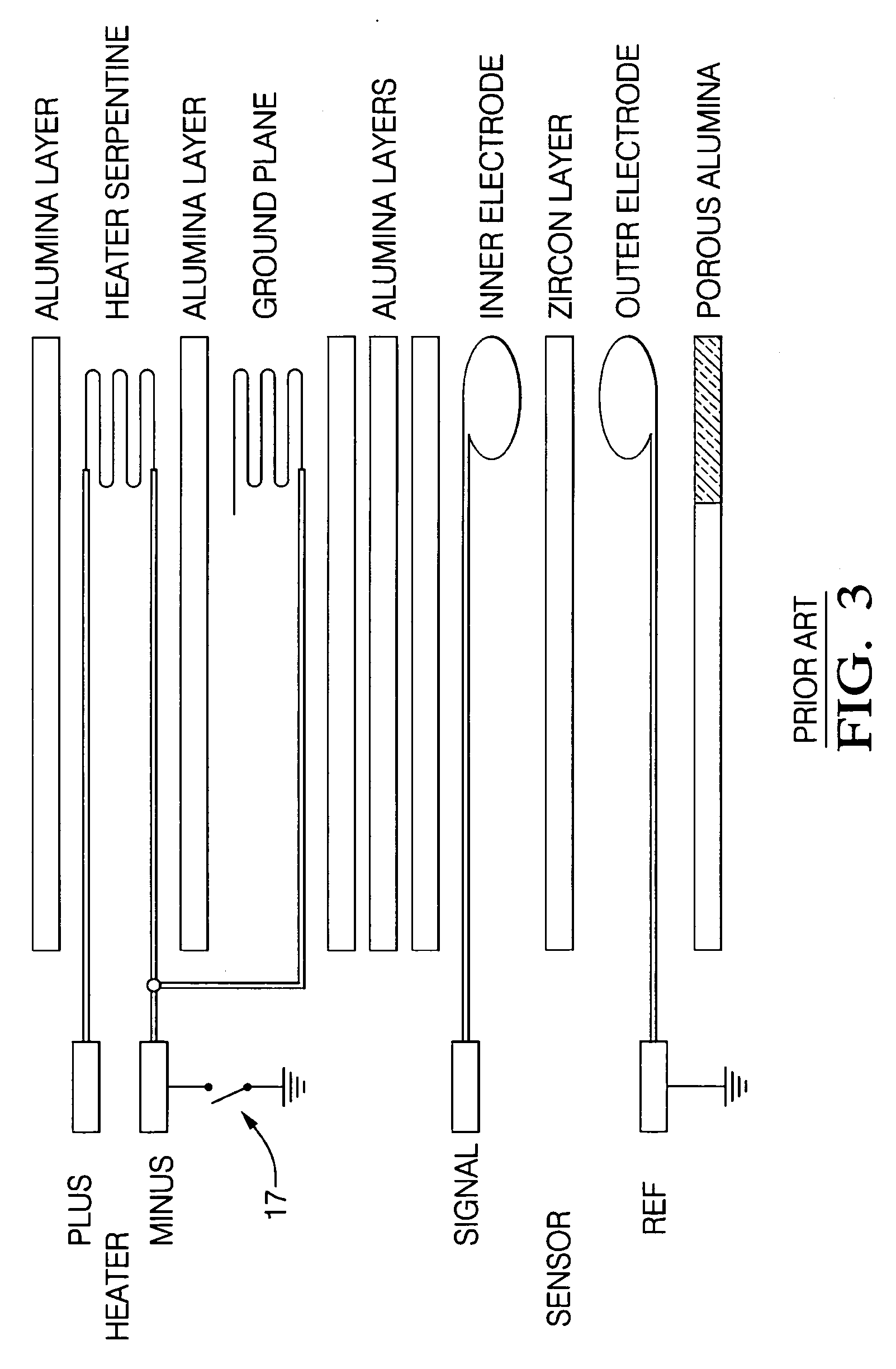

ActiveUS20090255916A1Not conducive to migrationReduced life-timeIncandescent ignitionOhmic-resistance electrodesGround planeSodium

Elimination of sodium contamination at the negative terminal of an electrical stri resistance heater (1, FIGS. 2 and 4) for a gas sensor (3) can be accomplished by providing a grounding plane (-18′) electrically connected to system ground and located between the heater (1) and the sensor (3).

Owner:DELPHI TECH IP LTD

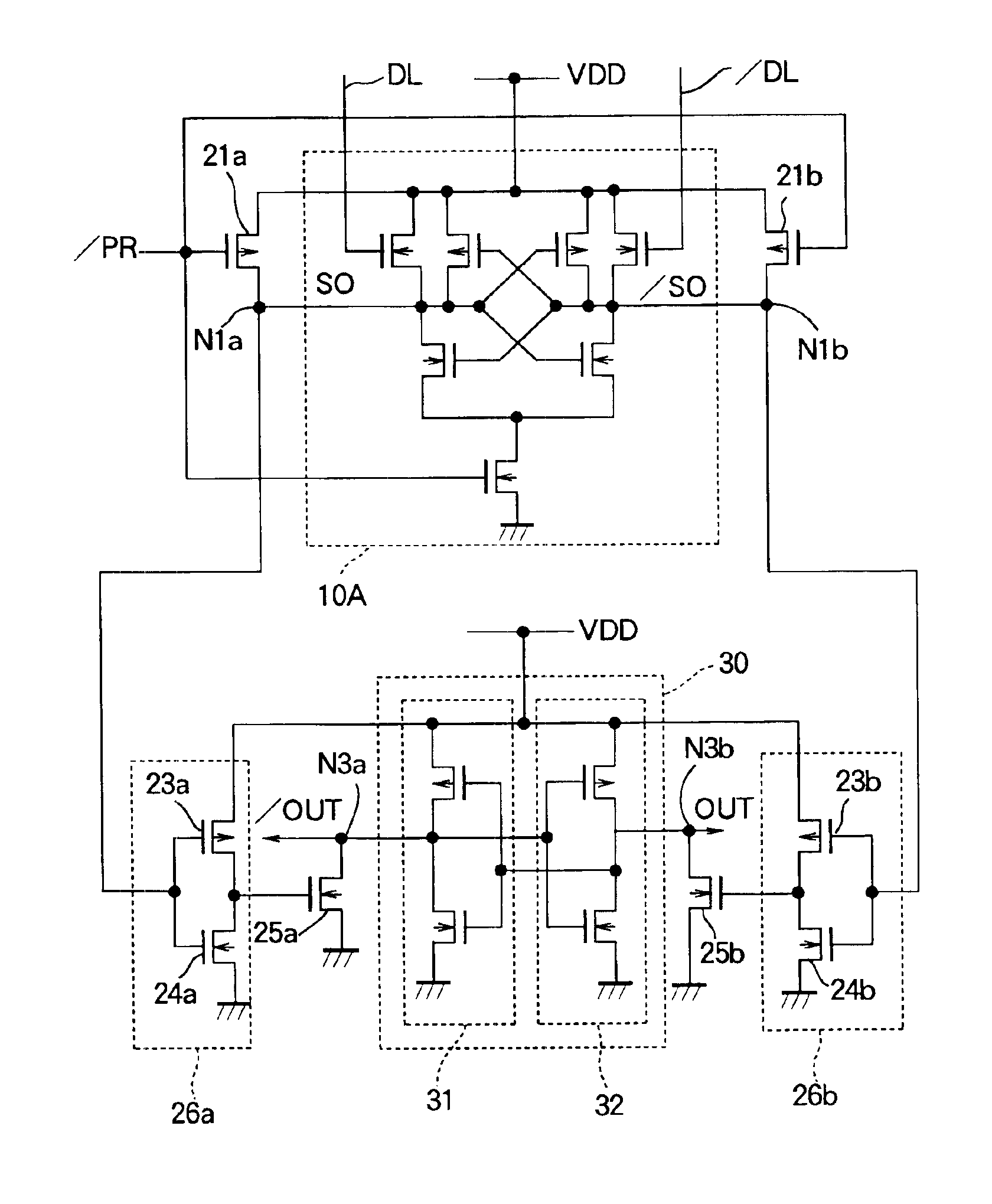

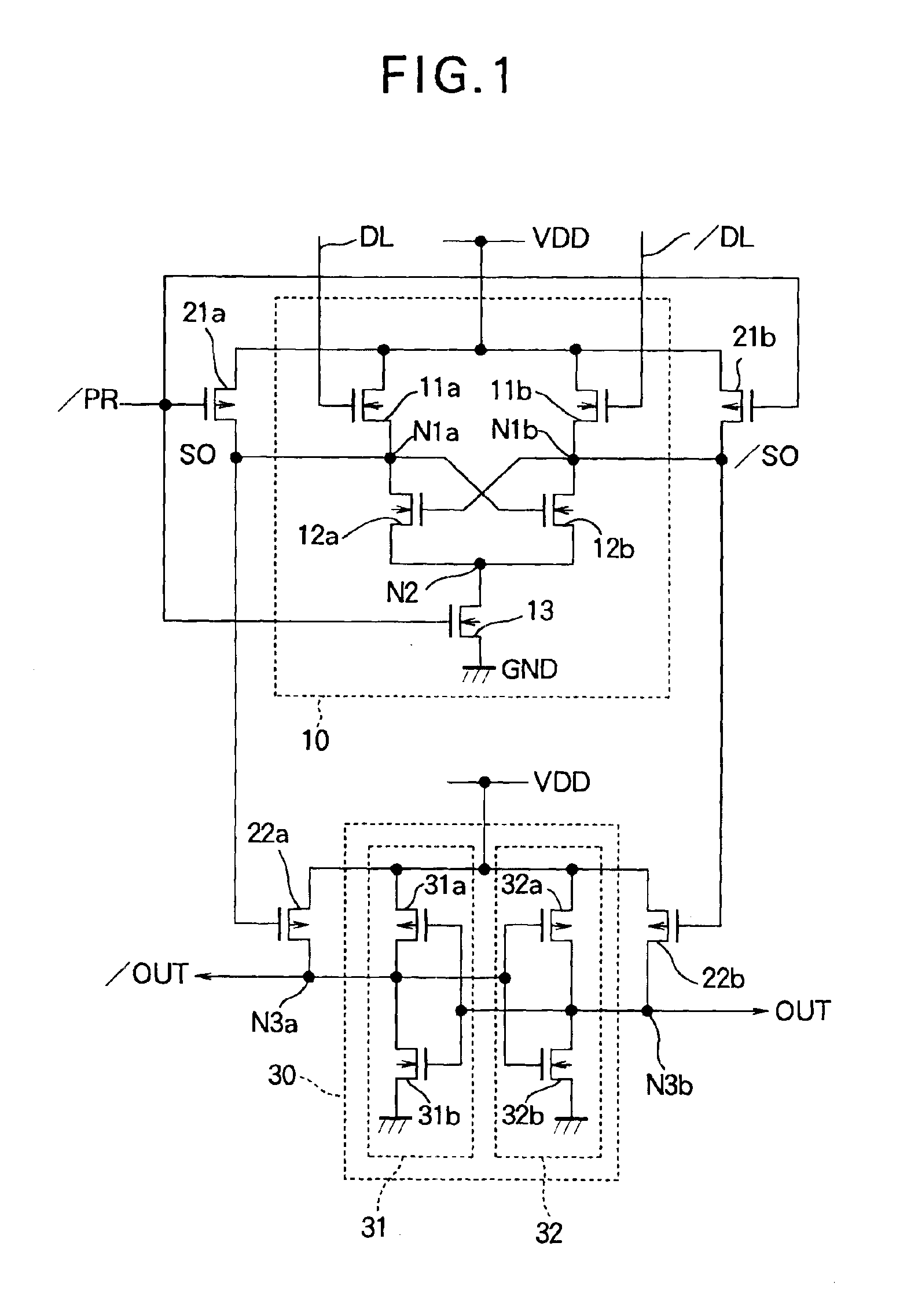

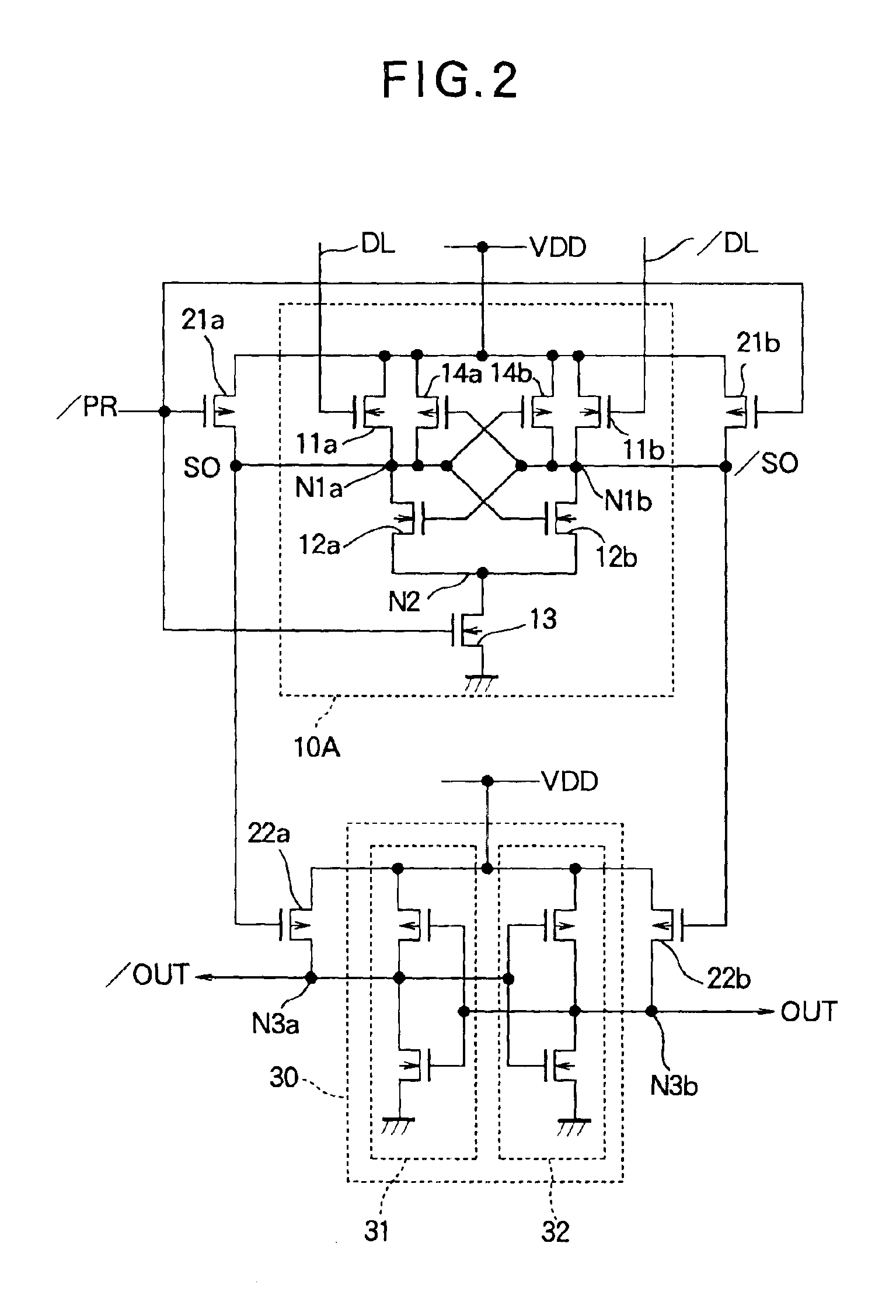

High-speed cross-coupled sense amplifier

InactiveUS6885222B2Avoid delayIncrease potential differenceMultiple input and output pulse circuitsCurrent/voltage measurementAudio power amplifierPotential difference

A sense amplifier has a pair of internal nodes that are precharged to a power-supply level. A first pair of n-channel transistors supplies current to the internal nodes responsive to a pair of data signals, both of which are initially high. When one of the data signals begins falling toward the low level, the corresponding n-channel transistor immediately reduces the current supplied to one of the internal nodes. A second pair of n-channel transistors, cross-coupled to the internal nodes, amplifies the resulting potential difference between the internal nodes, thereby pulling down the potential of one of the internal nodes. An output signal is generated from one or both of the internal nodes. The output signal is obtained quickly, because amplification begins without delay.

Owner:LAPIS SEMICON CO LTD

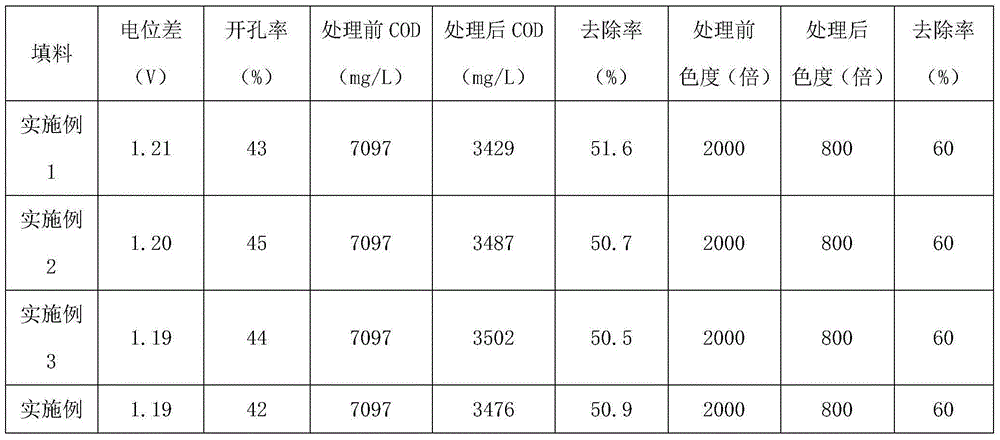

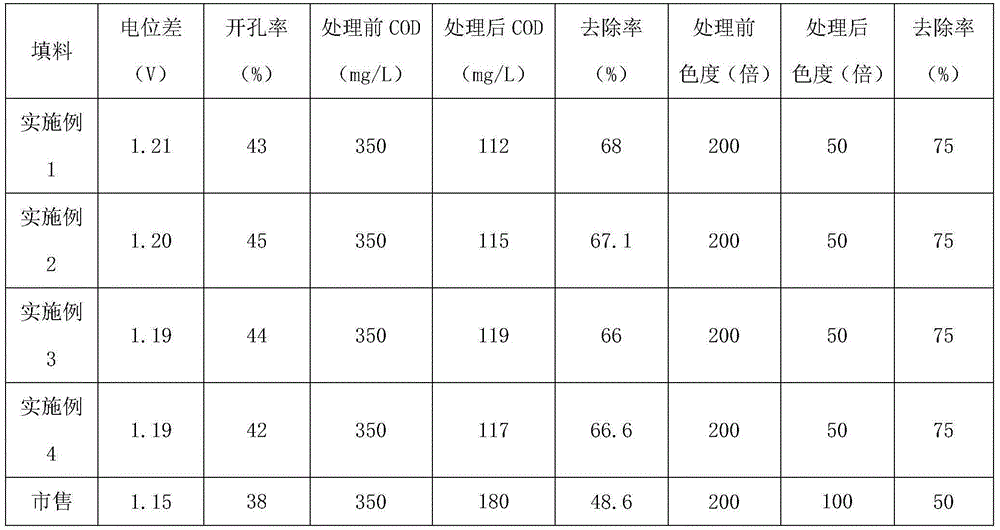

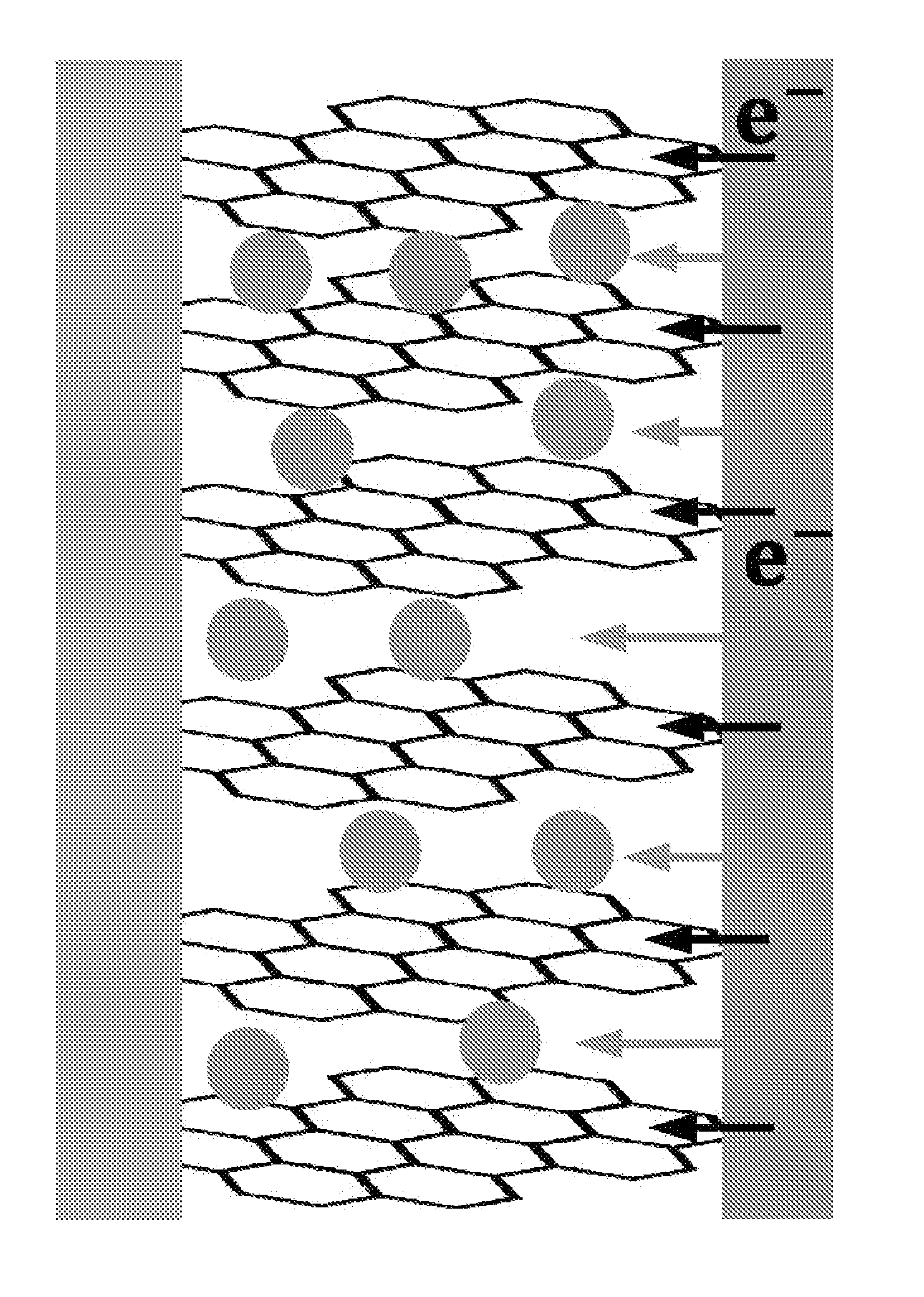

Composite micro-electrolysis filler as well as preparation method and application thereof

ActiveCN105110427ASolve easy hardeningSolving Passivation ProblemsWater/sewage treatmentElectrolysisIron powder

The invention discloses composite micro-electrolysis filler as well as a preparation method and application thereof, and belongs to the field of wastewater treatment. The micro-electrolysis filler is prepared from the raw materials such as iron powder, charcoal active powder, a dispersing agent, a binding agent, a catalyst and the like. By applying the micro-electrolysis filler into the wastewater treatment, the problem that traditional micro-electrolysis filler is likely to harden and passivate can be solved, the biodegradability of wastewater can be obviously improved, and the wastewater processing efficiency is improved.

Owner:东营国安化工有限公司

Iron-based copper for treating organic sewage and sewage treatment method

InactiveCN102849824AImprove degradation efficiencyIncrease potential differenceWater/sewage treatmentElectrolysisElectrochemical degradation

The invention relates to an iron-based copper high-efficient microelectrolytic material which contains a lot of nonuniform iron-copper microelectrode primary batteries and is formed by coating copper on cast iron granular carrier surfaces in a crystal grain form by a chemical conversion method. When organic sewage flows through a fixed bed reactor formed by the material, the reaction efficiency is controlled by the flow rate. With the material and the fixed bed reaction technology, the problem of low electrochemical degradation efficiency of organic pollutant macromolecules in sewage by common granular iron-carbon microelectrolytic materials and granular iron-copper microelectrolytic materials in current sewage treatment process is solved.

Owner:WUHAN COMEON ENVIRONMENT ENG

Method for preparation of graphene using spontaneous process

ActiveUS20150275378A1Low defectReduce impurityElectrolysis componentsPhotography auxillary processesGraphite electrodeAlcohol

The present invention relates to a method for preparing graphene using a spontaneous process, and particularly, to a method for mass-producing high-quality graphene composed of a single layer or several layers by using lithium intercalation of a graphite electrode occurring during the process of charging a lithium ion battery and a lithium ion capacitor in the preparation of graphene to form a graphite intercalation compound, and performing exfoliation through a reaction with water (or alcohol).

Owner:KOREA INST OF SCI & TECH

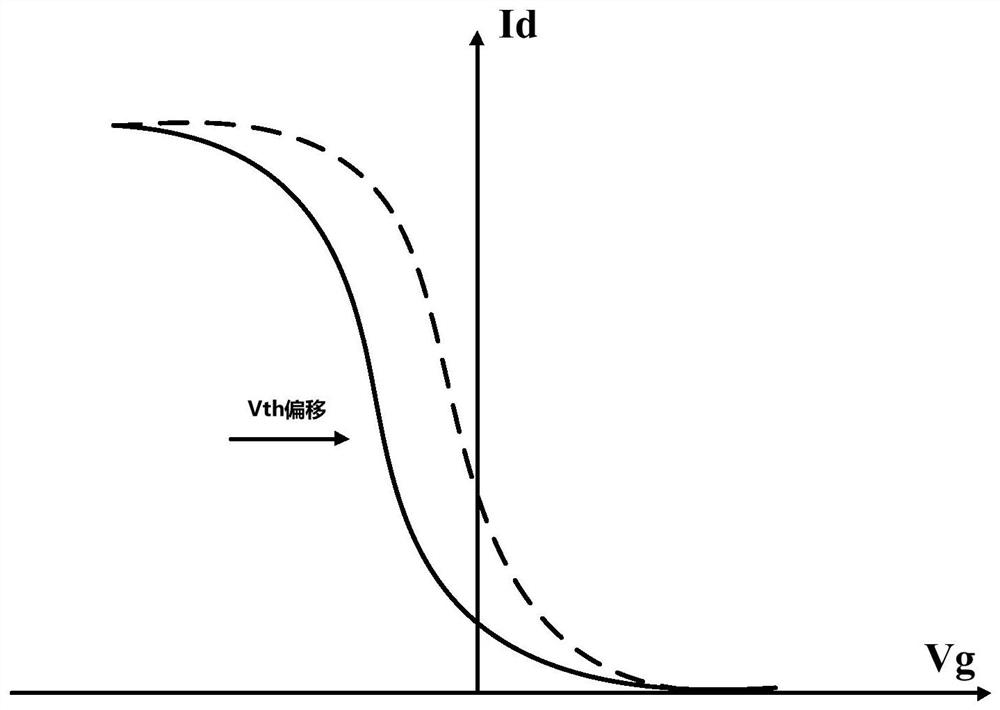

Display panel, driving method thereof and display device

PendingCN112133242AReduces the phenomenon of threshold voltage driftIncrease potential differenceStatic indicating devicesDriving currentDisplay device

The embodiment of the invention discloses a display panel, a driving method thereof and a display device. The display panel comprises a pixel circuit and a light-emitting element, wherein the pixel circuit comprises a data writing module, a driving module and a compensation module; the data writing module is used for selectively providing a data signal for the driving module; the driving module isused for providing driving current for the light-emitting element and comprises a driving transistor; and the compensation module is used for compensating the threshold voltage of the driving transistor. The working process of the pixel circuit comprises a bias stage, in the bias stage, the data writing module and the driving module are started, the compensation module is turned off, and data signals are written into the drain electrode of the driving transistor and used for adjusting the bias state of the driving transistor. In the embodiment of the invention, the bias stage is added and used for adjusting the voltage of the gate electrode, the source electrode or the drain electrode of the driving transistor and weakening the threshold voltage drift of the driving transistor caused by the non-bias stage.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

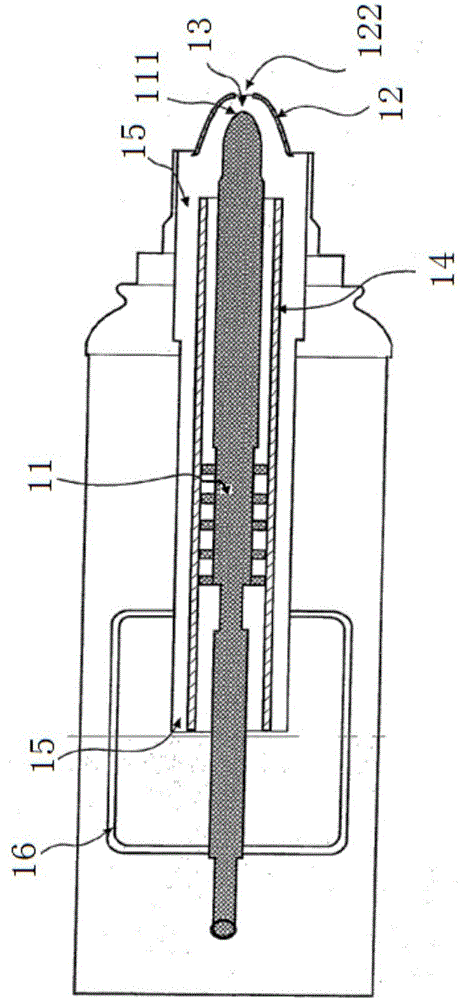

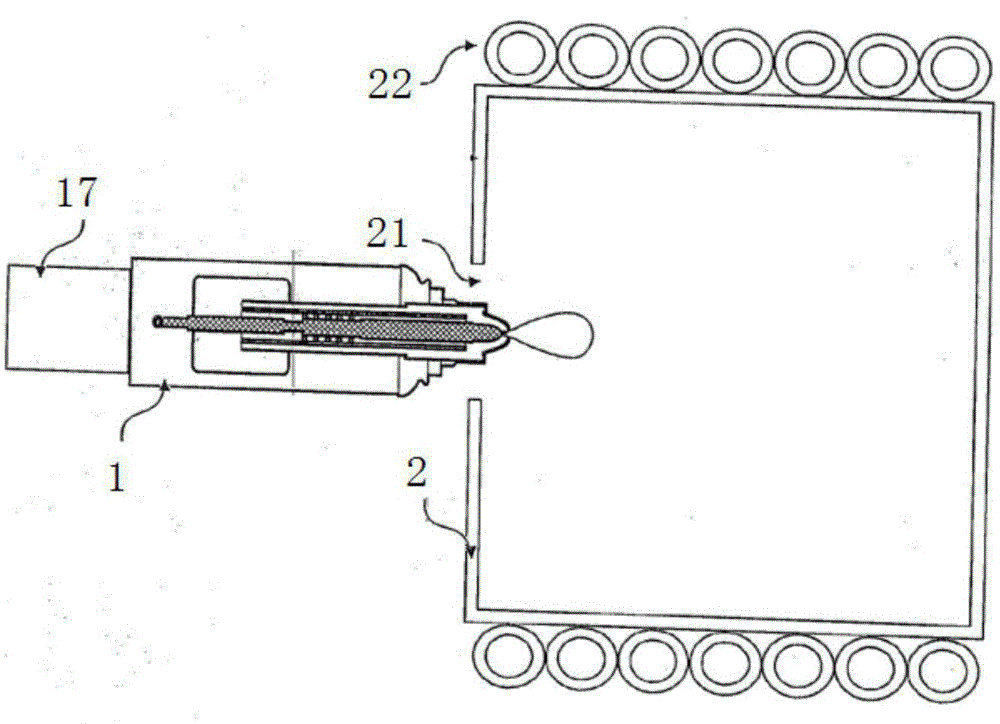

Plasma heater and plasma heating device

InactiveCN105066419APlay a cooling roleReduce the amount of waterWater heatersPlasma techniqueElectricityNew energy

The invention discloses a plasma heater. The plasma heater comprises a cathode and a nozzle. A plasma generation space is formed by the head of the cathode and the nozzle. The cathode is sleeved with a tubular structure. The tubular structure is sleeved with a channel. The channel is communicated with a water supply system. One end of the channel extends to the plasma generation space. The nozzle comprises a nozzle wall and a nozzle opening located in the nozzle wall. The invention further discloses a plasma heating device. Compared with old-fashioned electric heating, the electricity consumption of the plasma heating device is reduced by at least 50 times, the water consumption can be ignored nearly, most water is recycled, and the service life of the plasma heating device can reach above 30 years. Compared with traditional consumption, gas combustion and electricity consumption, cost is low, the electricity consumption is low, the heat value is high, outside and inside restrictions are avoided, the application space is broad, the plasma heating device is a new energy support project, a national energy crisis is solved, and the plasma heating device is one of sustainable development projects.

Owner:张建超

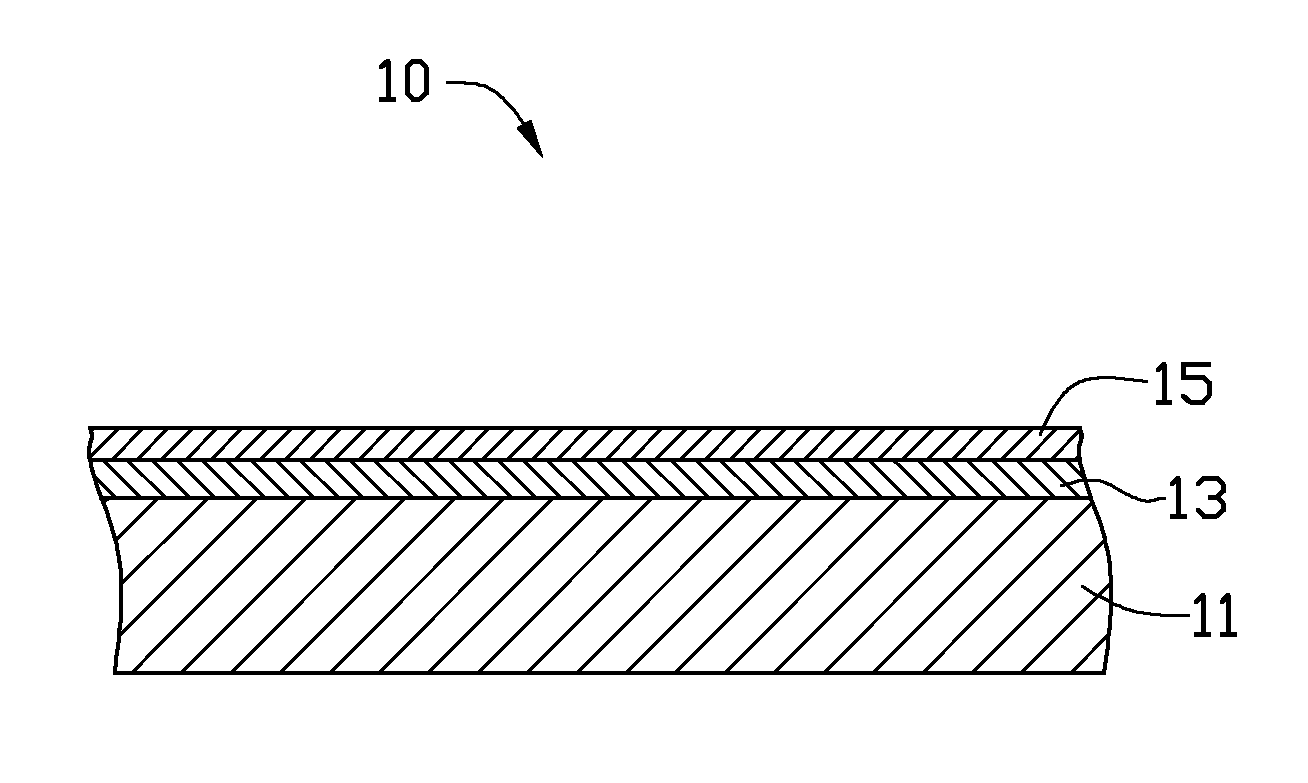

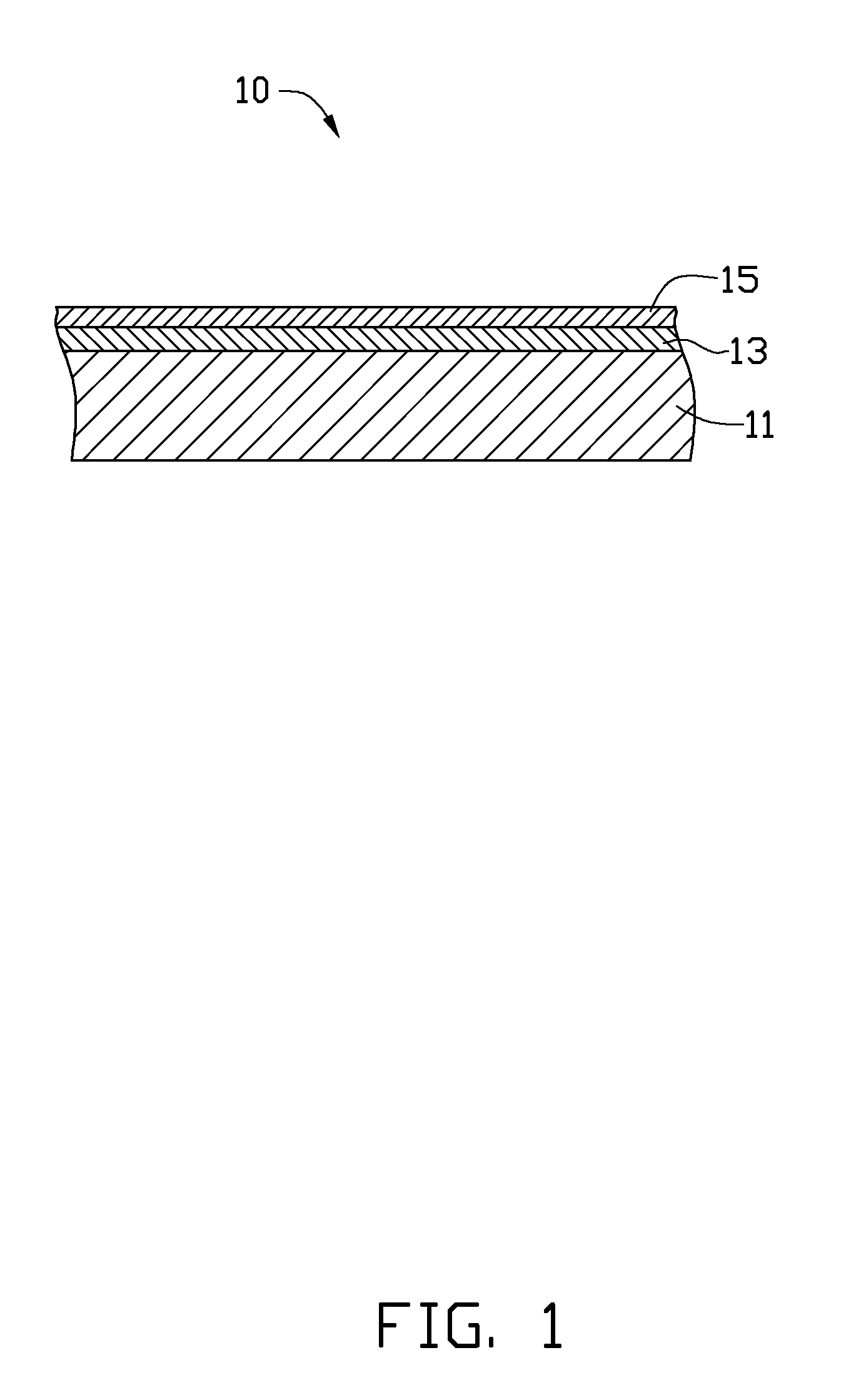

Coated article and method for making the same

InactiveUS20130029174A1Accelerate galvanic corrosionIncrease potential differenceHot-dipping/immersion processesVacuum evaporation coatingAlloyBoron

A coated article includes a substrate, an anti-corrosion layer formed on the substrate, and a decorative layer formed on the anti-corrosion layer. The anti-corrosion layer is an amorphous alloy layer containing elements of iron, chromium, boron and M, wherein M is one or more selected from the group consisting of phosphorus, carbon and silicon. A method for making the coated article is also described.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

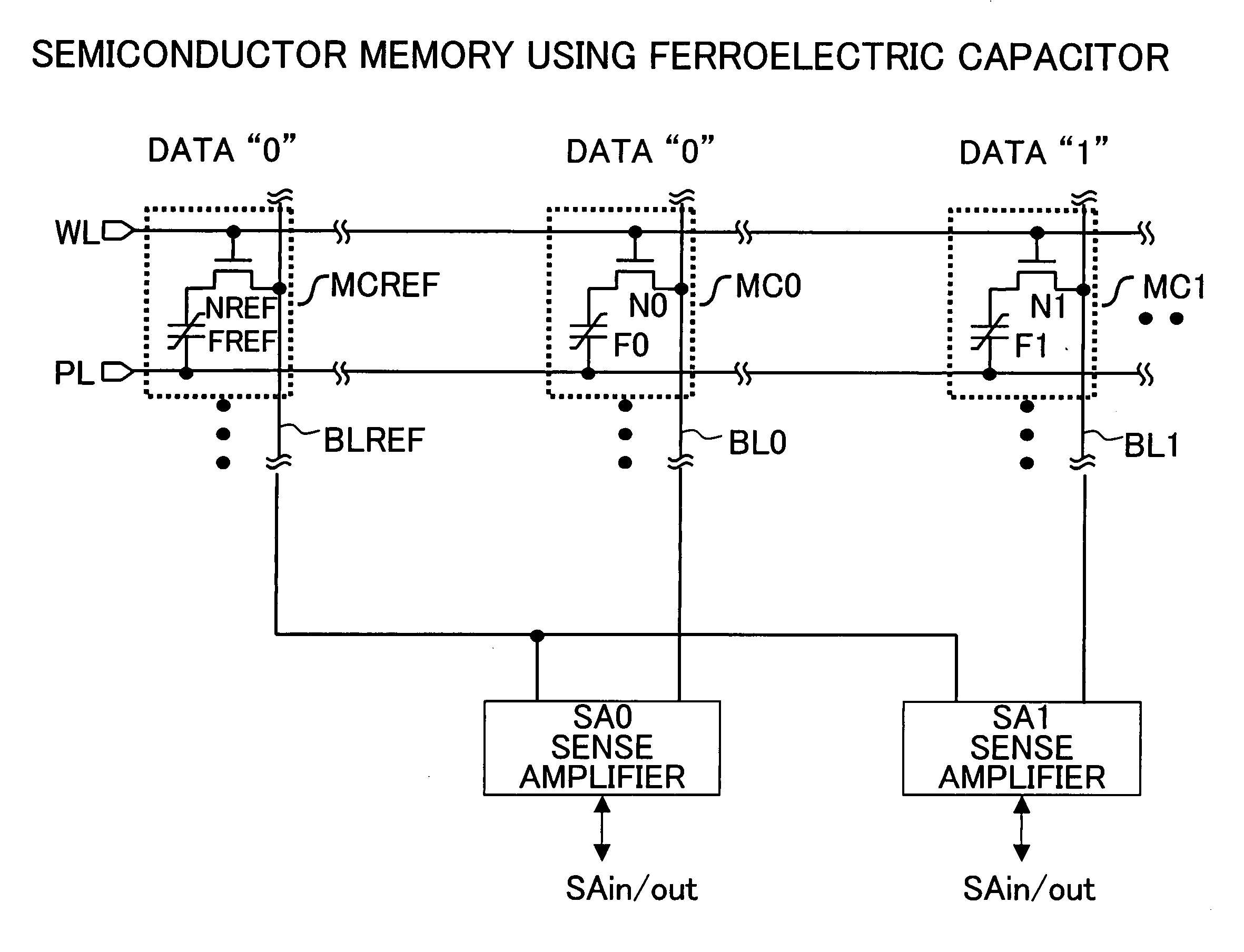

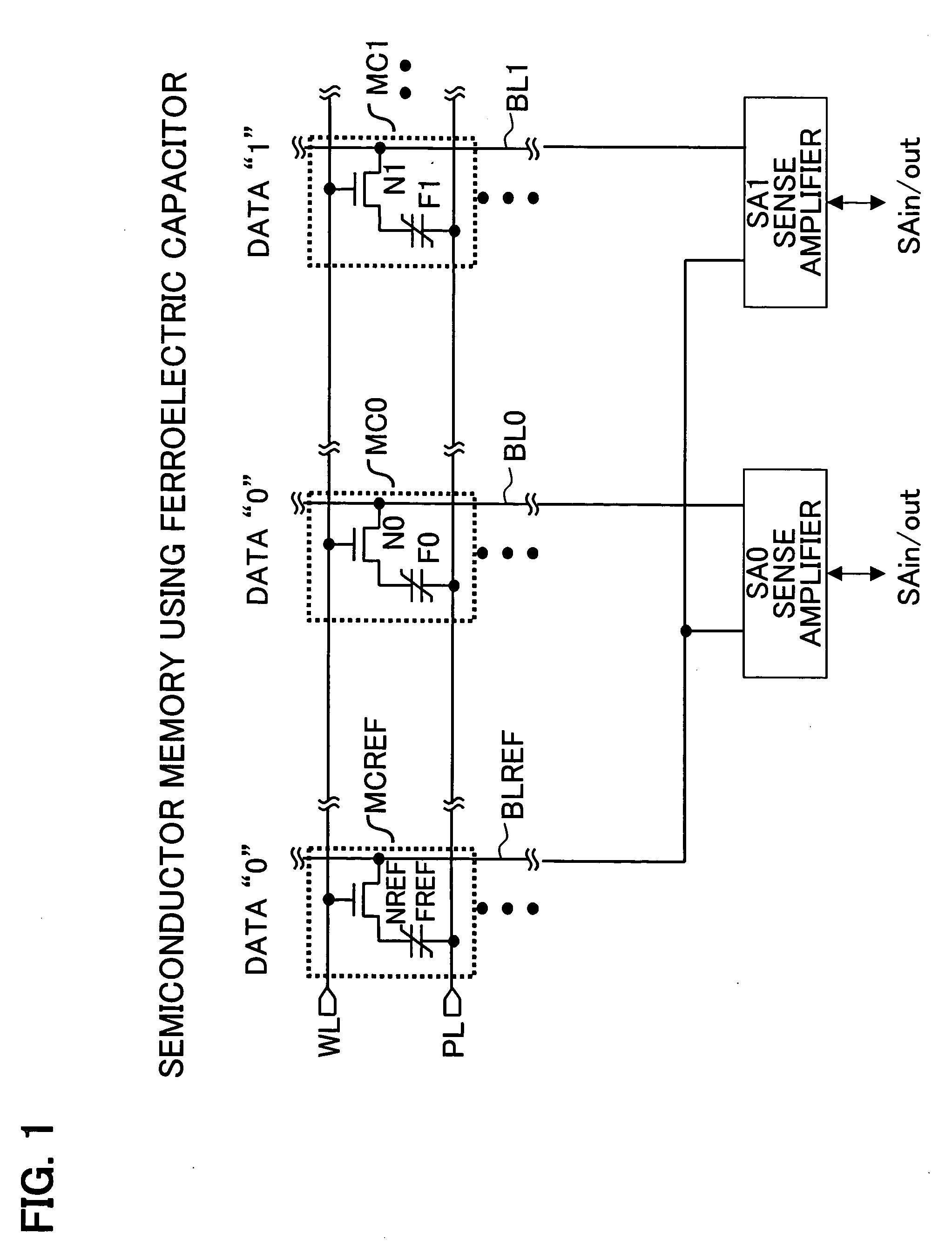

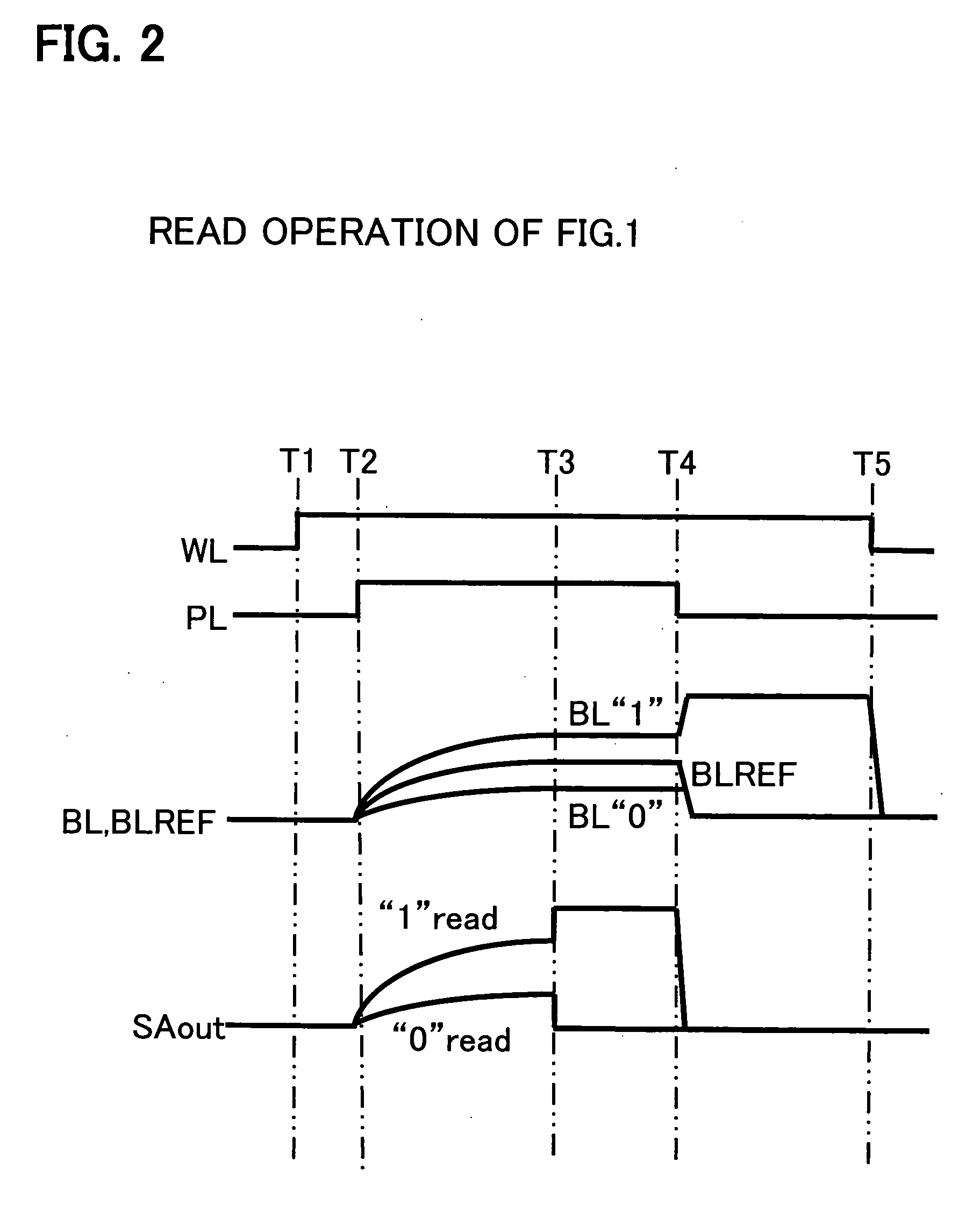

Semiconductor memory

ActiveUS20060146625A1Raise the potentialAvoid distractionRead-only memoriesDigital storageCapacitanceBit line

The semiconductor memory has word lines; normal memory cells each having a storage capacitor; normal bit lines connected to the normal memory cells; a reference memory cell having a capacitor storing prescribed data; and a reference bit line connected to the reference memory cell. When a word line is selected, the potential of normal bit lines and of reference bit line changes according to the charge on the storage capacitors and on the reference capacitor. A current mirror circuit is also provided, which has a first transistor drain of which is connected to the reference bit line and second transistors drains of which are respectively connected to normal bit lines, the gates of the first and second transistors being connected in common to the reference bit line. Thus even though the capacitance values of ferroelectric capacitors is scattered, the scattering in bit line potentials during read operations can be prevented.

Owner:FUJITSU SEMICON MEMORY SOLUTION LTD +1

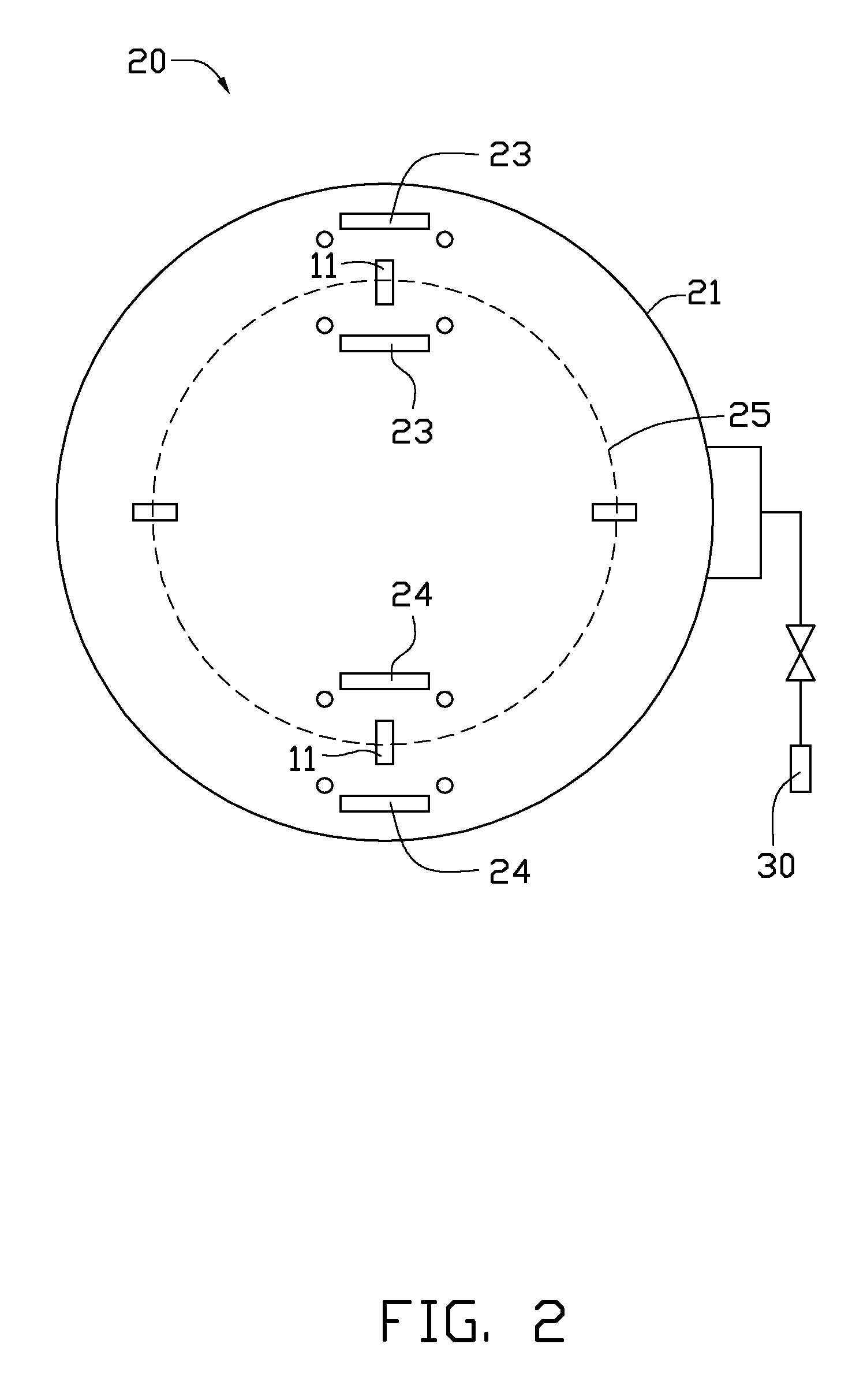

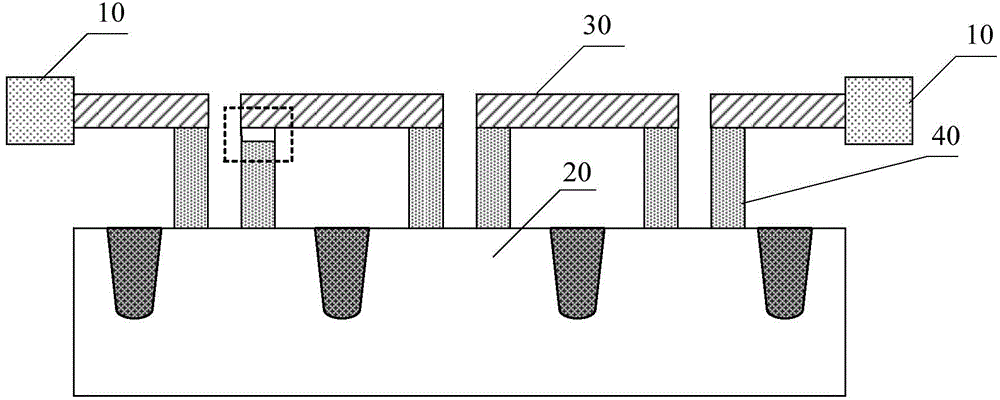

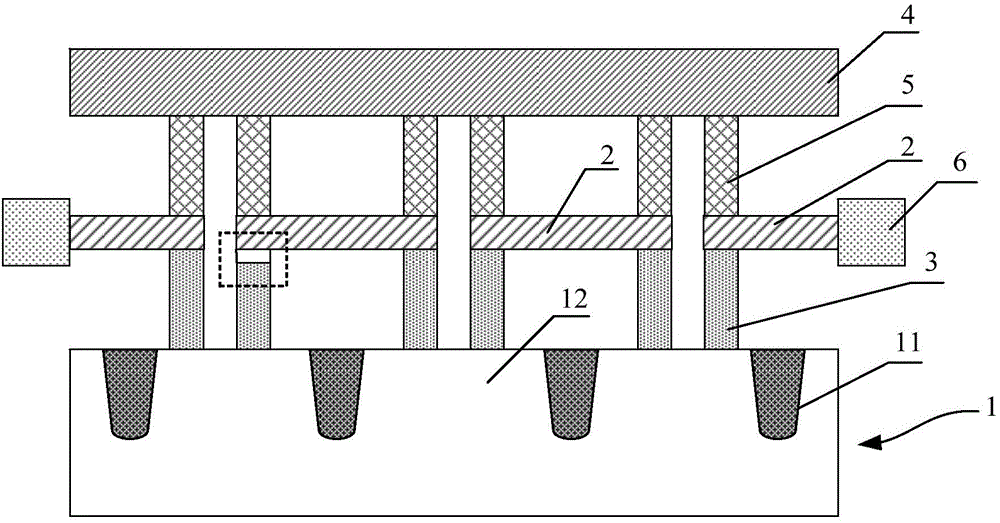

Test structure and test method

ActiveCN105304614AIncrease potential differenceRespond to process uniformity in all directionsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsTest structureVoltage contrast

The invention provides a test structure. The test structure comprises a substrate layer and a plurality of discrete first inter-layer metal layers, wherein the first inter-layer metal layers are in electrical connection with a plurality of first contact plugs; and the test structure further comprises a continuously distributed second inter-layer metal layer, wherein the second inter-layer metal layer is in electrical connection with the first inter-layer metal layers through a plurality of second contact plugs. According to the invention, the first inter-layer metal layers are connected to a big second inter-layer metal layer through the second contact plugs, thus, the effect of grounding is realized, and potential difference of the surface of the first contact plugs after the metal is in broken line connection is enhanced; and based on the principle of voltage contrast of a scanning electron microscope, light and shade degree of the first contact plugs can be observed from the back of a wafer so as to reflect whether the first contact plugs are contacted well with the first inter-layer metal layers, thus, locations of defect can be found quickly, process defects can be reflected, and the aim of early defect monitoring is realized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

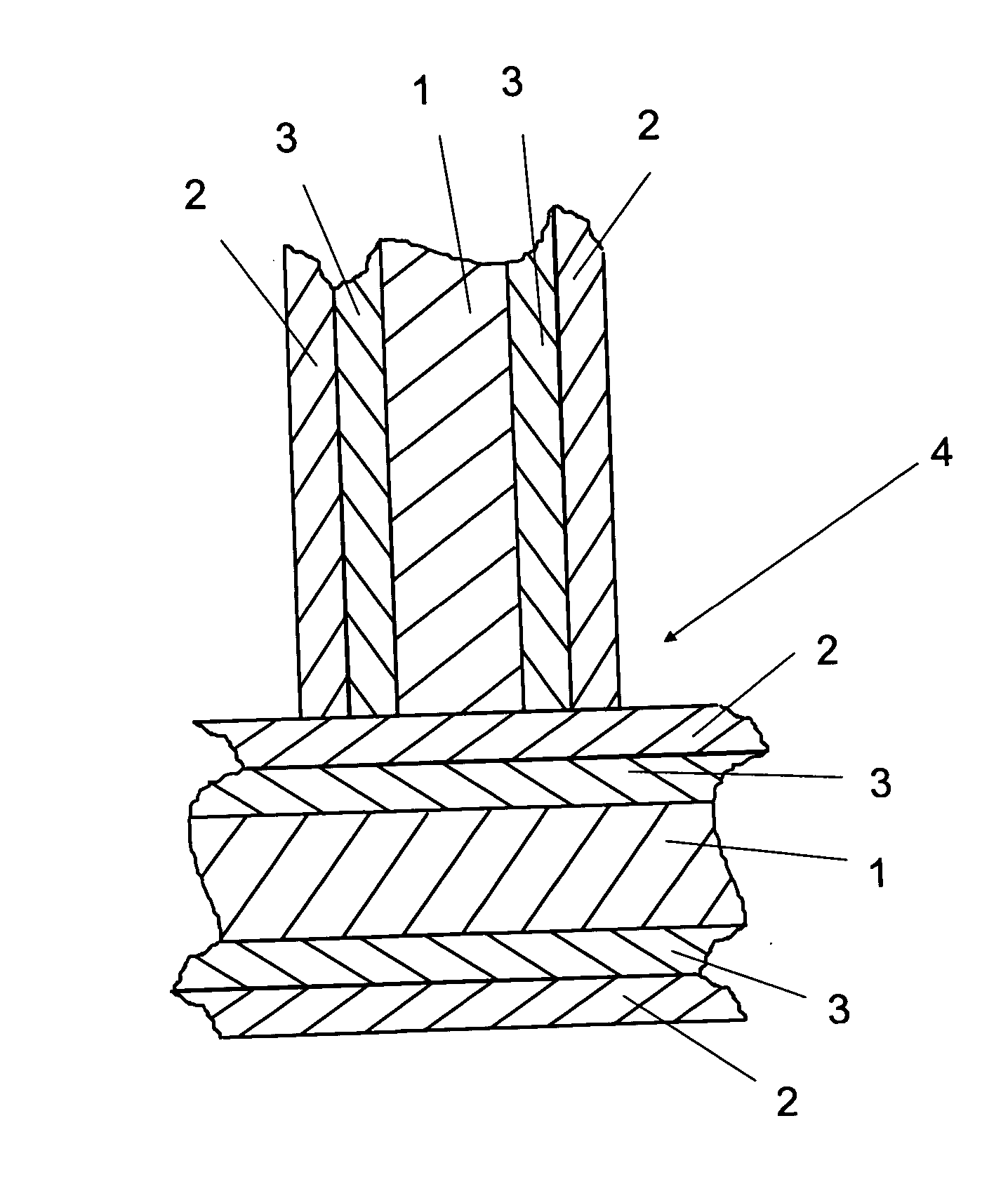

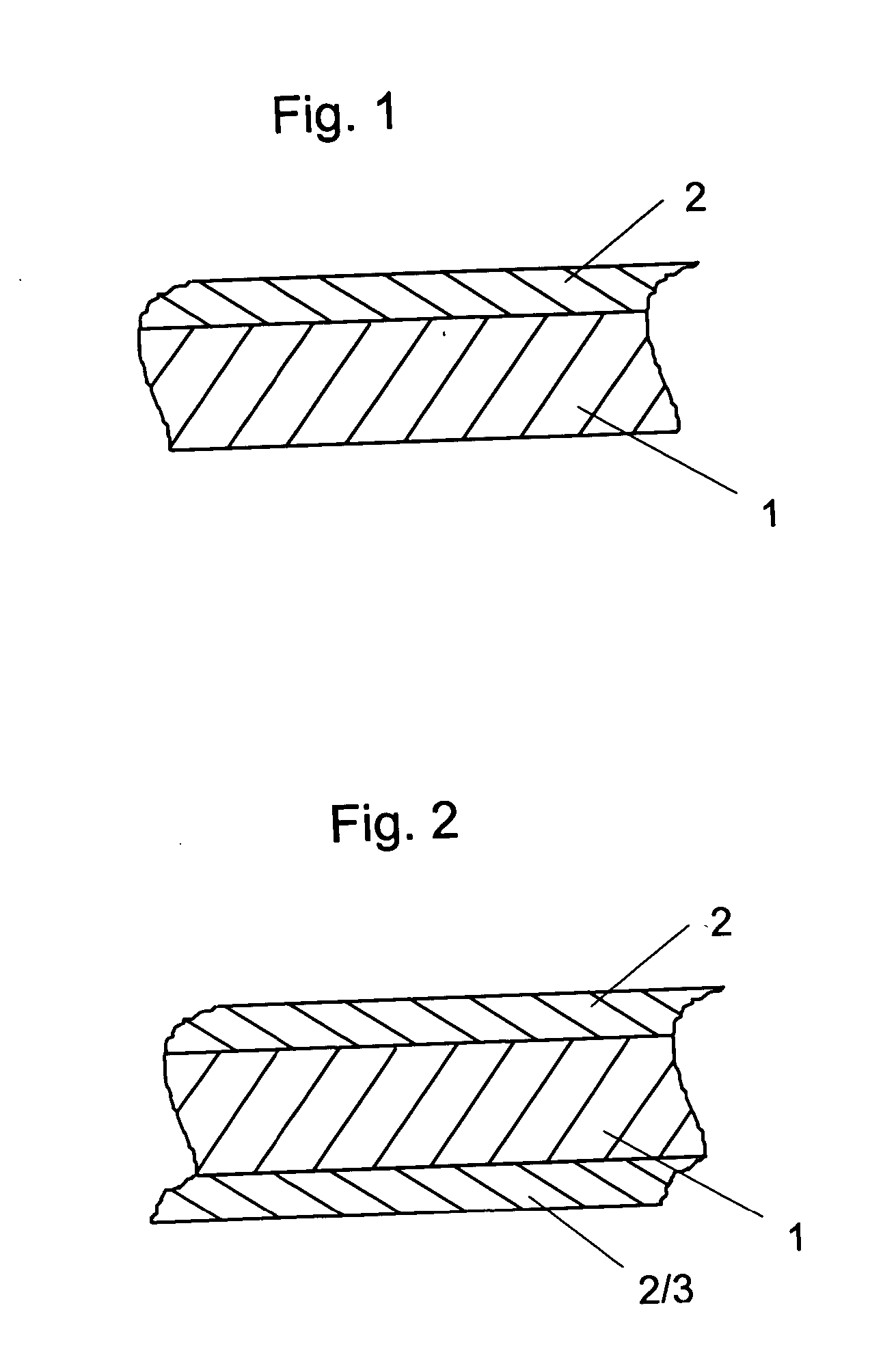

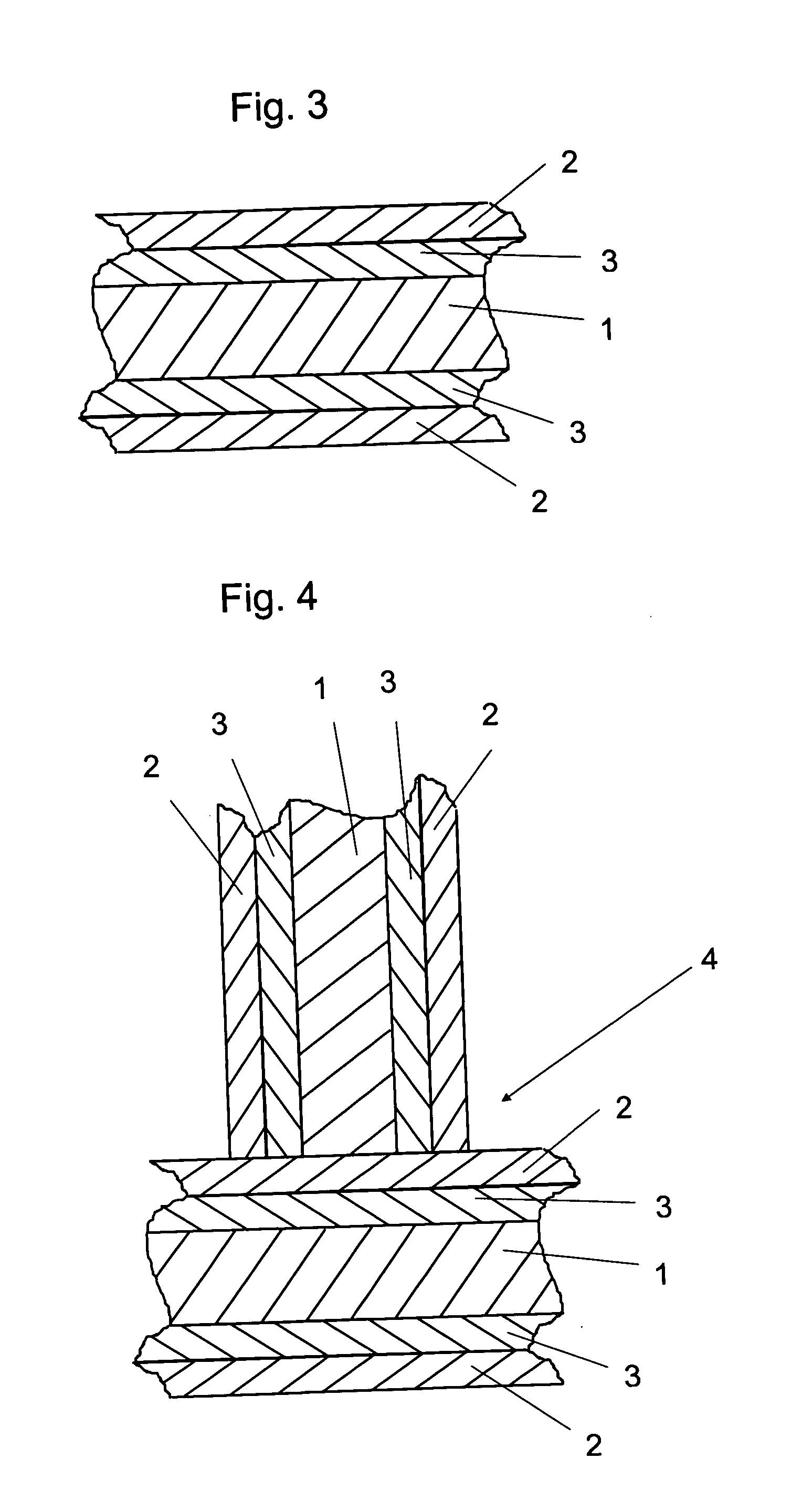

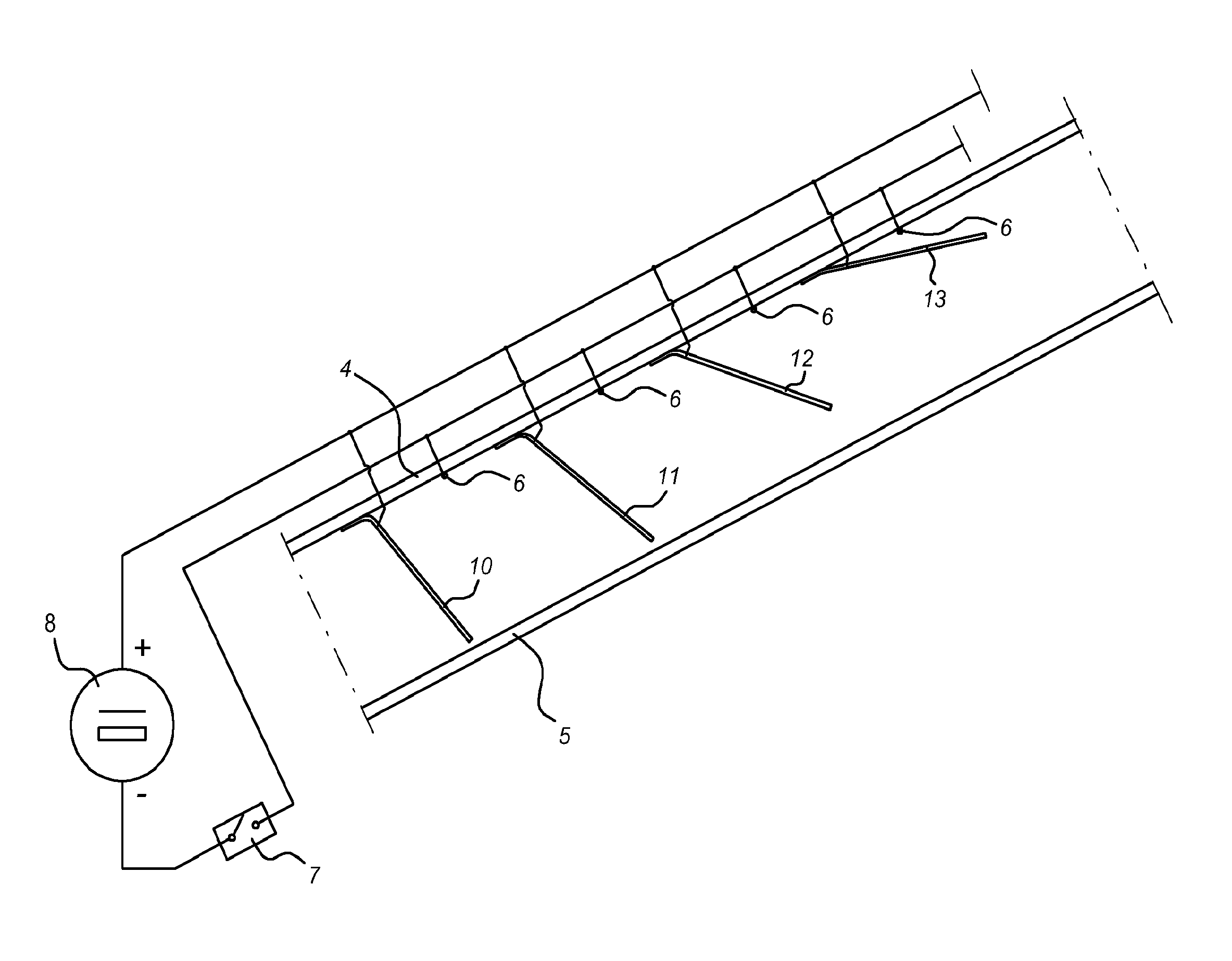

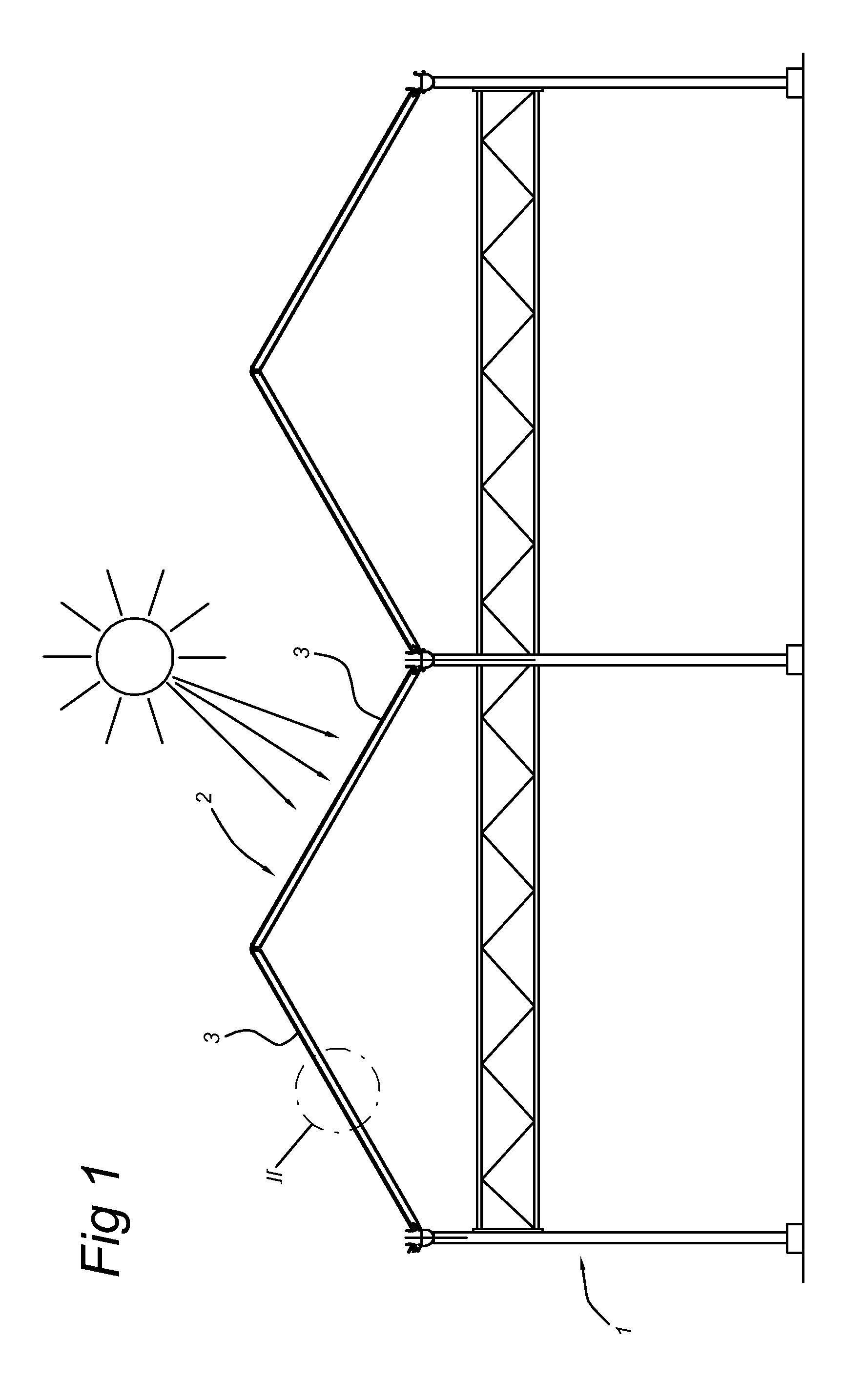

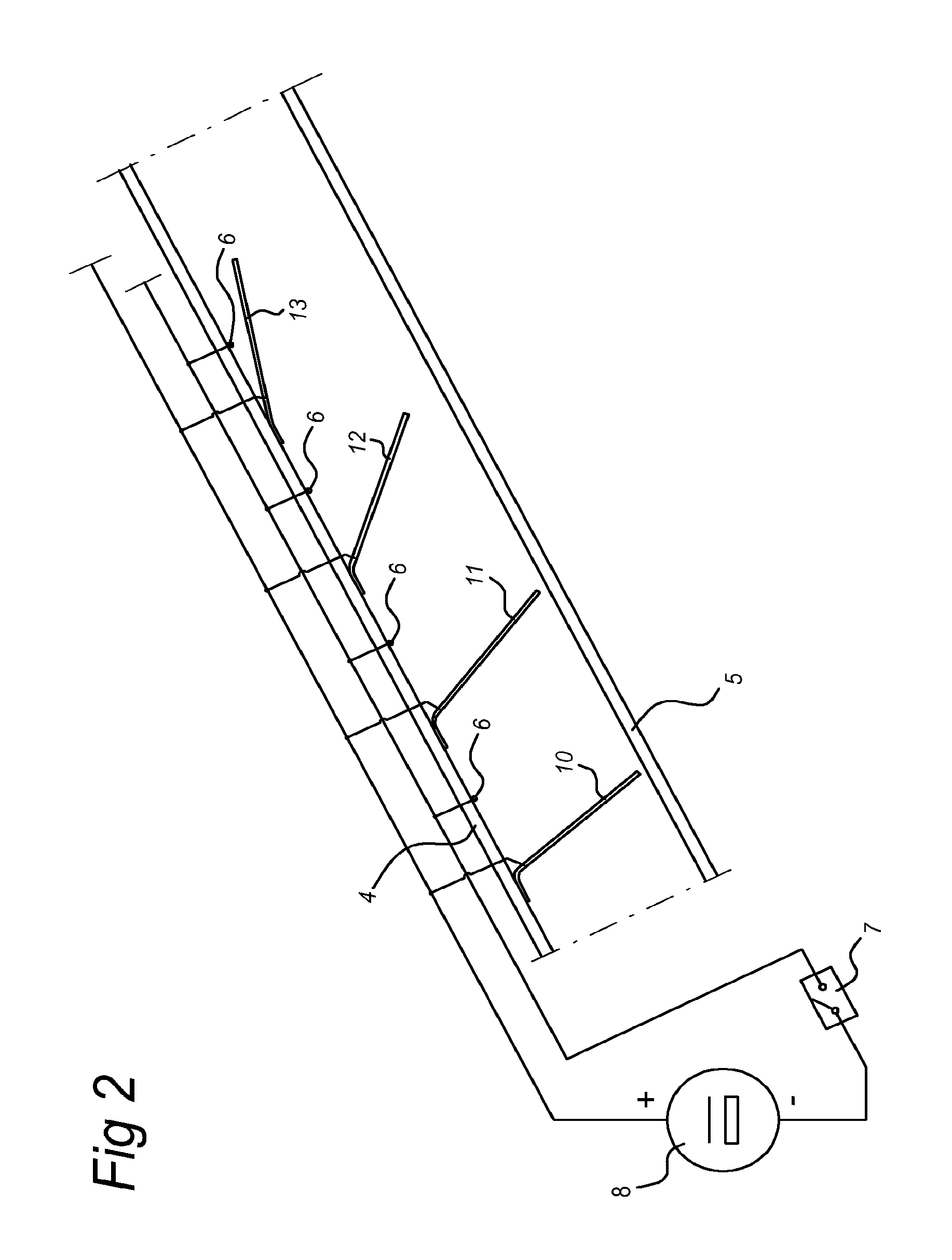

Strip assembly

ActiveUS8024891B2Prevent penetrationEnsures operationPhotovoltaic supportsRoof covering using slabs/sheetsPolyesterElectrical resistance and conductance

Strip assembly consisting of a number of strips hingeably attached to influence or not to influence light. Strips can be displaced between two positions by static charging / discharging with respect to a support attached near the strip. A voltage source provides the strips / further electrodes with the respective voltage. The strips can be configured to be (partially) non-transparent, allowing light effects to be obtained. In addition, it is possible to configure various strips differently. The strips preferably consist of a foil material allowing an especially simple construction with the aid of a film hinge. Suitable materials include polycarbonate, polyester or plastics material based on aromatics. The surface resistance is preferably at most 1000 MΩ. A broad range of uses are possible. One use is that in greenhouses but the present invention can also be applied at other locations where protection from light is necessary or specific light effects are desired.

Owner:SUNWAVES BV

Preparation method of nanometer iron-copper-carbon micro electrolysis material for organic waste water treatment

ActiveCN102942242AIncreased active surface areaImprove oxidation efficiencyWater/sewage treatmentAmmonium sulfatePollutant

The present invention discloses a preparation method of a nanometer iron-copper-carbon micro electrolysis material for organic waste water treatment. The preparation method comprises: mixing acrylic acid and water; adding copper-iron hydrotalcite particles to the acrylic acid solution, wherein per g of the copper-iron hydrotalcite particles is corresponding to 3-5 mmol of the acrylic acid, and the copper-iron hydrotalcite particles are screened through a 20-50 mesh sieve; adding ammonium persulfate, heating, washing with deionized water, drying, grinding, and screening through a 20-40 mesh sieve to obtain powder; heating the obtained powder under a vacuum condition to 600-700 DEG C, and carrying out calcination for 2-4 h; adding 2-4 g of the resulting product into a flask, adding 20 ml of deionized water, introducing N2 to carry out protection, stirring, then adding a KBH4 solution, and carrying out continuous stirring; and carrying out centrifugation separation, and carrying out constant temperature drying for 5-6 h at a temperature of 60-70 DEG C under N2 protection to obtain the nanometer iron-copper-carbon micro electrolysis material for organic waste water treatment, wherein an activated surface area can be increased, pollutants can be absorbed, a nanometer effect of the nano-scale iron-copper-carbon can be provided, and oxidation efficiency can be improved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Multiple layer nickel plating technique with superior antiseptic property

InactiveCN101063218AIncrease potential differenceImprove corrosion resistanceMulti effectMetallic Nickel

Owner:深圳市天泽科技实业有限公司

Display panel, driving method thereof and display device

PendingCN112116890AIncrease potential differenceBalance shift phenomenonStatic indicating devicesComputer hardwareDriving current

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Method for oxidation treatment of sewage by novel Fe-C microelectrolysis-Fenton reagent

ActiveCN101704596AReduce utilizationIn line with the principle of treating waste with wasteMultistage water/sewage treatmentWater/sewage treatment by oxidationFenton reagentSlag

The invention relates to a sewage treatment method, in particular to a method for comprehensively utilizing heavy slag and gas ashes of a blast furnace. The method is characterized in that a novel Fe-C microelectrolysis-Fenton reagent consisting of the heavy slag and gas ashes of the blast furnace is used for oxidation treatment of the organics in sewage; subsequently the exposure of gas is utilized to effectively remove the suspension organics and colloid generated due to the oxidation treatment of the Fe-C microelectrolysis-Fenton reagent, thus removing the contamination in the sewage and resolvable organics difficult for biodegradation. The method reduces the production cost for sewage treatment, simultaneously utilizes the heavy slag and gas ashes of the blast furnace comprehensively, is environment-friendly and economical, and has greater application and development prospects.

Owner:杨忠刚

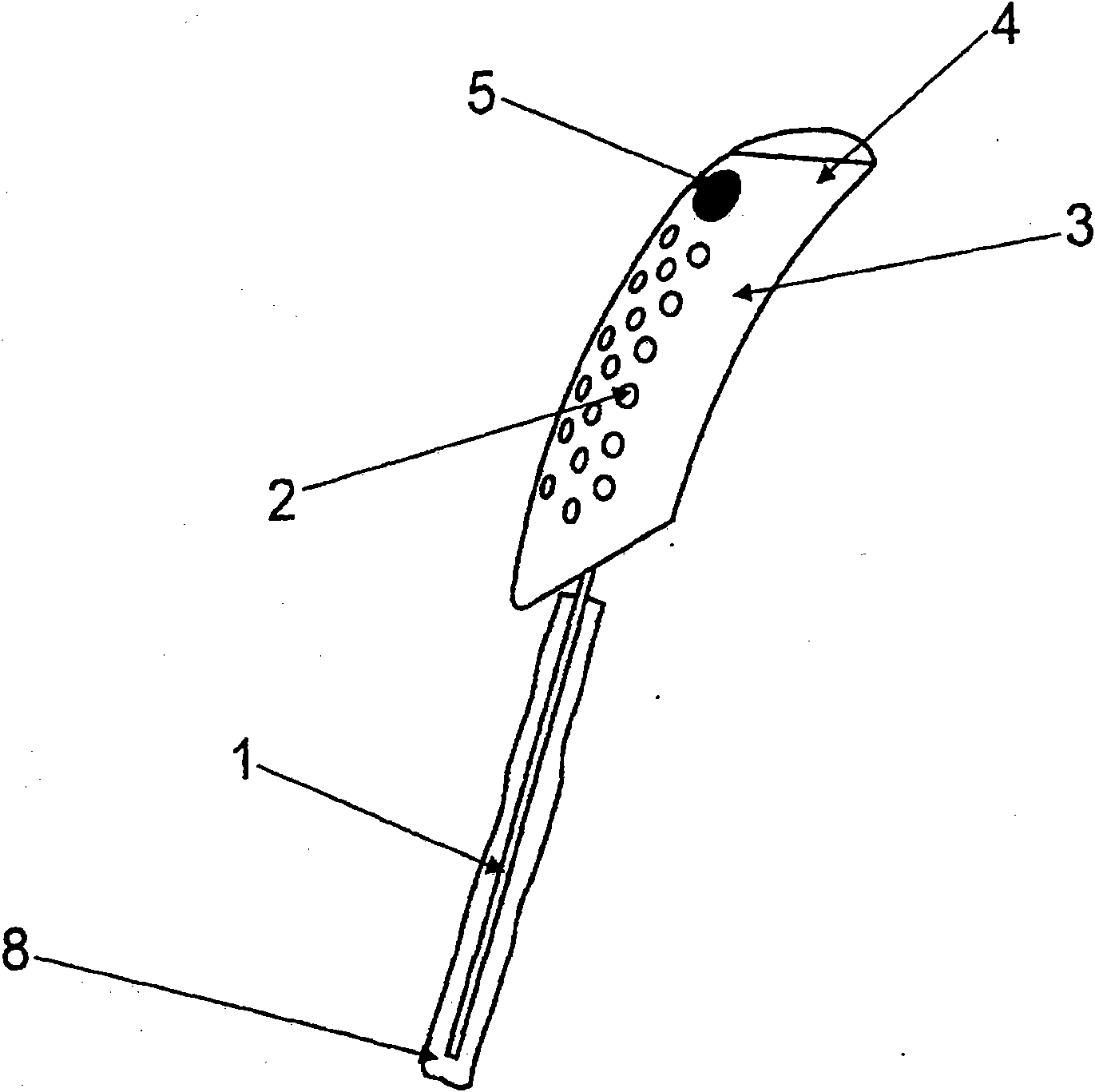

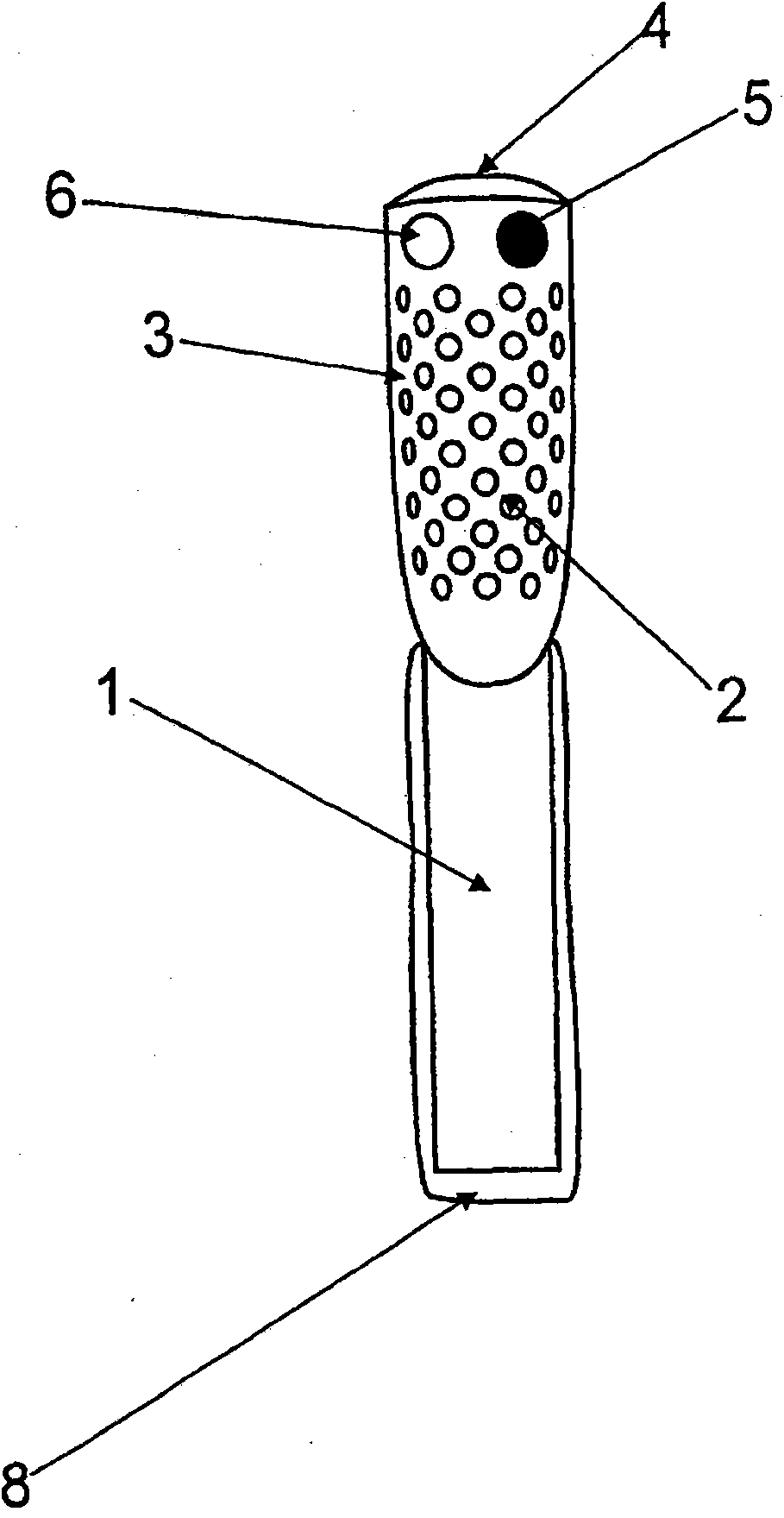

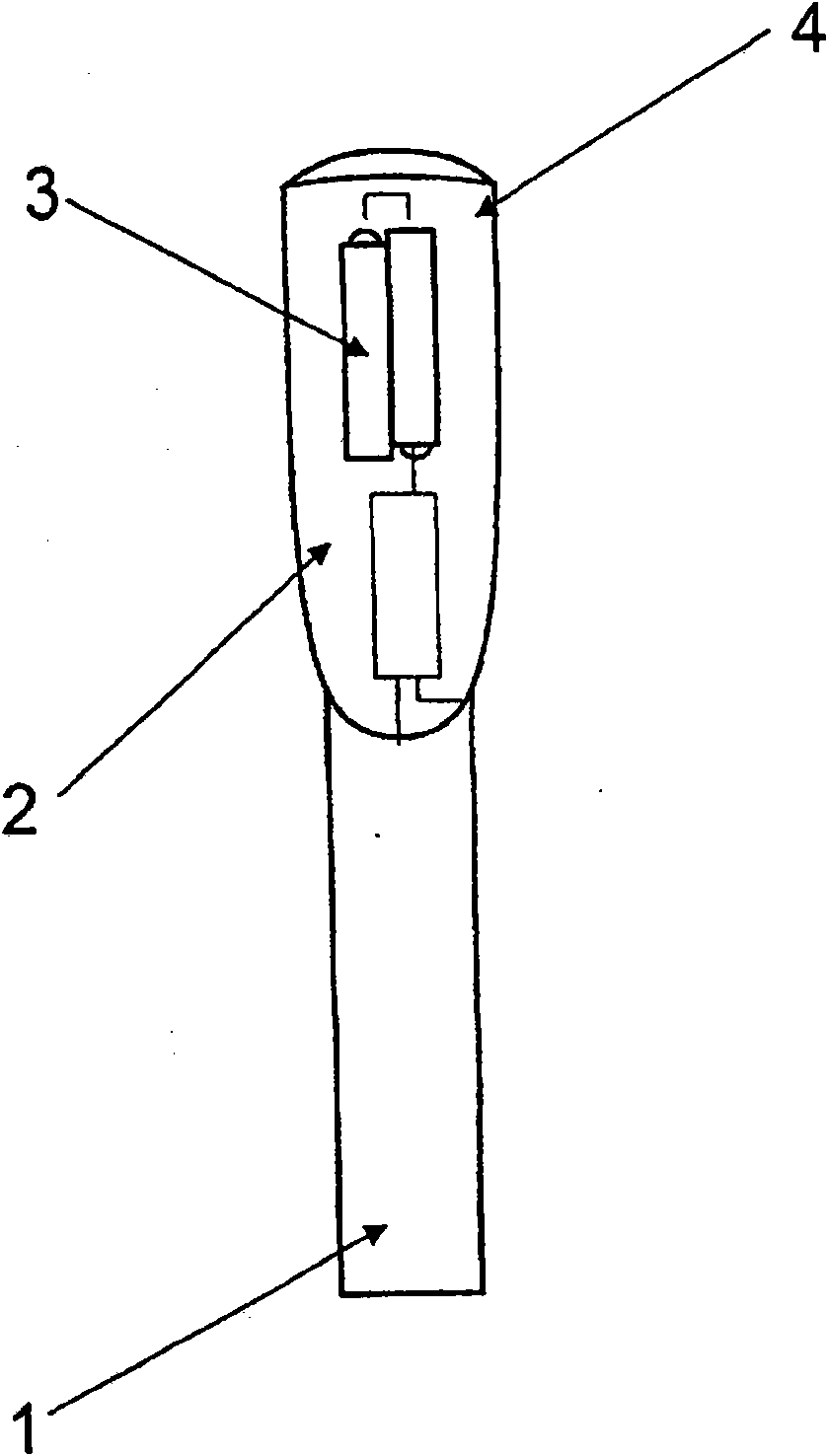

Electrostatic dust catcher

InactiveCN101945609ASimple and economical to operateSimple and economical productionCarpet cleanersFloor cleanersVoltage sourceElectrode

The invention relates to electrostatic dust catcher comprising a first (1) and a second electrode (2) and a voltage source (3) for applying an electrical voltage between the two electrodes (1, 2), characterized in that the first electrode (1) is designed as a dust catching device and the second electrode (2) is grounded.

Owner:CARL FREUDENBERG KG

Magnetic read sensor using spin hall effect

ActiveUS9099119B2Increase potential differenceOutput signalMagnetic property measurementsRecord information storagePower flowConductive polymer

A magnetic sensor utilizing the spin Hall effect to polarize electrons for use in measuring a magnetic field. The sensor eliminates the need for a pinned layer structure or antiferromagnetic layer (AFM layer), thereby reducing gap thickness for increased data density. The sensor includes a non-magnetic, electrically conductive layer that is configured to accumulate electrons predominantly of one spin at a side thereof when a current flows there-through. A magnetic free layer is located adjacent to the side of the non-magnetic, electrically conductive layer. A change in the direction of magnetization in the free layer relative to the orientation of the spin polarized electrons causes a change in voltage output of the sensor.

Owner:WESTERN DIGITAL TECH INC

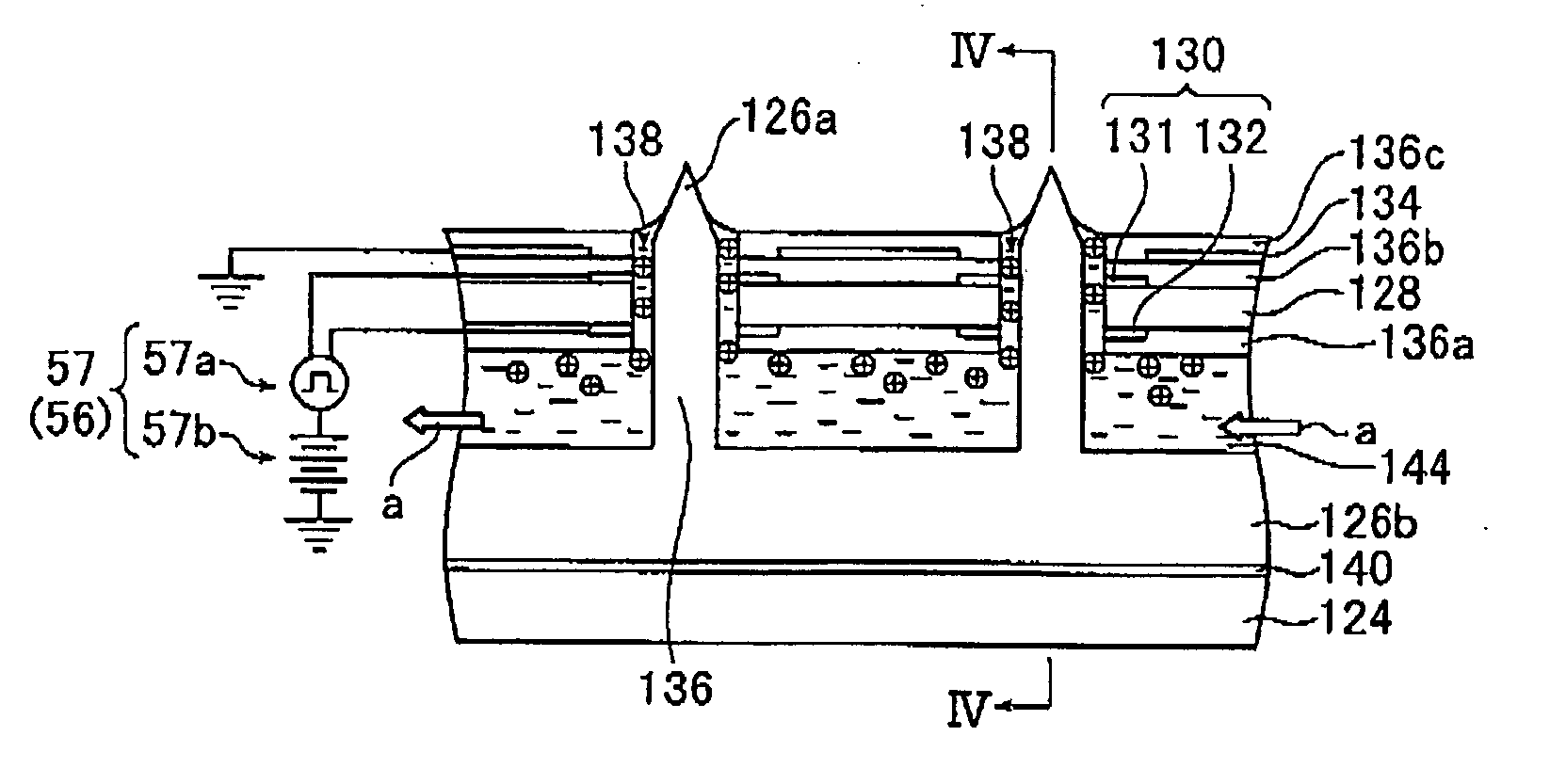

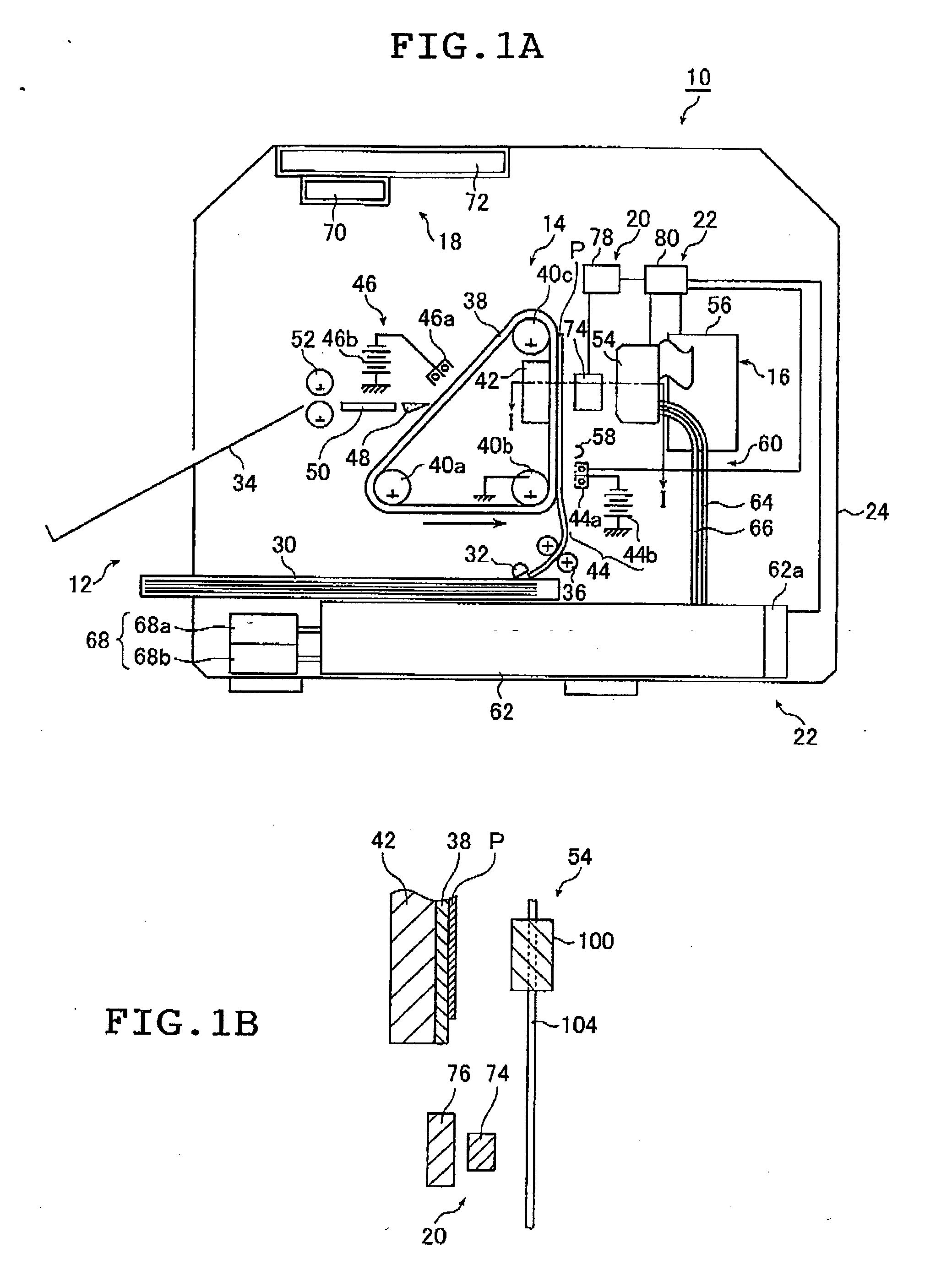

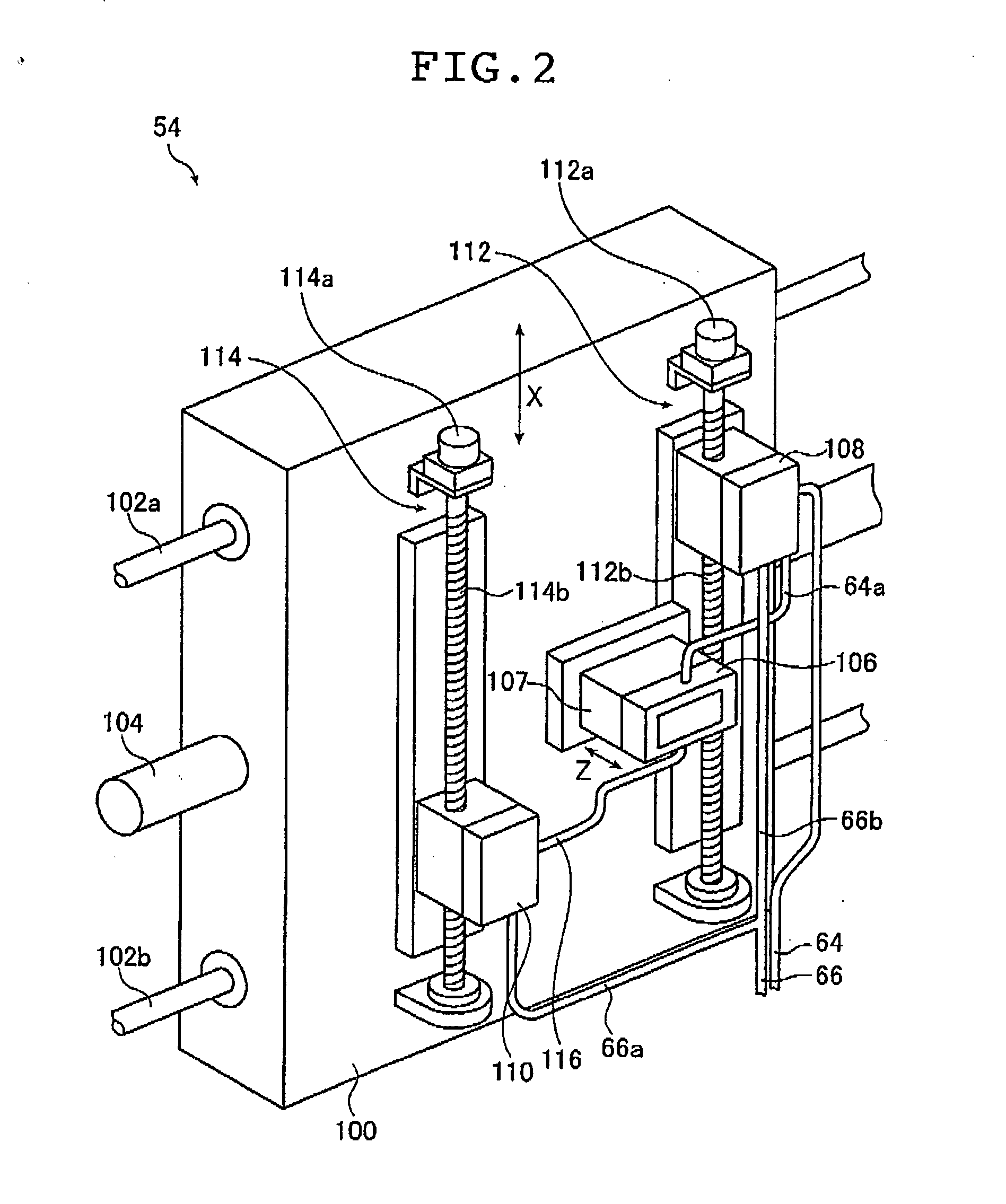

Ink jet recording apparatus and method of controlling the same

InactiveUS20050200657A1Stable recordImprove image qualityPower drive mechanismsOther printing apparatusEngineeringRecording media

Owner:FUJIFILM CORP +1

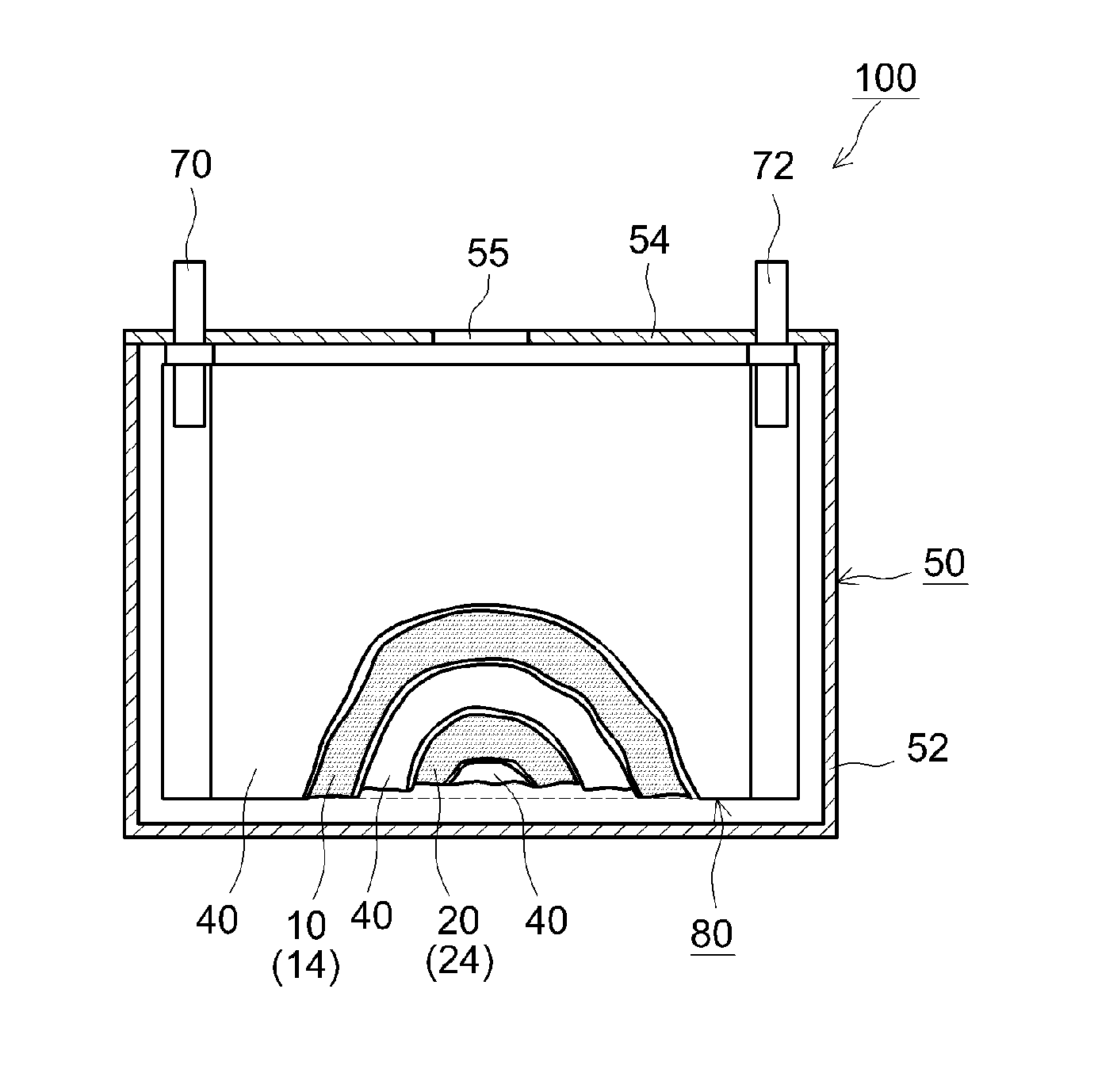

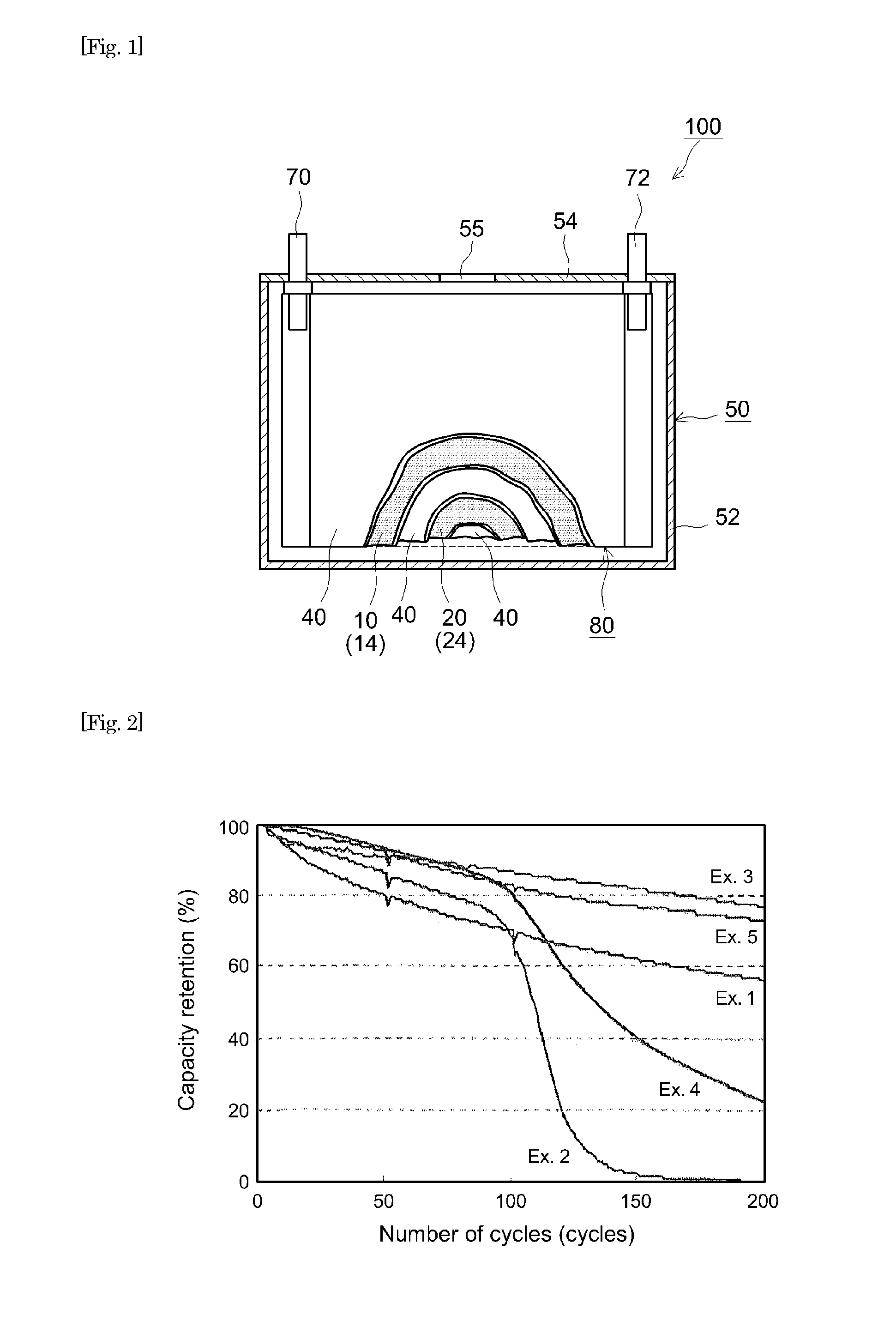

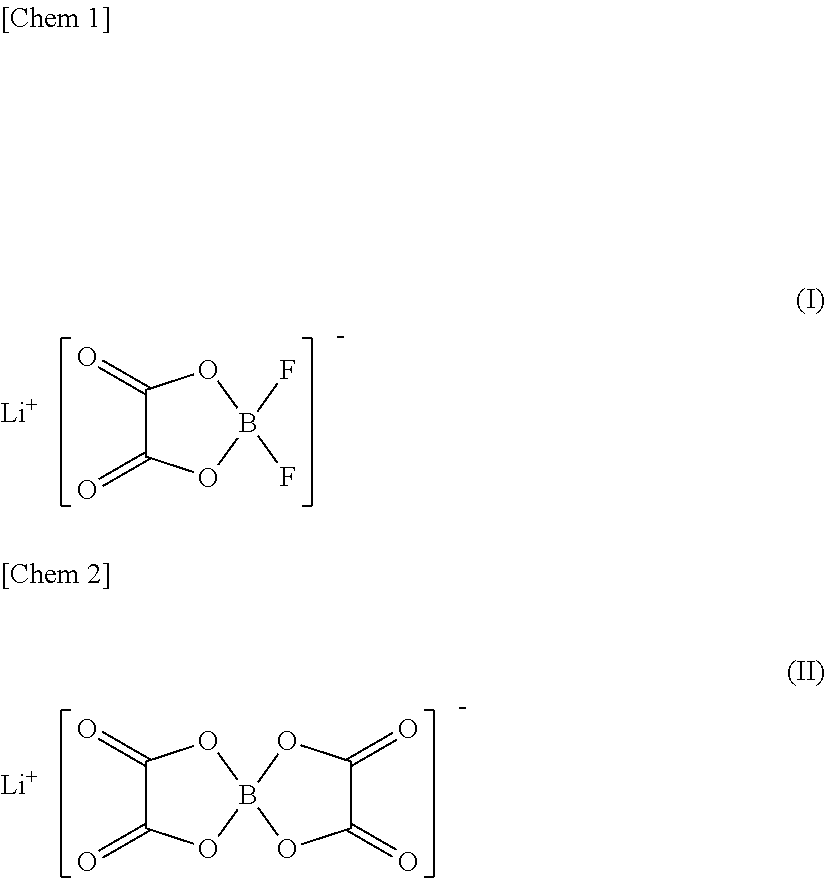

Non-aqueous electrolyte secondary battery and assembly thereof

ActiveUS20150311563A1Improve battery performanceExcellent high rate characteristicsOrganic electrolyte cellsSecondary cellsInorganic phosphateLithium metal

Provided is a non-aqueous electrolyte secondary battery combining excellent input / output performance with great durability (cycle characteristics) and an assembly thereof. The present invention provides a non-aqueous electrolyte secondary battery assembly. The positive electrode has a maximum operating voltage of 4.3 V or higher relative to lithium metal, comprising a positive electrode active material and an ion-conductive inorganic phosphate compound. The non-aqueous electrolyte solution comprises a supporting salt, an oxalatoborate-type compound, and a non-aqueous solvent. The non-aqueous solvent is formed of a non-fluorinated solvent. This invention also provides a non-aqueous electrolyte secondary battery obtained by charging the non-aqueous electrolyte secondary battery assembly.

Owner:TOYOTA JIDOSHA KK

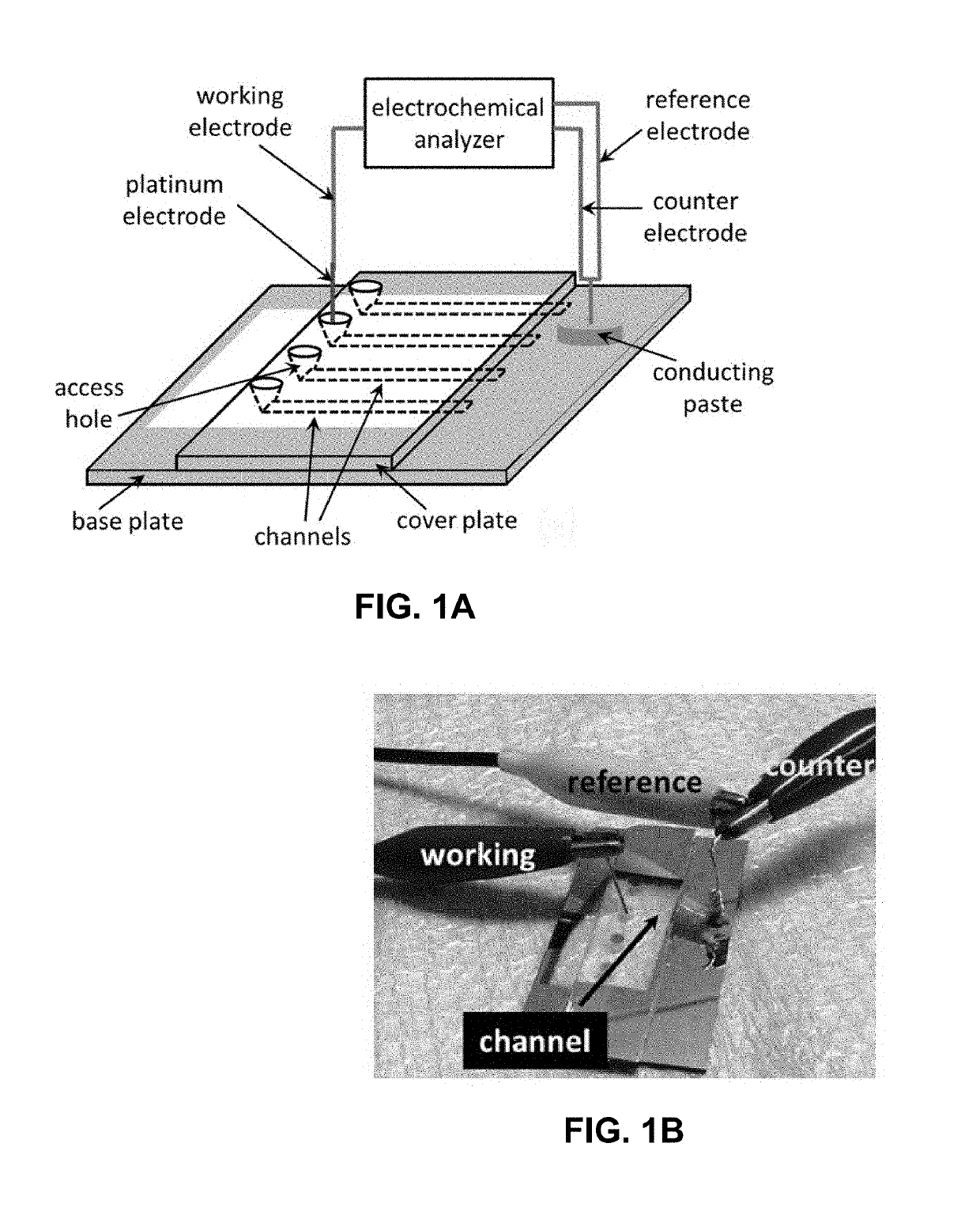

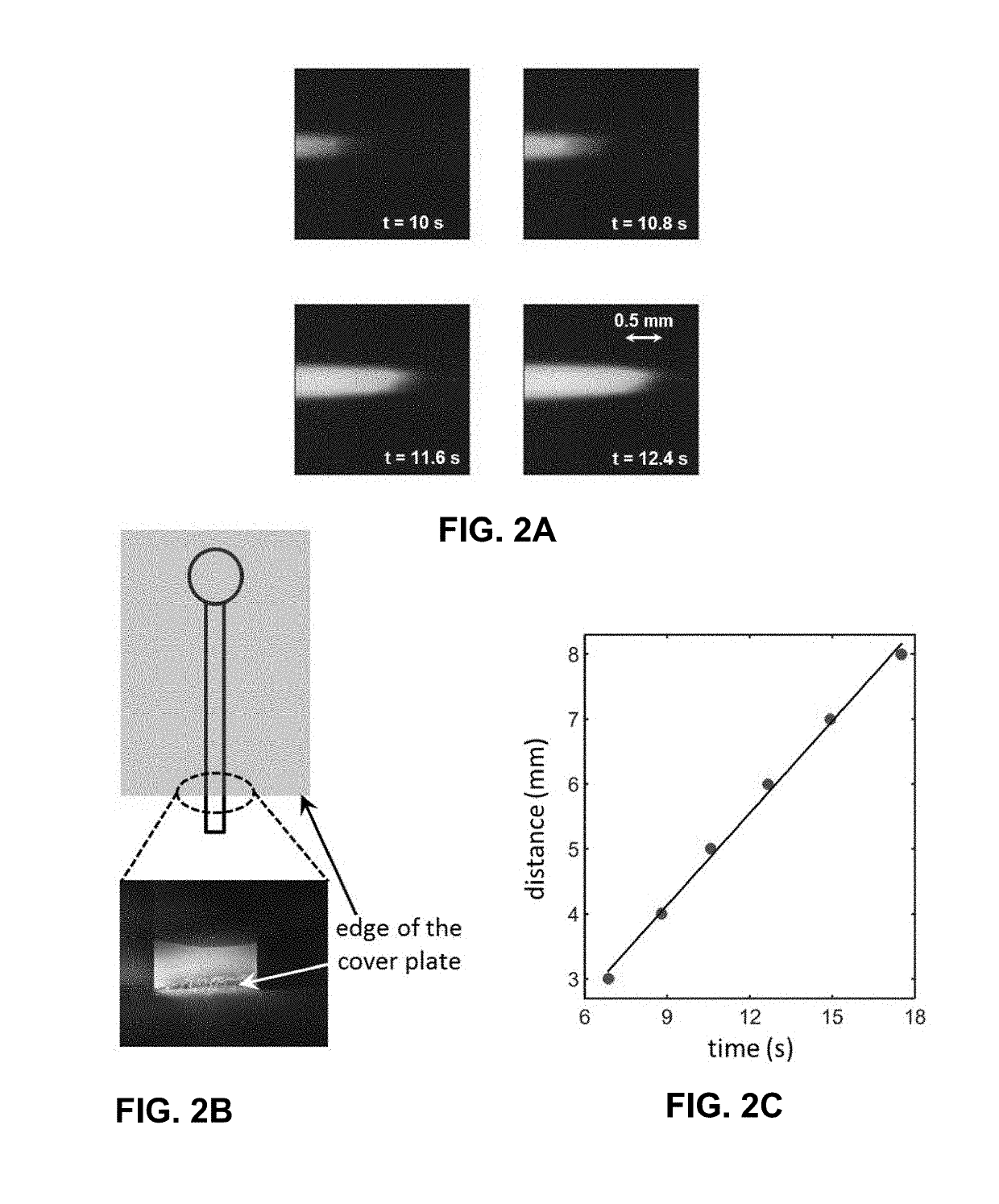

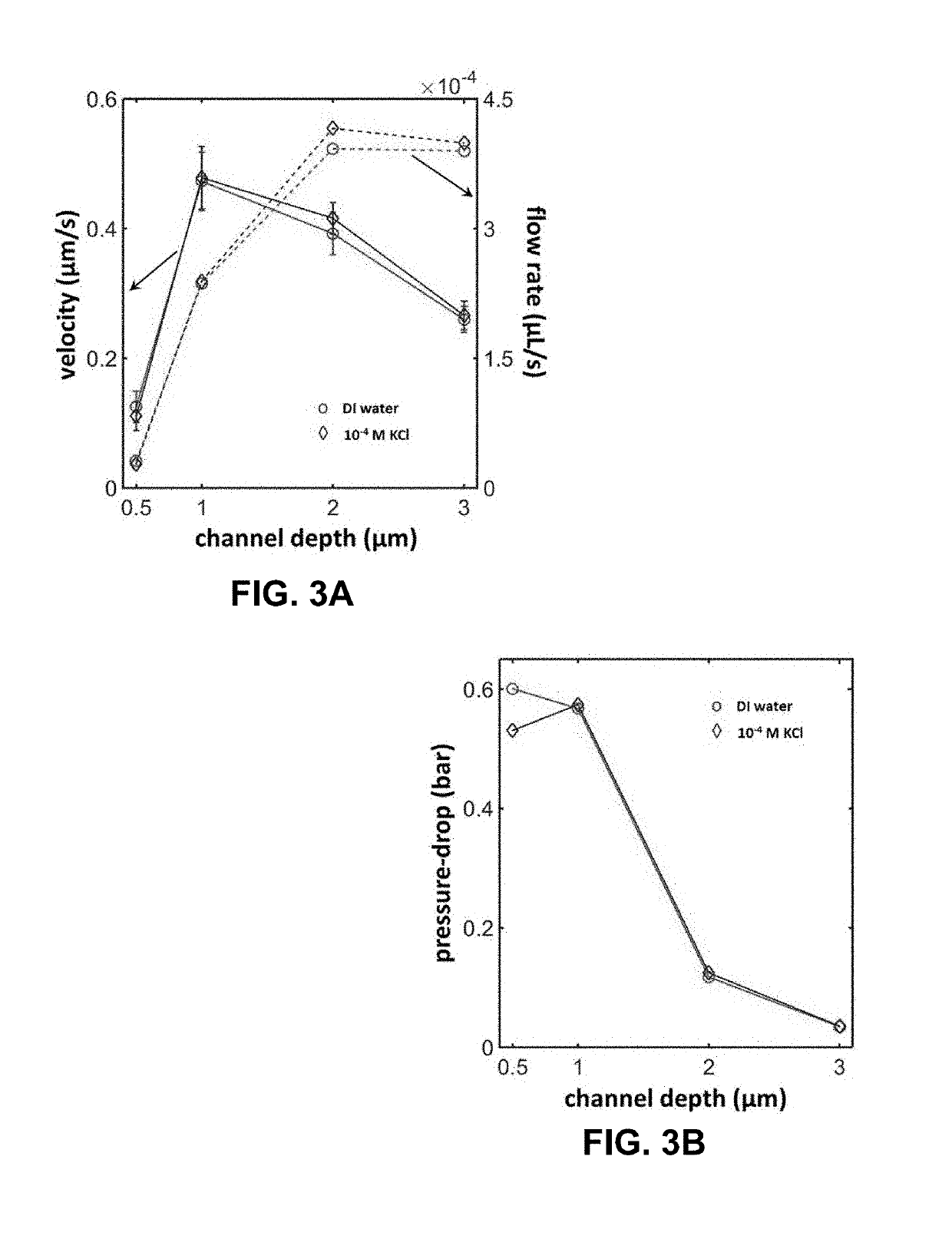

Electrical Energy Generation in Fluidic Channels and Membranes Using Spontaneous Capillary Flow

ActiveUS20190097257A1Improve fluid flowIncrease energy generatedElectrolyte moving arrangementsCell electrodesFluidic channelMicro fluidic

Described herein are systems and methods for the generation of electric current and / or electric potential utilizing micro- or nano-channels and capillary flow, including fluidic or microfluidic batteries and electrochemical cells. The provided systems and methods use capillary force to promote fluid flow through micro- and nano-fluidic channels by evaporating fluid at one terminus of the channel, and the resulting fluid flow generates electric potential and or current. Advantageously, the described systems and methods remove the need for pressurized vessels or external pumps, increasing net energy generation and decreasing complexity and size of potential fluidic batteries.

Owner:UNIVERSITY OF WYOMING

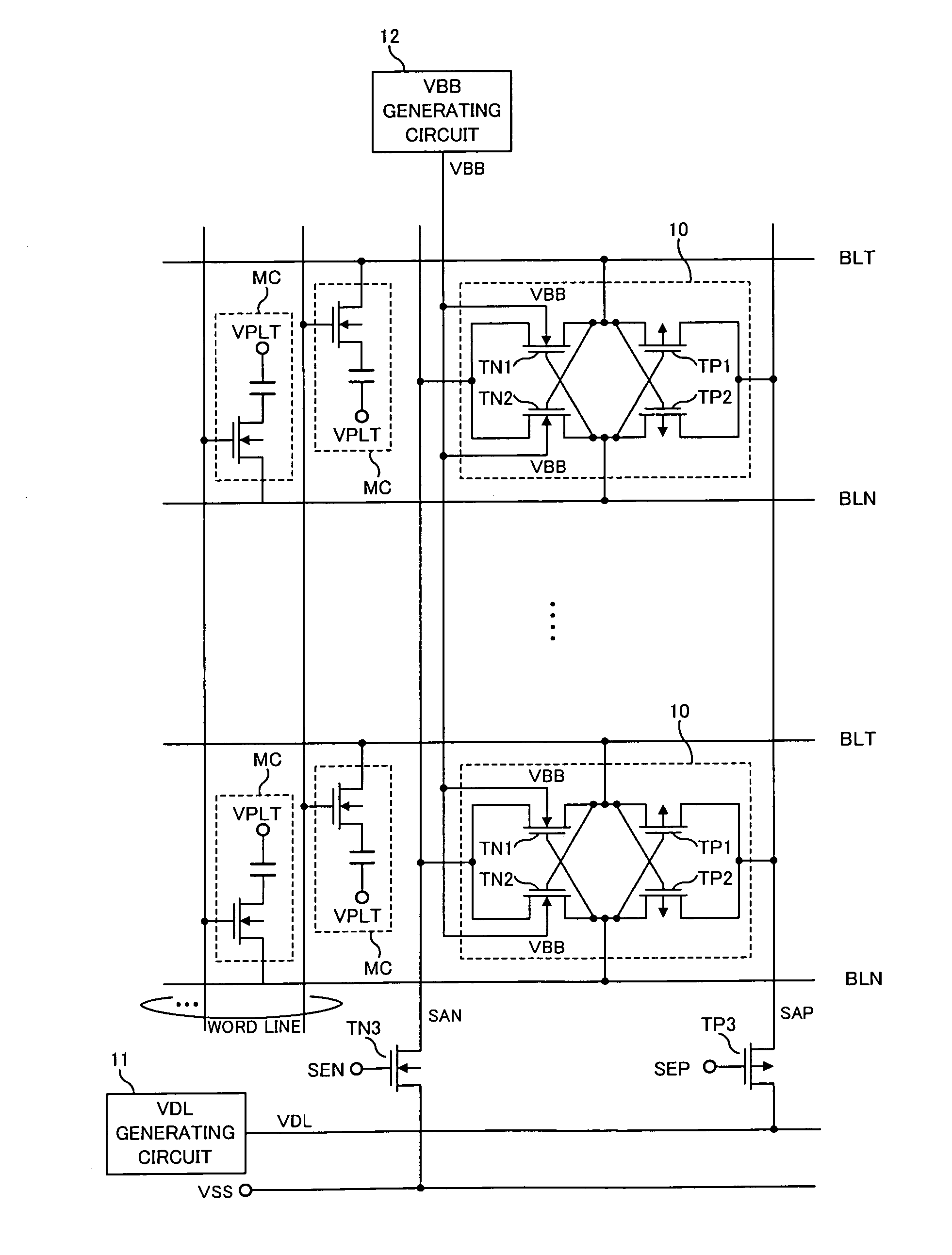

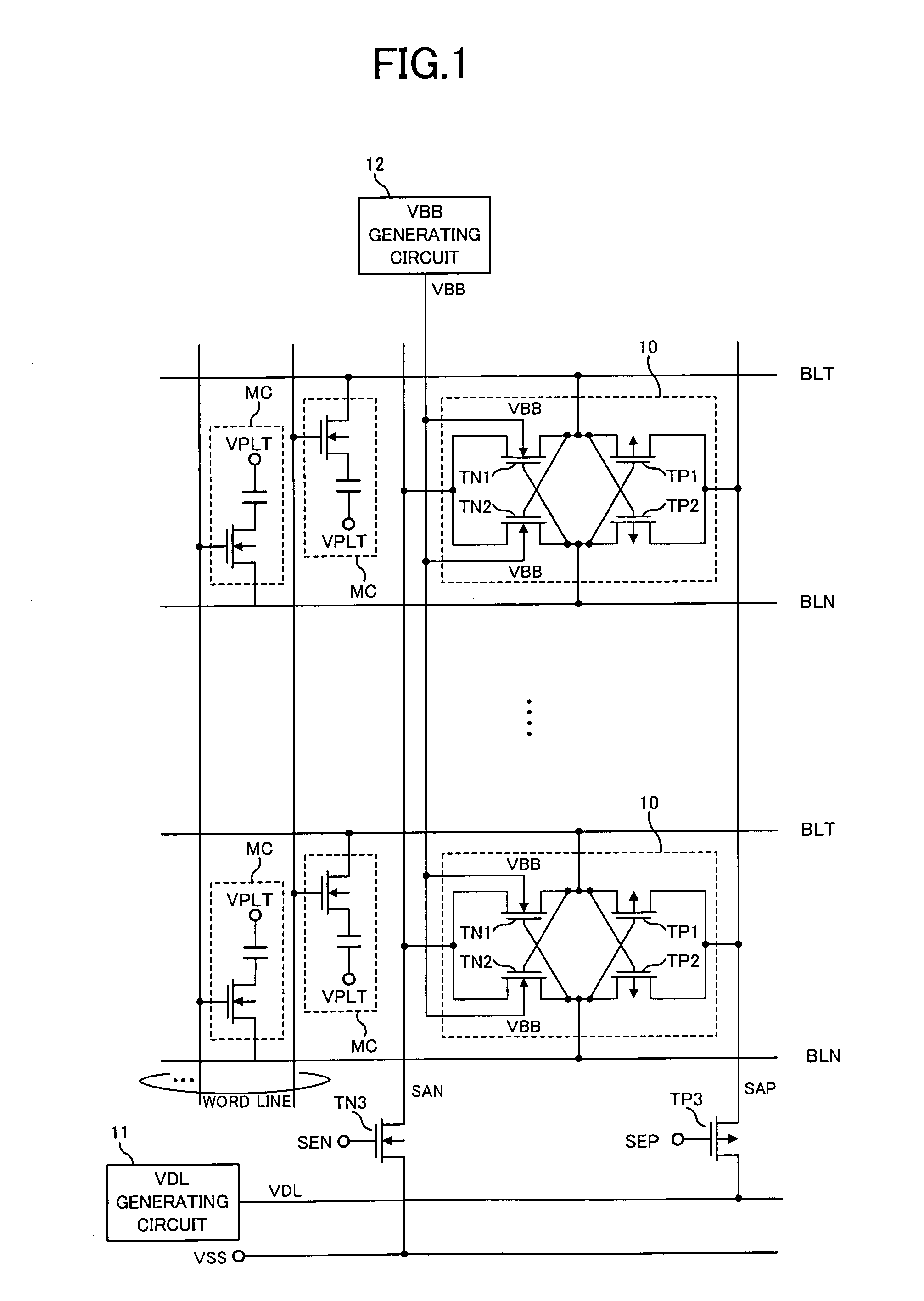

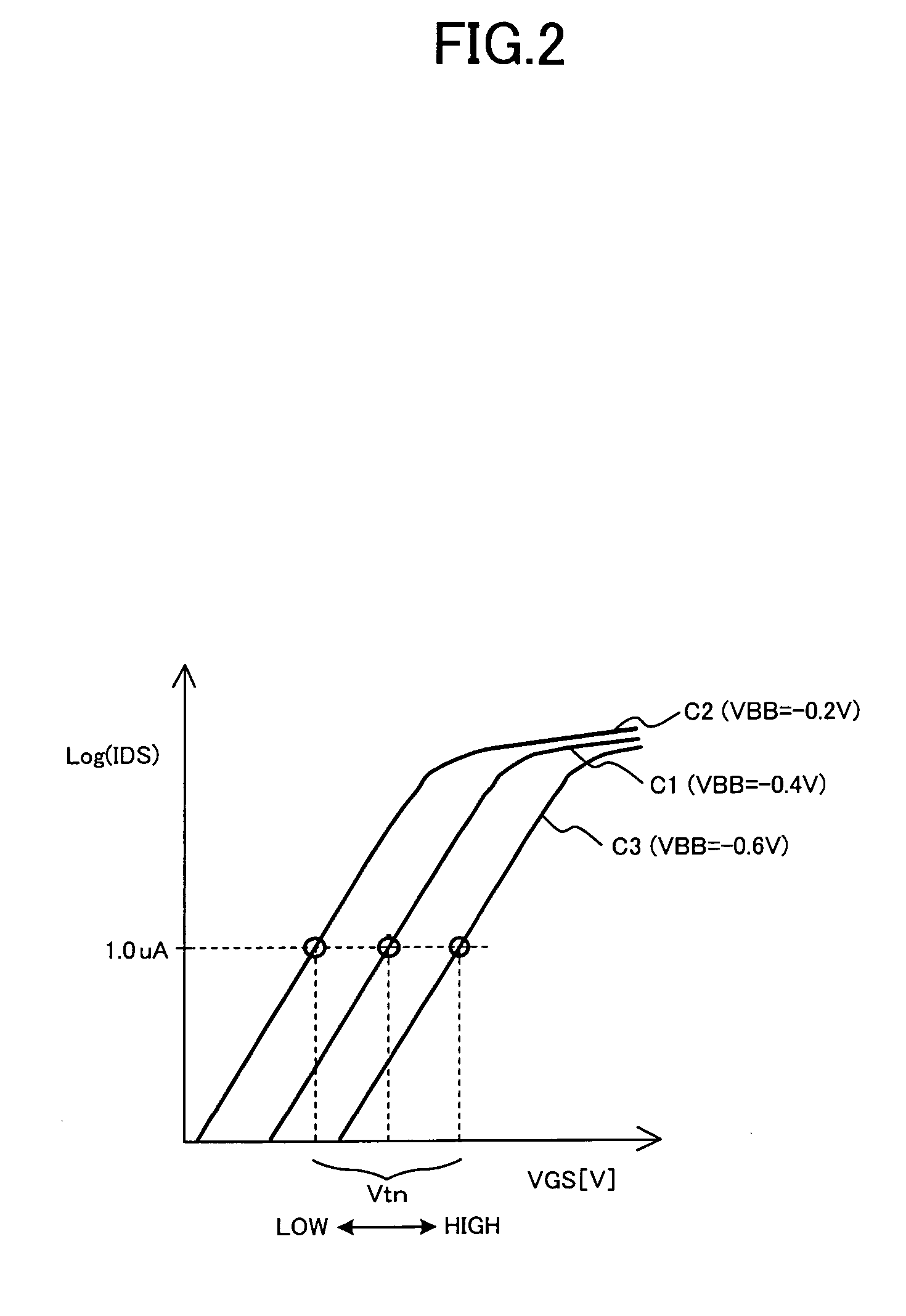

Semiconductor memory device

A semiconductor memory device comprising: a sense amplifier which includes a pair of first NMOS transistors and a pair of PMOS transistors connected to a bit line pair as a complementary pair; a back bias generating circuit which generates a back bias voltage to be applied to the first NMOS transistors in a state in which a predetermined current is flowing through a second NMOS transistor having approximately the same operating characteristic as that of the first NMOS transistors, and performs a feedback control in response to a threshold voltage of the second NMOS transistor; and control means which performs control in a sensing operation of the sense amplifier such that the pair of first NMOS transistors operates previously and after a lapse of a predetermined time the pair of first PMOS transistors operates.

Owner:PS4 LUXCO SARL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com