Electrostatic dust catcher

An electrostatic vacuum cleaner, vacuum cleaner technology, applied in the direction of electrostatic cleaning, chemical instruments and methods, and carpet cleaning, can solve the problems of limited electric field density, limited maximum polarization effect, and reduced effective power of known equipment. Effects of good reliability, avoidance of leverage, good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

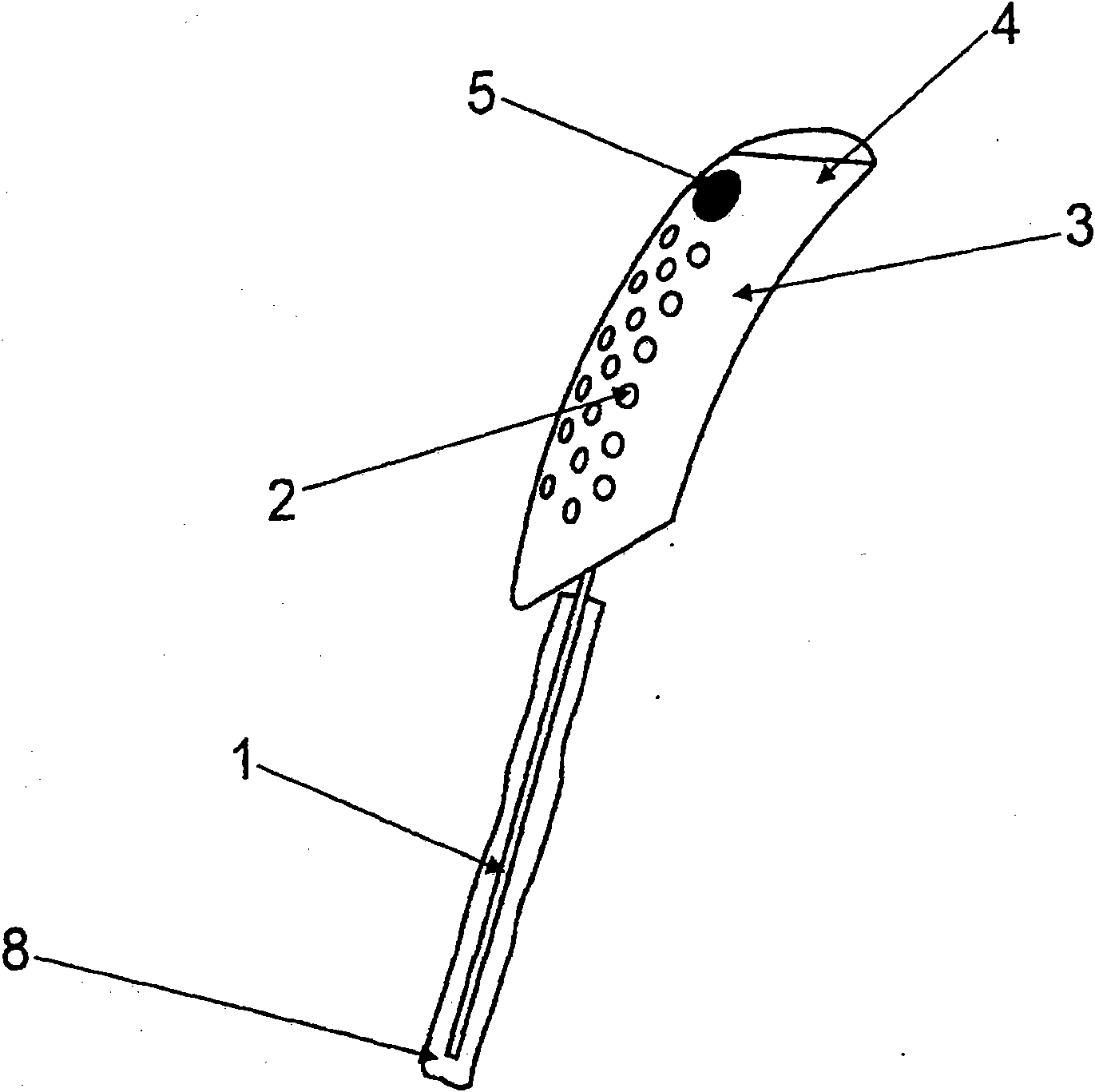

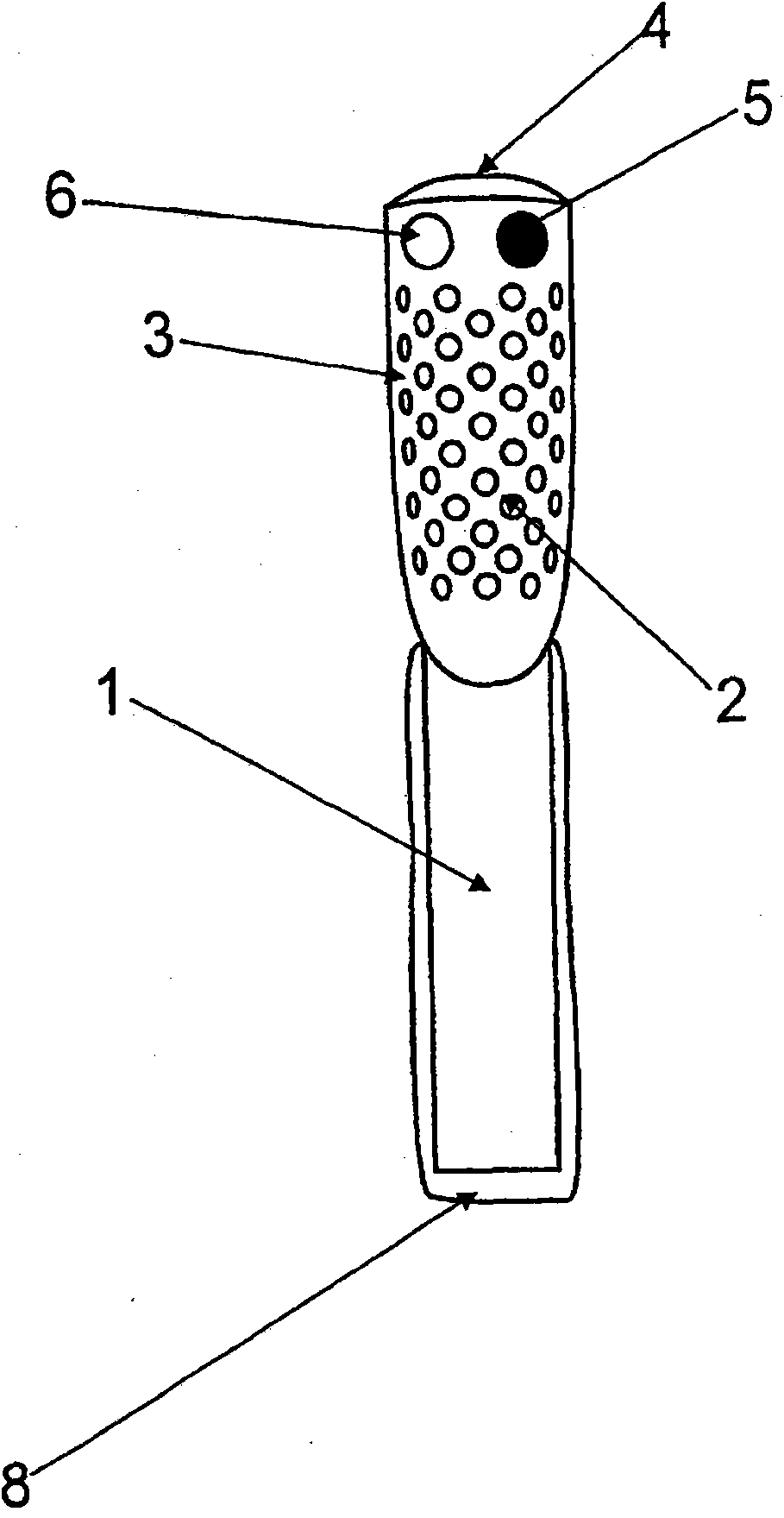

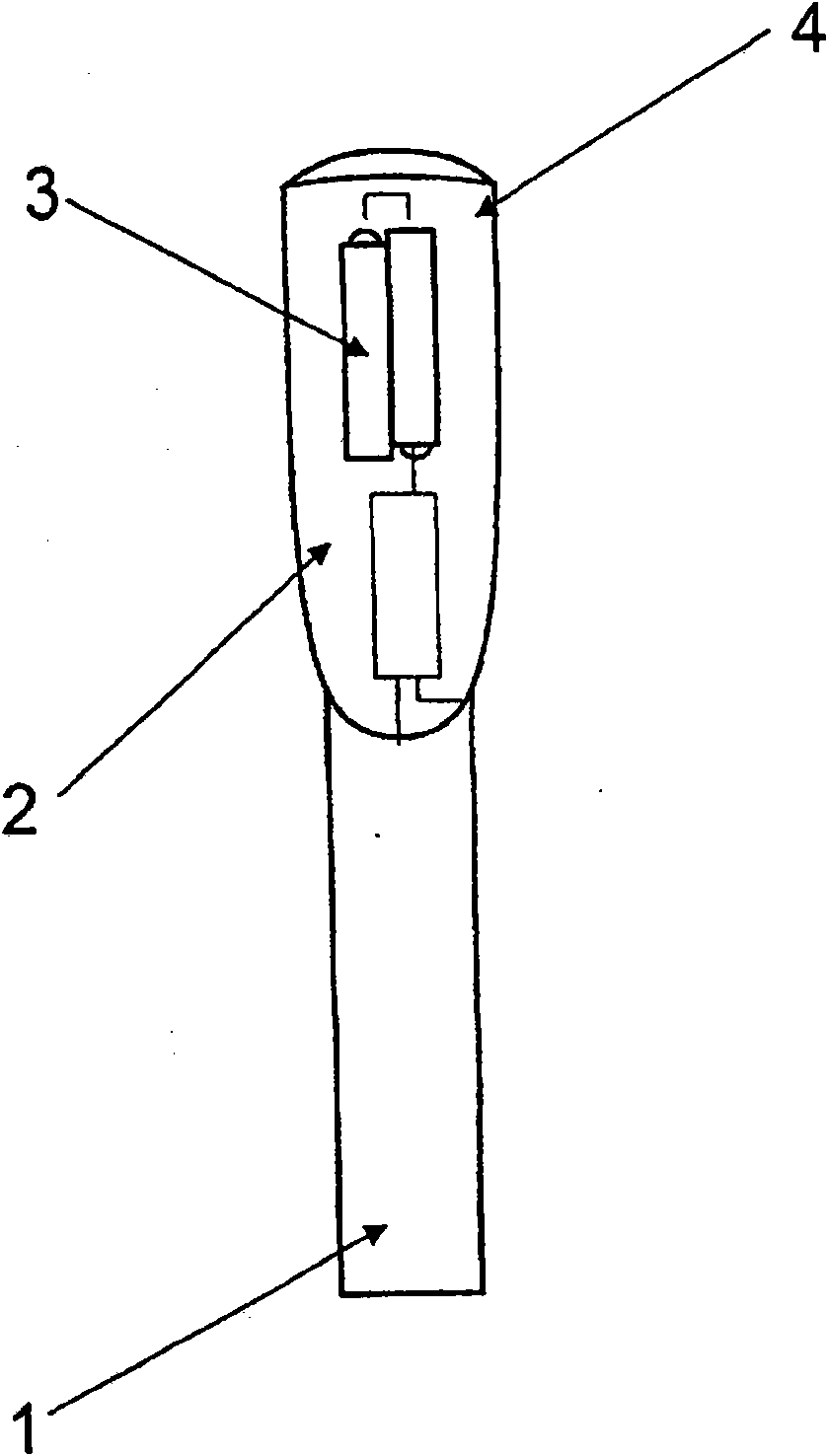

[0028] exist Figures 1 to 4 Two embodiments of electrostatic cleaners are shown in , each of which is mainly composed of a handle 4 and a dust collection device fixed on the handle 4 . The dust collecting device is formed by a first electrode 1 which, in the exemplary embodiment shown here, is completely surrounded by a bag-shaped dust cloth 8 . The dust cloth can consist entirely or partly of microfibres.

[0029] The handle 4 is formed by the second electrode 2 , wherein a voltage source 3 is arranged inside the handle 4 and is protectively surrounded by the handle 4 . In the present invention, the voltage source 3 is a battery or a rechargeable accumulator with an output voltage, and a circuit with a voltage divider and a bridge rectifier for converting the output voltage into a high-frequency high voltage, wherein the high-frequency high The voltage is converted to a static high voltage by a rectifier and applied to a capacitor. In this embodiment, the output voltage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com