Method for puncturing iron core by motor wire-insertion preventing winding

A winding pair and iron core technology, which is used in the field of aviation motor embedding to prevent winding to iron core breakdown, can solve the problems of breakdown failure of winding withstand voltage test, easy damage of winding insulation, and breakdown of iron core insulation, etc. Processing quality and reliability, avoidance of insulation damage, the effect of large economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

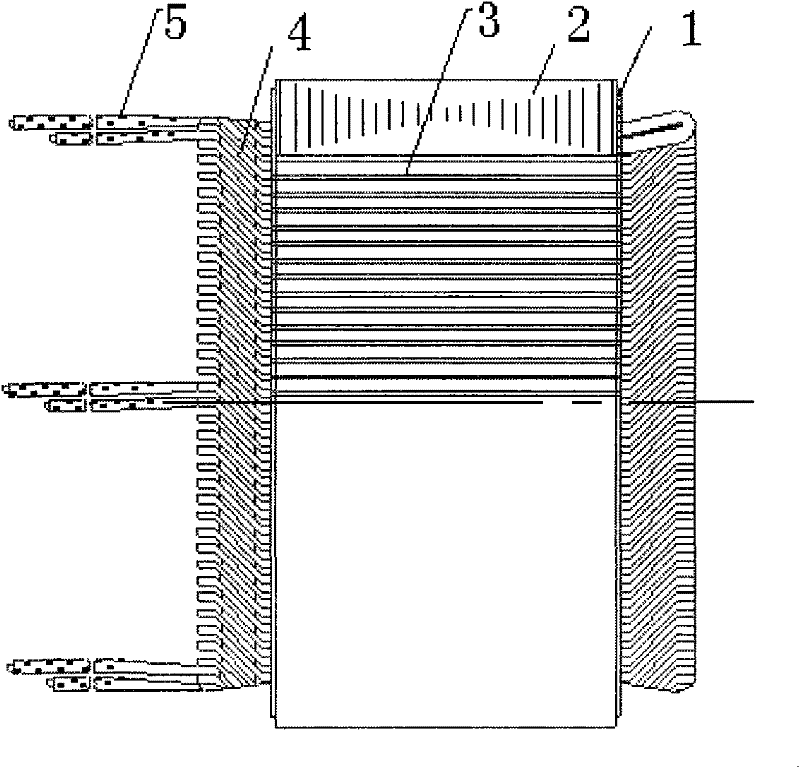

[0025] The embodiment is a DC starter generator. The compensation winding assembled by the stator adopts MYFB-0.13 double-strand wrapped flat copper wire with a specification of 1.25X5 to pass and wrap the embedded wire on the pole core.

[0026] 1. Stack the motor stator pole core punching sheets according to the number of stator pole core laminations and stack thickness requirements to form a stator pole core and fasten it with electron beam welding;

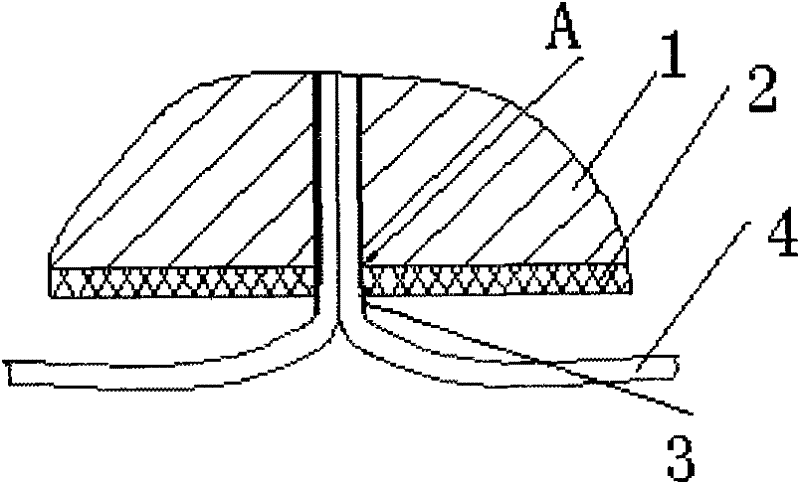

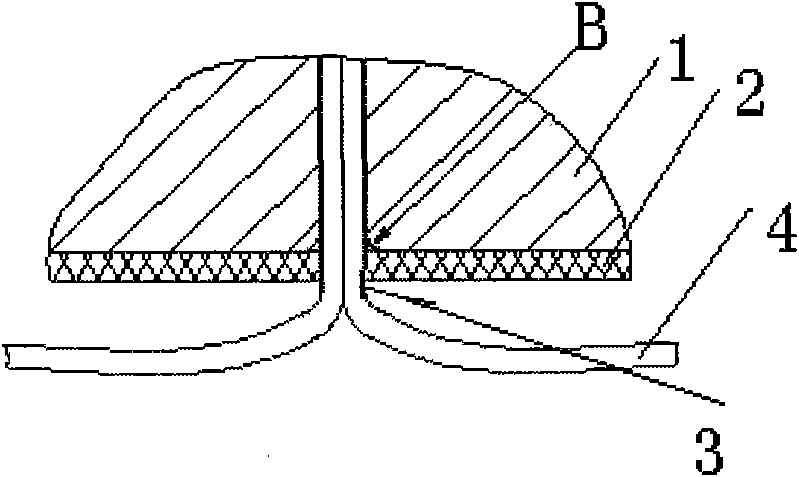

[0027] 2. File the rounded corners R0.8 around the slots at both ends of the stator magnetic pole core, and then glue the two insulating end plates with 204 glue to prevent the slots of the core during the wire embedding process. The sharp edge will damage the insulation of the groove and the outer insulation of the double-strand flat copper wire;

[0028] 3. During the wire embedding operation, leave a 1mm stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com